A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials

Abstract

1. Introduction

2. Scientometric Analysis

2.1. Methodology

2.2. Scientific Mapping Results and Discussions

2.2.1. Annual Publication Trends

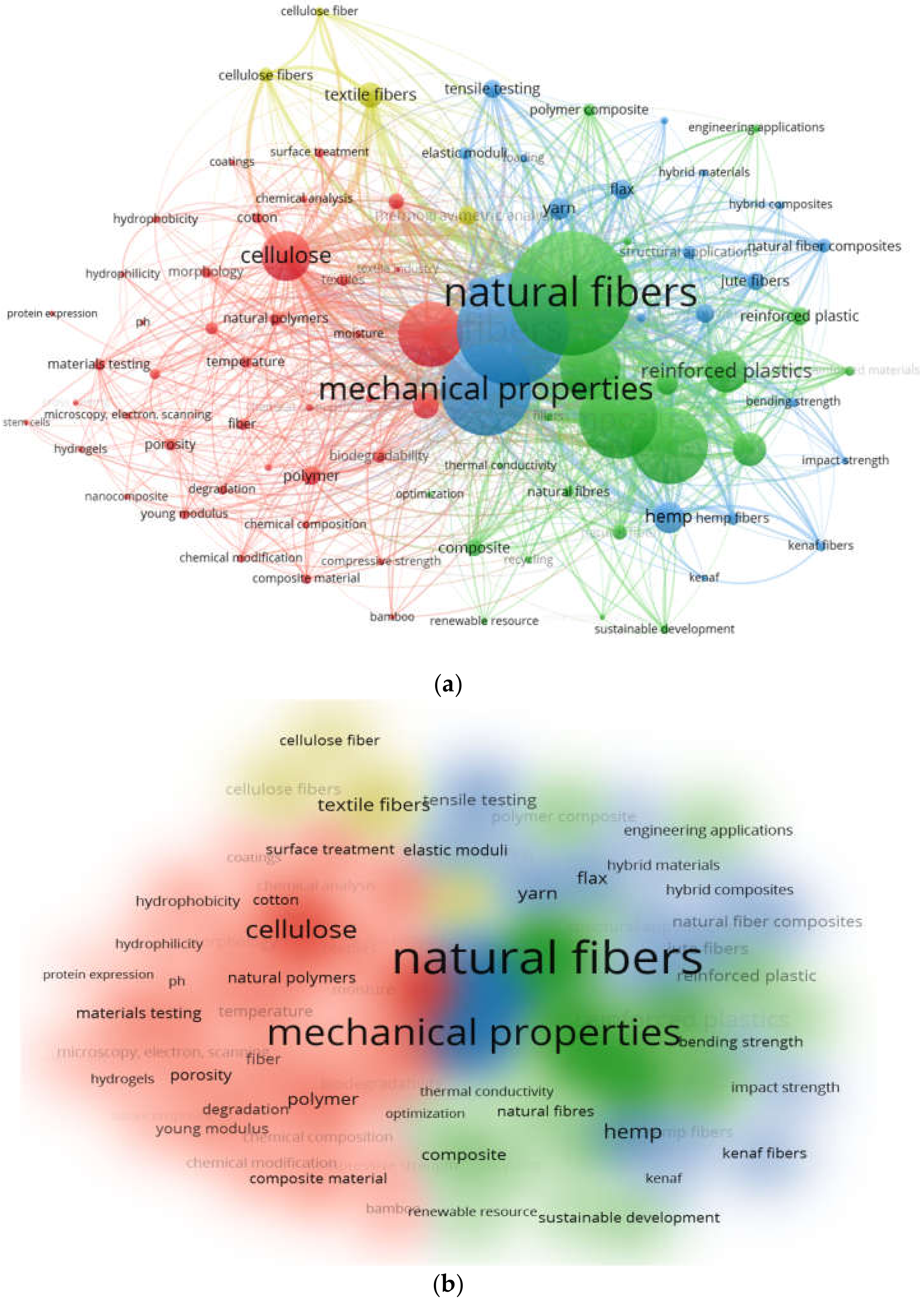

2.2.2. Scientific Mapping of Keyword Co-Occurrence

3. Plant Fiber Types and Annual Production

4. Properties of Plant Fibers

4.1. Chemical Composition

4.2. Physical and Mechanical Properties

5. Treatment Methods of Plant Fibers

6. Application of Plant Fibers as Construction and Building Materials

6.1. Mechanical Properties of Plant-Fiber-Reinforced Cementitious Composites

6.1.1. Compressive Strength

6.1.2. Flexural Strength

7. Conclusions

- Scientometric analysis revealed an emerging trend of plant fibers for cementitious composites, with a considerable rise in the last five years. Furthermore, it was found from the analysis that there is a strong linkage of plant fiber keywords with sustainability, sustainable development, and environmental impact. Hence, it can be said that multiple techniques to reduce environmental degradation by using plant fibers are under consideration today. In this scenario, the interest in the usage of ecologically and environmentally friendly plant fibers and composites has been steadily increasing over the last decade. Their excellent specific properties, environmental advantages, multiscale structure applications, abundant availability, low cost, and technical feasibility are among the reasons behind the popularity that they have gained.

- The plant fibers that are most commonly incorporated in various composites are coir, flax, jute, hemp, and wheat straw, while sugar palm, roselle, and kenaf are emerging fibers due to their high stiffness and mechanical strength, which make them appropriate for multiple applications in the civil engineering field. Generally, the composition of plant fibers is lignin, cellulose, hemicellulose, and pectin. As reported by several researchers, cellulose is the key factor behind the appreciable mechanical properties of plant fibers, as cellulose provides good structural integrity and shape to the fibers. The facial interaction of plant fibers with the surrounding matrix, due to their smaller particle size, enhances the reinforcement effectiveness to a greater extent. However, the structural applications of plant fibers are still quite limited due to the poor fiber–matrix adhesion and low moisture resistance. These limitations of plant fibers can be eliminated by chemical treatments such as alkalization, benzoylation, silane, and acetylation treatment. Among these, alkali treatment has emerged as an effective and economical method.

- Plant-fiber-reinforced composites have several major applications as construction and building materials, including earthquake-resistant housing, bridge piers, canal linings, soil reinforcement, pavements, etc. The mechanical properties of various plant-fiber-reinforced cementitious composites in terms of compressive and flexural strength have been reported in several studies as being improved by up to 43% and 67%, respectively, with respect to reference composites.

- Processing of natural resources by consuming fossil fuels to meet the construction industry’s needs leads to environmental degradation. Furthermore, agricultural/plant waste burning is also a major contributor to air/environmental pollution. Heading towards sustainable development, the incorporation of plant fibers—e.g., agricultural waste/byproducts—as an alternative to synthetic fibers for reinforcement in different composites can play a significant role in sustainable development by reducing landfill pollution. However, the long-term performance of plant fibers (e.g., agricultural waste) and their reinforced composites is questionable, due to their organic nature.

8. Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodgers, P.A.; Milton, A. Research Methods for Product Design; University of Strathclyde: Glasgow, UK, 2013; p. 192. [Google Scholar]

- Vinod, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Yagnaraj, Y.; Khan, S. Extraction and Characterization of Natural Fiber from Stem of Cardiospermum halicababum. J. Nat. Fibers 2019, 18, 898–908. [Google Scholar] [CrossRef]

- Kadier, A.; Ilyas, R.A.; Huzaifah, M.R.M.; Harihastuti, N.; Sapuan, S.M.; Harussani, M.M.; Azlin, N.M.N.; Yuliasni, R.; Ibrahim, R.; Atikah, M.S.N.; et al. Use of industrial wastes as sustainable nutrient sources for bacterial cellulose (BC) production: Mechanism, advances, and future perspectives. Polymers 2021, 13, 3365. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Xian, G.; Li, C.; Huang, X.; Xin, M. Effect of fiber hybridization types on the mechanical properties of carbon/glass fiber reinforced polymer composite rod. Mech. Adv. Mater. Struct. 2021, 1–13. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, F.; Li, C.; Hong, B. Hygrothermal resistance of pultruded carbon, glass and carbon/glass hybrid fiber reinforced epoxy composites. Constr. Build. Mater. 2021, 315, 125710. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments. J. Mater. Res. Technol. 2021, 14, 2812–2831. [Google Scholar] [CrossRef]

- Yang, Q.; Hong, B.; Lin, J.; Wang, D.; Zhong, J.; Oeser, M. Study on the reinforcement effect and the underlying mechanisms of a bitumen reinforced with recycled glass fiber chips. J. Clean. Prod. 2019, 251, 119768. [Google Scholar] [CrossRef]

- Hong, B.; Xian, G. Ageing of a thermosetting polyurethane and its pultruded carbon fiber plates subjected to seawater immersion. Constr. Build. Mater. 2018, 165, 514–522. [Google Scholar] [CrossRef]

- Alyousef, R.; Mohammadhosseini, H.; Ebid, A.A.K.; Alabduljabbar, H.; Ngian, S.P.; Huseien, G.F.; Mohamed, A.M. Enhanced Acoustic Properties of a Novel Prepacked Aggregates Concrete Reinforced with Waste Polypropylene Fibers. Materials 2022, 15, 1173. [Google Scholar] [CrossRef]

- Dilfi, K.F.; Balan, A.; Bin, H.; Xian, G.; Thomas, S. Effect of surface modification of jute fiber on the mechanical properties and durability of jute fiber-reinforced epoxy composites. Polym. Compos. 2018, 39, E2519–E2528. [Google Scholar] [CrossRef]

- Alaskar, A.; Albidah, A.; Alqarni, A.S.; Alyousef, R.; Mohammadhosseini, H. Performance evaluation of high-strength concrete reinforced with basalt fibers exposed to elevated temperatures. J. Build. Eng. 2020, 35, 102108. [Google Scholar] [CrossRef]

- Petroudy, S.D. Physical and Mechanical Properties of Natural Fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–83. [Google Scholar]

- Rognoli, V.; Karana, E.; Pedgley, O. Natural fibre composites in product design: An investigation into material perception and acceptance. In Proceedings of the 2011 Conference on Designing Pleasurable Products and Interfaces, Milano, Italy, 22–25 June 2011; pp. 1–4. [Google Scholar]

- Ilyas, R.; Sapuan, S.; Asyraf, M.; Atikah, M.; Ibrahim, R.; Norrrahim, M.N.; Yasim-Anuar, T.A.; Megashah, L.N. Mechanical and Dynamic Mechanical Analysis of Bio-Based Composites. In Mechanical and Dynamic Properties of Biocomposites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021; pp. 49–76. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Efficiency of basalt fiber length and content on mechanical and microstructural properties of hybrid fiber concrete. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2135–2152. [Google Scholar] [CrossRef]

- Samaei, S.E.; Berardi, U.; Soltani, P.; Taban, E. Experimental and modeling investigation of the acoustic behavior of sustainable kenaf/yucca composites. Appl. Acoust. 2021, 183, 108332. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane bagasse waste fibers as novel thermal insulation and sound-absorbing materials for application in sustainable buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Abdi, D.D.; Monazzam, M.; Taban, E.; Putra, A.; Golbabaei, F.; Khadem, M. Sound absorption performance of natural fiber composite from chrome shave and coffee silver skin. Appl. Acoust. 2021, 182, 108264. [Google Scholar] [CrossRef]

- Samaei, S.E.; Berardi, U.; Taban, E.; Soltani, P.; Mousavi, S.M. Natural fibro-granular composite as a novel sustainable sound-absorbing material. Appl. Acoust. 2021, 181, 108157. [Google Scholar] [CrossRef]

- Taban, E.; Valipour, F.; Abdi, D.D.; Amininasab, S. Mathematical and experimental investigation of sound absorption behavior of sustainable kenaf fiber at low frequency. Int. J. Environ. Sci. Technol. 2020, 18, 2765–2780. [Google Scholar] [CrossRef]

- Taban, E.; Amininasab, S.; Soltani, P.; Berardi, U.; Abdi, D.D.; Samaei, S.E. Use of date palm waste fibers as sound absorption material. J. Build. Eng. 2021, 41, 102752. [Google Scholar] [CrossRef]

- Taban, E.; Soltani, P.; Berardi, U.; Putra, A.; Mousavi, S.M.; Faridan, M.; Samaei, S.E.; Khavanin, A. Measurement, modeling, and optimization of sound absorption performance of Kenaf fibers for building applications. Build. Environ. 2020, 180, 107087. [Google Scholar] [CrossRef]

- Taban, E.; Mirzaei, R.; Faridan, M.; Samaei, E.; Salimi, F.; Tajpoor, A.; Ghalenoei, M. Morphological, acoustical, mechanical and thermal properties of sustainable green Yucca (Y. gloriosa) fibers: An exploratory investigation. J. Environ. Health Sci. Eng. 2020, 18, 883–896. [Google Scholar] [CrossRef]

- Alyousef, R.; Mohammadhosseini, H.; Deifalla, A.F.; Ngian, S.P.; Alabduljabbar, H.; Mohamed, A.M. Synergistic effects of modified sheep wool fibers on impact resistance and strength properties of concrete composites. Constr. Build. Mater. 2022, 336, 127550. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Ramu, P.; Kumar, C.J.; Palanikumar, K. Mechanical Characteristics and Terminological Behavior Study on Natural Fiber Nano reinforced Polymer Composite—A Review. Mater. Today Proc. 2019, 16, 1287–1296. [Google Scholar] [CrossRef]

- Otto, G.P.; Moisés, M.P.; Carvalho, G.; Rinaldi, A.W.; Garcia, J.C.; Radovanovic, E.; Fávaro, S.L. Mechanical properties of a polyurethane hybrid composite with natural lignocellulosic fibers. Compos. Part B Eng. 2017, 110, 459–465. [Google Scholar] [CrossRef]

- Ude, A.U.; Eshkoor, R.A.; Azhari, C.H. Crashworthy characteristics of axial quasi-statically compressed Bombyx mori composite cylindrical tubes: Experimental. Fibers Polym. 2017, 18, 1594–1601. [Google Scholar] [CrossRef]

- Ude, A.U.; Azhari, C.H. Lateral crashworthiness response of bombyx mori fibre/glass–fibre/epoxy hybrid composite cylindrical tubes-experimental. AIMS Mater. Sci. 2019, 6, 1227–1239. [Google Scholar] [CrossRef]

- Mulenga, T.; Ude, A.U.; Chinnasamy, V. Concise review on the mechanical characteristics of hybrid natural fibres with filler content. AIMS Mater. Sci. 2020, 7, 650–664. [Google Scholar] [CrossRef]

- De Azevedo, A.R.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Węcławski, B.T.; Fan, M.; Hui, D. Compressive behaviour of natural fibre composite. Compos. Part B Eng. 2014, 67, 183–191. [Google Scholar] [CrossRef]

- Tisserat, B.; Montesdeoca, N.; Boddu, V.M. Accelerated Thermal Aging of Bio-Based Composite Wood Panels. Fibers 2020, 8, 32. [Google Scholar] [CrossRef]

- Shireesha, Y.; Suresh, B.V.; Bahubalendruni, M.R.; Nandipati, G. Experimental Investigation on Mechanical Properties of Bi-Directional Hybrid Natural Fibre Composite (HNFC). Mater. Today Proc. 2019, 18, 165–174. [Google Scholar] [CrossRef]

- Bambach, M.R. Direct comparison of the structural compression characteristics of natural and synthetic fiber-epoxy composites: Flax, jute, hemp, glass and carbon fibers. Fibers 2020, 8, 62. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Alyousef, R.; Mohammadhosseini, H.; Ebid, A.A.K.; Alabduljabbar, H.; Ngian, S.P.; Mohamed, A.M. Durability Enhancement of Sustainable Concrete Composites Comprising Waste Metalized Film Food Packaging Fibers and Palm Oil Fuel Ash. Sustainability 2022, 14, 5253. [Google Scholar] [CrossRef]

- Parbin, S.; Waghmare, N.K.; Singh, S.K.; Khan, S. Mechanical properties of natural fiber reinforced epoxy composites: A review. Procedia Comput. Sci. 2019, 152, 375–379. [Google Scholar] [CrossRef]

- Eshkoor, R.; Ude, A.; Sulong, A.; Zulkifli, R.; Ariffin, A.; Azhari, C. Energy absorption and load carrying capability of woven natural silk epoxy–triggered composite tubes. Compos. Part B Eng. 2015, 77, 10–18. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Effect of pre-treatment and content of wheat straw on energy absorption capability of concrete. Constr. Build. Mater. 2019, 224, 572–583. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Effect of Fibre Content on Splitting-Tensile Strength of Wheat Straw Reinforced Concrete for Pavement Applications. Key Eng. Mater. 2018, 765, 349–354. [Google Scholar] [CrossRef]

- Farooqila, M.; Ali, M. Compressive behavior of wheat straw reinforced concrete for pavement applications. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Farooqi, M.U.; Ali, M. Effect of Fibre Content on Compressive Strength of Wheat Straw Reinforced Concrete for Pavement Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 422, 012014. [Google Scholar] [CrossRef]

- Li, L.; Khan, M.; Bai, C.; Shi, K. Uniaxial Tensile Behavior, Flexural Properties, Empirical Calculation and Microstructure of Multi-Scale Fiber Reinforced Cement-Based Material at Elevated Temperature. Materials 2021, 14, 1827. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-Ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of Supplementary Cementitious Materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Khan, U.A.; Jahanzaib, H.M.; Khan, M.; Ali, M. Improving the Tensile Energy Absorption of High Strength Natural Fiber Reinforced Concrete with Fly-Ash for Bridge Girders. In Key Engineering Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2018; Volume 765, pp. 335–342. [Google Scholar]

- De Azevedo, A.R.G.; Nascimento, M.; Carmo, D.D.; Marvila, M.T.; Xavier, G.D.C.; Monteiro, S.N. Environmental and Durability Perspective of the Use of Curaua Fiber Treated in Mortars. J. Renew. Mater. 2022, 10, 2409–2429. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; Cecchin, D.; Costa, J.M.; de Castro Xavier, G.; Carmo, D.; Monteiro, S.N. Durability of coating mortars containing açaí fibers. Case Stud. Constr. Mater. 2020, 13, e00406. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Cao, M.; Mao, Y.; Khan, M.; Si, W.; Shen, S. Different testing methods for assessing the synthetic fiber distribution in cement-based composites. Constr. Build. Mater. 2018, 184, 128–142. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Khan, M.; Yin, H.; Guan, J. Review on different testing methods and factors affecting fracture properties of fiber reinforced cementitious composites. Constr. Build. Mater. 2020, 273, 121766. [Google Scholar] [CrossRef]

- Cao, M.; Xie, C.; Li, L.; Khan, M. Effect of different PVA and steel fiber length and content on mechanical properties of CaCO3 whisker reinforced cementitious composites. Mater. Construcción 2019, 69, 200. [Google Scholar] [CrossRef]

- Onyekwere, O.; Igboanugo, A.; Adeleke, T. Optimisation of acetylation parameters for reduced moisture absorption of bamboo fibre using Taguchi experimental design and genetic algorithm optimisation tools. Niger. J. Technol. 2019, 38, 104. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mishra, M.; Oksman, K. Chemical composition, crystallinity and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofiber. BioResources 2009, 4, 626–639. [Google Scholar]

- Alyousef, R.; Mohammadhosseini, H.; Ebid, A.A.K.; Alabduljabbar, H. An Integrated Approach to Using Sheep Wool as a Fibrous Material for Enhancing Strength and Transport Properties of Concrete Composites. Materials 2022, 15, 1638. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, G.M.G.; Cecchin, D.; de Azevedo, A.R.G.; Valadão, I.C.R.P.; Costa, K.A.; Rodrigues, T.; Ferreira, F.; Amaral, P.I.S.; Hüther, C.M.; Sousa, F.A.; et al. Bibliometric analysis on the use of natural fibers in construction materials. Agron. Res. 2021, 19, 1455–1466. [Google Scholar]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Liao, H.; Tang, M.; Luo, L.; Li, C.; Chiclana, F.; Zeng, X.-J. A Bibliometric Analysis and Visualization of Medical Big Data Research. Sustainability 2018, 10, 166. [Google Scholar] [CrossRef]

- Markoulli, M.P.; Lee, C.I.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Saka, A.B.; Chan, D.W.M. A Scientometric Review and Metasynthesis of Building Information Modelling (BIM) Research in Africa. Buildings 2019, 9, 85. [Google Scholar] [CrossRef]

- Goulden, S.; Erell, E.; Garb, Y.; Pearlmutter, D. Green building standards as socio-technical actors in municipal environmental policy. Build. Res. Inf. 2015, 45, 414–425. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Contribution of plant fibers in improving the behavior and capacity of reinforced concrete for structural applications. Constr. Build. Mater. 2018, 182, 94–107. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Laila, A.M.D.; Rahmah, M. Curing behaviour of unsaturated polyester resin and interfacial shear stress of sugar palm fibre. J. Mech. Eng. Sci. 2017, 11, 2650–2664. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Halim, N.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; Wan Yunus, W.M.Z.; Farid, M.A.A.; et al. Performance evaluation of cellulose nanofiber reinforced polymer composites. Funct. Compos. Struct. 2021, 3, 024001. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Hassan, M.A.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Nishida, H. Performance Evaluation of Cellulose Nanofiber with Residual Hemicellulose as a Nanofiller in Polypropylene-Based Nanocomposite. Polymers 2021, 13, 1064. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Kadier, A.; Kalil, M.S.; Atikah, M.S.N.; Ibrahim, R.; Asrofi, M.; Abral, H.; et al. Nanocellulose/starch biopolymer nanocomposites: Processing, manufacturing, and applications. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 65–88. [Google Scholar]

- De Azevedo, A.R.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; Lima, T.; Fediuk, R.; Olisov, A. Investigation of the potential use of curauá fiber for reinforcing mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Jones, D.; Ormondroyd, G.; Curling, S.; Popescu, C.-M.; Popescu, M.-C. Chemical Compositions of Natural Fibres. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 23–58. [Google Scholar]

- Yang, H.-S.; Kim, D.-J.; Kim, H.-J. Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Jiang, D.; An, P.; Cui, S.; Sun, S.; Zhang, J.; Tuo, T. Effect of Modification Methods of Wheat Straw Fibers on Water Absorbency and Mechanical Properties of Wheat Straw Fiber Cement-Based Composites. Adv. Mater. Sci. Eng. 2020, 2020, 5031025. [Google Scholar] [CrossRef]

- Chin, C.S.; Nepal, B. Material Properties of Agriculture Straw Fibre-Reinforced Concrete. In EcoWISE—Innovative Approaches to Socio-Ecological Sustainability; Springer: Singapore, 2018; pp. 109–120. [Google Scholar] [CrossRef]

- Bederina, M.; Belhadj, B.; Ammari, M.; Gouilleux, A.; Makhloufi, Z.; Montrelay, N.; Quéneudéc, M. Improvement of the properties of a sand concrete containing barley straws—Treatment of the barley straws. Constr. Build. Mater. 2016, 115, 464–477. [Google Scholar] [CrossRef]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical Characterization of Natural Straw Fibers as Aggregates for Construction Materials Applications. Materials 2014, 7, 3034–3048. [Google Scholar] [CrossRef]

- Bainbridge, D.A. Houses of straw. Resour. Eng. Technol. 2005, 12, 7–8. [Google Scholar]

- De Azevedo, A.R.G.; Marvila, M.T.; Antunes, M.L.P.; Rangel, E.C.; Fediuk, R. Technological Perspective for Use the Natural Pineapple Fiber in Mortar to Repair Structures. Waste Biomass Valor. 2021, 12, 5131–5145. [Google Scholar] [CrossRef]

- González, O.M.; Velín, A.; García, A.; Arroyo, C.R.; Barrigas, H.L.; Vizuete, K.; Debut, A. Representative Hardwood and Softwood Green Tissue-Microstructure Transitions per Age Group and Their Inherent Relationships with Physical–Mechanical Properties and Potential Applications. Forests 2020, 11, 569. [Google Scholar] [CrossRef]

- Norizan, M.N.; Malaysia, M.U.P.; Abdan, K.; Salit, M.S.; Mohamed, R.; Mara, M.U.T. Physical, Mechanical and Thermal Properties of Sugar Palm Yarn Fibre Loading on Reinforced Unsaturated Polyester Composite. J. Phys. Sci. 2017, 28, 115–136. [Google Scholar] [CrossRef]

- Thakur, V.; Siṅgha, A.S. Biocomposites; Smithers Rapra Technology Ltd.: Shropshire, UK, 2013. [Google Scholar]

- Mohanty, A.; Fatima, S. Biocomposites for Industrial Noise Control. In Green Biorenewable Biocomposites from Knowledge to Industrial Applications; Taylor & Francis: Abingdon, UK, 2015; pp. 220–261. [Google Scholar]

- Kamaruddin, Z.H.; Jumaidin, R.; Selamat, M.Z.; Ilyas, R. Characteristics and Properties of Lemongrass (Cymbopogan Citratus): A Comprehensive Review. J. Nat. Fibers 2021, 1–18. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Nik Wan, F.; Zulkifli, F.; Harussani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Haghdan, S.R.; Smith, G.D. Sources of Lignin. In Lignin in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–11. [Google Scholar]

- Teixeira, E.D.M.; Bondancia, T.J.; Teodoro, K.B.R.; Corrêa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Sugarcane bagasse whiskers: Extraction and characterizations. Ind. Crop. Prod. 2011, 33, 63–66. [Google Scholar] [CrossRef]

- Ansell, M.P.; Mwaikambo, L.Y. The Structure of Cotton and Other Plant Fibres. In Handbook of Textile Fibre Structure; Elsevier: Amsterdam, The Netherlands, 2009; pp. 62–94. [Google Scholar]

- Syafri, E.; Kasim, A.; Abral, H.; Asben, A. Cellulose nanofibers isolation and characterization from ramie using a chemical-ultrasonic treatment. J. Nat. Fibers 2018, 16, 1145–1155. [Google Scholar] [CrossRef]

- Gassan, J.; Chate, A.; Bledzki, A.K. Calculation of elastic properties of natural fibers. J. Mater. Sci. 2001, 36, 3715–3720. [Google Scholar] [CrossRef]

- Silva, F.; Melo Filho, J.; Toledo Filho, R.; Fairbairn, E. Effect of Reinforcement Ratio on the Mechanical Response of Compression Molded Sisal Fiber Textile Reinforced Concrete. In High Performance Fiber Reinforced Cement Composites (HPFRCC5); Springer: Berlin/Heidelberg, Germany, 2007; pp. 175–182. [Google Scholar]

- Barreto, A.; Rosa, D.; Fechine, P.; Mazzetto, S. Properties of sisal fibers treated by alkali solution and their application into cardanol-based biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 492–500. [Google Scholar] [CrossRef]

- Kumar, P.S.S.; Allamraju, K.V. A review of natural fiber composites [Jute, Sisal, Kenaf]. Mater. Today Proc. 2019, 18, 2556–2562. [Google Scholar] [CrossRef]

- Kumre, A.; Rana, R.; Purohit, R. A Review on mechanical property of sisal glass fiber reinforced polymer composites. Mater. Today Proc. 2017, 4, 3466–3476. [Google Scholar] [CrossRef]

- Kumar, R.; Obrai, S.; Sharma, A. Chemical modifications of natural fiber for composite material. Chem. Sin. 2011, 2, 219–228. [Google Scholar]

- Zainudin, E.; Yan, L.H.; Haniffah, W.; Jawaid, M.; Alothman, O.Y. Effect of coir fiber loading on mechanical and morphological properties of oil palm fibers reinforced polypropylene composites. Polym. Compos. 2013, 35, 1418–1425. [Google Scholar] [CrossRef]

- Daud, Z.; Hatta, M.Z.M.; Kassi, A.S.M.; Aripi, A.M. Analysis of the Chemical Compositions and Fiber Morphology of Pineapple (Ananas comosus) Leaves in Malaysia. J. Appl. Sci. 2014, 14, 1355–1358. [Google Scholar] [CrossRef]

- Cherian, B.M.; Leão, A.L.; de Souza, S.F.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Isolation of nanocellulose from pineapple leaf fibres by steam explosion. Carbohydr. Polym. 2010, 81, 720–725. [Google Scholar] [CrossRef]

- Sonar, T.; Patil, S.; Deshmukh, V.; Acharya, R. Natural fiber reinforced polymer composite material—A review. IOSR J. Mech. Civ. Eng. 2015, 4, 142–147. [Google Scholar]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Mwaikambo, L. Review of the history, properties and application of plant fibres. Afr. J. Sci. Technol. 2006, 7, 121. [Google Scholar]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N.; Ilyas, R. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Medina, A.A.; Baucis, A.G.; Catalan, M.A.; Andia, I.R.; Trangoni, F.; Razquin, M.; Pampiglioni, A.; Vuillermet, A. Características y propiedades físicas de la madera de álamos cultivados en Río Negro, Patagonia Argentina. Madera Bosques 2018, 24, e2411434. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Mani, S.; Lim, C.J.; Womac, A.R.; Hoque, M.; Peng, J.; Jayashankar, T.; Nalmi, L.J.; et al. Physical characterization of wet and dry wheat straw and switchgrass—Bulk and specific density. In Proceedings of the 2007 ASAE Annual Meeting, Minneapolis, MN, USA, 17–20 June 2007; p. 1. [Google Scholar]

- O’Dogherty, M.; Huber, J.; Dyson, J.; Marshall, C. A Study of the Physical and Mechanical Properties of Wheat Straw. J. Agric. Eng. Res. 1995, 62, 133–142. [Google Scholar] [CrossRef]

- United States Department of Agricultural (USDA). Annual Production of Wheat. Available online: https://www.ers.usda.gov/topics/crops/wheat/ (accessed on 14 March 2022).

- Searle, S.; Malins, C. Availability of Cellulosic Residues and Wastes in the EU; International Council on Clean Transportation: Washington, DC, USA, 2013. [Google Scholar]

- Bakker, R.; Elbersen, H.; Poppens, R.; Lesschen, J.P. Rice Straw and Wheat Straw-Potential Feedstocks for the Biobased Economy; NL Agency, WUR, Food Valley: Wageningen, The Netherlands, 2013. [Google Scholar]

- Farooqi, M.U. Potential Utilization of Wheat Straw in Concrete for Pavement Applications from Engineering Perspectives. Ph.D. Thesis, Capital University of Science and Technology, Islamabad, Pakistan, 2021. [Google Scholar]

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef]

- Mtui, G.Y. Recent advances in pretreatment of lignocellulosic wastes and production of value added products. Afr. J. Biotechnol. 2009, 8, 1398–1415. [Google Scholar]

- Zakaria, M.R.; Fujimoto, S.; Hirata, S.; Hassan, M.A. Ball Milling Pretreatment of Oil Palm Biomass for Enhancing Enzymatic Hydrolysis. Appl. Biochem. Biotechnol. 2014, 173, 1778–1789. [Google Scholar] [CrossRef]

- Pereira, P.H.F.; de Freitas Rosa, M.; Cioffi, M.O.H.; de Carvalho Benini, K.C.C.; Milanese, A.C.; Voorwald, H.J.C.; Mulinari, D.R. Vegetal fibers in polymeric composites: A review. Polímeros 2015, 25, 9–22. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-dispersed cellulose nanofiber in low density polyethylene nanocomposite by liquid-assisted extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Tsukegi, T.; Nishida, H. Sustainable one-pot process for the production of cellulose nanofiber and polyethylene/cellulose nanofiber composites. J. Clean. Prod. 2018, 207, 590–599. [Google Scholar] [CrossRef]

- Sharip, N.S.; Yasim-Anuar, T.A.T.; Norrrahim, M.N.F.; Shazleen, S.S.; Nurazzi, N.M.; Sapuan, S.M.; Ilyas, R.A. A Review on Nanocellulose Composites in Biomedical Application. In Composites in Biomedical Applications; CRC Press: Boca Raton, FL, USA, 2020; pp. 161–190. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffin, H.; Yasim-Anuar, T.A.T.; Hassan, M.A.; Nishida, H.; Tsukegi, T. One-pot nanofibrillation of cellulose and nanocomposite production in a twin-screw extruder. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012034. [Google Scholar] [CrossRef]

- Fareez, I.M.; Jasni, A.H.; Norrrahim, M.N.F. Nanofibrillated Cellulose Based Bio-Phenolic Composites. In Phenolic Polymers Based Composite Materials; Springer: Berlin/Heidelberg, Germany, 2021; pp. 139–151. [Google Scholar]

- Faiz Norrrahim, M.N.; Mohd Kasim, N.A.; Knight, V.F.; Mohamad Misenan, M.S.; Janudin, N.; Ahmad Shah, N.A.; Kasim, N.; Wan Yusoff, W.Y.; Mohd Noor, S.A.; Jamal, S.H.; et al. Nanocellulose: A bioadsorbent for chemical contaminant remediation. RSC Adv. 2021, 11, 7347–7368. [Google Scholar] [CrossRef]

- George, J.; Sabapathi, S. Cellulose nanocrystals: Synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 2015, 8, 45. [Google Scholar] [CrossRef]

- Bismarck, A.; Mishra, S.; Lampke, T. Plant Fibers as Reinforcement for Green Composites. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Rai, A.; Joshi, Y. Applications and properties of fibre reinforced concrete. J. Eng. Res. Appl. 2014, 4, 123–131. [Google Scholar]

- Doan, T.T.L. Investigation on Jute Fibres and Their Composites Based on Polypropylene and Epoxy Matrices; Technical University of Dresden: Dresden, Germany, 2006. [Google Scholar]

- Luo, S.; Netravali, A.N. Interfacial and mechanical properties of environment-friendly “green” composites made from pineapple fibers and poly(hydroxybutyrate-co-valerate) resin. J. Mater. Sci. 1999, 34, 3709–3719. [Google Scholar] [CrossRef]

- Baiardo, M.; Zini, E.; Scandola, M. Flax fibre–polyester composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 703–710. [Google Scholar] [CrossRef]

- Sankar, P.H.; Reddy, Y.M.; Reddy, K.H.; Kumar, M.A.; Ramesh, A. The Effect of Fiber Length on Tensile Properties of Polyester Resin Composites Reinforced by the Fibers of Sansevieria trifasciata. Int. Lett. Nat. Sci. 2014, 8, 7–13. [Google Scholar] [CrossRef]

- Behdouj, Z.; Jamshidi, M.; Latifi, M.; Halvaei, M. Study on effect of fiber cross section shape of polypropylene fibers on mechanical properties of cement composites. In Proceedings of the 4th International Conference on Concrete & Development, Jelgava, Latvia, April 2013. [Google Scholar]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Mukhopadhyay, S.; Fangueiro, R. Physical Modification of Natural Fibers and Thermoplastic Films for Composites—A Review. J. Thermoplast. Compos. Mater. 2009, 22, 135–162. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Polym. Mech. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Wood fibres as reinforcements in natural fibre composites: Structure, properties, processing and applications. In Natural Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–65. [Google Scholar]

- Mohnty, A.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, B.R.; Hinrichsen, G. Natural Fibers, Biopolymers, and Biocomposites: An Introduction. In Natural Fibers, Biopolymers and Biocomposites; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Coffin, D. Wood biocomposites–extending the property range of paper products. In Mechanics of Paper Products; De Gruyter Textbook: Berlin/Heidelberg, Germany, 2011; Volume 10. [Google Scholar]

- Lilholt, H.; Lawther, J.M. Natural Organic Fibres. In Comprehensive Composite Materials; Kelly, A., Zweben, C., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Yan, L.; Su, S.; Chouw, N. Microstructure, flexural properties and durability of coir fibre reinforced concrete beams externally strengthened with flax FRP composites. Compos. Part B Eng. 2015, 80, 343–354. [Google Scholar] [CrossRef]

- Amiandamhen, S.O.; Meincken, M.; Tyhoda, L. Natural Fibre Modification and Its Influence on Fibre-matrix Interfacial Properties in Biocomposite Materials. Fibers Polym. 2020, 21, 677–689. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Putra, A.; Or, K.H.; Selamat, M.Z.; Nor, M.J.M.; Hassan, M.H.; Prasetiyo, I. Sound absorption of extracted pineapple-leaf fibres. Appl. Acoust. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Marvila, M.T.; Zanelato, E.B.; Lima, T.E.S.; Cecchin, D.; Souza, J.S.; Barbosa, M.Z.; Monteiro, S.N.; Rocha, H.A.; Alexandre, J.; et al. Evaluation of Different Methods of Surface Treatment of Natural Açai Fiber Added in Cementitious Composites. In Characterization of Minerals, Metals, and Materials; Springer: Cham, Switzerland, 2021; pp. 383–391. [Google Scholar] [CrossRef]

- Godara, S.S. Effect of chemical modification of fiber surface on natural fiber composites: A review. Mater. Today Proc. 2019, 18, 3428–3434. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Recent advances of natural fibers based green rubber composites: Properties, current status, and future perspectives. J. Appl. Polym. Sci. 2021, 138, 50866. [Google Scholar] [CrossRef]

- Raghavendra Rao, H.; Varada Rajulu, A.; Ramachandra Reddy, G.; Hemachandra Reddy, K. Flexural and Compressive Properties of Bamboo and Glass Fiber-reinforced Epoxy Hybrid Composites. J. Reinf. Plast. Compos. 2010, 29, 1446–1450. [Google Scholar] [CrossRef]

- Bam, S.; Gundu, D.; Onu, F. The effect of chemical treatments on the mechanical and physical properties of bagasse filler reinforced low density polyethylene composite. Am. J. Eng. Res. 2019, 8, 95–98. [Google Scholar]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Manimaran, P.; Verma, A.; Sanjay, M.R.; Siengchin, S.; Kandakodeeswaran, K.; Geetha, M. A novel palm sheath and sugarcane bagasse fiber based hybrid composites for automotive applications: An experimental approach. Polym. Compos. 2020, 42, 512–521. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Khan, B.A.; Chevali, V.S.; Na, H.; Zhu, J.; Warner, P.; Wang, H. Processing and properties of antibacterial silver nanoparticle-loaded hemp hurd/poly(lactic acid) biocomposites. Compos. Part B Eng. 2016, 100, 10–18. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, C.; Zuo, Q.; Yousfani, S.H.S.; Anuar, N.I.S.; Zakaria, S.; Liu, X. Effect of Alkali Treatment on Interfacial and Mechanical Properties of Kenaf Fibre Reinforced Epoxy Unidirectional Composites. Sains Malays. 2019, 48, 173–181. [Google Scholar] [CrossRef]

- Reddy, B.R.; Dhoria, S.H. Effect of alkaline treatment on mechanical properties of kenaf fiber reinforced polyester composites. AIP Conf. Proc. 2018, 1943, 020097. [Google Scholar] [CrossRef]

- Shi, J.; Shi, S.Q.; Barnes, H.M.; Horstemeyer, M.F.; Wang, G. Kenaf Bast Fibers—Part II: Inorganic Nanoparticle Impregnation for Polymer Composites. Int. J. Polym. Sci. 2011, 2011, 736474. [Google Scholar] [CrossRef]

- Anand, P.; Rajesh, D.; Kumar, M.S.; Raj, I.S. Investigations on the performances of treated jute/Kenaf hybrid natural fiber reinforced epoxy composite. J. Polym. Res. 2018, 25, 94. [Google Scholar] [CrossRef]

- Yadav, A.; Gupta, M.K. Development and characterization of jute composites for sustainable product: Effect of chemical treatments and polymer coating. Mater. Res. Express 2019, 7, 015306. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem. Concr. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Arfaoui, M.; Dolez, P.; Dubé, M.; David, É. Development and characterization of a hydrophobic treatment for jute fibres based on zinc oxide nanoparticles and a fatty acid. Appl. Surf. Sci. 2017, 397, 19–29. [Google Scholar] [CrossRef]

- Jothibasu, S.; Mohanamurugan, S.; Vijay, R.; Lenin Singaravelu, D.L.; Vinod, A.; Sanjay, M.R. Investigation on the mechanical behavior of areca sheath fibers/jute fibers/glass fabrics reinforced hybrid composite for light weight applications. J. Ind. Text. 2020, 49, 1036–1060. [Google Scholar] [CrossRef]

- Mohamed, S.; Zainudin, E.; Sapuan, S.; Azaman, M.; Arifin, A. Introduction to Natural Fiber Reinforced Vinyl Ester and Vinyl Polymer Composites. In Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2018; pp. 1–25. [Google Scholar] [CrossRef]

- Debeli, D.K.; Qin, Z.; Guo, J. Study on the pre-treatment, physical and chemical properties of ramie fibers reinforced poly (lactic acid)(PLA) biocomposite. J. Nat. Fibers 2018, 15, 596–610. [Google Scholar] [CrossRef]

- Tang, B.; Yao, Y.; Li, J.; Qin, S.; Zhu, H.; Kaur, J.; Chen, W.; Sun, L.; Wang, X. Functional Application of Noble Metal Nanoparticles In Situ Synthesized on Ramie Fibers. Nanoscale Res. Lett. 2016, 10, 366. [Google Scholar] [CrossRef]

- Le Moigne, N.; Longerey, M.; Taulemesse, J.-M.; Bénézet, J.-C.; Bergeret, A. Study of the interface in natural fibres reinforced poly (lactic acid) biocomposites modified by optimized organosilane treatments. Ind. Crops Prod. 2014, 52, 481–494. [Google Scholar] [CrossRef]

- Ajith, A.; Xian, G.; Li, H.; Sherief, Z.; Thomas, S. Surface grafting of flax fibres with hydrous zirconia nanoparticles and the effects on the tensile and bonding properties. J. Compos. Mater. 2015, 50, 627–635. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef]

- Krishnaiah, P.; Manickam, S.; Ratnam, C.T.; Raghu, M.; Parashuram, L.; Prashantha, K.; Jeon, B.-H. Surface-treated short sisal fibers and halloysite nanotubes for synergistically enhanced performance of polypropylene hybrid composites. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A state-of-the-art review on soil reinforcement technology using natural plant fiber materials: Past findings, present trends and future directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef]

- Santos, R.D.; Thomas, S.; Ferreira, S.R.; Silva, F.A.; Combariza, M.Y.; Blanco-Tirado, C.; Ovalle-Serrano, S.A.; Souza, F.G., Jr.; Oliveira, G.E.; Filho, R.D.T. Molecular grafting of nanoparticles onto sisal fibers-adhesion to cementitious matrices and novel functionalities. J. Mol. Struct. 2021, 1234, 130171. [Google Scholar] [CrossRef]

- Arsyad, M. Sodium Hydroxide and Potassium Permanganate Treatment on Mechanical Properties of Coconut Fibers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 619, 012011. [Google Scholar] [CrossRef]

- Yew, B.S.; Muhamad, M.; Mohamed, S.B.; Wee, F.H. Effect of Alkaline Treatment on Structural Characterisation, Thermal Degradation and Water Absorption Ability of Coir Fibre Polymer Composites. Sains Malays. 2019, 48, 653–659. [Google Scholar] [CrossRef]

- Ali, M. Use of coconut fibre reinforced concrete and coconut-fibre ropes for seismic-resistant construction. Mater. Construcción 2016, 66, e073. [Google Scholar] [CrossRef][Green Version]

- Chougan, M.; Ghaffar, S.H.; Al-Kheetan, M.J.; Gecevicius, M. Wheat straw pre-treatments using eco-friendly strategies for enhancing the tensile properties of bio-based polylactic acid composites. Ind. Crop. Prod. 2020, 155, 112836. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Rajini, N.; Saba, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S. Effect of Alkali Treatment on Mechanical and Morphological Properties of Pineapple Leaf Fibre/Polyester Composites. J. Polym. Environ. 2019, 27, 1191–1201. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.; Saba, N.; Jawaid, M.; Alothman, O.Y.; Nasir, M.; Almutairi, Z. Thermal, physical properties and flammability of silane treated kenaf/pineapple leaf fibres phenolic hybrid composites. Compos. Struct. 2018, 202, 1330–1338. [Google Scholar] [CrossRef]

- Mondal, M.I.H.; Islam, M.K.; Ahmed, F. Effect of Silane Coupling Agents on Cotton Fibre Finishing. J. Nat. Fibers 2021, 1–14. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Chiang, C.-L. Preparation of cotton fibers with antibacterial silver nanoparticles. Mater. Lett. 2008, 62, 3607–3609. [Google Scholar] [CrossRef]

- Xuan, L.H.; Han, G.P.; Wang, D.; Cheng, W.L.; Gao, X.; Chen, F.; Li, Q.D. Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites. Materials 2017, 10, 456. [Google Scholar] [CrossRef]

- Tserki, V.; Panayiotou, C.; Zafeiropoulos, N.E. A Study of the Effect of Acetylation and Propionylation on the Interface of Natural Fibre Biodegradable Composites. Adv. Compos. Lett. 2005, 14. [Google Scholar] [CrossRef]

- Hossain, S.I.; Hasan, M.; Hasan, N.; Hassan, A. Effect of Chemical Treatment on Physical, Mechanical and Thermal Properties of Ladies Finger Natural Fiber. Adv. Mater. Sci. Eng. 2013, 2013, 824274. [Google Scholar] [CrossRef]

- Latiff, A.S.M.; Ishak, M.R.; Norkhairunnisa, M.; Ya, A.M. Mechanical Properties of Benzoylation Treated Sugar Palm Fiber and Its Composite. Int. J. Recent Technol. Eng. 2020, 8, 4248–4252. [Google Scholar] [CrossRef]

- Valášek, P.; Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; D’Amato, R.; Ruggiero, A. Influence of Alkali Treatment on the Microstructure and Mechanical Properties of Coir and Abaca Fibers. Materials 2021, 14, 2636. [Google Scholar] [CrossRef]

- Wang, H.; Memon, H.; Hassan, E.A.M.; Miah, S.; Ali, A. Effect of Jute Fiber Modification on Mechanical Properties of Jute Fiber Composite. Materials 2019, 12, 1226. [Google Scholar] [CrossRef]

- Jumaidin, R.; Adam, N.W.; Ilyas, R.A.; Hussin, M.S.F.; Taha, M.M.; Mansor, M.R.; Azlan, U.A.-A.; Yob, M.S. Water transport and physical properties of sugarcane bagasse fibre reinforced thermoplastic potato starch biocomposite. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 273–281. [Google Scholar]

- Asrofi, M.; Sapuan, S.M.; Ilyas, R.A.; Ramesh, M. Characteristic of composite bioplastics from tapioca starch and sugarcane bagasse fiber: Effect of time duration of ultrasonication (Bath-Type). Mater. Today Proc. 2020, 46, 1626–1630. [Google Scholar] [CrossRef]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 5258621. [Google Scholar] [CrossRef]

- Jaafar, C.A.; Zainol, I.; Ishak, N.; Ilyas, R.; Sapuan, S. Effects of the liquid natural rubber (LNR) on mechanical properties and microstructure of epoxy/silica/kenaf hybrid composite for potential automotive applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Suriani, M.; Zainudin, H.A.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M.; Mustapha, R. Kenaf Fiber/Pet Yarn Reinforced Epoxy Hybrid Polymer Composites: Morphological, Tensile, and Flammability Properties. Polymers 2021, 13, 1532. [Google Scholar] [CrossRef]

- Mazani, N.; Sapuan, S.; Sanyang, M.; Atiqah, A.; Ilyas, R. Design and Fabrication of a Shoe Shelf from Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.; Ilyas, R.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Nassiopoulos, E.; Njuguna, J. Thermo-mechanical performance of poly (lactic acid)/flax fibre-reinforced biocomposites. Mater. Des. 2015, 66, 473–485. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Sapuan, S.; Ilyas, R. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym. Test. 2019, 81, 106186. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Pratama, A.B.; Fajri, N.; Sapuan, S.; Ilyas, R. Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocoll. 2019, 98, 105266. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. eXPRESS Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Limsiriwong, N.; Kongjindamunee, R.; Surakit, S. Effect of Agar and Cotton Fiber on Properties of Thermoplastic Waxy Rice Starch Composites. J. Polym. Environ. 2011, 20, 88–95. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Chandrasekar, M.; Senthilkumar, K.; Ilyas, R.A.; Sapuan, S.M.; Hariram, N.; Rajulu, A.V.; Rajini, N.; Siengchin, S. Characterization, Thermal and Antimicrobial Properties of Hybrid Cellulose Nanocomposite Films with in-Situ Generated Copper Nanoparticles in Tamarindus indica Nut Powder. J. Polym. Environ. 2020, 29, 1134–1142. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, R. PLA-coated sisal fibre-reinforced polyester composite: Water absorption, static and dynamic mechanical properties. J. Compos. Mater. 2019, 53, 65–72. [Google Scholar] [CrossRef]

- Jumaidin, R.; Diah, N.; Ilyas, R.; Alamjuri, R.; Yusof, F. Processing and Characterisation of Banana Leaf Fibre Reinforced Thermoplastic Cassava Starch Composites. Polymers 2021, 13, 1420. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef]

- Suriani, M.; Radzi, F.S.M.; Ilyas, R.; Petrů, M.; Sapuan, S.; Ruzaidi, C. Flammability, tensile, and morphological properties of oil palm empty fruit bunches fiber/pet yarn-reinforced epoxy fire retardant hybrid polymer composites. Polymers 2021, 13, 1282. [Google Scholar] [CrossRef] [PubMed]

- Rozilah, A.; Jaafar, C.N.A.; Sapuan, S.M.; Zainol, I.; Ilyas, R.A. The Effects of Silver Nanoparticles Compositions on the Mechanical, Physiochemical, Antibacterial, and Morphology Properties of Sugar Palm Starch Biocomposites for Antibacterial Coating. Polymers 2020, 12, 2605. [Google Scholar] [CrossRef] [PubMed]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline Cellulose as Reinforcement for Polymeric Matrix Nanocomposites and its Potential Applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- De Lima, T.E.S.; de Azevedo, A.R.G.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef]

- De Azevedo, A.; Rocha, H.A.; Marvila, M.T.; Cecchin, D.; de Castro Xavier, G.; da Silva, R.C.; Ferraz, P.F.P.; Conti, L.; Rossi, G. Application of pineapple fiber in the development of sustainable mortars. Agron. Res. 2021, 19. [Google Scholar] [CrossRef]

- Femandez, J. Flax fiber reinforced concrete-a natural fiber biocomposite for sustainable building materials. WIT Trans. Built Environ. 2002, 59. [Google Scholar] [CrossRef]

- Gram, H.-E. Durability of Natural Fibres in Concrete; Cement-Och Betonginst: Stocholm, Sweden, 1983. [Google Scholar]

- Filho, R.D.T.; Joseph, K.; Ghavami, K.; England, G.L. The use of sisal fibre as reinforcement in cement based composites. Rev. Bras. Eng. Agrícola Ambient. 1999, 3, 245–256. [Google Scholar] [CrossRef]

- Paramasivam, P.; Nathan, G.; Gupta, N.D. Coconut fibre reinforced corrugated slabs. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 19–27. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H., Jr.; John, V.M.; Cincotto, M.A. Developments on vegetable fibre–cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Ghavami, K.; England, G.L.; Scrivener, K. Development of vegetable fibre–mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Munawar, S.S.; Umemura, K.; Kawai, S. Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles. J. Wood Sci. 2007, 53, 108–113. [Google Scholar] [CrossRef]

- Filho, R.T.; Ghavami, K.; Sanjuán, M.A.; England, G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Terai, M.; Minami, K. Fracture Behavior and Mechanical Properties of Bamboo Reinforced Concrete Members. Procedia Eng. 2011, 10, 2967–2972. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Flexural strengthening of RC beams using natural sisal and artificial carbon and glass fabric reinforced composite system. Sustain. Cities Soc. 2014, 10, 195–206. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Marvila, M.T.; Rocha, H.A.; de Azevedo, A.R.G.; Colorado, H.A.; Zapata, J.F.; Vieira, C.M.F. Use of natural vegetable fibers in cementitious composites: Concepts and applications. Innov. Infrastruct. Solut. 2021, 6, 180. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Alexandre, J.; Zanelato, E.B.; Monteiro, S.N.; Cecchin, D.; Amaral, L.F. Mortars with Pineapple Fibers for Use in Structural Reinforcement. In Characterization of Minerals, Metals, and Materials 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 721–728. [Google Scholar]

- Azevedo, A.R.; Lima, T.E.; Reis, R.H.; Oliveira, M.S.; Candido, V.S.; Monteiro, S.N. Guaruman fiber: A promising reinforcement for cement-based mortars. Case Stud. Constr. Mater. 2022, 16. [Google Scholar] [CrossRef]

- Azevedo, A.; Lima, T.; Simonassi, N.; Ribeiro, M.P.; Filho, F.G.; Monteiro, S. Piassava Fiber: A Novel Reinforcement for Cement-Based Matrix Composites. Concilium 2022, 22, 379–390. [Google Scholar] [CrossRef]

- Merta, I.; Tschegg, E. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Albahttiti, M.T.; Rasheed, H.A.; Perić, D.; Davis, L. Assessment of wheat fibre reinforced cementitious matrix. IES J. Part A Civ. Struct. Eng. 2013, 6, 211–221. [Google Scholar] [CrossRef]

- Yan, L.; Zhao, Y.-Q.; Yang, J.-J.; Yang, Z.-Z.; Zhao, S.-B. Effect of wheat straw fibre on performance of cement paste. Hunningtu 2012, 2, 60–62. [Google Scholar]

- Li, C.F.; Chen, G.P.; Zhu, S.W. Study on the Properties of Straw Fiber Reinforced Cement-Based Composite. Appl. Mech. Mater. 2013, 368–370, 997–1000. [Google Scholar] [CrossRef]

- Liu, D.; Yao, Q.; Jia, Y. Experimental study of vegetable fiber–mortar composites in ecological and energy-saving composite wall. J. Beijing Jiaotong Univ. 2011, 35, 34–36. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and durability of coconut-fiber-reinforced concrete in aggressive environments. Constr. Build. Mater. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 2019, 203, 174–187. [Google Scholar] [CrossRef]

- Kundu, S.P.; Chakraborty, S.; Chakraborty, S. Effectiveness of the surface modified jute fibre as fibre reinforcement in controlling the physical and mechanical properties of concrete paver blocks. Constr. Build. Mater. 2018, 191, 554–563. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.; Choi, Y.; Lee, H.; Song, G. An Investigation of Mechanical Properties of Jute Fiber-Reinforced Concrete. In High Performance Fiber Reinforced Cement Composites 6; Springer: Berlin/Heidelberg, Germany, 2012; pp. 75–82. [Google Scholar]

- Rahman, S.; Azad, A. Investigation on mechanical strength of jute fiber reinforced concrete JFRC compared to plain concrete. Int. J. Sci. Eng. Res. 2018, 9, 560–564. [Google Scholar]

- Krishna, T.S.V.; Yadav, B.M. A comparative study of jute fiber reinforced concrete with plain cement concrete. Int. J. Res. Eng. Technol. 2016, 5, 111–116. [Google Scholar]

- Liu, B.; Zhang, L.Z.; Liu, Q.X.; Ji, T. Study on Behaviors of Jute Fiber Reinforced Cement Based Materials. Appl. Mech. Mater. 2012, 253–255, 508–511. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Bideci, S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Kaplan, G.; Bayraktar, O.Y. The effect of hemp fiber usage on the mechanical and physical properties of cement based mortars. Res. Eng. Struct. Mater. 2021. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers 2022, 10, 31. [Google Scholar] [CrossRef]

- Fadhil, S.; Yaseen, M. The Effect of Adding Different Types of Natural Fibers on Mechanical Properties and Impact Resistance of Concrete. Res. J. Appl. Sci. Eng. Technol. 2015, 9, 1091–1096. [Google Scholar] [CrossRef]

- Abirami, R.; Vijayan, D.; John, S.J.; Albert, A.; Alex, A.K. Experimental study on concrete properties using pineapple leaf fiber. Int. J. Adv. Res. Eng. Technol. 2020, 11, 913–920. [Google Scholar]

- Mathew, L.; Paul, M.M. Mechanical properties of pineapple fibre reinforced concrete subjected to high temperature. GRD J.—Glob. Res. Dev. J. Eng. 2017, 2, 200–205. [Google Scholar]

- Patrick, K.; Onchiri, R.O.; Mang’Uriu, G.N. Developing Suitable Proportions for the Production of Pineapple Leaf Fibers Reinforced Normal Strength Concrete. Open J. Civ. Eng. 2019, 9, 185–194. [Google Scholar] [CrossRef]

- Bayapureddy, Y.; Muniraj, K.; Mutukuru, M.R.G. Sugarcane bagasse ash as supplementary cementitious material in cement composites: Strength, durability, and microstructural analysis. J. Korean Ceram. Soc. 2020, 57, 513–519. [Google Scholar] [CrossRef]

- Khalid, F.S.; Herman, H.S.; Azmi, N.B. Properties of Sugarcane Fiber on the Strength of the Normal and Lightweight Concrete. MATEC Web Conf. Ser. 2017, 103, 1021. [Google Scholar] [CrossRef]

- Patel, D.; Patel, V. Application of sugarcane bagasse fibres as concrete composites for rigid pavement. Indian J. Res 2015, 4, 4–5. [Google Scholar]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Gomina, M.; Boutouil, M. Enhancement of the long-term mechanical performance of flax fiber-reinforced cementitious composites by using alternative binders. J. Build. Eng. 2021, 40, 102323. [Google Scholar] [CrossRef]

- Yaremko, C. Durability of Flax Fibre Reinforced Concrete; University of Saskatchewan: Saskatoon, SK, Canada, 2012. [Google Scholar]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Cai, X.; Xu, S. Uniaxial compressive properties of ultra high toughness cementitious composite. J. Wuhan Univ. Technol. Sci. Ed. 2011, 26, 762–769. [Google Scholar] [CrossRef]

- Kesner, K.; Billington, S. Experimental response of precast infill panels made with DFRCC. In Proceedings of the DFRCC Int’l Workshop, Tokyo, Japan, 21–22 October 2002; pp. 289–298. [Google Scholar]

- Karihaloo, B.L.; Wang, J. Micromechanics of Fiber-Reinforced Cementitious Composites. Adv. Eng. Mater. 2000, 2, 726–732. [Google Scholar] [CrossRef]

- Van Nguyen, C.; Mangat, P. Properties of rice straw reinforced alkali activated cementitious composites. Constr. Build. Mater. 2020, 261, 120536. [Google Scholar] [CrossRef]

- Baruah, P.; Talukdar, S. A comparative study of compressive, flexural, tensile and shear strength of concrete with fibres of different origins. Indian Concr. J. 2007, 81, 17–24. [Google Scholar]

- Razmi, A.; Mirsayar, M. On the mixed mode I/II fracture properties of jute fiber-reinforced concrete. Constr. Build. Mater. 2017, 148, 512–520. [Google Scholar] [CrossRef]

- Patel, R.; Patel, V. Using jute fiber in cement concrete pavement with IRC mix design and ambuja mix design. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 1092–1095. [Google Scholar]

- Jamshaid, H.; Mishra, R.K.; Raza, A.; Hussain, U.; Rahman, L.; Nazari, S.; Chandan, V.; Muller, M.; Choteborsky, R. Natural Cellulosic Fiber Reinforced Concrete: Influence of Fiber Type and Loading Percentage on Mechanical and Water Absorption Performance. Materials 2022, 15, 874. [Google Scholar] [CrossRef]

- Marke, M.; Marke, A. Comparative evaluation of the flexural strength of concrete and colcrete. Niger. J. Technol. 2010, 29, 13–22. [Google Scholar]

- Khan, M.; Ali, M. Effect of super plasticizer on the properties of medium strength concrete prepared with coconut fiber. Constr. Build. Mater. 2018, 182, 703–715. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M.; Ahmed, S. Effectiveness of Calcium Carbonate Whisker in Cementitious Composites. Period. Polytech. Civ. Eng. 2020, 64, 265–275. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Guan, J.; Liu, Z.; Khan, M. Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Compos. Part B Eng. 2021, 224, 109219. [Google Scholar] [CrossRef]

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2021, 319, 126130. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 2021, 23, 346–364. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt Fibers in Modified Whisker Reinforced Cementitious Composites. Period. Polytech. Civ. Eng. 2022, 66. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2020, 22, 535–549. [Google Scholar] [CrossRef]

- Ali, B.; Raza, S.S.; Hussain, I.; Iqbal, M. Influence of different fibers on mechanical and durability performance of concrete with silica fume. Struct. Concr. 2020, 22, 318–333. [Google Scholar] [CrossRef]

- Ali, B.; Fahad, M.; Ullah, S.; Ahmed, H.; Alyousef, R.; Deifalla, A. Development of Ductile and Durable High Strength Concrete (HSC) through Interactive Incorporation of Coir Waste and Silica Fume. Materials 2022, 15, 2616. [Google Scholar] [CrossRef]

- Ali, B. Development of environment-friendly and ductile recycled aggregate concrete through synergetic use of hybrid fibers. Environ. Sci. Pollut. Res. 2022, 29, 34452–34463. [Google Scholar] [CrossRef]

| Plant Fiber | Source | Chemical Composition | Physical/Mechanical Properties | Reference | Annual Production | Approx. Cost | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lignin | Cellulose | Hemi–Cellulose | Crystallinity | Tensile Strength | Tensile Modulus | Density | Elongation at Break | Production | Reference | Price per Ton | Reference | |||

| Wt.% | Wt.% | Wt.% | Wt.% | MPa | GPa | g/cm3 | % | – | (×103) | – | USD | – | ||

| Bamboo | Stem | 10.2 | 73.8 | 12.5 | 40–60 | 140–230 | 11–17 | 1.25 | 2 | [14,74,85,86,87] | 10,000 | [88,89] | 500 | [89,90] |

| Sugarcane Bagasse | Stem | 25–32 | 32–34 | 19–24 | 76 | 290 | 17 | 1.5 | 1–3 | [74,86,91,92] | – | – | – | – |

| Hemp | Stem | 3–5 | 70–92 | 18–22 | 50–90 | 690 | 70 | 1.48 | 1.6–4 | [4,14,27,57,74,93,94,95] | 215 | [88,89] | 1550 | [89,90] |

| Kenaf | Stem | 15–19 | 44–87 | 22 | 48.2 | 215 | 53 | 1.45 | 1.6 | 770 | 400 | |||

| Jute | Stem | 5–13 | 51–84 | 12–20 | 50–80 | 393–773 | 15.4–26.5 | 1.3 | 1.5–2.5 | 2500 | 950 | |||

| Ramie | Stem | 0.6–1 | 68–76 | 13–15 | 55.5 | 560 | 24.5 | 1.5 | 2.5–3.8 | 100 | – | – | ||

| Flax | Stem | 2.2–5 | 60–81 | 14–20.6 | 50–90 | 345–1035 | 27.6 | 0.6–1.1 | 2.7–3.2 | 810 | 3150 | [89,90,96] | ||

| Sisal | Leaf | 8–11 | 67–78 | 10–14.2 | 50–70 | 347–700 | 9.4–22 | 1.03–1.5 | 2–2.5 | [74,95,97,98,99,100] | 380 | 650 | ||

| Coir | Fruit | 40–45 | 32–43 | 0.15–0.25 | 27–33 | 139 | 4–6 | 1.2 | 30 | [74,95,101] | 100 | – | – | |

| Pineapple | Fruit | 4.2 | 66.2 | 19.5 | 35.9 | 400–627 | 1.44 | 0.8–1.6 | 14.5 | [74,102,103] | – | – | 455 | [89,90] |

| Cotton | Seed | – | – | – | – | 287–587 | 5–12 | 1.5–1.6 | 7–8 | [104,105,106,107] | 18,500 | [88,89,108] | – | – |

| Wood | Stem | – | – | – | – | – | 7–70 | 0.5–1.4 | – | [105,109] | 1,750,000 | – | – | |

| Wheat Straw | Stem | 18.9–25.1 | 43.1–44.7 | 32.9–35.3 | 57.5 | 21.2–40 | 4.76–6.58 | 0.02–0.11 | 5.4 | [110,111,112] | 731,460 | [113,114,115,116] | 60 | [116] |

| Plant Fibers | Geometric Dimensions | Mechanical Properties | |||

|---|---|---|---|---|---|

| Mean Length | Mean Width | Aspect Ratio | Stiffness | Ultimate Stress | |

| (mm) | (μm) | (-) | (GPa) | (MPa) | |

| Bamboo | 2.7 | 14 | 193 | - | - |

| Sugarcane Bagasse | 0.68–1.7 | 20–22.8 | 29.8–85 | - | - |

| Jute | 2 | 20 | 100 | 20–55 | 200–500 |

| Hemp | 25 | 25 | 1000 | 30–60 | 300–800 |

| Coir | 0.7 | 20 | 35 | - | - |

| Wheat Straw | 15 | 15 | 100 | - | - |

| Ramie | 12–15 | 20–75 | 2000–6000 | - | - |

| Cotton | 25 | 20 | 1250 | - | - |

| Sisal | 3 | 20 | 150 | 9–22 | 100–800 |

| Kenaf | 5 | 21 | 238 | - | - |

| Flax | 33 | 19 | 1737 | 50–70 | 500–900 |

| References | [14,143,144,145,146] | [14,147] | |||

| Plant Fibers | Treatment Techniques | References |

|---|---|---|

| Bamboo | Acetylation, potassium permanganate, fiber hybridization | [56,156,157] |

| Sugarcane Bagasse | acetylation, alkali, stearic acid, fiber hybridization, hydrogen peroxide | [153,158,159,160] |

| Hemp | Potassium permanganate, nanoparticle grafting | [161,162] |

| Kenaf | Alkali, nanoparticle grafting, fiber hybridization | [163,164,165,166] |

| Jute | Alkali, benzoylation, sodium bicarbonate, fiber hybridization, water immersion, nanoparticle grafting | [153,159,166,167,168,169,170] |

| Ramie | Steam blasting, nanoparticle grafting, silane | [171,172,173] |

| Flax | Silane, nanoparticle grafting, fiber hybridization | [174,175,176] |

| Sisal | Alkali, acetylation, nanoparticle grafting, water immersion | [168,177,178,179,180] |

| Coir | Alkali, permanganate, fiber hybridization, water immersion | [168,181,182,183,184] |

| Pineapple | Alkali, fiber hybridization | [185,186] |

| Cotton | Silane, surface fibrillation, nanoparticle grafting | [120,187,188] |

| Wheat Straw | Alkali, boiling, fiber hybridization, water immersion, nanoparticle grafting | [43,44,46,184,189] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. https://doi.org/10.3390/ma15124362

Amin MN, Ahmad W, Khan K, Ahmad A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials. 2022; 15(12):4362. https://doi.org/10.3390/ma15124362

Chicago/Turabian StyleAmin, Muhammad Nasir, Waqas Ahmad, Kaffayatullah Khan, and Ayaz Ahmad. 2022. "A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials" Materials 15, no. 12: 4362. https://doi.org/10.3390/ma15124362

APA StyleAmin, M. N., Ahmad, W., Khan, K., & Ahmad, A. (2022). A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials, 15(12), 4362. https://doi.org/10.3390/ma15124362