The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review

Abstract

:1. Introduction

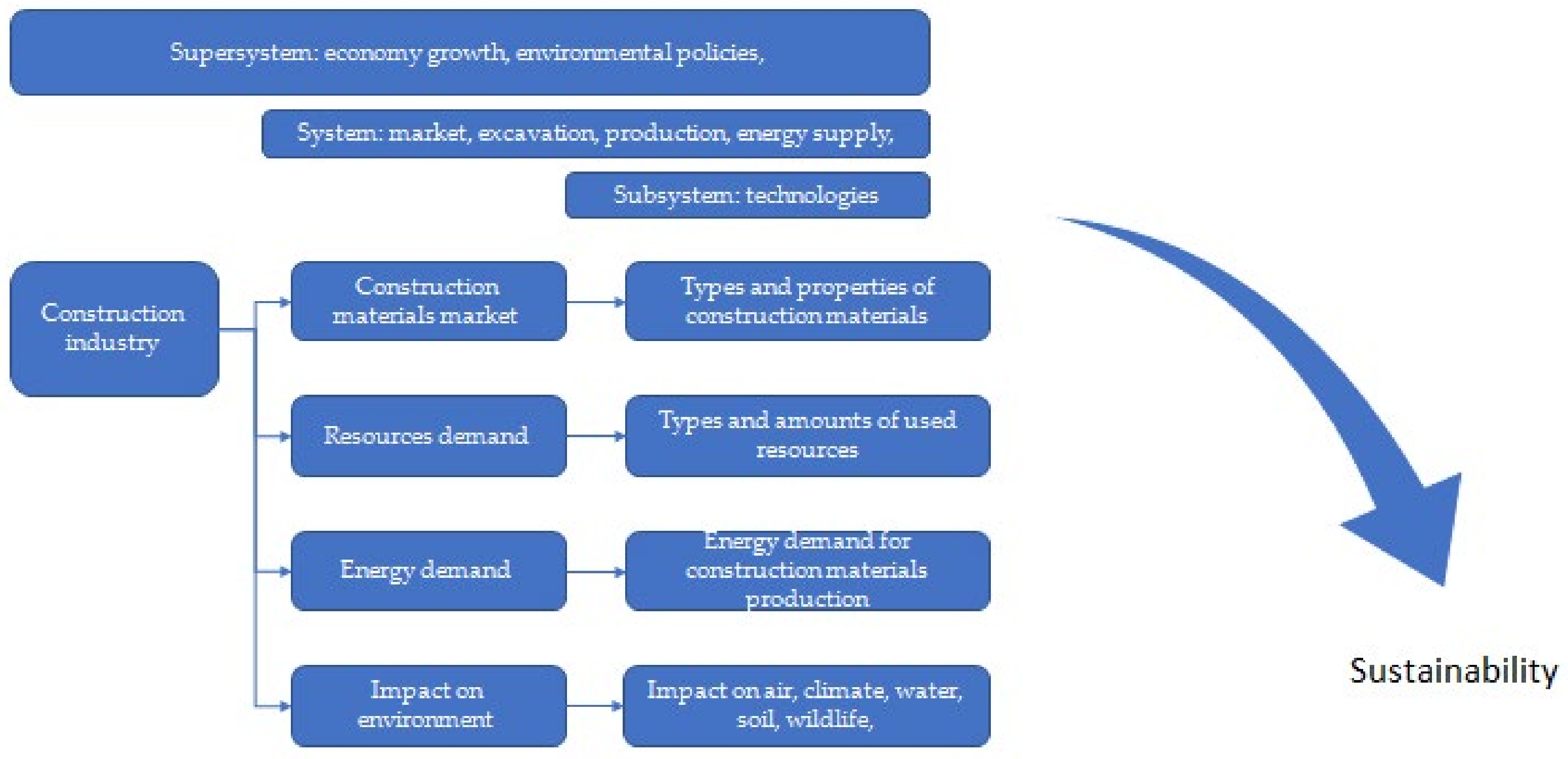

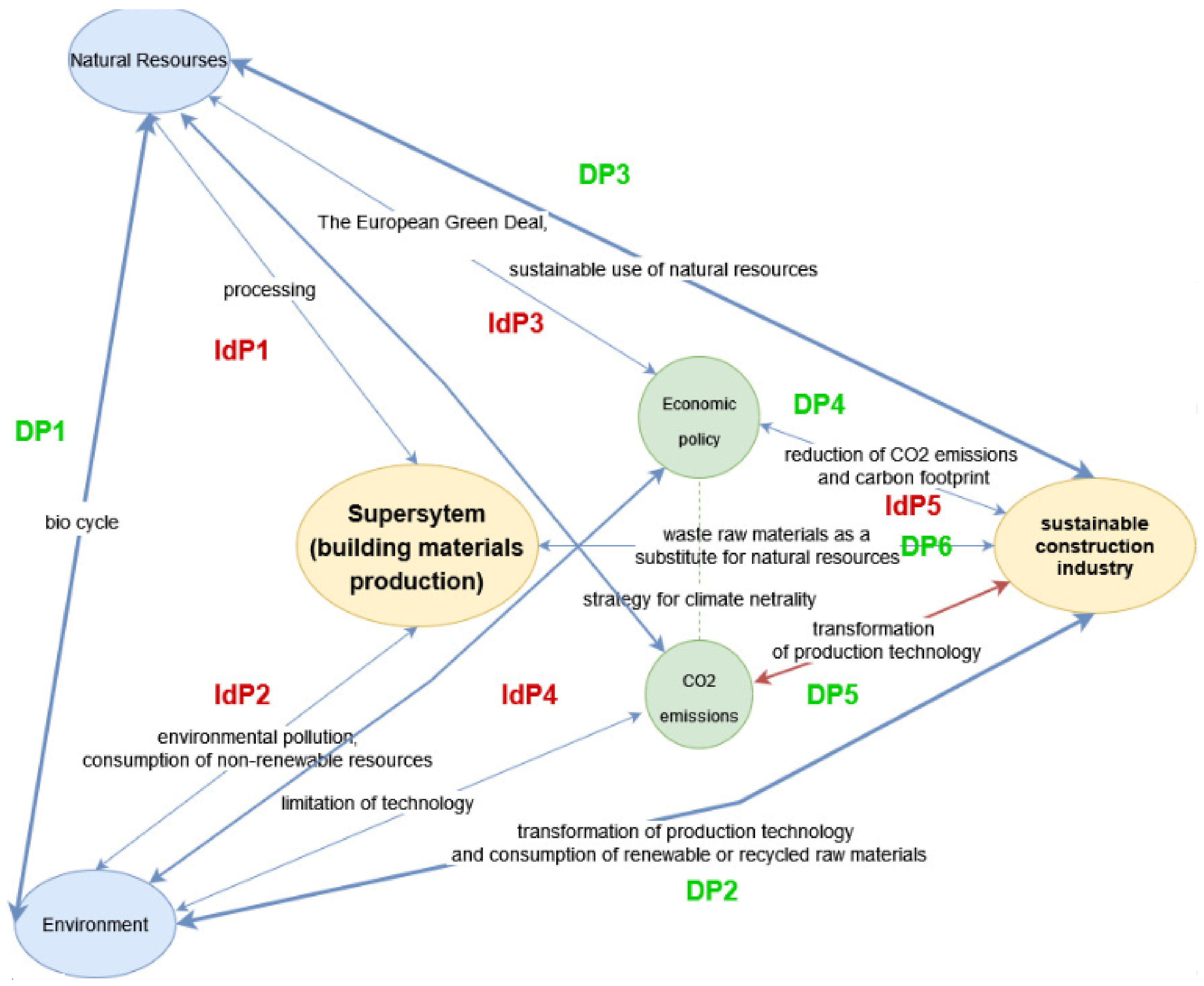

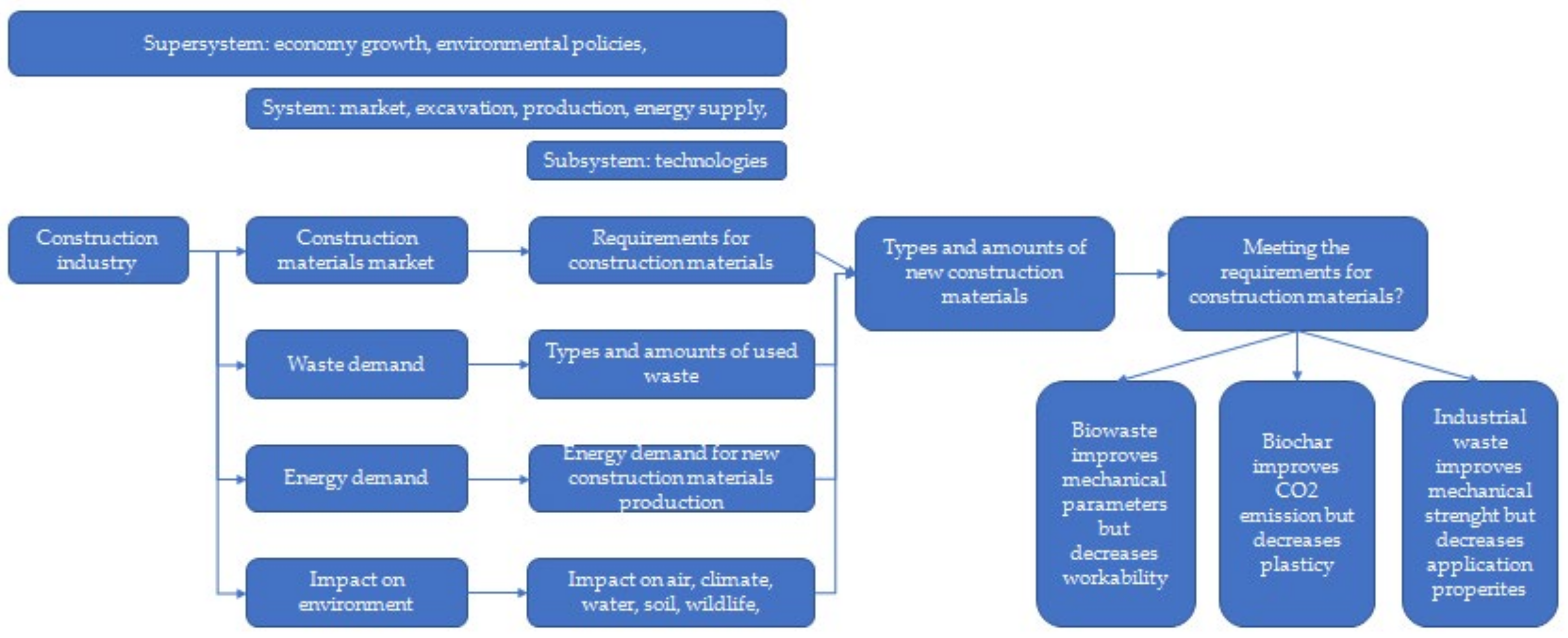

2. Building Material Management—The Selection of Raw Materials and Production

3. Characteristics of Waste

4. The Use of Biowaste in the Production of Building Materials

4.1. Utilization of Lignin Waste

- Fragmentation or depolymerization, where its structure is broken down into aromatic monomers;

- Modification with the creation of new chemically active locations;

- Chemical modification of hydroxyl groups.

4.2. Use of Hemp Fiber Waste

4.3. Utilization of Bamboo Fiber Waste

- Mechanical extraction, where a bamboo fiber is obtained by means of steam under appropriate pressure in a mechanical press;

- Grinding.

4.4. The Use of Recycled Fibers (Textile Fibers and Textiles)

- Low-end fibers with a high tensile strength and a low modulus of elasticity (plastic);

- High-end fibers with a high tensile strength and a high modulus of elasticity (brittle).

5. The Use of Waste of Mineral Origins in the Production of Building Materials

5.1. Reuse of Waste from Coal Mining

- The first one is mining waste, generated in the course of mining works. It is mainly a waste rock in the form of large rock fragments.

- The second group consists of mining waste: waste rocks, which are deposited in the bottom and roof of coal seams, and overgrowths, which, during the exploitation of coal seams, get into the output and are extracted with the waste to the surface, then separated in the processing plant [86].

5.2. Reuse of Waste from Copper Ore Flotation

5.3. Reuse of Ashes from the Incineration of Municipal Solid Waste and Biomass

5.4. Reuse of Slag Waste from Municipal Waste Incineration

5.5. Reuse of Sulfur Waste

6. The Use of Biochar

- Chemical composition (depending on the substrate and the pyrolysis process);

- Stability (low susceptibility to degradation and microbiological decomposition);

- pH (neutral or alkaline);

- The content of micro- and macroelements (including calcium, phosphorus, and magnesium);

- Micropollutants such as heavy metal ions, dioxins, and polycyclic aromatic hydrocarbons (PAHs);

- Low thermal conductivity—the ability to absorb water (up to 5 times higher than its specific weight).

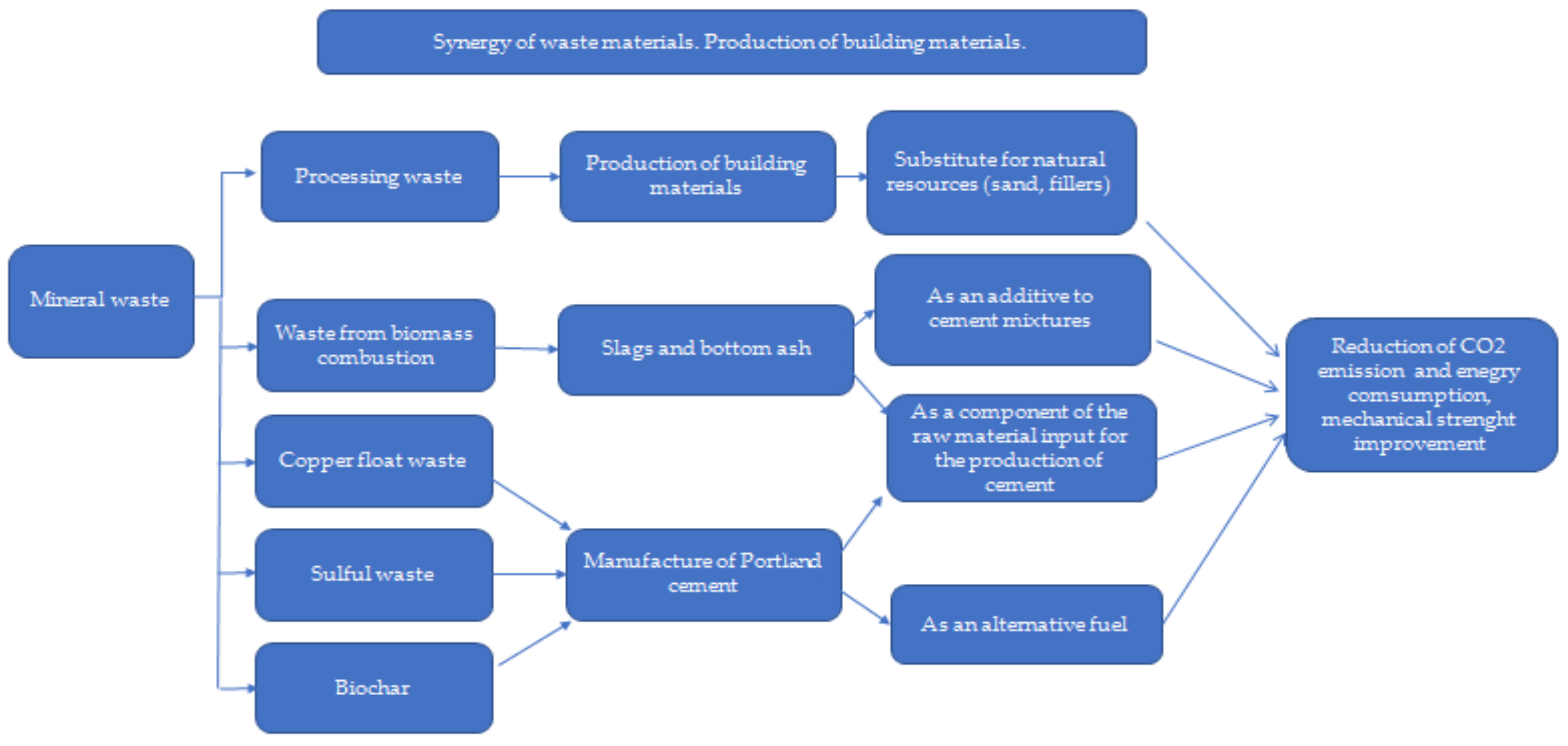

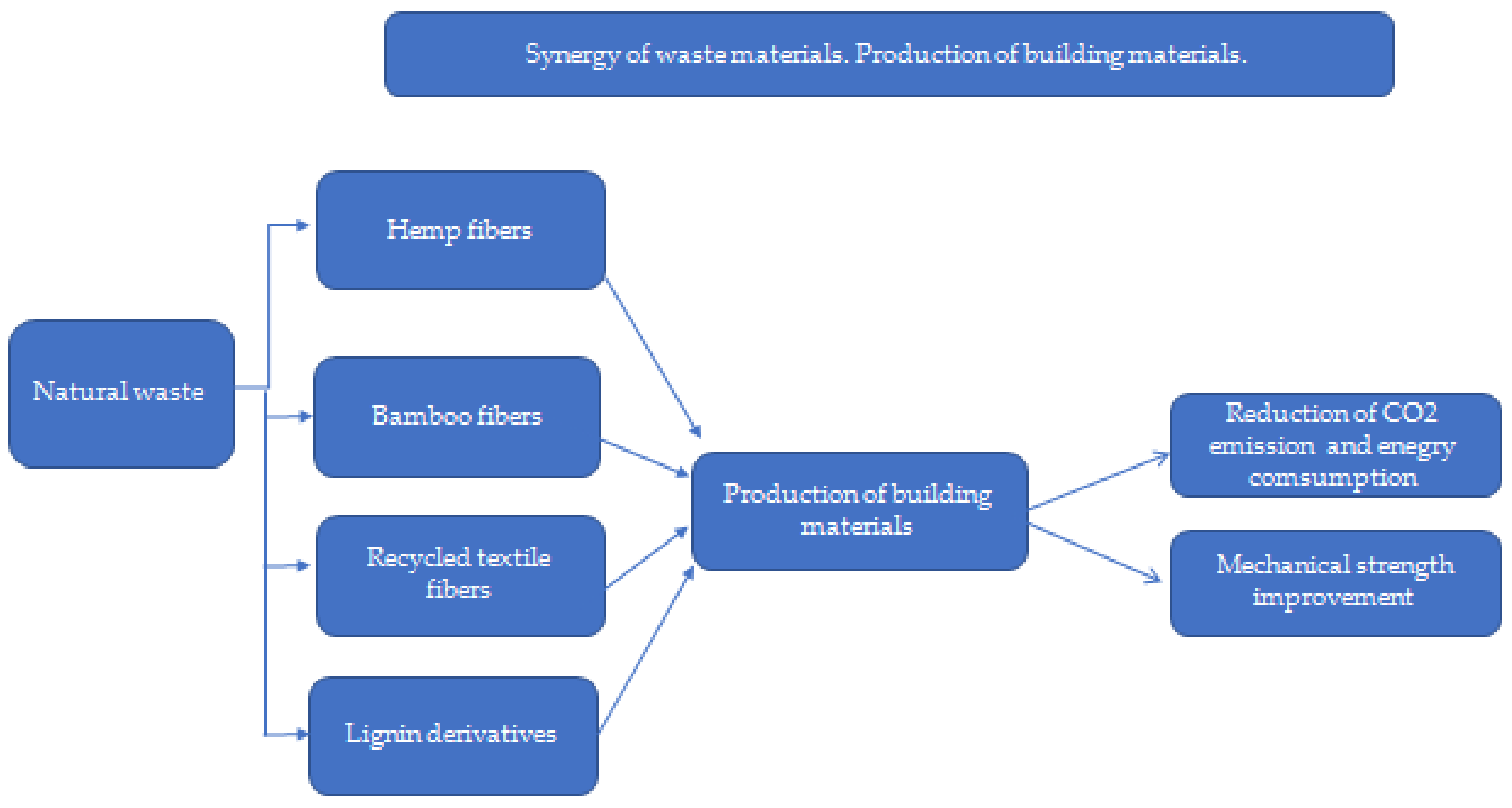

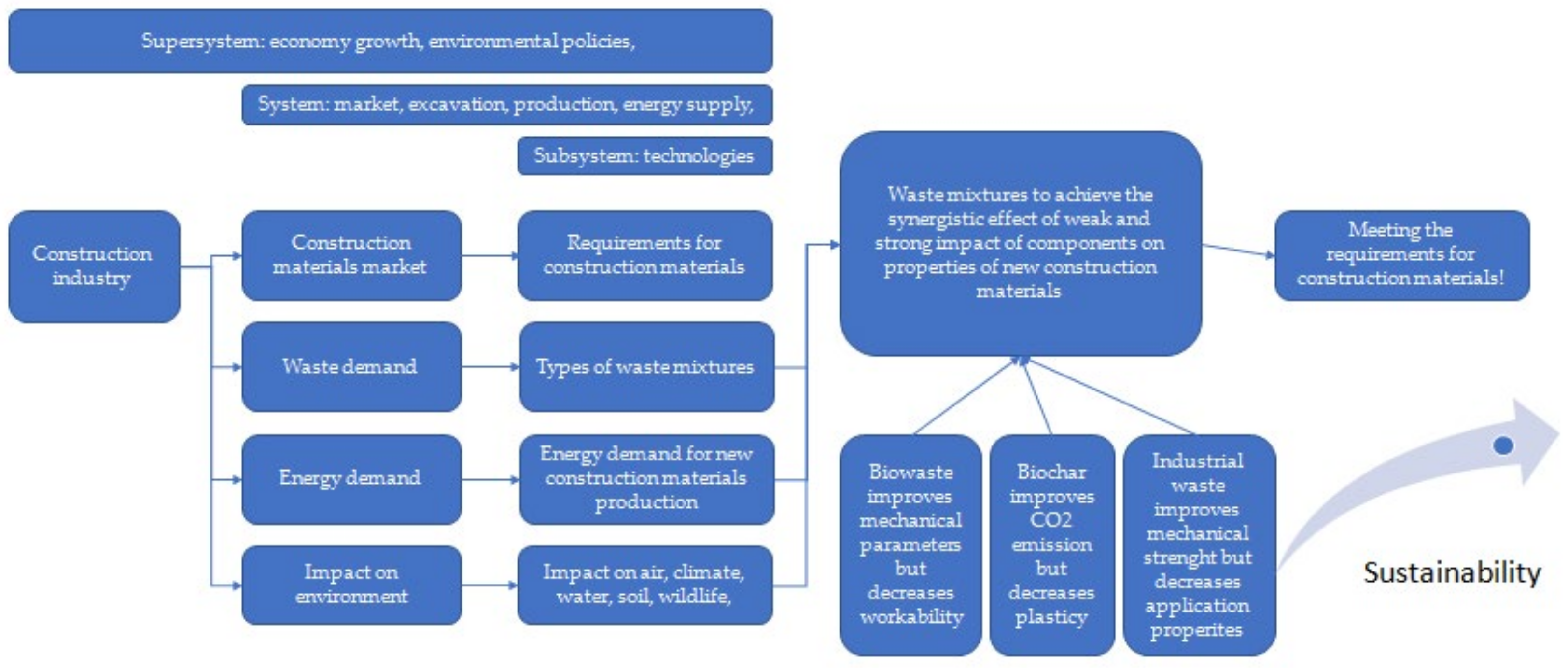

7. Synergy of the Simultaneous Addition of Biowaste and Mineral Waste

- In order to prevent the excessive use of natural resources in the production of construction products such as concrete or mortars, we can successfully use mineral waste. With the removal of impurities and the selection of granulation, they can replace natural fillers without affecting the final properties of construction products.

- In cement production, flotation wastes can be used as a substitute for margal in raw meal for Portland cement production, and flotation wastes can be used as major or minor components or as an alternative fuel. In the production of cement itself, part of it can be replaced with fly ash from the incineration of municipal waste, where, in this process, the fly ash reacts with the calcium hydroxide of the cement, finally giving much more durable and stronger compounds. Additionally, fly ash reduces CO2 emissions and energy consumption. Sulfur waste and biochar work similarly. As already mentioned, the production of cement is a very energy-intensive process, and it is responsible for the majority of carbon dioxide (CO2) emissions released into the atmosphere, while the production of biochar reduces CO2 emissions released into the atmosphere. Replacing some of the cement with the described waste is a beneficial alternative to reducing CO2 emissions and energy consumption, while maintaining the standard parameters of the cement produced.

- The workability of concrete and cement mixes: The addition of natural fibers, such as hemp, bamboo, or recycled textile fibers, as well as the addition of biomass fly ashes, adversely affect the plasticity of the mixes, thus lowering the mix viscosity. To prevent this, it is necessary to use plasticizers, and a solution may be the use of lignin derivatives of waste raw materials, which have a positive effect on the application properties while contributing to the reduction of CO2 emissions. The addition of biochar also reduces the decrease in the viscosity of the mixture, thus favorably reducing the carbon footprint in the finished biocomposite.

- The mechanical strength of concrete and cement mixtures with the use of precipitation: The addition of waste such as fly ash from biomass combustion, sulfur waste, biochar, and natural fibers positively influences the final mechanical strength.

- The tightness and frost resistance of concrete mixes: The addition of copper flotation waste positively improves these properties, but adversely affects the mechanical strength of the concrete mix. The addition of ash, sulfur, or biochar may improve this parameter.

8. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polish Central Statistical Office. Statistical Data June 2021. Available online: https://stat.gov.pl/obszary-tematyczne/przemysl-budownictwo-srodki-trwale/budownictwo/budownictwo-w-2021-roku,13,13.html (accessed on 12 December 2021).

- ITB Brochure—Sustainable Construction in the EU. Available online: https://www.itb.pl/epd.html (accessed on 12 December 2021).

- EEC Poland. Green Building. Available online: https://www.eecpoland.eu/2021/pl/wiadomosci/zielone-budownictwo-dopiero-raczkuje-przed-branza-daleka-droga,489128.html (accessed on 7 January 2022).

- IPCC Report. Climate Change 2021: The Physical Science Basis, the Working Group I Contribution to the Sixth Assessment Report. 2021. Available online: https://www.ipcc.ch/report/sixth-assessment-report-working-group-i/ (accessed on 7 January 2022).

- Polish Cement Association. Polish Cement. 2021. Available online: https://www.polskicement.pl/aktualnosci/co2-zmienia-oblicze-przemyslu-cementowego (accessed on 7 January 2022).

- UNEP. Report ‘Greening the Building Supply Chain’. 2021. Available online: https://www.unep.org/resources/global-environment-outlook-6 (accessed on 7 January 2022).

- European Green Deal. COM (2019) 640 Final, 2019. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_pl (accessed on 8 January 2022).

- 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://plgbc.org.pl/wp-content/uploads/2021/06/Mapa-drogowa-dekarbonizacji-2050.pdf (accessed on 8 December 2021).

- EPD. Environmental Declaration, i.e., towards Zero-Carbon Construction; ITB Building Research Institute: Warsaw, Poland, 2019; Available online: https://www.itb.pl/oferta1.html (accessed on 7 December 2021).

- PIE. Available online: https://pie.net.pl/wp-content/uploads/2021/09/Tygodnik-Gospodarczy-PIE_38-2021.pdf (accessed on 8 January 2022).

- PIE. Available online: https://pie.net.pl/wp-content/uploads/2021/12/Miesiecznik-Makro_11-21.pdf (accessed on 8 January 2022).

- Sales Data for the Purchasing Department of Selena FM; Selena FM SA Group: Wrocław, Poland, 2021.

- Educational Platform of the Ministry of Education and Science. Renewable and Non-Renewable Energy Sources and Its Saving. Available online: https://zpe.gov.pl/a/odnawialne-i-nieodnawialne-zrodla-energii-i-jej-oszczedzanie/DXgcliG2B (accessed on 9 January 2022).

- ODTIK. Available online: https://www.triz.oditk.pl/strefa-wiedzy/podstawy-triz/najkrocej-czym-jest-triz (accessed on 9 January 2022).

- Official Journal of the European Union. COMMISSION DECISION of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council (Text with EEA Relevance) (2014/955/EU); Official Journal of the European Union: Luxembourg, 2014. [Google Scholar]

- Journal of Laws of 2021, Item 2151. The Act of 17 November 2021 Amending the Act on Waste and Some Other Acts. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20210002151 (accessed on 10 December 2021).

- Regulation of the Minister of Environment, Natural Resources and Forestry of 24 December 1997 on the Classification of Waste. Available online: https://www.prawo.pl/akty/dz-u-1997-162-1135,16799265.html (accessed on 10 January 2022).

- Commission Notice on Technical Guidelines on the Classification of Waste (2018/C 124/01); Official Journal EUC: Luxembourg, 2018.

- Builder Polska. Available online: https://builderpolska.pl/2018/11/16/najnowsze-swiatowe-trendy-w-budownictwie-ekologicznym/ (accessed on 10 January 2022).

- Lignin. Dictionary of the Polish Language; PWN; Polish Scientific Publishing House: Warsaw, Poland, 2021; Available online: https://encyklopedia.pwn.pl/haslo/lignina;3932541.html (accessed on 7 December 2021).

- Adler, E. Lignin chemistry—Past, present and future. Wood Sci. Technol. 1977, 11, 169–218. [Google Scholar] [CrossRef]

- Lin, S.Y.; Dence, C.W. Methods in Lignin Chemistry; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Wen, Y.; Yuan, Z.; Liu, X.; Qu, J.; Yang, S. Preparation and characterization of lignin-containing cellulose nanofibril from poplar high-yield pulp via TEMPO-mediated oxidation and homogenization. ACS Sustain. 2019, 7, 6131–6139. [Google Scholar] [CrossRef]

- Coyle, W. The Future of Biofuels: Global Perspective; Amber Waves-Economic Research Service: Washington, DC, USA, 2008; Volume 5, pp. 24–29.

- Jędrzejczak, P.; Collins, M.N.; Jesionowsk, T.; Klapiszewski, Ł. The role of lignin and lignin-based materials in sustainable construction—A comprehensive review. Int. J. Biol. Macromol. 2021, 198, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, S.; Colmenares, J.C.; Xu, Y.-J. A sustainable approach for lignin valorization by heterogeneous photocatalysis. Green Chem. 2016, 18, 594–607. [Google Scholar] [CrossRef]

- Pandey, M.P.; Kim, C.S. Lignin depolymerization and conversion: A review of thermochemical methods. Chem. Eng. Technol. 2011, 34, 29–41. [Google Scholar] [CrossRef]

- Torres, L.A.Z.; Woiciechowsk, I.A.L.; de Andrade Tanobe, V.O.; Karp, S.G.; Lorenci, L.C.G.; Faulds, C.; Soccol, C.R. A review on lignocellulose/poly (vinyl alcohol) composites: Cleaner approaches for greener materials. Cellulose 2021, 28, 10741–10764. [Google Scholar] [CrossRef]

- Lora, J.H.; Glasser, W.G. Recent industrial applications of lignin: A sustainable alternative to nonrenewable materials. J. Polym. Environ. 2002, 10, 39–48. [Google Scholar] [CrossRef]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. Bioresources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Lange, H.; Decina, S.; Crestini, C. Oxidative upgrade of lignin—Recent routes reviewed. Eur. Polym. J. 2013, 49, 1151–1173. [Google Scholar] [CrossRef] [Green Version]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Klapiszewski, L.; Bartczak, P.; Wysokowski, M.; Jankowska, M.; Kabat, K.; Jesionowski, T. Silica conjugated with Kraft lignin and its use as a novel ‘green’ sorbent for hazardous metal ions removal. Chem. Eng. J. 2015, 260, 684–693. [Google Scholar] [CrossRef]

- Thakur, K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in green polymer composites from lignin for multifunctional applications: A review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Culebras, M.; Pishnamazi, M.; Walker, G.M.; Collins, M.N. Facile tailoring of structures for controlled release of paracetamol from sustainable lignin derived platforms. Molecules 2021, 26, 1593. [Google Scholar] [CrossRef] [PubMed]

- Yu, O.; Kim, K.H. Lignin to materials: A focused review on recent novel lignin applications. Appl. Sci. 2020, 10, 4626. [Google Scholar] [CrossRef]

- Chatel, G.; Roger, S.R.D. Review: Oxidation of lignin using ionic liquids—An innovative strategy to produce renewable chemicals. ACS Sustain. Chem. Eng. 2014, 2, 322–339. [Google Scholar] [CrossRef]

- EN 934-2; Admixture for Concrete, Mortar and Grout. Th. 2: Concrete Admixtures. Definitions, Requirements, Compliance, Marking and Labeling. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Szruba, M. Chemical admixtures and additives modifying the properties of concrete. Mod. Civ. Eng. 2016, 2, 22–27. [Google Scholar]

- Ouyang, X.; Qiu, X.; Chen, P. Physicochemical characterization of calcium lignosulfonate—A potentially useful water reducer. Colloid Surf. A 2006, 282–283, 489–497. [Google Scholar] [CrossRef]

- Yu, G.; Li, B.; Wang, H.; Liu, C.; Mu, X. Preparation of concrete superplasticizer by oxidation-sulfomethylation of sodium lignosulfonate. Bioresources 2013, 8, 1055–1063. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Zhang, Y.; Liu, C.; Yu, G.; Li, B.; Mu, X.; Pen, H. Preparation of concrete water reducer via fractionation and modification extracted from pine wood by formic acid. ACS Sustain. Chem. Eng. 2017, 5, 4214–4222. [Google Scholar] [CrossRef]

- Huang, C.; Ma, J.; Zhang, W.; Huang, G.; Yong, Q. Preparation of lignosulfonates from biorefinery lignins by sulfomethylation and their application as a water reducer for concrete. Polymers 2018, 10, 841. [Google Scholar] [CrossRef] [Green Version]

- Gupta, C.; Nadelman, E.; Washburn, N.R.; Kurtis, K.E. Lignopolymer superplasticizers for low-CO2 cements. ACS Sustain. Chem. Eng. 2017, 5, 4041–4049. [Google Scholar] [CrossRef]

- Kalliola, A.; Vehmas, T.; Liitiä, T. Tamminen, Alkali-O2 oxidized lignin—A bio-based concrete plasticizer. Ind. Crop. Prod. 2015, 74, 150–157. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, H.; Yang, C.; Zhang, Y.; Xu, J.; Lu, M. Synthesis and super retarding performance in cement production of diethanolamine modified surfactant. Constr. Build. Mater. 2014, 52, 116–121. [Google Scholar] [CrossRef]

- Klapiszewski, L.; Klapiszewska, I.; Slosarczyk, A.; Jesionowski, T. Lignin-based hybrid admixtures and their role in cement composite fabrication. Molecules 2019, 24, 3544. [Google Scholar] [CrossRef] [Green Version]

- Slosarczyk, A.; Klapiszewska, I.; Jedrzejczak, P.; Klapiszewski, L.; Jesionowski, T. Biopolymer-based hybrids as effective admixtures for cement composites. Polymers 2020, 12, 1180. [Google Scholar] [CrossRef]

- Clean, J. Lignin as a potential source of high-added value compounds: A review. J. Clean. Prod. 2020, 263, 121499. [Google Scholar] [CrossRef]

- Borgesa, G.; Baggeb, C.L.; Orozcoc, R. A literature review and meta-analyses of cannabis use and suicidality. J. Affect. Disord. 2016, 195, 63–74. [Google Scholar] [CrossRef]

- Świechowska, I. Hemp is a cursed or forgotten plant, 2019. In Centrum Doradztwa Rolniczego w Brwinowie Oddział w Poznaniu, Instytut Ochrony Roślin—Państwowy Instytut Badawczy; Agricultural Advisory Center in Brwinów, Poznań Branch, Institute of Plant Protection—National Research Institute: Poznań, Poland, 2019; ISBN 978-83-60232-96-5. [Google Scholar]

- Motyka, M.; Marcinkowski, J.T. Use of cannabis derivatives. Part II. Application in medicine vs. health consequences. Probl. Hig. Epidemiol. 2014, 95, 21–27. [Google Scholar]

- Cerino, P.; Buonerba, C.; Cannazza, G.; D’Auria, J.; Ottoni, E.; Fulgione, A.; Di Stasio, A.; Pierri, B.; Gallo, A. A Review of Hemp as Food and Nutritional Supplement Published. Cannabis Cannabinoid Res. 2016, 6, 19–27. [Google Scholar] [CrossRef] [Green Version]

- Mańkowski, J. Influence of Dewing Methods on the Quantity and Quality of Single-Form. Flax Fiber; Instytut Włókien Naturalnych i Roślin Zielarskich: Poznań, Poland, 2014. [Google Scholar]

- Cierpucha, W. Technology of Cultivation and Processing of Industrial Hemp; Collective Work Edited by the Institute of Natural Fibers and Medicinal Plants: Poznań, Poland, 2013. [Google Scholar]

- Bevan, R.; Woolley, T. Hemp Lime Construction: A Guide to Building with Hemp Lime Composites; BRE Press: Bracknell, UK, 2010. [Google Scholar]

- Brzyski, P.; Fic, S. The use of raw materials obtained from the cultivation of hemp in various industries. Econ. Reg. Stud. 2017, 10, 100–113. [Google Scholar] [CrossRef] [Green Version]

- Pietruszka, B.; Gołębiewski, M. Properties of hemp-based construction products. Przegląd Bud. 2019, 90. [Google Scholar]

- Muratordom. Available online: https://muratordom.pl/budowa/inne-technologie-budowlane/beton-konopny-materialy-naturalne-do-budowania-dom-z-konopi-aa-dsFD-DZ59-r2eV.html (accessed on 11 January 2022).

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Fibers Industrial hemp fibers: An overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef] [Green Version]

- Kamiński, S.; Lawrence, A.; Trujilo, D.J.A. Structural use of bamboo: Part 1: Introduction to bamboo. Struct. Eng. 2016, 94, 40–43. [Google Scholar]

- Liu, W.; Hui, C.; Wang, F.; Wang, M.; Liu, G.; Khalil, A. Review of the Resources and Utilization of Bamboo in China, Bamboo—Current and Future Prospects; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Zakikhani, P.; Zahari, R.; Sultan, M.T.H.; Majid, D.L. Extraction and preparation of bamboo fibre-reinforced composites. Mater. Des. 2014, 63, 820–828. [Google Scholar] [CrossRef]

- Womga, K.J. Fracture characterisation of short bamboo fiber rainforced polyester composites. Mater. Des. 2010, 31, 4147–4154. [Google Scholar] [CrossRef]

- Innerself. Available online: https://pl.climateimpactnews.com/adaptation/4281-building-with-bamboo-can-cool-the-climate (accessed on 12 January 2022).

- Kumar, G. Review on Feasibility of Bamboo in Modern Construction. Int. J. Pf Civ. Eng. SSRG-IJCE 2015, 2, 66–70. [Google Scholar]

- Plangsriskul, N.; Dorsano, N. Characterization of Bamboo and Analysis of Bonding Strength and Internal Strength as a Structural Member in Reinforced Concrete; Senior Project; California Polytechnical State University: San Luis Obispo, CA, USA, 2011. [Google Scholar]

- Murni–Dewi, S.; Wijaya, M.N.; Remayanti, C. The Use of Bamboo Fiber in Reinforced Concrete Beam to Reduce Crack. AIP Conf. Proc. 2017, 1887, 020003. [Google Scholar] [CrossRef] [Green Version]

- Osman, E.A.; Al-Bahadly. The Mechanical Properties of Natural Fiber Composites. Ph.D. Thesis, Swinburne University of Technology, Hawthorn, VIC, Australia, 2017. [Google Scholar]

- Ede, A.N.; Joshua, M.; Nduka, D.O.; Oshogbunu, O.A.; Brando, G. Influence of bamboo fiber and limestone powder on the properties of self-compacting concrete (Reviewing editor). Cogent Eng. 2020, 7, 1721410. [Google Scholar] [CrossRef]

- Teraz Środowisko. Available online: https://www.teraz-srodowisko.pl/aktualnosci/recykling-tekstylia-odziez-odpady-tekstylne-10891.html (accessed on 16 December 2021).

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. J. Sustain. Cem.-Based Mater. 2021, 11, 28–42. [Google Scholar] [CrossRef]

- Wang, Y. Carpet recycling technologies. In Recycling in Textiles; Wang, Y., Ed.; Woodhead Publishing: Cambridge, UK, 2006. [Google Scholar]

- Meran, C.; Ozturk, O.; Yuksel, M. Examination of the possibility of recycling and utilizing recycled polyethylene and polypropylene. Mater. Design. 2008, 29, 701–705. [Google Scholar] [CrossRef]

- Morley, N.; McGill, I.; Bartlett, C. Maximising Reuse and Recycling of UK Clothing and Textiles; A research report completed for the Department for Environment, Food and Rural Affairs by Oakdene Hollins Ltd.; Department for Environment, Food and Rural Affair: London, UK, 2009.

- Mohammadhosseini, H.; Tahir, M.M.; Sayyed, M.I. Strength and transport properties of concrete composites incorporating waste carpet fibres and palm oil fuel ash. J. Build. Eng. 2020, 435–457. [Google Scholar] [CrossRef]

- Ghosni, N.; Samali, B.; Vessalas, K. Evaluation of mechanical properties of carpet fibre reinforced concrete. In From Materials to Structures: Advancement through Innovation; Taylor & Franics Group: London, UK, 2013; pp. 275–279. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A. Physical and mechanical properties of concrete containing fibers from industrial carpet waste. Int. J. Res. Eng. Technol. 2014, 2, 464–468. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.C.; Li, V.C. Concrete reinforcement with recycled fibers. J. Mater. Civ. Eng. 2000, 12, 2723. [Google Scholar] [CrossRef]

- Awal, A.; Mohammadhosseini, H.; Hossain, M.Z. Strength, modulus of elasticity and shrinkage behaviour of concrete containing waste carpet fiber. Int. J. Geomat. 2015, 9, 1441–1446. [Google Scholar] [CrossRef]

- Barerra, B.; Pombo, M.M.O.; Navacerrada, M.A. Textile fibre waste bindered with natural hydraulic lime. Compos. Part. B-Eng. 2016, 94, 26–33. [Google Scholar] [CrossRef]

- Wodziński, P. The use of mineral waste in the construction of municipal landfills. Politech. Łódzka 2009, 11. [Google Scholar]

- WNP. Available online: https://www.wnp.pl/gornictwo/tyle-odpadow-wytworzyly-zaklady-gornicze,464196.html (accessed on 17 December 2021).

- European Parliament and Council (EU). 2018/851 of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/legal-content/pl/ALL/?uri=CELEX%3A32018L0851 (accessed on 12 November 2021).

- Bolweki, A.; Wyszomirsk, I.P.; Budkiewicz, M. Ceramic Raw Materials; AGH, University of Science and Technology, Geological Publishing House: Warsaw, Poland, 1991. [Google Scholar]

- Szlugaj, J. Mineralogical and Petrographic Characteristics of Mining Waste from Selected Hard Coal Mines in Terms of Their Use for the Production of Mineral Aggregates; Institute of Mineral and Energy Management; PAN: Kraków, Poland, 2020. [Google Scholar]

- Moosberg-Bustnes, H.; Lagerblad, B.; Forssberg, E. The function of fillers in concrete. Mater. Struct. 2004, 37, 74. [Google Scholar] [CrossRef]

- Łuszczkiewicz, A. Conceptual use of flotation waste from the processing of copper ores in the Legnico—Głogowski region. J. Pol. Miner. Eng. Soc. 2020, 1. [Google Scholar]

- Ozel, A.; Turan, S.; Coruh, S.; Ergun, O.N. Production of brown and black pigments by using flotation waste from copper slag. Waste Manag. Resour. 2006, 24, 125–133. [Google Scholar] [CrossRef]

- Coruh, S. Copper Flotation Waste; Cutler, J.C., Ed.; Encyclopedia of Earth: Washington, DC, USA, 2007. [Google Scholar]

- Kudełko, J.; Nitek, D. The use of waste from mining activities as substitutes for mineral resources. Cuprum Ore Min. Sci. Technol. Mag. 2011, 3, 51–63. [Google Scholar]

- Miletic, S. Portland cement klinker production with the copper flotation waste. Cuprum 2011, 3. [Google Scholar]

- SWECO. Available online: https://blogs.sweco.pl/2019/09/26/jak-potezny-jest-slad-weglowy-budownictwa (accessed on 20 December 2021).

- Berry, E.E.; Malhotra, V.M. Fly-ash for use in concrete—A critical-review. J. Am. Concr. Inst. 1980, 77, 59–73. [Google Scholar]

- Soto-Izquierdo, I.; Antonio-Ramalho, M. Use of Residual Powder Obtained from Organic Waste to Partially Replace Cement in Concrete; Universidad Nacional de Colombia: Bogota, Colombia, 2016. [Google Scholar] [CrossRef]

- Pera, J.; Coutaz, L.; Ambroise, J.; Chababbet, M. Use of Incinerator Bottom Ash in Concrete. Cem. Concr. Res. 1997, 27, 1–5. [Google Scholar] [CrossRef]

- Lin, K.L.; Wang, K.S.; Tzeng, B.Y.; Lin, C.Y. The Reuse of Municipal Solid Waste Incinerator Fly Ash Slag as a Cement Substitute. Resour. Conserv. Recycl. 2003, 39, 315–324. [Google Scholar] [CrossRef]

- Ferraris, M.; Salvo, M.; Ventrell, A.; Buzzi, L.; Veglia, M. Use of Vitrifi ed MSWI Bottom Ashes for Concrete Production. Waste Manag. 2009, 29, 1041–1047. [Google Scholar] [CrossRef]

- Keppert, M.; Reiterman, P.; Pavlík, Z.; Pavlíková, M.; Jerman, M.; Černý, R. Municipal solid waste incineration ashes and their potential for partial replacement of Portland cement and fine aggregates in concrete. Cem. Wapno Beton 2010, 15, 187. [Google Scholar]

- EN 12620; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, released 30 June. 2008; ISBN 78 0 580 63327 0.

- Latz, M.; Popławski, J. Utilization of Fly Ash from Biomass in the Production of Cement Composites; Faculty of Construction and Environmental Sciences, Bialystok Technical University: Bialystok, Poland, 2021. [Google Scholar]

- Mądrawski, J.; Kostrzewski, W. The issue of using waste type waste from the incineration of municipal waste for the production of concrete. Build. Rev. 2017, 9. [Google Scholar]

- Sorlini, S.; Abba, A.; Collivignarelli, C. Recovery of MSWI and soil washing residues of concrete aggregates. Waste Manag. 2011, 31, 289–297. [Google Scholar] [CrossRef]

- Helbrych, P. Recycling of Sulfur Polymers from the Purification of Copper and Other Non-Ferrous Metals in Concrete Composites; Faculty of Civil Engineering, Częstochowa University of Technology, Construction with Optimized Energy Potentia: Częstochowa, Poland, 2019; Volume 1.1. [Google Scholar]

- Bahrami, A.; Mohtadi, H.; Mohammad, H. Preparation of sulfurmortar from modified sulfur. Iran. J. Chem. Chem. Eng. 2008, 27, 123–1027. [Google Scholar] [CrossRef]

- Cholerzyński, A.; Tomczak, W.; Świtalski, J. Application of Sulfur Concretes for Solidification of Radioactive Waste and Construction of Repositories; Institute of Atomic Energy, Radioactive Waste Treatment Experimental Station: Otwock-Świerk, Poland, 2000. [Google Scholar]

- Halbiniak, J.; Blukacz, A. Recycling of industrial waste in concrete composites. Constr. Optim. Energy Potential 2018, 2016, 29–34. [Google Scholar] [CrossRef]

- Helbrych, P. Recycling of sulfur polymers from the purification of copper and other non-ferrous metals in concrete composites. Constr. Optim. Potential Energy 2019, 8, 1. [Google Scholar] [CrossRef]

- Książek, M. The Use of Cement Composites Impregnated with Polymerized Sulfur Waste in Construction; Wrocław University of Technology, Building Materials: Wrocław, Poland, 2015; Volume 10. [Google Scholar]

- 2018 Conference Biochar in Poland—Science, Technology, Business, 28 May 2018, Institute of Ceramics and Building Materials in Opole. Available online: http://www.refertil.info/news/biochar-poland-biochar-poland-science-technology-business-2016 (accessed on 12 December 2021).

- Sonosfereza. Available online: https://sozosfera.pl/srodowisko-i-gospodarka/biowegiel-co-to-jest/ (accessed on 23 January 2022).

- Akinyemia, A. Recent advancements in the use of biochar for cementitious applications: A review. J. Build. Eng. 2020, 32, 101705. [Google Scholar] [CrossRef]

- Haselbach, L.; Thomas, A. Carbon sequestration in concrete sidewalk samples. Construct. Build. Mater. 2014, 54, 47–52. [Google Scholar] [CrossRef]

- Sha, O.Y.; Mirza, M.S.; Wu, X. CO2 sequestration using calcium-silicate concrete. Can. J. Civ. Eng. 2006, 33, 776–784. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors determining the potential of biochar as a carbon capturing and sequestering construction material: Critical review. J. Mater. Civ. Eng. 2017, 29, 781–814. [Google Scholar] [CrossRef]

- Malińska, K. Biochar is the answer to current environmental problems. Environ. Eng. Prot. 2012, 15, 387–403. [Google Scholar] [CrossRef]

- Jakubiak, M.; Kordylewski, W. Biomass torrefaction. Burn. Arch. 2009, 10, 1–2. [Google Scholar]

- Bis, Z. Biochar—A return to the past, an opportunity for the future. Pure energy. Appl. Sci. 2012, 9, 1139. [Google Scholar]

- Wan, L.; Chen, L.; Tsang, D.C.W.; Yang, B.G.J.; Shen, Z.; Hou, D.; SikOk, Y.; SunPoon, C. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Diatta, A.A.; Fike, J.H.; Battaglia, M.L.; Galbraith, J.M.; Baig, M.B. Effects of biochar on soil fertility and crop productivity in arid regions: A review. Arab. J. Geosci. 2020, 13, 595. [Google Scholar] [CrossRef]

- Fingerlakesbiochar. Available online: http://fingerlakesbiochar.com/markets-for-biochar (accessed on 12 December 2021).

- Marris, E. Putting the carbon back: Black is the new green. Nature 2006, 442, 624–626. [Google Scholar] [CrossRef]

- Demirbas, A. Heavy metal sorption onto agro-based waste materials: A review. J. Hazard. Mater. 2008, 157, 220–229. [Google Scholar] [CrossRef] [PubMed]

- Oleszczuk, P.; Jośko, J.; Futa, B.; Pasieczna-Patkowska, S.; Pałys, A.; Kraska, P. Effect of pesticides on microorganisms, enzymatic activity and plant in biochramended soil. Geoderma 2014, 214–215, 10–18. [Google Scholar] [CrossRef]

- Samsuri, A.; Sadegh-Zadeh, F.; Seh-Bardan, B. Characterization of biochars produced from oil palm and rice husks and their adsorption capacities for heavy metals. Int. J. Environ. Sci. Technol. 2014, 11, 967–976. [Google Scholar] [CrossRef]

- Tan, X.; Liu, Y.; Zeng, G.; Wang, X.; Hu, X.; Gu, Y.; Yang, Z. Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere 2015, 125, 70–85. [Google Scholar] [CrossRef]

- Yuan, J.H.; Xu, R.K.; Zhang, H. The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour. Technol. 2011, 102, 3488–3497. [Google Scholar] [CrossRef]

- Ślęzak, E.; Poluszyńska, J. The Sorption Possibilities of the Biochar as a Decontaminating Agent from Aquatic Environment; Scientific Works of Institute of Ceramics and Building Materials: Opole, Poland, 2018; Volume 33, pp. 62–72. ISSN 1899-3230. [Google Scholar]

- Restuccia, L.; Ahushnood, R.; Ahmad, S.; Restuccia, L.; Spoto, C.; Jagdale, P.; Tulliani, J.E.; Ferro, G.A. Carbonized nano/microparticles for enhanced mechanical properties and electromagnetic interference shielding of cementitious materials. Front. Struct. Civ. Eng. 2016, 10, 209–213. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical properties of mortar containing bio-char from pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Tokarski, D.; Ickiewicz, I. Repairs of Historic Walls with Complementary Layers with the Addition of Biochar; University of Technology: Białystok, Poland, 2021. [Google Scholar]

- CSN EN 1934; Thermal Properties of Buildings. Determination of Thermal Resistance by the Hot Box Method Using a Heat Meter-Masonry. European Committee for Standardization: Brussels, Belgium, 1999.

- Yun, T.S.; Jeong, Y.J.; Han, T.S.; Youm, K.S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

| Waste Group Code according to 2014/955/EU: Commission Decision of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council | Waste Group Name | Reference |

|---|---|---|

| 01 (01 01; 01 02; 01 03; 01 04; 01 05) | Coal waste, waste from the extraction of copper ores and other minerals. | [18] |

| 02 | Waste from the agricultural sector, horticulture, plant production. | [18] |

| 03 | Waste from the wood processing sector and the production of panels and furniture, and from paper processing, including pulp and cardboard. | [18] |

| 04 | Waste from the textile industry. | [18] |

| 06 06 | Waste from the chemical processes of sulfur production and processing and desulfurization processes. | [18] |

| 10 | Waste from thermal processes. | [18] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryłko-Polak, I.; Komala, W.; Białowiec, A. The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review. Materials 2022, 15, 4078. https://doi.org/10.3390/ma15124078

Ryłko-Polak I, Komala W, Białowiec A. The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review. Materials. 2022; 15(12):4078. https://doi.org/10.3390/ma15124078

Chicago/Turabian StyleRyłko-Polak, Iwona, Wojciech Komala, and Andrzej Białowiec. 2022. "The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review" Materials 15, no. 12: 4078. https://doi.org/10.3390/ma15124078

APA StyleRyłko-Polak, I., Komala, W., & Białowiec, A. (2022). The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review. Materials, 15(12), 4078. https://doi.org/10.3390/ma15124078