Fractographic and Microhardness Evaluation of All-Ceramic Hot-Pressed and CAD/CAM Restorations after Hydrothermal Aging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Abutment Preparation

2.2. CAD/CAM Dental Restorations Fabrication

2.3. Hot-Pressing Samples Fabrication

2.4. Adhesive Placement of the Restorations

2.5. Hydrothermal Aging of the Samples

2.6. Static Loading Test

2.7. Fractographic Failure Analysis

2.8. Vickers Microhardness Testing

2.9. Statistical Analysis

3. Results

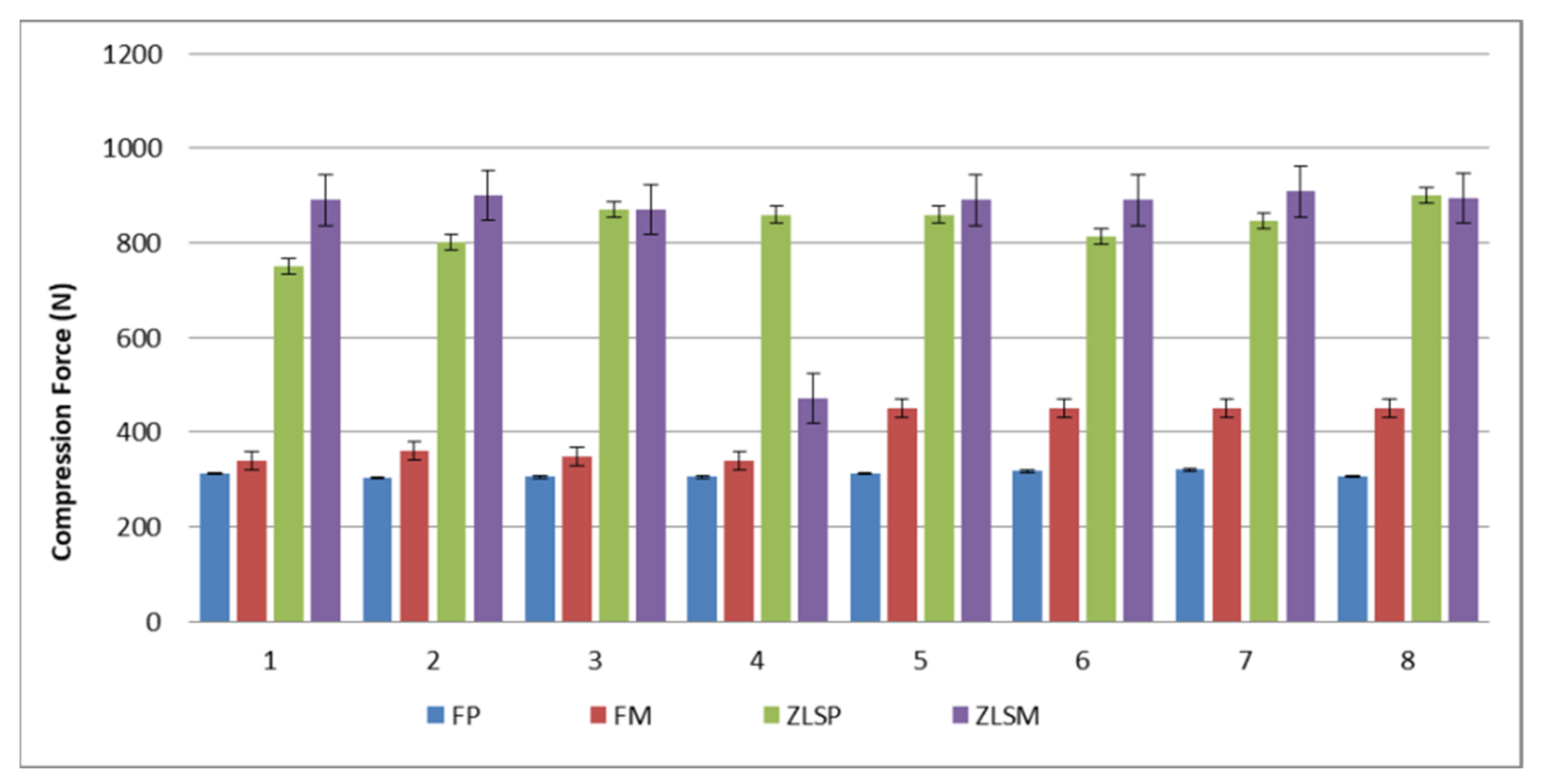

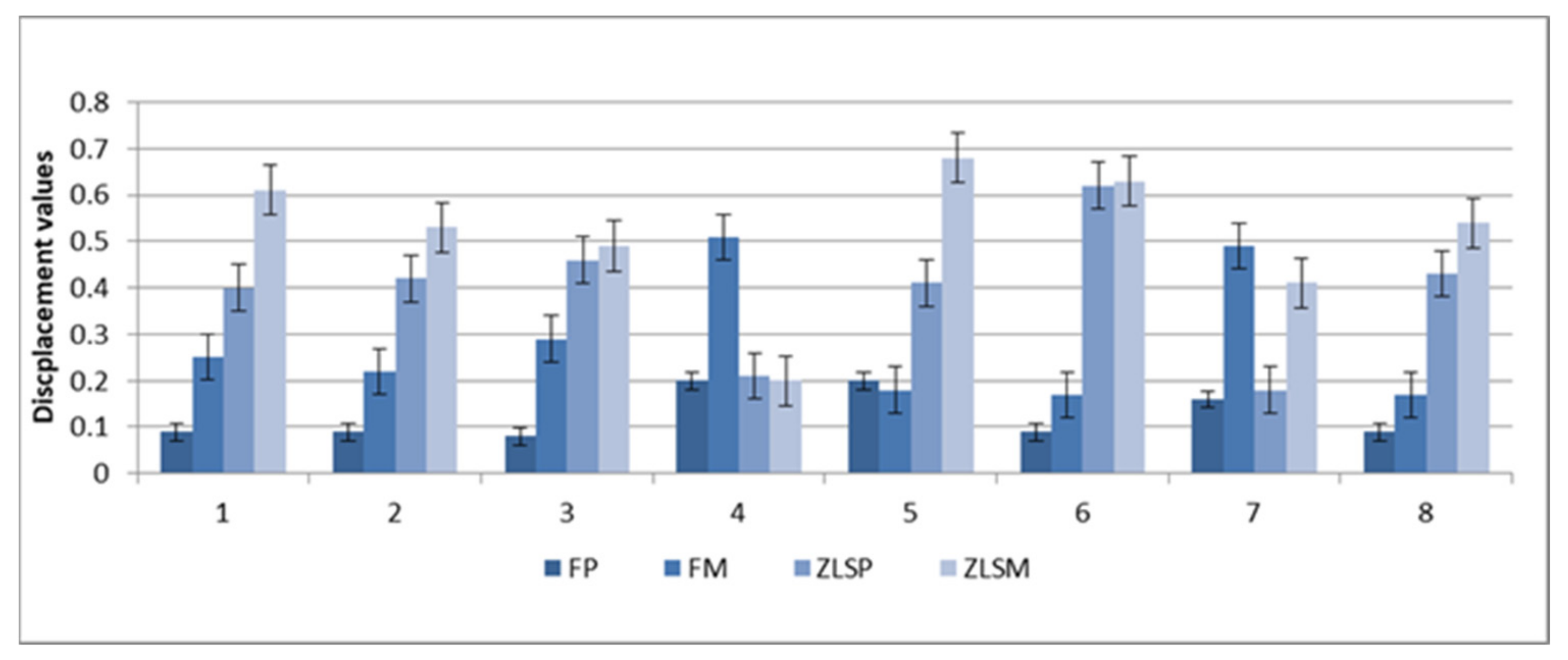

3.1. Fracture Resistance for the Cemented Crowns

3.2. Vickers Microhardness Evaluation

3.3. Fractographic Failure Analysis

4. Discussion

5. Conclusions

- (1)

- Fracture resistance for the heat-pressed cemented crowns is lower compared to the milled ceramics;

- (2)

- The ZLS glass-ceramic revealed higher mechanical properties, microhardness, and fracture toughness compared to the F glass-ceramic;

- (3)

- Thermal aging had a significant effect on the microhardness values;

- (4)

- The ZLSM restorations had better performance compared to the other materials, both hot-pressed and milled.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Christensen, G.J. Porcelain-fused-to-metal vs. nonmetalcrowns. J. Am. Dent. Assoc. 1999, 130, 409–411. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sailer, I.; Lawn, B.R. Fatigue of dental ceramics. J. Dent. 2013, 41, 1135–1147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Lee, J.J.-W.; Srikanth, R.; Lawn, B.R. Edge chipping andflexural resistance of monolithic ceramics. Dent. Mater. 2013, 29, 1201–1208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Christensen, G.J. Is the rush to all-ceramic crowns justified. J. Am. Dent. Assoc. 2014, 145, 192–194. [Google Scholar] [CrossRef]

- Blatz, M.B. Long-term clinical success of all-ceramic posterior restorations. Quintessence Int. 2002, 33, 415–426. [Google Scholar]

- Pjetursson, B.E.; Sailer, I.; Zwahlen, M.; Hämmerle, C.H. A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3 years. Part I: Single crowns. Clin. Oral Implants Res. 2007, 18, 73–85. [Google Scholar] [CrossRef]

- Reiss, B. Long-term clinical performance of cerec restorations and the variables affecting treatment success. Compend. Contin. Educ. Dent. 2001, 22, 14–18. [Google Scholar]

- Øilo, M.; Gjerdet, N.R. Fractographic analyses of all-ceramic crowns: A study of 27 clinically fractured crowns. Dent. Mater. 2013, 29, e78–e84. [Google Scholar] [CrossRef]

- Øilo, M.; Tvinnereim, H.M.; Gjerdet, N.R. Qualitative and quantitative fracture analyses of high-strength ceramics. Eur. J. Oral Sci. 2009, 117, 187–193. [Google Scholar] [CrossRef]

- Aboushelib, M.N.; de Jager, N.; Kleverlaan, C.J.; Feilzer, A.J. Effect of loading method on the fracture mechanics of two layered all-ceramic restorative systems. Dent. Mater. 2007, 23, 952–959. [Google Scholar] [CrossRef]

- Taskonak, B.; Mecholsky, J.J., Jr.; Anusavice, K.J. Fracture surface analysis of clinically failed fixed partial dentures. J. Dent. Res. 2006, 85, 277–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shenoy, A.; Shenoy, N. Dental ceramics: An update. J. Conserv. Dent. 2010, 13, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Mclean, J.W. Evolution of dental ceramics in the twentieth century. J. Prosthet. Dent. 2001, 85, 61–66. [Google Scholar] [CrossRef]

- Anusavice, K.J. Phillips Science of Dental Materials; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Fasbinder, D.J.; Dennison, J.B.; Heys, D.; Nelva, G. A clinicalevaluation of chairside lithium disilicate CAD/CAM crowns: A two-year report. J. Am. Dent. Assoc. 2010, 141, 4S–10S. [Google Scholar] [CrossRef] [PubMed]

- Porojan, L.; Savencu, C.; Porojan, S. Application of heat-pressed ceramics for single-tooth restorations. Rev. Chim. 2016, 1, 123–126. [Google Scholar]

- Kern, M.; Sasse, M.; Wolfart, S. Ten-year outcome of three-unitfixed dental prostheses made from monolithic lithiumdisilicate ceramic. J. Am. Dent. Assoc. 2012, 143, 234–240. [Google Scholar] [CrossRef]

- Reich, S.; Schierz, O. Chair-side generated posterior lithiumdisilicate crowns after 4 years. Clin. Oral Investig. 2013, 17, 1765–1772. [Google Scholar] [CrossRef]

- Furtado de Mendonca, A.; Shahmoradi, M.; Gouvêa, C.V.D.; De Souza, G.M.; Ellakwa, A. Microstructural and mechanical characterization of CAD/CAM materials for monolithic dental restorations. J. Prosthodont. 2019, 28, e587–e594. [Google Scholar] [CrossRef]

- Monteiro, J.B.; Riquieri, H.; Prochnow, C.; Guilardi, L.F.; Pereira, G.K.R.; Borges, A.L.S.; de Melo, R.M.; Valandro, L.F. Fatigue failure load of two resin-bonded zirconia-reinforced lithium silicate glass-ceramics: Effect of ceramic thickness. Dent. Mater. 2018, 34, 891–900. [Google Scholar] [CrossRef] [Green Version]

- Elsaka, S.E.; Elnaghy, A.M. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 2016, 32, 908–914. [Google Scholar] [CrossRef]

- Vasiliu, R.D.; Porojan, S.D.; Porojan, L. In Vitro Study of Comparative Evaluation of Marginal and Internal Fit between Heat-Pressed and CAD-CAM Monolithic Glass-Ceramic Restorations after Thermal Aging. Materials 2020, 13, 4239. [Google Scholar] [CrossRef] [PubMed]

- Mavriqi, L.; Valente, F.; Murmura, G.; Sinjari, B.; Macrì, M.; Trubiani, O.; Caputi, S.; Traini, T. Lithium disilicate and zirconia reinforced lithium silicate glass-ceramics for CAD/CAM dental restorations: Biocompatibility, mechanical and microstructural properties after crystallization. J. Dent. 2022, 119, 104054. [Google Scholar] [CrossRef] [PubMed]

- Al-Haj Husain, N.; Dürr, T.; Özcan, M.; Brägger, U.; Joda, T. Mechanical stability of dental CAD-CAM restoration materials made of monolithic zirconia, lithium disilicate, and lithium disilicate-strengthened aluminosilicate glass ceramic with and without fatigue conditions. J. Prosthet. Dent. 2021; in press. [Google Scholar] [CrossRef] [PubMed]

- Leung, B.T.; Tsoi, J.K.; Matinlinna, J.P.; Pow, E.H. Comparison of mechanical properties of three machinable ceramics with an experimental fluorophlogopite glass ceramic. J. Prosthet. Dent. 2015, 114, 440–446. [Google Scholar] [CrossRef]

- Pires-de-Souza Fde, C.; Casemiro, L.A.; Garcia Lda, F.; Cruvinel, D.R. Color stability of dental ceramics submitted to accelerated aging after repeated firings. J. Prosthet. Dent. 2009, 101, 13–18. [Google Scholar] [CrossRef]

- Øilo, M.; Kvam, K.; Tibballs, J.E.; Gjerdet, N.R. Clinically relevant fracture testing of all-ceramic crowns. Dent. Mater. 2013, 29, 815–823. [Google Scholar] [CrossRef]

- Scherrer, S.S.; Quinn, J.B.; Quinn, G.D.; Kelly, J.R. Failure analysis of ceramic clinical cases using qualitative fractography. Int. J. Prosthodont. 2006, 19, 185–192. [Google Scholar]

- Scherrer, S.S.; Quinn, G.D.; Quinn, J.B. Fractographic failure analysis of a Procera® allceram crown using stereo and scanning electron microscopy. Dent. Mater. 2008, 24, 1107–1113. [Google Scholar] [CrossRef] [Green Version]

- Aboushelib, M.N. Fatigue and fracture resistance of zirconia crowns prepared with different finish line designs. J. Prosthodont. 2012, 21, 22–27. [Google Scholar] [CrossRef]

- Thompson, J.Y.; Anusavice, K.J.; Naman, A.; Morris, H.F. Fracture surface characterization of clinically failed all-ceramic crowns. J. Dent. Res. 1994, 73, 1824–1832. [Google Scholar] [CrossRef]

- Atay, A.; Oruc, S.; Ozen, J.; Sipahi, C. Effect of accelerated aging on the color stability of feldspathic ceramic treated with various surfacetreatments. Quintessence Int. 2008, 39, 603–609. [Google Scholar] [PubMed]

- Turgut, S.; Bagis, B. Color stability of laminate veneers: An in vitro study. J. Dent. 2011, 39 (Suppl. 3), e57–e64. [Google Scholar] [CrossRef] [PubMed]

- Kelly, J.R.; Benetti, P. Ceramic materials in dentistry: Historical evolution and current practice. Aust. Dent. J. 2011, 56 (Suppl. 1), 84–96. [Google Scholar] [CrossRef]

- Taskonak, B.; Yan, J.; Mecholsky, J.J., Jr. Fracture Surface Analysis of Dental Ceramics. In Fractography of Glasses and Ceramic V, Ceramic Transaction; Varner, J.R., Quinn, G.D., Wightman, M., Eds.; The American Ceramic Society; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 199, pp. 271–279. [Google Scholar]

- Ohlmann, B.; Rammelsberg, P.; Schmitter, M.; Schwarz, S.; Gabbert, O. All-ceramic inlay-retained fixed partial dentures: Preliminary results from a clinical study. J. Dent. 2008, 36, 692–696. [Google Scholar] [CrossRef] [PubMed]

- Marchack, B.W.; Futatsuki, Y.; Marchack, C.B.; White, S.N. Customization of milled zirconia copings for all-ceramic crowns: A clinical report. J. Prosthet. Dent. 2008, 99, 169–173. [Google Scholar] [CrossRef]

- Rekow, E.D.; Silva, N.R.; Coelho, P.G.; Zhang, Y.; Guess, P.C. Thompson VP. Performance of dental ceramics: Challenges for improvements. J. Dent. Res. 2011, 90, 937–952. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kokubo, Y.; Tsumita, M.; Sakurai, S.; Suzuki, Y.; Tokiniwa, Y.; Fukushima, S. Five-year clinical evaluation of In-Ceram crowns fabricated using GN-I (CAD/CAM) system. J. Oral Rehabil. 2011, 38, 601–607. [Google Scholar] [CrossRef]

- Poiate, I.A.; de Vasconcellos, A.B.; de Santana, R.B.; Poiate, E. Three-dimensionalstress distribution in the human periodontal ligament in masticatory, parafunctional, and trauma loads: Finite element analysis. J. Periodontol. 2009, 80, 1859–1867. [Google Scholar] [CrossRef]

- Quinn, J.B.; Quinn, G.D.; Kelly, J.R.; Scherrer, S.S. Fractographic analyses of three.ceramic whole crown restoration failures. Dent. Mater. 2005, 2, 920–929. [Google Scholar] [CrossRef]

- Moressi, A.L.; D’Amario, M.; Monaco, A. Effect of critical thermal cycling on the flexural strength of resin composites. J. Oral Sci. 2015, 57, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 66, 1336–1339. [Google Scholar] [CrossRef]

- Caleb, B.; Hailee, R.; Abdallah, A. Mechanical properties of resin-ceramic CAD-CAM materials after accelerated aging. J. Prosthet. Dent. 2018, 119, 954–958. [Google Scholar]

- Sasipin, L.; Hidekazu, T.; Maho, S.; Naohiko, I. Mechanical properties of composite resin blocks for CAD/CAM. Dent. Mater. J. 2014, 33, 705–710. [Google Scholar]

- Quirynen, M.; Marechal, M.; Busscher, H.J.; Weerkamp, A.H.; Darius, P.L.; van Steenberghe, D. The influence of surface free energy and surface roughness on early plaque formation. An in vivo study in man. J. Clin. Periodontol. 1990, 17, 138–144. [Google Scholar] [CrossRef]

- Kamolporn, W.; Viritpon, S.; Kanchana, N.M.; Pasutha, T. Improving shear bond strength between feldspathic porcelain and zirconia substructure with lithium disilicate glass-ceramic liner. Dent. Mater. J. 2015, 34, 302–309. [Google Scholar]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.F. Evaluation of mechanical and optical behavior of current aesthetic dental restorative CAD/CAM composites. J. Mech. Behav. Biomed. Mater. 2015, 55, 1–11. [Google Scholar]

- Vasiliu, R.-D.; Porojan, S.-D.; Bîrdeanu, M.-I.; Uțu, I.-D.; Porojan, L. The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems. Crystals 2020, 10, 160. [Google Scholar] [CrossRef] [Green Version]

- Vasiliu, R.D.; Porojan, S.D.; Bîrdeanu, M.I.; Porojan, L. Effect of Thermocycling, Surface Treatments and Microstructure on the Optical Properties and Roughness of CAD-CAM and Heat-Pressed Glass Ceramics. Materials 2020, 13, 381. [Google Scholar] [CrossRef] [Green Version]

- Waltimo, A.; Könönen, M. A novel bite force recorder and maximal isometric bite force values for healthy young adults. Scand. J. Dent. Res. 1993, 101, 171–175. [Google Scholar] [CrossRef]

- Hong-Soo, S.; Soo-Bok, H.; Soo-Hwang, S.; Yu-Mi, L.; Bum-Soon, L. Effect of height of titanium link on the retention of zirconia abutment in the titanium-zirconia bicomponent abutments. Korean J. Dent. Mater. 2013, 40, 223–234. [Google Scholar]

- Lin, Y.T.; Shen, Y.F.; Wei, P.C.; Hsu, K.W. Clinical evaluation of two-piece zirconia abutments with bonded titanium inserts for implant-supported restorations. J. Prosthet. Dent. 2020, 123, 449–454. [Google Scholar] [CrossRef] [PubMed]

- Gibbs, C.H.; Mahan, P.E.; Mauderli, A.; Lundeen, H.C.; Walsh, E.K. Limits of human bite strength. J. Prosthet. Dent. 1986, 56, 226–229. [Google Scholar] [CrossRef]

- Schmidt, K.K.; Chiayabutr, Y.; Phillips, K.M.; Kois, J.C. Influence of preparation design and existing condition of tooth structure on load to failure of ceramic laminate veneers. J. Prosthet. Dent. 2011, 105, 374–382. [Google Scholar] [CrossRef]

- Ahlers, M.O.; Morig, G.; Blunck, U.; Hajto, J.; Probster, L.; Frankenberger, R. Guidelines for the preparation of CAD/CAM ceramic inlays and partial crowns. Int. J. Comput. Dent. 2009, 12, 309–325. [Google Scholar]

- Steiner, M.; Mitsias, M.E.; Ludwig, K.; Kern, M. In vitro evaluation of a mechanical testing chewing simulator. Dent. Mater. 2009, 25, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Friedlander, L.D.; Munoz, C.A.; Goodacre, C.J.; Doyle, M.G.; Moote, B.K. The effect of tooth preparation design on breaking slrength of Dicor cniwns. Part I. Int. J. Prosthodont. 1990, 3, l59–166. [Google Scholar]

- Trajtenberg, C.P.; Caram, S.J.; Kiat-amnuay, S. Microleakage of all-ceramic crowns using self-etching resin luting agents. Oper. Dent. 2008, 33, 392–399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mandikos, M.N.; McGivney, G.P.; Davis, E.; Bush, P.J.; Carter, J.M. A comparison of the wear resistance and hardness of indirect composite resins. J. Prosthet. Dent. 2001, 85, 386–395. [Google Scholar] [CrossRef]

- Hudson, J.D.; Goldstein, G.R.; Georgescu, M. Enamel wear caused by three different restorative materials. J. Prosthet. Dent. 1995, 74, 647–654. [Google Scholar] [CrossRef]

- Jagger, D.C.; Harrison, A. An in vitro investigation into the wear effects of selected restorative materials on dentine. J. Oral Rehabil. 1995, 22, 349–354. [Google Scholar] [CrossRef]

- Olivera, A.B.; Marques, M.M. Esthetic restorative materials and opposing enamel wear. Oper. Dent. 2008, 33, 332–337. [Google Scholar] [CrossRef] [PubMed]

- Wendler, M.; Belli, R.; Petschelt, A.; Mevec, D.; Harrer, W.; Lube, T.; Danzer, R.; Lohbauer, U. Chairside CAD/CAM materials. Part 2: Flexural strength testing. Dent. Mater. 2017, 33, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Wendler, M.; Belli, R.; Valladares, D.; Petschelt, A.; Lohbauer, U. Chairside CAD/CAM materials. Part 3: Cyclic fatigue parameters and lifetime predictions. Dent. Mater. 2018, 34, 910–921. [Google Scholar] [CrossRef] [PubMed]

- Zarone, F.; Ruggiero, G.; Leone, R.; Breschi, L.; Leuci, S.; Sorrentino, R. Zirconia-reinforced lithium silicate (ZLS) mechanical and biological properties: A literature review. J. Dent. 2021, 109, 103661. [Google Scholar] [CrossRef]

| Material | Chemical Composition | Manufacturer | Processing Technology |

|---|---|---|---|

| (1) Vita PM9 (FP) | 50% (vol%) leucite crystals embedded in the residual glass | Vita Zahnfabrick | Hot-pressing |

| (2) Celtra Press (ZLSP) | a glass matrix and lithium disilicate crystals having a crystal length of about 1.5 µm plus nano-scale lithium phosphate 10% (ZrO2) | Degudent Dentply | Hot-pressing |

| (3) Vita Mark II (FM) | <20 wt% feldspathic crystals (average particle size 4 µm) > 80 wt% glass matrix | Vita Zahnfabrick | Milling |

| (4) Vita Suprinity (ZLSM) | The silica content of 55–65 wt% the lithia (15–21 wt%) zirconia (8–12 wt%) nanoparticle size 0.5–0.7 µm | Vita Zahnfabrick | Milling |

| Type of Ceramic | Type of Glaze |

|---|---|

| FP, FM, ZLSM | Vita Akzent Plus Glaze LT (Vita Zahnfabrick, Bad Sackingen, Germany) |

| ZLSP | Dentsply Universal Stain (Dentsply, Hanau, Germany) |

| Parameters | Vita PM9 | Celtra Press |

|---|---|---|

| Starting temperature | 700 °C | 700 °C |

| Hold time | 20 min | 30 min |

| Vacuum level | 47 hPa | 45 hPa |

| Press time | 10 min | 3 min |

| Heat rate | 50 °C/min | 40 °C/min |

| Press temperature | 1000 °C | 860 °C |

| Press pressure | 3 bar | 3 bar |

| Samples | Before tc (HVN) (GPa) | After tc (HVN) (GPa) |

|---|---|---|

| FP | 650 * | 600 |

| FM | 680 a | 615 |

| ZLSP | 725 * | 690 |

| ZLSM | 896 a | 730 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasiliu, R.D.; Uțu, I.-D.; Rusu, L.; Boloș, A.; Porojan, L. Fractographic and Microhardness Evaluation of All-Ceramic Hot-Pressed and CAD/CAM Restorations after Hydrothermal Aging. Materials 2022, 15, 3987. https://doi.org/10.3390/ma15113987

Vasiliu RD, Uțu I-D, Rusu L, Boloș A, Porojan L. Fractographic and Microhardness Evaluation of All-Ceramic Hot-Pressed and CAD/CAM Restorations after Hydrothermal Aging. Materials. 2022; 15(11):3987. https://doi.org/10.3390/ma15113987

Chicago/Turabian StyleVasiliu, Roxana Diana, Ion-Dragoș Uțu, Lucian Rusu, Adrian Boloș, and Liliana Porojan. 2022. "Fractographic and Microhardness Evaluation of All-Ceramic Hot-Pressed and CAD/CAM Restorations after Hydrothermal Aging" Materials 15, no. 11: 3987. https://doi.org/10.3390/ma15113987

APA StyleVasiliu, R. D., Uțu, I.-D., Rusu, L., Boloș, A., & Porojan, L. (2022). Fractographic and Microhardness Evaluation of All-Ceramic Hot-Pressed and CAD/CAM Restorations after Hydrothermal Aging. Materials, 15(11), 3987. https://doi.org/10.3390/ma15113987