Fabrication and Mechanical Testing of the Uniaxial Graded Auxetic Damper

Abstract

:1. Introduction

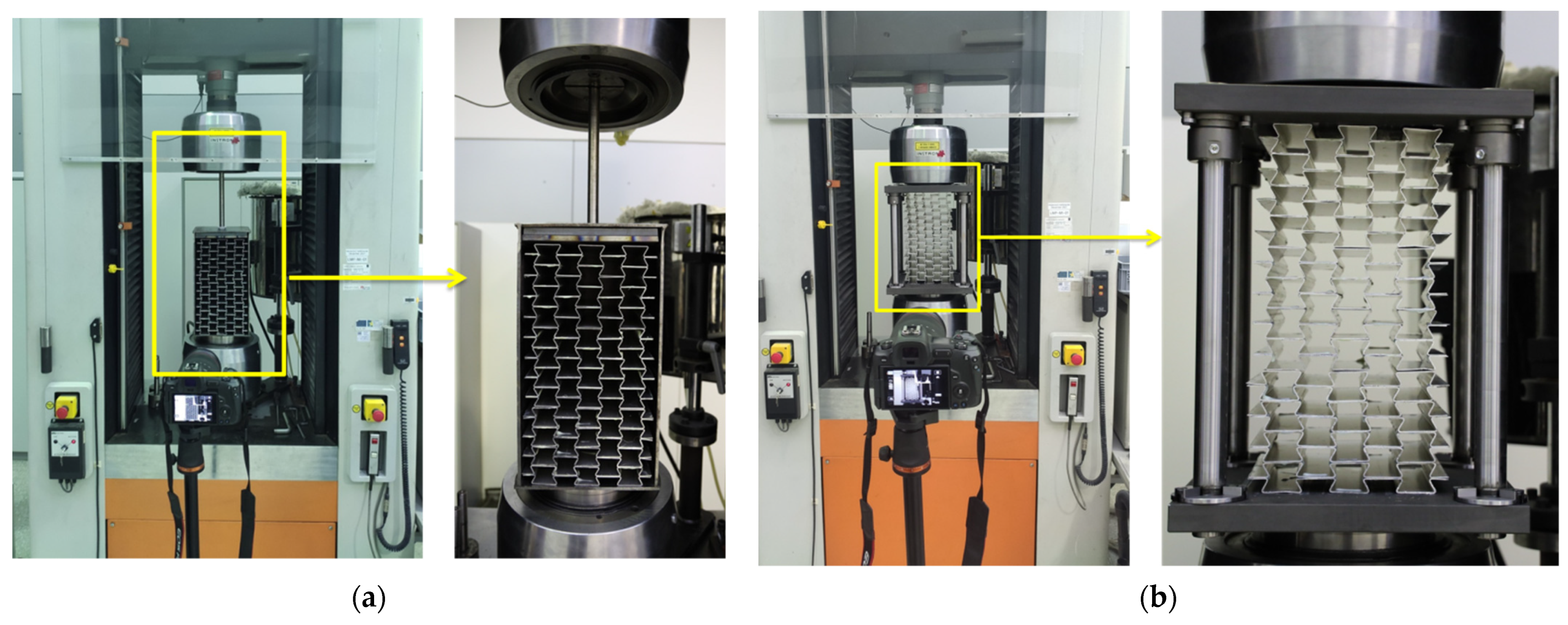

2. Fabrication and Experimental Testing

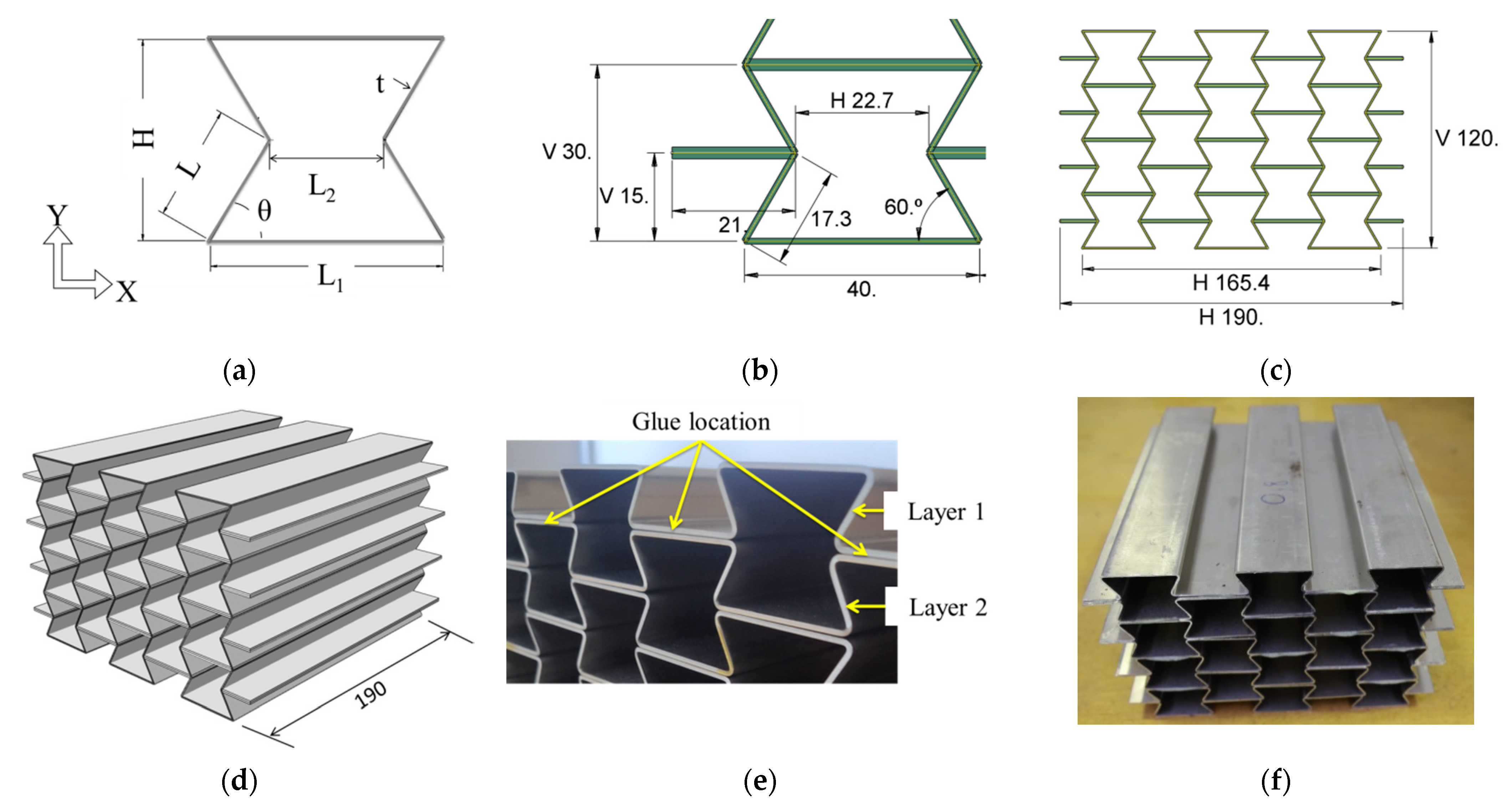

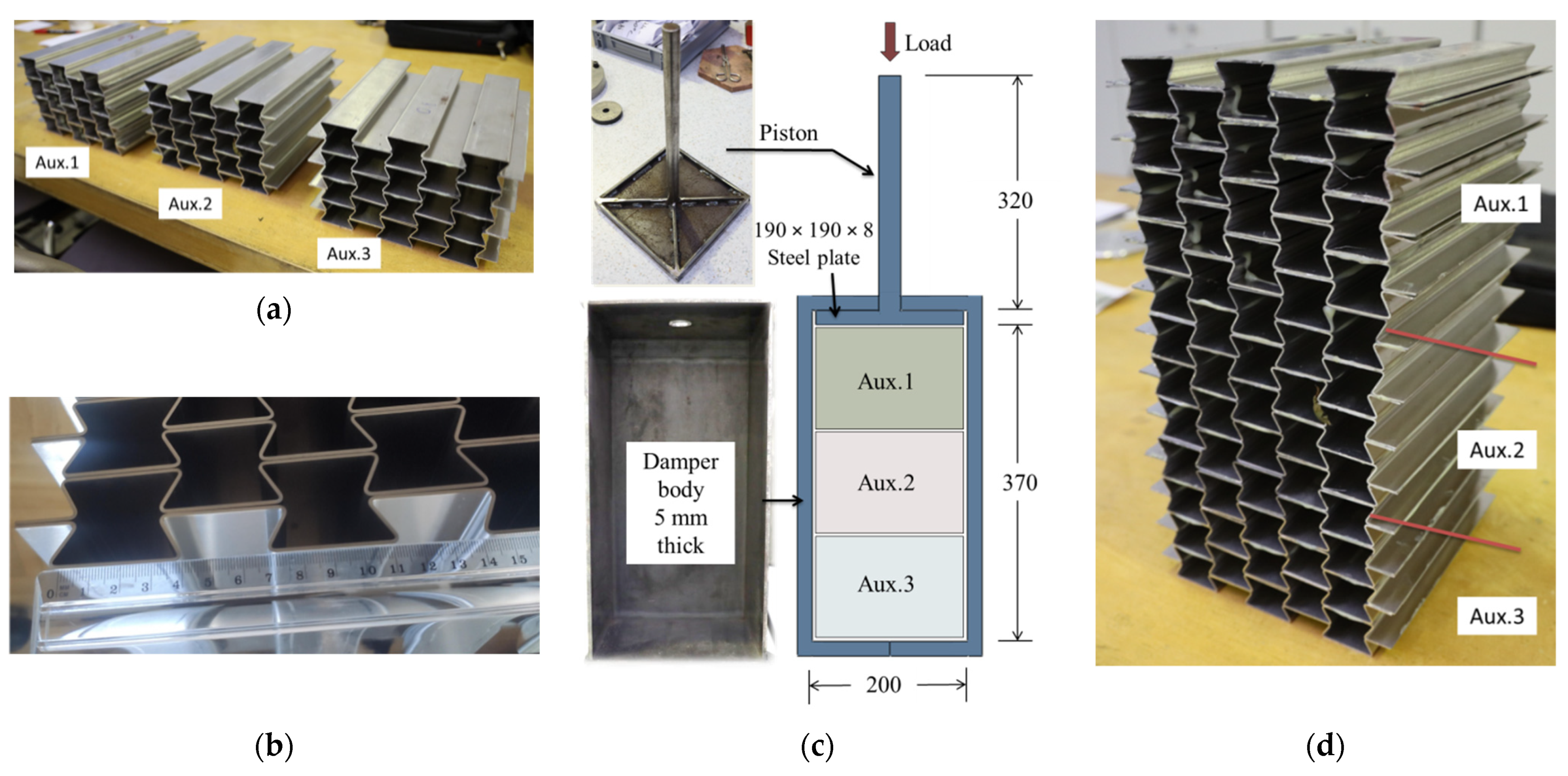

2.1. Geometry and Fabrication of the UGAD

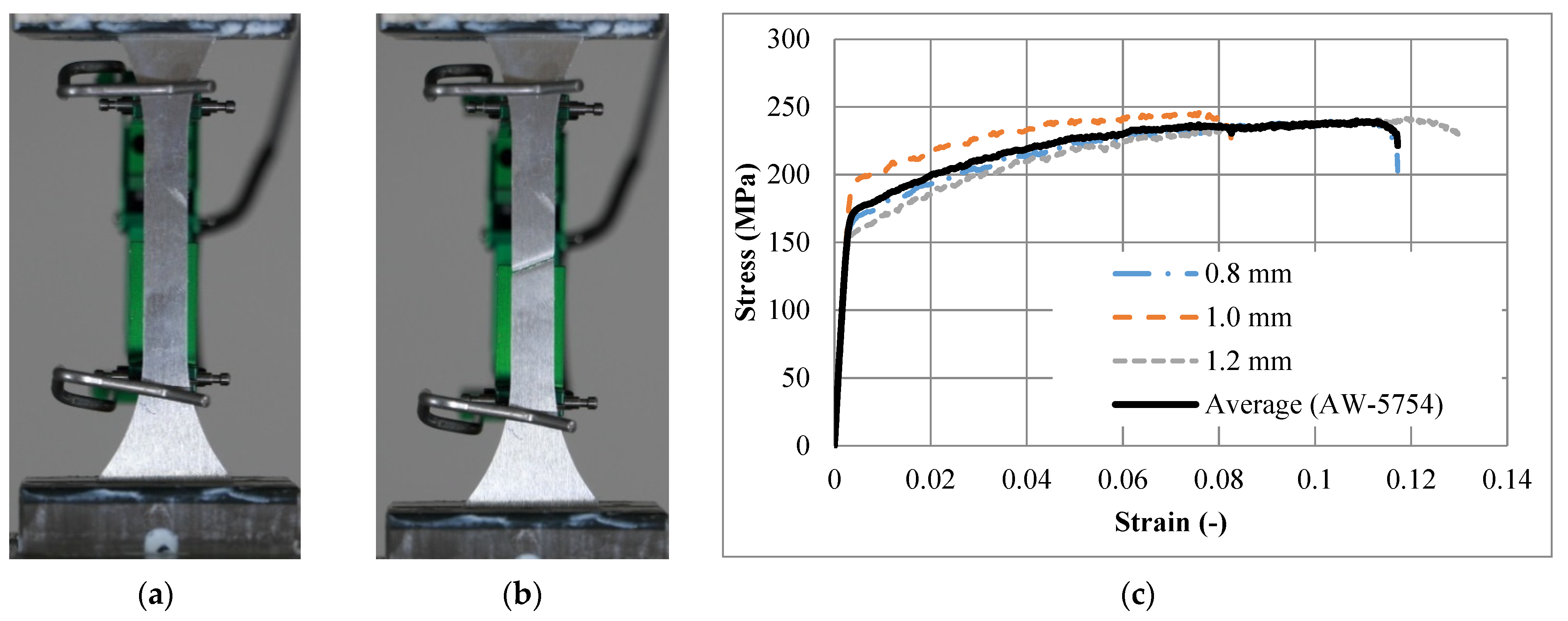

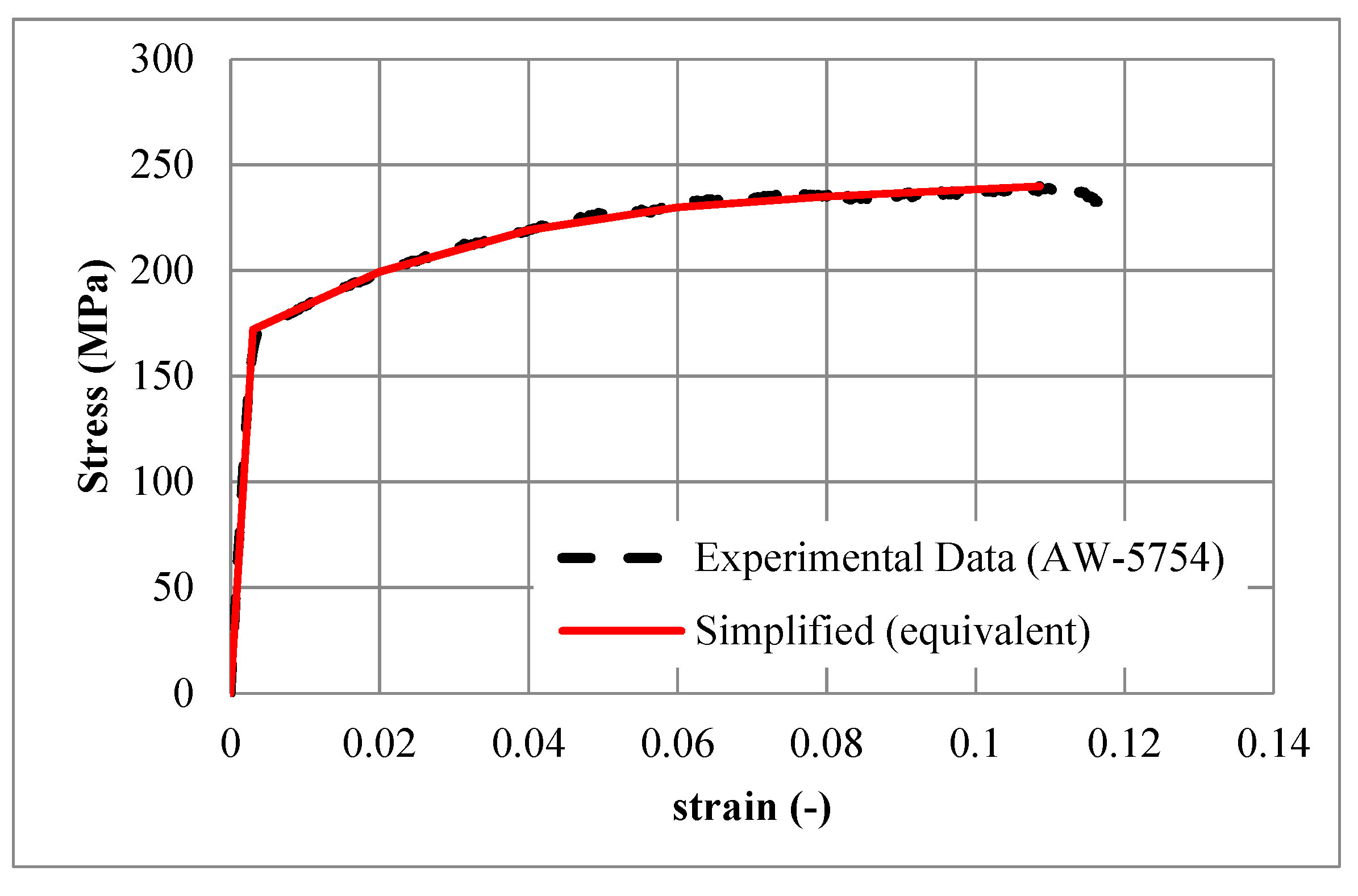

2.2. Material Properties of the Aluminium Alloy

2.3. Experimental Testing of the UGAD

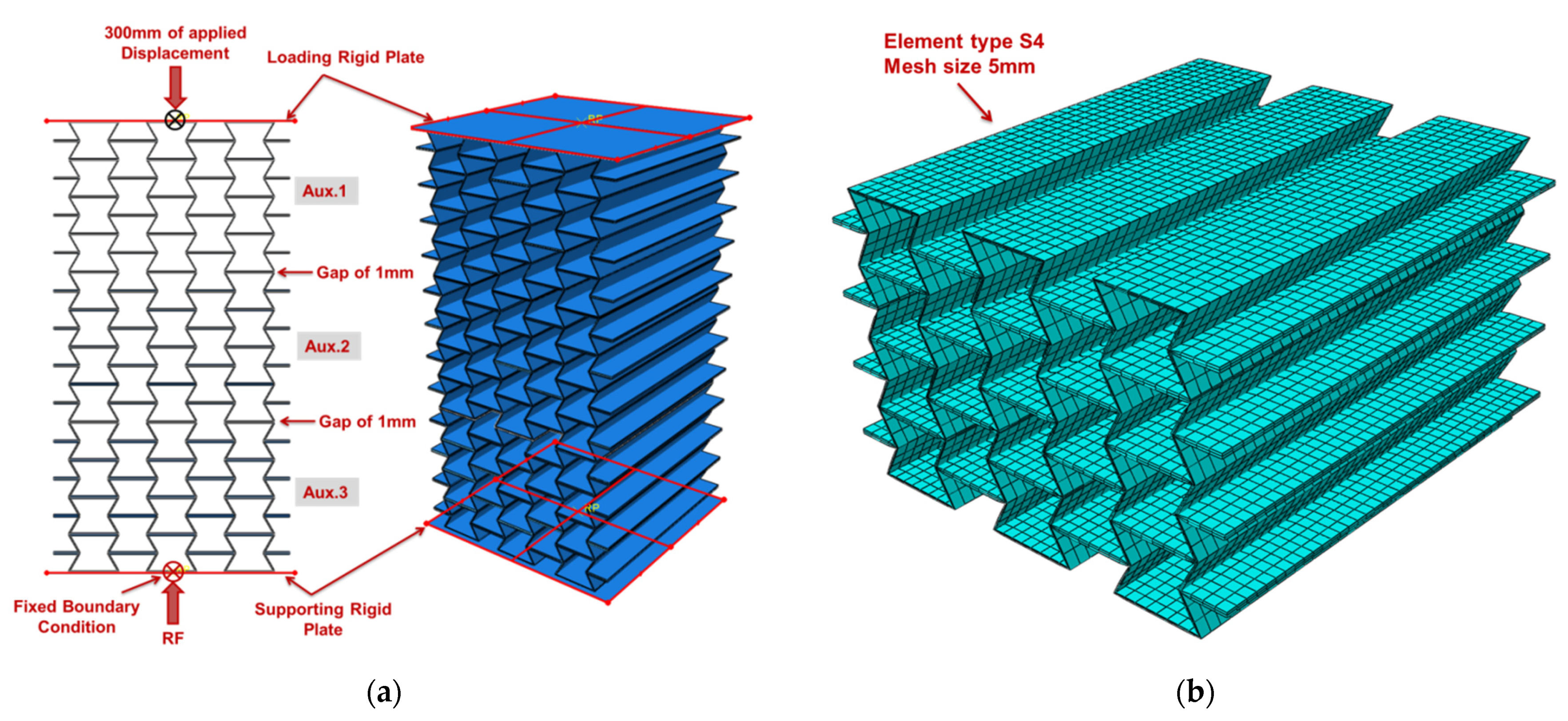

3. Computational Simulations

3.1. Computational Model

3.2. Loading

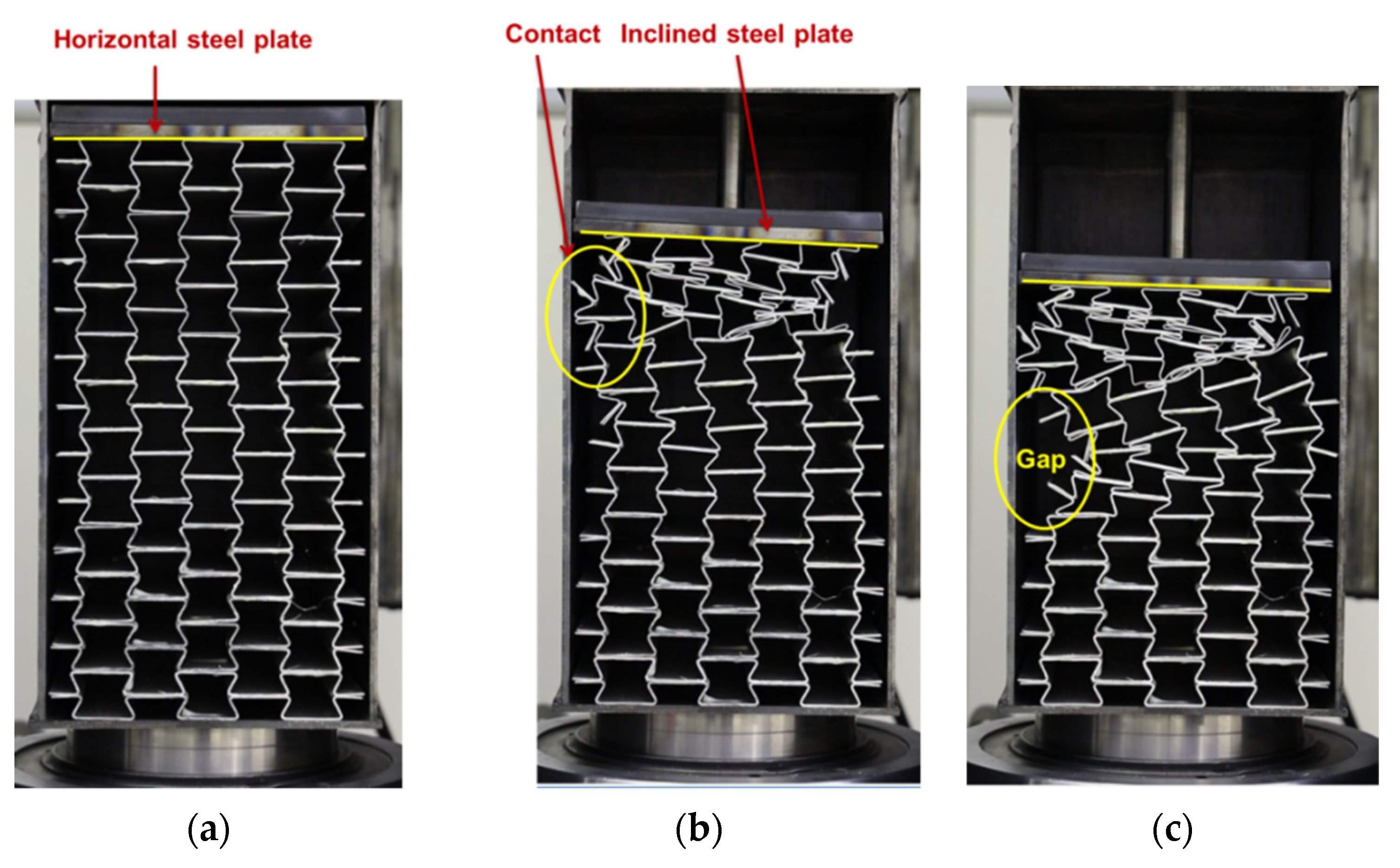

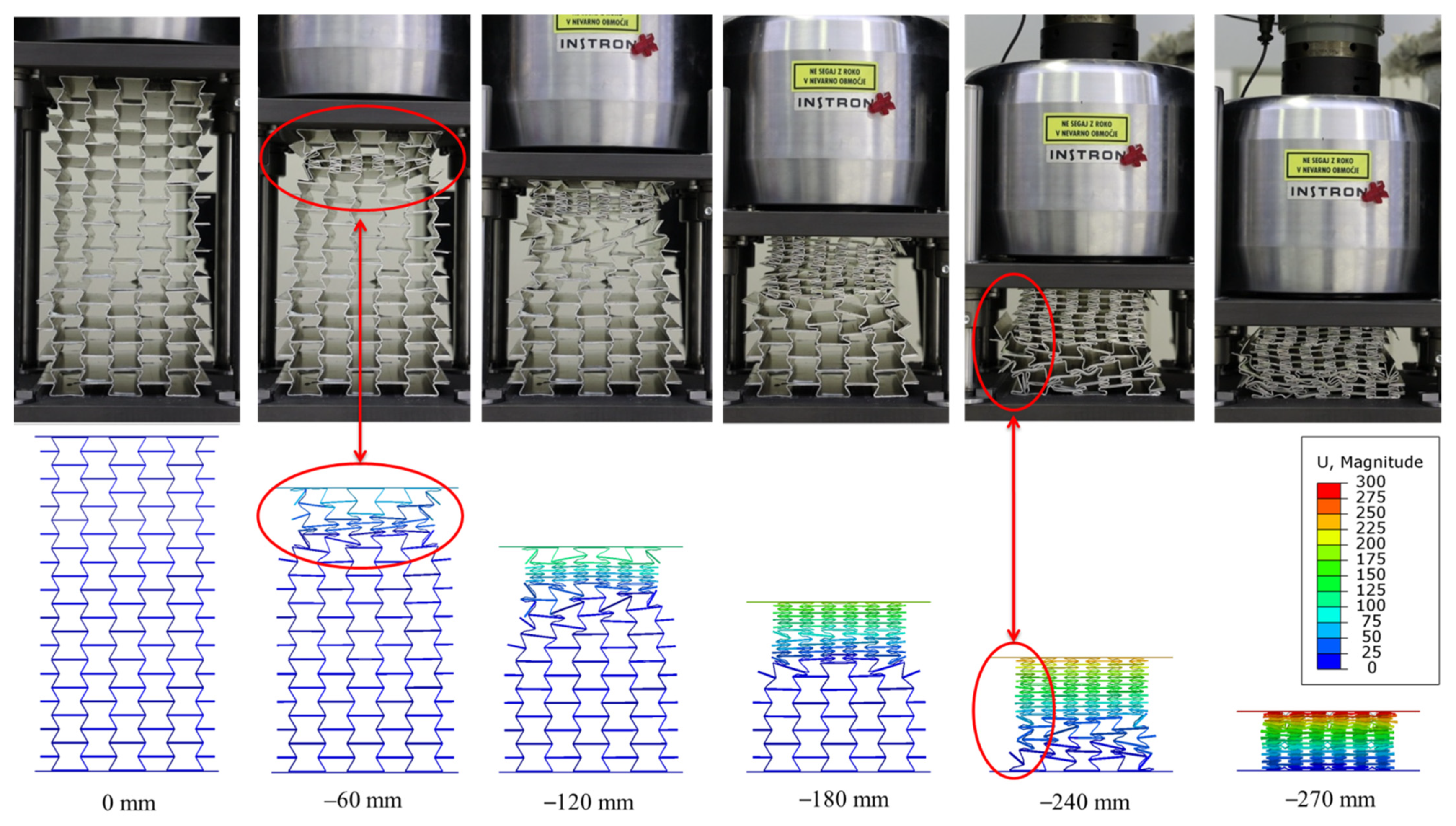

4. Results and Discussion

5. Conclusions

- -

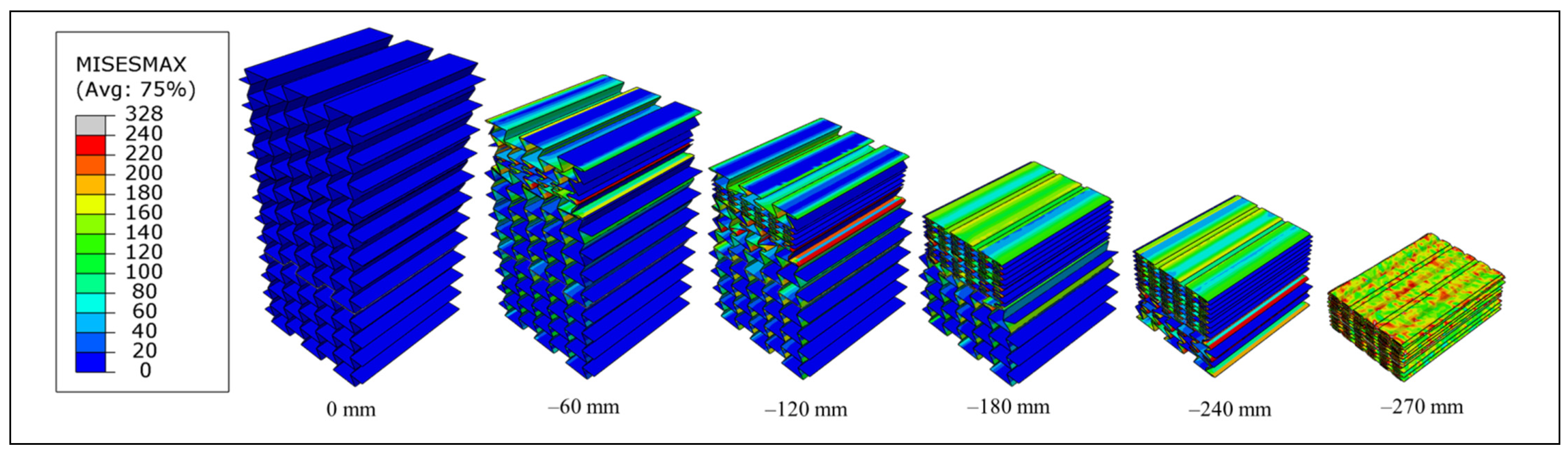

- The deformation patterns and progressive collapse of fabricated auxetic cores are in excellent agreement with the computational predictions, which validates the accuracy of the used computational and material models.

- -

- The epoxy adhesive, LOCTITE® EA 9466, was successfully used to bond the auxetic layers with high efficiency without needing extra rivets.

- -

- A negative Poisson’s ratio (auxetic behaviour) was observed in all three re-entrant auxetic cores. The lateral shrinkage makes it easier to replace the deformed cores once crashed, without the need to replace the entire UGAD.

- -

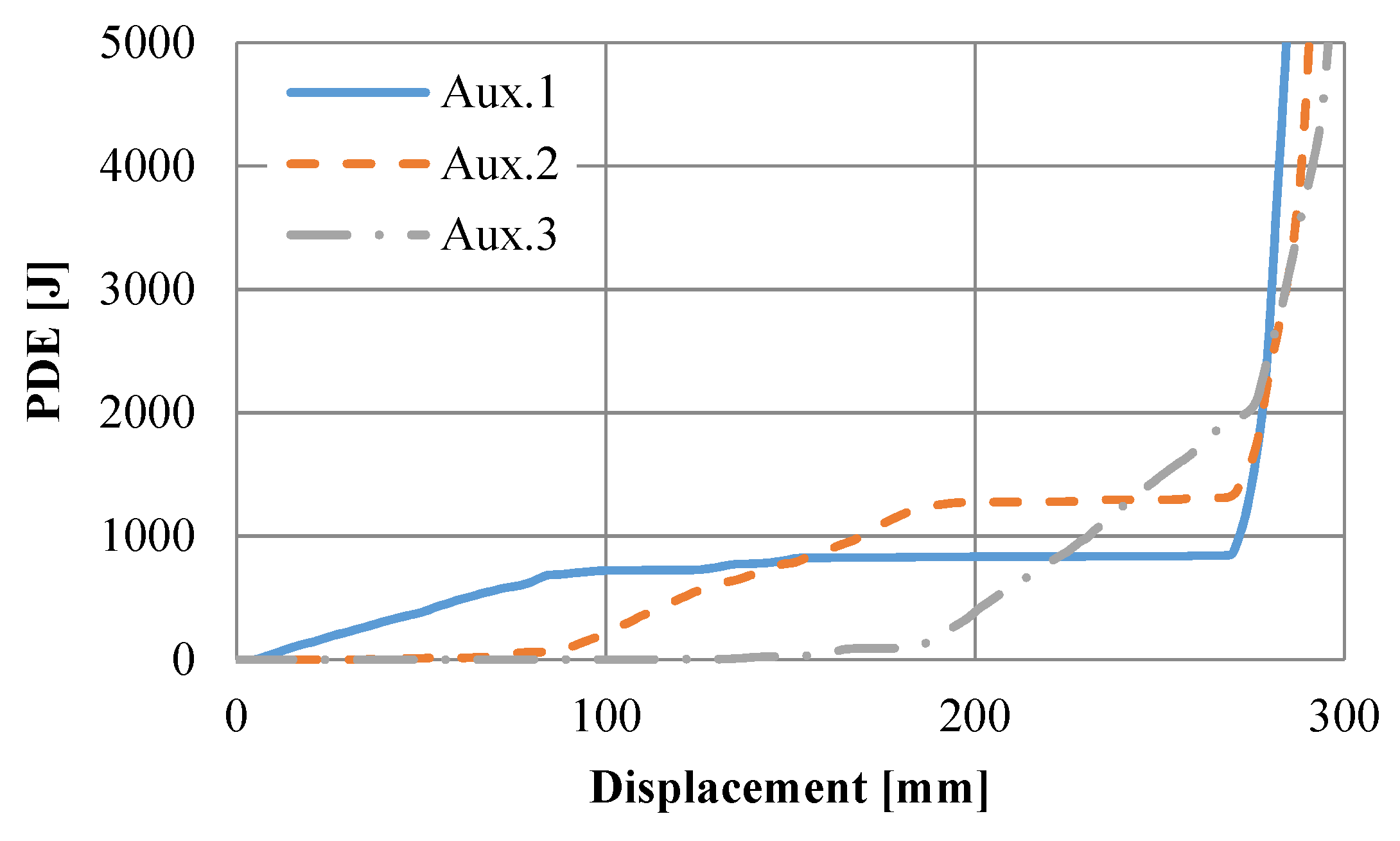

- The force–displacement relationships of the UGADs revealed a short linear response, followed by a broad plateau region, and a final rapid densification zone. The plateau region was divided into step-wise zones based on the behaviour of the three different auxetic cores. The fabricated samples showed high compatibility with the computational predictions.

- -

- The computational model showed that the internal energy in the auxetic cores was mainly composed of plastic dissipation energy (PDE). Moreover, a relatively high value of specific energy absorption (SEA) was observed, which reflects the superior energy-absorption potential of the fabricated UGAD.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Z.D.; Liao, Y.X.; Ge, T.; Xu, C. Experimental and Theoretical Study of Viscoelastic Dampers with Different Matrix Rubbers. J. Eng. Mech. 2016, 142, 04016051. [Google Scholar] [CrossRef]

- Kovács, T.A.; Nyikes, Z.; Figuli, L. Development of a Composite Material for Impact Load. Acta Mater. Transylvanica 2019, 2, 105–109. [Google Scholar] [CrossRef] [Green Version]

- Al-Rifaie, H.; Studziński, R.; Gajewski, T.; Malendowski, M.; Sumelka, W.; Sielicki, P.W. A New Blast Absorbing Sandwich Panel with Unconnected Corrugated Layers—Numerical Study. Energies 2021, 14, 214. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams: A Design Guide; Elsevier Science: Burlington, MA, USA, 2000. [Google Scholar]

- Lehmhus, D.; Vesenjak, M.; de Schampheleire, S.; Fiedler, T. From stochastic foam to designed structure: Balancing cost and performance of cellular metals. Materials 2017, 10, 922. [Google Scholar] [CrossRef] [Green Version]

- Al-Rifaie, H.; Sumelka, W. Improving the blast resistance of large steel gates-Numerical study. Materials 2020, 13, 2121. [Google Scholar] [CrossRef]

- Schwartz, D.S.; Shih, D.S.; Wadley, H.N.G.; Evans, A.G. Porous and Cellular Materials for Structural Applications; Materials Research Society: Warrendale, PA, USA, 1998; Volume 521. [Google Scholar]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Static and dynamic axial crush performance of in-situ foam-filled tubes. Compos. Struct. 2015, 124, 128–139. [Google Scholar] [CrossRef]

- Tanaka, S.; Hokamoto, K.; Irie, S.; Okano, T.; Ren, Z.; Vesenjak, M.; Itoh, S. High-velocity impact experiment of aluminum foam sample using powder gun. Meas. J. Int. Meas. Confed. 2011, 44, 2185–2189. [Google Scholar] [CrossRef]

- Vesenjak, M.; Kovačič, A.; Tane, M.; Borovinšek, M.; Nakajima, H.; Ren, Z. Compressive properties of lotus-type porous iron. Comput. Mater. Sci. 2012, 65, 37–43. [Google Scholar] [CrossRef]

- Vesenjak, M.; Hokamoto, K.; Matsumoto, S.; Marumo, Y.; Ren, Z. Uni-directional porous metal fabricated by rolling of copper sheet and explosive compaction. Mater. Lett. 2016, 170, 39–43. [Google Scholar] [CrossRef]

- Sanders, W.; Gibson, L. Mechanics of BCC and FCC hollow-sphere foams. Mater. Sci. Eng. A 2003, 352, 150–161. [Google Scholar] [CrossRef]

- Stöbener, K.; Baumeister, J.; Rausch, G.; Rausch, M. Forming metal foams by simpler methods for cheaper solutions. Met. Powder Rep. 2005, 60, 12–16. [Google Scholar] [CrossRef]

- Vesenjak, M.; Gacnik, F.; Krstulovic-Opara, L.; Ren, Z. Behavior of composite advanced pore morphology foam. J. Compos. Mater. 2011, 45, 2823–2831. [Google Scholar] [CrossRef]

- Sulong, M.A.; Vesenjak, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Compressive properties of Advanced Pore Morphology (APM) foam elements. Mater. Sci. Eng. A 2014, 607, 498–504. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Auxetic cellular materials—A Review. Stroj. Vestn. J. Mech. Eng. 2016, 62, 485–493. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.T.; Uzun, M.; Patel, I. Workings of auxetic nano-materials. J. Achiev. Mater. Manuf. Eng. 2011, 49, 585–593. [Google Scholar]

- Schwerdtfeger, J.; Heinl, P.; Singer, R.F.; Körner, C. Auxetic cellular structures through selective electron beam melting. Phys. Status Solidi B 2010, 247, 269–272. [Google Scholar] [CrossRef]

- Al-Rifaie, H.; Sumelka, W. Auxetic Damping Systems for Blast Vulnerable Structures. In Handbook of Damage Mechanics: Nano to Macro Scale for Materials and Structures; Voyiadjis, G.Z., Ed.; Springer: New York, NY, USA, 2020; pp. 1–23. [Google Scholar]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int. J. Solids Struct. 2015, 69–70, 475–490. [Google Scholar] [CrossRef]

- Bückmann, T.; Stenger, N.; Kadic, M.; Kaschke, J.; Frölich, A.; Kennerknecht, T.; Eberl, C.; Thiel, M.; Wegener, M. Tailored 3D Mechanical Metamaterials Made by Dip-in Direct-Laser-Writing Optical Lithography. Adv. Mater. 2012, 24, 2710–2714. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A.; Marcellin-Little, D.J.; West, H.A.; Lascelles, B.D.X.; Aman, R. Flexural properties of Ti6Al4V rhombic dodecahedron open cellular structures fabricated with electron beam melting. Addit. Manuf. 2014, 1–4, 2–11. [Google Scholar] [CrossRef]

- Friis, E.A.; Lakes, R.S.; Park, J.B. Negative Poisson’s ratio polymeric and metallic foams. J. Mater. Sci. 1988, 23, 4406–4414. [Google Scholar] [CrossRef]

- Mohsenizadeh, S.; Alipour, R.; Rad, M.S.; Nejad, A.F.; Ahmad, Z. Crashworthiness assessment of auxetic foam-filled tube under quasi-static axial loading. Mater. Des. 2015, 88, 258–268. [Google Scholar] [CrossRef]

- Hou, S.; Liu, T.; Zhang, Z.; Han, X.; Li, Q. How does negative Poisson’s ratio of foam filler affect crashworthiness? Mater. Des. 2015, 82, 247–259. [Google Scholar] [CrossRef]

- Yang, L.; Harrysson, O.; West, H.; Cormier, D. Compressive properties of Ti–6Al–4V auxetic mesh structures made by electron beam melting. Acta Mater. 2012, 60, 3370–3379. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Schury, F.; Stingl, M.; Wein, F.; Singer, R.F.; Körner, C. Mechanical characterisation of a periodic auxetic structure produced by SEBM. Phys. Status Solidi 2012, 249, 1347–1352. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Duarte, I.; Tanaka, S.; Hokamoto, K.; Krstulović-Opara, L.; Guo, B.; Chen, P.; Ren, Z. Compressive Behaviour of Closed-Cell Aluminium Foam at Different Strain Rates. Materials 2019, 12, 4108. [Google Scholar] [CrossRef] [Green Version]

- Novak, N.; Vesenjak, M.; Krstulović-Opara, L.; Ren, Z. Mechanical characterisation of auxetic cellular structures built from inverted tetrapods. Compos. Struct. 2018, 196, 96–107. [Google Scholar] [CrossRef]

- Borovinšek, M.; Vesenjak, M.; Ren, Z. Estimating the base material properties of sintered metallic hollow spheres by inverse engineering procedure. Mech. Mater. 2016, 100, 22–30. [Google Scholar] [CrossRef]

- Vesenjak, M.; Veyhl, C.; Fiedler, T. Analysis of anisotropy and strain rate sensitivity of open-cell metal foam. Mater. Sci. Eng. A 2012, 541, 105–109. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. Computational Simulation and Optimization of Functionally Graded Auxetic Structures Made From Inverted Tetrapods. Phys. Status Solidi B 2017, 254, 1600753. [Google Scholar] [CrossRef]

- Strek, T.; Jopek, H.; Nienartowicz, M. Dynamic response of sandwich panels with auxetic cores. Phys. Status Solidi B 2015, 252, 1540–1550. [Google Scholar] [CrossRef]

- Boldrin, L.; Hummel, S.; Scarpa, F.; Di Maio, D.; Lira, C.; Ruzzene, M.; Remillat, C.D.L.; Lim, T.-C.; Rajasekaran, R.; Patsias, S. Dynamic behaviour of auxetic gradient composite hexagonal honeycombs. Compos. Struct. 2016, 149, 114–124. [Google Scholar] [CrossRef] [Green Version]

- Imbalzano, G.; Tran, P.; Ngo, T.D.; Lee, P.V.S. A Numerical Study of Auxetic Composite Panels under Blast Loadings. Compos. Struct. 2013, 135, 339–352. [Google Scholar] [CrossRef]

- Yang, S.; Qi, C.; Wang, D.; Gao, R.; Hu, H.; Shu, J. A comparative study of ballistic resistance of sandwich panels with aluminum foam and auxetic honeycomb cores. Adv. Mech. Eng. 2013, 5, 589216. [Google Scholar] [CrossRef]

- Al-Rifaie, H.; Sumelka, W. The Development of a New Shock Absorbing Uniaxial Graded Auxetic Damper (UGAD). Materials 2019, 12, 2573. [Google Scholar] [CrossRef] [Green Version]

- Al-Rifaie, H.; Sumelka, W. ‘Tłumik Jednoosiowy dla układów Bezpieczeństwa Bram, Drzwi lub Okien’/‘Uniaxial Damper as a Safety System for Gates, Doors or Windows. Patent No. 238840, 11 October 2021. [Google Scholar]

- Remennikov, A.; Kalubadanage, D.; Ngo, T.; Mendis, P.; Alici, G.; Whittaker, A. Development and performance evaluation of large-scale auxetic protective systems for localised impulsive loads. Int. J. Prot. Struct. 2019, 10, 390–417. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Peixinho, N.; Meireles, J. Significance of cell number on the bulk elastic properties of auxetic reentrant lattices. Sci. Technol. Mater. 2018, 30, 8–12. [Google Scholar] [CrossRef]

- Rudawska, A.; Wahab, M.A. The effect of cataphoretic and powder coatings on the strength and failure modes of EN AW-5754 aluminium alloy adhesive joints. Int. J. Adhes. Adhes. 2019, 89, 40–50. [Google Scholar] [CrossRef]

- Abaqus Analysis User Manual; Dassault Systémes: Vélizy-Villacoublay, France, 2007.

- Abaqus Verification Manual; Dassault Systémes: Vélizy-Villacoublay, France, 2004.

| Aux.1 | Aux.2 | Aux.3 | |

|---|---|---|---|

| Constant parameters | = 60° | ||

| t (mm) | 0.8 | 1.0 | 1.2 |

| t/L | 0.046 | 0.058 | 0.069 |

| Mass (kg) | 1.109 | 1.348 | 1.603 |

| (kg/m3) | 255.92 | 311.17 | 370.04 |

| 0.10 | 0.12 | 0.14 | |

| Porosity p (%) | 90.4 | 88.3 | 86.1 |

| No. of fabricated samples | 3 | 3 | 3 |

| Mechanical Properties | E (MPa) | ʋ | Density (kg/m3) |

|---|---|---|---|

| 63,177 | 0.33 | 2660 | |

| Stress | Strain | Plastic Strain | |

| Yield Point | 172.09 | 0.0030 | 0.0000 |

| 199.36 | 0.0200 | 0.0170 | |

| 219.08 | 0.0400 | 0.0370 | |

| 229.89 | 0.0600 | 0.0570 | |

| 235.01 | 0.0800 | 0.0770 | |

| Ultimate Point | 239.81 | 0.1086 | 0.1056 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Rifaie, H.; Novak, N.; Vesenjak, M.; Ren, Z.; Sumelka, W. Fabrication and Mechanical Testing of the Uniaxial Graded Auxetic Damper. Materials 2022, 15, 387. https://doi.org/10.3390/ma15010387

Al-Rifaie H, Novak N, Vesenjak M, Ren Z, Sumelka W. Fabrication and Mechanical Testing of the Uniaxial Graded Auxetic Damper. Materials. 2022; 15(1):387. https://doi.org/10.3390/ma15010387

Chicago/Turabian StyleAl-Rifaie, Hasan, Nejc Novak, Matej Vesenjak, Zoran Ren, and Wojciech Sumelka. 2022. "Fabrication and Mechanical Testing of the Uniaxial Graded Auxetic Damper" Materials 15, no. 1: 387. https://doi.org/10.3390/ma15010387

APA StyleAl-Rifaie, H., Novak, N., Vesenjak, M., Ren, Z., & Sumelka, W. (2022). Fabrication and Mechanical Testing of the Uniaxial Graded Auxetic Damper. Materials, 15(1), 387. https://doi.org/10.3390/ma15010387