Effect of Carbon Nanofibers on Physical, Adhesion and Rheological Properties of Liquid Epoxidized Natural Rubber Modified Asphalt

Abstract

:1. Introduction

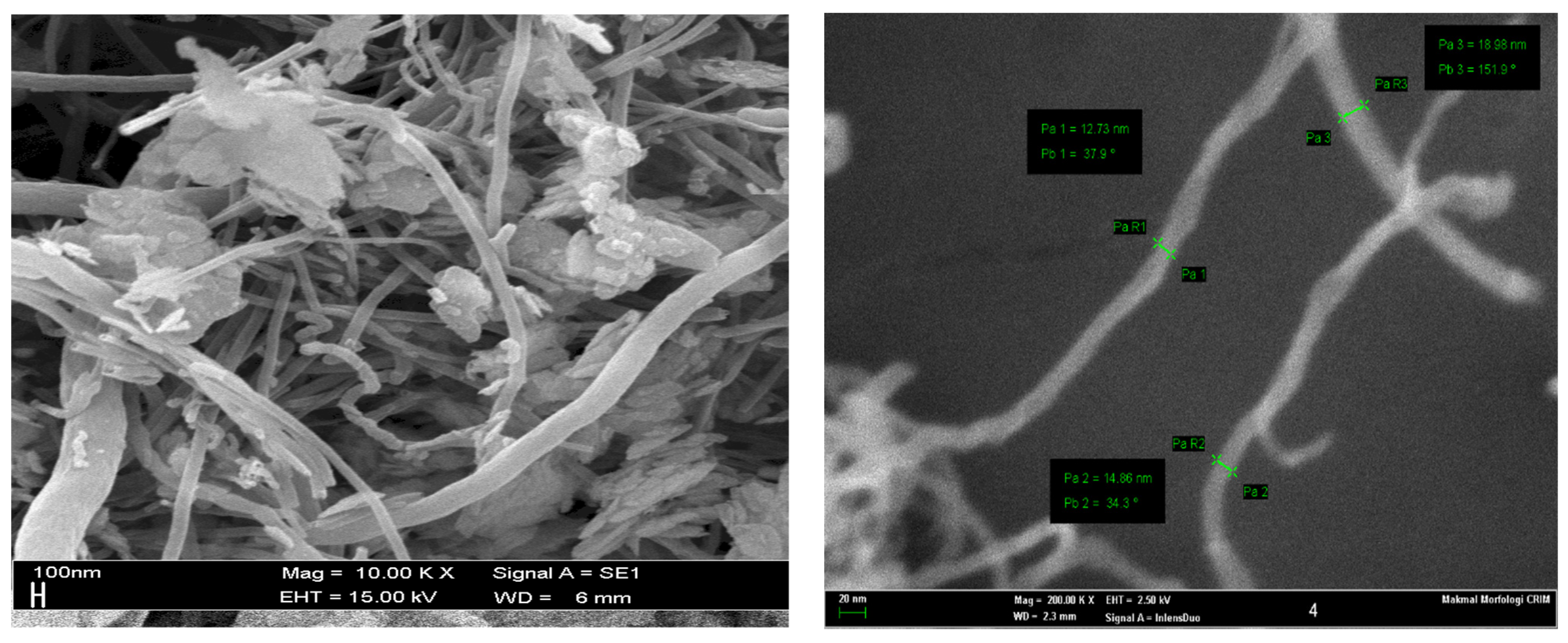

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Binders

2.3. Conventional Physical Properties

2.4. Temperature Susceptibility

2.5. Elastic Recovery

2.6. Atomic Force Microscopy

2.7. Dynamic Shear Rheometer

2.8. Statistical Analysis

3. Results and Discussions

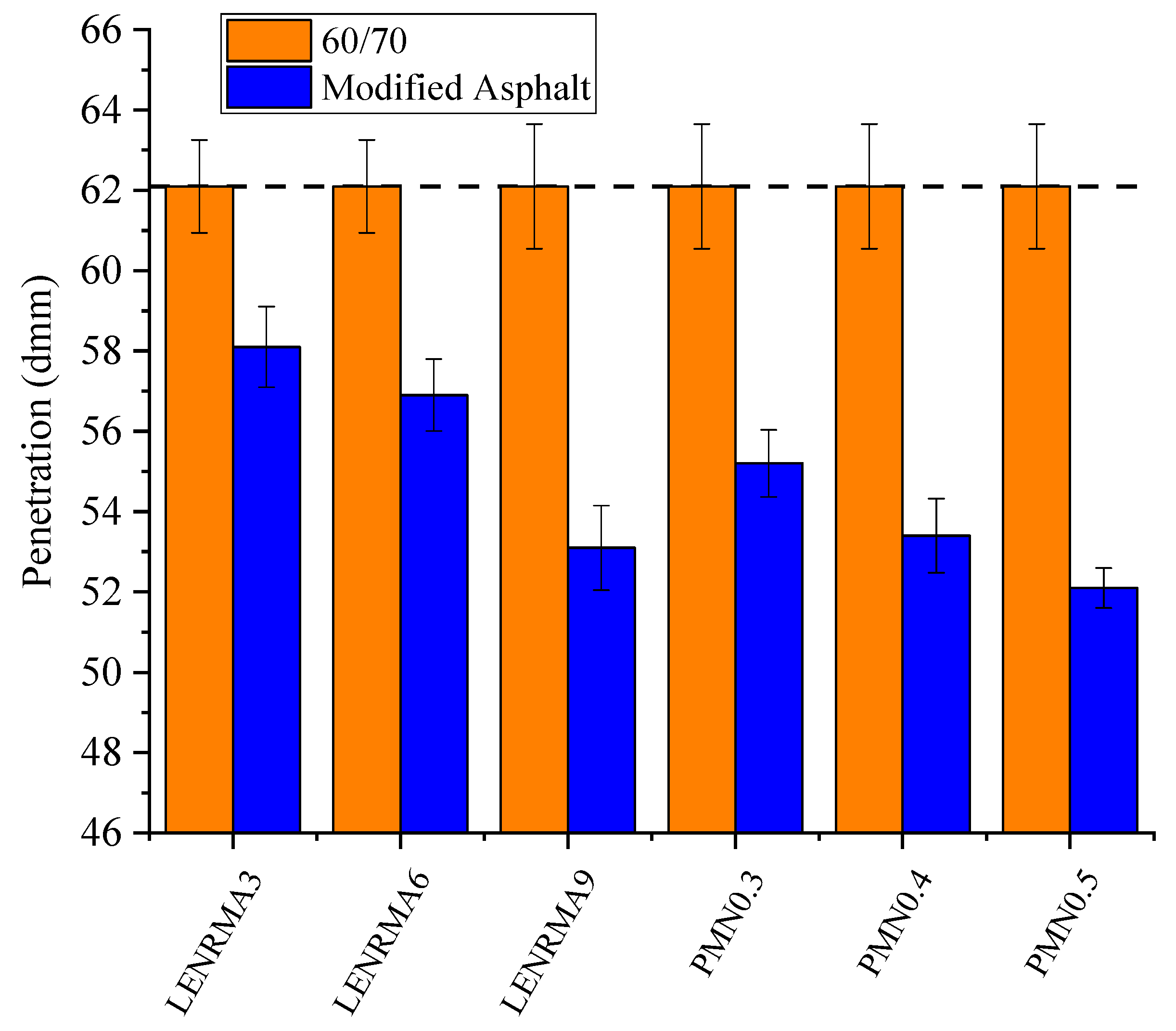

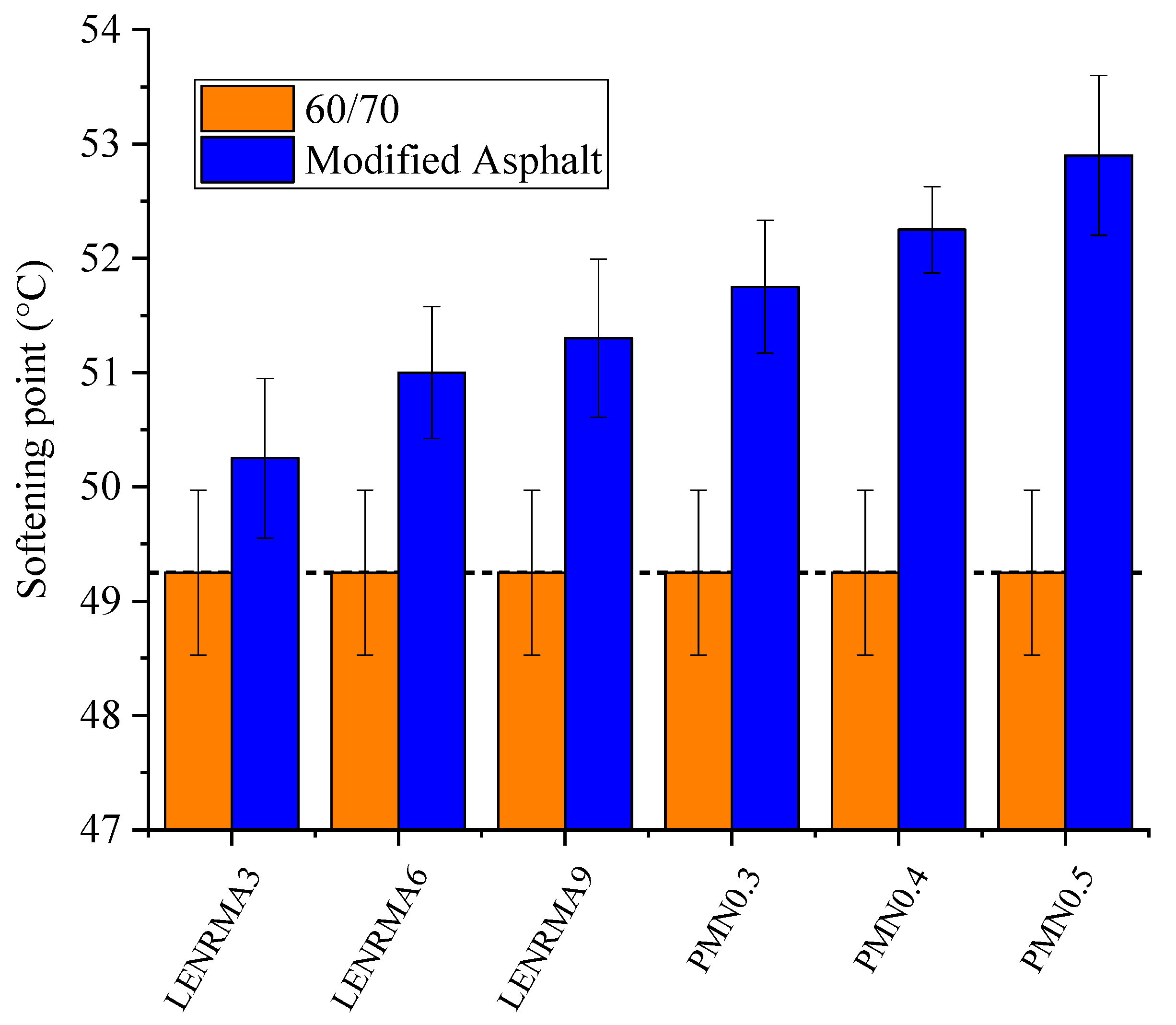

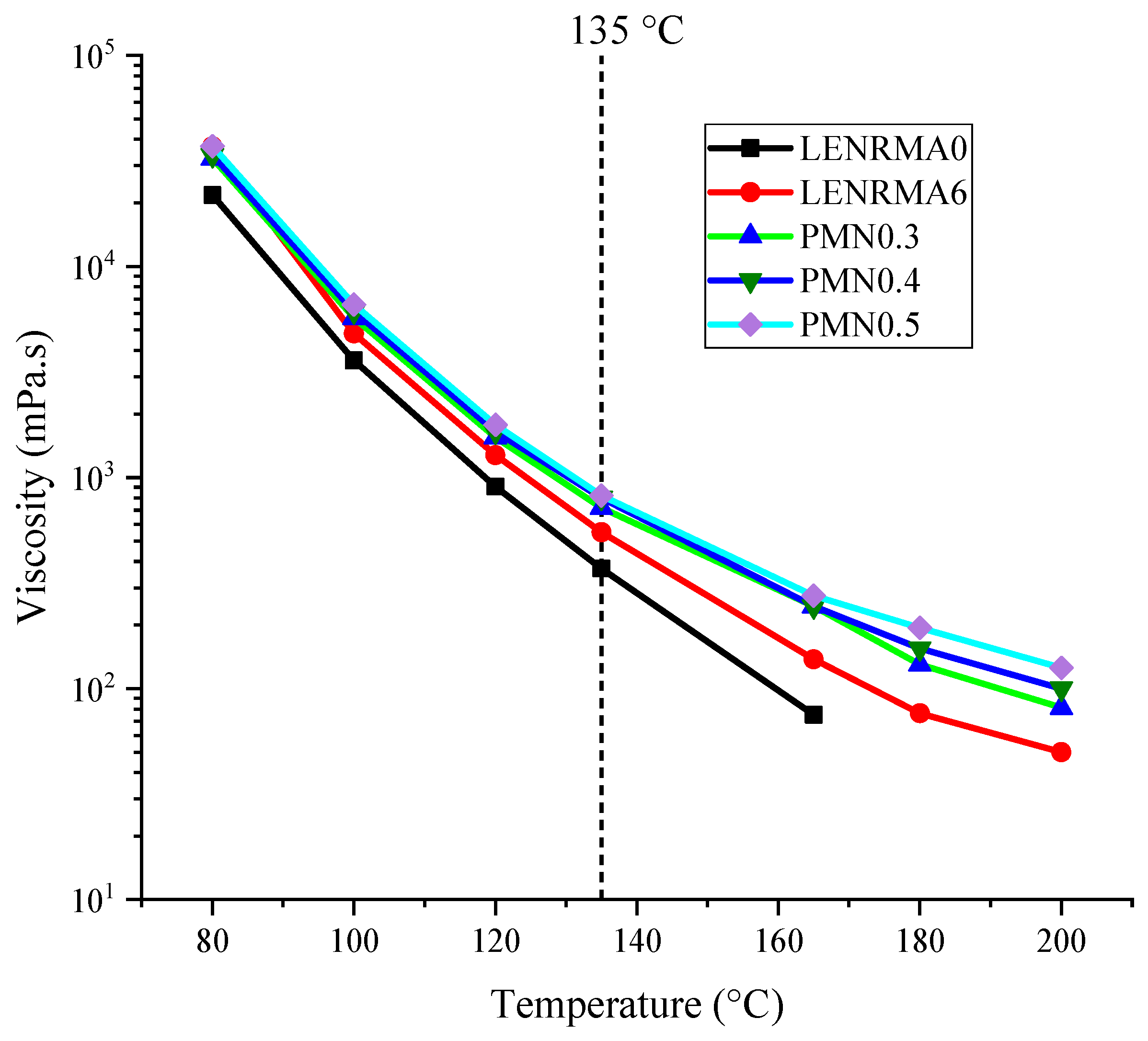

3.1. Conventional Physical Properties

3.1.1. Penetration Test Results

3.1.2. Softening Point Test Results

3.1.3. Rotational Viscosity Test Results

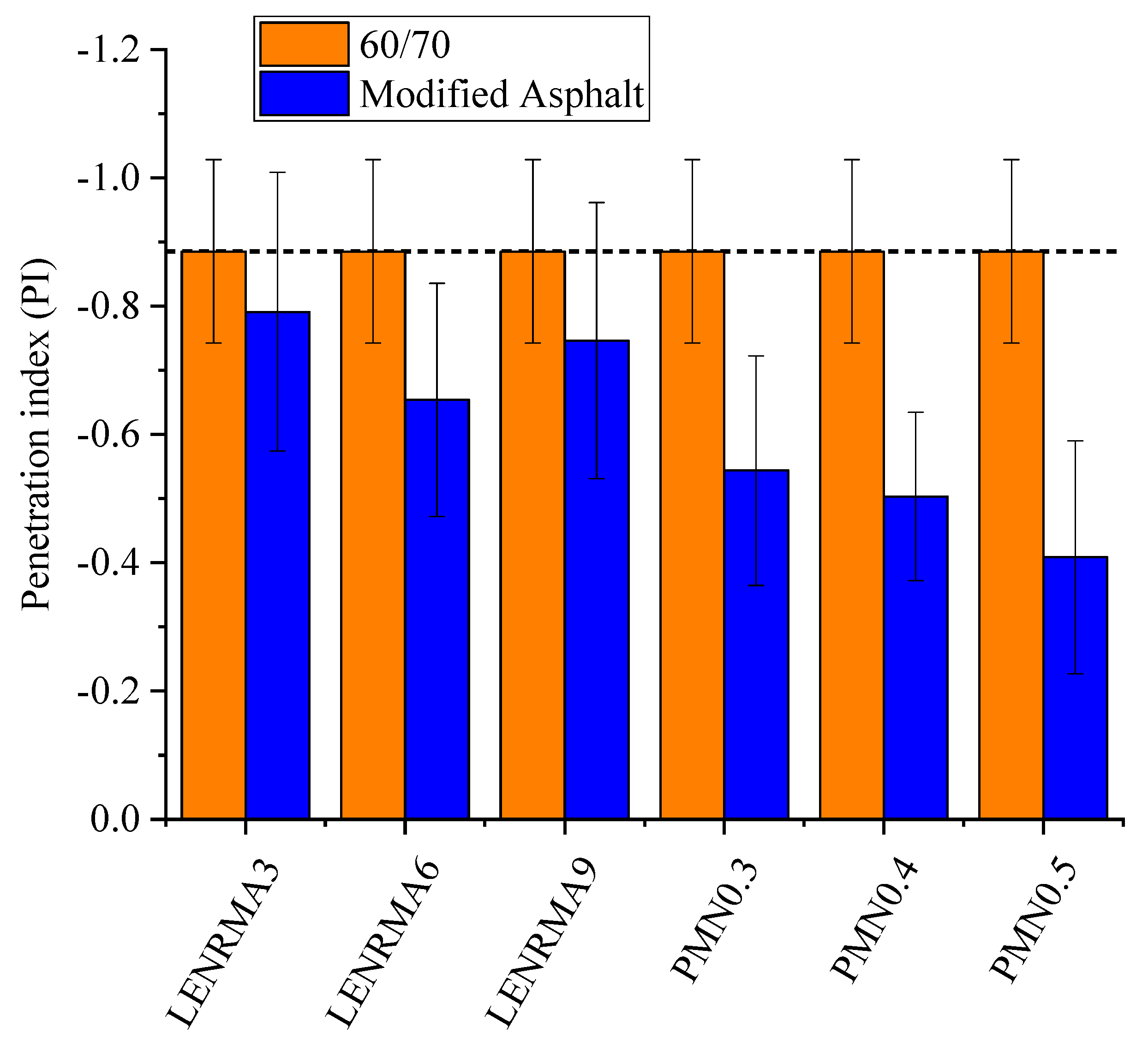

3.2. Temperature Susceptibility

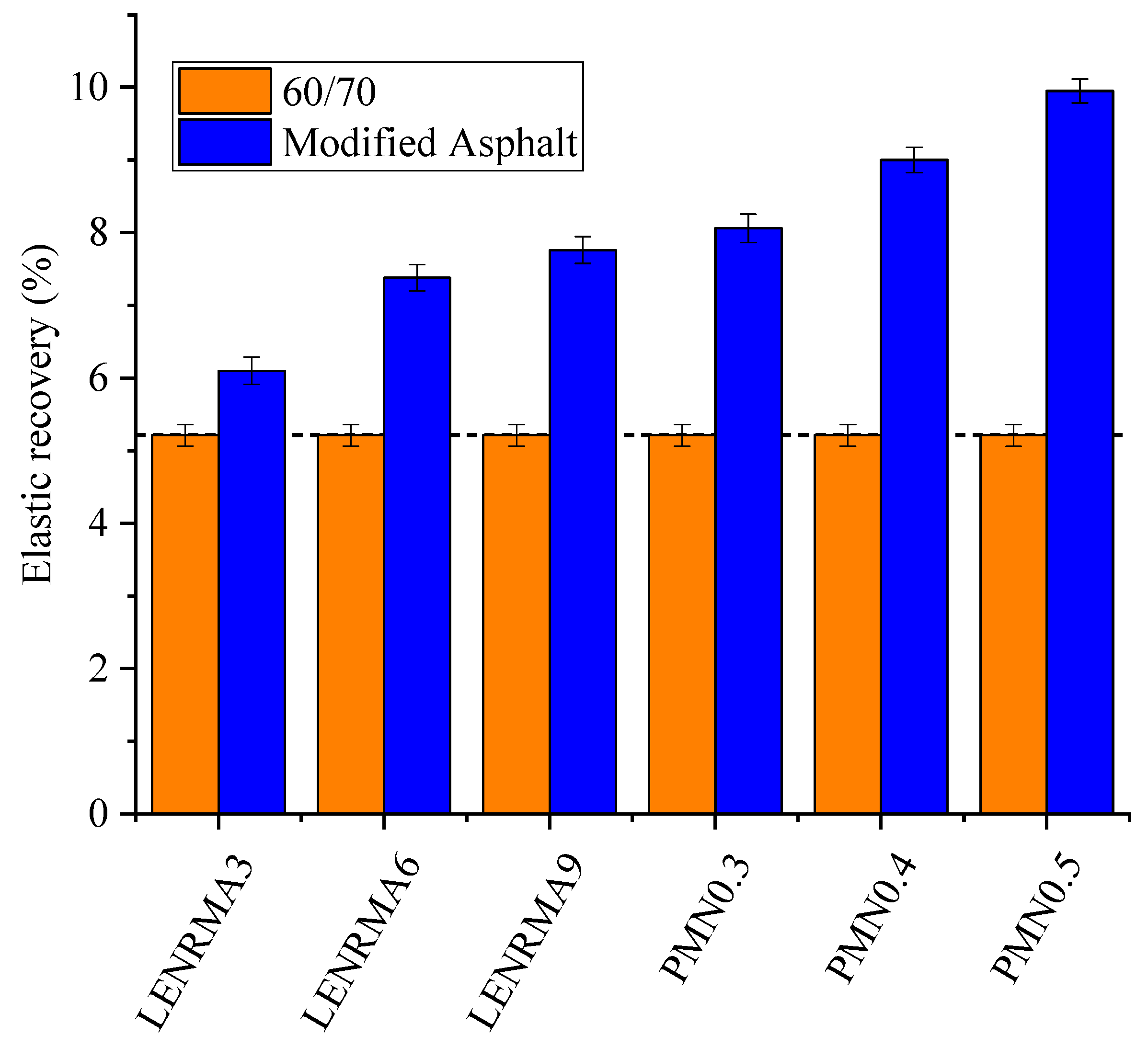

3.3. Elastic Recovery

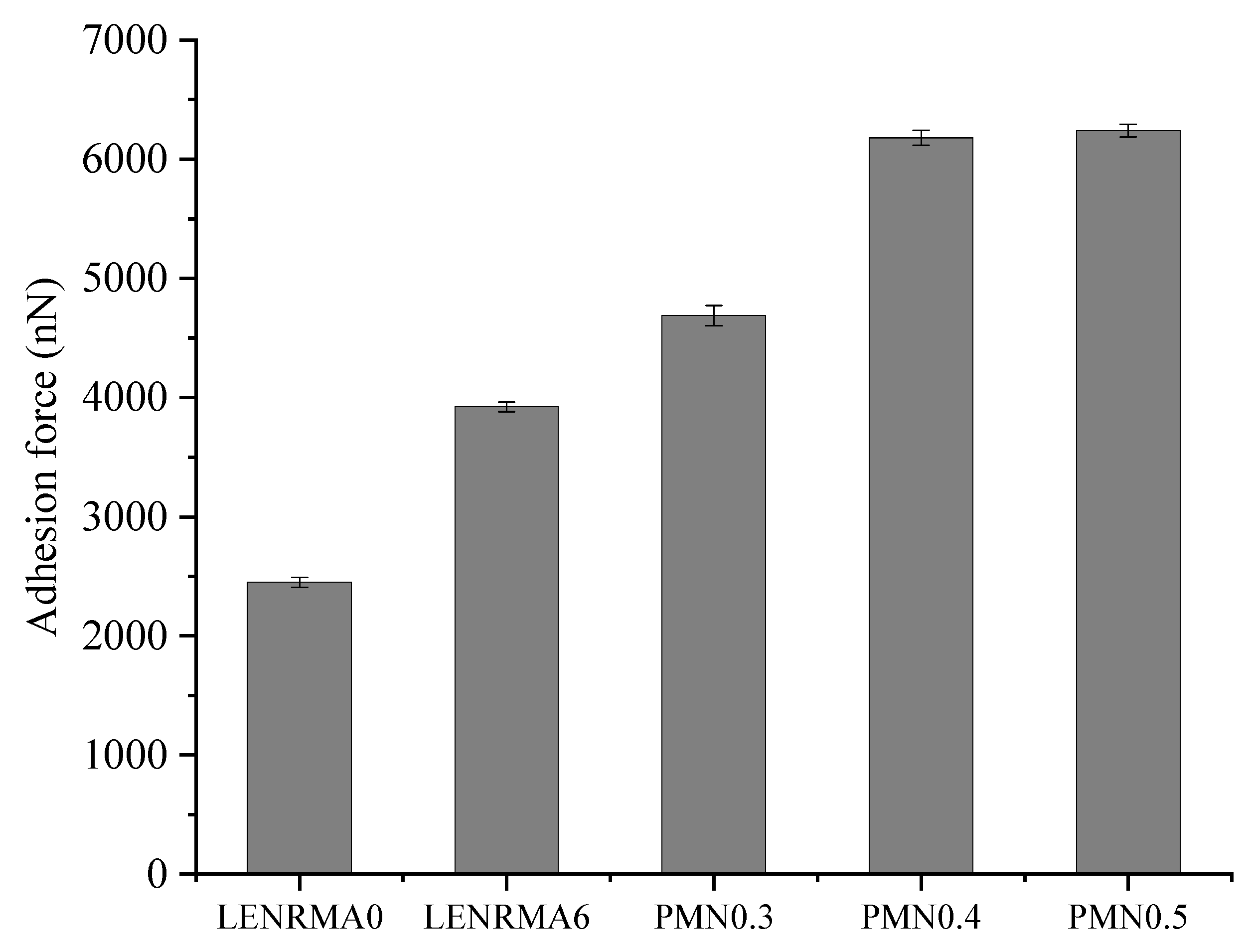

3.4. Atomic Force Microscopy

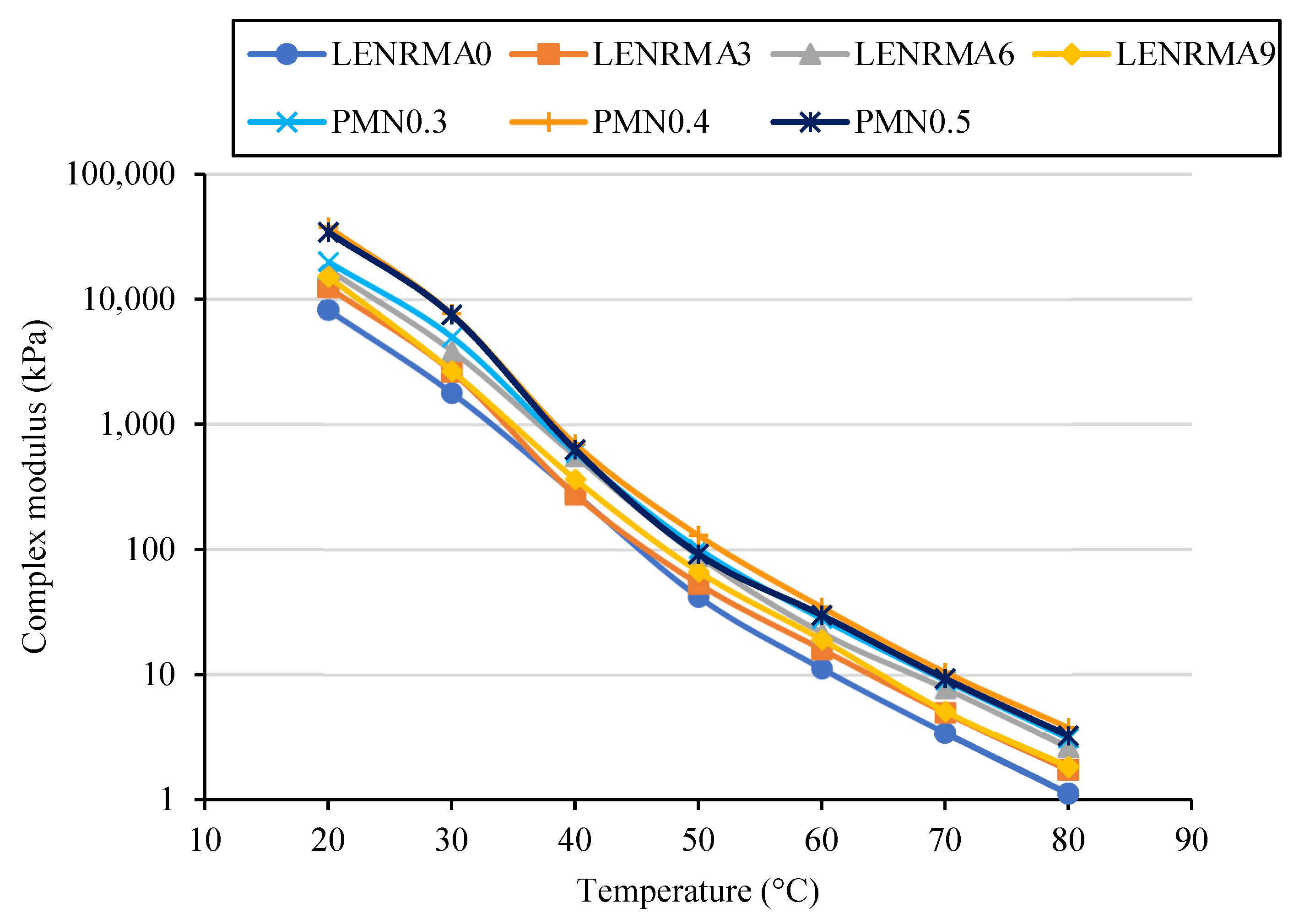

3.5. Rheological Properties

3.5.1. Isochronal Plots

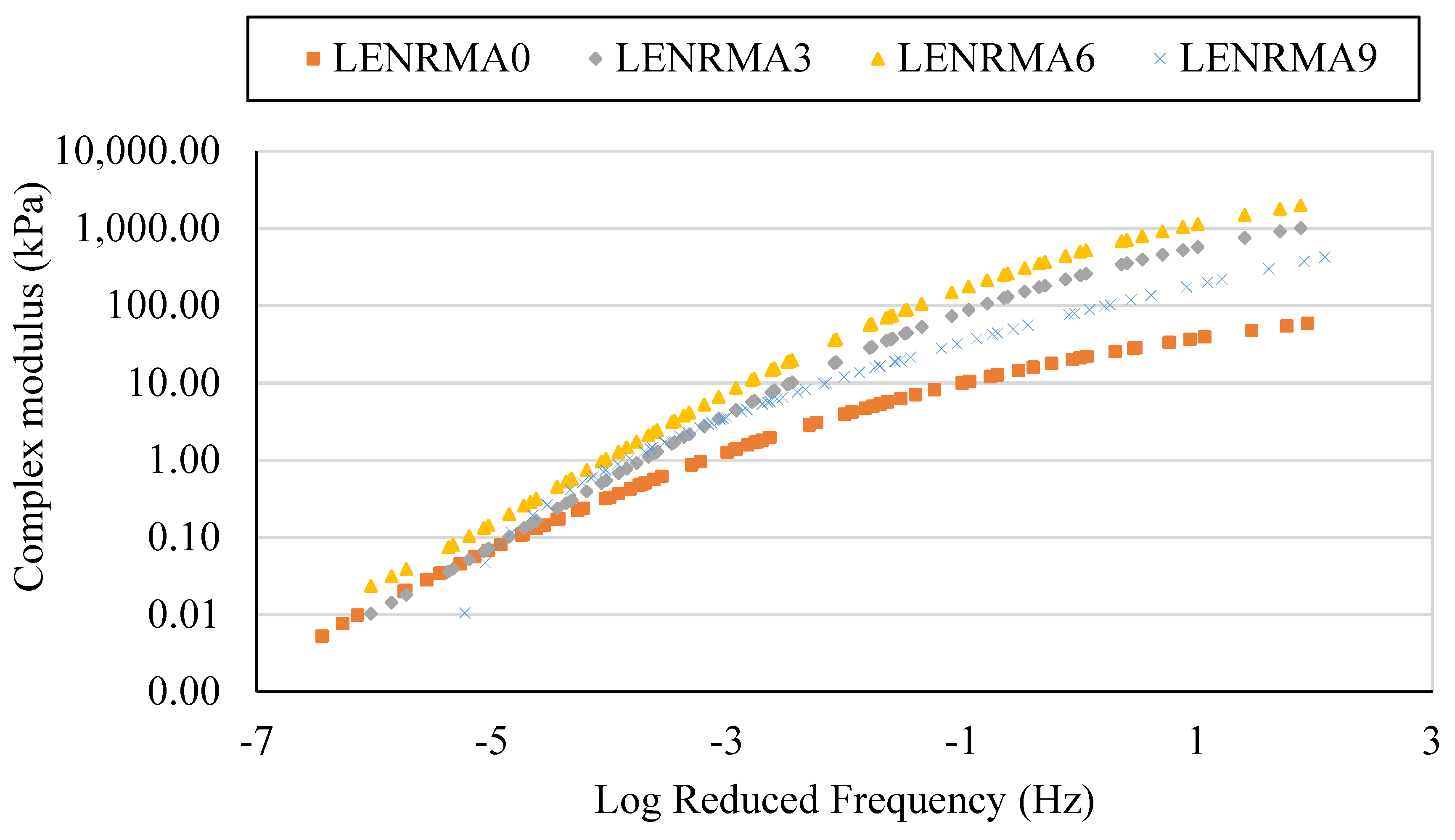

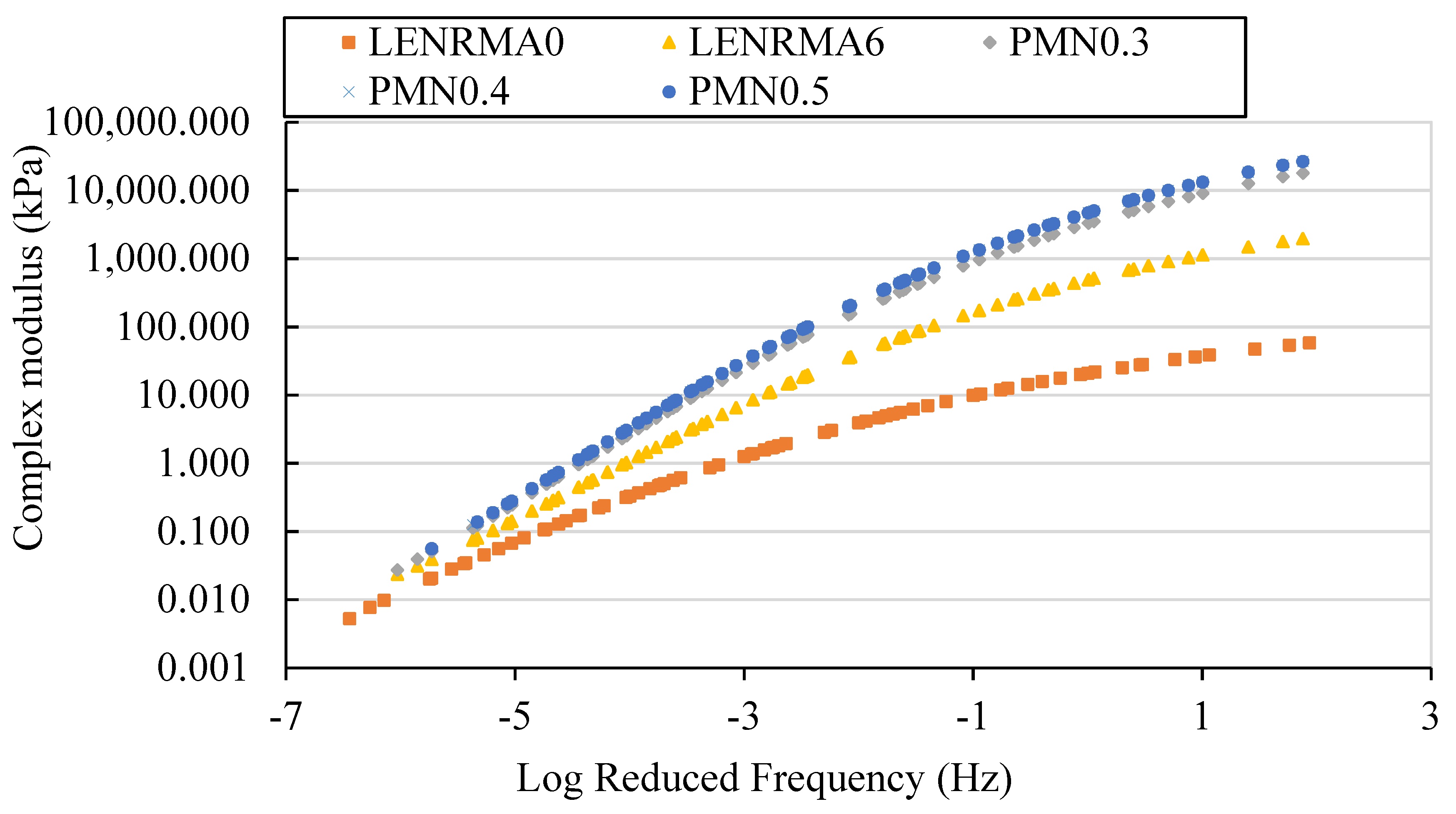

3.5.2. Master Curves

3.5.3. SHRP Rutting Parameter

3.6. Statistical Analysis Results

4. Conclusions and Future Directions

- Results of physical properties showed that the addition of LENR and composite LENR/CNFs into base asphalt led to a decrease in penetration and temperature susceptibility and increase in softening points, which indicates the improvement of base and rubberized asphalt consistency. PMN0.5 showed the best consistency among all tested binders.

- The highest elasticity recovery was also achieved for the PMN0.5 binder among all tested binders, which could reflect the possible enhancement of the tensile properties of modified binders. Binders modified with 0.4 and 0.5% of CNF showed significant high adhesion performance among all tested binders.

- Addition of 0.3 to 0.5% of CNFs into LENR-modified asphalt exhibited a significant increase in the adhesion forces which reflects the improvement of bonding and interlocking strength that is expected between modified binders and aggregate.

- The addition of 0.3 to 0.5% of CNFs into rubberized asphalt enhanced the viscosity and complex modulus of LENR-modified binders with an increase in CNFs, which indicates the improvement of the stiffness and hardness of the modified binders.

- Binders modified with 6% LENR and 0.4% CNF content provided the best performance of stiffness and temperature susceptibility represented by the complex modulus value over the wide range of testing temperatures.

- SHRP rutting parameter showed an improvement due to the addition of CNFs into LENR-modified binders. PMN0.4 exhibited the highest G*/sinδ value of 3.25 kPa at 80 °C compared to 1.1 kPa for LENRMB0, indicating the higher rutting resistance of LENR/CNFs composite binders at high-temperature applications.

- Statistical analysis presented that the effects of CNFs on the physical, adhesion, and rheological properties of base and LENR-modified asphalt is statistically significant within 95% confidence of interval.

- Correlation coefficient (R2) obtained from the statistical analysis for the effects of CNFs showed values between 0.84 and 0.99, which reflects that at least 84% of the improvement in the performance of asphalt was due to the addition of CNFs.

- In conclusion, the contents of LENR and CNFs that showed the appropriate physical, adhesion, and rheological performance in this study and can be recommended as an optimum are 6% of LENR and 0.4% CNFs by weight of base asphalt.

- It is recommended that further indepth investigations on the storage stability, physicochemical, morphological, and thermal properties of CNFs/LENR composite asphalt binders to be conducted.

- The low-temperature performance evaluation of CNFs/LENR composite asphalt binders can be performed in the regions where the low-temperature failure is a major concern.

- Life cycle cost analysis is recommended to be studied to evaluate the long-term performance of the LENR and LENR/CNFs composite asphalt binders compared to the base asphalt binder.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hunter, R.N.; Self, A.; Read, J.; Hobson, E. The Shell Bitumen Handbook; ICE Publishing: London, UK, 2015. [Google Scholar]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Yusoff, N.I.M.; Khairuddin, F.H.; Memon, A.M. Evaluation of the high-temperature rheological performance of tire pyrolysis oil-modified bio-asphalt. Int. J. Pavement Eng. 2021, 1–16. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Napiah, M.; Sutanto, M.; Habib, N.Z.; Bala, N.; Kumalasari, I.; Ghaleb, A. Application of nano silica particles to improve high-temperature rheological performance of tyre pyrolysis oil-modified bitumen. Road Mater. Pavement Des. 2021, 1–19. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Kumar, P.; Garg, R. Rheology of waste plastic fibre-modified bitumen. Int. J. Pavement Eng. 2011, 12, 449–459. [Google Scholar] [CrossRef]

- Hernández, G.; Medina, E.M.; Sánchez, R.; Mendoza, A.M. Thermomechanical and rheological asphalt modification using styrene− butadiene triblock copolymers with different microstructure. Energy Fuels 2006, 20, 2623–2626. [Google Scholar] [CrossRef]

- Zhang, B.; Xi, M.; Zhang, D.; Zhang, H.; Zhang, B. The effect of styrene–butadiene–rubber/montmorillonite modification on the characteristics and properties of asphalt. Constr. Build. Mater. 2009, 23, 3112–3117. [Google Scholar] [CrossRef]

- Yaacob, H.; Mughal, M.A.; Jaya, R.P.; Hainin, M.R.; Jayanti, D.S.; Wan, C.N.C. Rheological properties of styrene butadiene rubber modified bitumen binder. J. Teknol. 2016, 78, 121–126. [Google Scholar] [CrossRef] [Green Version]

- Ameri, M.; Mansourian, A.; Sheikhmotevali, A.H. Investigating effects of ethylene vinyl acetate and gilsonite modifiers upon performance of base bitumen using Superpave tests methodology. Constr. Build. Mater. 2012, 36, 1001–1007. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Koting, S.; Karim, M.R. Performance evaluation of crumb rubber modified stone mastic asphalt pavement in Malaysia. Adv. Mater. Sci. Eng. 2013, 2013, 304676. [Google Scholar] [CrossRef] [Green Version]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable practice in pavement engineering through value-added collective recycling of waste plastic and waste tyre rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Napiah, M.; Sutanto, M.; Alaloul, W.; Bala, N. Effects of Tire Pyrolysis Oil (TPO) on the Rheological Properties of Bitumen. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: London, UK, 2021; p. 012074. [Google Scholar]

- Nejad, F.M.; Aghajani, P.; Modarres, A.; Firoozifar, H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 2012, 26, 481–489. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Wang, H.; Chen, R.; Wellner, F. Structural and Mechanical Evolution of the Multiphase Asphalt Rubber during Aging based on Micromechanical Back-Calculation and Experimental Methods. Mater. Des. 2022, 2022, 110421. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Yussof, N.I.M.; Napiah, M.; Sutanto, M. A review of using natural rubber in the modification of bitumen and asphalt mixtures used for road construction. J. Teknol. 2019, 81, 81–88. [Google Scholar] [CrossRef]

- Poovaneshvaran, S.; Hasan, M.R.M.; Jaya, R.P. Impacts of recycled crumb rubber powder and natural rubber latex on the modified asphalt rheological behaviour, bonding, and resistance to shear. Constr. Build. Mater. 2020, 234, 117357. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Agus Mustofa, B.; Sutanto, M.H.; Sunarjono, S.; Bala, N. Aging and Rheological Properties of Latex and Crumb Rubber Modified Bitumen Using Dynamic Shear Rheometer. J. Eng. Technol. Sci. 2020, 52, 385–398. [Google Scholar] [CrossRef]

- Al-Mansob, R.A.; Ismail, A.; Alduri, A.N.; Azhari, C.H.; Karim, M.R.; Yusoff, N.I.M. Physical and rheological properties of epoxidized natural rubber modified bitumens. Constr. Build. Mater. 2014, 63, 242–248. [Google Scholar] [CrossRef]

- Al-Mansob, R.A.; Ismail, A.; Rahmat, R.A.O.; Borhan, M.N.; Alsharef, J.M.; Albrka, S.I.; Karim, M.R. The performance of epoxidised natural rubber modified asphalt using nano-alumina as additive. Constr. Build. Mater. 2017, 155, 680–687. [Google Scholar] [CrossRef]

- Azhar, N.H.A.; Rasid, H.M.; Yusoff, S.F.M. Epoxidation and hydroxylation of liquid natural rubber. Sains Malays. 2017, 46, 485–491. [Google Scholar] [CrossRef]

- Darji, D.; Yusof, N.H.; Rasdi, F.R.M. Shelf life of liquid epoxidized natural rubber (LENR). In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 040007. [Google Scholar]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Yang, J.; Tighe, S. A review of advances of nanotechnology in asphalt mixtures. Procedia-Soc. Behav. Sci. 2013, 96, 1269–1276. [Google Scholar] [CrossRef] [Green Version]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Zoorob, S.E.; Usman, A. Influence of nanosilica particles on the high-temperature performance of waste denim fibre-modified bitumen. Int. J. Pavement Eng. 2022, 23, 207–220. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Muniandy, R.; Mahdi, L.; Yunus, R.B.; Hasham, S.; Aburkaba, E. Effect of organic montmorillonite nanoclay concentration on the physical and rheological properties of asphalt binder. Aust. J. Basic Appl. Sci. 2013, 7, 429–437. [Google Scholar]

- Ahmad, N.; Nasir, M.A.; Hafeez, M.; Rafi, J.; Zaidi, S.B.A.; Haroon, W. Carbon nanotubes (CNTs) in asphalt binder: Homogeneous dispersion and performance enhancement. Appl. Sci. 2018, 8, 2651. [Google Scholar]

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement Des. 2018, 19, 1499–1522. [Google Scholar] [CrossRef]

- Khattak, M.J.; Khattab, A.; Rizvi, H.R. Characterization of carbon nano-fiber modified hot mix asphalt mixtures. Constr. Build. Mater. 2013, 40, 738–745. [Google Scholar] [CrossRef]

- Jahromi, S.G. Effect of carbon nanofiber on mechanical behavior of asphalt concrete. Int. J. Sustain. Constr. Eng. Technol. 2015, 6, 57–66. [Google Scholar]

- Al-Mansob, R.A.; Ismail, A.; Yusoff, N.I.M.; Albrka, S.I.; Azhari, C.H.; Karim, M.R. Rheological characteristics of unaged and aged epoxidised natural rubber modified asphalt. Constr. Build. Mater. 2016, 102, 190–199. [Google Scholar] [CrossRef]

- Daniel, N.; Hassan, N.; Idham, M.; Jaya, R.; Hainin, M.; Ismail, C.; Puan, O.; Azahar, N. IOP Conference Series: Materials Science and Engineering. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: London, UK, 2019; p. 012063. [Google Scholar]

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D36/D36M-14(2020); Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM D6084; Standard Test Method for Elastic Recovery of Asphalt Materials by Ductilometer. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2014; pp. 668–672.

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008; Volume 8.

- Liang, M.; Liang, P.; Fan, W.; Qian, C.; Xin, X.; Shi, J.; Nan, G. Thermo-rheological behavior and compatibility of modified asphalt with various styrene–butadiene structures in SBS copolymers. Mater. Des. 2015, 88, 177–185. [Google Scholar] [CrossRef]

| Material | Properties | Standard Method | Value |

|---|---|---|---|

| LENR | Specific gravity | - | 0.50 |

| Asphalt | Specific Gravity | ASTM D70 | 1.03 |

| Penetration @ 25 °C | ASTM D5 | 62.1 | |

| Softening point (°C) | ASTM D36 | 49.25 | |

| Viscosity (Pa.s) @ 135 °C | ASTM D4402 | 0.37 | |

| Ductility (cm) @ 25 °C | ASTM D113 | ≥100 | |

| CNFs | Diameter (nm) | - | 200 |

| Length (μm) | - | 50–200 | |

| Apparent density (kg/m3) | - | 30–300 |

| Binders | IDs |

|---|---|

| Base asphalt | LENRMA0 |

| Base asphalt + 3% LENR | LENRMA3 |

| Base asphalt + 6% LENR | LENRMA6 |

| Base asphalt + 9% LENR | LENRMA9 |

| Base asphalt + 6% LENR + 0.3% CNF | PMN0.3 |

| Base asphalt + 6% LENR + 0.4% CNF | PMN0.4 |

| Base asphalt + 6% LENR + 0.5% CNF | PMN0.5 |

| Parameter | Sum of Squares | df | Mean Square | F-Value Square | p-Value | R2 | Std. Dev. | C.V. % |

|---|---|---|---|---|---|---|---|---|

| Penetration value @ 25 °C | 39.76 | 1 | 39.76 | 54.17 | 0.018 | 0.9644 | 0.86 | 1.49 |

| Softening point | 2.38 | 1 | 2.38 | 38.24 | 0.0252 | 0.9503 | 0.25 | 0.49 |

| Viscosity @ 135 °C | 0.11 | 1 | 0.11 | 6.54 | 0.1249 | 0.7658 | 0.13 | 2.12 |

| Penetration index | 0.024 | 2 | 0.012 | 3.24 | 0.3655 | 0.8664 | 0.061 | 7.91 |

| Penetration viscosity number | 0.18 | 2 | 0.090 | 11.32 | 0.2056 | 0.9577 | 0.089 | 20.50 |

| Elastic recovery | 3.99 | 1 | 3.99 | 53.80 | 0.0181 | 0.9642 | 0.27 | 4.12 |

| G*@ 60 °C and 0.1 Hz | 31,804.39 | 2 | 15,902.19 | 1.12 | 0.5556 | 0.6913 | 119.16 | 46.69 |

| G*@ 60 °C and 10 Hz | 1.301 × 108 | 2 | 6.503 × 107 | 1.16 | 0.5493 | 0.6983 | 7496.2 | 39.40 |

| G*/sinδ @60 °C and 10 Hz | 1.353 × 108 | 2 | 6.766 × 107 | 1.17 | 0.5476 | 0.700 | 7613.4 | 39.47 |

| Parameter. | Sum of Squares | df | Mean Square | F-Value Square | p-Value | R2 | Std. Dev. | C.V. % |

|---|---|---|---|---|---|---|---|---|

| Penetration value @ 25 °C | 58.84 | 1 | 58.84 | 188.27 | 0.0053 | 0.9895 | 0.56 | 1.00 |

| Softening point | 7.58 | 1 | 7.58 | 236.74 | 0.0042 | 0.9916 | 0.18 | 0.35 |

| Viscosity @ 135 °C | 1.259 × 105 | 1 | 1.259 × 105 | 49.55 | 0.0196 | 0.9612 | 50.40 | 7.44 |

| Penetration index | 0.13 | 1 | 0.13 | 112.01 | 0.0088 | 0.9825 | 0.034 | 5.76 |

| Penetration viscosity number | 0.54 | 2 | 0.27 | 10,552.83 | 0.0069 | 0.9999 | 0.005 | 2.81 |

| Elastic recovery | 12.58 | 1 | 12.58 | 7.044 × 105 | <0.0001 | 0.9999 | 0.003 | 0.052 |

| Adhesion force | 9.137 × 106 | 1 | 9.137 × 106 | 53.10 | 0.0183 | 0.9637 | 414.81 | 8.48 |

| G*@ 60 °C and 0.1 Hz | 62,384.55 | 1 | 62,384.55 | 13.21 | 0.0681 | 0.8685 | 68.72 | 19.02 |

| G*@ 60 °C and 10 Hz | 2.608 × 108 | 1 | 2.608 × 108 | 10.79 | 0.0815 | 0.8437 | 4915 | 18.99 |

| G*/sinδ @60 °C and 10 Hz | 2.705 × 108 | 1 | 2.705 × 108 | 10.94 | 0.0805 | 0.8454 | 4973 | 18.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mansob, R.A.; Katman, H.Y.; Al-Sabaeei, A.M.; Zamzami, M.; Al-Fakih, A.; Wei, W.K.; Jassam, T.M.; Alsharef, J.; Surol, S.B.; Yusof, N.H.; et al. Effect of Carbon Nanofibers on Physical, Adhesion and Rheological Properties of Liquid Epoxidized Natural Rubber Modified Asphalt. Materials 2022, 15, 3870. https://doi.org/10.3390/ma15113870

Al-Mansob RA, Katman HY, Al-Sabaeei AM, Zamzami M, Al-Fakih A, Wei WK, Jassam TM, Alsharef J, Surol SB, Yusof NH, et al. Effect of Carbon Nanofibers on Physical, Adhesion and Rheological Properties of Liquid Epoxidized Natural Rubber Modified Asphalt. Materials. 2022; 15(11):3870. https://doi.org/10.3390/ma15113870

Chicago/Turabian StyleAl-Mansob, Ramez A., Herda Yati Katman, Abdulnaser M. Al-Sabaeei, Muhammad Zamzami, Amin Al-Fakih, Willy Kuay Wei, Taha M. Jassam, Jamal Alsharef, Salihah B. Surol, Nurul H. Yusof, and et al. 2022. "Effect of Carbon Nanofibers on Physical, Adhesion and Rheological Properties of Liquid Epoxidized Natural Rubber Modified Asphalt" Materials 15, no. 11: 3870. https://doi.org/10.3390/ma15113870

APA StyleAl-Mansob, R. A., Katman, H. Y., Al-Sabaeei, A. M., Zamzami, M., Al-Fakih, A., Wei, W. K., Jassam, T. M., Alsharef, J., Surol, S. B., Yusof, N. H., & Koting, S. (2022). Effect of Carbon Nanofibers on Physical, Adhesion and Rheological Properties of Liquid Epoxidized Natural Rubber Modified Asphalt. Materials, 15(11), 3870. https://doi.org/10.3390/ma15113870