Artificial Neural Network Modelling of the Effect of Vanadium Addition on the Tensile Properties and Microstructure of High-Strength Tempcore Rebars

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Experimental Procedures

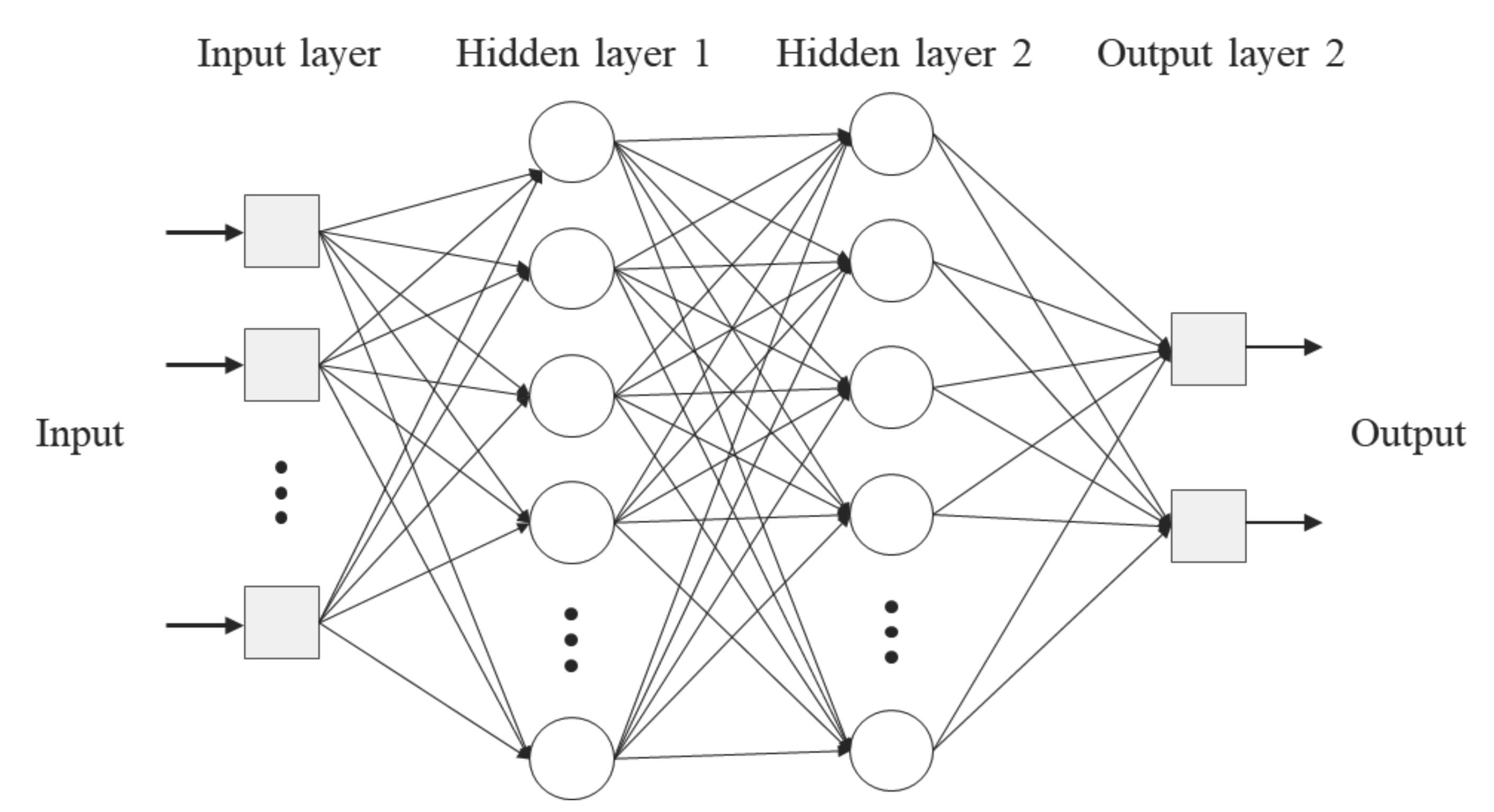

2.2. ANN Modelling Procedure

3. Results and Discussion

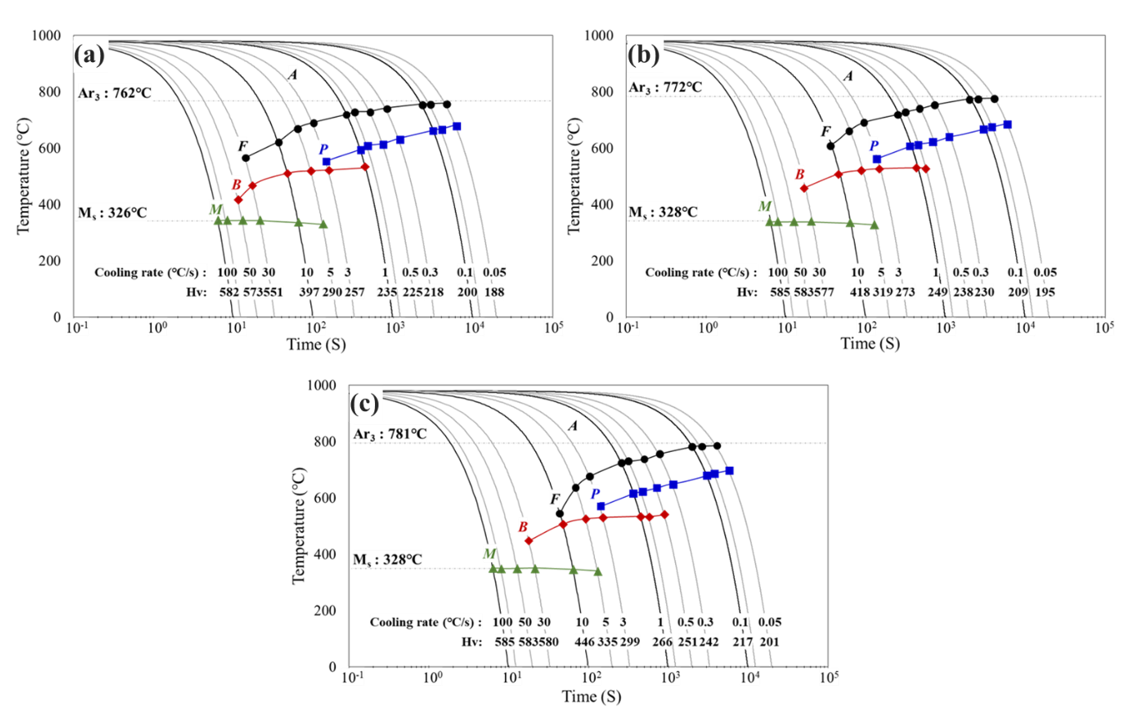

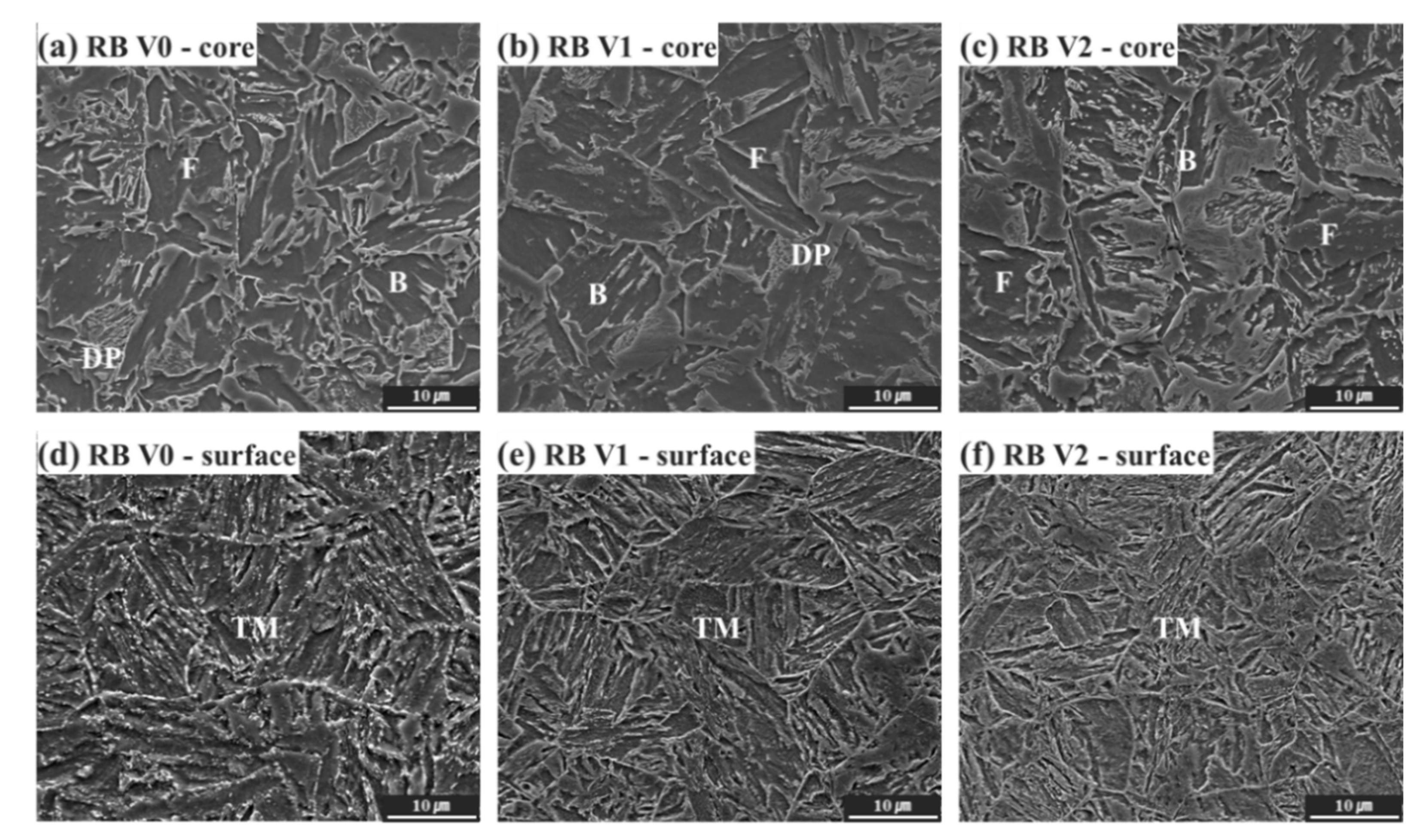

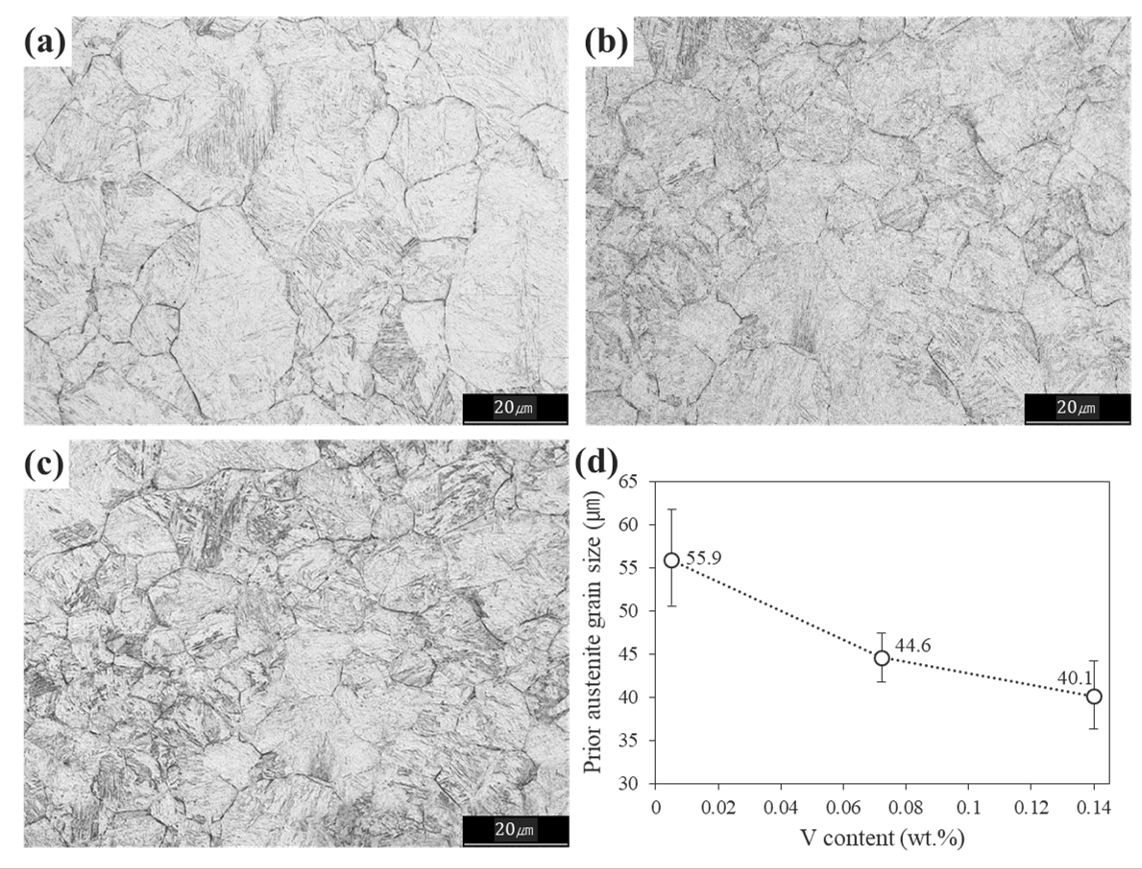

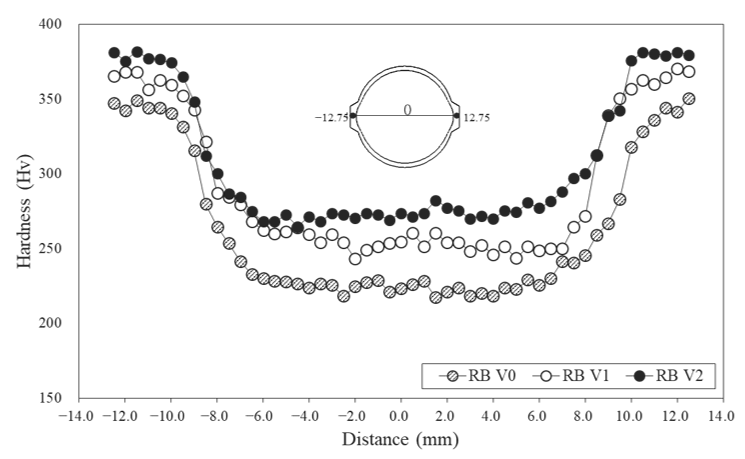

3.1. CCT Diagram and Microstructure of Tempcore Rebars of various V Contents

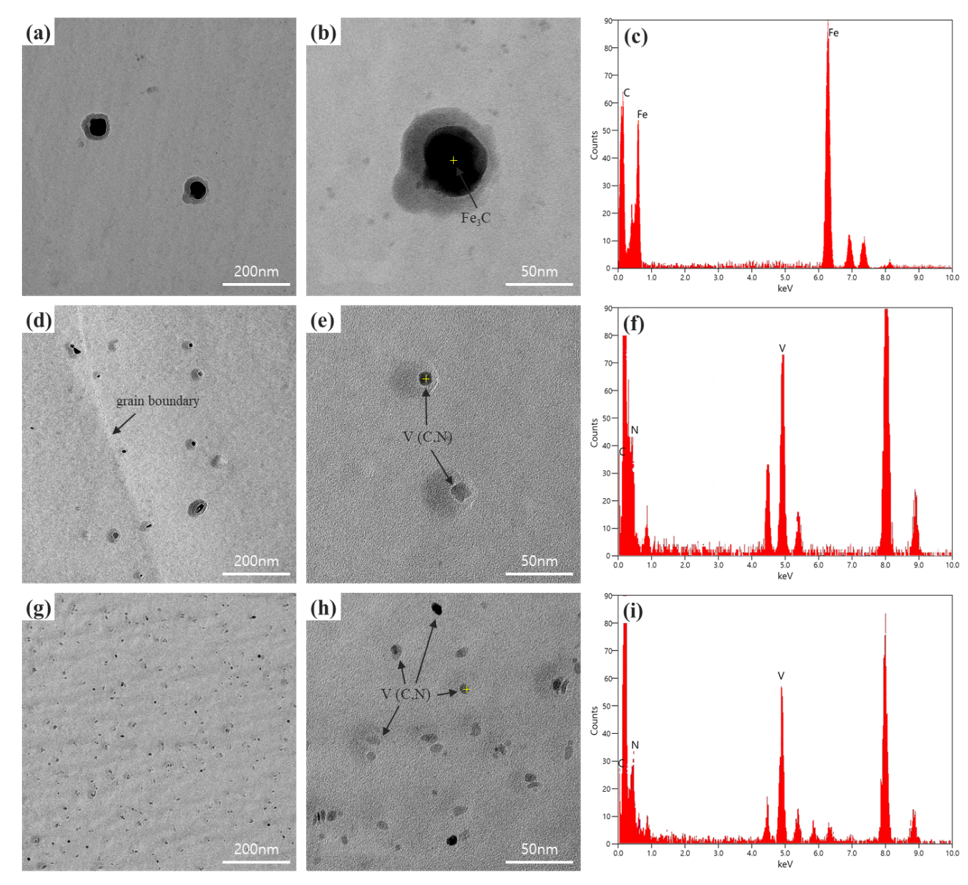

3.2. Precipitates in Tempcore Rebars with Various V Contents

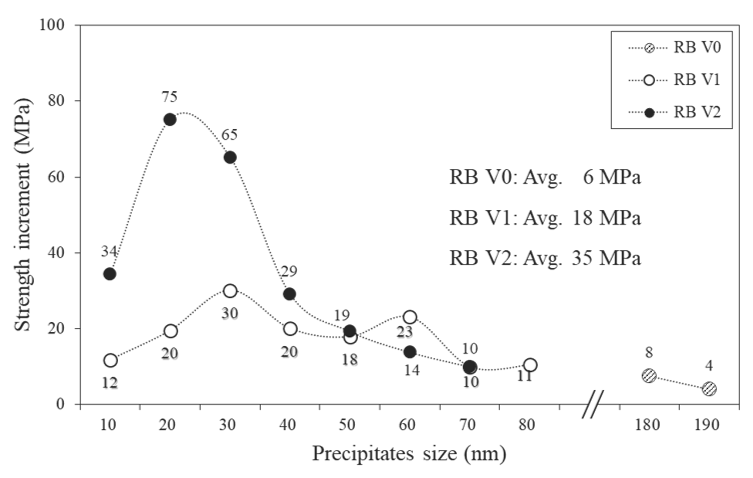

3.3. Mechanical Properties as a Function of the Precipitates

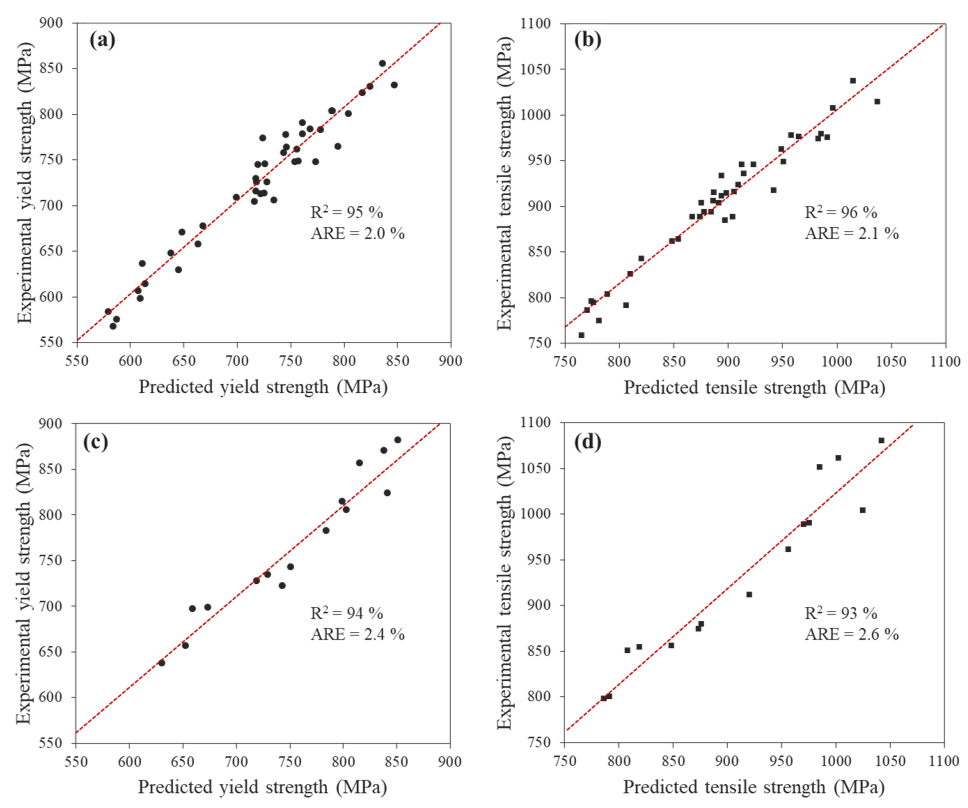

3.4. Prediction of Tensile Properties Using ANN

4. Conclusions

- (1)

- As the V content increased from 0.005 to 0.140 wt.%, the Ar3 temperature increased and the bainite transformation curve was observed on the CCT diagram even at a low cooling rate. Therefore, the rebar core produced by the Tempcore process was observed to have a more bainitic microstructure as the V content increased.

- (2)

- The average PAGS of specimen RB V2, which had the highest V content (0.140 wt.%) was 40.1 μm, which was significantly reduced compared with specimen RB V0 (55.9 μm). This was associated with the solubility of precipitates for various V contents: grain refinement occurred in specimen RB V2 because of the pinning effect of V (C, N), which was not completely dissolved, and the solute drag effect of the dissolved V atoms during the Tempcore process.

- (3)

- V(C, N) primarily precipitated in the matrix, and the number of fine precipitates below 20 nm increased as the V content increased. The Ashby–Orowan model successfully demonstrated that the V(C, N) precipitates contributed significantly to the strengthening mechanism (specifically the yield strength) of the Tempcore rebar.

- (4)

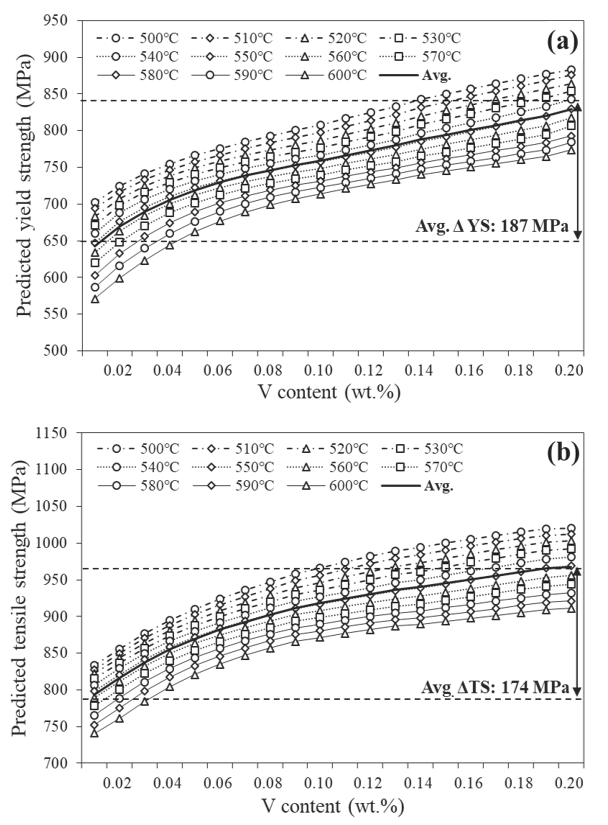

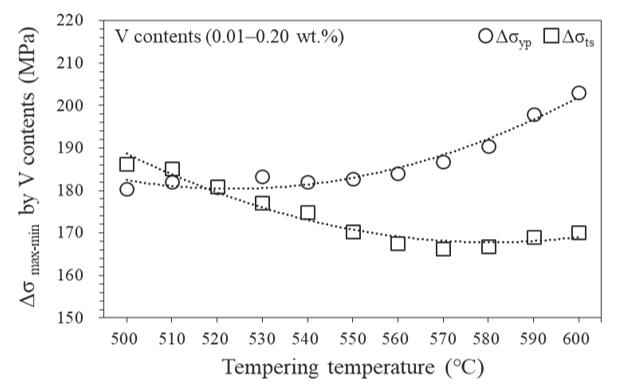

- The ANN model successfully predicted the yield and tensile strengths of the Tempcore rebar using the main parameters such as the V content and self-tempering temperature. The data trained by the ANN model showed a high reproducibility of over 93% of R-square and the average relative error was in the range of 2.4–2.6% with the testing data.

- (5)

- The ANN prediction results show that V contents in the range of 0.01–0.20 wt.%, are more effective in increasing the yield strength at high self-tempering temperatures ≥530 °C. This result is expected to provide outstanding guidelines for optimising the V content and Tempcore process conditions for obtaining high-strength rebars in the steel industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, W.; Wang, K.; Kodur, V.; Wang, B. Mechanical properties of high-strength Q690 steel at elevated temperature. J. Mater. Civ. Eng. 2018, 30, 04018062. [Google Scholar] [CrossRef]

- Coelho, A.M.G.; Bijlaard, F. High strength steel in buildings and civil engineering structures: Design of connections. Adv. Struct. Eng. 2010, 13, 413–429. [Google Scholar] [CrossRef]

- Javidan, F.; Heidarpour, A.; Zhao, X.L.; Fallahi, H. Fundamental behaviour of high strength and ultra-high strength steel subjected to low cycle structural damage. Eng. Struct. 2017, 143, 427–440. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, G.Q.; Chen, S.W.; Sun, F.F. Experimental and numerical study on the behavior of axially compressed high strength steel box-columns. Eng. Struct. 2014, 58, 79–91. [Google Scholar] [CrossRef]

- Anggraini, R.; Tavio; Raka, I.G.P.; Agustiar. Stress-strain relationship of high-strength steel (HSS) reinforcing bars. In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2018; Volume 1964, p. 020025. [Google Scholar] [CrossRef]

- Egger, J.E.; Rojas, F.R.; Massone, L.M. High-Strength Reinforcing Steel Bars: Low Cycle Fatigue Behavior Using RGB Methodology. Int. J. Concr. Struct. Mater. 2021, 15, 38. [Google Scholar] [CrossRef]

- Pan, H.B.; Zhang, M.J.; Liu, W.M.; Yan, J.; Wang, H.T.; Xie, C.S.; Guo, Z. Effects of micro-alloying and production process on precipitation behaviors and mechanical properties of HRB600. J. Iron Steel Res. Int. 2017, 24, 536–543. [Google Scholar] [CrossRef]

- Karmakar, A.; Sahu, P.; Neogy, S.; Chakrabarti, D.; Mitra, R.; Mukherjee, S.; Kundu, S. Effect of cooling rate and chemical composition on microstructure and properties of naturally cooled vanadium-microalloyed steels. Metall. Mater. Trans. A 2017, 48, 1581–1595. [Google Scholar] [CrossRef]

- Balliger, N.K.; Honeycombe, R.W.K. The effect of nitrogen on precipitation and transformation kinetics in vanadium steels. Metall. Trans. A 1980, 11, 421–429. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, C.; Li, Z.; Zhai, Y.; Wang, J.; Liu, Z. Effect of final cooling temperature on the microstructure and mechanical properties of high-strength anti-seismic rebar. Mater. Res. Express 2021, 8, 096525. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Nayak, S.; Venkatasurya, P.K.C.; Ramuni, V.; Somani, M.C.; Karjalainen, L.P. Nanograined/ultrafine-grained structure and tensile deformation behavior of shear phase reversion-induced 301 austenitic stainless steel. Metall. Mater. Trans. A 2010, 41, 2162–2174. [Google Scholar] [CrossRef]

- Chen, C.Y.; Yen, H.W.; Kao, F.H.; Li, W.C.; Huang, C.Y.; Yang, J.R.; Wang, S.H. Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater. Sci. Eng. A 2009, 499, 162–166. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.D.; Wang, B.X.; Wang, G.D.; Misra, R.D.K. The relationship between microstructural evolution and mechanical properties of heavy plate of low-mn steel during ultra fast cooling. Metall. Mater. Trans. A 2015, 46, 2834–2843. [Google Scholar] [CrossRef][Green Version]

- Lee, S.I.; Lim, H.S.; Hwang, B. Effect of Micro-Alloying Elements on Recrystallization Behavior of Carbon Steels at Different Strain Rates. Korean J. Mater. Res. 2016, 26, 535–541. [Google Scholar] [CrossRef]

- Sage, A.M. Effect of vanadium, nitrogen, and aluminium on the mechanical properties of reinforcing bar steels. Met. Technol. 1976, 3, 65–70. [Google Scholar] [CrossRef]

- Ahmed, E.; Ibrahim, S.; Galal, M.; Elnekhaily, S.A.; Allam, T. Microstructure and mechanical properties of V-alloyed rebars subjected to Tempcore process. Metals 2021, 11, 246. [Google Scholar] [CrossRef]

- Nikolaou, J.; Papadimitriou, G.D. Microstructures and mechanical properties after heating of reinforcing 500 MPa class weldable steels produced by various processes (Tempcore, microalloyed with vanadium and work-hardened). Constr. Build. Mater. 2004, 18, 243–254. [Google Scholar] [CrossRef]

- Choi, W.; Choi, S.; Bae, S.; Kang, N. Computational Modelling and Experimental Analysis of Hardness and Microstructure of Reinforcing Bars Produced by Tempcore Process. Met. Mater. Int. 2021. [Google Scholar] [CrossRef]

- Hong, T.W.; Lee, S.I.; Shim, J.H.; Lee, M.G.; Lee, J.; Hwang, B. Artificial Neural Network for Modeling the Tensile Properties of Ferrite-Pearlite Steels: Relative Importance of Alloying Elements and Microstructural Factors. Met. Mater. Int. 2021. [Google Scholar] [CrossRef]

- Hosseini, S.M.K.; Zarei-Hanzaki, A.; Panah, M.Y.; Yue, S. ANN model for prediction of the effects of composition and process parameters on tensile strength and percent elongation of Si–Mn TRIP steels. Mater. Sci. Eng. A 2004, 374, 122–128. [Google Scholar] [CrossRef]

- Khalaj, G.; Azimzadegan, T.; Khoeini, M.; Etaat, M. Artificial neural networks application to predict the ultimate tensile strength of X70 pipeline steels. Neural Comput. Appl. 2013, 23, 2301–2308. [Google Scholar] [CrossRef]

- Cetinel, H.; Özyiğit, H.A.; Özsoyeller, L. Artificial neural networks modeling of mechanical property and microstructure evolution in the Tempcore process. Comput. Struct. 2002, 80, 213–218. [Google Scholar] [CrossRef]

- Kim, J.; Ku, J.; Park, Y.; Kim, Y.; Hwang, Y.; Kim, H.; Murugan, S.; Ku, N. Study on Nugget Diameter Prediction of Resistance Spot Welding Using an Artificial Neural Network. J. Weld. Join. 2021, 39, 649–657. [Google Scholar] [CrossRef]

- Lee, D.; Jin, C.; Rhee, S. Study on Real-Time Porosity Defect Detection Through Neural Network Structure Optimization using Genetic Algorithm in GMAW. J. Weld. Join. 2021, 39, 542–551. [Google Scholar] [CrossRef]

- Churyumov, A.; Kazakova, A.; Churyumova, T. Modelling of the steel high-temperature deformation behaviour using artificial neural network. Metals 2022, 12, 447. [Google Scholar] [CrossRef]

- Honysz, R. Modeling the Chemical Composition of Ferritic Stainless Steels with the Use of Artificial Neural Networks. Metals 2021, 11, 724. [Google Scholar] [CrossRef]

- Anderson, D.; McNeill, G. Artificial neural networks technology. Kaman Sci. Corp. 1992, 258, 1–83. [Google Scholar]

- Khalaj, G.; Yoozbashizadeh, H.; Khodabandeh, A.; Nazari, A. Artificial neural network to predict the effect of heat treatments on Vickers microhardness of low-carbon Nb microalloyed steels. Neural Comput. Appl. 2013, 22, 879–888. [Google Scholar] [CrossRef]

- Hakim, S.J.S.; Razak, H.A. Adaptive neuro fuzzy inference system (ANFIS) and artificial neural networks (ANNs) for structural damage identification. Struct. Eng. Mech. Int. J. 2013, 45, 779–802. [Google Scholar] [CrossRef]

- Crooks, M.J.; Garratt-Reed, A.J.; Vander Sande, J.B.; Owen, W.S. The isothermal austenite-ferrite transformation in some deformed vanadium steels. Metall. Trans. A 1982, 13, 1347–1353. [Google Scholar] [CrossRef]

- Glišić, D.; Radović, N.; Koprivica, A.; Fadel, A.; Drobnjak, D. Influence of reheating temperature and vanadium content on transformation behavior and mechanical properties of medium carbon forging steels. ISIJ Int. 2010, 50, 601–606. [Google Scholar] [CrossRef][Green Version]

- Adrian, H. A mechanism for effect of vanadium on hardenability of medium carbon manganese steel. Mater. Sci. Technol. 1999, 15, 366–378. [Google Scholar] [CrossRef]

- Khare, S.; Lee, K.; Bhadeshia, H.K.D.H. Relative effects of Mo and B on ferrite and bainite kinetics in strong steels. Int. J. Mater. Res. 2009, 100, 1513–1520. [Google Scholar] [CrossRef]

- Furuhara, T.; Moritani, T.; Sakamoto, K.; Maki, T. Substructure and crystallography of degenerate pearlite in an Fe-C binary alloy. In Materials Science Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2007; Volume 539, pp. 4832–4837. [Google Scholar] [CrossRef]

- Hosny, S.; Gepreel, M.A.H.; Ibrahim, M.G.; Bassuony, A.R. Simulation of Tempcore Process for 500 MPa Steel Bars. Met. Mater. Int. 2020, 27, 3359–3370. [Google Scholar] [CrossRef]

- Li, D.D.; Zhang, T.; Liu, J.Y.; Li, J. Vanadium & Titanium’s Effects on High Strength Weathering Steel’s Impact Toughness in CGHAZ. In Advanced Materials Research; Trans Tech Publications Ltd.: Bach, Switzerland, 2014; Volume 910, pp. 118–122. [Google Scholar] [CrossRef]

- Barbacki, A.; Honeycombe, R.W.K. Transitions in carbide morphology in molybdenum and vanadium steels. Metallography 1976, 9, 277–291. [Google Scholar] [CrossRef]

- Davenport, A.T.; Honeycombe, R.W.K. Precipitation of carbides at γ—α boundaries in alloy steels. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 322, 191–205. [Google Scholar] [CrossRef]

- Narita, K. Physical chemistry of the groups IVa (Ti, Zr), Va (V, Nb, Ta) and the rare earth elements in steel. Trans. Iron Steel Inst. Jpn. 1975, 15, 145–152. [Google Scholar] [CrossRef]

- Huo, X.; Xia, J.; Li, L.; Peng, Z.; Chen, S.; Peng, C.T. A review of research and development on titanium microalloyed high strength steels. Mater. Res. Express 2018, 5, 062002. [Google Scholar] [CrossRef]

- Khalid, F.A.; Edmonds, D.V. Interphase precipitation in microalloyed engineering steels and model alloy. Mater. Sci. Technol. 1993, 9, 384–396. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T. Effects of α/γ orientation relationship on VC interphase precipitation in low-carbon steels. Scr. Mater. 2013, 69, 17–20. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Lian, Y.; Ma, M.; Zhao, C.; Ye, H.; Li, G.; Zhang, C.; Huang, J. Effects of vanadium content on the carbides transformation and strengthening mechanism of MPS700V hot-work die steel at room and elevated temperatures. Mater. Sci. Eng. A 2021, 813, 141091. [Google Scholar] [CrossRef]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Wang, P.; Li, Z.; Lin, G.; Zhou, S.; Yang, C.; Yong, Q. Influence of vanadium on the microstructure and mechanical properties of medium-carbon steels for wheels. Metals 2018, 8, 978. [Google Scholar] [CrossRef]

- Gündüz, S.; Cochrane, R.C. Influence of cooling rate and tempering on precipitation and hardness of vanadium microalloyed steel. Mater. Des. 2005, 26, 486–492. [Google Scholar] [CrossRef]

- Hwang, B.; Shim, J.H.; Lee, M.G.; Lee, J.; Jung, J.H.; Kim, B.S.; Won, S.B. Technical developments and trends of earthquake resisting high-strength reinforcing steel bars. J. Korean Inst. Met. Mater. 2016, 54, 862–874. [Google Scholar] [CrossRef]

| Material | Chemical Composition (wt. %) | Mechanical Property | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | V | Fe | YS (MPa) | TS (MPa) | El. (%) | |

| RB V0 | 0.28 | 1.39 | 0.20 | 0.013 | 0.009 | 0.005 | Bal. | 652 | 791 | 13.3 |

| RB V1 | 0.27 | 1.42 | 0.21 | 0.016 | 0.008 | 0.072 | Bal. | 750 | 904 | 11.6 |

| RB V2 | 0.28 | 1.40 | 0.19 | 0.015 | 0.008 | 0.140 | Bal. | 796 | 948 | 9.1 |

| Rebar Diameter (mm) | Reheating Temp. (°C) | Finishing Roll Temp. (°C) | Quenching Time (s) | Number of the Cooler (ea.) | Self-Tempering Temp. (°C) |

|---|---|---|---|---|---|

| 25 | 1020 | 980 | 4.3–4.8 | 26 | 540 |

| Range | Mean | Standard Deviation | |

|---|---|---|---|

| Inputs | |||

| Chemical composition (wt. %) | |||

| C | 0.26–0.31 | 0.28 | 0.014 |

| Mn | 1.30–1.44 | 1.39 | 0.030 |

| V | 0.005–0.200 | 0.084 | 0.058 |

| Cr | 0.09–0.199 | 0.142 | 0.021 |

| Mo | 0.011–0.027 | 0.019 | 0.004 |

| P | 0.017–0.026 | 0.020 | 0.002 |

| S | 0.011–0.020 | 0.016 | 0.003 |

| Tempcore process parameters (°C) | |||

| Self–tempering temperature | 501–600 | 1.70 | 30.89 |

| Outputs | |||

| Mechanical properties (MPa) | |||

| Yield strength | 579–847 | 720 | 72 |

| Tensile strength | 727–1037 | 880 | 80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, W.; Won, S.; Kim, G.-S.; Kang, N. Artificial Neural Network Modelling of the Effect of Vanadium Addition on the Tensile Properties and Microstructure of High-Strength Tempcore Rebars. Materials 2022, 15, 3781. https://doi.org/10.3390/ma15113781

Choi W, Won S, Kim G-S, Kang N. Artificial Neural Network Modelling of the Effect of Vanadium Addition on the Tensile Properties and Microstructure of High-Strength Tempcore Rebars. Materials. 2022; 15(11):3781. https://doi.org/10.3390/ma15113781

Chicago/Turabian StyleChoi, Woonam, Sungbin Won, Gil-Su Kim, and Namhyun Kang. 2022. "Artificial Neural Network Modelling of the Effect of Vanadium Addition on the Tensile Properties and Microstructure of High-Strength Tempcore Rebars" Materials 15, no. 11: 3781. https://doi.org/10.3390/ma15113781

APA StyleChoi, W., Won, S., Kim, G.-S., & Kang, N. (2022). Artificial Neural Network Modelling of the Effect of Vanadium Addition on the Tensile Properties and Microstructure of High-Strength Tempcore Rebars. Materials, 15(11), 3781. https://doi.org/10.3390/ma15113781