Strain-Enhanced Thermoelectric Performance in GeS2 Monolayer

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

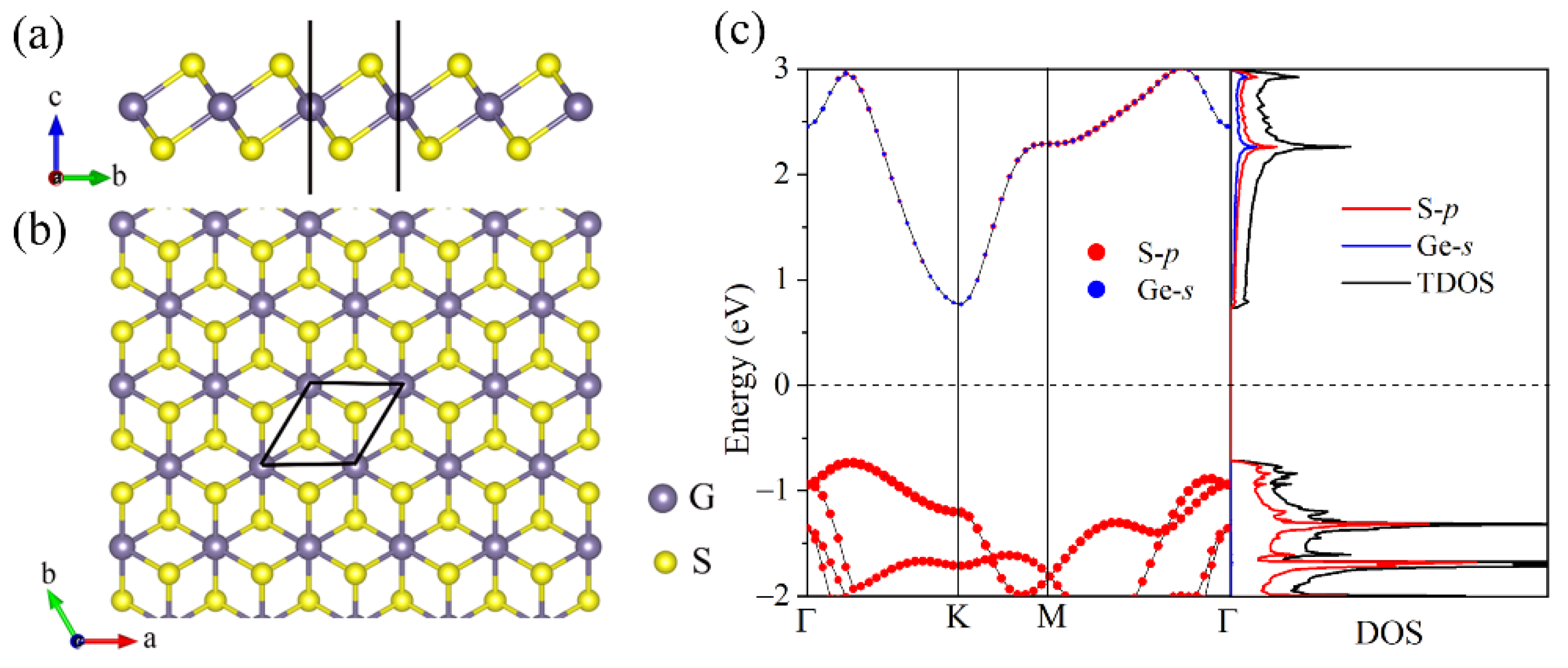

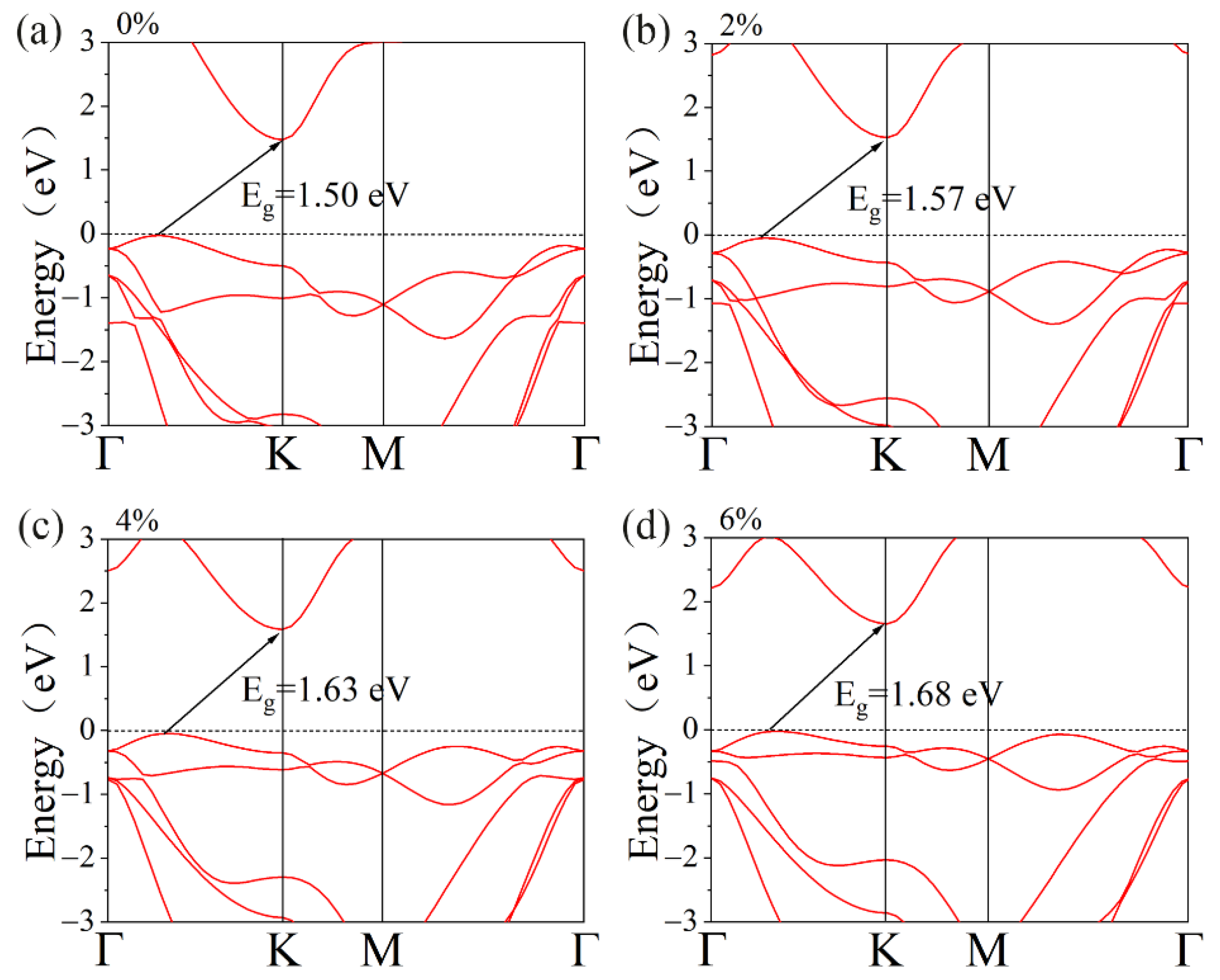

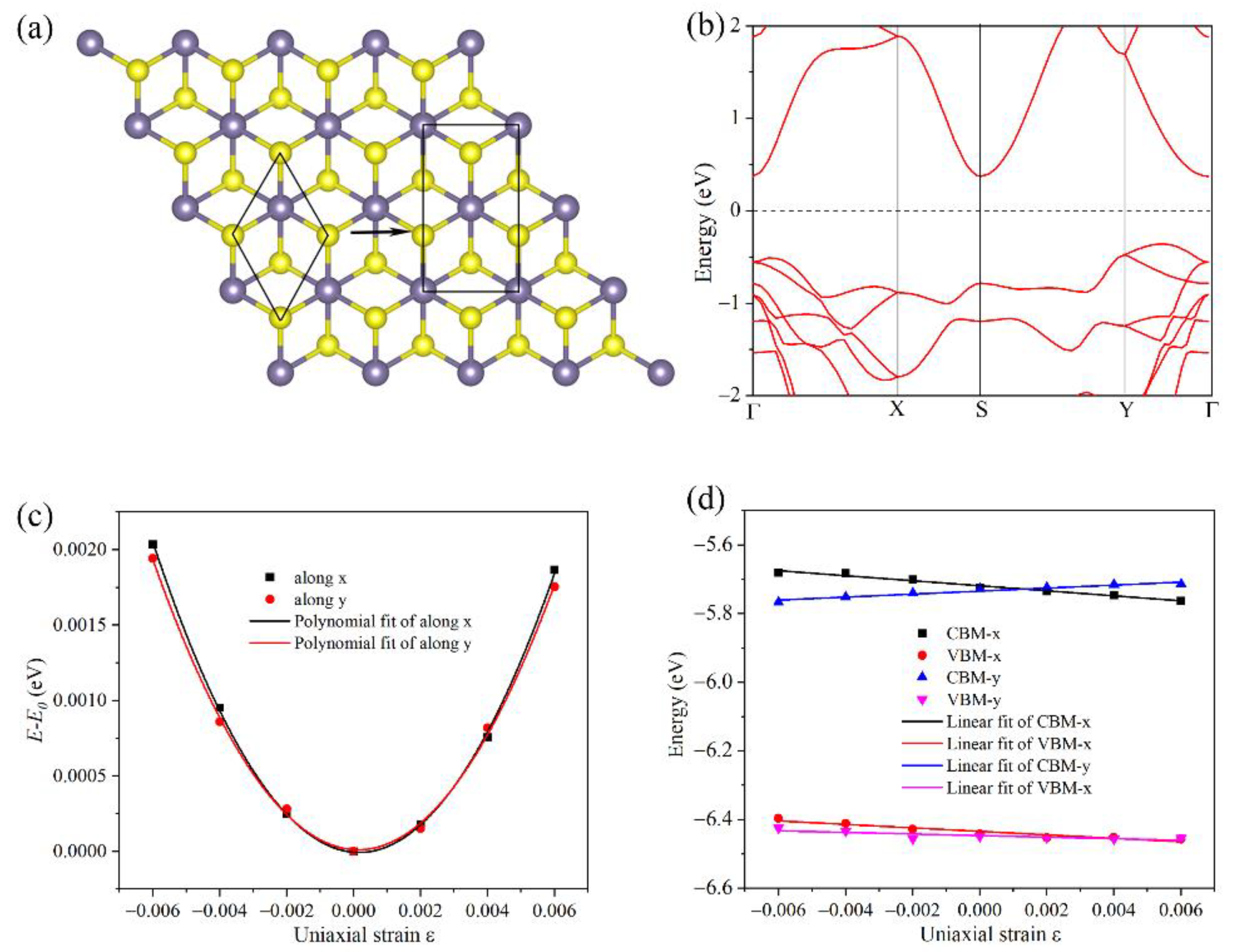

3.1. Structural Stability and Band Structure

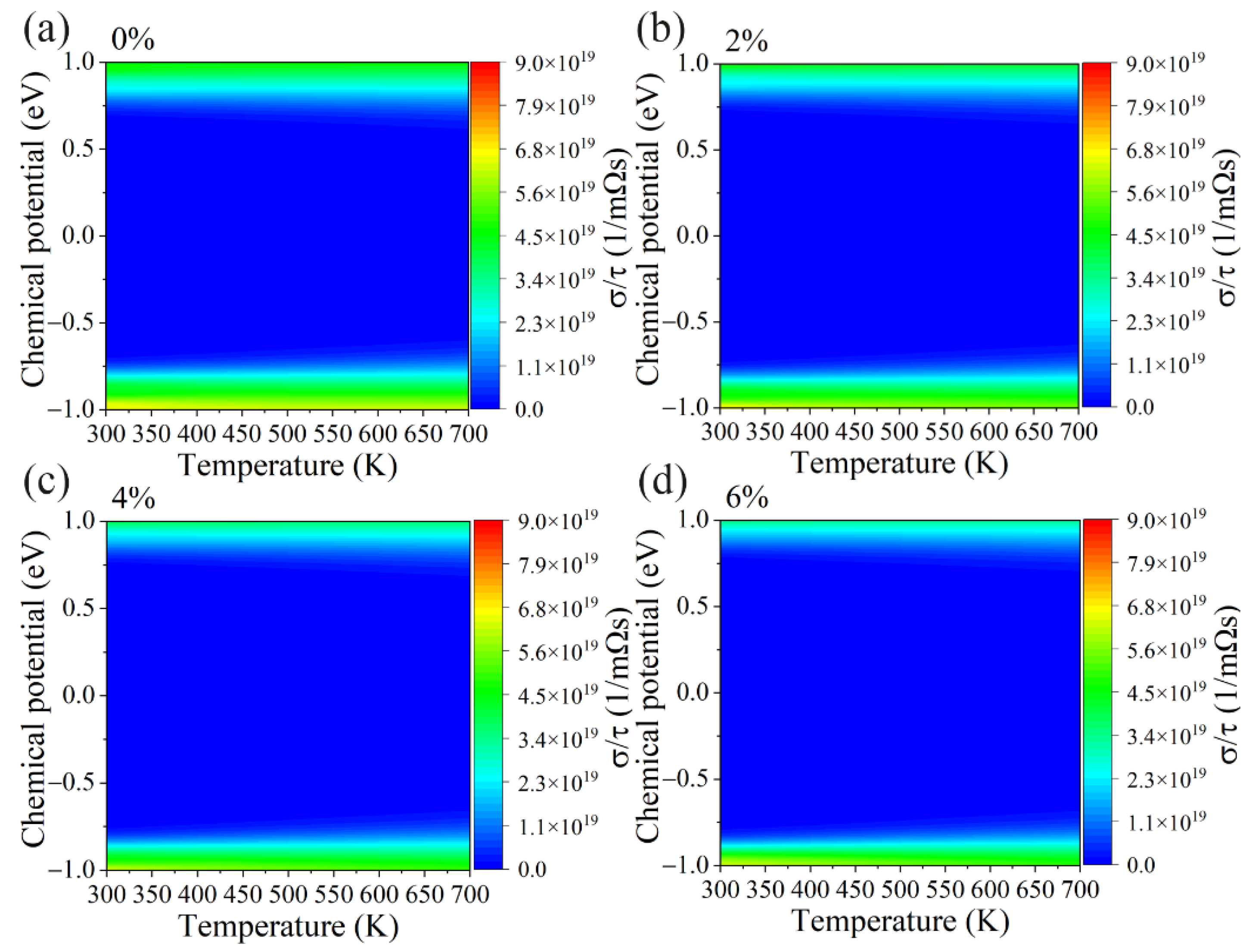

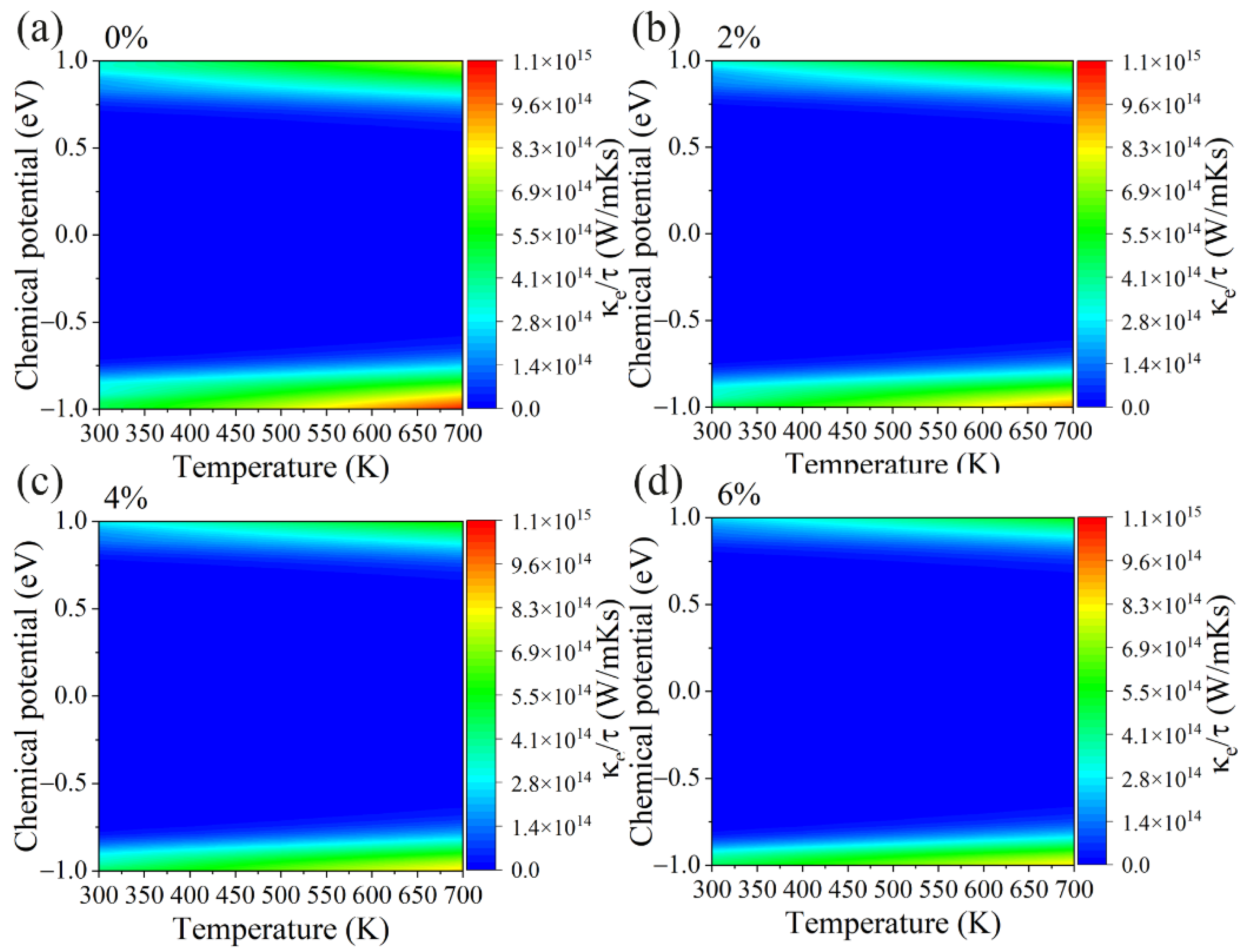

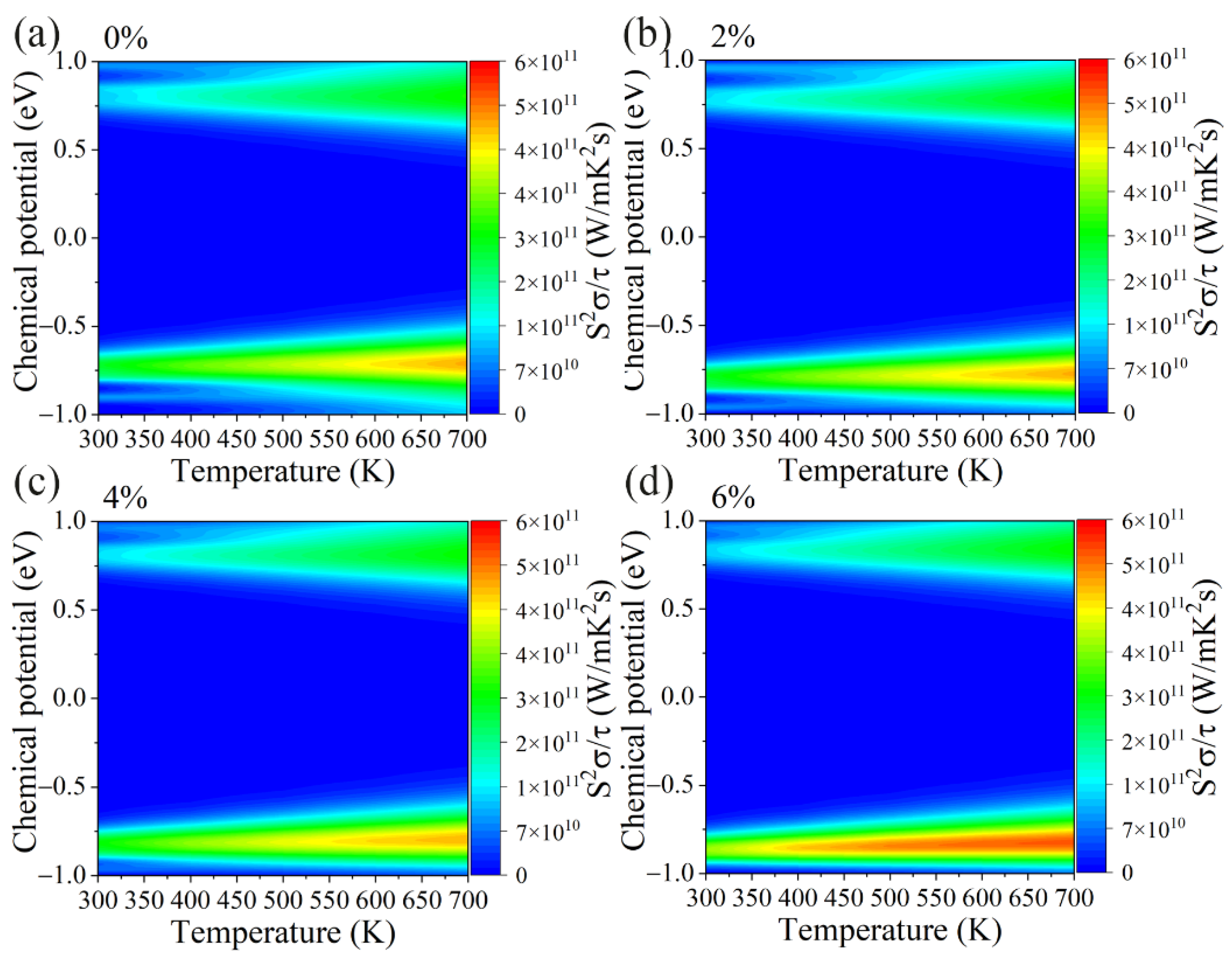

3.2. Electronic Transport Properties

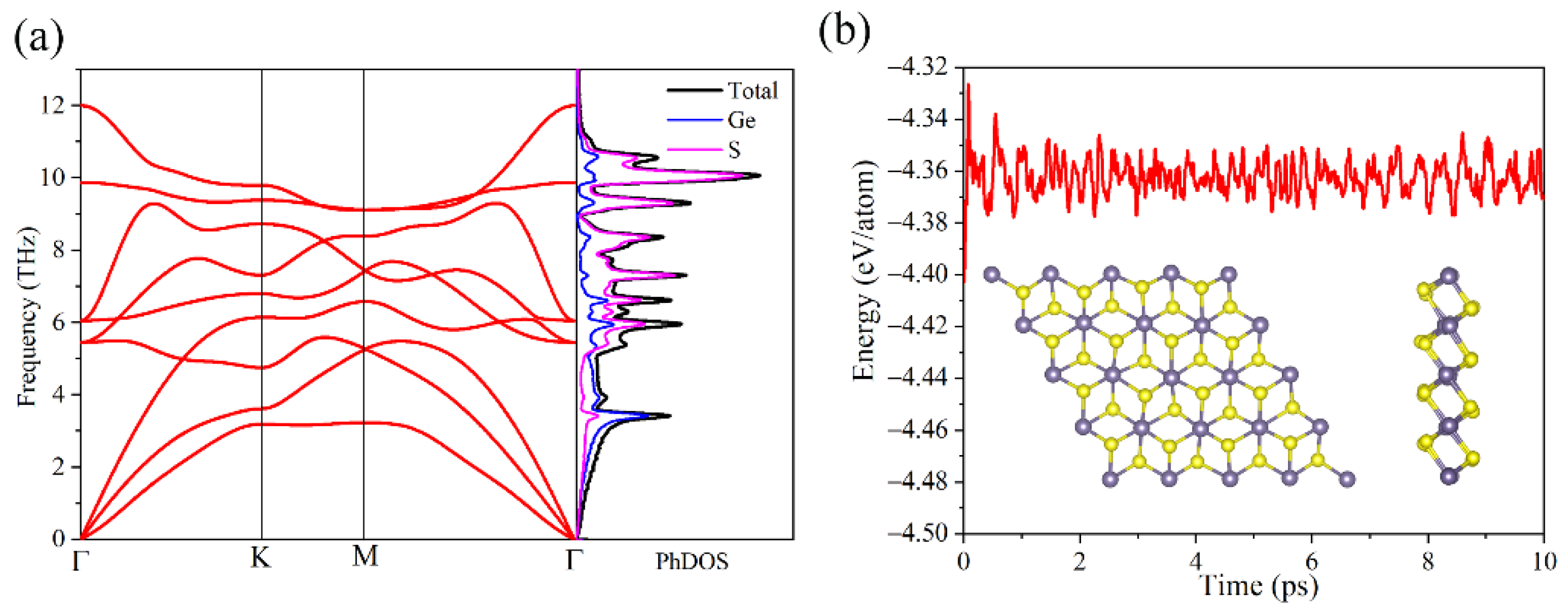

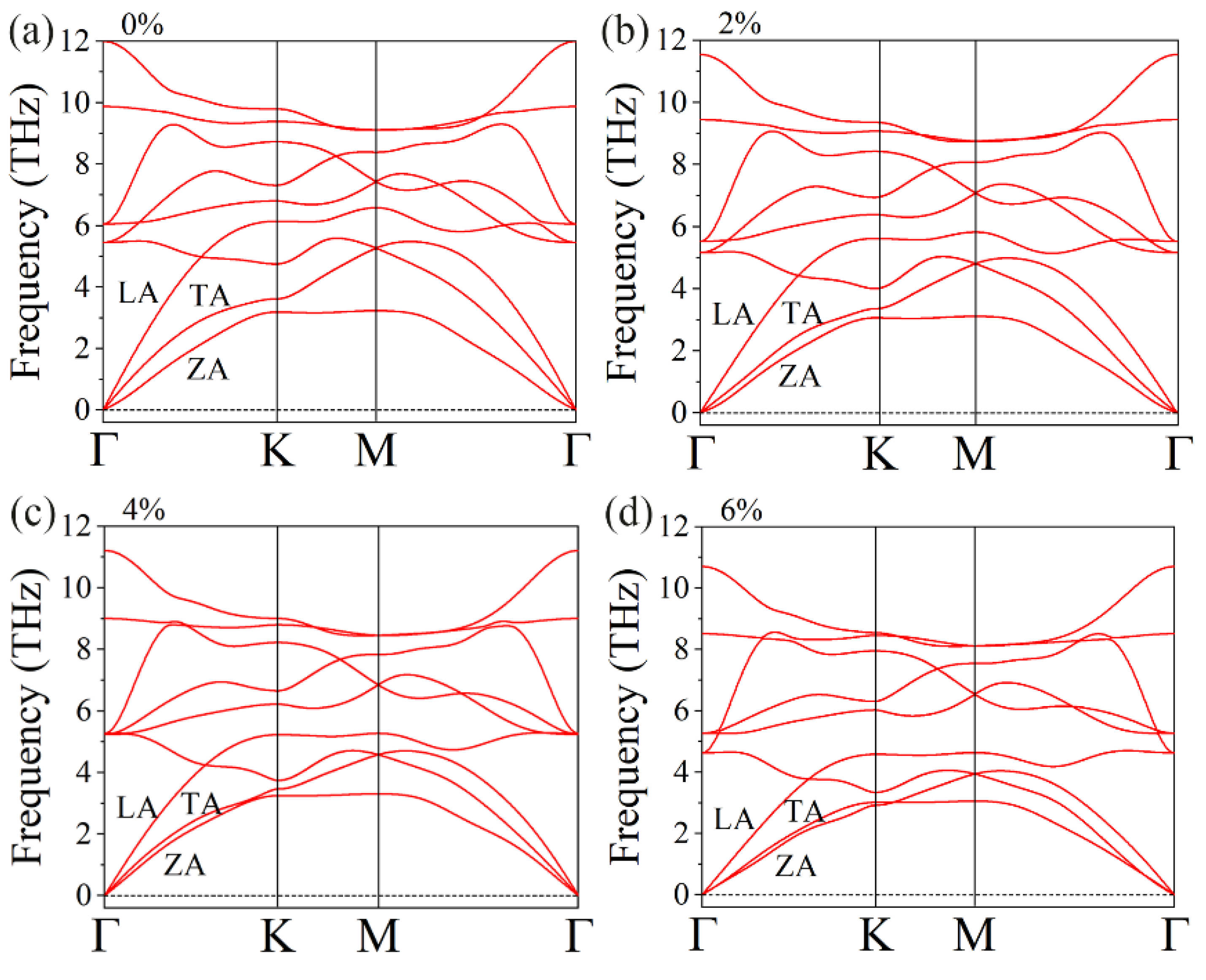

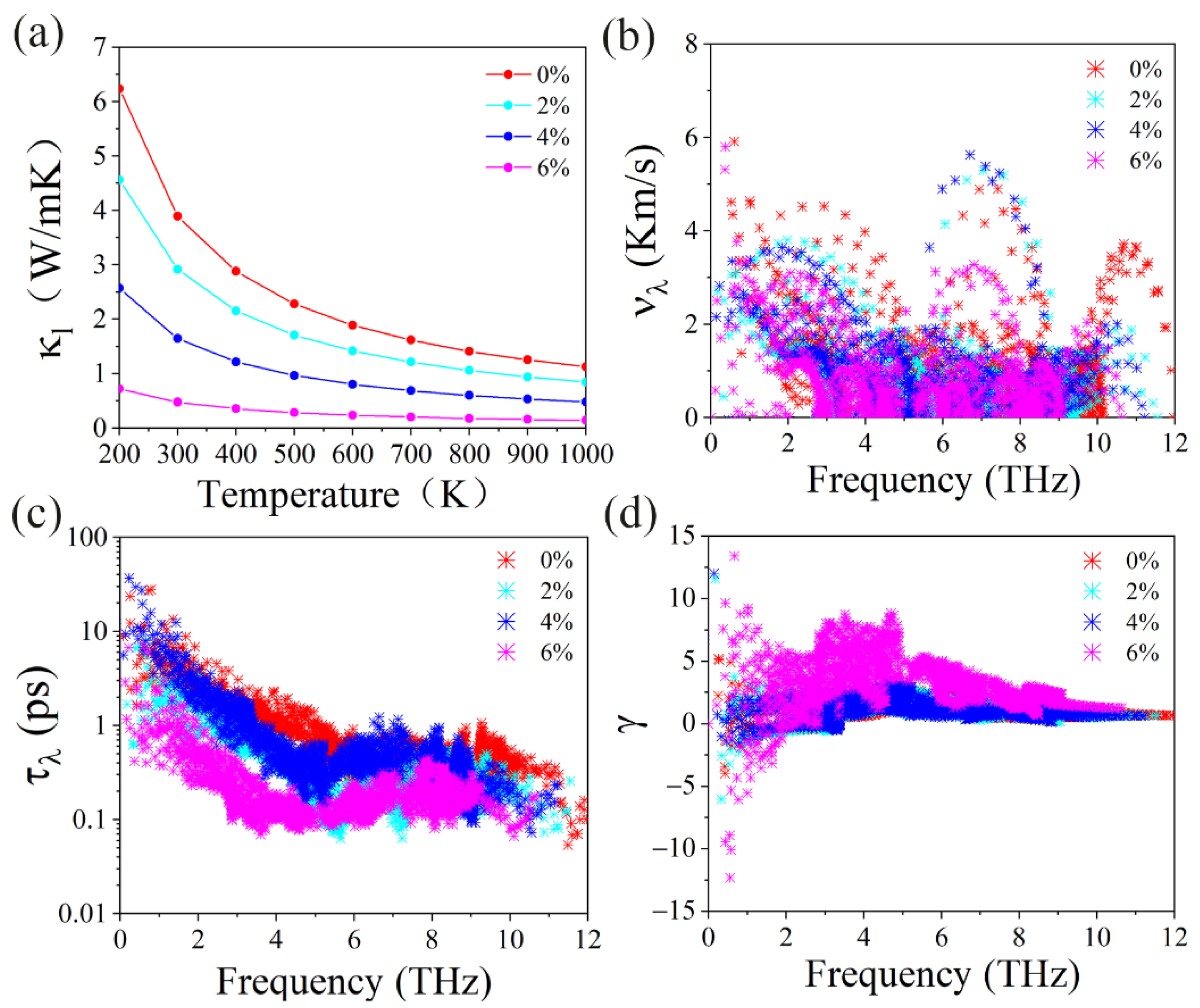

3.3. Phonon Dispersion Curves and Transport Properties

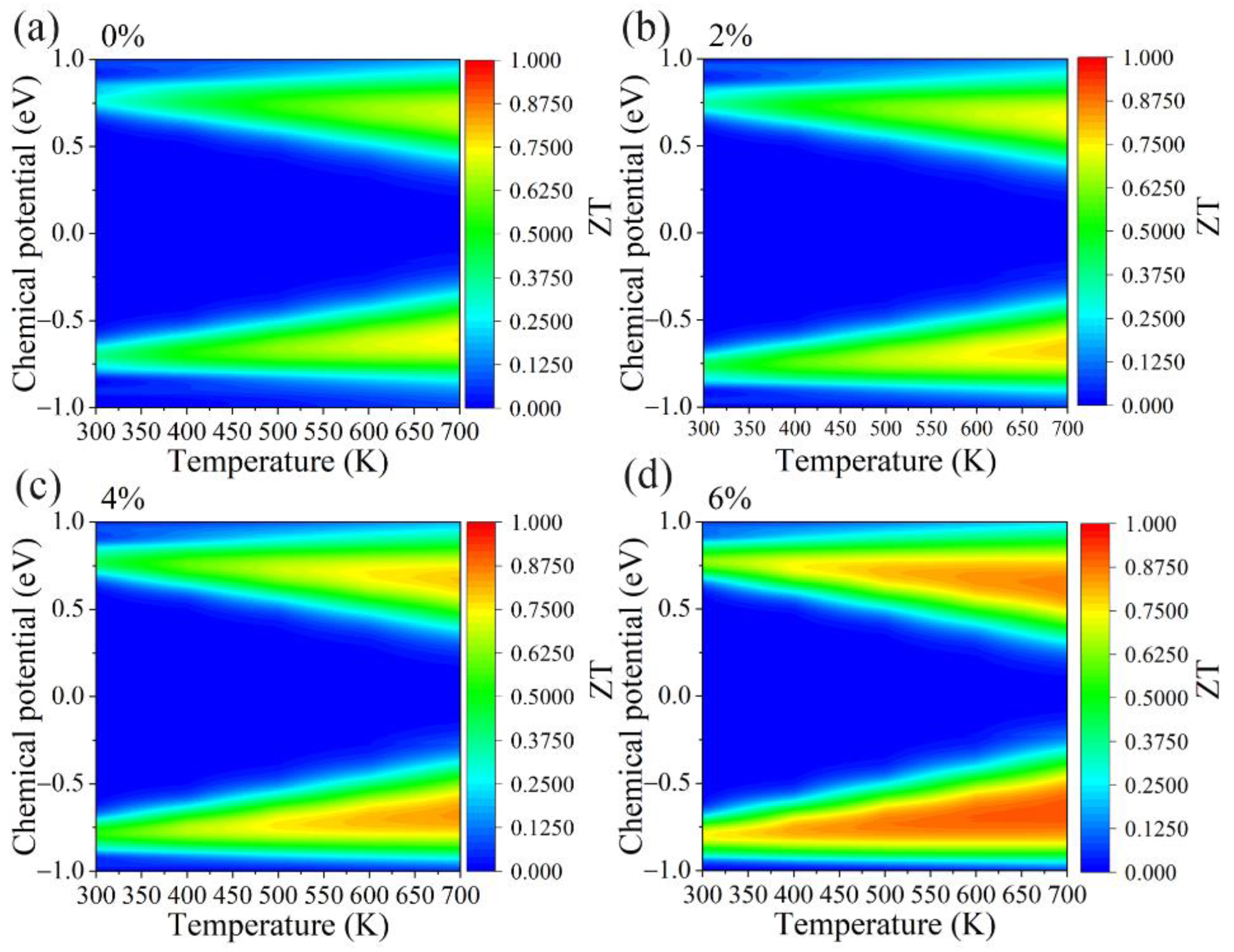

3.4. Thermoelectric Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, J.; Tritt Terry, M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef] [Green Version]

- Mbaye, M.T.; Pradhan, S.K.; Bahoura, M. Data-driven thermoelectric modeling: Current challenges and prospects. J. Appl. Phys. 2021, 130, 190902. [Google Scholar] [CrossRef]

- Yang, J.; Xi, L.; Qiu, W.; Wu, L.; Shi, X.; Chen, L.; Yang, J.; Zhang, W.; Uher, C.; Singh, D.J. On the tuning of electrical and thermal transport in thermoelectrics: An integrated theory—Experiment perspective. Npj Comput. Mater. 2016, 2, 15015. [Google Scholar] [CrossRef] [Green Version]

- Xiong, R.; Sa, B.; Miao, N.; Li, Y.-L.; Zhou, J.; Pan, Y.; Wen, C.; Wu, B.; Sun, Z. Structural stability and thermoelectric property optimization of Ca2Si. RSC Adv. 2017, 7, 8936–8943. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.-L.; Yang, H.; Zhou, W.-X.; Wang, B.; Xu, N.; Xie, G. KAgX (X = S, Se): High-performance layered thermoelectric materials for medium-temperature applications. ACS Appl. Mater. Inter. 2020, 12, 36102–36109. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez Moreno, J.J.; Cao, J.; Fronzi, M.; Assadi, M.H.N. A review of recent progress in thermoelectric materials through computational methods. Mater. Renew. Sustain. Energy 2020, 9, 16. [Google Scholar] [CrossRef]

- Li, D.; Gong, Y.; Chen, Y.; Lin, J.; Khan, Q.; Zhang, Y.; Li, Y.; Zhang, H.; Xie, H. Recent progress of two-dimensional thermoelectric materials. Nanomicro Lett. 2020, 12, 36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gan, Y.; Wang, G.; Zhou, J.; Sun, Z. Prediction of thermoelectric performance for layered IV-V-VI semiconductors by high-throughput ab initio calculations and machine learning. Npj Comput. Mater. 2021, 7, 176. [Google Scholar] [CrossRef]

- Li, Z.; Miao, N.; Zhou, J.; Sun, Z.; Liu, Z.; Xu, H. High thermoelectric performance of few-quintuple Sb2Te3 nanofilms. Nano Energy 2018, 43, 285–290. [Google Scholar] [CrossRef]

- Zhu, X.L.; Liu, P.F.; Zhang, J.; Zhang, P.; Zhou, W.X.; Xie, G.; Wang, B.T. Monolayer SnP3: An excellent p-type thermoelectric material. Nanoscale 2019, 11, 19923–19932. [Google Scholar] [CrossRef]

- Xie, Q.-Y.; Liu, P.-F.; Ma, J.-J.; Kuang, F.-G.; Zhang, K.-W.; Wang, B.-T. Monolayer SnI2: An excellent p-type thermoelectric material with ultralow lattice thermal conductivity. Materials 2022, 15, 3147. [Google Scholar] [CrossRef] [PubMed]

- Kaur, K.; Khandy, S.A.; Dhiman, S.; Sharopov, U.B.; Singh, J. Computational prediction of thermoelectric properties of 2D materials. Electron. Struct. 2022, 4, 023001. [Google Scholar] [CrossRef]

- Sevinçli, H.; Cuniberti, G. Enhanced thermoelectric figure of merit in edge-disordered zigzag graphene nanoribbons. Phys. Rev. B 2010, 81, 113401. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Gabor, N.M.; Alden, J.S.; van der Zande, A.M.; McEuen, P.L. Photo-thermoelectric effect at a graphene interface junction. Nano Lett. 2010, 10, 562–566. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, H.J.; Cheng, L.; Wei, J.; Liang, J.H.; Fan, D.D.; Jiang, P.H.; Sun, L.; Shi, J. High thermoelectric performance can be achieved in black phosphorus. J. Mater. Chem. C 2016, 4, 991–998. [Google Scholar] [CrossRef] [Green Version]

- Saito, Y.; Iizuka, T.; Koretsune, T.; Arita, R.; Shimizu, S.; Iwasa, Y. Gate-Tuned Thermoelectric Power in Black Phosphorus. Nano Lett. 2016, 16, 4819–4824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fei, R.; Faghaninia, A.; Soklaski, R.; Yan, J.-A.; Lo, C.; Yang, L. Enhanced thermoelectric efficiency via orthogonal electrical and thermal conductances in phosphorene. Nano Lett. 2014, 14, 6393–6399. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.-G.; Shi, X.; Zhao, L.-D.; Zou, J. High-performance SnSe thermoelectric materials: Progress and future challenge. Prog. Mater. Sci. 2018, 97, 283–346. [Google Scholar] [CrossRef] [Green Version]

- Xu, P.; Fu, T.; Xin, J.; Liu, Y.; Ying, P.; Zhao, X.; Pan, H.; Zhu, T. Anisotropic thermoelectric properties of layered compound SnSe2. Sci. Bull. 2017, 62, 1663–1668. [Google Scholar] [CrossRef] [Green Version]

- Sarikurt, S.; Kocabaş, T.; Sevik, C. High-throughput computational screening of 2D materials for thermoelectrics. J. Mater. Chem. A 2020, 8, 19674–19683. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Y.-W. Thermoelectric properties of two-dimensional transition metal dichalcogenides. J. Mater. Chem. C 2017, 5, 7684–7698. [Google Scholar] [CrossRef]

- Hong, J.; Lee, C.; Park, J.-S.; Shim, J.H. Control of valley degeneracy in MoS2 by layer thickness and electric field and its effect on thermoelectric properties. Phys. Rev. B 2016, 93, 035445. [Google Scholar] [CrossRef] [Green Version]

- Wickramaratne, D.; Zahid, F.; Lake, R.K. Electronic and thermoelectric properties of few-layer transition metal dichalcogenides. J. Chem. Phys. 2014, 140, 124710. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Feng, W.; Shen, C.; Sun, Z.; Qi, H.; Yang, M.; Liu, Y.; Wu, Y.; Wu, X. The verification of thermoelectric performance obtained by high-throughput calculations: The case of GeS2 monolayer from first-principles calculations. Front. Mater. 2021, 8, 709757. [Google Scholar] [CrossRef]

- Sa, B.; Li, Y.-L.; Qi, J.; Ahuja, R.; Sun, Z. Strain engineering for phosphorene: The potential application as a photocatalyst. J. Phys. Chem. C 2014, 118, 26560–26568. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Chen, Y.; Jiang, C. Strain engineering of two-dimensional materials: Methods, properties, and applications. InfoMat 2021, 3, 397–420. [Google Scholar] [CrossRef]

- Du, J.; Yu, H.; Liu, B.; Hong, M.; Liao, Q.; Zhang, Z.; Zhang, Y. Strain engineering in 2D material-based flexible optoelectronics. Small Methods 2021, 5, 2000919. [Google Scholar] [CrossRef]

- Panneerselvam, I.R.; Kim, M.H.; Baldo, C.; Wang, Y.; Sahasranaman, M. Strain engineering of polar optical phonon scattering mechanism—An effective way to optimize the power-factor and lattice thermal conductivity of ScN. Phys. Chem. Chem. Phys. 2021, 23, 23288–23302. [Google Scholar] [CrossRef] [PubMed]

- Lou, X.; Li, S.; Chen, X.; Zhang, Q.; Deng, H.; Zhang, J.; Li, D.; Zhang, X.; Zhang, Y.; Zeng, H.; et al. Lattice strain leads to high thermoelectric performance in polycrystalline SnSe. ACS Nano 2021, 15, 8204–8215. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, G.; Zhang, Y.-W.; Peng, L.-M. Strain engineering on the thermal conductivity and heat flux of thermoelectric Bi2Te3 nanofilm. Nano Energy 2015, 17, 104–110. [Google Scholar] [CrossRef]

- Guo, S.-D. Biaxial strain tuned thermoelectric properties in monolayer PtSe2. J. Mater. Chem. C 2016, 4, 9366–9374. [Google Scholar] [CrossRef]

- Blochl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Hafner, J. Ab-initio simulations of materials using VASP: Density-functional theory and beyond. J. Comput. Chem. 2008, 29, 2044–2078. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Peng, L.; Li, K.; Zhu, L.; Zhou, J.; Miao, N.; Sun, Z. ALKEMIE: An intelligent computational platform for accelerating materials discovery and design. Comput. Mater. Sci. 2021, 186, 110064. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perdew, J.; Burke, K.; Ernzerhof, M. Perdew, burke, and ernzerhof reply. Phys. Rev. Lett. 1998, 80, 891. [Google Scholar] [CrossRef]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192. [Google Scholar] [CrossRef]

- Heyd, J.; Scuseria, G.E.; Ernzerhof, M. Hybrid functionals based on a screened Coulomb potential. J. Chem. Phys. 2003, 118, 8207–8215. [Google Scholar] [CrossRef] [Green Version]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef] [Green Version]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef] [Green Version]

- Madsen, G.K.H.; Singh, D.J. BoltzTraP. A code for calculating band-structure dependent quantities. Comput. Phys. Commun. 2006, 175, 67–71. [Google Scholar] [CrossRef] [Green Version]

- Togo, A.; Oba, F.; Tanaka, I. First-principles calculations of the ferroelastic transition between rutile-type and CaCl2-type SiO2 at high pressures. Phys. Rev. B 2008, 78, 134106. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Carrete, J.; Katcho, N.A.; Mingo, N. ShengBTE: A solver of the Boltzmann transport equation for phonons. Comput. Phys. Commun. 2014, 185, 1747–1758. [Google Scholar] [CrossRef]

- Ding, W.; Hu, L.; Dai, J.; Tang, X.; Wei, R.; Sheng, Z.; Liang, C.; Shao, D.; Song, W.; Liu, Q.; et al. Highly ambient-sTable 1T-MoS2 and 1T-WS2 by hydrothermal synthesis under high magnetic fields. ACS Nano 2019, 13, 1694–1702. [Google Scholar] [CrossRef]

- Nandi, P.; Rawat, A.; Ahammed, R.; Jena, N.; De Sarkar, A. Group-IV(A) Janus dichalcogenide monolayers and their interfaces straddle gigantic shear and in-plane piezoelectricity. Nanoscale 2021, 13, 5460–5478. [Google Scholar] [CrossRef] [PubMed]

- Taheri, A.; Pisana, S.; Singh, C.V. Importance of quadratic dispersion in acoustic flexural phonons for thermal transport of two-dimensional materials. Phys. Rev. B 2021, 103, 235426. [Google Scholar] [CrossRef]

- Chaurasiya, R.; Tyagi, S.; Singh, N.; Auluck, S.; Dixit, A. Enhancing thermoelectric properties of Janus WSSe monolayer by inducing strain mediated valley degeneracy. J. Alloy. Compd. 2021, 855, 157304. [Google Scholar] [CrossRef]

- Li, Y.; Ma, K.; Fan, X.; Liu, F.; Li, J.; Xie, H. Enhancing thermoelectric properties of monolayer GeSe via strain-engineering: A first principles study. Appl. Surf. Sci. 2020, 521, 146256. [Google Scholar] [CrossRef]

- Jonson, M.; Mahan, G.D. Mott’s formula for the thermopower and the Wiedemann-Franz law. Phys. Rev. B 1980, 21, 4223–4229. [Google Scholar] [CrossRef]

- Wei, Q.-L.; Zhu, X.-L.; Liu, P.-F.; Wu, Y.-Y.; Ma, J.-J.; Liu, Y.-B.; Li, Y.-H.; Wang, B.-T. Quadruple-layer group-IV tellurides: Low thermal conductivity and high performance two-dimensional thermoelectric materials. Phys. Chem. Chem. Phys. 2021, 23, 6388–6396. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Xia, Q.; Zhang, J.; Ma, S.; Wang, Y.; Xu, Q.; Li, J.; Wang, Y. High figure of merit of monolayer Sb2Te2Se of ultra low lattice thermal conductivity. Comput. Mater. Sci. 2020, 177, 109588. [Google Scholar] [CrossRef]

- Song, H.-Y.; Sun, J.-J.; Li, M. Enhancement of monolayer HfSe2 thermoelectric performance by strain engineering: A DFT calculation. Chem. Phys. Lett. 2021, 784, 139109. [Google Scholar] [CrossRef]

- Zhou, W.X.; Cheng, Y.; Chen, K.Q.; Xie, G.; Wang, T.; Zhang, G. Thermal conductivity of amorphous materials. Adv. Funct. Mater. 2019, 30, 1903829. [Google Scholar] [CrossRef]

- Cai, Y.; Zhang, G.; Zhang, Y.-W. Polarity-reversed robust carrier mobility in monolayer MoS2 nanoribbons. J. Am. Chem. Soc. 2014, 136, 6269–6275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rawat, A.; Jena, N.; Dimple; De Sarkar, A. A comprehensive study on carrier mobility and artificial photosynthetic properties in group VI B transition metal dichalcogenide monolayers. J. Mater. Chem. A 2018, 6, 8693–8704. [Google Scholar] [CrossRef]

- Zhang, P.; Jiang, E.; Ouyang, T.; Tang, C.; He, C.; Li, J.; Zhang, C.; Zhong, J. Potential thermoelectric candidate monolayer silicon diphosphide (SiP2) from a first-principles calculation. Comput. Mater. Sci. 2021, 188, 110154. [Google Scholar] [CrossRef]

- Li, G.; Yao, K.; Gao, G. Strain-induced enhancement of thermoelectric performance of TiS2 monolayer based on first-principles phonon and electron band structures. Nanotechnology 2018, 29, 015204. [Google Scholar] [CrossRef]

| Direction | Carrier Type | E1 (eV) | C2D (N m−1) | m*/m0 | μ (cm2 V−1 s−1) | τ (ps) |

|---|---|---|---|---|---|---|

| x | e | 7.310 | 52.9 | 0.21 | 321.52 | 0.04 |

| h | 5.065 | 52.9 | 0.88 | 37.41 | 0.02 | |

| y | e | 4.359 | 49.9 | 0.68 | 79.80 | 0.03 |

| h | 2.302 | 49.9 | 1.19 | 93.43 | 0.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, X.; Xiong, R.; Cui, Z.; Wen, C.; Ma, J.-J.; Wang, B.-T.; Sa, B. Strain-Enhanced Thermoelectric Performance in GeS2 Monolayer. Materials 2022, 15, 4016. https://doi.org/10.3390/ma15114016

Ruan X, Xiong R, Cui Z, Wen C, Ma J-J, Wang B-T, Sa B. Strain-Enhanced Thermoelectric Performance in GeS2 Monolayer. Materials. 2022; 15(11):4016. https://doi.org/10.3390/ma15114016

Chicago/Turabian StyleRuan, Xinying, Rui Xiong, Zhou Cui, Cuilian Wen, Jiang-Jiang Ma, Bao-Tian Wang, and Baisheng Sa. 2022. "Strain-Enhanced Thermoelectric Performance in GeS2 Monolayer" Materials 15, no. 11: 4016. https://doi.org/10.3390/ma15114016