Experimental Study of Soft Ballistic Packages with Embroidered Structures Fabricated by Using the Tailored Fiber Placement Technique

Abstract

:1. Introduction

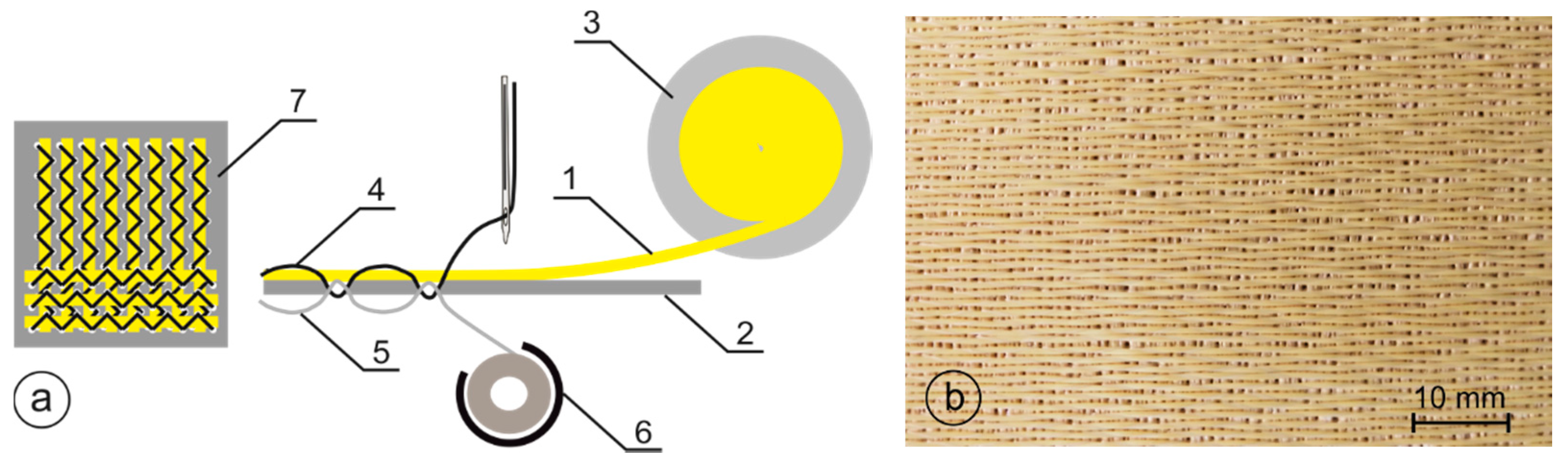

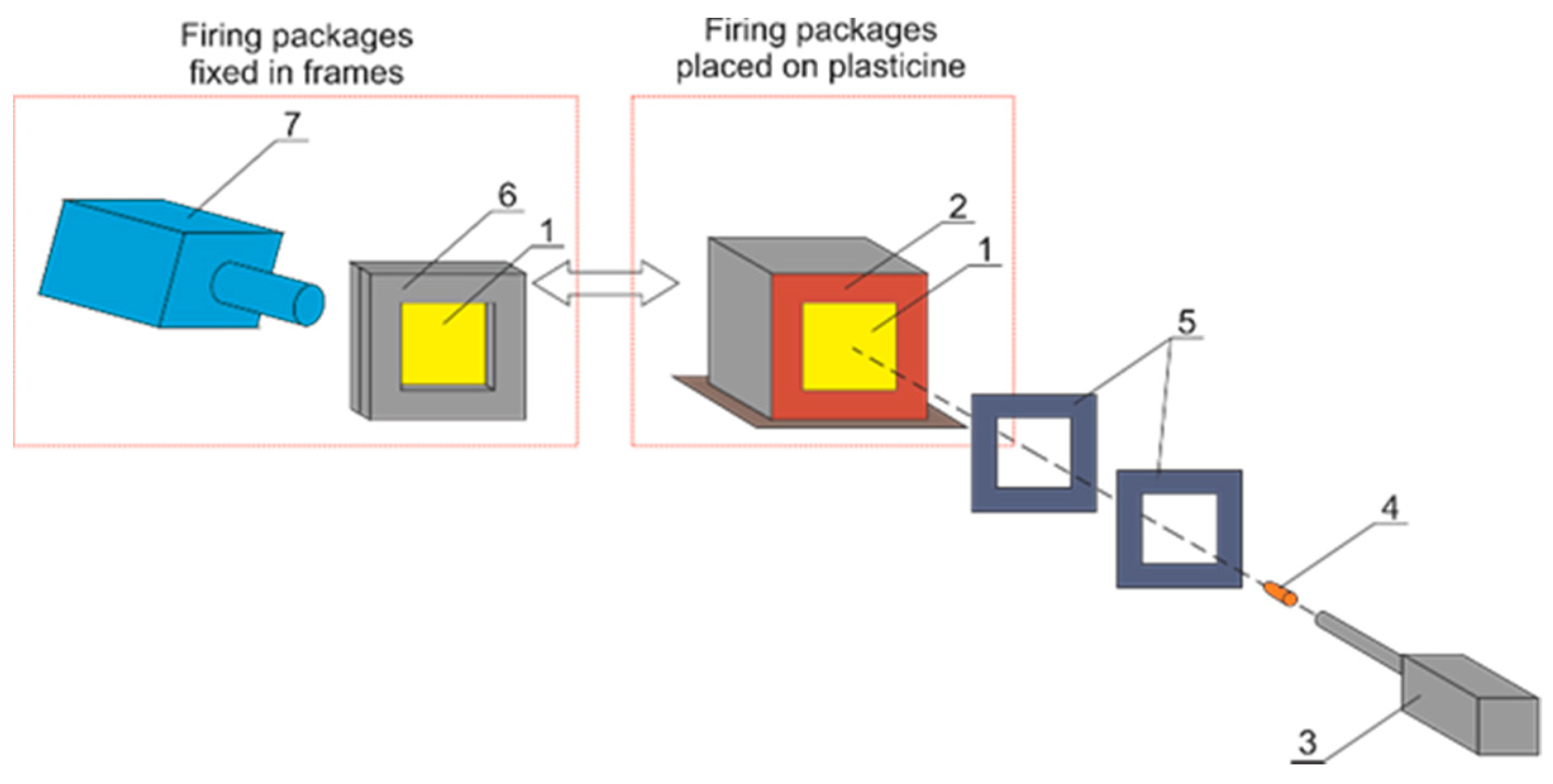

2. Materials and Methods

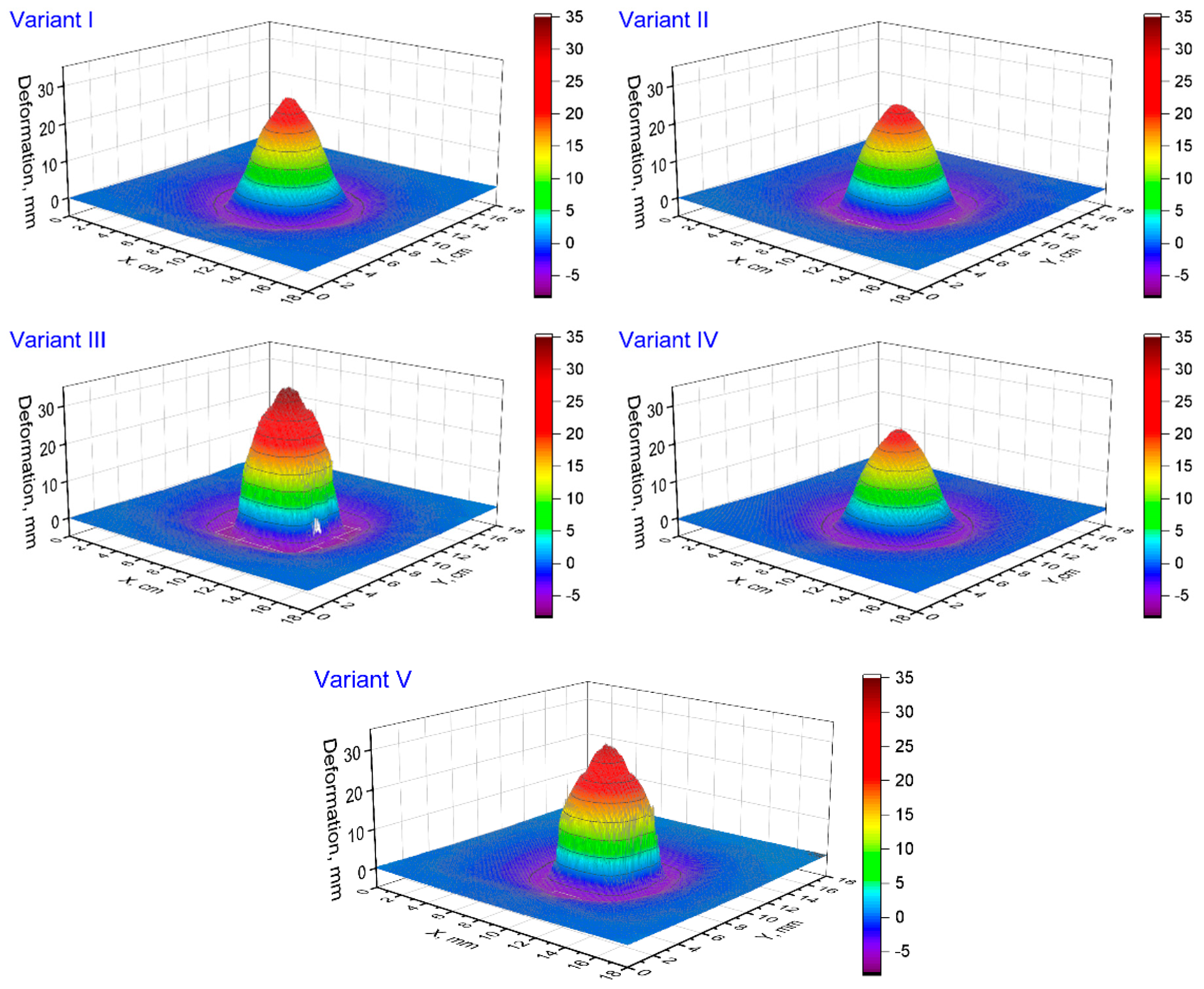

3. Results

4. Conclusions

- The article presents ballistic studies of para-aramid embroidered structures, which so far have not been considered as layers of textile ballistic packages. Comparative ballistics studies of embroidered and woven structures have shown that they have opposing advantages and disadvantages in terms of ballistic shock response.

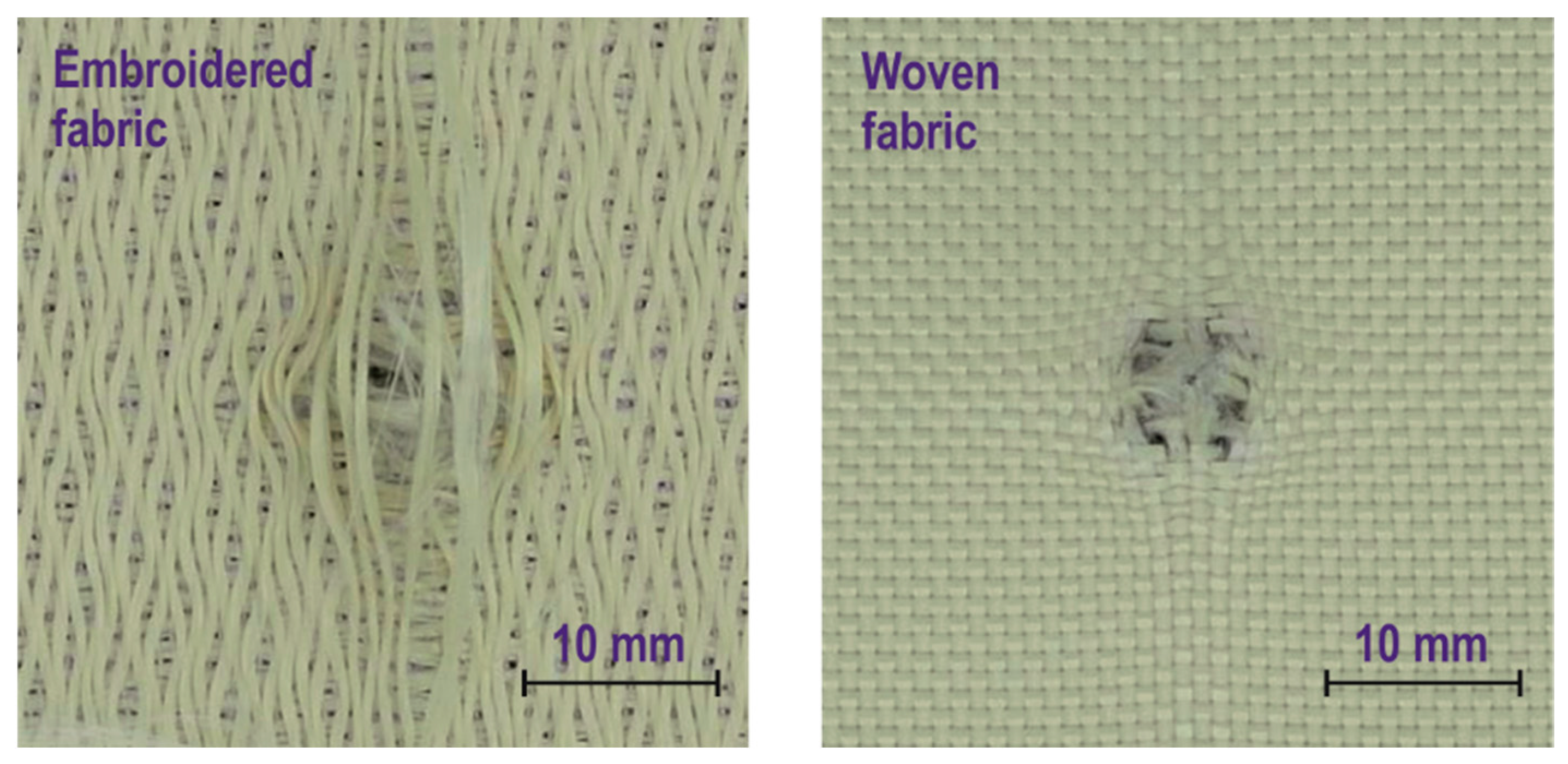

- In the case of embroidered structures, the advantages are straight threads and the lack of interlacing, which is conducive to high propagation speed, which has a positive effect on the lower transverse deformation of the bundle. The disadvantage of these structures is the sliding of the threads in contact with the front of the bullet, which adversely affects the number of shot layers in the ballistic package.

- In the case of woven structures, the advantage is the structure jammed by the interweaving of the weft and warp threads, which prevents the threads from sliding apart in contact with the face of the bullet, and the disadvantages of this structure are that the weft and warp threads are wrapped in, and the speed of stress wave propagation is lower due to the interwoven structure, which promotes increased transverse deformation.

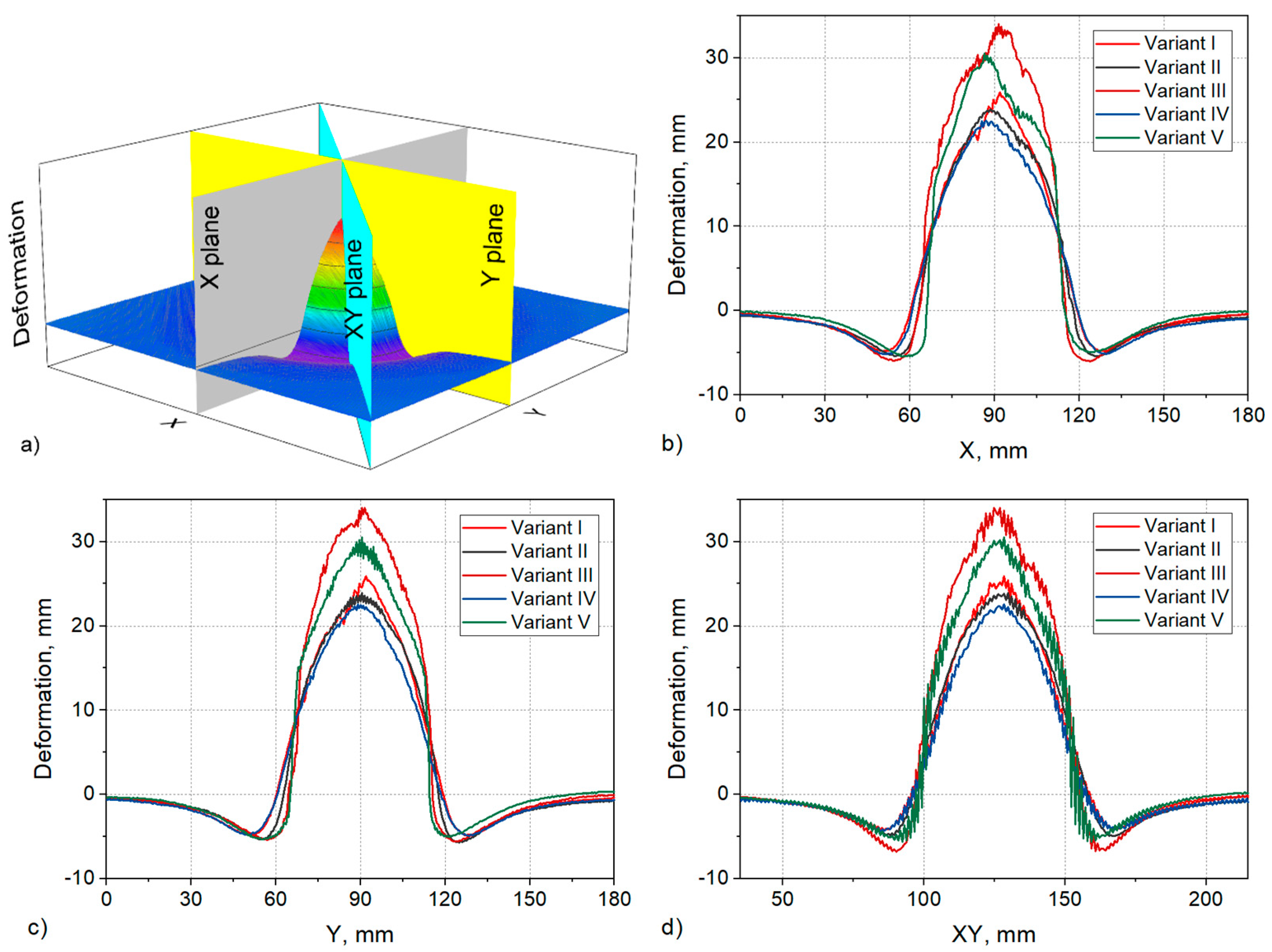

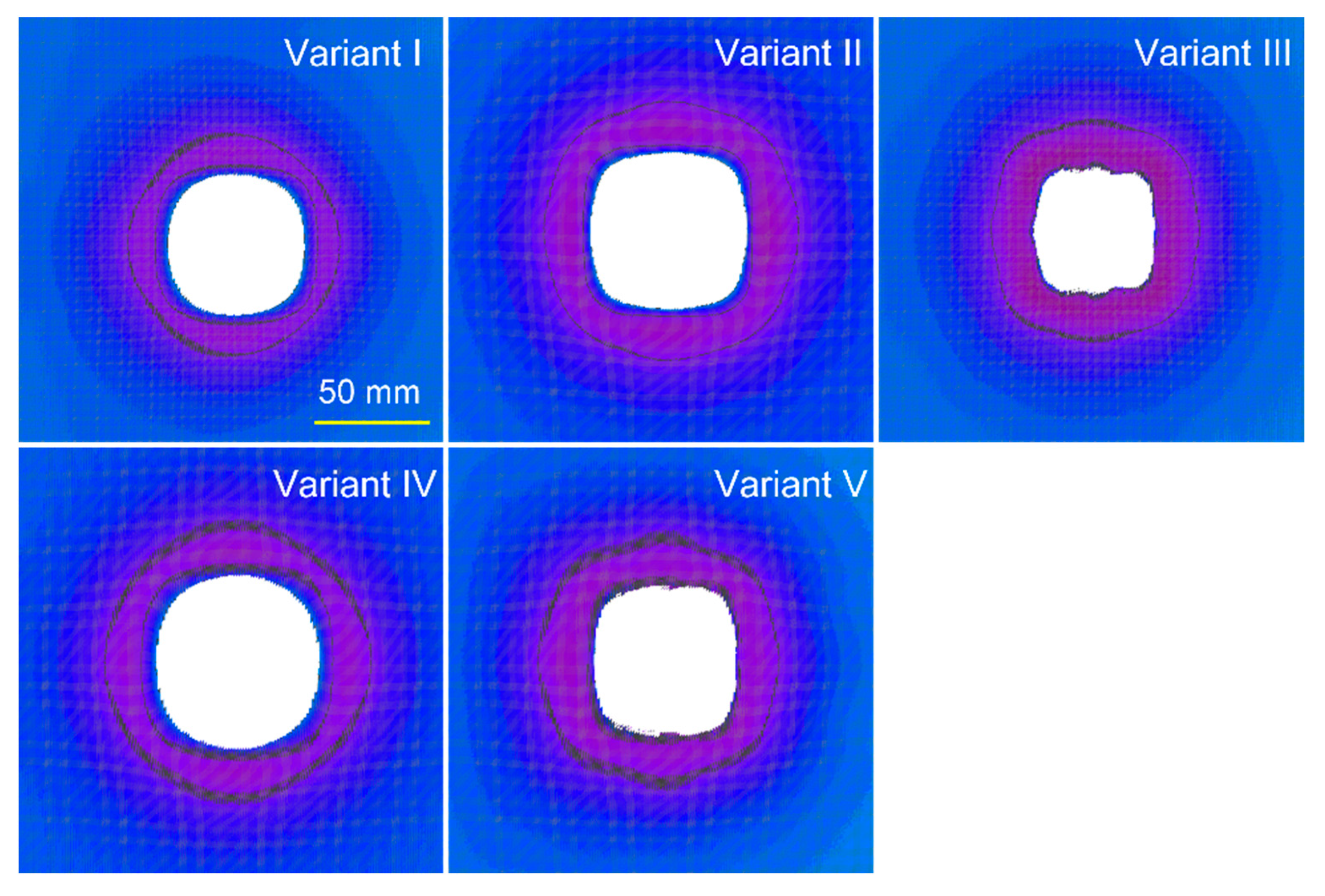

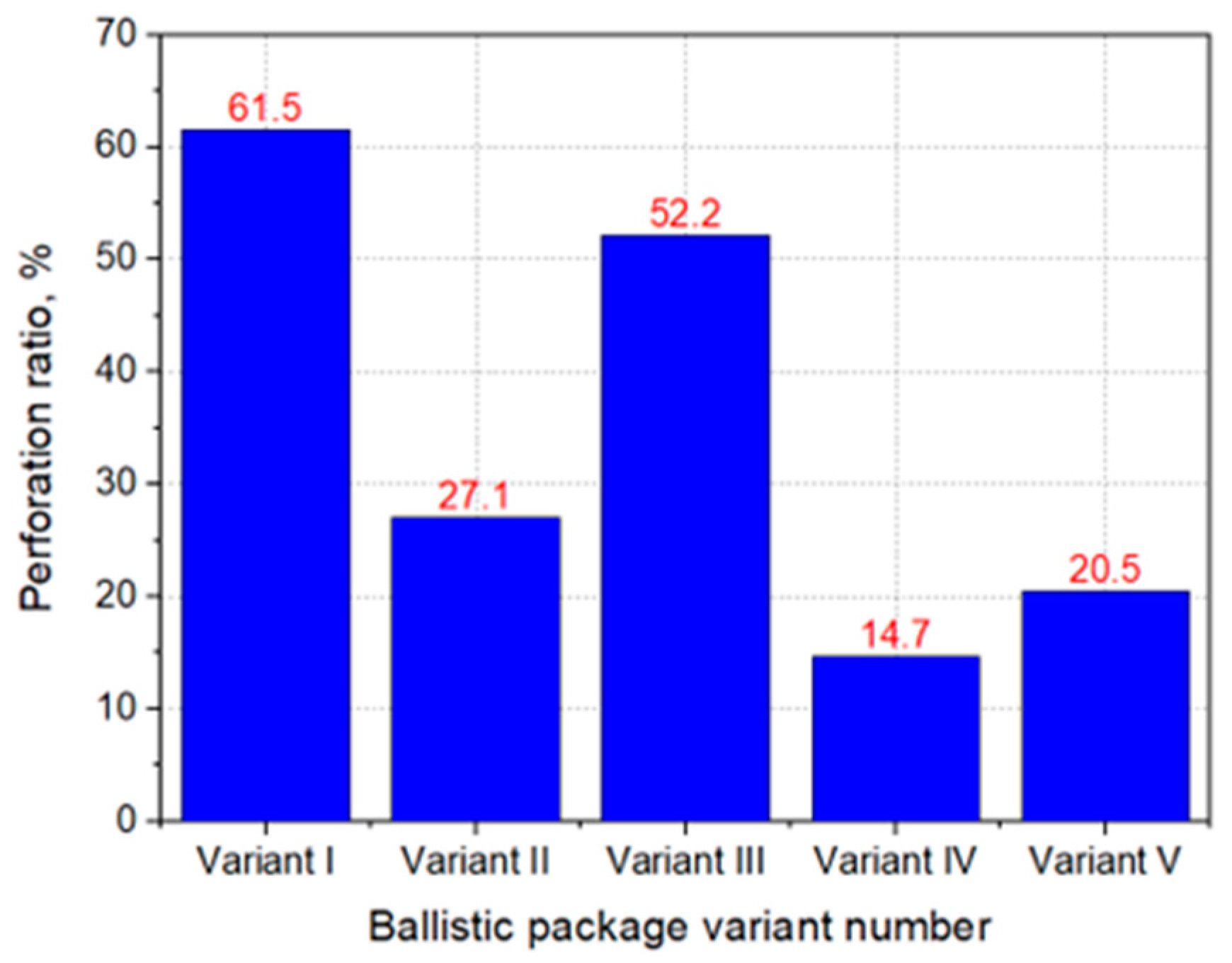

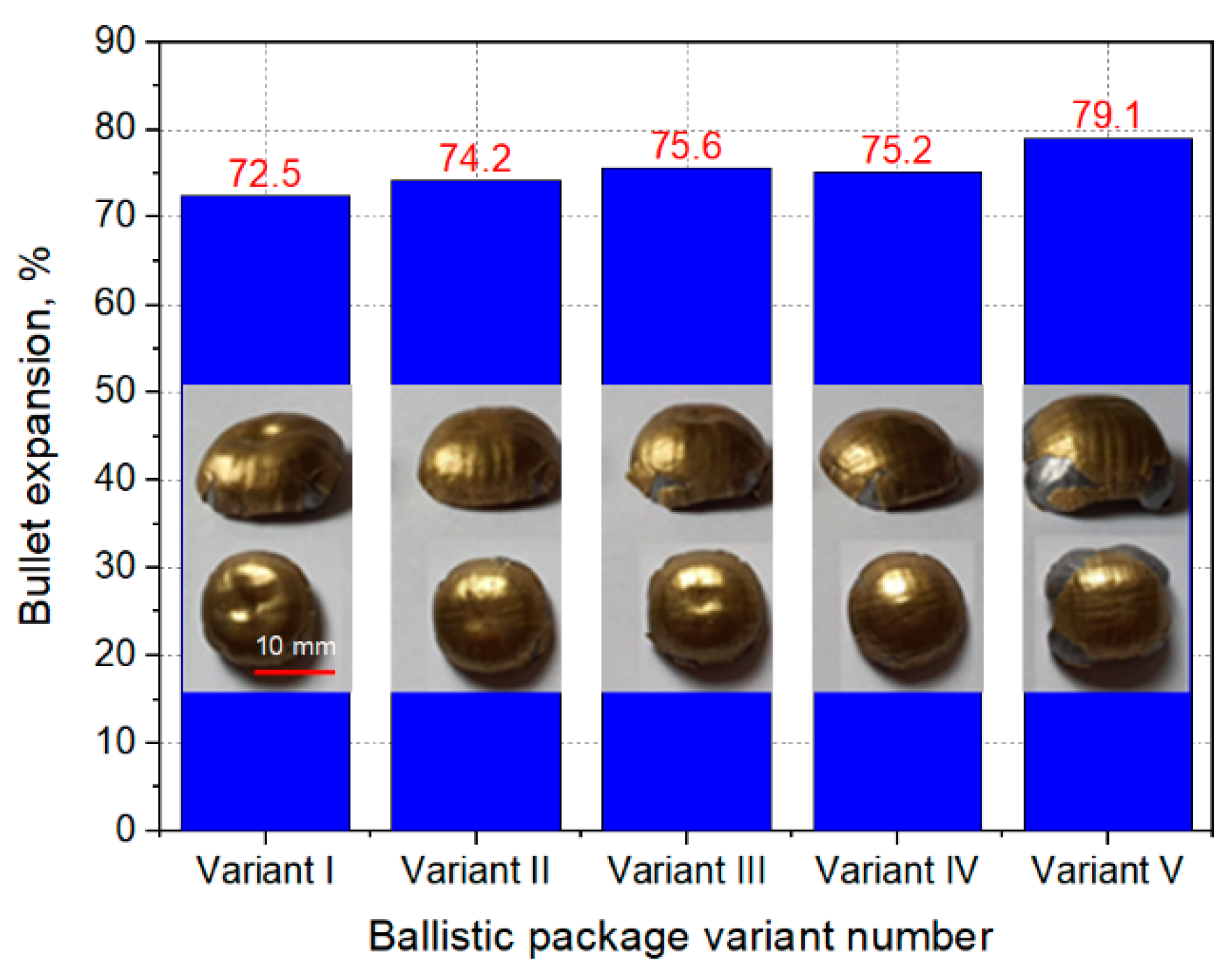

- Considering the advantages and disadvantages of both structures, it is advantageous to assemble a multilayer hybrid bundle with woven structures on the front and embroidered structures on the back, such as the tested variant of the IV package. This package achieved the smallest maximum plasticine deformation of 22.6 mm, the largest inlet cavity area and the smallest perforation rate of 14.7%. For comparison, for a ballistic package with a traditional design, composed only of woven structures, the values were 30.5 mm, respectively, the area of the inlet cavity was smaller, and the perforation rate was 20.5%.

- Further research into embroidered structures for use in ballistic packages is warranted in three directions:

- The execution of structures embroidered on para-aramid fabric, which will allow to eliminate the non-woven substrate, which does not have any effect in dissipating the kinetic energy of the bullet and only unnecessarily increases the weight of the ballistic package;

- The execution of multi-axis embroidered structures;

- Numerical modeling of a bullet impact in embroidered and hybrid structures and finding the most optimal arrangement of the woven and embroidered layers in a ballistic package.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Öberg, E.; Dean, J.; Clyne, T. Effect of inter-layer toughness in ballistic protection systems on absorption of projectile energy. Int. J. Impact Eng. 2015, 76, 75–82. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, X. Investigation of energy absorption mechanisms in a soft armor panel under ballistic impact. Text. Res. J. 2017, 87, 2475–2486. [Google Scholar]

- Bilisik, K.; Turhan, A.Y. Multidirectional stitched layered aramid woven fabric structures and their experimental characteri-zation of ballistic performance. Text. Res. J. 2009, 79, 1331–1343. [Google Scholar] [CrossRef]

- Bilisik, K.; Korkmaz, M. Multilayered and multidirectionally-stitched aramid woven fabric structures: Experimental characteri-zation of ballistic performance by considering the yarn pull-out test. Text. Res. J. 2010, 80, 1697–1720. [Google Scholar] [CrossRef]

- Liang, Z.; Lee, H.; Suaris, W. Micromechanics-based constitutive modeling for unidirectional laminated composites. Int. J. Solids Struct. 2006, 43, 5674–5689. [Google Scholar] [CrossRef] [Green Version]

- Selm, B.; Bischoff, B.; Seidl, R. Embroidery and smart textiles. In Smart Fibres, Fabrics and Clothing: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2001; pp. 218–225. [Google Scholar]

- Report on TFP Technique (Erläuterungen zur TFP-Technologie). Available online: https://www.hightex-dresden.de/Technologien/TFP-Technologie/434l1/ (accessed on 9 March 2022).

- Mecnika, V.; Hoerr, M.; Krieviņš, I.; Jockenhoevel, S.; Gries, T. Technical Embroidery for Smart Textiles: Review. Mater. Sci. Text. Cloth. Technol. 2015, 9, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Bilisik, K. Three-dimensional braiding for composites: A review. Text. Res. J. 2012, 83, 1414–1436. [Google Scholar] [CrossRef]

- Bilisik, K.; Karaduman, N.S.; Bilisik, N.E.; Bilisik, H.E. Three-dimensional fully interlaced woven preforms for composites. Text. Res. J. 2013, 83, 2060–2084. [Google Scholar] [CrossRef]

- Chen, X.; Yang, D. Use of 3D angle-interlock woven fabric for seamless female body Armour: Part I: Ballistic evaluation. Text. Res. J. 2010, 80, 1581–1588. [Google Scholar]

- Lefebvre, M.; Boussu, F. High energy absorption of warp interlock fabrics: Application to high speed impact of fragments. In Proceedings of the 9th International DYMAT Conference, Brussels, Belgium, 7–11 September 2009; pp. 429–435. [Google Scholar]

- Lee, B.; Leong, K.H.; Herszberg, I. Effect of weaving on the tensile properties of carbon fibre tows and woven composites. J. Reinf. Plast. Compos. 2001, 20, 652–670. [Google Scholar]

- Callus, P.; Mouritz, A.; Bannister, M.; Leong, K. Tensile properties and failure mechanisms of 3D woven GRP composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1277–1287. [Google Scholar] [CrossRef]

- Wright, T.; Bechtold, T.; Bernhard, A.; Manian, A.P.; Scheiderbauer, M. Tailored fibre placement of carbon fibre rovings for reinforced polypropylene composite part 1: PP infusion of carbon reinforcement. Compos. Part B Eng. 2019, 162, 703–711. [Google Scholar] [CrossRef]

- Poniecka, A.; Barburski, M.; Urbaniak, U. Mechanical Properties of Composites Reinforced with Technical Embroidery Made of Flax Fibers. Autex Res. J. 2021. [Google Scholar] [CrossRef]

- Soukup, R.; Hamacek, A.; Mracek, L.; Reboun, J. Textile based temperature and humidity sensor elements for healthcare applications. In Proceedings of the 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 7–11 May 2014; pp. 407–411. [Google Scholar]

- Acti, T.; Chauraya, A.; Zhang, S.; Whittow, W.G.; Seager, R.; Vardaxoglou, J.C.; Dias, T. Embroidered Wire Dipole Antennas Using Novel Copper Yarns. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 638–641. [Google Scholar] [CrossRef] [Green Version]

- Shafti, A.; Ribas Manero, R.B.; Borg, A.M.; Althoefer, K.; Howard, M.J. Embroidered Electromyography: A Systematic Design Guide. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 1472–1480. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Estrada, M.; Moradi, B.; Fernández-Garcia, R.; Gil, I. Impact of Conductive Yarns on an Embroidery Textile Moisture Sensor. Sensors 2019, 19, 1004. [Google Scholar] [CrossRef] [Green Version]

- Aguiló-Aguayo, N.; Amade, R.; Hussain, S.; Bertran, E.; Bechtold, T. New Three-Dimensional Porous Electrode Concept: Vertically-Aligned Carbon Nanotubes Directly Grown on Embroidered Copper Structures. Nanomaterials 2017, 7, 438. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Lillehoj, P.B. Embroidered electrochemical sensors for biomolecular detection. Lab Chip 2016, 16, 2093–2098. [Google Scholar] [CrossRef]

- Weder, M.; Hegemann, D.; Amberg, M.; Hess, M.; Boesel, L.F.; Abächerli, R.; Meyer, V.R.; Rossi, R.M. Embroidered Electrode with Silver/Titanium Coating for Long-Term ECG Monitoring. Sensors 2015, 15, 1750–1759. [Google Scholar] [CrossRef] [Green Version]

- Wen, J.; Xu, B.; Zhou, J. Toward Flexible and Wearable Embroidered Supercapacitors from Cobalt Phosphides-Decorated Conductive Fibers. Nano-Micro Lett. 2019, 11, 89. [Google Scholar] [CrossRef] [Green Version]

- Report on The Manufacture of Structural Composites Using Embroidery Techniques (MASCET). Available online: http://www.ellisdev.co.uk/mascet1.html (accessed on 25 February 2022).

- Kim, M.-S.; Park, C.-Y.; Cho, C.-M.; Jun, S.-M. A multi-band smart skin antenna design for flight demonstration. In Proceedings of the 8th European Conference on Antennas and Propagation (EuCAP 2014), The Hague, The Netherlands, 6–11 April 2014; pp. 2855–2859. [Google Scholar]

- Ghorbani, K. Conformal load bearing antenna structure using Carbon Fibre Reinforced Polymer (CFRP). In Proceedings of the 2014 International Workshop on Antenna Technology: Small Antennas, Novel EM Structures and Materials, and Applications (iWAT), Sydney, NSW, Australia, 4–6 March 2014; p. 118. [Google Scholar]

- Ali, M.; Bishop, N.; Baron, W.; Smyers, B.; Tuss, J.; Zeppettella, D. A MEMS reconfigurable pixel microstrip patch antenna for conformal load bearing antenna structures (CLAS) concept. In Proceedings of the 2014 IEEE Antennas and Propagation Society International Symposium (APSURSI), Memphis, TN, USA, 6–11 July 2014; pp. 1093–1094. [Google Scholar]

- Wang, Z.; Zhang, L.; Bayram, Y.; Volakis, J.L. Embroidered Conductive Fibers on Polymer Composite for Conformal Antennas. IEEE Trans. Antennas Propag. 2012, 60, 4141–4147. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Bayram, Y.; Volakis, J.L. Multilayer printing of embroidered RF circuits on polymer composites. In Proceedings of the IEEE International Symposium on Antennas and Propagation (APSURSI), Spokane, WA, USA, 3–8 July 2011; pp. 278–281. [Google Scholar]

- Molla, M.T.I. Surface-mount manufacturing for E-textile circuits. In Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017; ACM: New York, NY, USA, 2017; pp. 18–25. [Google Scholar]

- Zheng, Y.; Jin, L.; Qi, J.; Liu, Z.; Xu, L.; Hayes, S.; Gill, S.; Li, Y. Performance evaluation of conductive tracks in fabricating e-textiles by lock-stitch embroidery. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Khan, M.U.A.; Raad, R.; Foroughi, J.; Raheel, M.S.; Houshyar, S. An octagonal-shaped conductive HC12 & LIBERATOR-40 thread embroidered chipless RFID for general IoT applications. Sens. Actuators A Phys. 2021, 318, 112485. [Google Scholar]

- Polanský, R.; Soukup, R.; Řeboun, J.; Kalčík, J.; Moravcová, D.; Kupka, L.; Švantner, M.; Honnerová, P.; Hamáček, A. A novel large-area embroidered temperature sensor based on an innovative hybrid resistive thread. Sens. Actuators A Phys. 2017, 265, 111–119. [Google Scholar] [CrossRef]

- Aigner, R.; Pointner, A.; Preindl, T.; Parzer, P.; Haller, M. Embroidered Resistive Pressure Sensors: A Novel Approach for Textile Interfaces. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020. [Google Scholar]

- Roh, J.-S. Textile touch sensors for wearable and ubiquitous interfaces. Text. Res. J. 2014, 84, 739–750. [Google Scholar] [CrossRef]

- Gonçalves, C.; da Silva, A.F.; Gomes, J.; Simoes, R. Wearable E-Textile Technologies: A Review on Sensors, Actuators and Control Elements. Inventions 2018, 3, 14. [Google Scholar] [CrossRef] [Green Version]

- Simegnaw, A.A.; Malengier, B.; Rotich, G.; Tadesse, M.G.; Van Langenhove, L. Review on the Integration of Microelectronics for E-Textile. Materials 2021, 14, 5113. [Google Scholar] [CrossRef]

- Aguayo, N.A.; Amann, P.; Espiñeira, P.P.; Petrasch, J.; Bechtold, T. X-ray micro tomography of three-dimensional embroidered current collectors for lithium-ion batteries. J. Power Sources 2016, 306, 826–831. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, N.; Hubmann, D.; Khan, F.U.; Arzbacher, S.; Bechtold, T. Water-based slurries for high-energy LiFePO4 batteries using embroidered current collectors. Sci. Rep. 2020, 10, 5565. [Google Scholar] [CrossRef]

- Kun, M.; Chan, C.; Ramakrishna, S.; Kulkarni, A.; Vadodaria, K. Textile-based scaffolds for tissue engineering. In Advanced Textiles for Wound Care; Woodhead Publishing: Sawston, UK, 2019; pp. 329–362. [Google Scholar]

- Zhao, Z.; Li, Q.; Dong, Y.; Gong, J.; Li, Z.; Zhang, J. Core-shell structured gold nanorods on thread-embroidered fabric-based microfluidic device for Ex Situ detection of glucose and lactate in sweat. Sens. Actuators B Chem. 2022, 353, 131154. [Google Scholar] [CrossRef]

- Liu, X.; Lillehoj, P.B. Embroidered electrochemical sensors on gauze for rapid quantification of wound biomarkers. Biosens. Bioelectron. 2017, 98, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Logothetis, I.; Fernandez-Garcia, R.; Troynikov, O.; Dabnichki, P.; Pirogova, E.; Gil, I. Embroidered electrodes for bioelectrical impedance analysis: Impact of surface area and stitch parameters. Meas. Sci. Technol. 2019, 30, 115103. [Google Scholar] [CrossRef]

- Pinkos, J.; Stempien, Z. Numerical and Experimental Comparative Analysis of Ballistic Performance of Packages Made of Biaxial and Triaxial Kevlar 29 Fabrics. Autex Res. J. 2020, 20, 203–219. [Google Scholar] [CrossRef]

- Hearle, J.W.S.; Leech, C.M.; Adeyefa, A.; Cork, C.R. Ballistic Impact Resistance of Multi-Layer Textile Fabrics; Technical Report Contract No. DAJA37-79-C-0532 1–244; University of Manchester, Institute of Science and Technology: Manchester, UK, 1981. [Google Scholar]

- Ávila, A.F.; de Oliveira, A.M.; Leão, S.G.; Martins, M.G. Aramid fabric/nano-size dual phase shear thickening fluid composites response to ballistic impact. Compos. Part A Appl. Sci. Manuf. 2018, 112, 468–474. [Google Scholar] [CrossRef]

- Stempień, Z. Effect of velocity of the structure-dependent tension wave propagation on ballistic performance of aramid woven fabrics. Fibres Text. East. Eur. 2011, 87, 74–80. [Google Scholar]

- Roylance, D.K.; Wang, S.S. Penetration Mechanics of Textile Structures; Technical Report Contract No. Daag 17-76-C-0013; Massachusetts Institute of Technology: Cambridge, UK, 1979. [Google Scholar]

- Roylance, D.K.; Wang, S.S. Penetration Mechanics of Textile Structures. In Ballistic Materials and Penetration Mechanics; Elsevier Scientific Publishing Co.: Amsterdam, The Netherlands, 1980; pp. 273–292. [Google Scholar]

- Kędzierski, P.; Morka, A. A comprehensive approach to the modelling and simulation of ballistic textiles. Compos. Struct. 2022, 292, 115643. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gloger, M.; Stempien, Z. Experimental Study of Soft Ballistic Packages with Embroidered Structures Fabricated by Using the Tailored Fiber Placement Technique. Materials 2022, 15, 4208. https://doi.org/10.3390/ma15124208

Gloger M, Stempien Z. Experimental Study of Soft Ballistic Packages with Embroidered Structures Fabricated by Using the Tailored Fiber Placement Technique. Materials. 2022; 15(12):4208. https://doi.org/10.3390/ma15124208

Chicago/Turabian StyleGloger, Maciej, and Zbigniew Stempien. 2022. "Experimental Study of Soft Ballistic Packages with Embroidered Structures Fabricated by Using the Tailored Fiber Placement Technique" Materials 15, no. 12: 4208. https://doi.org/10.3390/ma15124208

APA StyleGloger, M., & Stempien, Z. (2022). Experimental Study of Soft Ballistic Packages with Embroidered Structures Fabricated by Using the Tailored Fiber Placement Technique. Materials, 15(12), 4208. https://doi.org/10.3390/ma15124208