Experimental Study on Triaxial Compressive Mechanical Properties of Polypropylene Fiber Coral Seawater Concrete

Abstract

:1. Introduction

2. Experimental Overview

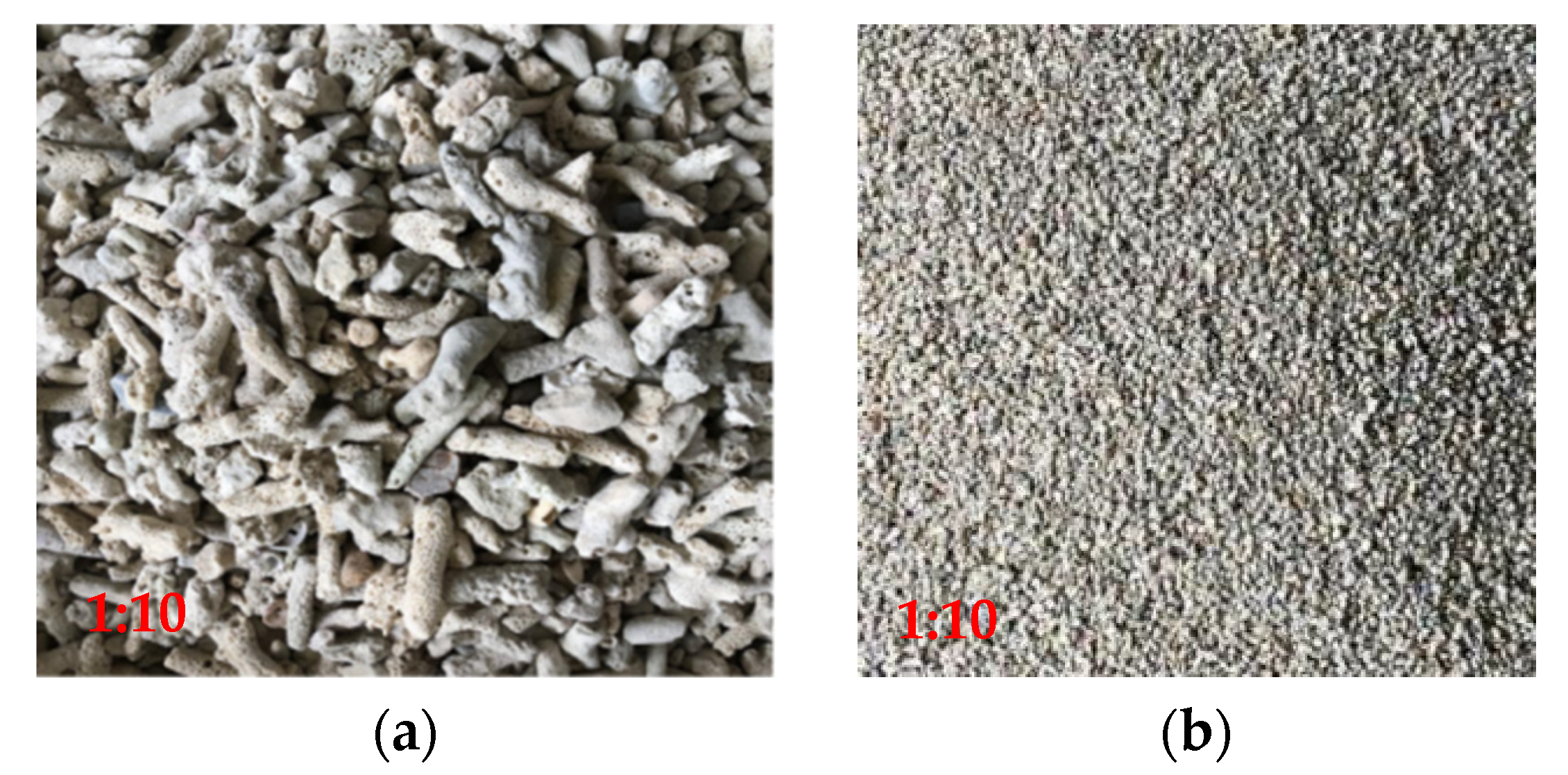

2.1. Test Materials

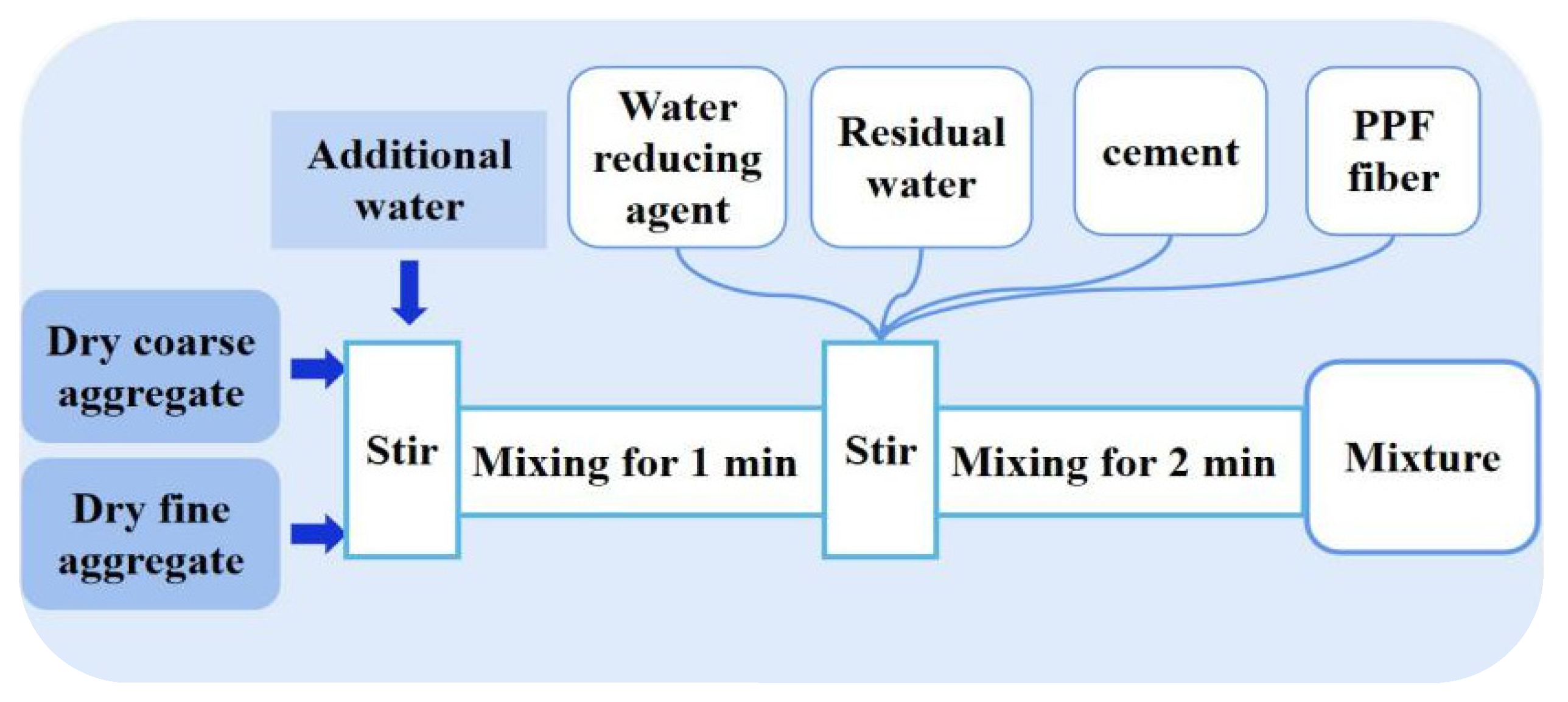

2.2. Test Piece Design

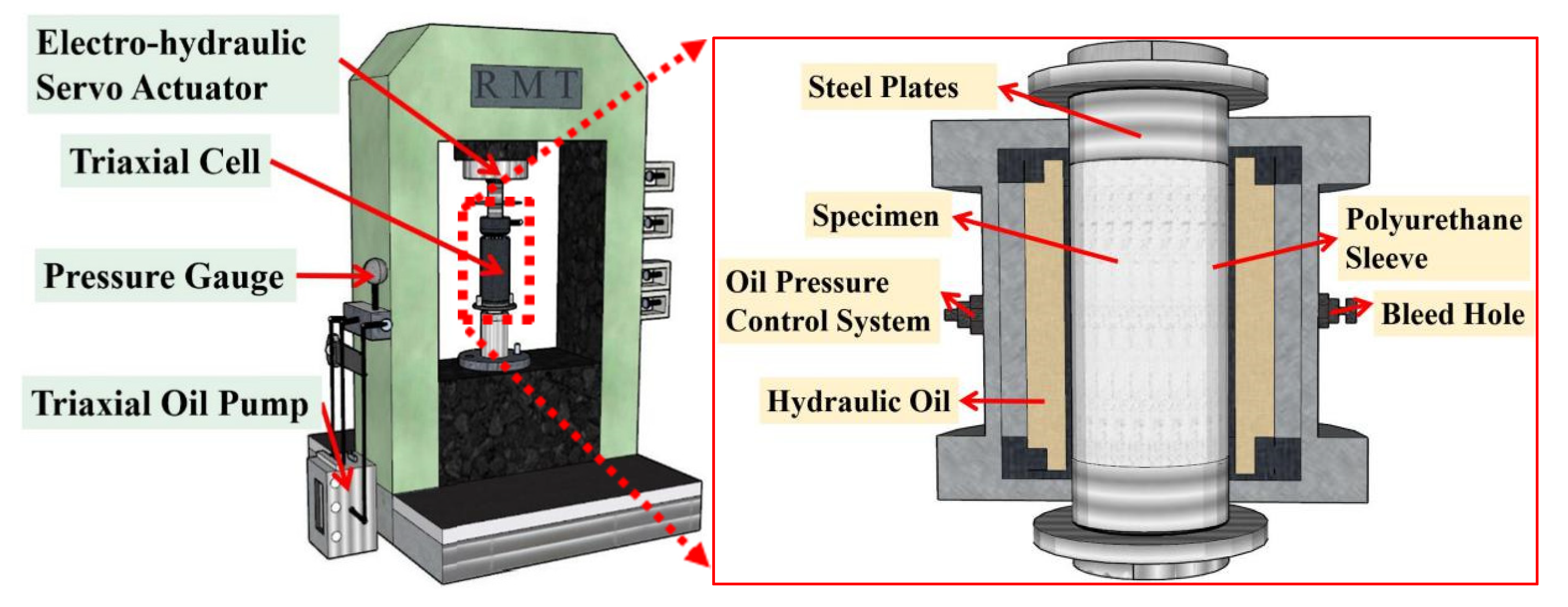

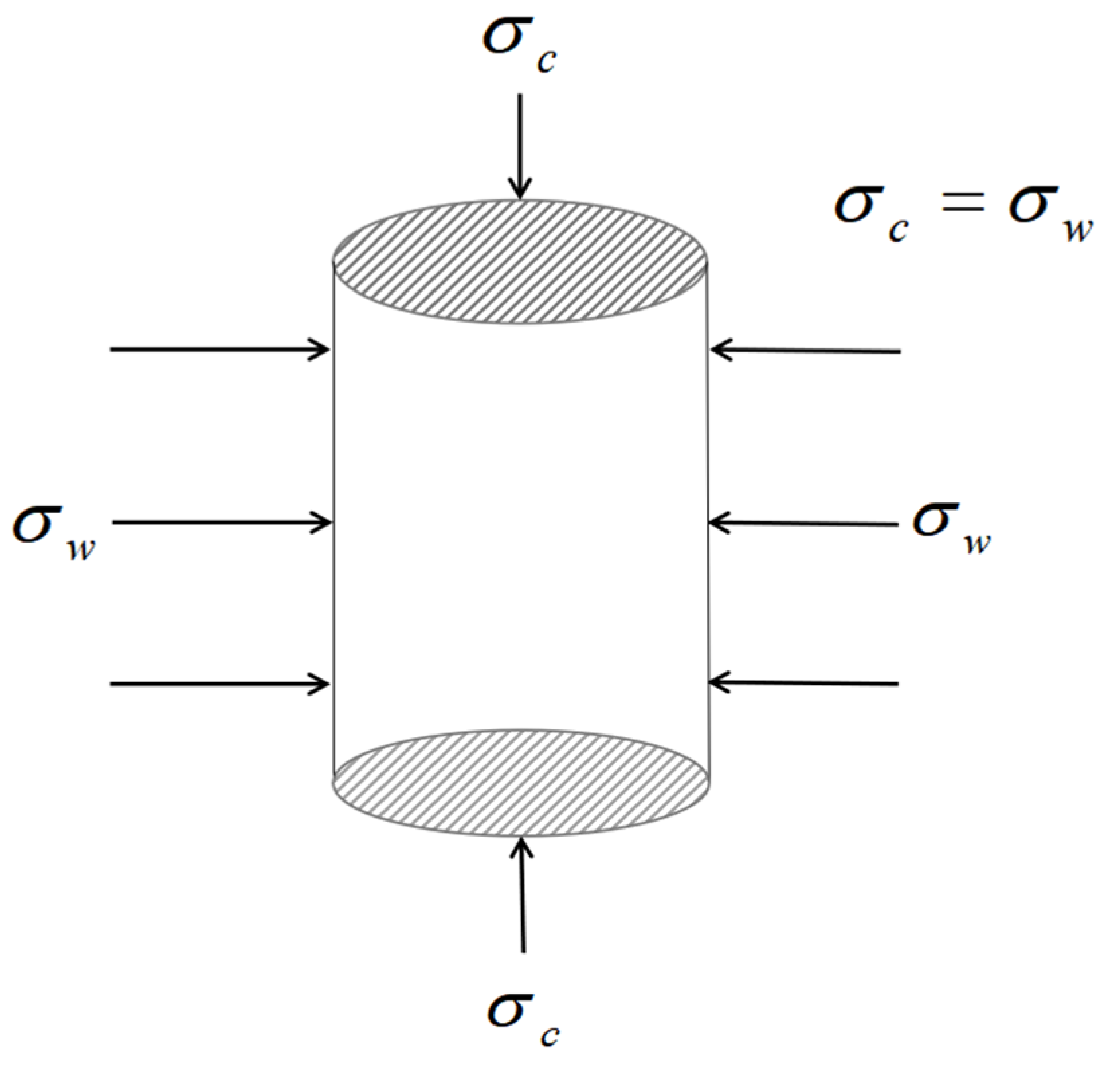

2.3. Loading Device and Loading Method

3. Experimental Results and Analysis

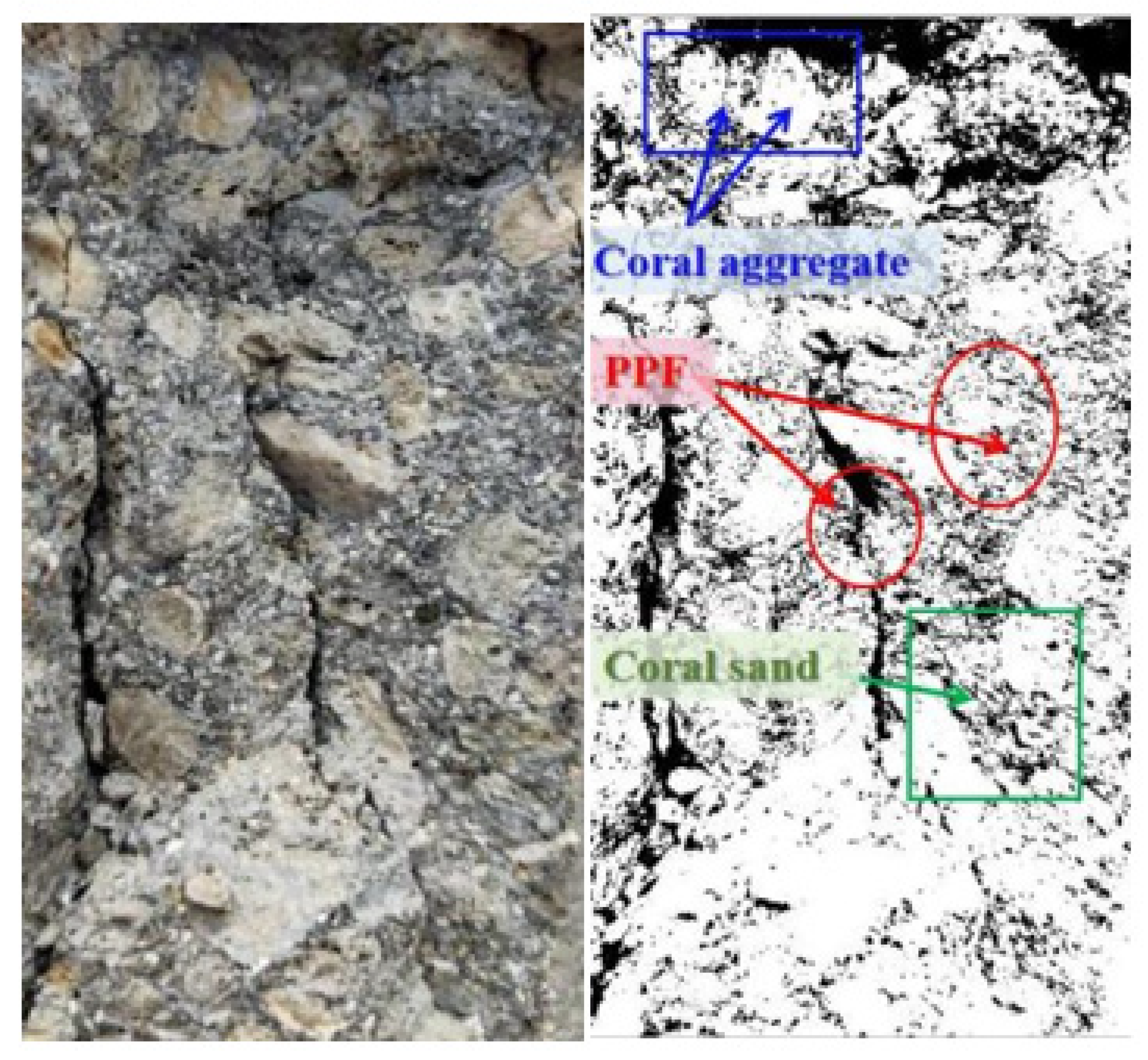

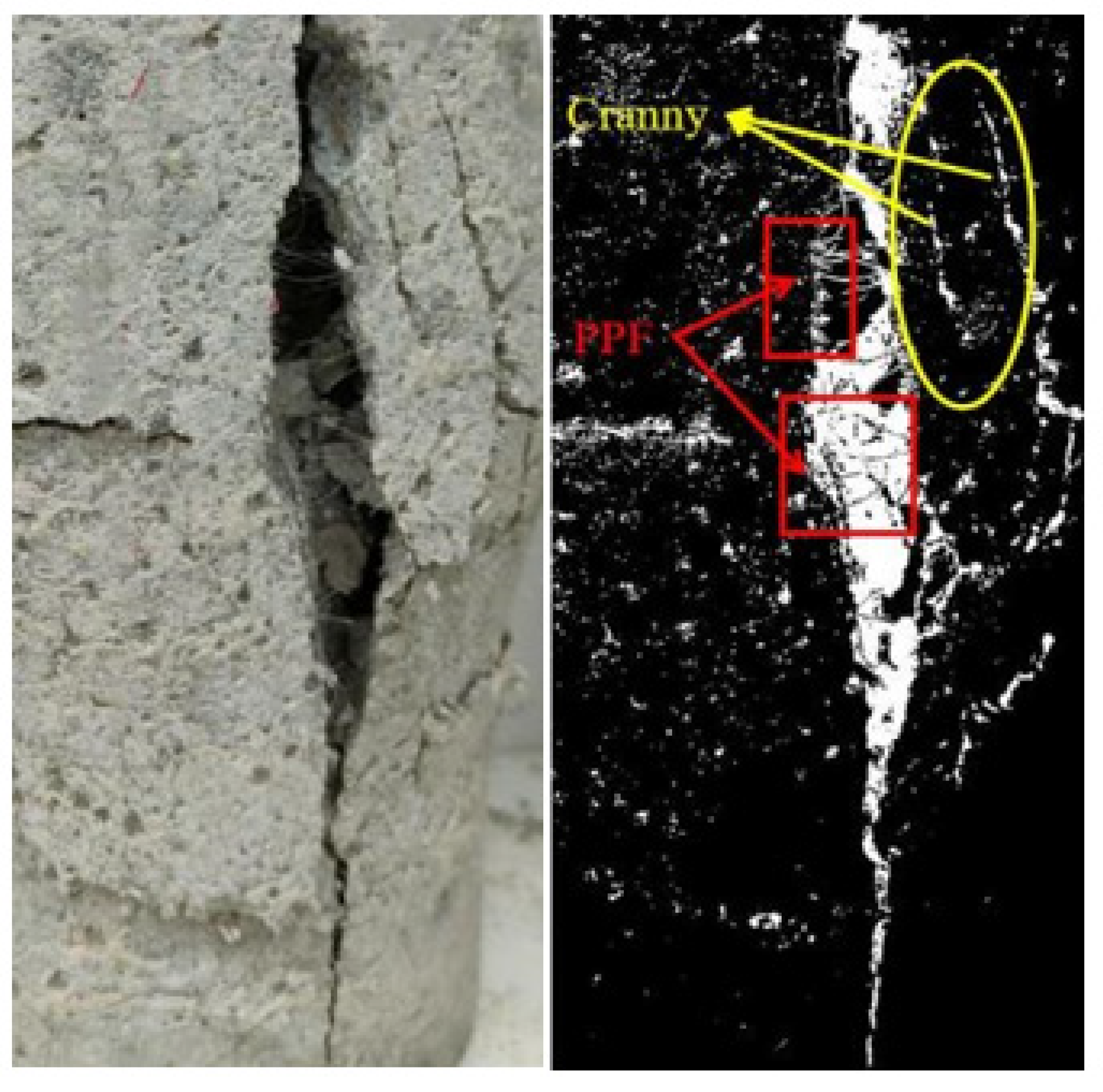

3.1. Specimen Damage Analysis

3.2. Damage Interface Characterization

3.3. Stress–Strain Curve

3.4. Curve Feature Point Parameters

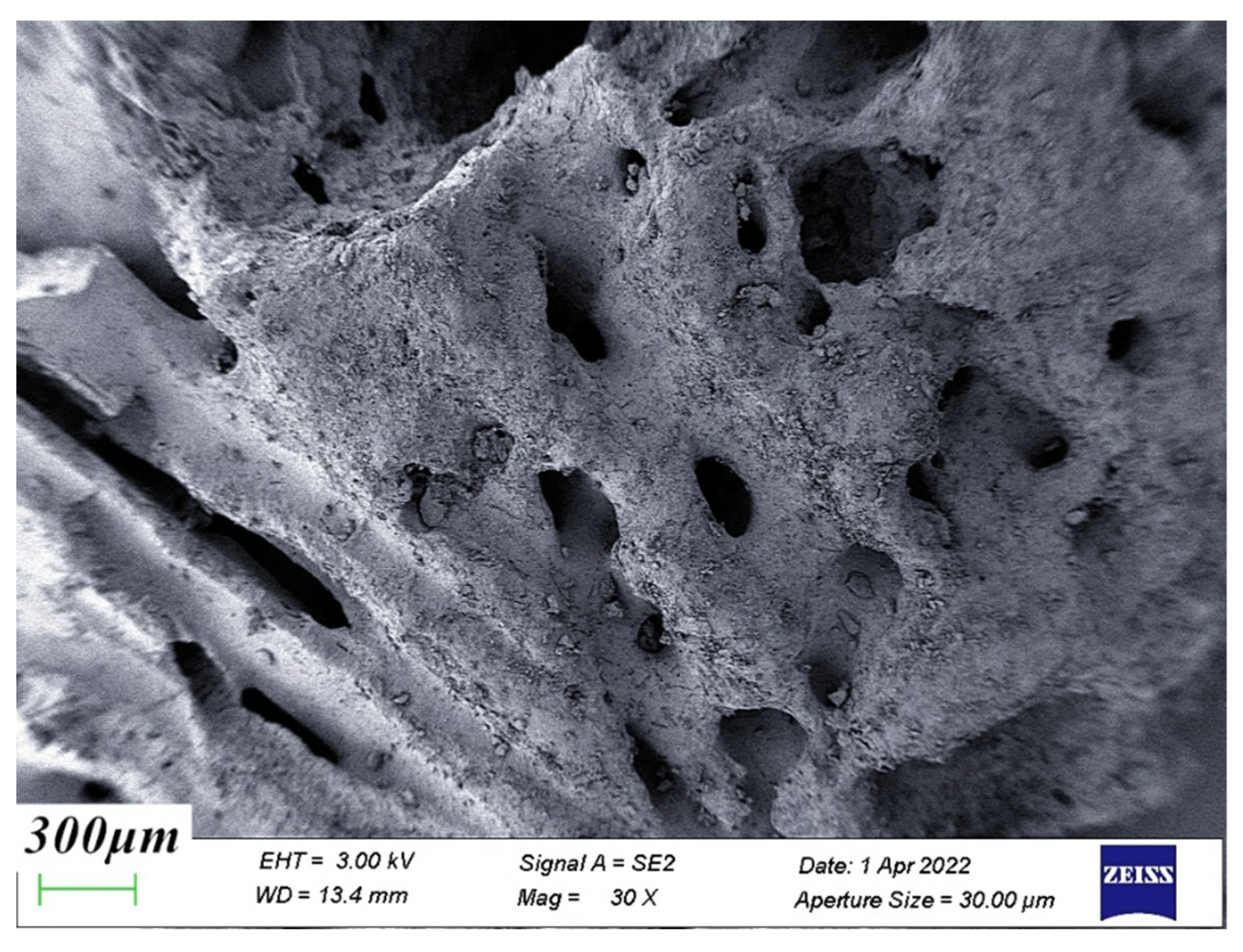

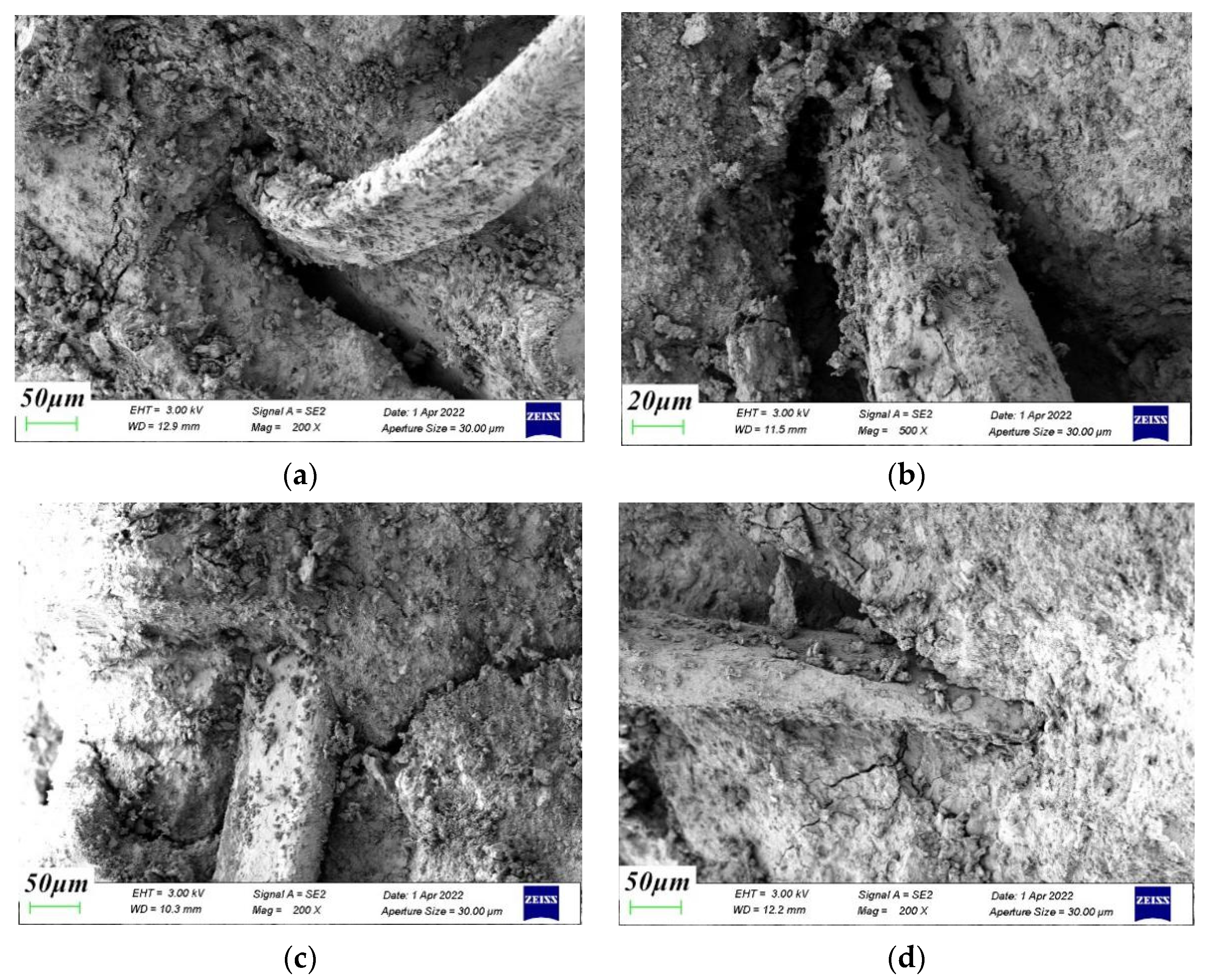

3.5. SEM Images and Analysis

4. Influencing Factors and Analysis

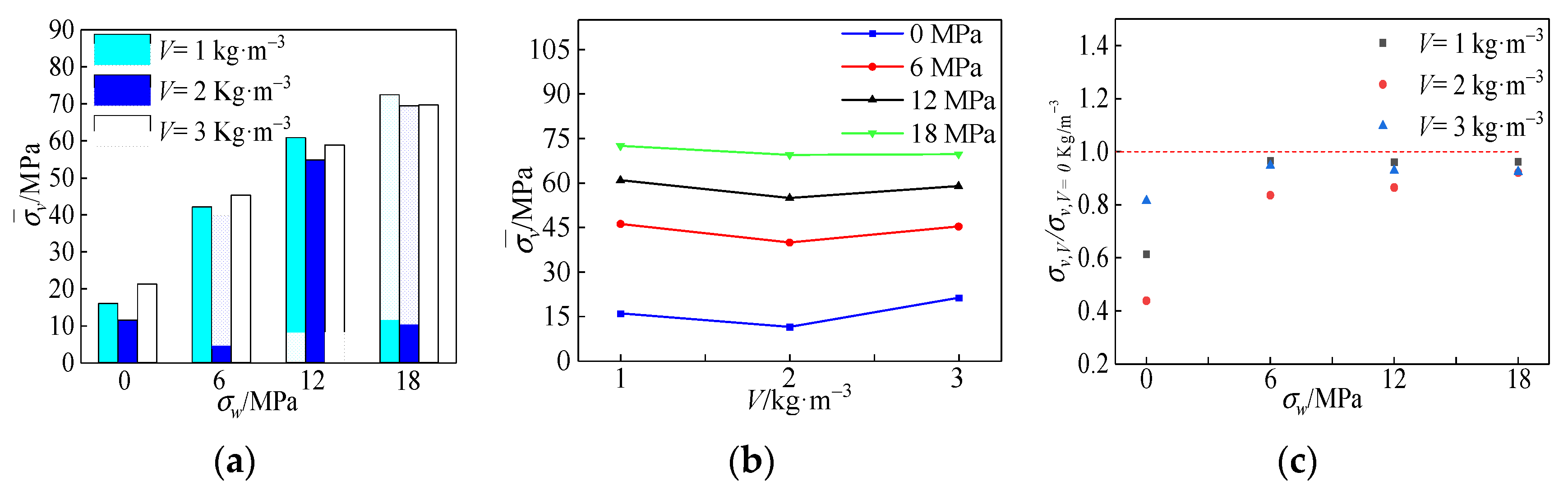

4.1. Peak Stress

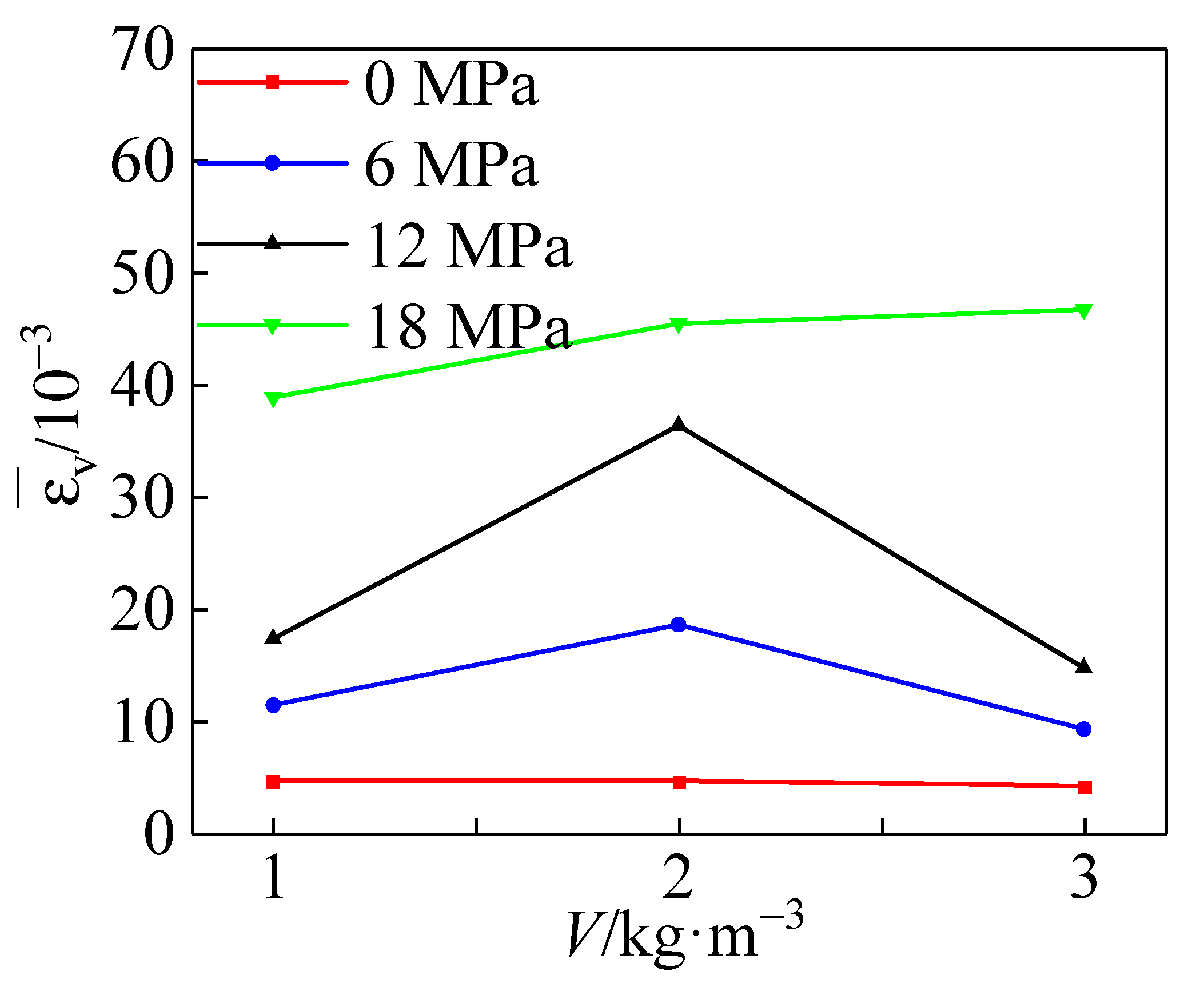

4.2. Peak Strain

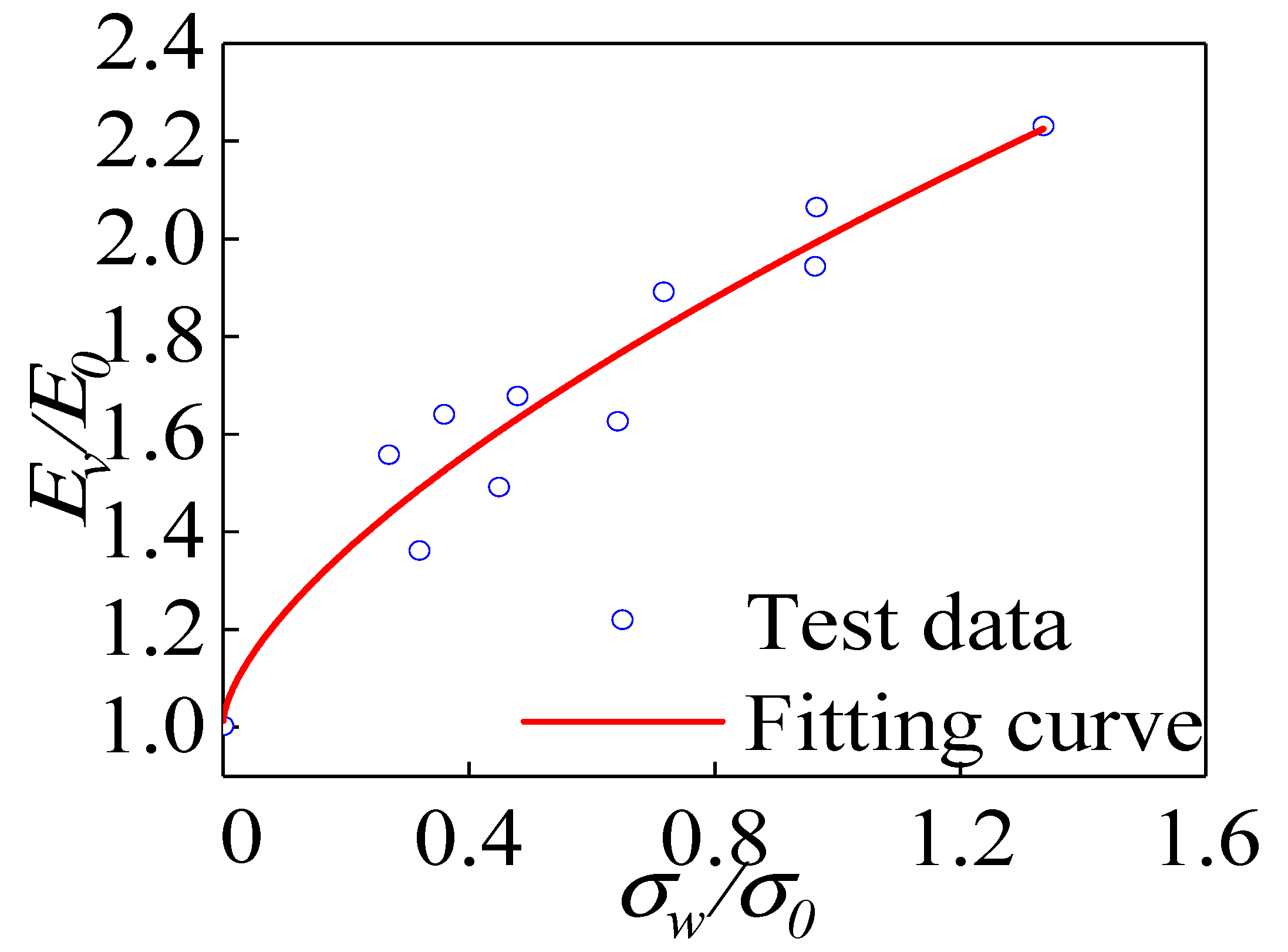

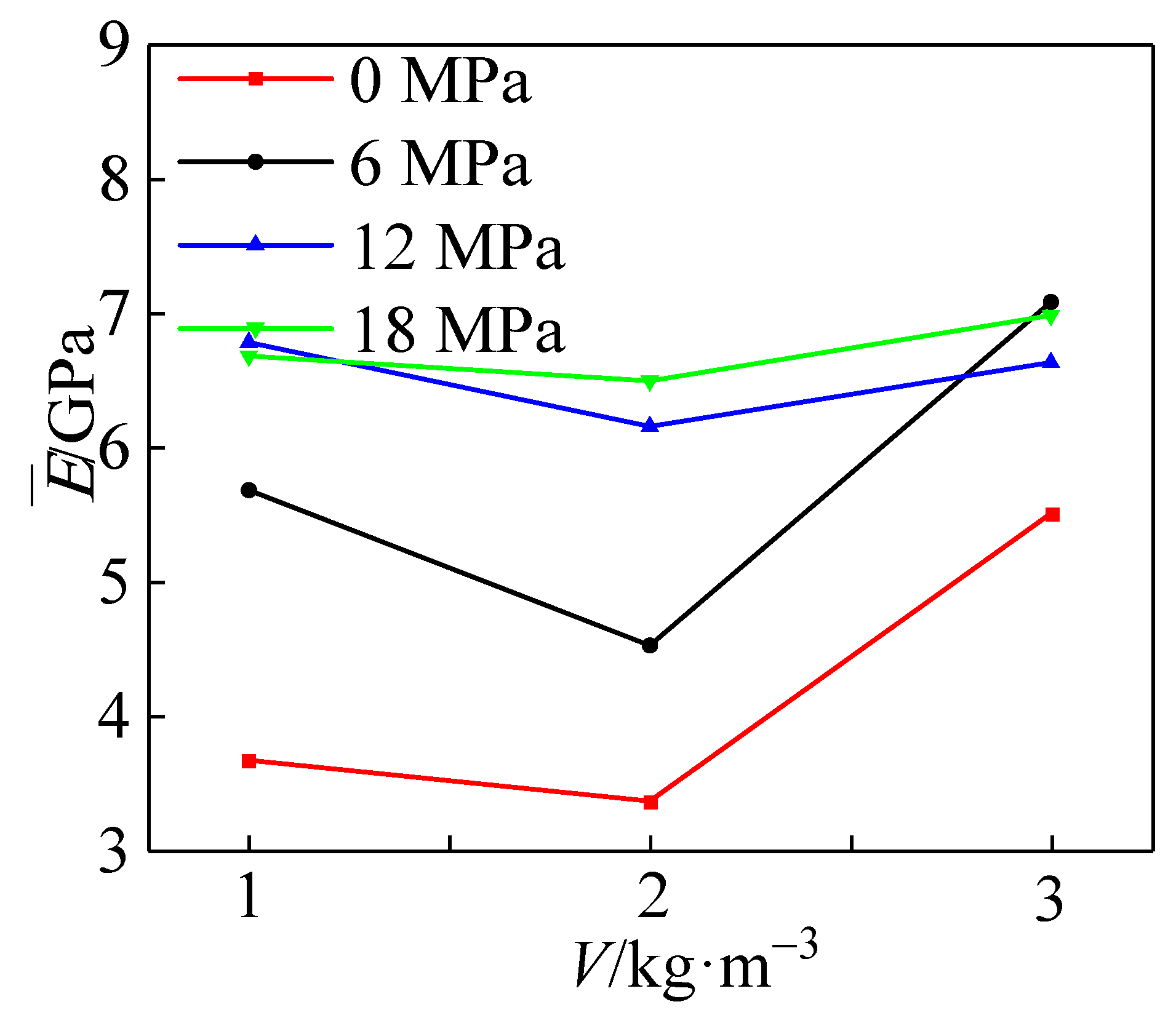

4.3. Elastic Modulus

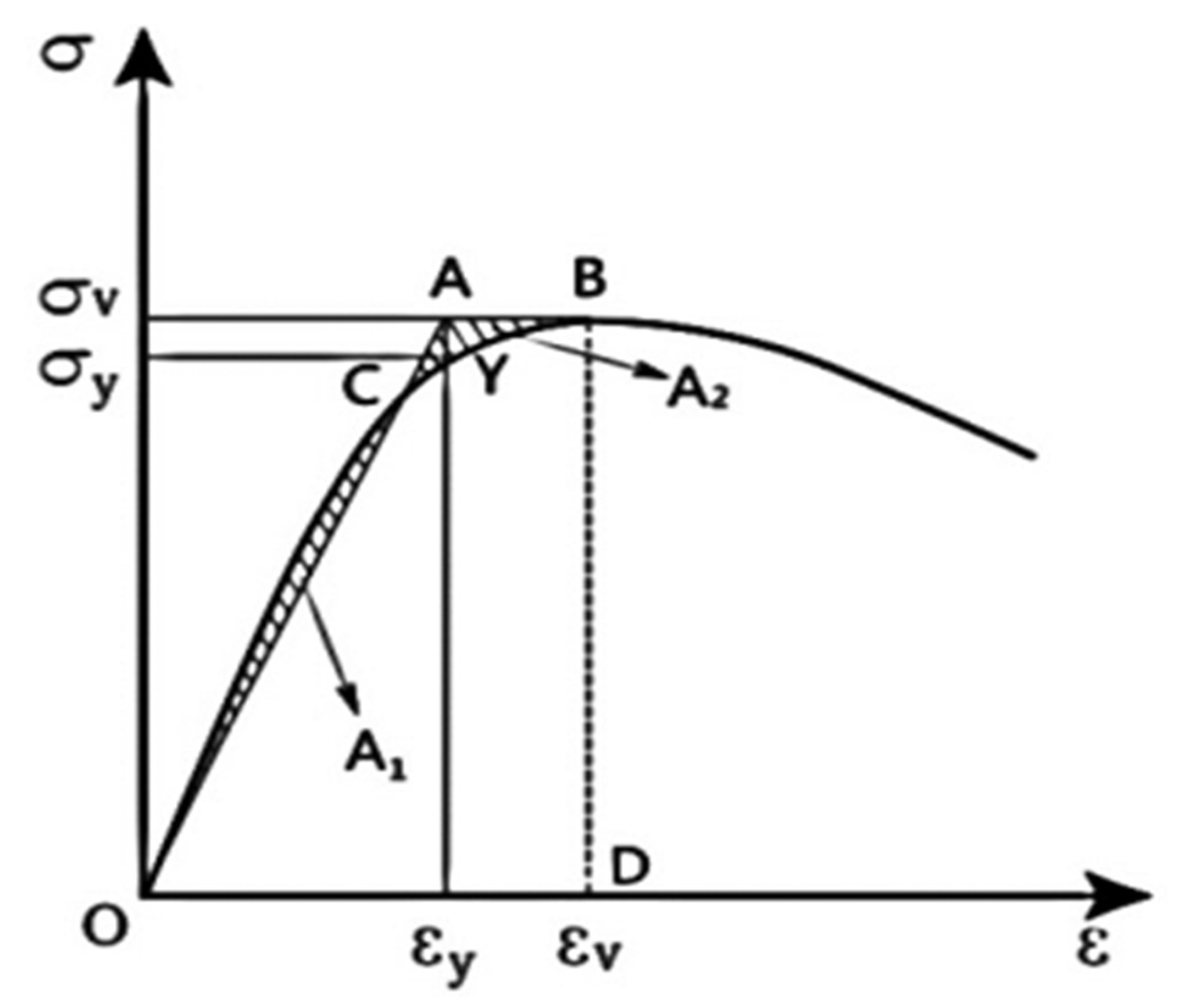

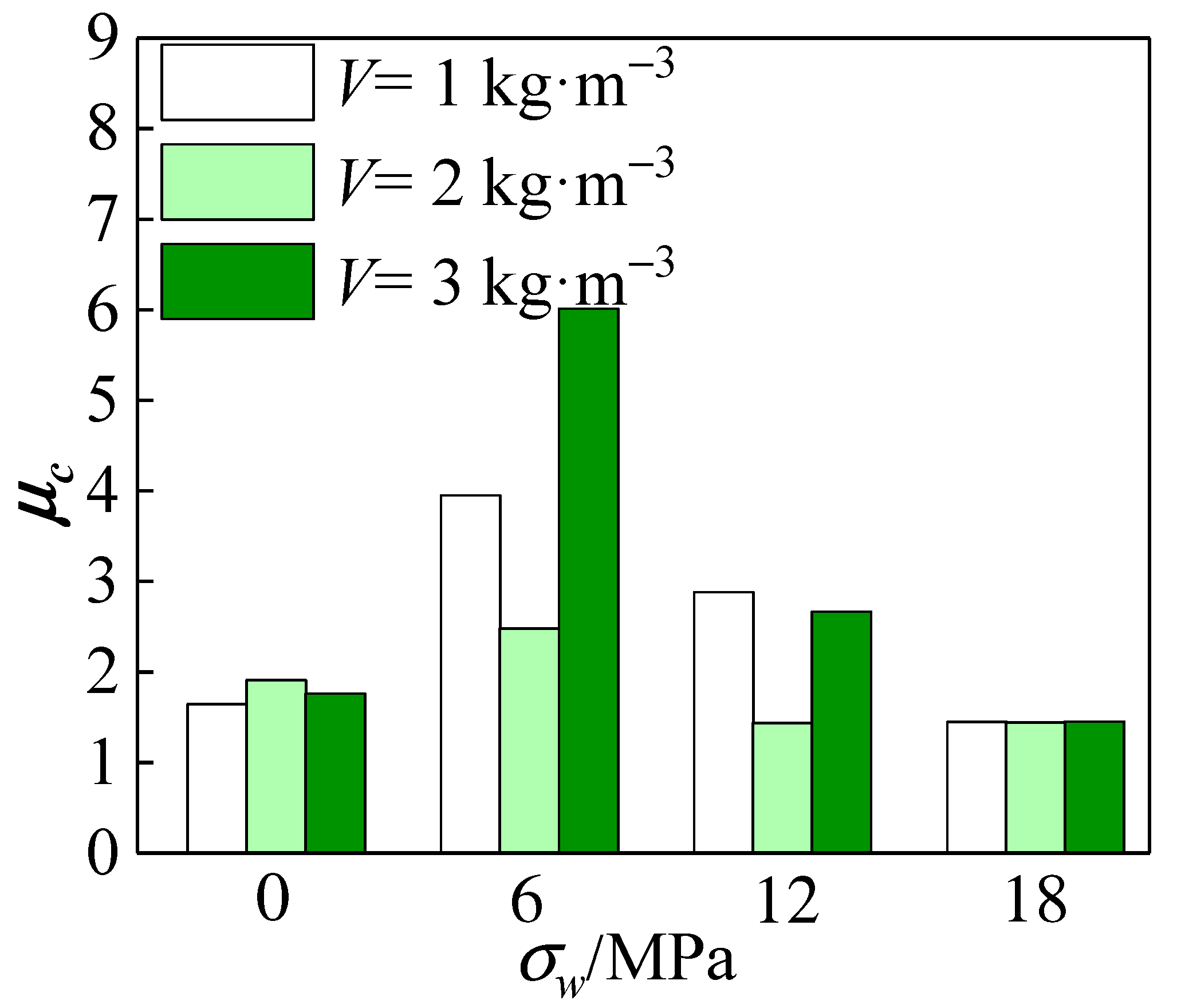

4.4. Ductility

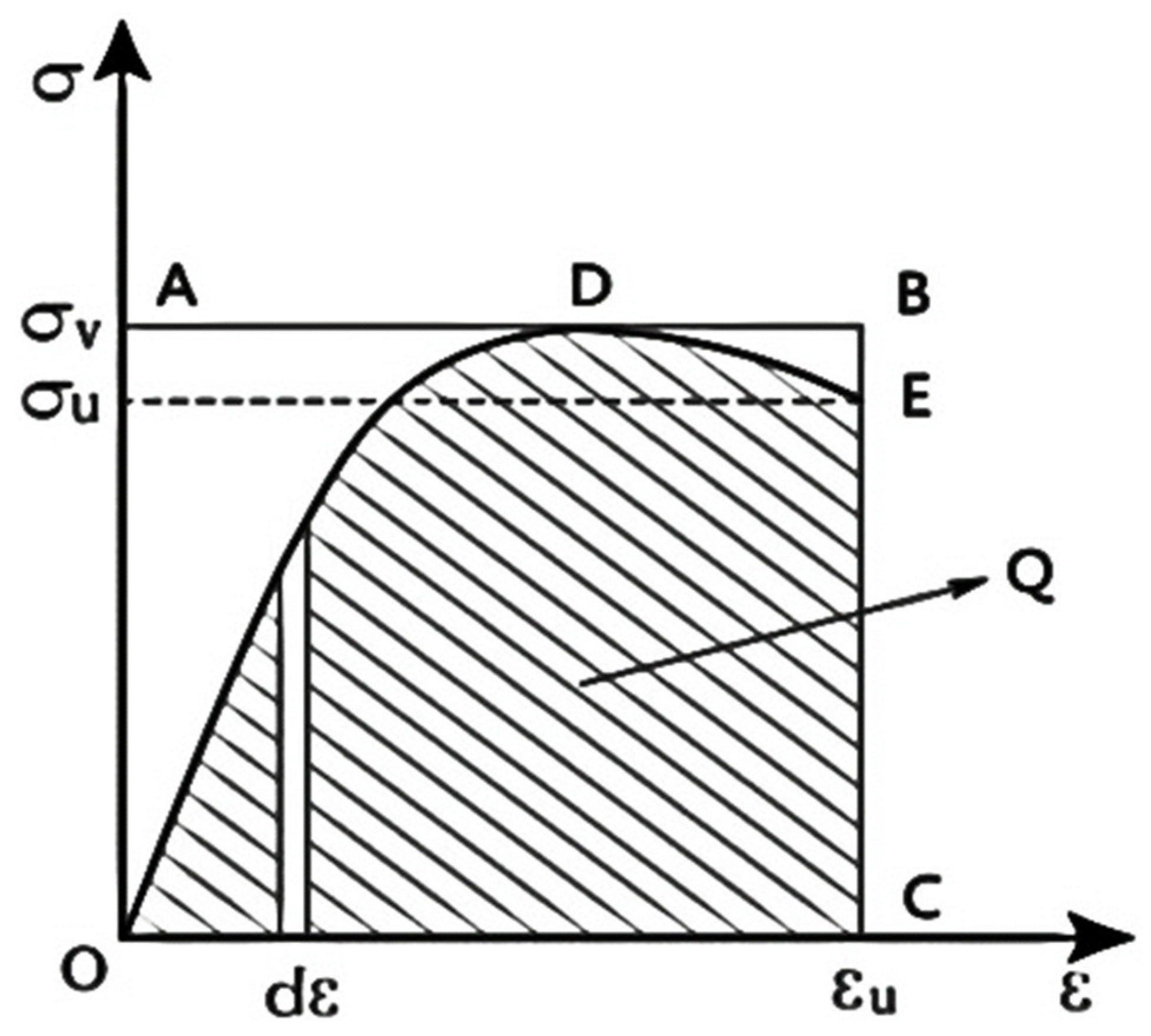

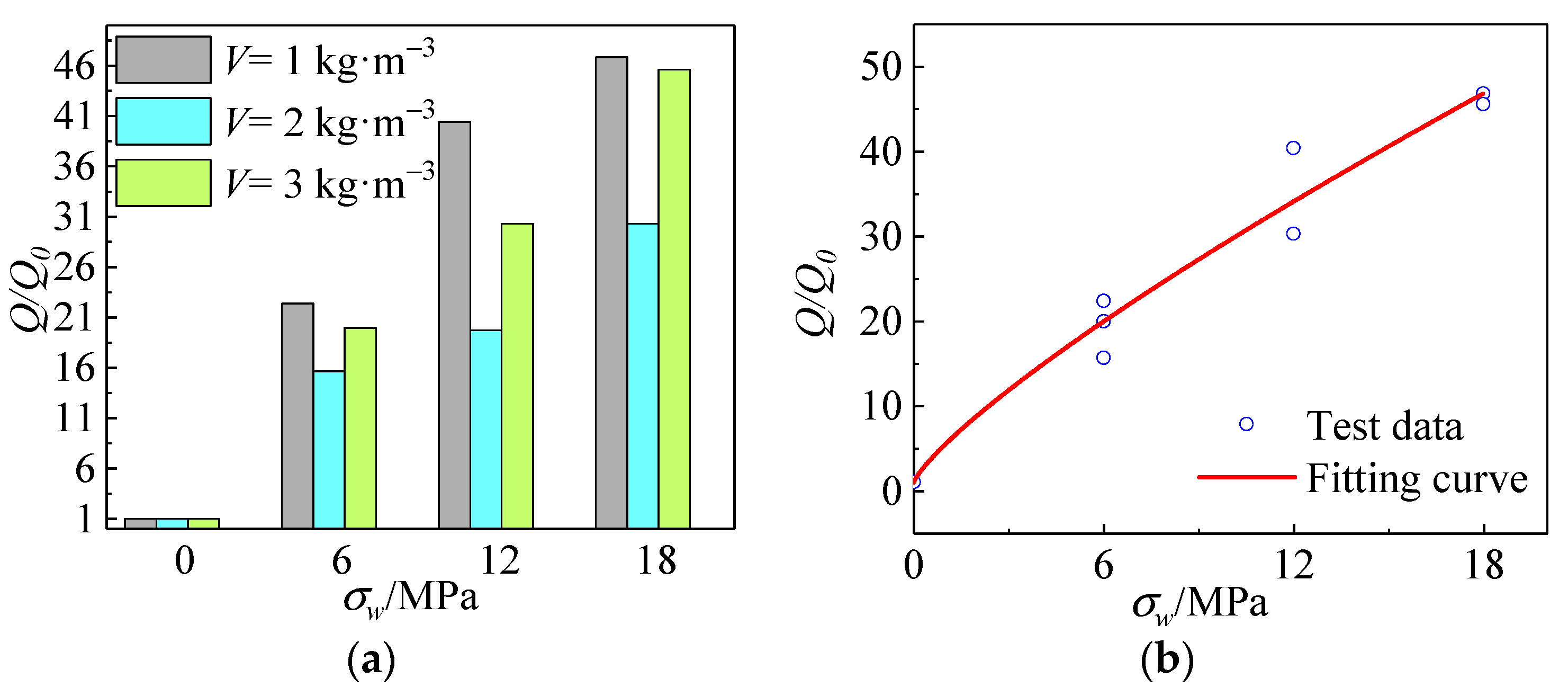

4.5. Energy Consumption

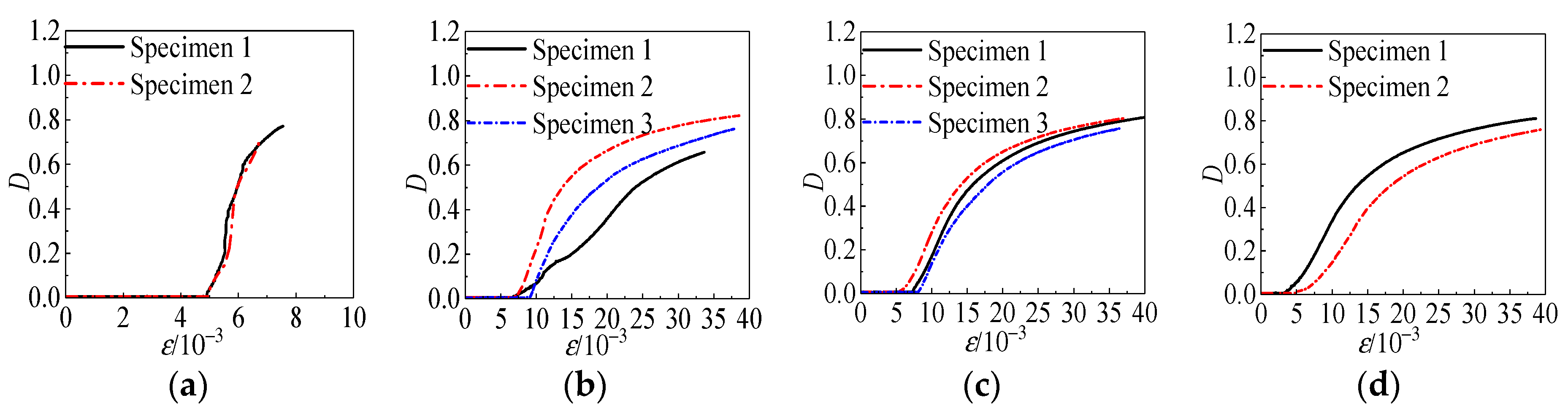

4.6. Damage Process Analysis

5. Conclusions

- (1)

- From the observation of the damaged specimens, the amount of polypropylene fiber addition and the confining pressure value have a significant influence on the mechanical strength of the specimens. The polypropylene fiber effectively reduced the crack width of the specimen and ensured the relative integrity of the specimen after damage. The crack pattern changed from vertical splitting damage to oblique splitting damage, and the width of the main crack decreased as the confining pressure value increased. The confining pressure value increased, and the crack pattern transformed into diagonal shear failure. When σw ≥ 18 MPa, the crack pattern changed to transverse shear damage, the main crack of the specimen disappeared, and the residual deformation increased.

- (2)

- Confining pressure value improves the plastic deformation capacity of polypropylene fiber all-coral seawater concrete, reduces the risk of local concrete instability, prevents vertical penetration cracks, increases axial bearing capacity, and increases peak stress, peak strain, and elastic modulus. When the confining pressure reached 18 MPa, the peak value of the curve disappeared completely. The post-peak curve rose slowly, and the peak stress of the sample was 4.66 times that of uniaxial compression.

- (3)

- The microstructure of polypropylene fiber was observed by scanning electron microscope. It was found that the surface of polypropylene fiber was smooth, long, and thin. Coral aggregate has a large apparent density and internal friction angle, which is helpful in improving the interfacial adhesion between aggregate and hardened mortar. The strength of concrete has been improved to a certain extent. Fiber is like microreinforcement, and its random and uniform three-dimensional spatial distribution can prevent the aggregate from sinking in the concrete. The fiber may bridge fractures and enhance the interface transition zone’s stability. It partially compensates for concrete imperfections and regulates the plastic shrinkage of concrete, effectively preventing the initiation and propagation of microcracks in fresh concrete.

- (4)

- When σw = 6 MPa, the ductility coefficient of all-coral seawater concrete increases by 133% compared with that of σw = 0 MPa; when σw ≥ 6 MPa, the ductility coefficient begins to decrease gradually, but the overall is still substantially higher than the uniaxial compression. The ductility increase is the smallest when the fiber content V = 2 kg·m−3.

- (5)

- The actual energy consumption increases and then levels off as the confining pressure value increases. When 0 MPa ≤ σw ≤ 6 MPa, and with the increase in fiber addition, the actual energy consumption shows a trend of first increasing and then decreasing, and with the further increase in the confining pressure value, the actual energy consumption tends to be stable. When σw = 18 MPa, the energy consumption coefficient reaches the maximum, about 39 times higher than that in the uniaxial compression state.

- (6)

- In general, the specimen’s damage coefficient curve becomes more oblong when the confining pressure value is raised. The later the initial damage appears, the slower the damage development process and the lower the damage degree. When 12 MPa ≤ σw ≤ 18 MPa, the strain of fiber-doped concrete when the initial damage occurs is almost twice the initial damage strain of fiberless concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Da, B. Research on the Preparation Technology, Durability and Mechanical Properties of Concrete Members of High Strength Coral Aggregate Seawater Concrete. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2017. [Google Scholar]

- Chen, Z.P.; Zhou, J.; Chen, Y.L.; Yao, R.S. Experimental study on mechanical properties of coral coarse aggregate seawater concrete. Chin. J. Appl. Mechan. 2020, 37, 1999–2006. [Google Scholar]

- Zhang, L.; Niu, D.T.; Wen, B.; Peng, G.; Sun, Z. Corrosion behavior of low alloy steel bars containing Cr and Al in coral concrete for ocean construction. Constr. Build. Mater. 2020, 258, 119564. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Dong, Z.; Wang, Q. Enhancement of bond performance of FRP bars with seawater coral aggregate concrete by utilizing ecoefficient slag-based alkali-activated materials. J. Compos. Constr. 2022, 26, 04021059. [Google Scholar] [CrossRef]

- Abdel-Kader, M.; Fouda, A. Effect of reinforcement on the response of concrete panels to impact of hard projectiles. Int. J. Impact Eng. 2014, 63, 1–17. [Google Scholar] [CrossRef]

- Lawler, J.S.; Zampini, D.; Shah, S.P. Microfiber and macrofiber hybrid fiber-reinforced concrete. J. Mater. Civil Eng. 2005, 17, 595–604. [Google Scholar] [CrossRef]

- Deng, M.L. Experimental Research on the Mechanical Properties of PP Fiber Reinforced Concrete and Application on Slope Support Project. Master’s Thesis, Chongqing University, Chongqing, China, 2013. [Google Scholar]

- Bagherzadeh, R.; Sadeghi, A.H.; Latifi, M. Utilizing polypropylene fibers to improve physical and mechanical properties of concrete. Text. Res. J. 2012, 82, 88–96. [Google Scholar] [CrossRef]

- Ke, X.; Fu, W.; Chen, Z. Mechanical properties of high-performance concrete under triaxial compression. Mag. Concrete Res. 2022, 74, 419–431. [Google Scholar] [CrossRef]

- Ilg, M.; Plank, J. A novel kind of concrete superplasticizer based on lignite graft copolymers. Cem. Concr. Res. 2016, 79, 123–130. [Google Scholar] [CrossRef]

- Ye, P.; Chen, Y.; Chen, Z.; Xu, J.; Wu, H. Failure criteria and constitutive relationship of lightweight aggregate concrete under triaxial compression. Materials 2022, 15, 507. [Google Scholar] [CrossRef] [PubMed]

- Howdyshell, P.A. The Use of Coral as an Aggregate for Portland Cement Concrete Structures; Army Construction Engineering Research Laboratory: Vicksburg, MS, USA, 1974. [Google Scholar]

- Huang, Y.J.; Li, X.W.; Lu, Y.; Wang, H.C.; Wang, Q.; Sun, H.S.; Li, D.Y. Effect of mix component on the mechanical properties of coral concrete under axial compression. Constr. Build. Mater. 2019, 223, 736–754. [Google Scholar] [CrossRef]

- Ehlert, R.A. Coral concrete at bikini atoll. Concrete Int. 1991, 13, 19–24. [Google Scholar]

- Arumugam, R.A.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.F.; Ma, H.Y.; Zhang, Y.D.; Yuan, Y.F.; Yu, Q.; Tan, Y.S.; Mi, Y.S. Experimental research on whole stress-strain curves of coral aggregate seawater concrete under uniaxial compression. J. Build. Struct. 2017, 38, 144–151. [Google Scholar]

- Jahangir, H.; Esfahani, M.R. Experimental analysis on tensile strengthening properties of steel and glass fiber reinforced inorganic matrix composites. Scientia Iranica 2021, 28, 1152–1166. [Google Scholar]

- Wang, G.; Wei, Y.; Miao, K.; Zheng, K.; Dong, F. Axial compressive behavior of seawater sea-sand coral aggregate concrete-filled circular FRP-steel composite tube columns. Constr. Build. Mater. 2022, 315, 125737. [Google Scholar] [CrossRef]

- Arefi, M.R.; Mollaahmadi, E. An experimental investigation into the effect of polypropylene fibers on mechanical properties of concrete. Mater. Sci. Eng. 2012, 745–753. [Google Scholar]

- Wang, Z.Z. Experiment Study on the Properties of Polypropylene Fiber Concrete. Master’s Thesis, Zhejiang University, Hangzhou, China, 2004. [Google Scholar]

- Xu, L.H.; Huang, B.; Li, B.; Chi, Y.; Li, C.N.; Shi, Y.C. Study on the stress-strain relation of polypropylene fiber reinforced concrete under cyclic compression. China Civil Eng. J. 2019, 52, 1–12. [Google Scholar]

- Shen, R.X. Mechanism of low synthetic fiber in concrete. In Proceedings of the Academician National Symposium on Science and Technology of Cement Based Composites, Wu Zhongwei has been Engaged in Science and Education Work for 60 Years, Beijing, China, 30 June 2004; pp. 12–15. [Google Scholar]

- Wang, L.; Shen, N.; Yu, D.P. Strengthening mechanism and microstructures of fiber reinforced coral concrete. In Proceedings of the Institution of Civil Engineers—Structures and Buildings; ICE: London, UK, 2021. [Google Scholar]

- GB/T 17431.2-2010; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. China Building Materials Federation. China National Standardization Administration Committee: Beijing, China, 2010.

- JGJ 12-2006; Ministry of Construction of the People’s Republic of China Industrial Standard of the People’s Republic of China. Technical Specification for Lightweight Aggregate Concrete Structures. China Construction Industry Press: Beijing, China, 2006.

- GB500010-2010; Code for Design Concrete Structures. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

- Liu, C.; Tang, C.; Shi, B.; Suo, W. Automatic quantification of crack patterns by image processing. Comput. Geosci. 2013, 57, 77–80. [Google Scholar] [CrossRef]

- Yang, H.; Liang, D.; Deng, Z.; Qin, Y. Effect of limestone powder in manufactured sand on the hydration products and microstructure of recycled aggregate concrete. Constr. Build. Mater. 2018, 188, 1045–1049. [Google Scholar] [CrossRef]

- Cui, J. HLA: Hysteretic Loop Analysis Program. Available online: http:/www.idcui.com/?p=11828 (accessed on 16 January 2022).

- Chen, Z.; Mo, L.; Song, C.; Zhang, Y. Investigation on compression properties of seawater-sea sand concrete. Adv. Concr. Constr. 2021, 2, 93–103. [Google Scholar] [CrossRef]

| Classification | Apparent Density (kg·m−3) | Stacking Density (kg·m−3) | Dimension/mm | Porosity (%) | Shell Content (%) | 1 h Water Absorption Rate (%) | Cl− Content (%) | Cylinder Compression Strength (MPa) | Fineness Modulus |

|---|---|---|---|---|---|---|---|---|---|

| Coral Coarse Aggregate | 1957.50 | 893.75 | 40–60 | 54.21 | 25.58 | 8.75% | 0.02 | 4.00 | |

| Coral sand | 1197.90 | 1055.00 | 2.5–5 | 41.51 | 31.72 | 19.40 | 0.21 | 2.85 |

| Type | Length (mm) | Diameter (μm) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| Polypropylene fiber | 18.0 | 32.7 | 469.0 | 4236.0 | 28.4 |

| Compound | NaCl | MgCl2 | Na2SO4 | CaCl2 | KCl | NaHCO3 | KBr |

|---|---|---|---|---|---|---|---|

| Content(%) | 1.070 | 0.220 | 0.220 | 0.053 | 0.053 | 0.007 | 0.007 |

| Strength Grade | Coarse Aggregate (kg·m−3) | Sand (kg·m−3) | Cement (kg·m−3) | Water (kg·m−3) | Additional Water (kg·m−3) | Water Reducer (%) | Net Water–Ash Ratio | Total Water–Ash Ratio |

|---|---|---|---|---|---|---|---|---|

| C30 | 749.00 | 749.00 | 613.00 | 215.20 | 119.80 | 0.20 | 0.35 | 0.55 |

| Specimen Number | Strength Grade | σw (MPa) | V (kg/m3) | Specimen Number | Strength Grade | σw (MPa) | V (kg/m3) |

|---|---|---|---|---|---|---|---|

| PF-1-0-A | C30 | 0 | 1 | PF-1-12-A | C30 | 12 | 1 |

| PF-1-0-B | C30 | 0 | 1 | PF-1-12-B | C30 | 12 | 1 |

| PF-1-0-C | C30 | 0 | 1 | PF-1-12-C | C30 | 12 | 1 |

| PF-2-0-A | C30 | 0 | 2 | PF-2-12-A | C30 | 12 | 2 |

| PF-2-0-B | C30 | 0 | 2 | PF-2-12-B | C30 | 12 | 2 |

| PF-2-0-C | C30 | 0 | 2 | PF-2-12-C | C30 | 12 | 2 |

| PF-3-0-A | C30 | 0 | 3 | PF-3-12-A | C30 | 12 | 3 |

| PF-3-0-B | C30 | 0 | 3 | PF-3-12-B | C30 | 12 | 3 |

| PF-3-0-C | C30 | 0 | 3 | PF-3-12-C | C30 | 12 | 3 |

| PF-1-6-A | C30 | 6 | 1 | PF-1-18-A | C30 | 18 | 1 |

| PF-1-6-B | C30 | 6 | 1 | PF-1-18-B | C30 | 18 | 1 |

| PF-1-6-C | C30 | 6 | 1 | PF-1-18-C | C30 | 18 | 1 |

| PF-2-6-A | C30 | 6 | 2 | PF-2-18-A | C30 | 18 | 2 |

| PF-2-6-B | C30 | 6 | 2 | PF-2-18-B | C30 | 18 | 2 |

| PF-2-6-C | C30 | 6 | 2 | PF-2-18-C | C30 | 18 | 2 |

| PF-3-6-A | C30 | 6 | 3 | PF-3-18-A | C30 | 18 | 3 |

| PF-3-6-B | C30 | 6 | 3 | PF-3-18-B | C30 | 18 | 3 |

| PF-3-6-C | C30 | 6 | 3 | PF-3-18-C | C30 | 18 | 3 |

| Specimen No. | Yield Point | Peak Point | Destruction Point | Elastic Modulus E (GPa) | |||

|---|---|---|---|---|---|---|---|

| Py (kN) | Δy (mm) | Pm (kN) | Δm (mm) | Pu (kN) | Δu (mm) | ||

| PF-1-0-A | 16.27 | 4.88 | 16.70 | 4.84 | 14.20 | 6.32 | 3.38 |

| PF-1-0-B | 17.66 | 4.62 | 18.65 | 4.96 | 15.85 | 5.06 | 4.03 |

| PF-1-0-C | 11.13 | 3.51 | 12.40 | 4.14 | 10.54 | 4.68 | 3.59 |

| PF-2-0-A | 10.71 | 3.21 | 11.956 | 5.75 | 10.16 | 8.29 | 4.23 |

| PF-2-0-B | 12.01 | 5.03 | 13.28 | 6.87 | 11.29 | 7.98 | 3.04 |

| PF-2-0-C | 6.33 | 6.41 | 9.00 | 10.85 | 7.65 | 15.31 | 2.82 |

| PF-3-0-A | 21.09 | 4.71 | 22.20 | 5.40 | 18.87 | 6.26 | 4.89 |

| PF-3-0-B | 18.32 | 3.27 | 18.33 | 3.34 | 15.58 | 4.77 | 5.31 |

| PF-3-0-C | 22.47 | 3.54 | 22.99 | 3.80 | 19.54 | 4.24 | 6.32 |

| PF-1-6-A | 40.86 | 7.38 | 42.04 | 8.12 | 39.29 | 38.52 | 5.54 |

| PF-1-6-B | 37.72 | 8.82 | 42.17 | 18.43 | 40.67 | 39.22 | 5.48 |

| PF-1-6-C | 52.35 | 8.87 | 54.22 | 10.17 | 46.09 | 14.47 | 6.02 |

| PF-2-6-A | 39.67 | 10.14 | 43.46 | 25.45 | 42.23 | 39.30 | 4.91 |

| PF-2-6-B | 31.86 | 10.35 | 36.32 | 22.82 | 35.26 | 39.26 | 4.53 |

| PF-2-6-C | 35.55 | 12.58 | 40.69 | 19.89 | 38.93 | 38.74 | 4.13 |

| PF-3-6-A | 41.92 | 6.11 | 44.73 | 7.54 | 39.90 | 39.77 | 7.61 |

| PF-3-6-B | 42.54 | 7.76 | 46.02 | 10.00 | 39.11 | 31.81 | 6.15 |

| PF-3-6-C | 42.64 | 6.12 | 45.08 | 7.65 | 38.32 | 31.89 | 7.49 |

| PF-1-12-A | 53.62 | 10.86 | 59.45 | 19.73 | 57.55 | 38.00 | 6.39 |

| PF-1-12-B | 57.39 | 10.76 | 62.57 | 26.33 | 61.11 | 38.29 | 6.55 |

| PF-1-12-C | 56.88 | 8.90 | 61.78 | 14.38 | 60.07 | 38.20 | 7.41 |

| PF-2-12-A | 47.33 | 13.33 | 52.16 | 35.80 | 51.97 | 36.22 | 4.99 |

| PF-2-12-B | 49.08 | 11.73 | 55.47 | 37.88 | 55.39 | 38.06 | 7.19 |

| PF-2-12-C | 51.49 | 11.65 | 56.90 | 35.86 | 56.66 | 35.87 | 6.29 |

| PF-3-12-A | 54.16 | 10.04 | 59.71 | 18.80 | 58.49 | 41.30 | 6.72 |

| PF-3-12-B | 54.74 | 10.73 | 60.00 | 15.08 | 58.02 | 36.25 | 6.12 |

| PF-3-12-C | 56.43 | 10.79 | 59.10 | 38.63 | 59.10 | 38.63 | 7.06 |

| PF-1-18-A | 65.47 | 14.15 | 72.87 | 38.54 | 72.54 | 39.08 | 6.63 |

| PF-1-18-B | 63.81 | 14.27 | 72.33 | 38.06 | 72.07 | 38.35 | 7.83 |

| PF-1-18-C | 66.00 | 16.01 | 72.51 | 40.15 | 71.77 | 41.13 | 5.58 |

| PF-2-18-A | 64.00 | 14.80 | 73.24 | 41.70 | 73.13 | 41.75 | 7.49 |

| PF-2-18-B | 56.34 | 20.96 | 65.88 | 49.59 | 65.66 | 50.63 | 5.50 |

| PF-2-18-C | |||||||

| PF-3-18-A | 62.92 | 14.44 | 68.04 | 50.58 | 67.92 | 51.10 | 6.06 |

| PF-3-18-B | 64.82 | 12.99 | 72.00 | 47.69 | 71.94 | 49.42 | 8.15 |

| PF-3-18-C | 64.27 | 13.62 | 70.038 | 47.64 | 69.71 | 47.78 | 6.74 |

| μ | P-0 | P-6 | P-12 | P-18 |

|---|---|---|---|---|

| P-1 kg·m−3 | 1.65 | 3.95 | 2.88 | 1.45 |

| P-2 kg·m−3 | 1.91 | 2.48 | 1.44 | 1.44 |

| P-3 kg·m−3 | 1.76 | 6.01 | 2.67 | 1.45 |

| Q | P-0 MPa | P-6 MPa | P-12 MPa | P-18 MPa |

|---|---|---|---|---|

| P-1 kg·m−3 | 49.75 | 1114.33 | 2010.98 | 2330.77 |

| P-2 kg·m−3 | 85.11 | 1333.96 | 1678.90 | 2580.25 |

| P-3 kg·m−3 | 65.38 | 1305.12 | 1981.80 | 2981.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.; Mo, L.; Pan, M.; Liu, L.; Chen, Z. Experimental Study on Triaxial Compressive Mechanical Properties of Polypropylene Fiber Coral Seawater Concrete. Materials 2022, 15, 4234. https://doi.org/10.3390/ma15124234

Shi H, Mo L, Pan M, Liu L, Chen Z. Experimental Study on Triaxial Compressive Mechanical Properties of Polypropylene Fiber Coral Seawater Concrete. Materials. 2022; 15(12):4234. https://doi.org/10.3390/ma15124234

Chicago/Turabian StyleShi, Hang, Linlin Mo, Mingyan Pan, Leiguo Liu, and Zongping Chen. 2022. "Experimental Study on Triaxial Compressive Mechanical Properties of Polypropylene Fiber Coral Seawater Concrete" Materials 15, no. 12: 4234. https://doi.org/10.3390/ma15124234

APA StyleShi, H., Mo, L., Pan, M., Liu, L., & Chen, Z. (2022). Experimental Study on Triaxial Compressive Mechanical Properties of Polypropylene Fiber Coral Seawater Concrete. Materials, 15(12), 4234. https://doi.org/10.3390/ma15124234