Constitutive Model of the Surface Roughening Behavior of Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Method

3. Construction of the Constitutive Model

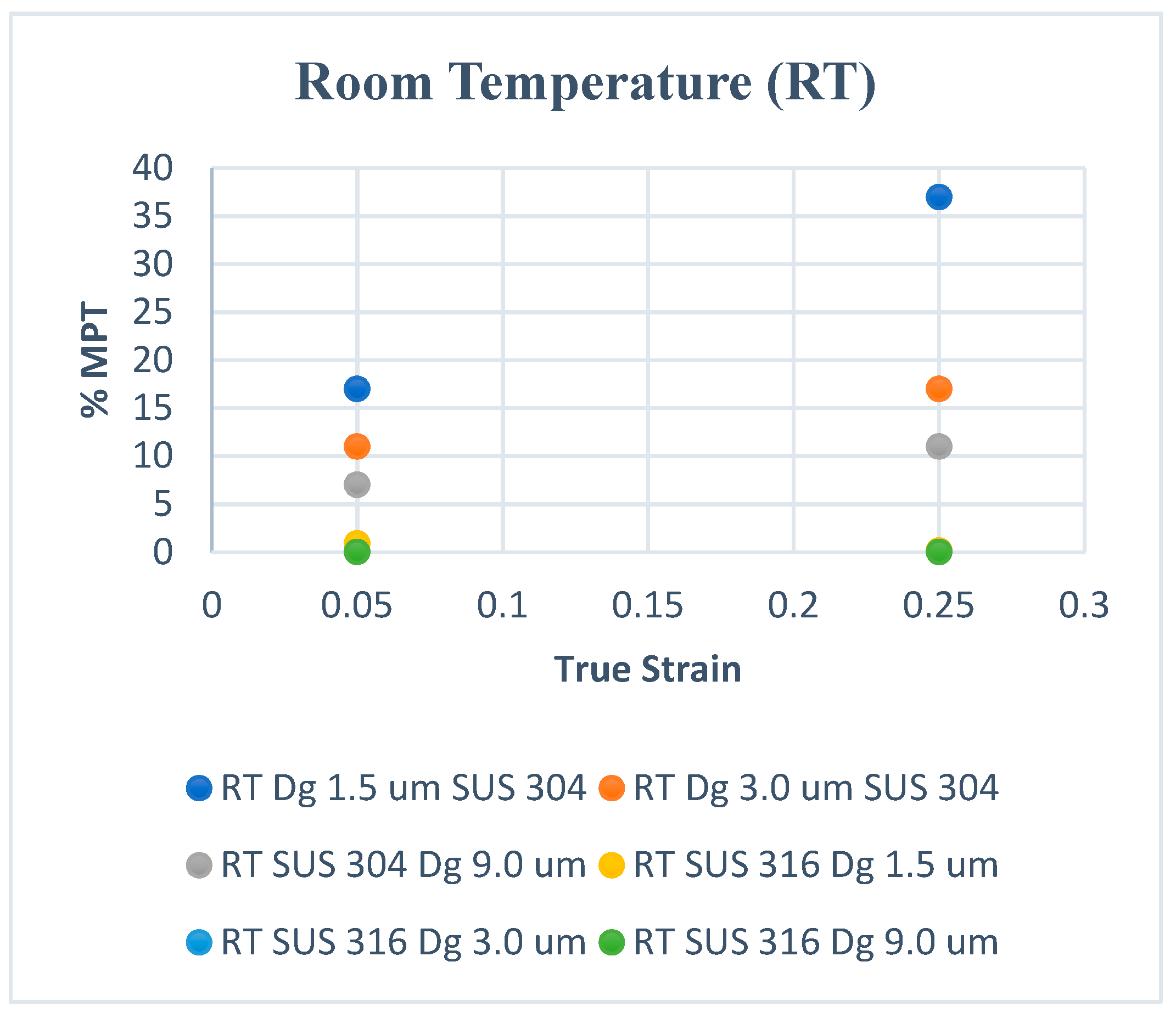

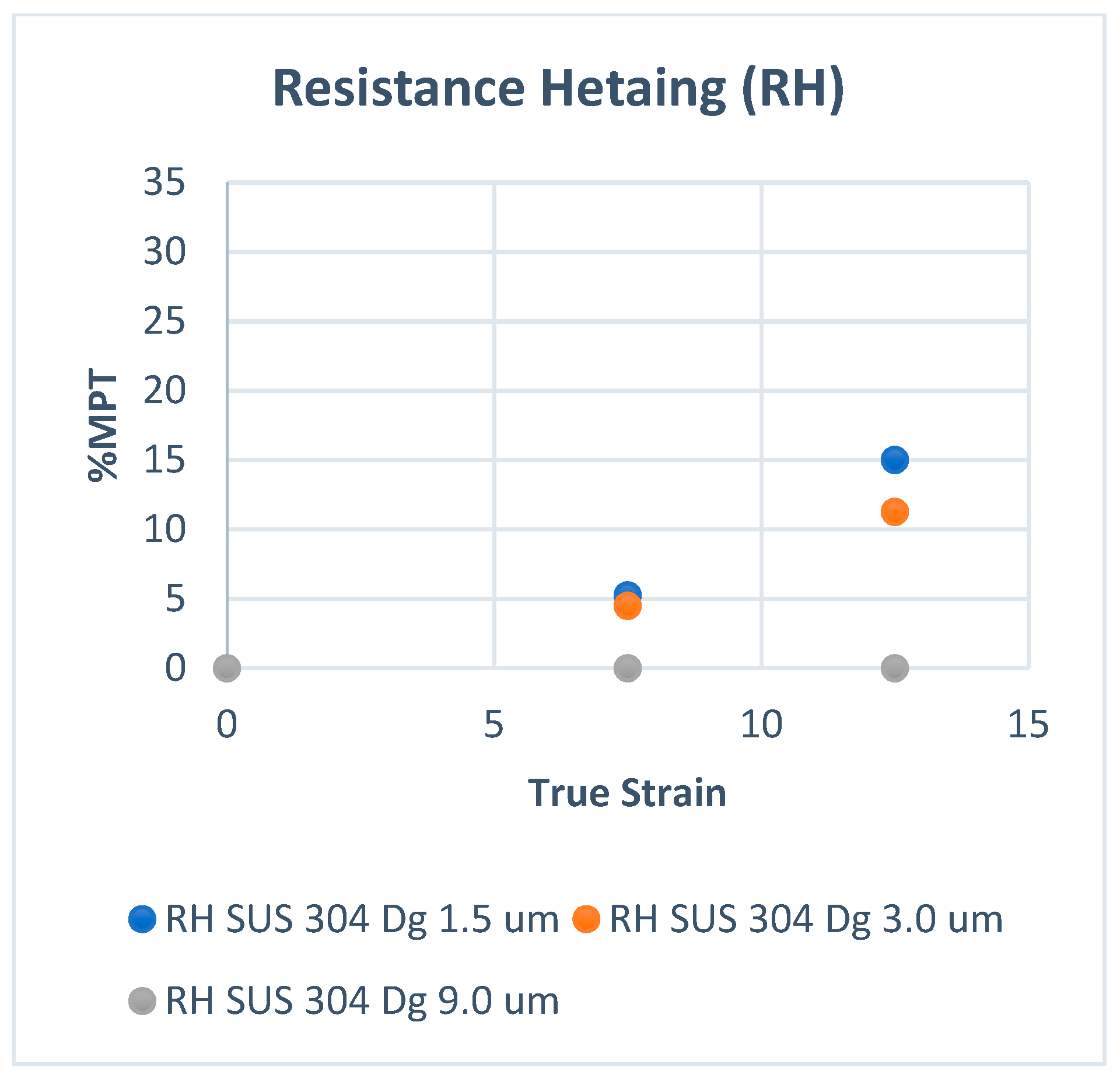

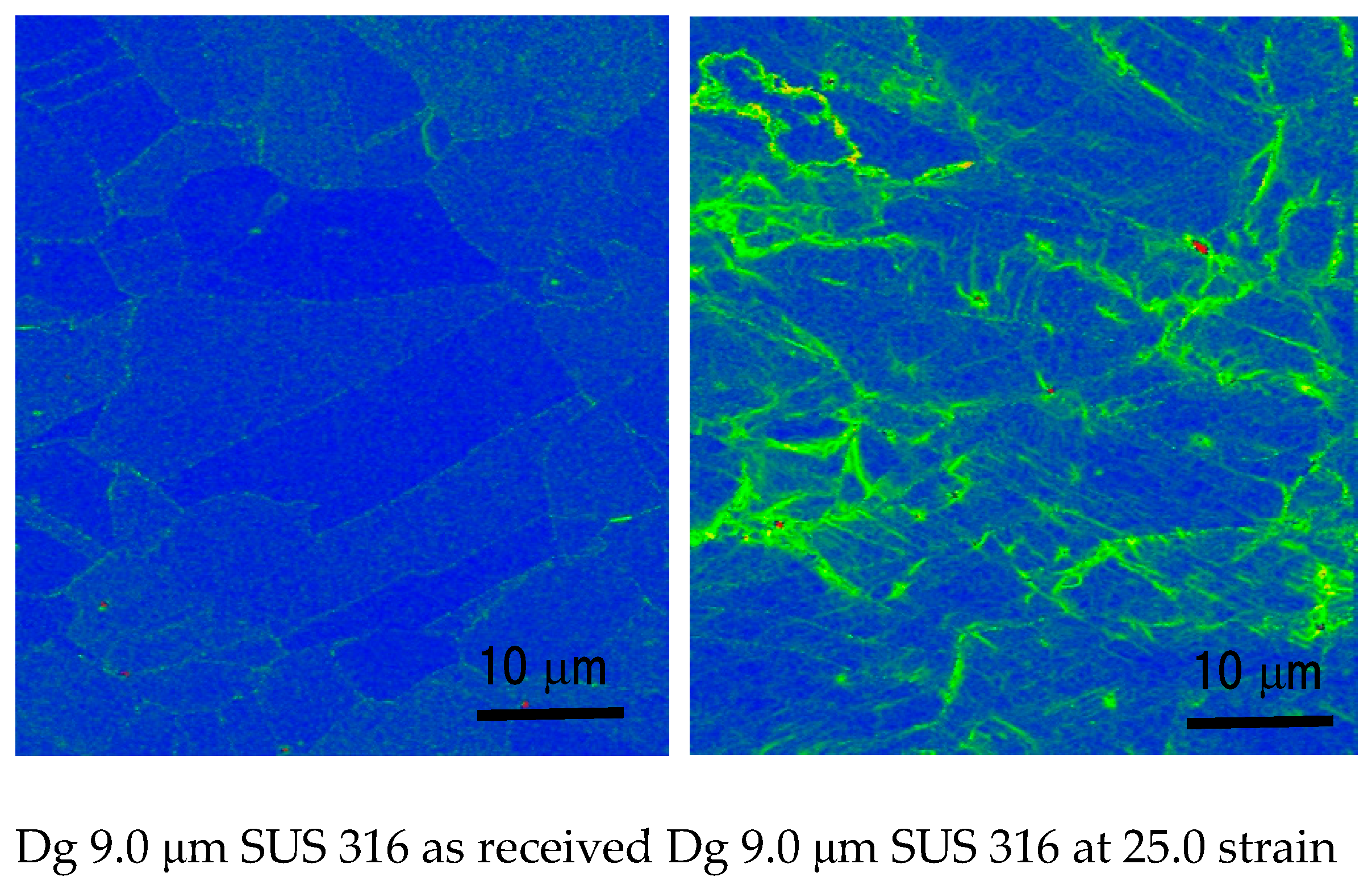

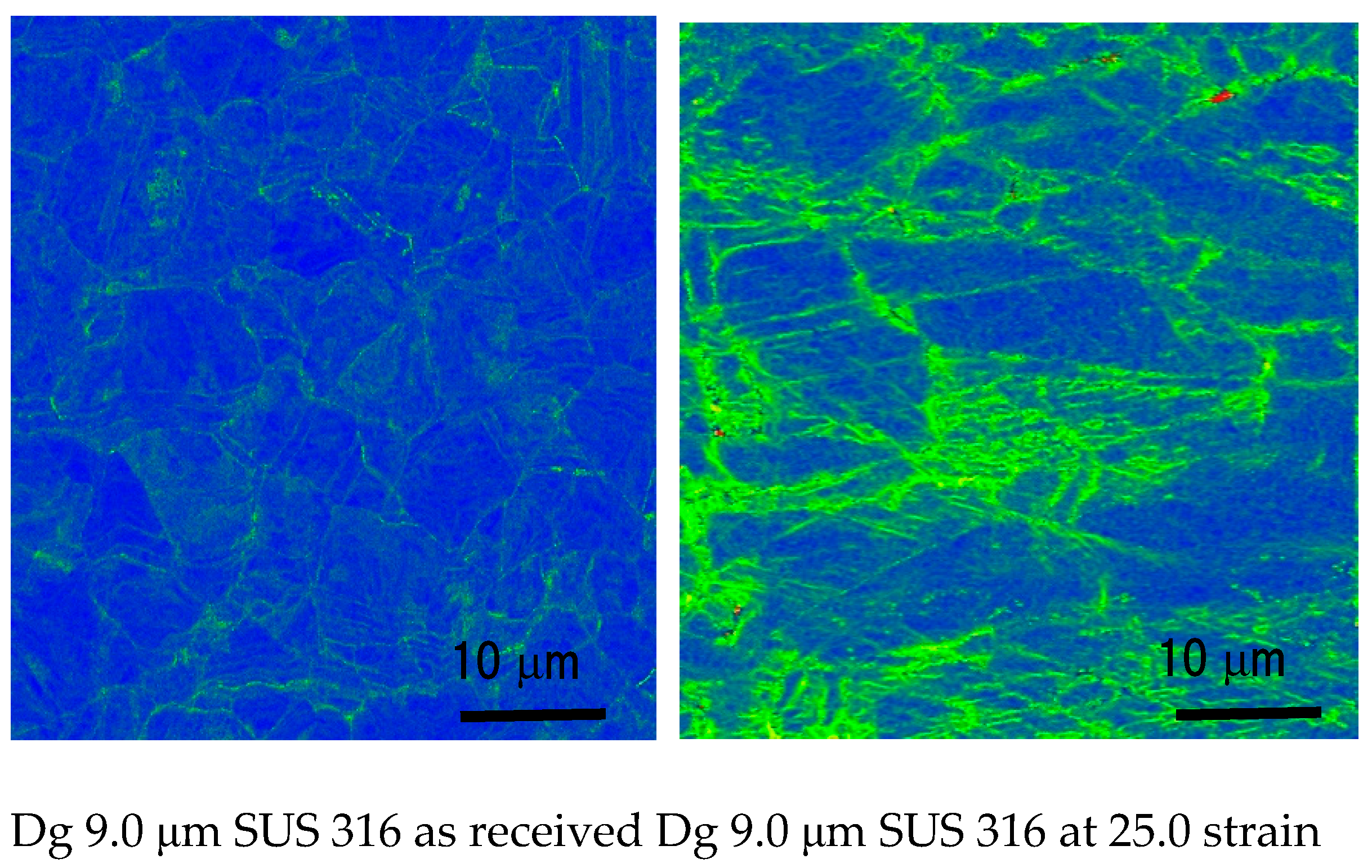

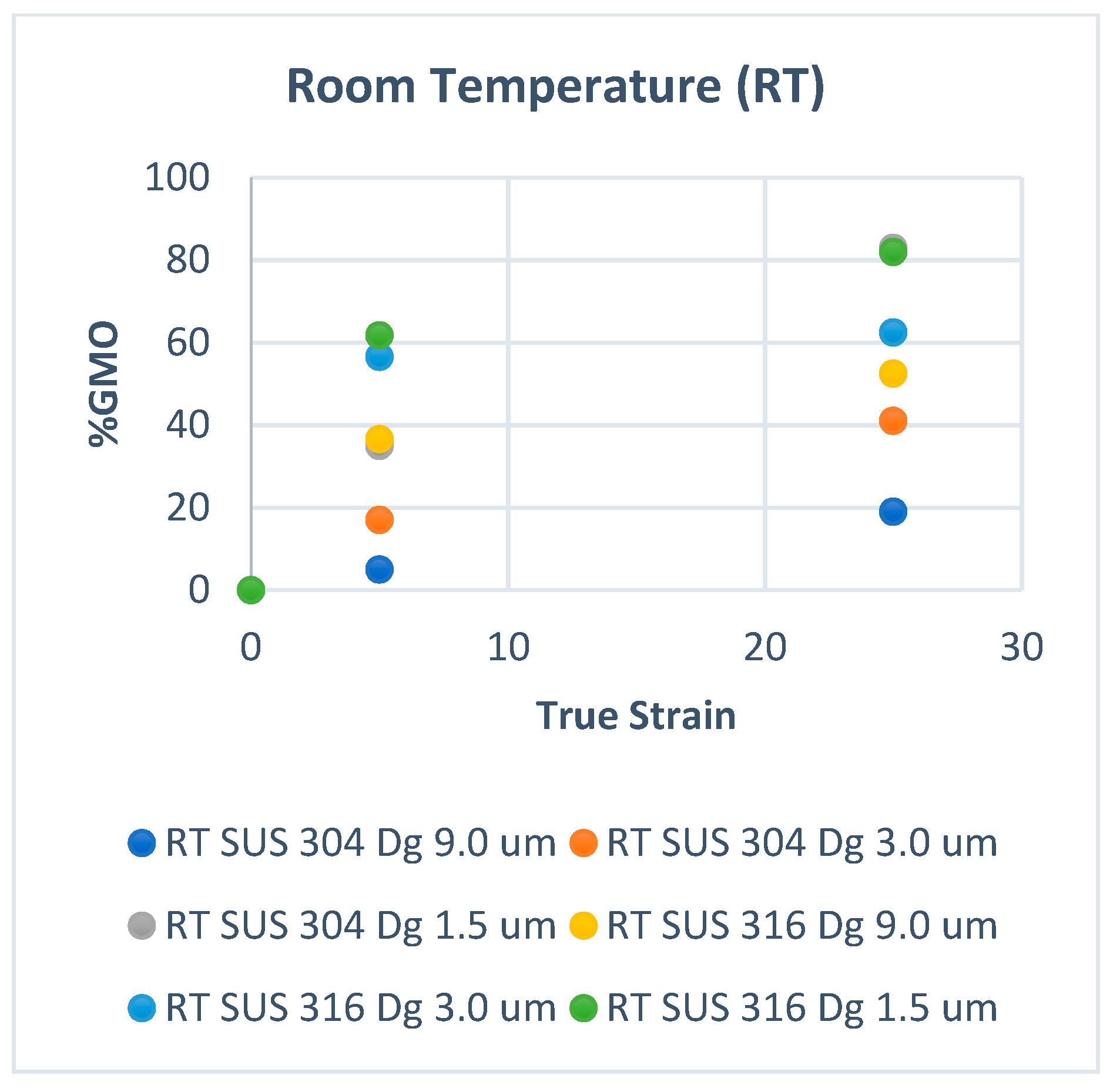

3.1. Influence of the Volume Fraction of MPT on Surface Roughening

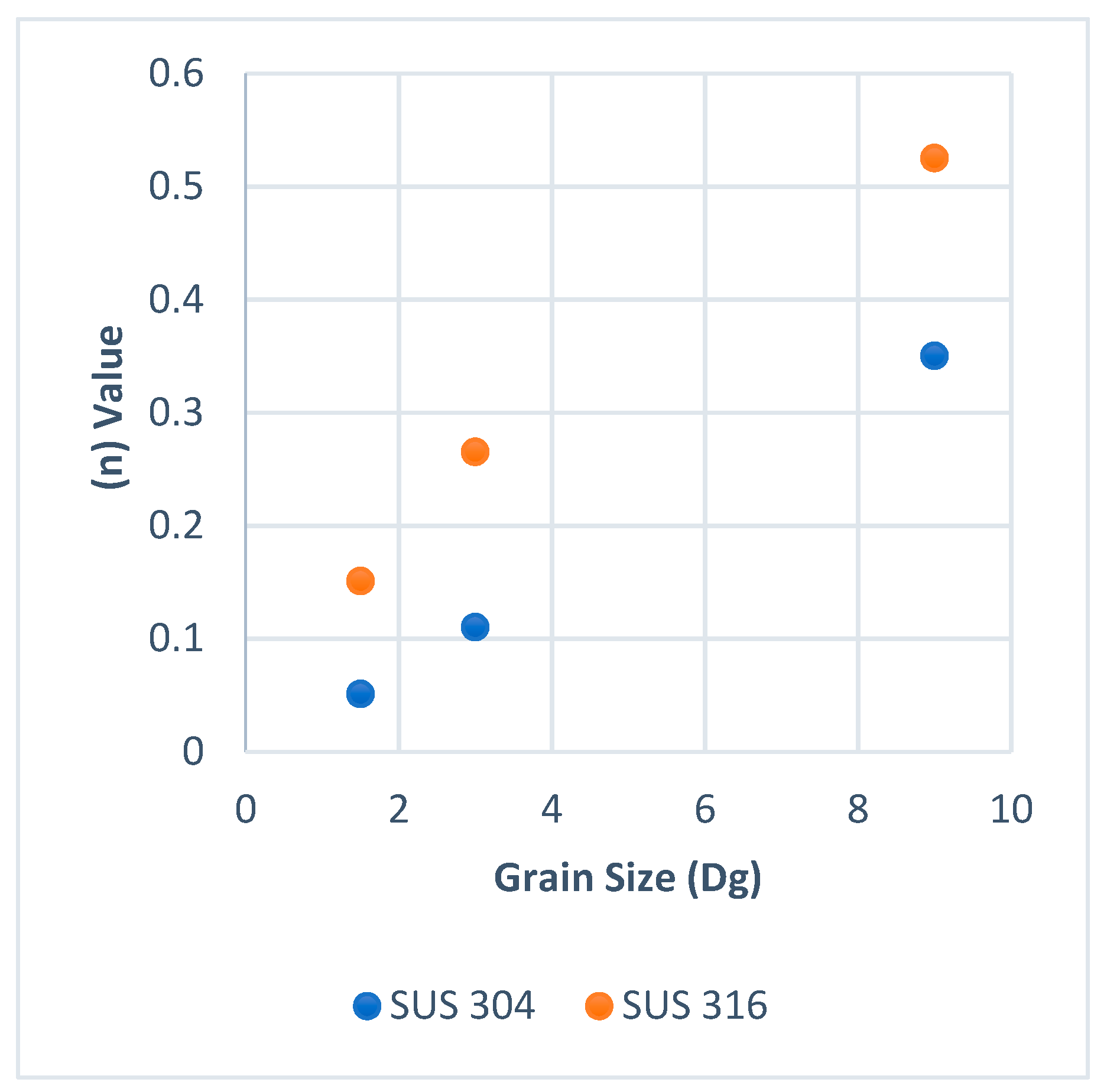

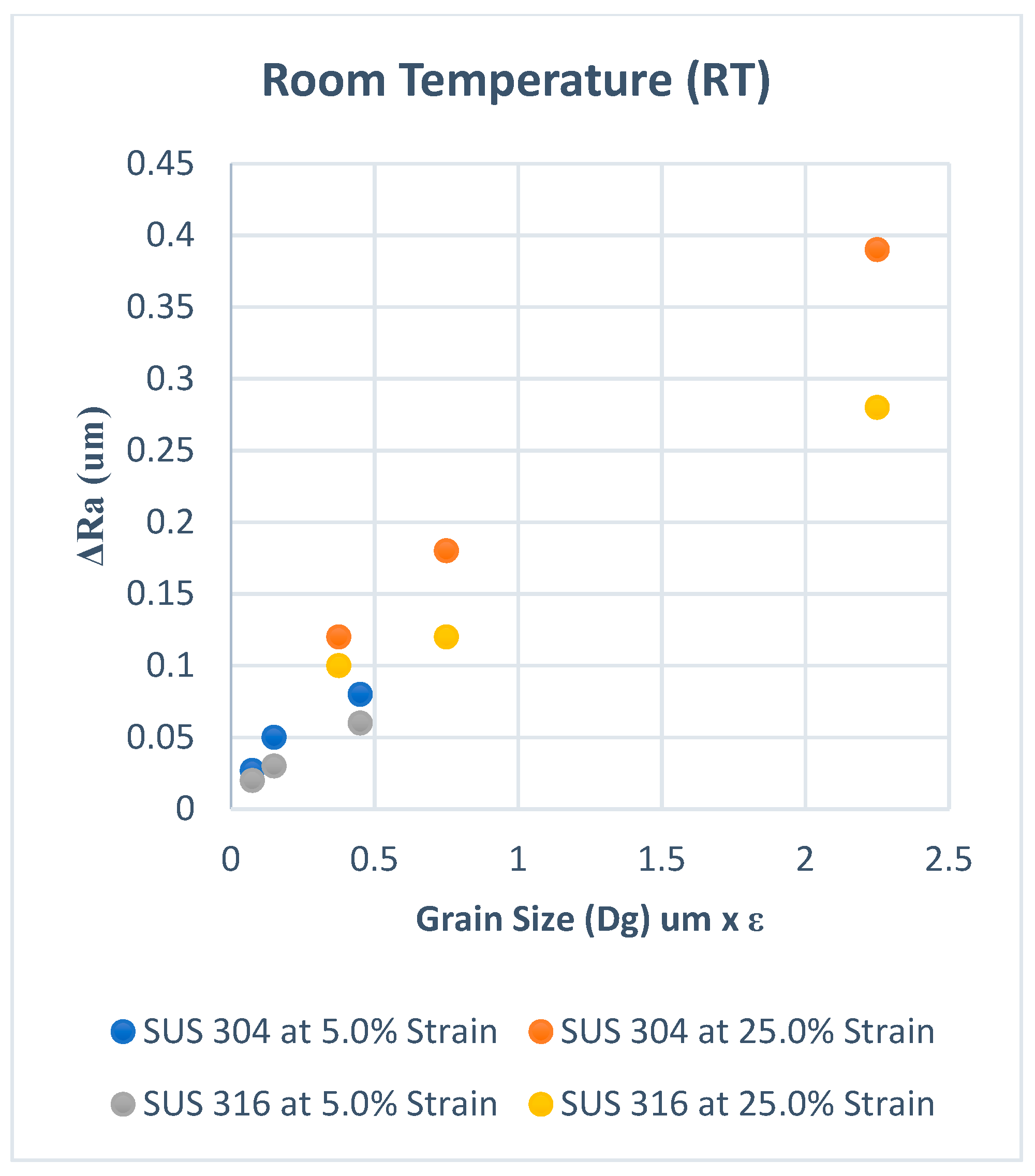

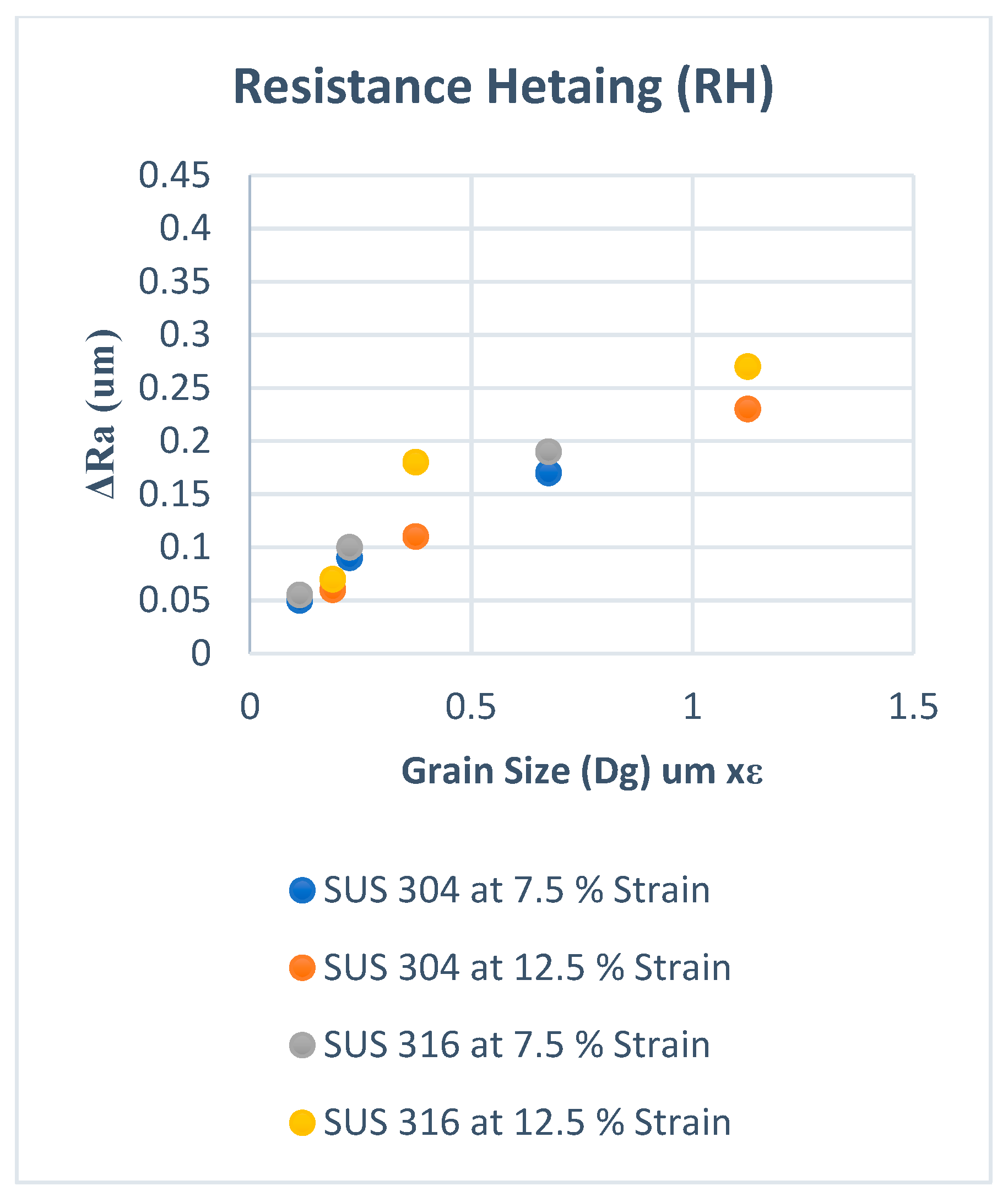

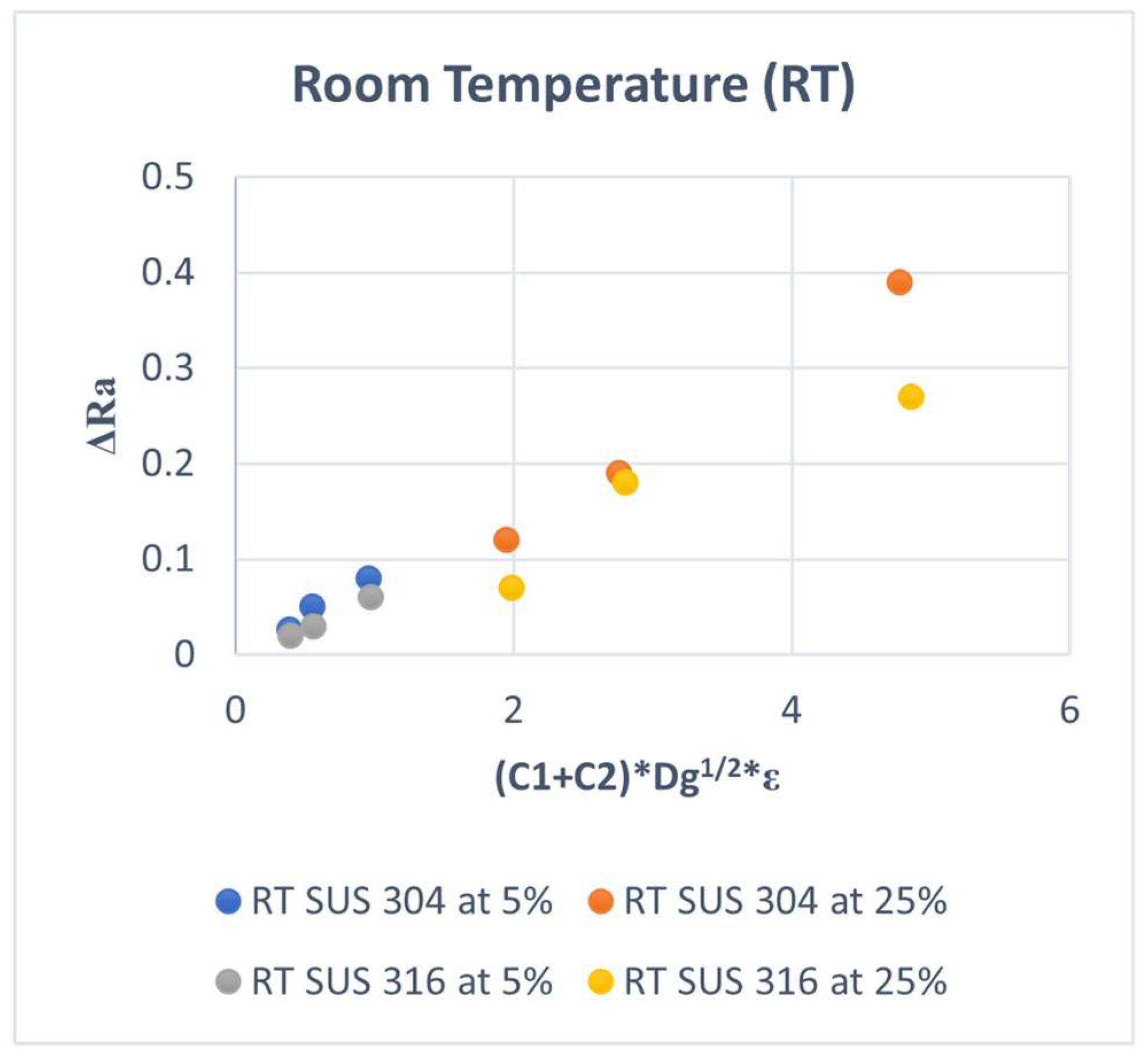

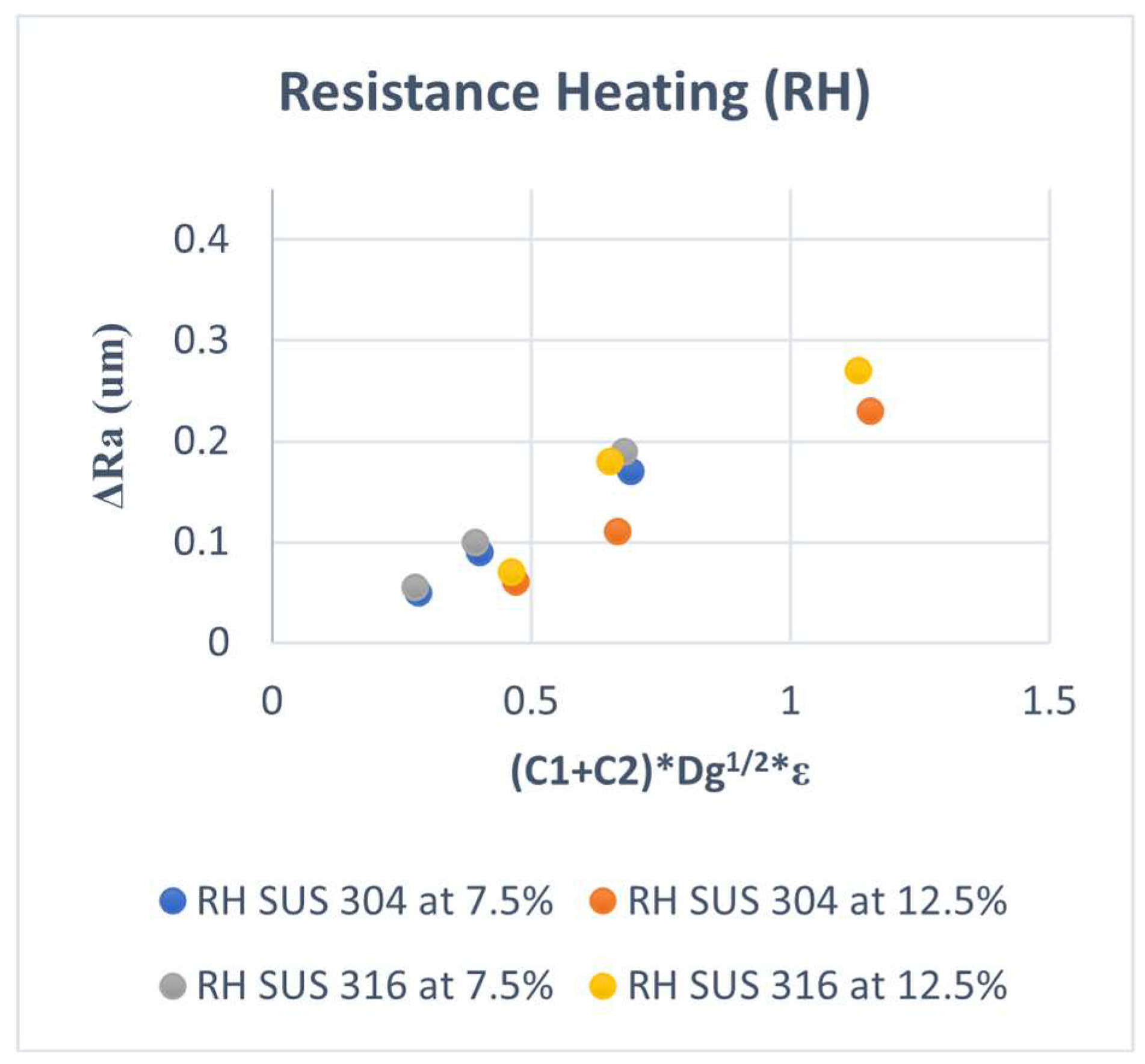

3.2. Quantitative Model

4. Conclusions

- The volume fraction of MPT and GMO after the tensile test is accounted for, and both FMPT and FGMO are proportional to the plastic strain;

- The MPT is considered to be a factor that influenced the surface roughening since the SUS 304 TMF showed higher surface roughness than SUS 316 at room temperature, but SUS 304 and SUS 316 TMF were almost the same at elevated temperatures at the same strain level;

- A new theoretical model that takes FMPT and FGMO into account is proposed, and the difference in the calculated surface roughness for SUS304 and SUS316 at various grain sizes becomes smaller in the new theoretical model than in the conventional models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Brussel, H.; Peirs, J.; Reynaerts, D.; Delchambre, A.; Reinhart, G.; Roth, N.; Weck, M.; Zussman, E. Assembly of microsystems. Ann. CIRP 2000, 49, 451–472. [Google Scholar] [CrossRef]

- Xue, Z.Y.; Zhou, S.; Wei, X.C. Influence of pre-transformed martensite on work-hardening behavior of SUS 304 metastable austenitic stainless steel. J. Iron Steel Res. Int. 2010, 17, 51–55. [Google Scholar] [CrossRef]

- Gillner, A.; Helrung, D.; Baye, A.; Schepp, F.; Erhardt, R. Miniarturisierung von Bauteilen Komponenten, 7; Umformtecniches Kolloquium: Darmstadt, Germany, 2000; pp. 107–116. [Google Scholar]

- Milad, M.; Zreiba, N.; Elhalouani, F.; Baradai, C. The effect of Cold Work on Structure and Properties of AISI 304 Stainless Steel. J. Mater. Process. Technol. 2008, 203, 80–85. [Google Scholar] [CrossRef]

- Sundaram, P.A. Deformation -induced surface roughening studies in an AISI 1090 spheroidized steel. Scr. Metall. Et Mater. 1995, 33, 1093–1099. [Google Scholar] [CrossRef]

- Furushima, T.; Aoto, K.; Alexandrov, S. A new compression test for determining free surface roughness evolution in thin metals. Metals 2019, 9, 451. [Google Scholar] [CrossRef] [Green Version]

- Dautzenberg, J.H.; Kals, J.A.G. Advanced Technology of Plasticity; Japan Society for Technology of Plasticity/Japan Society of Precision Engineering: Tokyo, Japan, 1984; Volume 1, p. 186. [Google Scholar]

- Diani, J.M.; Parks, D.M. Effects of strain state on the kinetics of strain-induced martensite in steels. J. Mech. Phys. Solids 1998, 46, 1613–1635. [Google Scholar] [CrossRef]

- Iwamoto, T.; Tsuta, T. Computational simulation of the dependence of the austenitic grain size on the deformation behavior of TRIP steels. Int. J. Plast. 2000, 16, 791–804. [Google Scholar] [CrossRef]

- Kubo, M.; Nakazawa, Y.; Hama, T.; Takuda, H. Effect of microstructure on surface roughening in stretch forming of steel sheets. ISIJ Int. 2017, 57, 2185–2193. [Google Scholar] [CrossRef] [Green Version]

- Becker, R. Effect of strain localization on surface roughening during sheet forming. Acta Mater. 1998, 46, 1385–1401. [Google Scholar] [CrossRef]

- Huang, J.X.; Ye, X.N.; Xu, Z. Effect of cold rolling on microstructure and mechanical properties of AISI 301LN metastable austenitic stainless steels. Iron Steel Res. Int. 2012, 19, 59–63. [Google Scholar] [CrossRef]

- Choi, J.Y.; Ji, J.H.; Hwang, S.W.; Park, K.T. Strain induced martensitic transformation of Fe-20Cr-5Mn-0,2Ni duplex stainless steel during cold rolling: Effects of nitrogen addition. Mater. Sci. Eng. A 2011, 528, 6012–6019. [Google Scholar] [CrossRef]

- Foecke, T.; Gnaeupel-Herold, T. Robustness of the sheet metal spring back cup test. Metall. Mater. Trans. A 2006, 37, 3503–3510. [Google Scholar] [CrossRef]

- Tsuyoshi, F.; Tetsuro, M.; Manabe, K.-I.; Alexandrov, S. Prediction of Free Surface Roughening by 2D and 3D model considering Material Inhomogeneity. J. Solid Mech. Mater. Eng. 2011, 5, 978–990. [Google Scholar]

- Nie, N.; Su, L.; Deng, G.; Li, H.; Yu, H.; Tieu, A.K. A review on plastic deformation induced surface/interface roughening of sheet metallic materials. J. Mater. Res. Technol. 2021, 15, 6574–6607. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Takakura, N.; Imatani, S. Increase in forming limit of sheet metals by removal of surface roughening with plastic strain (balanced biaxial stretching of aluminium sheets and foils. J. Mater. Processing Technol. 1995, 48, 27–34. [Google Scholar] [CrossRef]

- Mahmudi, R.; Mehdizadeh, M. Surface roughening during uniaxial and equibiaxial stretching of 70-30 brass sheets. J. Mater. Processing Technol. 1998, 80–81, 707–712. [Google Scholar] [CrossRef]

- Kubo, M.; Hama, T.; Tsunemi, Y.; Nakazawa, Y.; Takuda, H. Influence of strain ratio on surface roughening in biaxial stretching of IF steel sheets. ISIJ Int. 2018, 58, 704–713. [Google Scholar] [CrossRef] [Green Version]

- Aziz, A.; Yang, M.; Shimizu, T.; Furushima, T. Effect of Martensitic Transformation and Grain Misorientation on The Surface Roughening of SUS 304 and 316 thin metal foils. Eng 2021, 2, 372–385. [Google Scholar] [CrossRef]

- Aziz, A.; Yang, M.; Shimizu, T.; Furushima, T. The relationship between surface roughening and resistance heating in austenitic thin metal foils of SUS 304 and SUS 316 during tensile test. Int. J. Res. Eng. Technol. 2021, 1. Available online: https://gnpublication.org/index.php/et/article/view/1942 (accessed on 25 April 2022).

- Mola, J.; Ren, M. On the hardness of high carbon ferrous martensite. IOP Conf. Mater. Sci. Eng. 2018, 373, 012004. [Google Scholar] [CrossRef]

- Qiu, Z.; Tetsuhide, S.; Tomomi, S.; Ming, Y. Tensile properties and constitutive model of ultra thin pure titanium foils at elevated temperatures in microforming assisted by resistance heating method. Mater. Des. 2014, 63, 389–397. [Google Scholar]

- Tomita, Y.; Shibutani, Y. Estimation of deformation behavior of trip steels-smooth/ringed—Notched specimen under monotonic and cyclic loading. Int. J. Plast. 2000, 16, 769–789. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, K.; Hayashi, M.; Takano-Satoh, K.; Matsunaga, H.; Mori, H.; Maki, K.; Onuki, Y.; Suzuki, S.; Stao, S. Characterization of dislocation rearrangement in FCC metals during work hardening using X-ray diffraction line—Profile analysis. Quantum Beam Sci. 2020, 4, 36. [Google Scholar] [CrossRef]

- Kishore, K.; Chandan, A.K.; Hung, P.T.; Kumar, S.; Kawasaki, M.; Gubicza, J. On the enhanced hardening ability and plasticity mechanism in a novel Mn-added-CoCrNi medium entropy alloy during high-pressure torsion. J. Alloys Compd. 2022, 9004, 163941. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain—Induced martensitic nucleation. Metall. Mater. Trans. A 1975, 6, 791. [Google Scholar] [CrossRef]

- Tetsu, N. Effect of deformation—Induced martensitic transformation on the plastic behavior of metastable austenitic stainless steel. Mater. Trans. JIM 1989, 30, 33–45. [Google Scholar]

- Moshtagi, M.; Sato, S. Characterization of dislocation evolution in cyclically loaded austenitic and ferritic stainless steel via XRD line profile analysis. ISIJ Int. 2019, 59, 1591–1598. [Google Scholar] [CrossRef] [Green Version]

- Furushima, T.; Tsunezaki, H.; Manabe, K.; Alexandrov, S. Ductile fracture and free surface roughening behavior of pure copper foils for micro/meso -scale forming. Int. J. Mach. Tool Manuf. 2014, 76, 34–48. [Google Scholar] [CrossRef]

- Furushima, T.; Hitomi, T.; Yutaro, H. Fracture and surface roughening behaviors in micro metal forming. In Proceedings of the 17th International Conference on Metal Forming, Metal Forming 2018, Toyohashi, Japan, 16–19 September 2018; Procedia Manufacturing. Volume 15, pp. 1481–1486. [Google Scholar]

- Tsuyoshi, F.; Hitomi, T.; Tomoko, N.; Manabe, K.-I.; Alexandrov, S. Prediction of Surface Roughening and Necking Behavior for Metal Foils by Inhomogeneous FE material Modelling. Key Eng. Mater. 2013, 554–557, 169–173. [Google Scholar]

- Tsuyoshi, F.; Tomoko, N.; Kanta, S. A new theoretical model of material inhomogeneity for prediction of surface roughening in micro metal forming. CIRP Ann.-Manuf. Technol. 2019, 68, 257–260. [Google Scholar]

- Kawata, H.; Yasutomi, T.; Shirakami, S.; Nakamura, K.; Sakurada, E. Deformation—Induced Martensite Transformation Behavior during Tensile and Compressive Deformation in Low-alloy TRIP Steel Sheets. ISIJ Int. 2021, 61, 527–536. [Google Scholar] [CrossRef]

- Meng, B.; Fu, M.W.; Fu, C.M.; Chen, K.S. Ductile fracture and deformation behavior in progressive microforming. Mater. Des. 2015, 83, 14–25. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aziz, A.; Yang, M.; Shimizu, T.; Furushima, T. Constitutive Model of the Surface Roughening Behavior of Austenitic Stainless Steel. Materials 2022, 15, 4348. https://doi.org/10.3390/ma15124348

Aziz A, Yang M, Shimizu T, Furushima T. Constitutive Model of the Surface Roughening Behavior of Austenitic Stainless Steel. Materials. 2022; 15(12):4348. https://doi.org/10.3390/ma15124348

Chicago/Turabian StyleAziz, Abdul, Ming Yang, Tetsuhide Shimizu, and Tsuyoshi Furushima. 2022. "Constitutive Model of the Surface Roughening Behavior of Austenitic Stainless Steel" Materials 15, no. 12: 4348. https://doi.org/10.3390/ma15124348

APA StyleAziz, A., Yang, M., Shimizu, T., & Furushima, T. (2022). Constitutive Model of the Surface Roughening Behavior of Austenitic Stainless Steel. Materials, 15(12), 4348. https://doi.org/10.3390/ma15124348