Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete

Abstract

:1. Introduction

2. Experimental Program

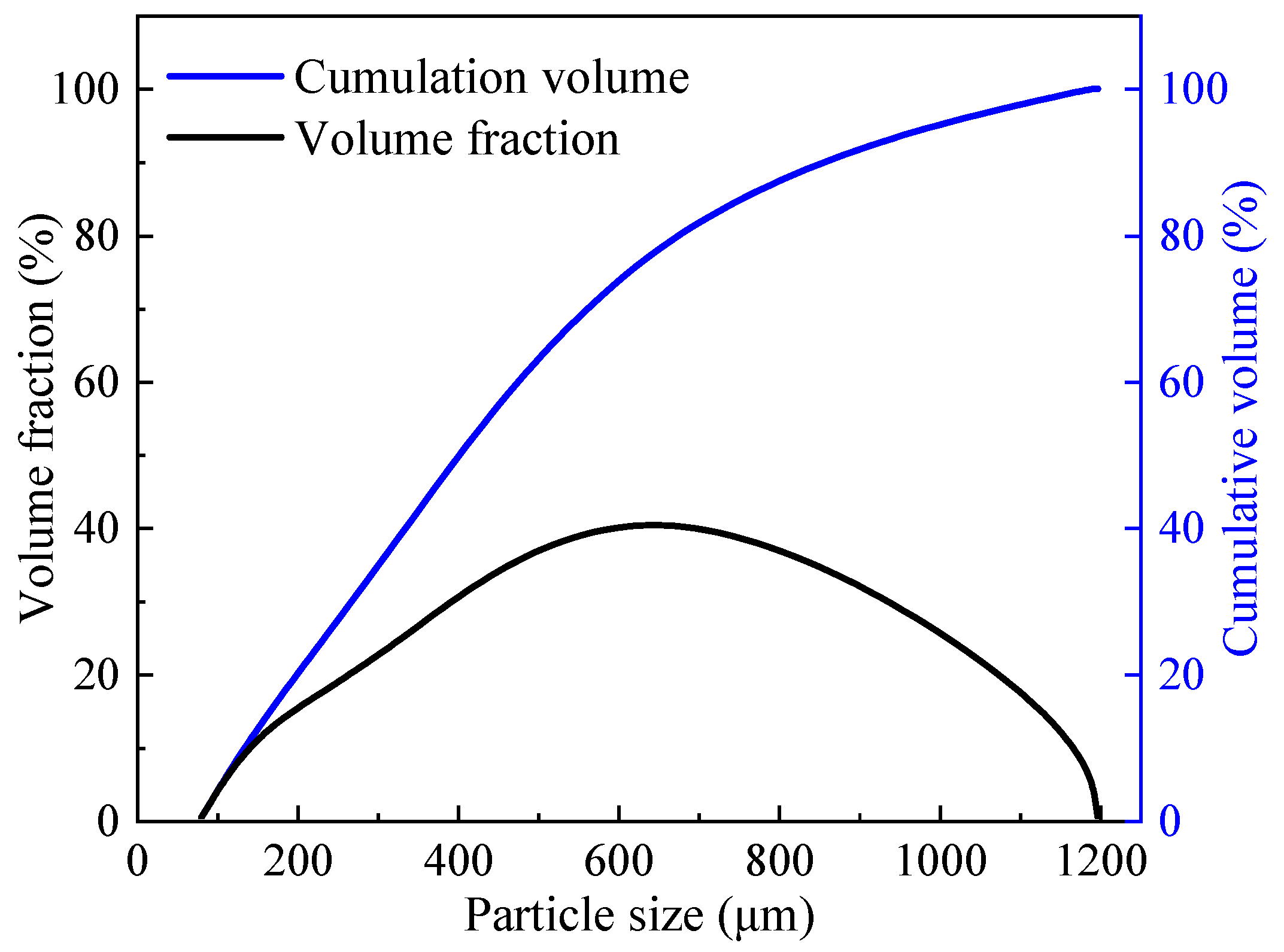

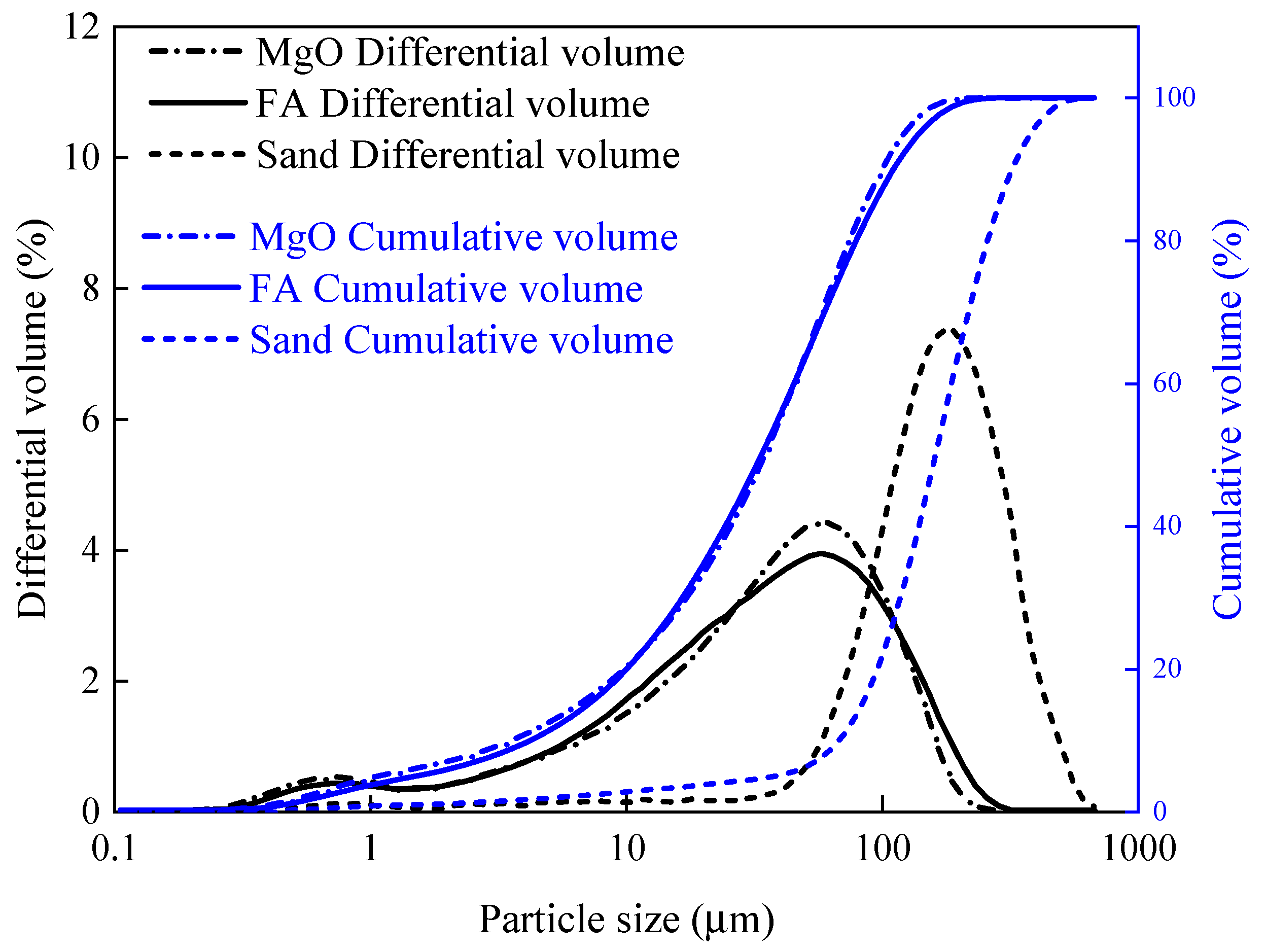

2.1. Materials

2.2. Mixture Proportions

2.3. Specimen Preparation

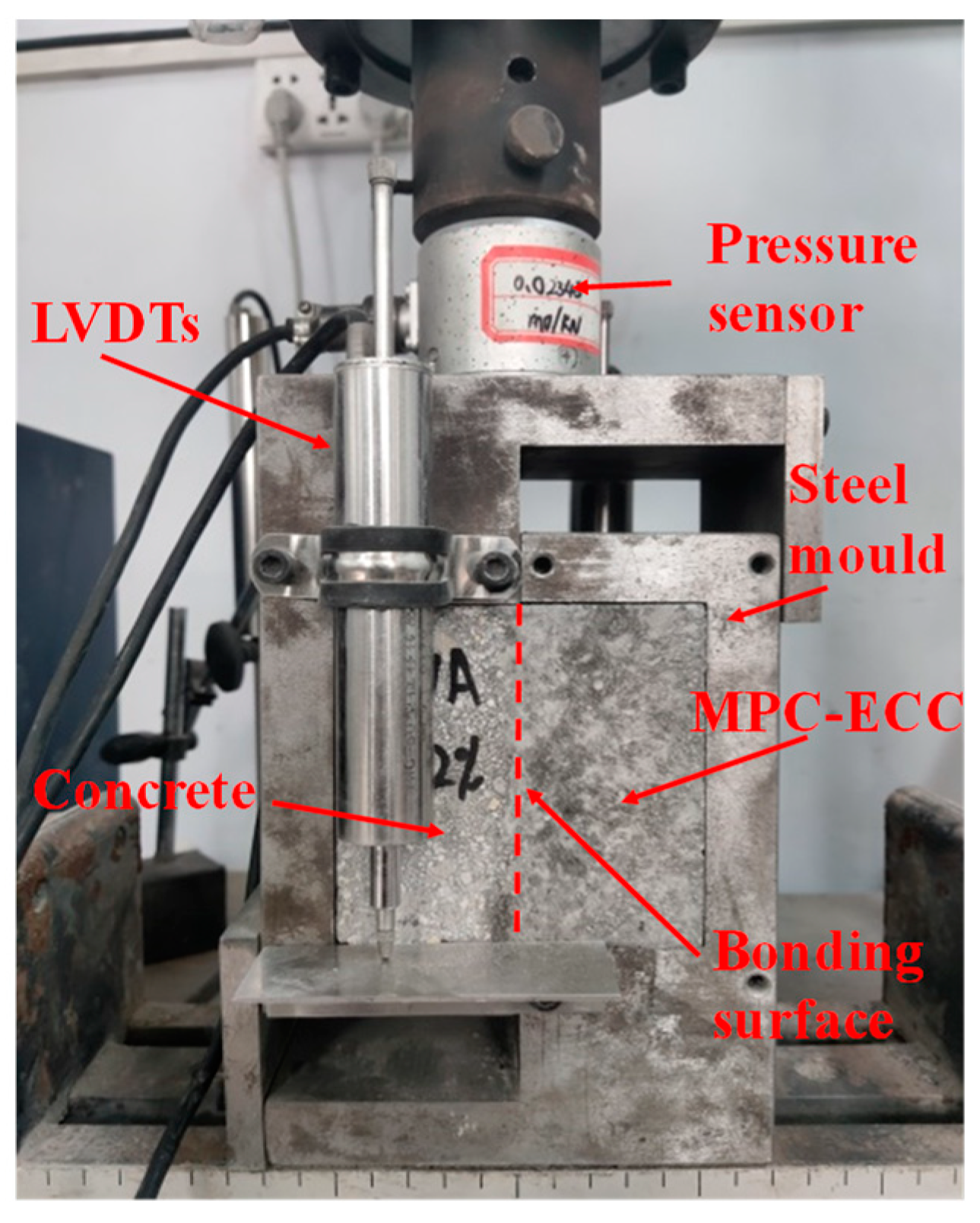

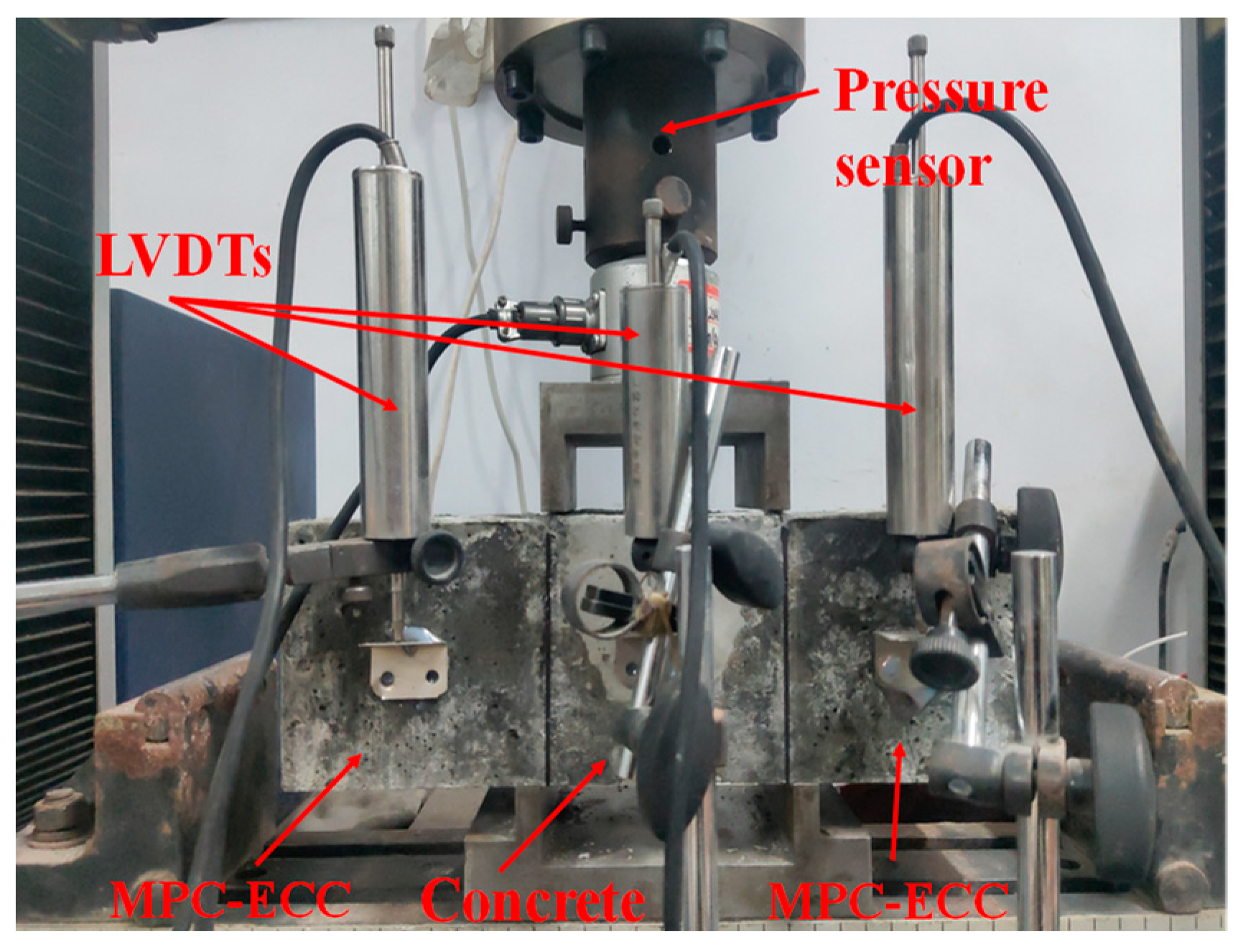

2.4. Test Methods

2.4.1. Single Shear Bond Strength Test

2.4.2. Double Shear Bond Strength Test

3. Results and Discussion

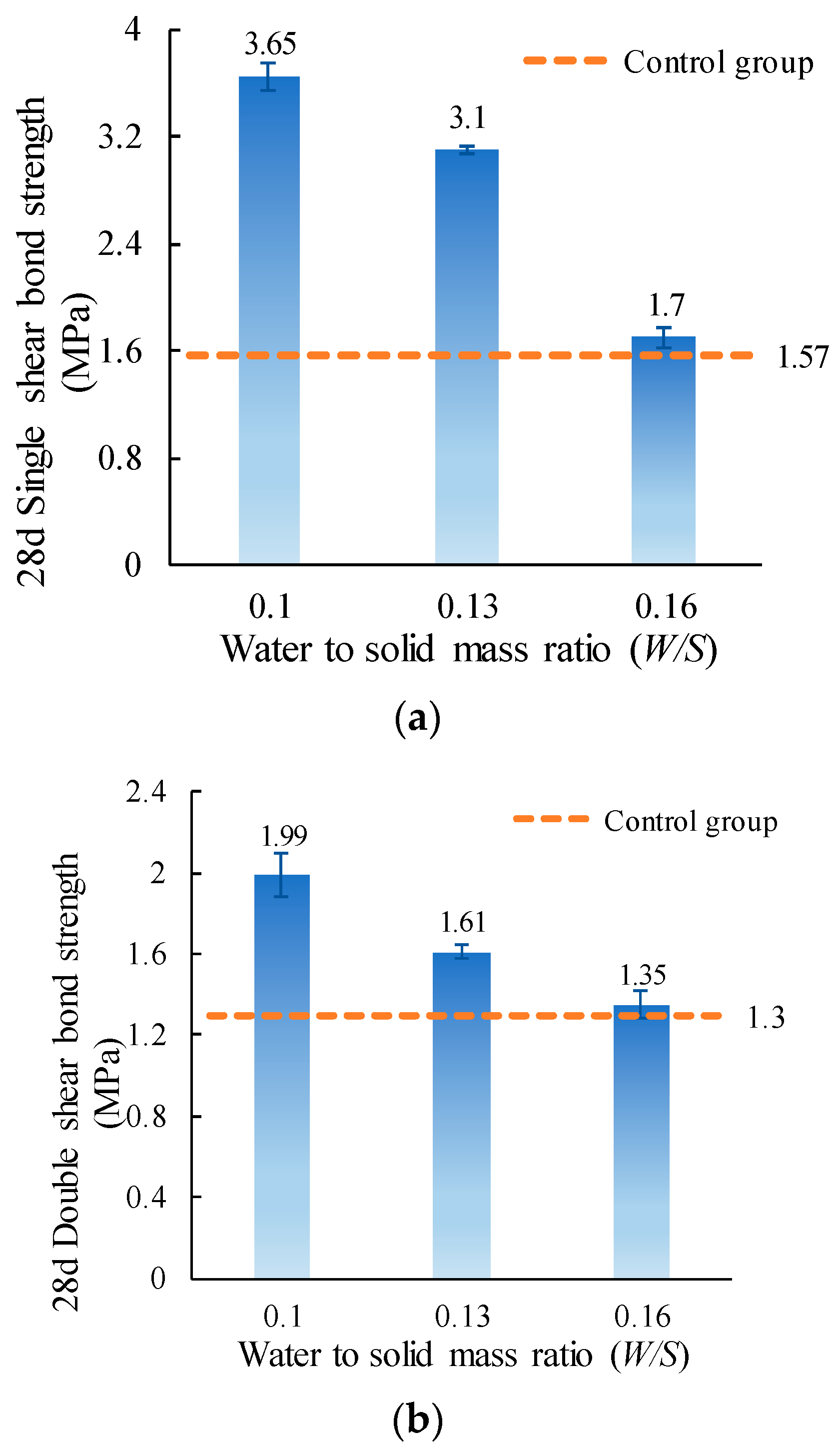

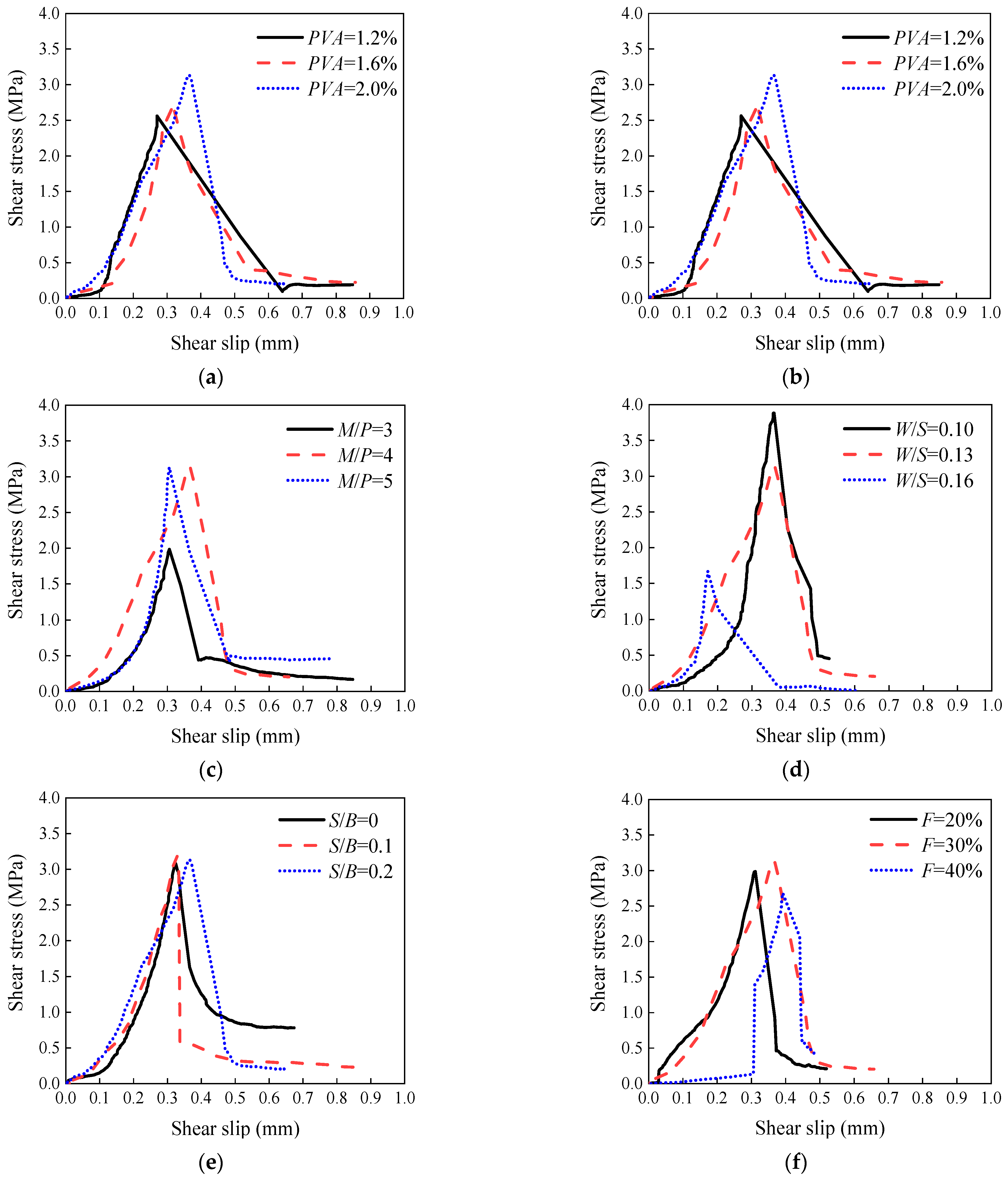

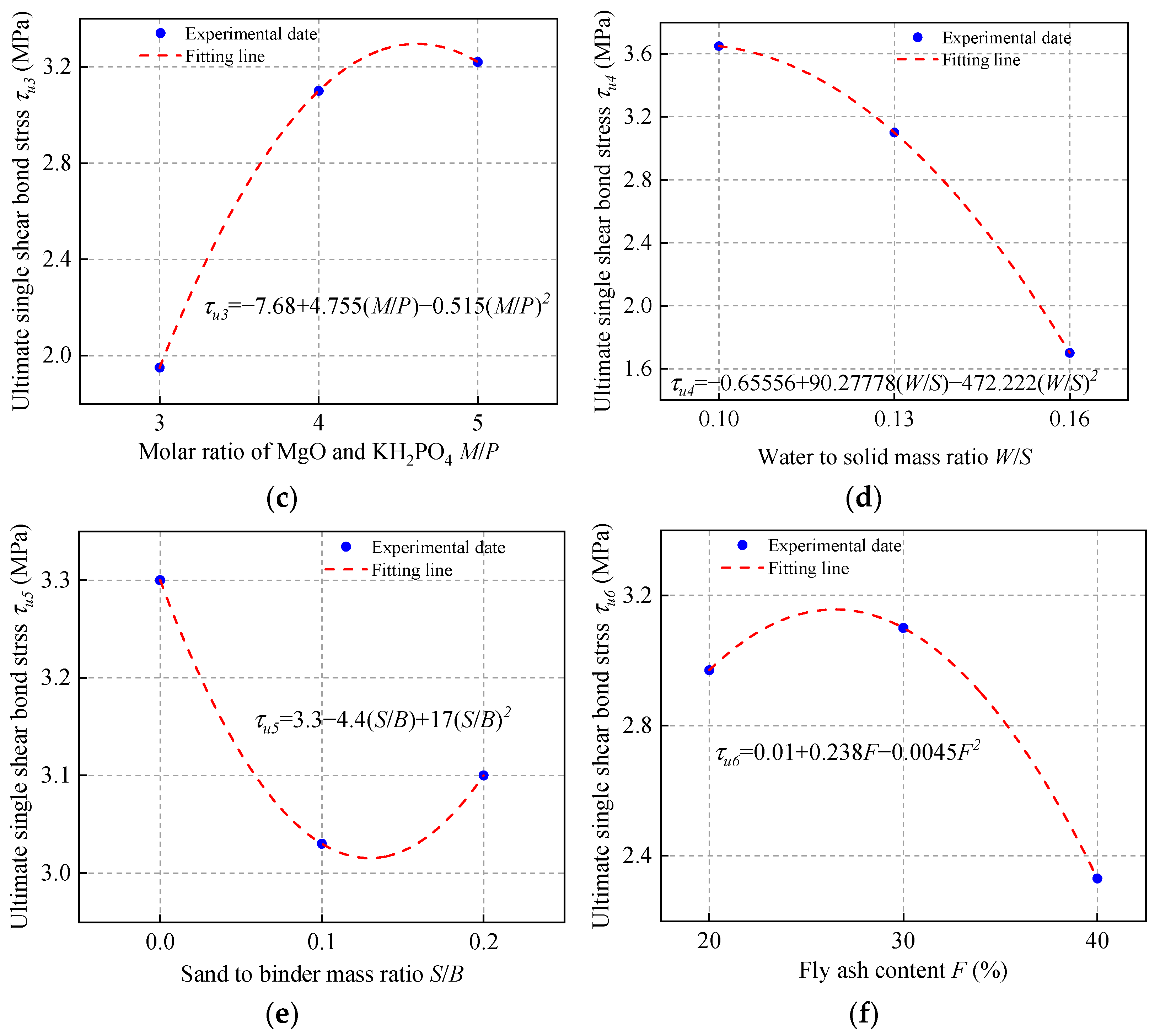

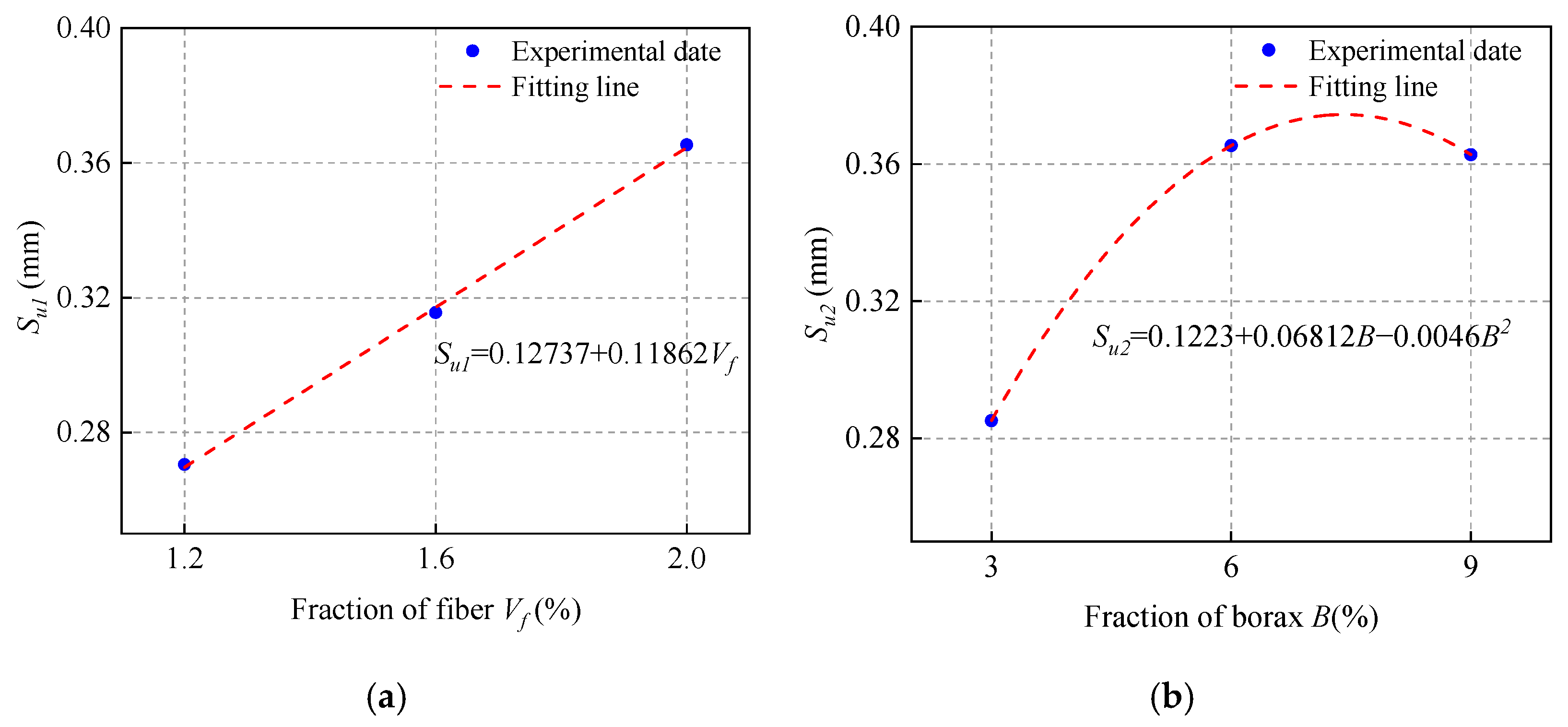

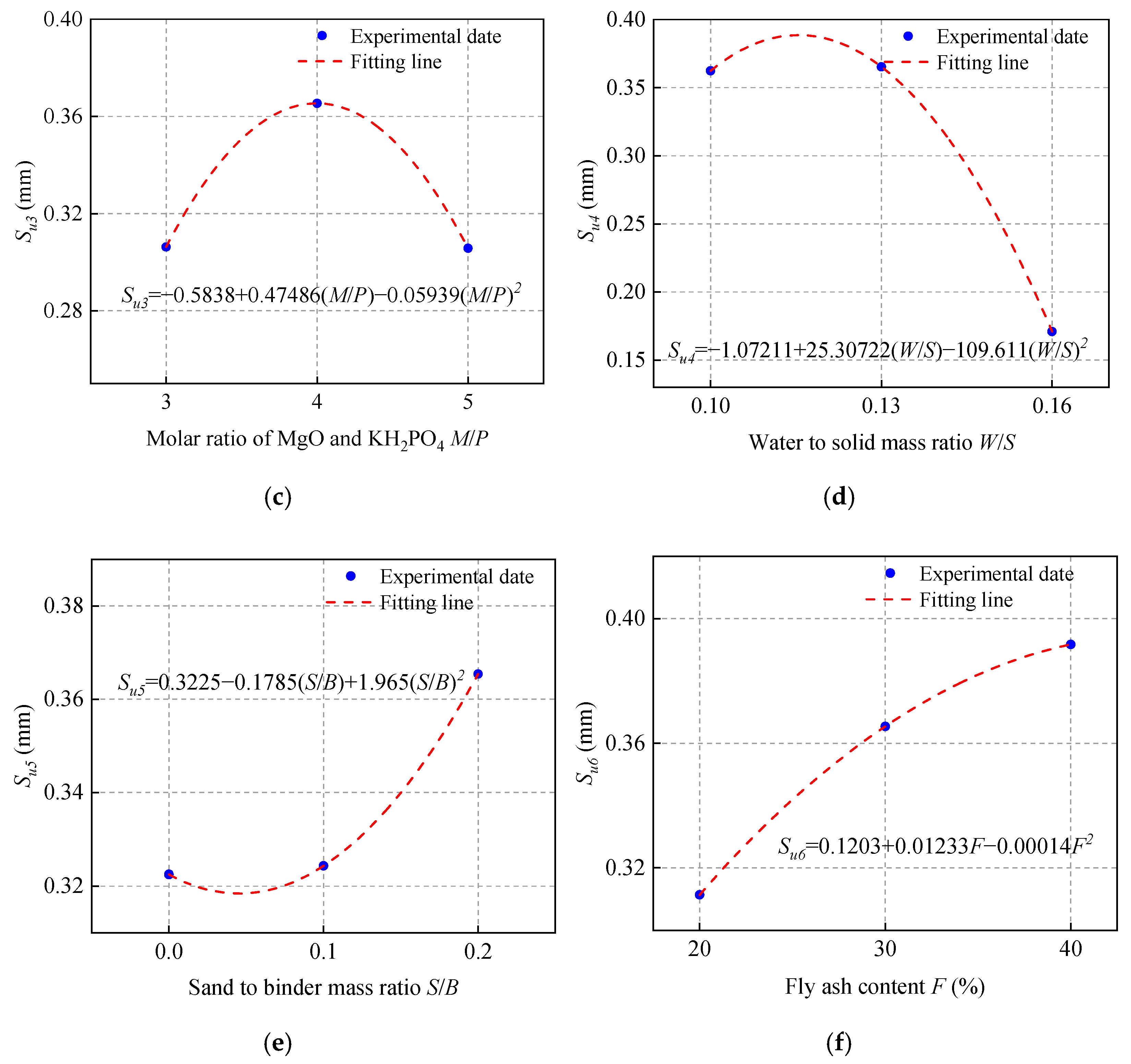

3.1. Effect of Water to Solid Mass Ratio (W/S)

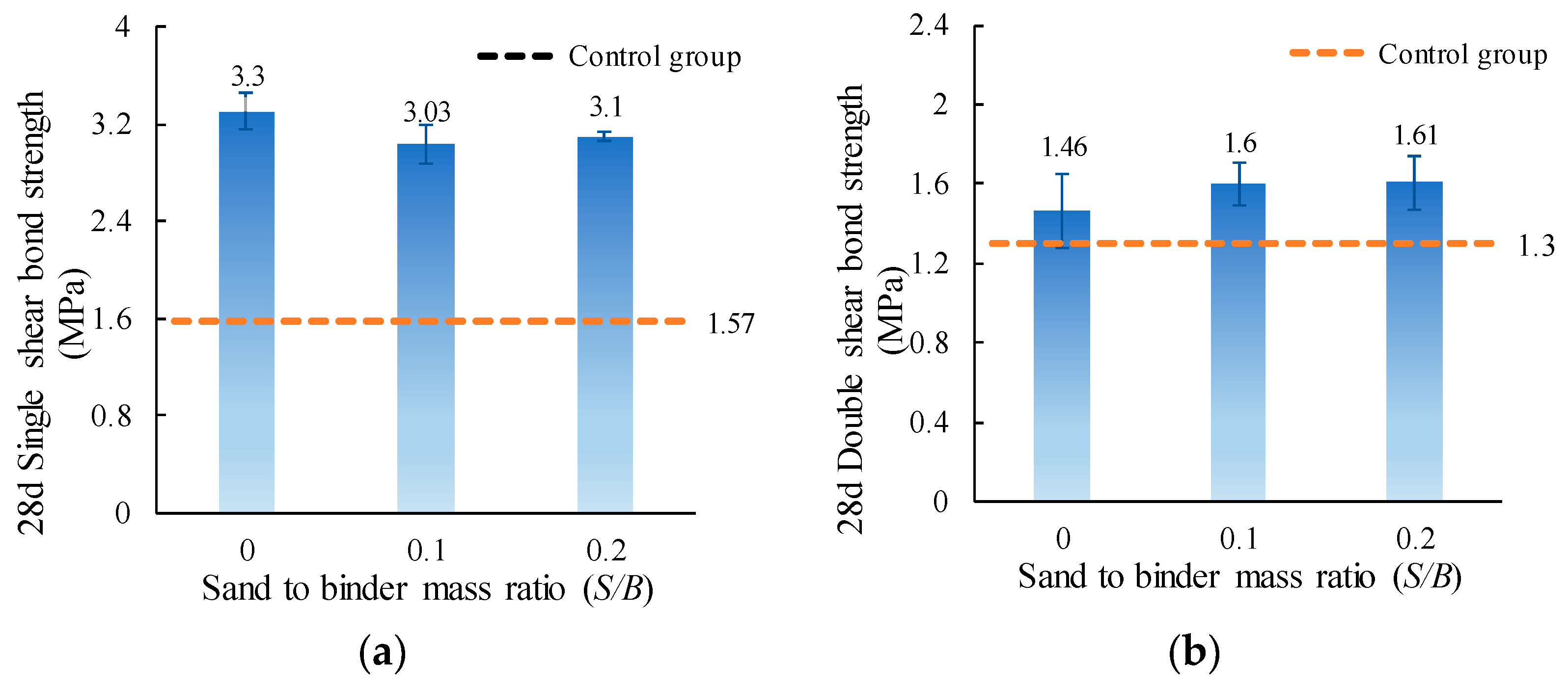

3.2. Effect of Sand to Binder Mass Ratio (S/B)

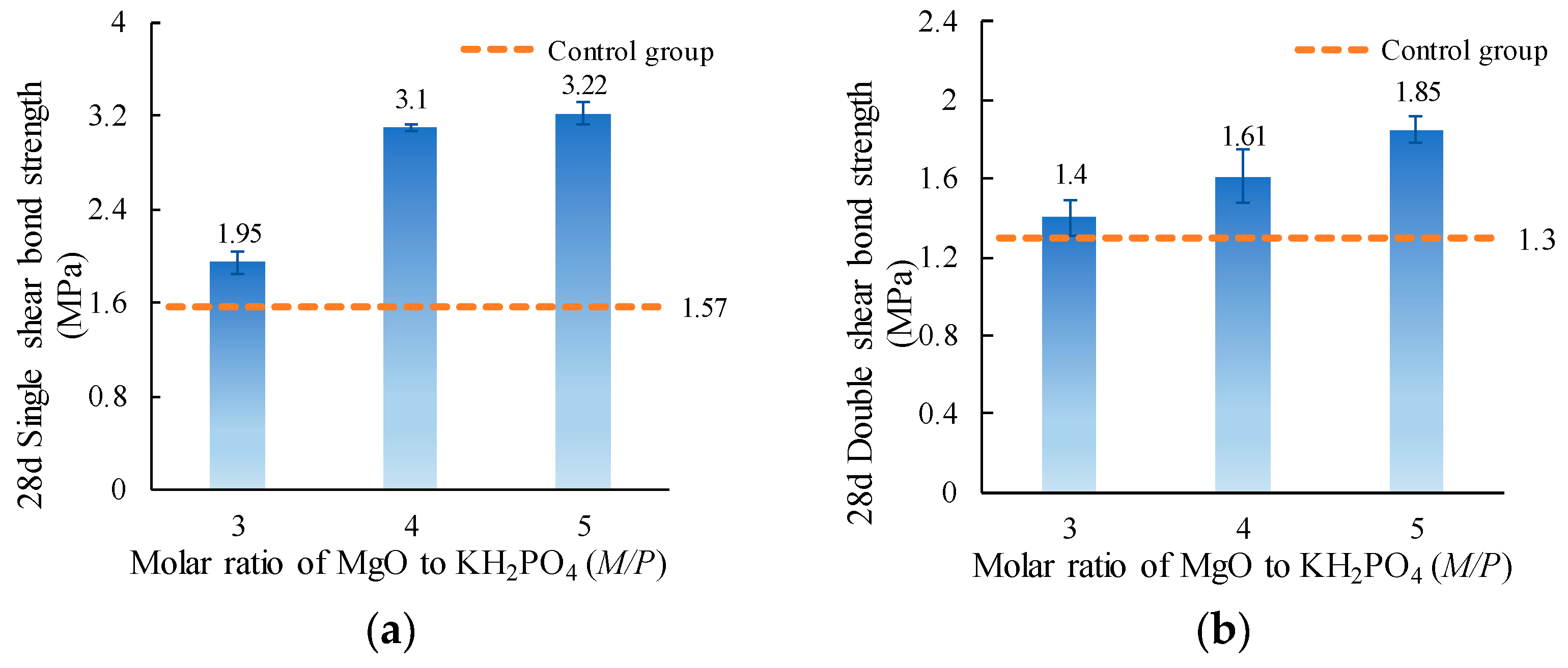

3.3. Effect of Magnesia to Phosphate Molar Ratio (M/P)

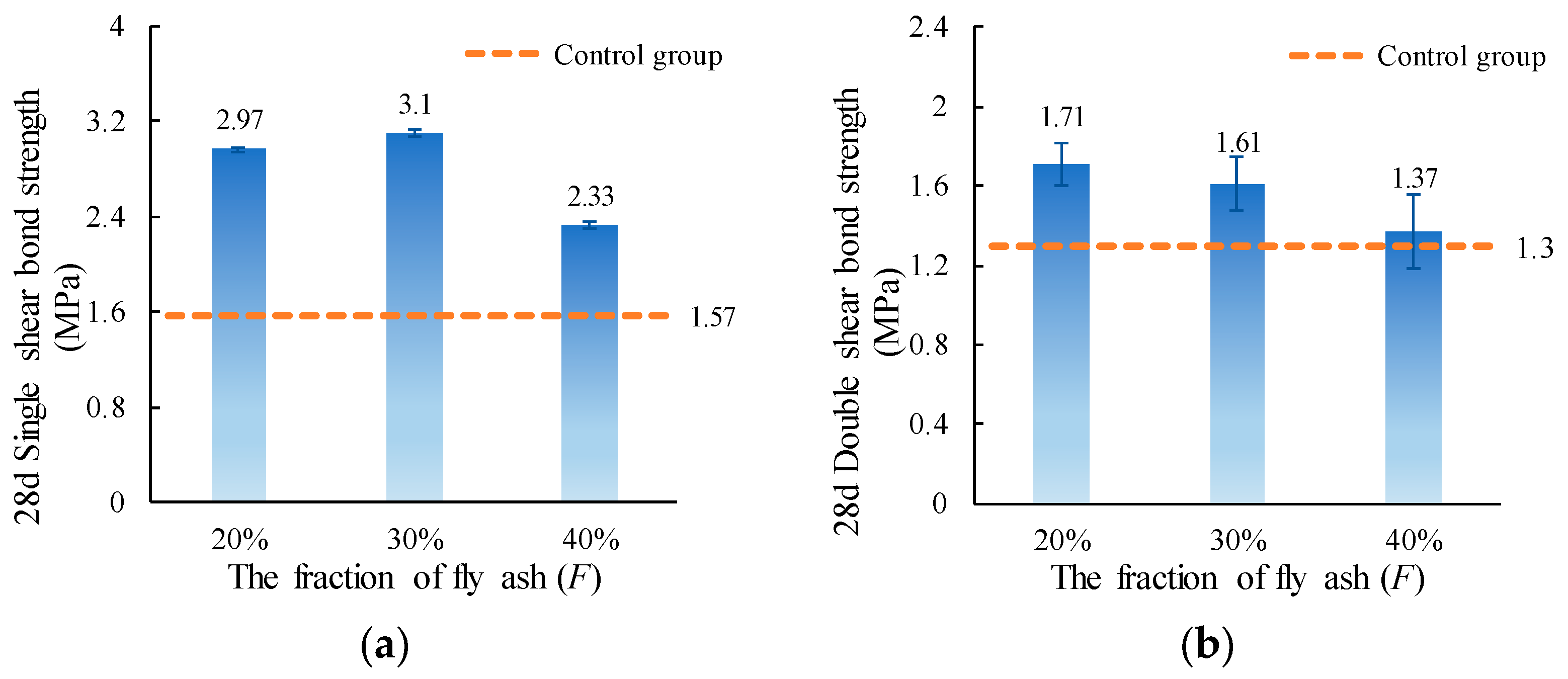

3.4. Effect of FA Content (F)

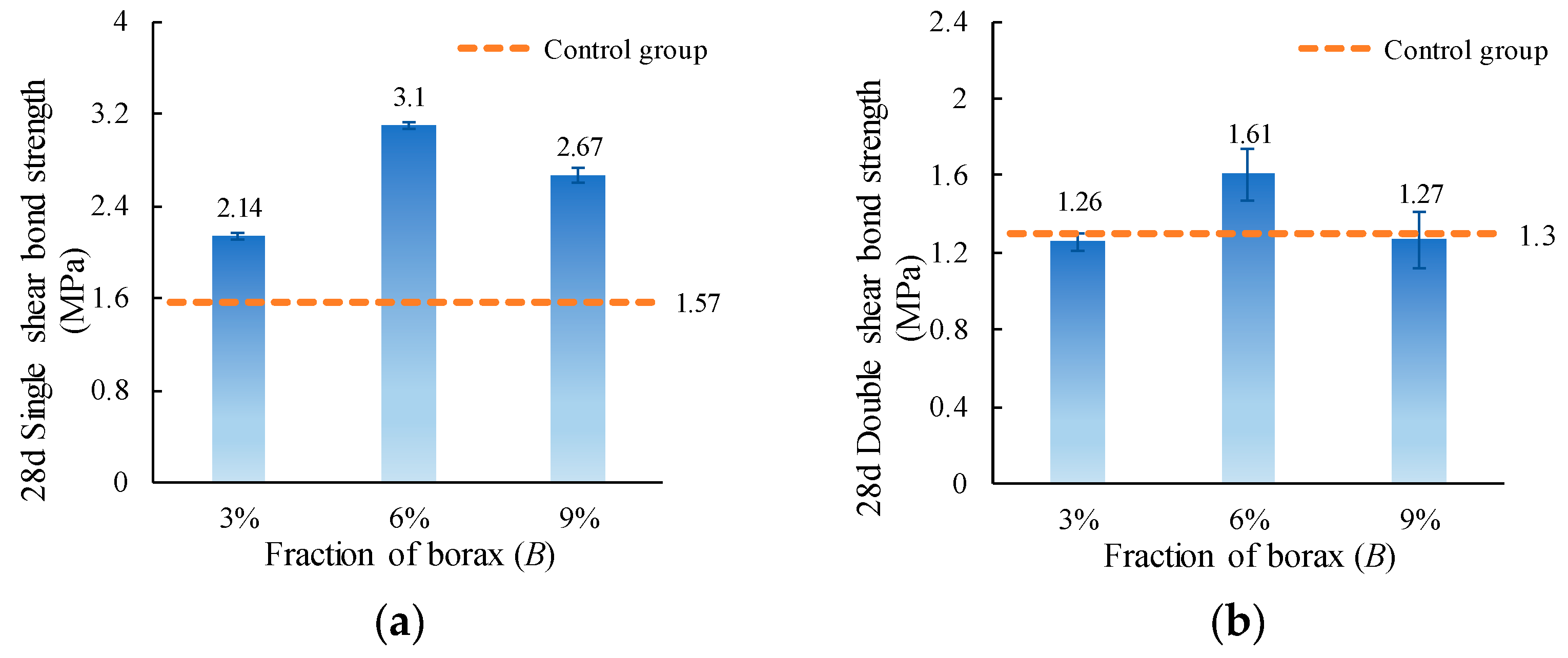

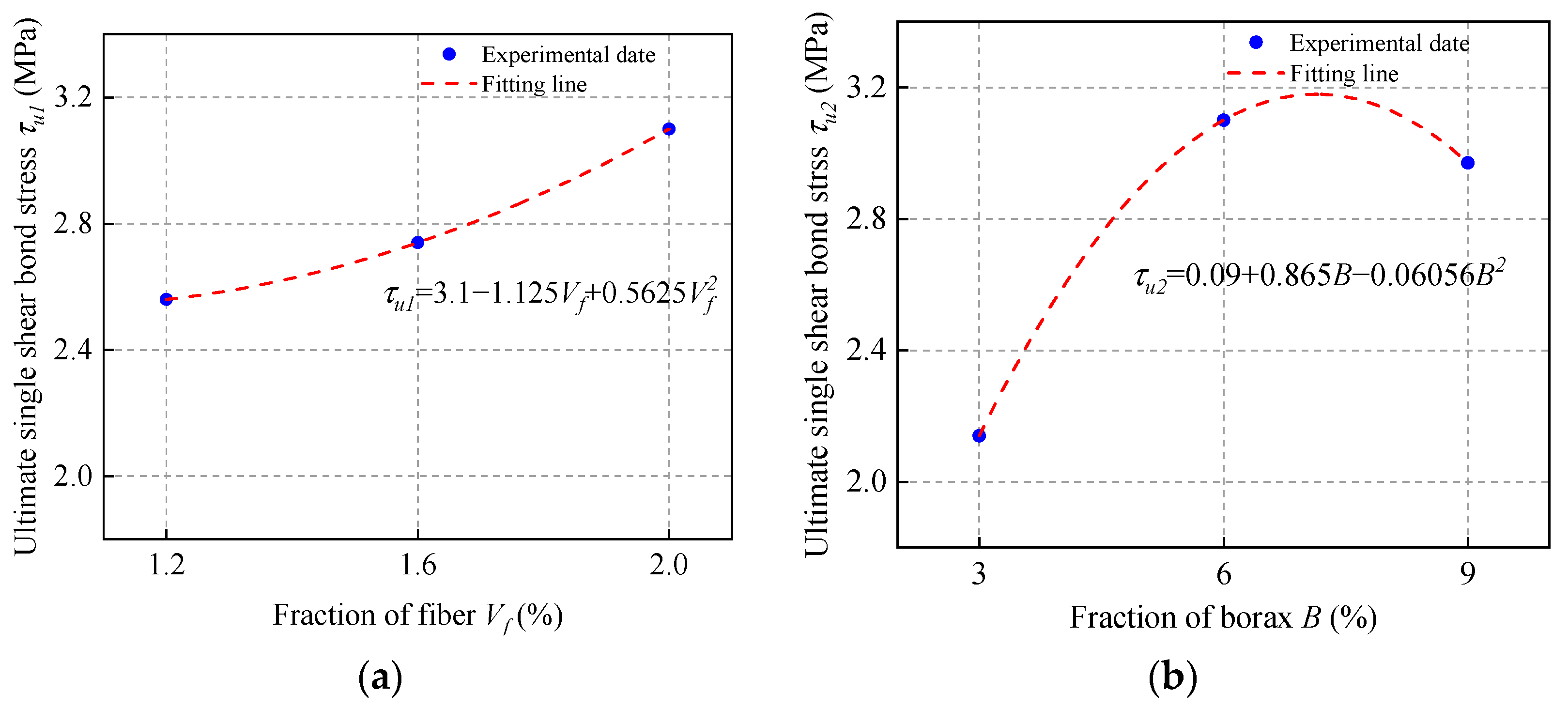

3.5. Effect of Borax Content (B)

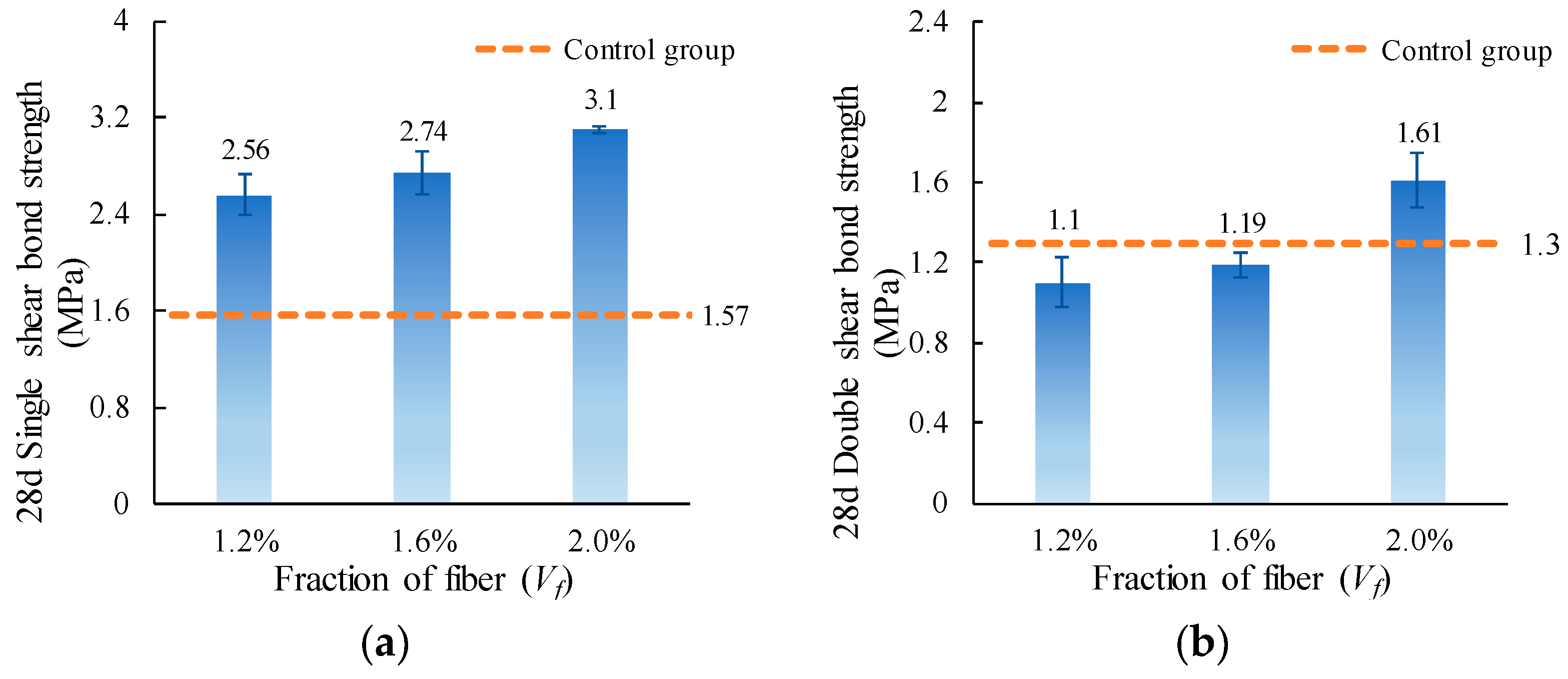

3.6. Effect of Fiber Volume Fraction (Vf)

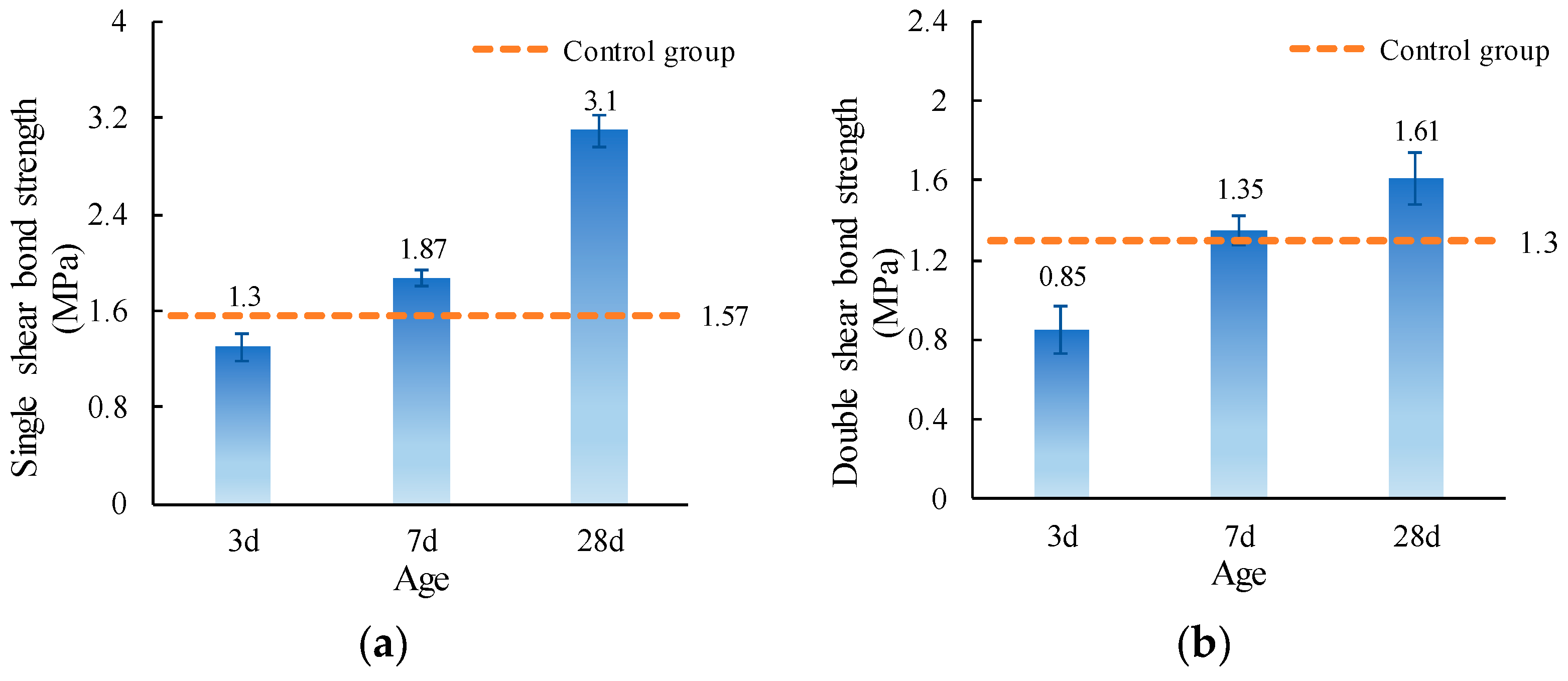

3.7. Effect of Curing Age

4. Bond–Slip Model of MPC-ECC with Ordinary Concrete

[−7.68 + 4.755(M/P) − 0.515 (M/P)2] [−0.65556 + 90.27778(W/S) − 472.2222 (W/S)2]

[3.3 − 4.4 (S/B) + 17 (S/B)2] (0.01 + 0.238F − 0.0045F2)

[−0.5838 + 0.47486 (M/P) − 0.05939 (M/P)2] [−1.07211 + 25.30722 (W/S) − 109.61111 (W/S)2]

[0.3225−0.1785(S/B)+1.965(S/B)2](0.1203+0.01233F−0.0001385F2)

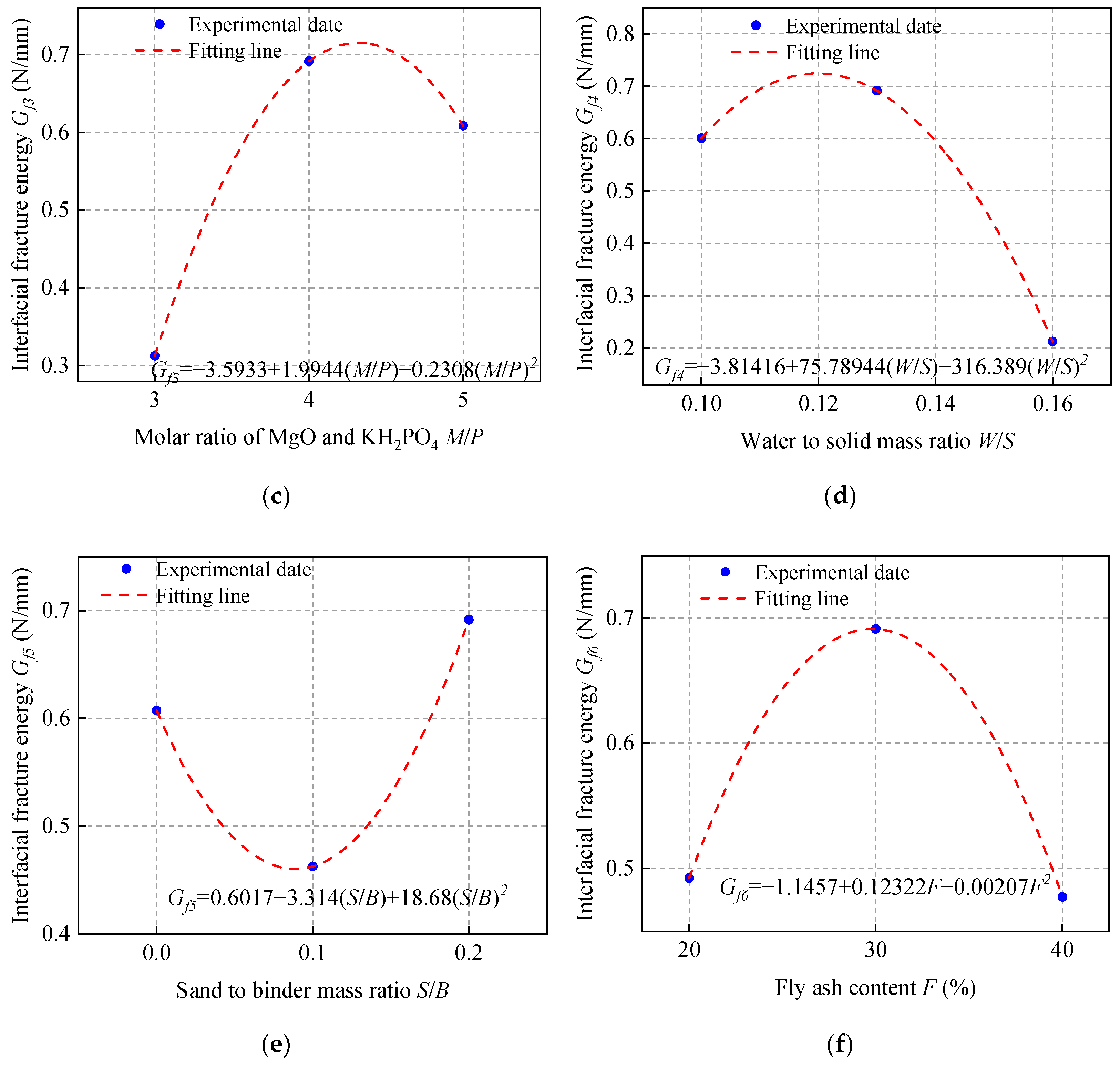

[−3.5933 + 1.9944 (M/P) − 0.2308 (M/P)2] [−3.81416 + 75.78944 (W/S) − 316.38889 (W/S)2]

[0.6071 − 3.314 (S/B) + 18.36 (S/B)2] (−1.1457 + 0.12322F − 0.00207F2)

5. Conclusions

- (1)

- The shear bond strength decreases as the W/S increases. The single shear bond strength and double shear bond strength are the highest at the W/S of 0.10, reaching 3.65 MPa and 1.99 MPa, respectively. But as the S/B increases, the effects of S/B on single shear bond strength and double shear bond strength are not obvious.

- (2)

- As the M/P and the fiber volume fraction increase, the shear bond strength increases. The single and double shear bond strengths are highest at M/P = 5, 3.22 MPa, and 1.85 MPa, respectively. This result is probably due to the microscopic morphology of hydration products at different M/P. The shear bond strength is highest at a fiber volume fraction of 2.0%.

- (3)

- The single and double shear bond strengths are highest at 30% and 20% FA content, 3.10 MPa and 1.70 MPa, respectively. The bond effect is best when FA content is between 20% and 30%, while the development of bond strength is not good when FA content is too high. Similarly, the single and double shear bond strengths of the specimens are highest at a borax dosage of 6%, reaching 3.10 MPa and 1.61 MPa, respectively. A too high or too low borax dosage is not conducive to the development of the bond strength.

- (4)

- The single and double shear bond strengths after 3 d of standard curing of MPC-ECC reached nearly 82.8% and 66.7% of those of the control group at 28 d, respectively. The double shear bond strength at 7 d reaches 100% of that of the control group at 28 d. The single and double shear bond strengths after 28 d of standard curing are all higher than those of the control group at 28 d, nearly twice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, D.; Sun, P.; Wang, A.; Xu, W. Research of Magnesium Phosphate Cement and Its Development Prospects. Mater. Rev. 2013, 9, 70–75. [Google Scholar]

- Kim, H.; Han, D.; Kim, K.; Romero, P. Performance assessment of repair material for deteriorated concrete slabs using chemically bonded cement. Constr. Build. Mater. 2020, 237, 117468. [Google Scholar] [CrossRef]

- Gardner, L.J.; Bernal, S.A.; Walling, S.A.; Corkhill, C.L.; Provis, J.L.; Hyatt, N.C. Characterisation of magnesium potassium phosphate cements blended with fly ash and ground granulated blast furnace slag. Cem. Concr. Res. 2015, 74, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Haque, M.A.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Evaluating the physical and strength properties of fibre reinforced magnesium phosphate cement mortar considering mass loss. Constr. Build. Mater. 2019, 217, 427–440. [Google Scholar] [CrossRef]

- Fa, N.S.; Chen, B. Experimental study of phosphate salts influencing properties of magnesium phosphate cement. Constr. Build. Mater. 2014, 65, 480–486. [Google Scholar]

- Li, Y.; Li, Y.; Shi, T.; Li, J. Experimental study on mechanical properties and fracture toughness of magnesium phosphate cement. Constr. Build. Mater. 2015, 96, 346–352. [Google Scholar] [CrossRef]

- Yu, J.; Ahmad, M.R.; Bing, C. Properties of magnesium phosphate cement containing steel slag powder. Constr. Build. Mater. 2018, 195, 140–147. [Google Scholar]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Seehra, S.S.; Gupta, S.; Kumar, S. Rapid setting magnesium phosphate cement for quick repair of concrete pavements—Characterisation and durability aspects. Cem. Concr. Res. 1993, 23, 254–266. [Google Scholar] [CrossRef]

- Sugama, T.; Kukacka, L.E. Characteristics of magnesium polyphosphate cements derived from ammonium polyphosphate solutions. Cem. Concr. Res. 1983, 13, 499–506. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, B.; Wu, X. Characteristics and durability test of magnesium phosphate cement-based material for rapid repair of concrete. Mater. Struct. 2000, 33, 229–234. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, B.; Zhang, S.; Wu, X. Properties and applications of magnesia–phosphate cement mortar for rapid repair of concrete. Cem. Concr. Res. 2000, 30, 1807–1813. [Google Scholar] [CrossRef]

- Ramezanianpour, A. Cylindrical specimen for measuring shrinkage in repaired concrete members. Constr. Build. Mater. 2005, 19, 107–116. [Google Scholar]

- Goodier, C.I.; Austin, S.A.; Robins, P.J. Low-volume wet-process sprayed concrete: Hardened properties. Mater. Struct. 2008, 41, 99. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Liang, B.; Zhang, L. Investigation of MPB with Super Early Strength for Repair of Concrete. J. Build. Mater. 2001, 4, 196–198. [Google Scholar]

- Yang, Q.B.; Zhang, S.Q.; Wu, X.L. Deicer-scaling resistance of phosphate cement-based binder for rapid repair of concrete. Cem. Concr. Res. 2002, 32, 165–168. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Li, Z.; You, C.; Dai, X.; Yue, Y.; Fan, Y. Mechanical properties of basalt fiber reinforced magnesium phosphate cement composites. Constr. Build. Mater. 2018, 188, 946–955. [Google Scholar] [CrossRef]

- Mraa, B.; Bing, C.; Jiang, Y.A. A comprehensive study of basalt fiber reinforced magnesium phosphate cement incorporating ultrafine fly ash. Compos. Part B Eng. 2019, 168, 204–217. [Google Scholar]

- Li, V.C.; Kanda, T. Innovations Forum: Engineered Cementitious Composites for Structural Applications. J. Mater. Civ. Eng. 1998, 10, 66–69. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C.; Wang, S.X.; Wu, C. Tensile strain-hardening behavior or polyvinyl alcohol engineered cementitious composite (PVA-ECC). Aci. Mater. J. 2001, 98, 483–492. [Google Scholar]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.A. Tensile Strain Hardening Behavior of PVA Fiber-Reinforced Engineered Geopolymer Composite. J. Mater. Civ. Eng. 2015, 27, 04015001. [Google Scholar] [CrossRef]

- Ranade, R.; Stults, M.D.; Lee, B.; Li, V.C. Effects of fiber dispersion and flaw size distribution on the composite properties of PVA-ECC. In High Performance Fiber Reinforced Cement Composites 6; RILEM Book Series; Springer: Dordrecht, The Netherlands, 2012; pp. 107–114. [Google Scholar]

- Yu, K.; Mcgee, W.; Ng, T.Y.; Zhu, H.; Li, V.C. 3D-printable engineered cementitious composites (3DP-ECC): Fresh and hardened properties. Cem. Concr. Res. 2021, 143, 106388. [Google Scholar] [CrossRef]

- Choi, J.I.; Song, K.I.; Song, J.K.; Lee, B.Y. Composite properties of high-strength polyethylene fiber-reinforced cement and cementless composites. Compos. Struct. 2016, 138, 116–121. [Google Scholar] [CrossRef]

- Yu, J.T.; Yu, K.Q.; Xu, S.L. Basic mechanical properties of ultra-high ductility cementitious composites: From 40 MPa to 120 MPa. Compos. Struct. 2018, 185, 634–645. [Google Scholar]

- Ranade, R.; Li, V.C.; Heard, W.F. Tensile Rate Effects in High Strength-High Ductility Concrete. Cem. Concr. Res. 2015, 68, 94–104. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Yu, K.Q.; Yu, J.T.; Dai, J.G.; Lu, Z.D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Zhang, R.; Matsumoto, K.; Hirata, T.; Ishizeki, Y.; Niwa, J. Application of PP-ECC in beam–column joint connections of rigid-framed railway bridges to reduce transverse reinforcements. Eng. Struct. 2015, 86, 146–156. [Google Scholar] [CrossRef]

- Zhong, R.; Zhang, F.; Poh, L.H.; Wang, S.; Le, H.T.N.; Zhang, M.-H. Assessing the effectiveness of UHPFRC, FRHSC and ECC against high velocity projectile impact. Cem. Concr. Compos. 2021, 120, 104013. [Google Scholar] [CrossRef]

- Kim, D.J.; Naaman, A.E.; Eltawil, S. High Performance Fiber Reinforced Cement Composites with Innovative Slip Hardending Twisted Steel Fibers. Int. J. Concr. Struct. Mater. 2009, 3, 119–126. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.; Ding, Y.; Liu, J.; Bai, Y. Energy dissipation characteristics of all-grade polyethylene fiber-reinforced engineered cementitious composites (PE-ECC). Cem. Concr. Compos. 2020, 106, 103459. [Google Scholar] [CrossRef]

- Feng, H.; Li, Z.; Wang, W.; Liu, G.; Zhang, Z.; Gao, D. Deflection hardening behaviour of ductile fibre reinforced magnesium phosphate cement-based composite. Cem. Concr. Compos. 2021, 121, 104079. [Google Scholar] [CrossRef]

- Li, D.X.; Feng, C.H. Study on Modification of the Magnesium Phosphate Cement-Based Material by Fly Ash. Adv. Mater. Res. 2011, 150–151, 1655–1661. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Shao, H.; Li, Z.; Lothenbach, B. Influence of fly ash on compressive strength and micro-characteristics of magnesium potassium phosphate cement mortars. Cem. Concr. Res. 2017, 99, 86–94. [Google Scholar] [CrossRef]

- GB/T 50107-2010; Concrete strength test and evaluation standard. National Standard of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

- GB 175-2007; Common Portland Cement: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. China National Standardization Administration: Beijing, China, 2007. (In Chinese)

- Shen, S.H. Experimental Study on Bending Property of High ductility Magnesium Phosphate Cement-Based Composites Under Low Temperature Curing Condition. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2020. (In Chinese). [Google Scholar]

- Ding, W.; Wei, Q.D. JGJ/T221—2010, Technical Regulations for the Application of Fibre Concrete. Constr. Tech. 2011, 40, 101–103. (In Chinese) [Google Scholar]

- Wang, A.J.; Zhang, J.; Li, J.M.; Ma, A.B.; Liu, L.T. Effect of liquid-to-solid ratios on the properties of magnesium phosphate chemically bonded ceramics. Mater. Sci. Eng. C 2013, 33, 2508–2512. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Liu, J.; Pei, H.; Li, Z. Effects of water content, magnesia-to-phosphate molar ratio and age on pore structure, strength and permeability of magnesium potassium phosphate cement paste. Mater. Design 2014, 64, 497–502. [Google Scholar] [CrossRef]

- Chau, C.K.; Qiao, F.; Li, Z. Microstructure of magnesium potassium phosphate cement. Constr. Build. Mater. 2011, 25, 2911–2917. [Google Scholar] [CrossRef]

- Zhang, X.C. Study of Interface Bond Behavior between Precast Ultra High Performance Concrete Repaired Layer and Existing Concrete Structure. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2016. (In Chinese). [Google Scholar]

- Zhou, N. The Research on Interfacial Bond Behavior of polyvinyl alcohol fiber Cement Mortar to Concrete. Master’s Thesis, Hunan University, Changsha, China, 2011. (In Chinese). [Google Scholar]

- Wang, A.J.; Yuan, Z.L.; Zhang, J.; Liu, L.T.; Li, J.M.; Liu, Z. Effect of raw material ratios on the compressive strength of magnesium potassium phosphate chemically bonded ceramics. Mater. Sci. Eng. C 2013, 33, 5058–5063. [Google Scholar] [CrossRef]

- Yang, Q.B.; Wu, X.L. Factors influencing properties of phosphate cement-based binder for rapid repair of concrete. Cem. Concr. Res. 1999, 29, 389–396. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects: I. The morphological effect of fly ash. Cem. Concr. Res. 2003, 33, 2023–2029. [Google Scholar] [CrossRef]

- Li, Y.; Shi, T.; Li, J. Effects of fly ash and quartz sand on water-resistance and salt-resistance of magnesium phosphate cement. Constr. Build. Mater. 2016, 105, 384–390. [Google Scholar] [CrossRef]

- Yang, J.; Qian, C. Effect of borax on hydration and hardening properties of magnesium and pottassium phosphate cement pastes. J. Wuhan Univ. Technol.-Mater. Sci. Ed 2010, 25, 613–618. [Google Scholar] [CrossRef]

| SiO2 Content | Mohs Hardness | Porosity | Specific Gravity (g/cm3) |

|---|---|---|---|

| 99.3% | 7.5 | 43% | 2.66 |

| Fineness (45-Micron Standard Square Hole Sieve Allowance) | Water Requirement Ratio | Loss on Ignition | Moisture Content | Sulfur Trioxide | Free Calcium |

|---|---|---|---|---|---|

| 6% | 92% | 4% | 3% | 1.48% | / |

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO |

|---|---|---|---|---|---|

| Percentage of mass (%) | 53.97 | 31.15 | 4.16 | 4.01 | 1.01 |

| Diameter (μm) | Length (mm) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| 40 | 12 | 1560 | 41 | 6.5 | 1.3 |

| Mineral Composition | C3S | C2S | C3A | C4AF | Gypsum |

|---|---|---|---|---|---|

| Mass percent (%) | 55.5 | 19.1 | 6.5 | 10.1 | 5 |

| Mineral Composition | C3S | C2S | C3A | C4AF | Gypsum |

|---|---|---|---|---|---|

| Mass percent (%) | 55.5 | 19.1 | 6.5 | 10.1 | 5 |

| Mix ID | W/S | S/B | M/P | Vf (%) | F (%) | B (%) |

|---|---|---|---|---|---|---|

| W/S-0.10 | 0.10 | |||||

| W/S-0.13 | 0.13 | 0.2 | 4 | 2.0% | 30% | 6% |

| W/S-0.16 | 0.16 | |||||

| S/B-0 | 0 | |||||

| S/B-0.1 | 0.13 | 0.1 | 4 | 2.0% | 30% | 6% |

| S/B-0.2 | 0.2 | |||||

| M/P-3 | 3 | 20% | ||||

| M/P-4 | 0.13 | 0.2 | 4 | 2.0% | 30% | 6% |

| M/P-5 | 5 | 40% | ||||

| Vf-1.2% | 1.2% | |||||

| Vf-1.6% | 0.13 | 0.2 | 4 | 1.6% | 30% | 6% |

| Vf-2.0% | 2.0% | |||||

| F-20% | 20% | |||||

| F-30% | 0.13 | 0.2 | 4 | 2.0% | 30% | 6% |

| F-40% | 40% | |||||

| B-3% | 3% | |||||

| B-6% | 0.13 | 0.2 | 4 | 2.0% | 30% | 6% |

| B-9% | 9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.; Feng, H.; Guo, Z.; Guo, A.; Wang, Y. Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete. Materials 2022, 15, 4851. https://doi.org/10.3390/ma15144851

Chang H, Feng H, Guo Z, Guo A, Wang Y. Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete. Materials. 2022; 15(14):4851. https://doi.org/10.3390/ma15144851

Chicago/Turabian StyleChang, Hongtao, Hu Feng, Zeyu Guo, Aofei Guo, and Yongkang Wang. 2022. "Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete" Materials 15, no. 14: 4851. https://doi.org/10.3390/ma15144851

APA StyleChang, H., Feng, H., Guo, Z., Guo, A., & Wang, Y. (2022). Bond Properties of Magnesium Phosphate Cement-Based Engineered Cementitious Composite with Ordinary Concrete. Materials, 15(14), 4851. https://doi.org/10.3390/ma15144851