Fire Properties of Bed Mattresses Focusing on the Fire Growth Rate and Flame Height

Abstract

:1. Introduction

2. Full-Scale Fire Test

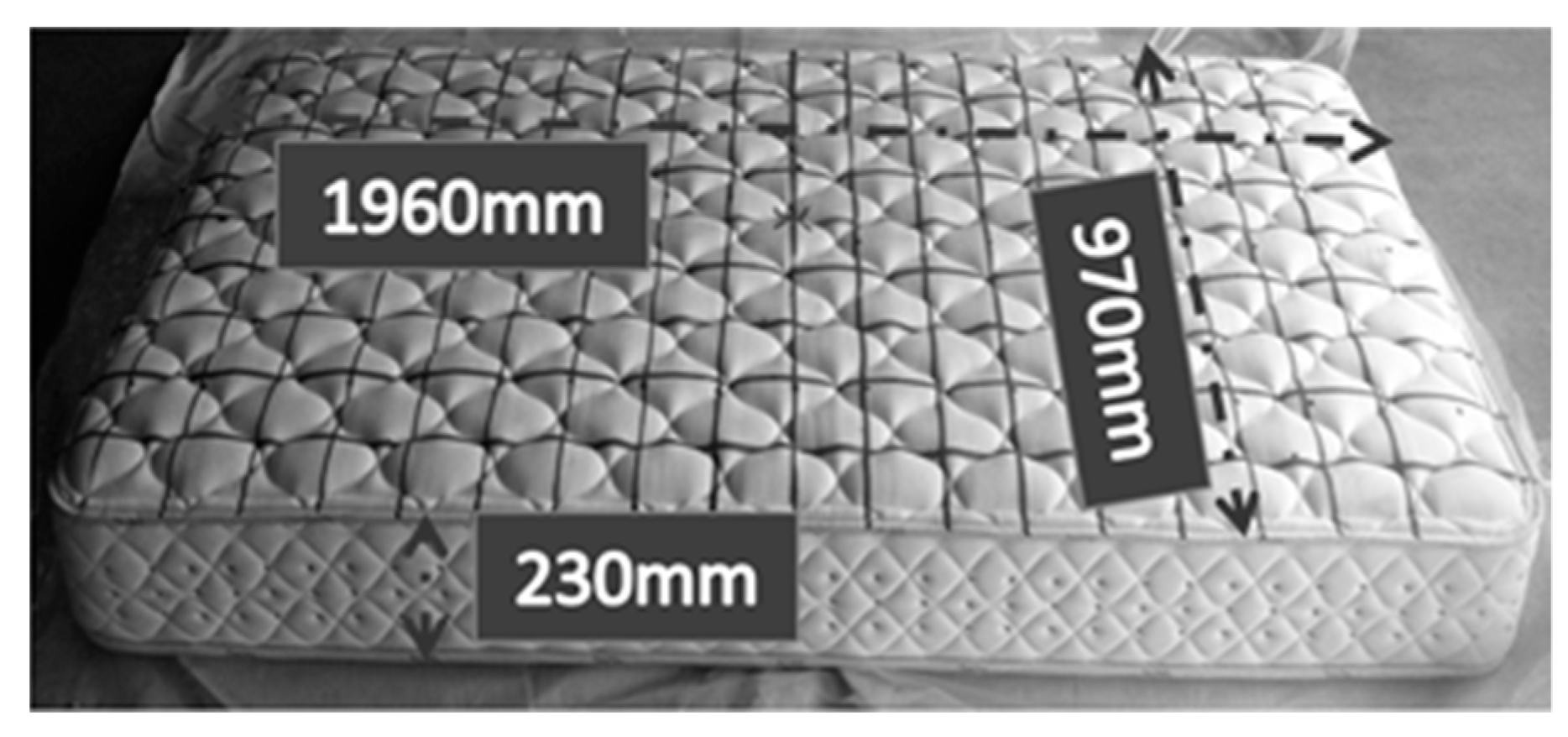

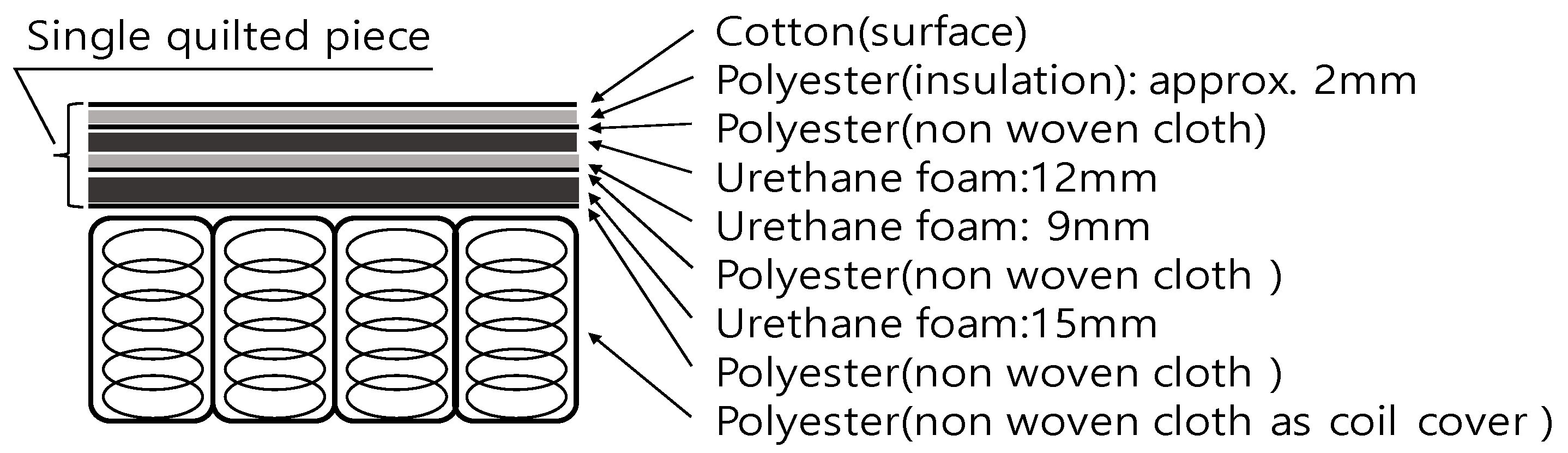

2.1. Experimental Overview

2.2. Experimental Location

2.3. Mattress Installation Height

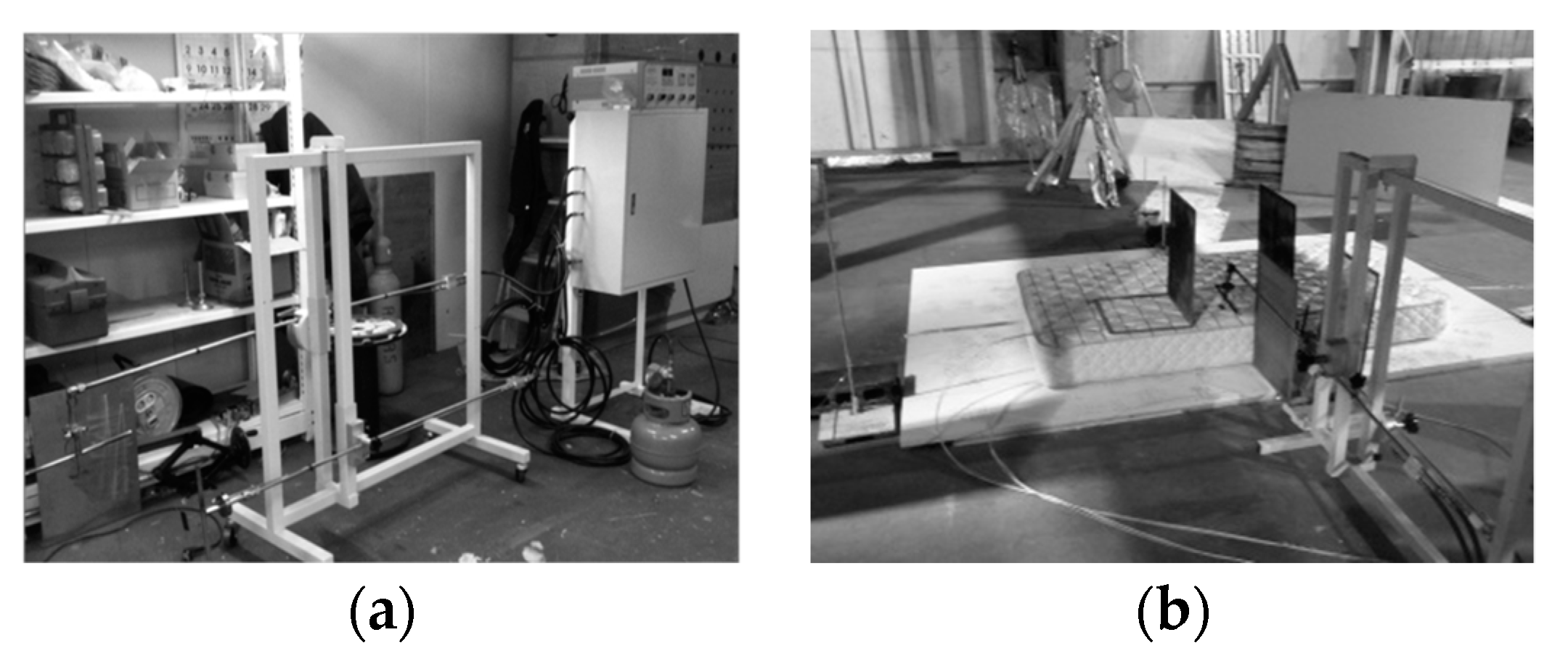

2.4. Ignition Method

2.5. Measurement Methods

2.5.1. Heat Release Rate and Total Heat Release

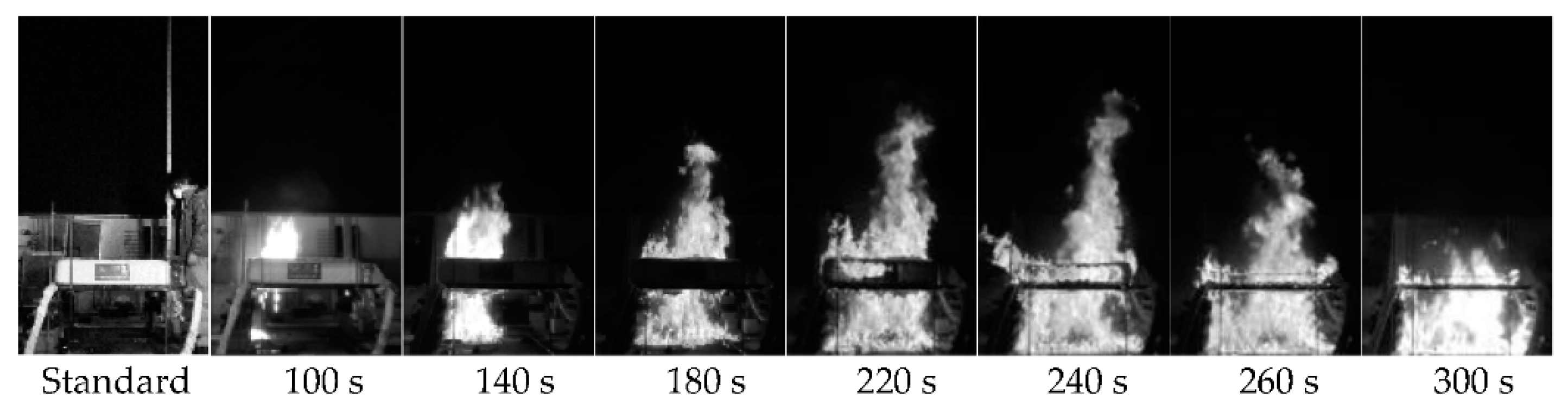

2.5.2. Flame Height

2.5.3. Statistical Analyses

3. Results

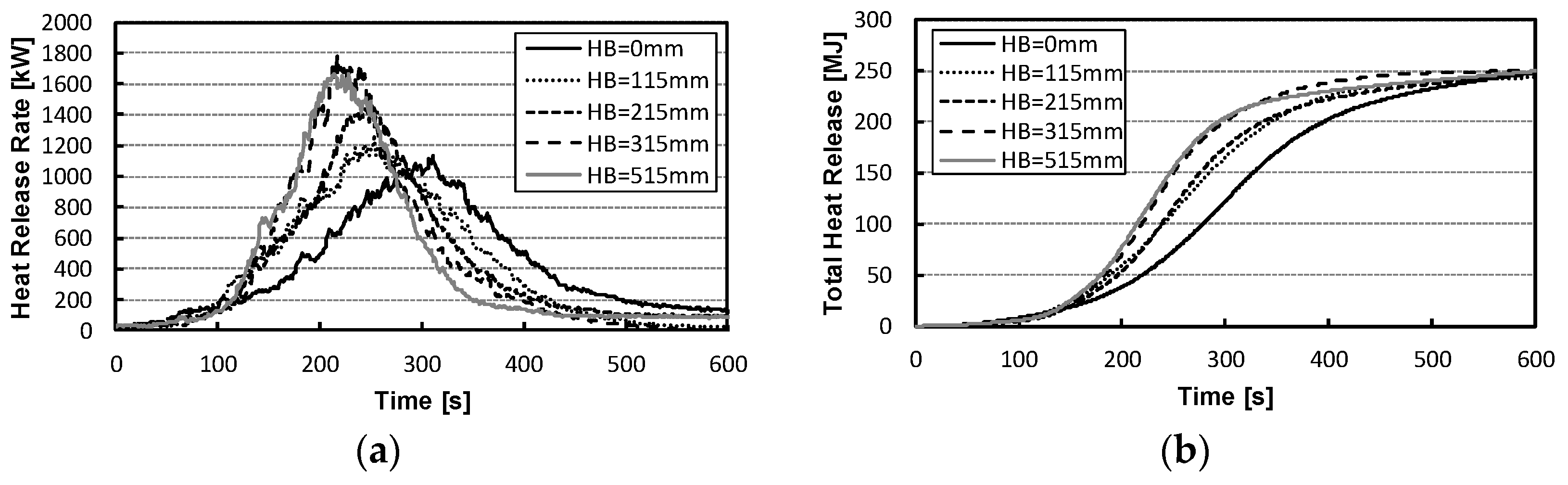

3.1. Heat Release Rate and Total Heat Release

3.2. Flame Height

4. Analysis of Experimental Results

4.1. Analysis of Fire Growth Rate

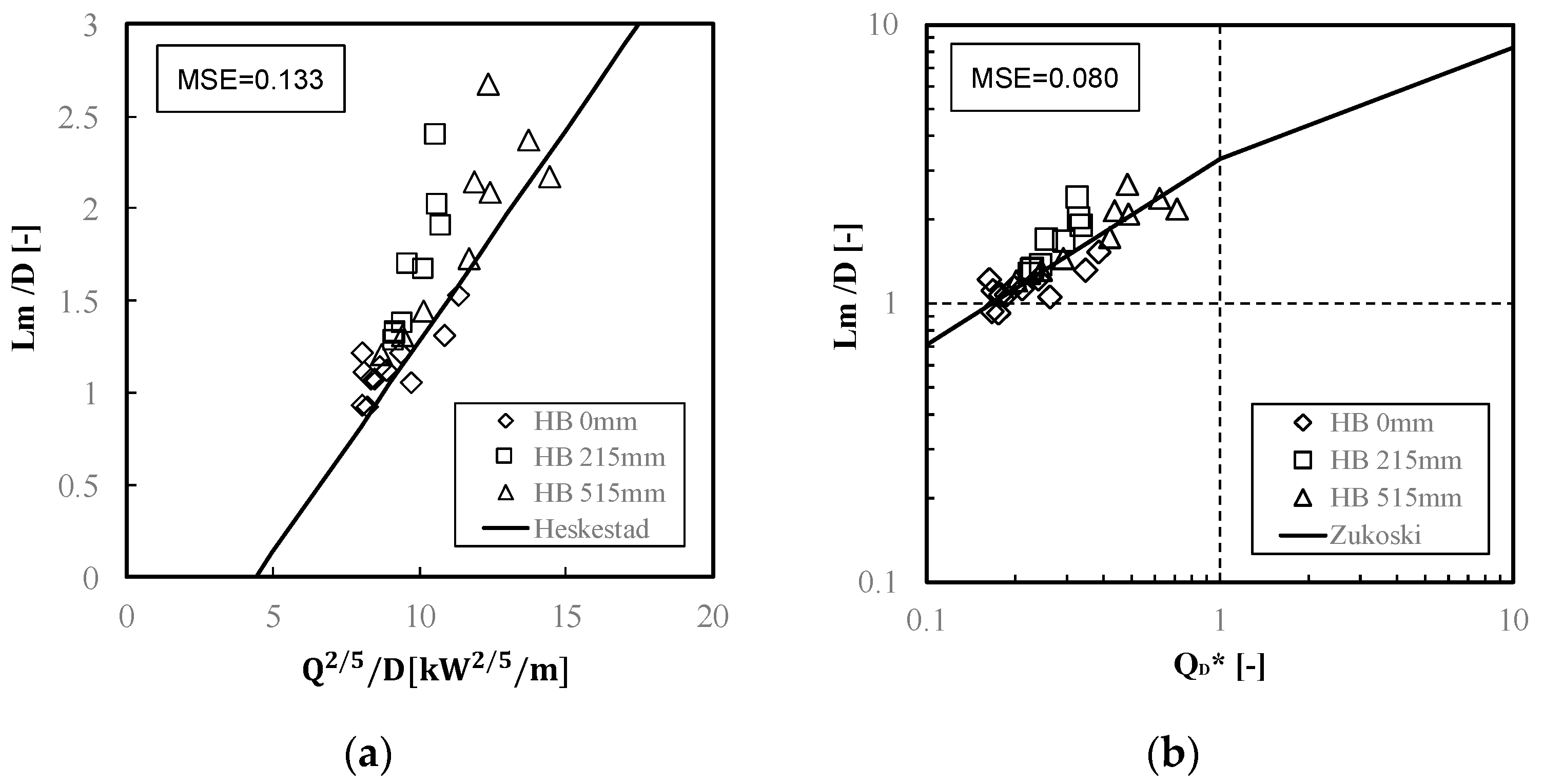

4.2. Flame Height Analysis

5. Conclusions

- (1)

- In the experiment with the mattress installed 0–515 mm on and above the floor, a trend was observed where the fire growth was faster, and the maximum HRR was larger at greater installation heights. Furthermore, the accumulated HRR over time earlier increased with a rise in installation height. The total heat release values for all the conditions were approximately 250 MJ at 600 s after ignition;

- (2)

- The higher the installation height of the mattress, the greater the fire growth rate and the shorter the fire growth time. In addition, as a result of the experiment, fire growth was classified as “medium”, according to the NFPA standard;

- (3)

- In descending order, according to the maximum flame height, the installed heights of the bed mattress HB were 515 mm, 215 mm, and 0 mm. The higher the installation height of the mattress was, the higher the flame height. In addition, the applicability of existing flame height model equations to the experimental results of the full-scale bed mattress combustion was largely confirmed. In addition, in measuring the flame height of the mattress, we checked whether it is reasonable to use the floor level (the point where the pool fire is) or the mattress top surface level (the flame origin by the mattress combustion) as the bottom level of the flame height, using the predictive formula. It was confirmed that the experimental results approximately coincided with these prediction results by adopting the floor level as the bottom of the flame.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nazaré, S.; Davis, R.D.; Butler, K. Assessment of factors affection fire performance of mattresses: A review. Fire Sci. Rev. 2012, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- White Paper on Fire Service in Japan, 2020 (Written in Japanese). Available online: https://www.fdma.go.jp/en/post1.html (accessed on 30 March 2022).

- El-Mahallawy, F.; Habik, S.D. Fundamentals and Technology of Combustion; Elsevier Science Ltd.: Oxford, UK, 2002. [Google Scholar]

- Newman, J.S.; Wieczorek, C.J. Chemical Flame Heights. Fire Saf. J. 2004, 39, 375–382. [Google Scholar] [CrossRef]

- Stratton, B.J. Determining Flame Height and Flame Pulsation Frequency and Estimating Heat Release Rate From 3D Flame Reconstruction. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2005. [Google Scholar]

- Heskestad, G. Luminous heights of turbulent diffusion flames. Fire Saf. J. 1983, 5, 103–108. [Google Scholar] [CrossRef]

- Zukoski, E.E.; Cetegen, B.M.; Kubota, T. Visible Structure of Buoyant Diffusion Flames. In Symposium (International) on Combustion; Elsevier: Pittsburgh, PA, USA, 1984; Volume 20, pp. 361–366. [Google Scholar]

- Fleischmann, C.M. Flammability tests for upholstered furniture and mattresses. In Chapter 7 in Flammability Testion of Materials used in Construction, Transport and Mining; Apte, V.B., Ed.; Woodhead Publishing: Cambridge, UK, 2006; pp. 164–186. [Google Scholar]

- ISO 12949; Standard Test Method for Measuring the Heat Release Rate of Low Flammability Mattresses and Mattress Sets. International Organization for Standards: Geneva, Switzerland, 2011.

- Barbrauskas, V.; Grayson, S.J. Heat Release in Fires; Chapter 3; Elsevier Applied Science: Pittsburgh, PA, USA, 1992; pp. 31–44. [Google Scholar]

- NFPA 92B; Standard for Smoke Management Systems in Malls, Atria, and Large Spaces, 2009 Edition. National Fire Protection Association: Quincy, MA, USA, 2009.

- NFPA 72; National Fire Alarm and Signaling Code. National Fire Protection Association: Quincy, MA, USA, 2017.

- Nelson, H.E. An Engineering Analysis of the Early Stages of Fire Development—The Fire at the Dupont Plaza Hotel and Casino—December 31, 1986; NBSIR 87-3560; U.S. Department of Commerce, National Bureau of Standards, National Engineering Laboratory Center for Fire Research: Gaithersburg, MD, USA, 1987.

| Classification of Fire Growth in NFPA 72 | Fire Growth Time (tg (s)) | Fire Growth Rate (α (kW/s2)) |

|---|---|---|

| Slow | 600 | 0.00293 |

| Medium | 300 | 0.0117 |

| Fast | 150 | 0.0469 |

| Ultra-fast | 75 | 0.1876 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, J.-J.; Mizuno, M.; Park, K.-W.; Lim, H.-J.; Cho, C.-G. Fire Properties of Bed Mattresses Focusing on the Fire Growth Rate and Flame Height. Materials 2022, 15, 3757. https://doi.org/10.3390/ma15113757

Jeong J-J, Mizuno M, Park K-W, Lim H-J, Cho C-G. Fire Properties of Bed Mattresses Focusing on the Fire Growth Rate and Flame Height. Materials. 2022; 15(11):3757. https://doi.org/10.3390/ma15113757

Chicago/Turabian StyleJeong, Jong-Jin, Masayuki Mizuno, Kye-Won Park, Hyeon-Jin Lim, and Chang-Geun Cho. 2022. "Fire Properties of Bed Mattresses Focusing on the Fire Growth Rate and Flame Height" Materials 15, no. 11: 3757. https://doi.org/10.3390/ma15113757

APA StyleJeong, J.-J., Mizuno, M., Park, K.-W., Lim, H.-J., & Cho, C.-G. (2022). Fire Properties of Bed Mattresses Focusing on the Fire Growth Rate and Flame Height. Materials, 15(11), 3757. https://doi.org/10.3390/ma15113757