Influence of Strain Rates during Severe Plastic Strain Processes on Microstructural and Mechanical Evolution in Pure Zinc

Abstract

:1. Introduction

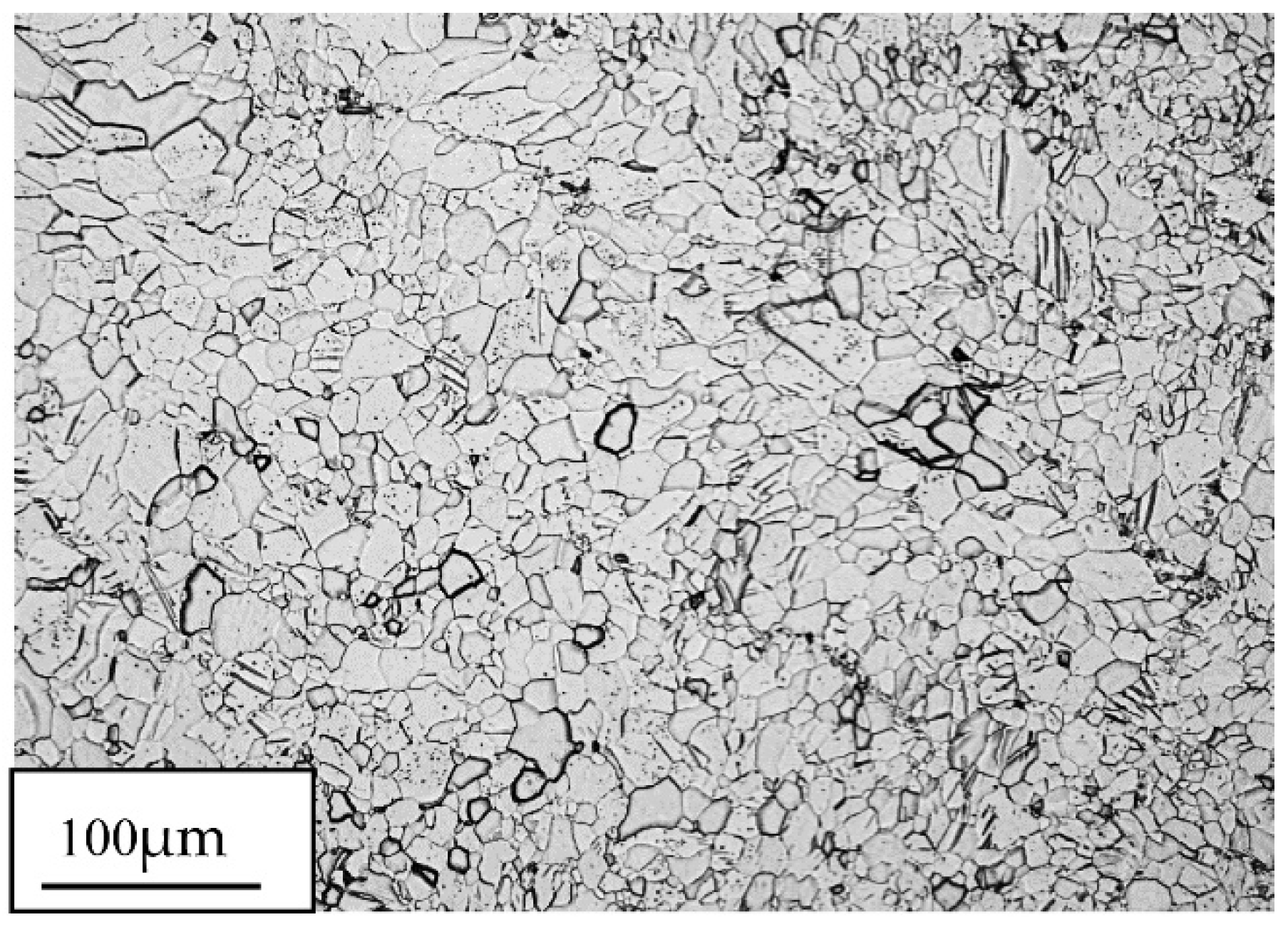

2. Materials and Methods

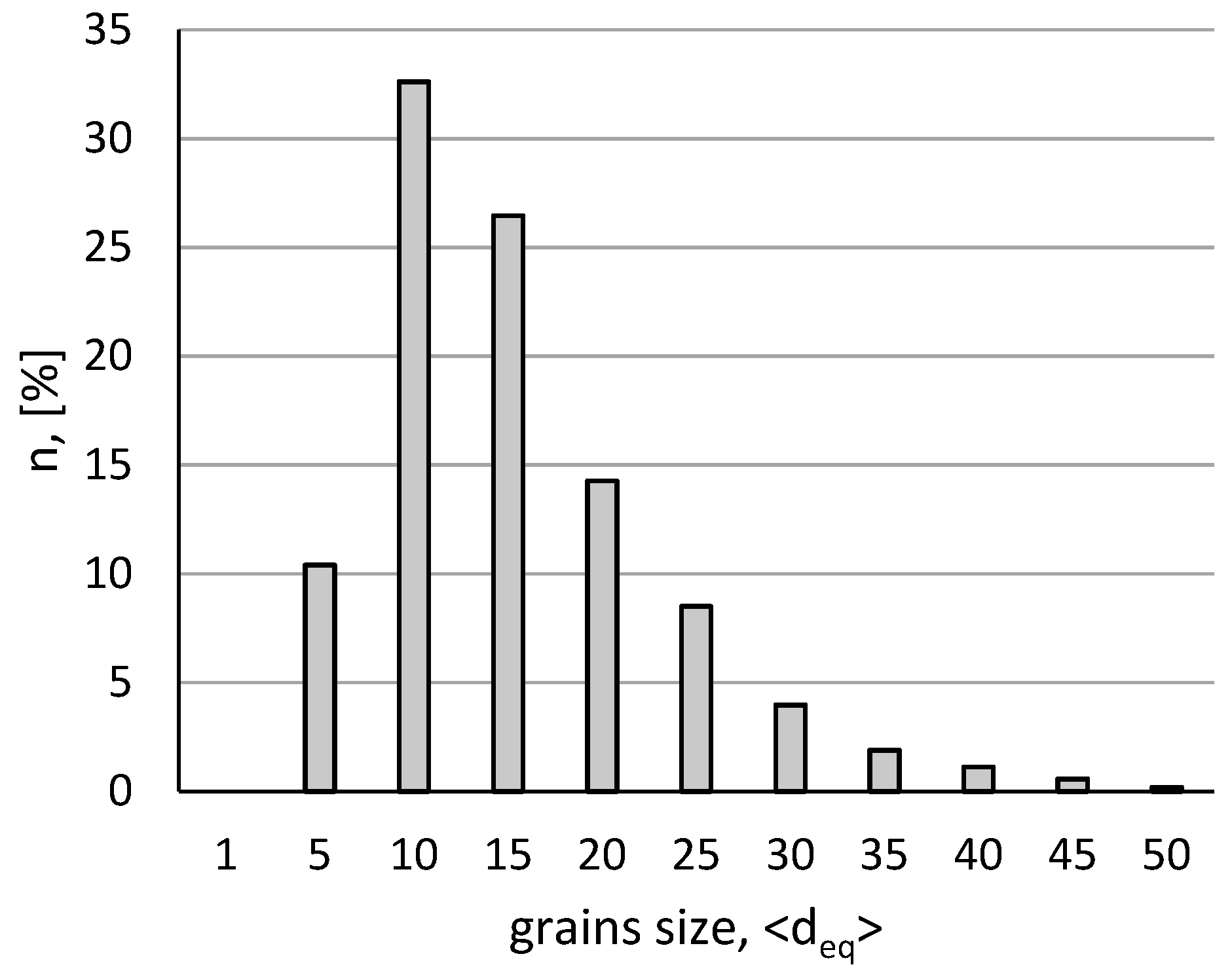

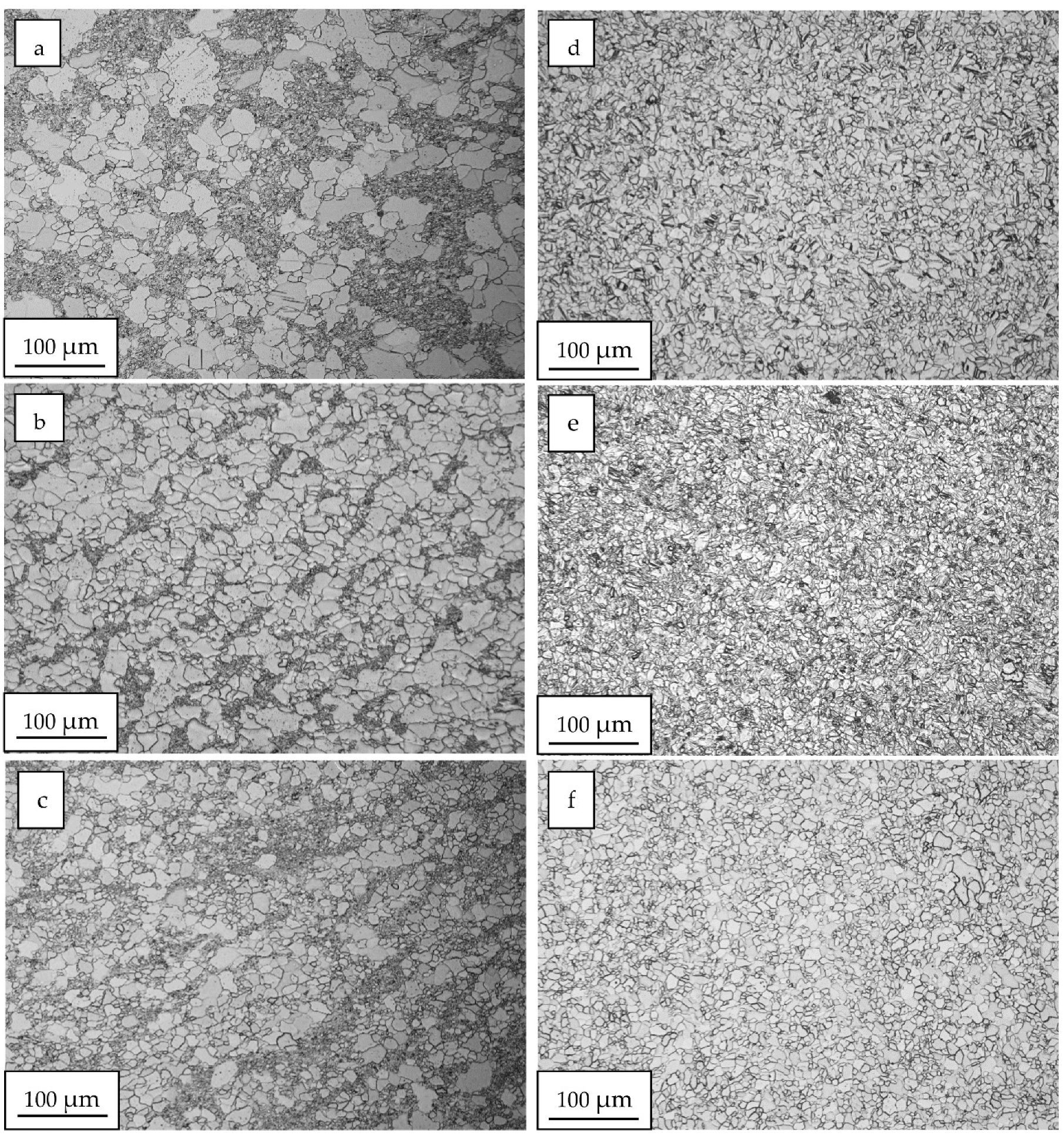

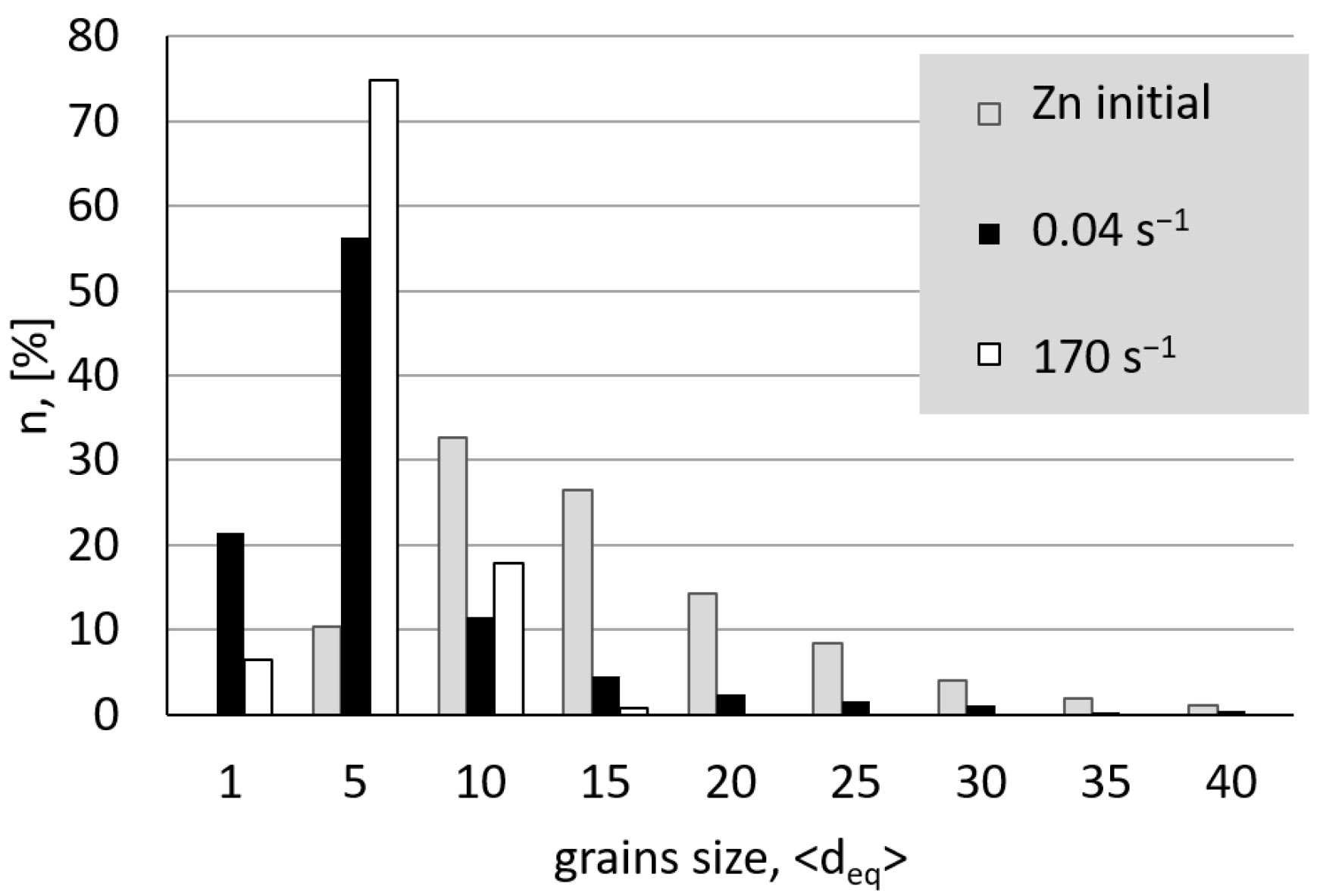

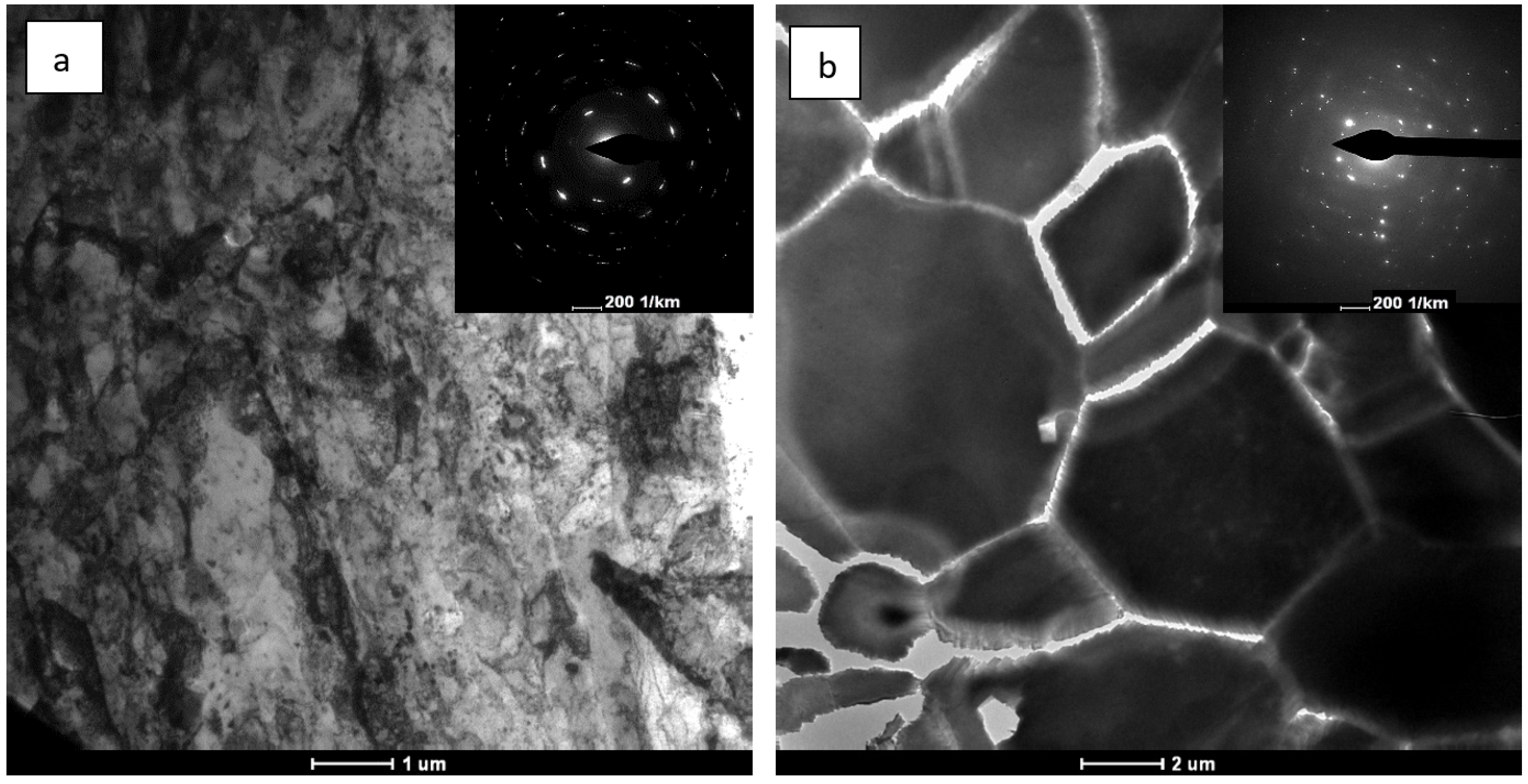

3. Microstructure

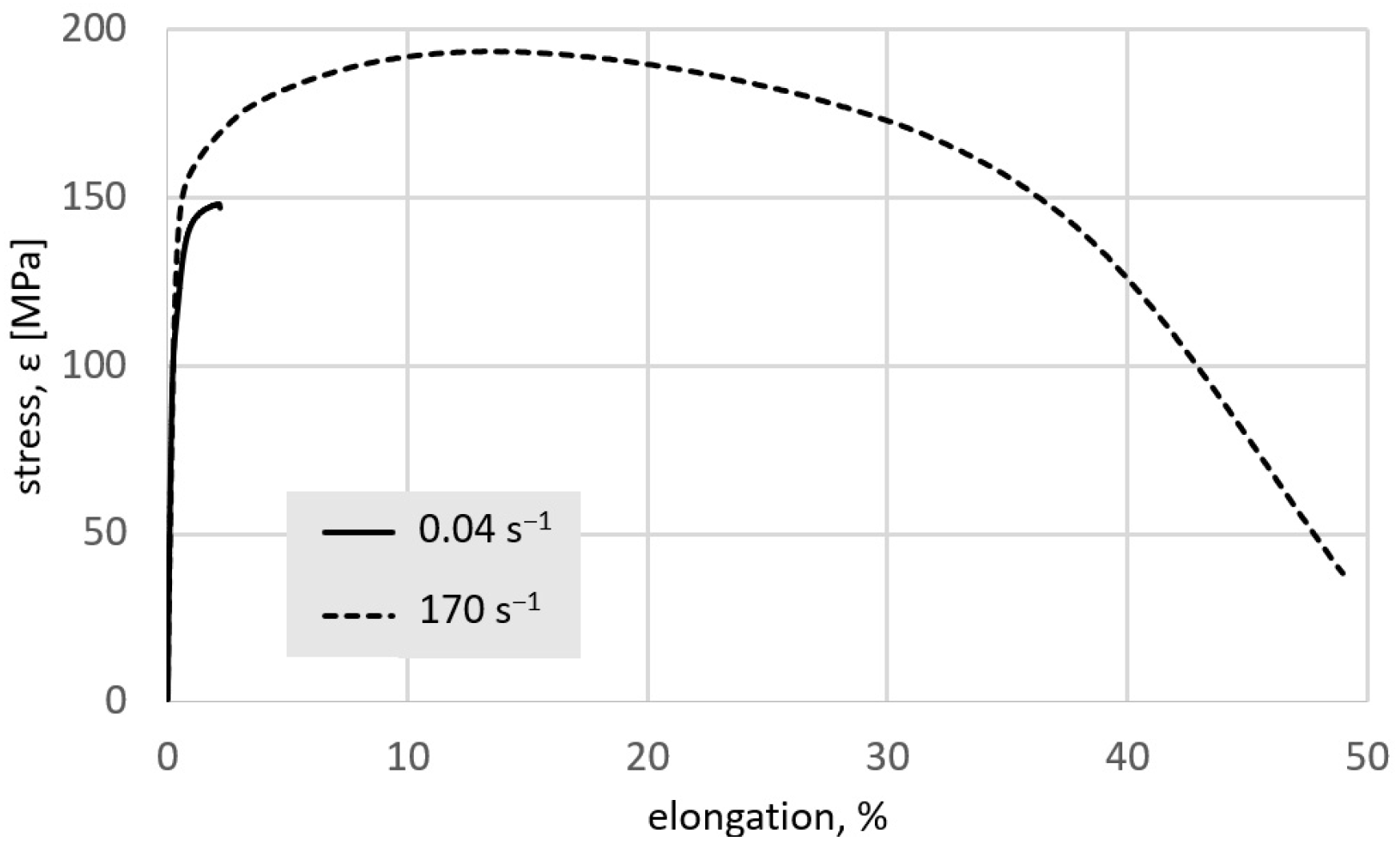

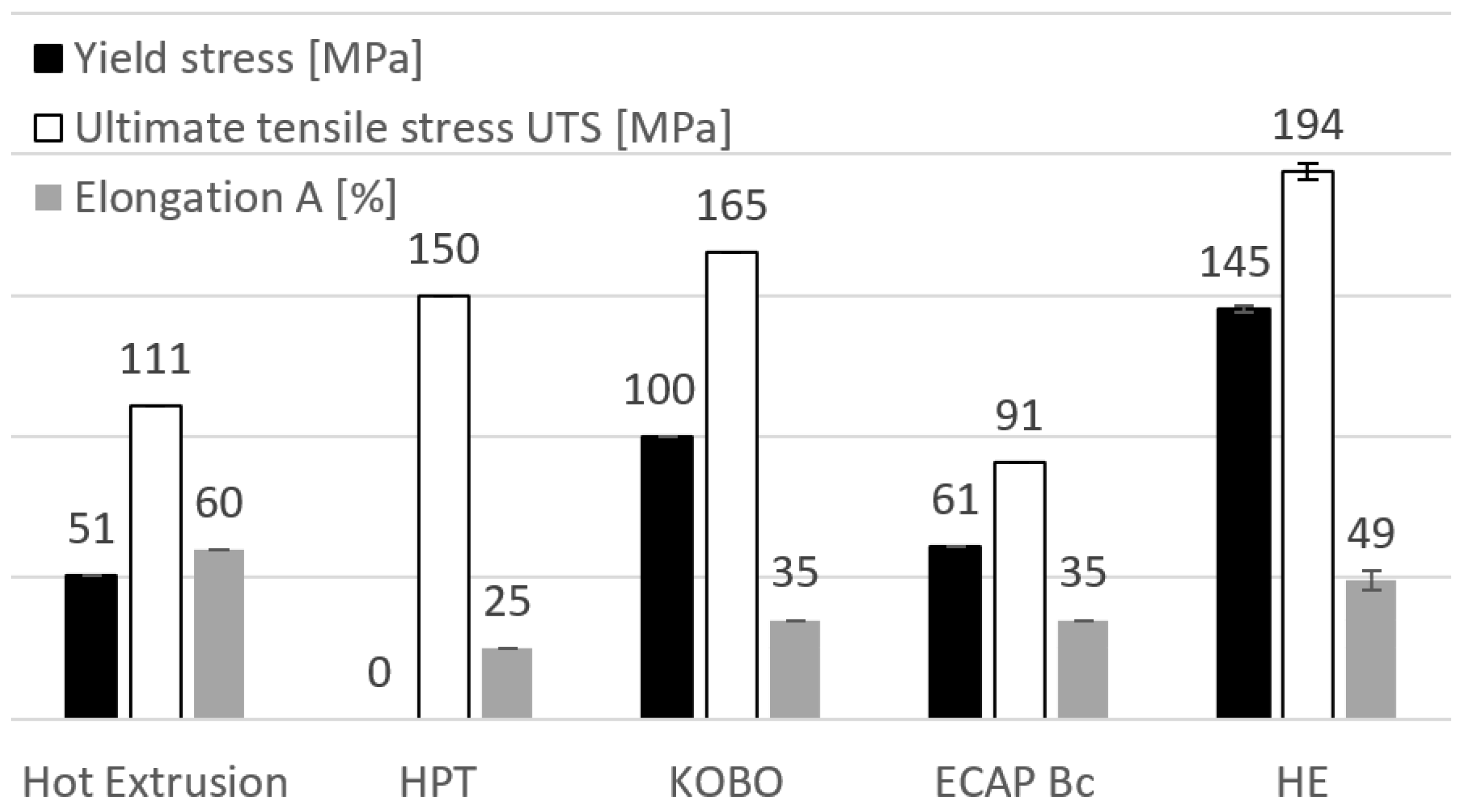

4. Mechanical Properties

5. Conclusions

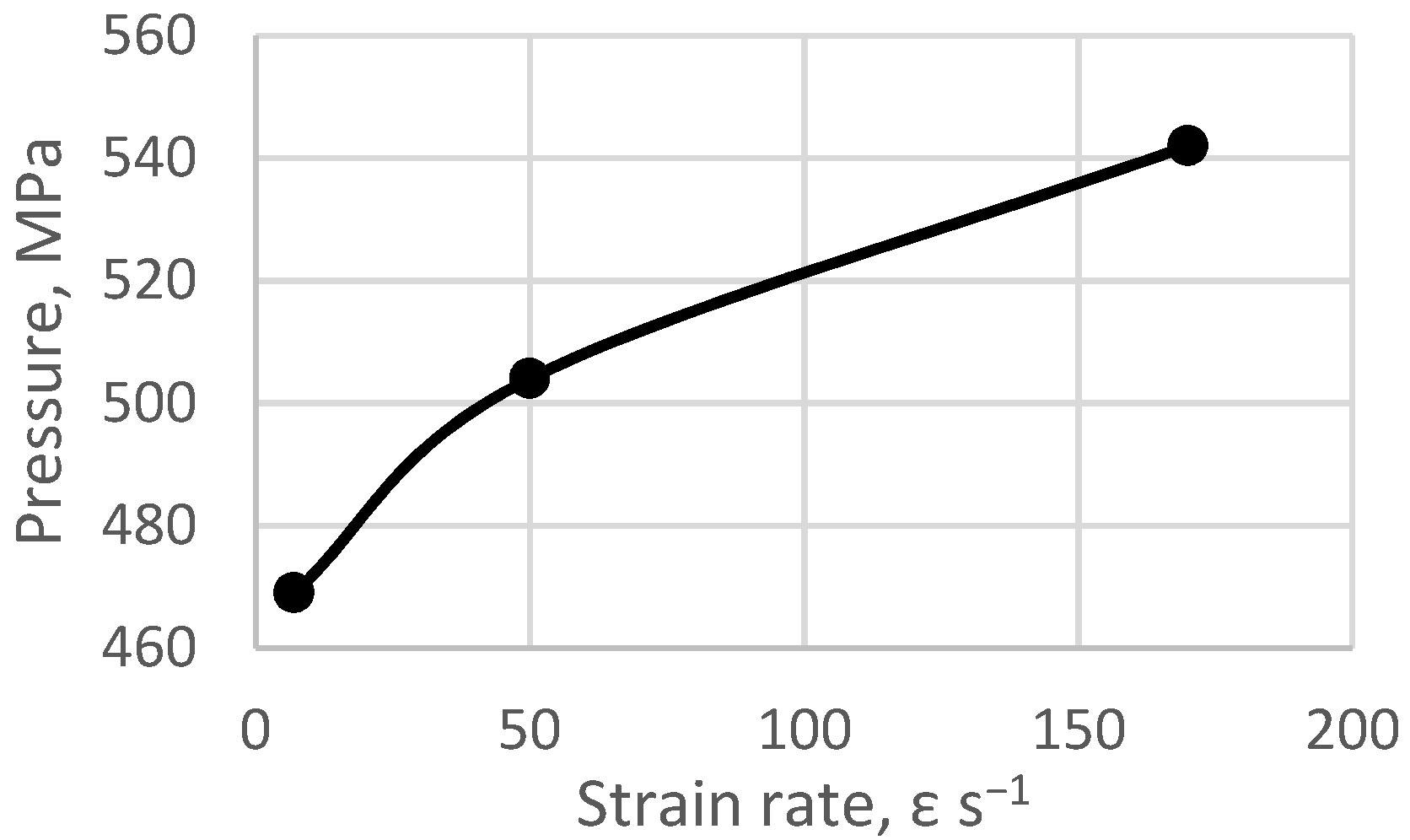

- ➢ Thanks to the use of unconventional methods for generating severe plastic deformation (SPD), namely the ECAP and HE processes, the influence of the plastic strain rate on the mechanical and structural properties of pure zinc in a wide range of plastic strains, between 0.04 s−1 and 170 s−1 was investigated.

- ➢ The test performed showed a strong dependence of changes in the microstructure on the plastic strain rate. For the rates in the range of 0.04 s−1 to 0.53 s−1 a bimodal microstructure was observed. Increasing the strain rate to 7 s−1 caused a significant change in the nature of the microstructure. The microstructure was homogeneous with equiaxed grains free from visible defects inside, which was related to the process of continuous dynamic recrystallization.

- ➢ The maximal plastic strain rate 170 s−1 resulted in obtaining the highest mechanical properties (UTS = 194 MPa, YS = 145 MPa) with the highest value of elongation (A = 49%), which in comparison to the material with bimodal microstructure increased more than seven-fold.

- ➢ The results obtained showed that the rate of plastic strain is a critical parameter in the processes generating large plastic deformations. Apart from the plastic deformation rate, which was constant for all the tests performed (ε ~ 2), the plastic strain rate can also have a significant effect on the final properties of the materials. This is of particular importance for materials with low melting points that are susceptible to the heat effects that occur during the plastic-working, such as the tested zinc, which recrystallizes at room temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Kent, D.; Zhan, H.; Doan, N.; Wang, C.; Yu, S.; Dargush, M.; Wang, G. Influence of strain rate and crystallographic orientation on dynamic recrystallization of pure Zn during room-temperature compression. J. Mater. Sci. Technol. 2021, 86, 237–250. [Google Scholar] [CrossRef]

- Venezuela, J.J.D.; Johnston, S.; Dargusch, M.S. The prospects for biodegradable zinc in wound closure applications. Adv. Healthc. Mater. 2019, 8, e1900408. [Google Scholar] [CrossRef]

- Zhu, D.H.; Cockerill, I.; Su, Y.C.; Zhang, Z.X.; Fu, J.Y.; Lee, K.W.; Ma, J.; Okpokwasili, C.; Tang, L.P.; Zheng, Y.F.; et al. Mechanical Strength, Biodegradation and in Vitro and in Vivo Biocompatibility of Zn Biomaterials. ACS Appl. Mater. Interfaces 2019, 11, 6809–6819. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.T.; Wang, C.; Liu, C.Q.; Chen, H.W.; Wu, Y.F.; Han, J.T.; Jia, Z.C.; Lin, W.J.; Zhang, D.Y.; Li, W.T.; et al. Evolution of the degradation mechanism of pure zinc stent in the one-year study of rabbit abdominal aorta model. Biomaterials 2017, 145, 92–105. [Google Scholar] [CrossRef] [PubMed]

- Bednarczyk, W.; Wątroba, M.; Kawałko, J.; Bała, P. Can zinc alloys be strengthened by grain refinement? A critical evaluation of the processing of low-alloyed binary zinc alloys using ECAP. Mater. Sci. Eng. A 2019, 748, 357–366. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Kawałko, J.; Wątroba, M.; Bała, P. Achieving room temperature superplasticity in the Zn-0.5Cu alloy processed via equal channel angular pressing. Mater. Sci. Eng. A 2018, 723, 126–133. [Google Scholar] [CrossRef]

- Demirtas, M.; Purcek, G.; Yanar, H.; Zhang, Z.J.; Zhang, Z.F. Effect of equal-channel angular pressing on room temperature superplasticity of quasi-single phase Zn-0.3Al alloy. Mater. Sci. Eng. A 2015, 644, 17–24. [Google Scholar] [CrossRef]

- Mostaed, E.; Sikora-Jasinska, M.; Mostaed, A.; Loffredo, S.; Demir, A.G.; Preuitali, B.; Mantouani, D.; Beanland, R.; Vedani, M. Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation. J. Mech. Behav. Biomed. Mater. 2016, 60, 581–602. [Google Scholar] [CrossRef]

- Mostaed, E.; Sikora-Jasinska, M.; Drelich, J.W.; Vedani, M. Zinc-based alloys for degradable vascular stent applications. Acta Biomater. 2018, 71, 1–23. [Google Scholar] [CrossRef]

- Li, B.; Joshi, S.; Azevedo, K.; Ma, E.; Ramesh, K.T.; Figueiredo, R.B.; Langdon, T.G. Dynamic testing at high strain rates of an ultrafine-grained magnesium alloy processed by ECAP. Mater. Sci. Eng. A 2009, 517, 24–29. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhao, X.C.; Yang, X.R. Strain Rate Sensitivity of Ultrafine-Grained CP-Ti Processed by ECAP at Room Temperature. Mater. Sci. Forum 2011, 667–669, 707–712. [Google Scholar] [CrossRef]

- Valdes-Tabernero, M.A.; Sancho-Cadenas, R.; Sabirov, I.; Murashkin, M.Y.; Ovid’ko, I.A.; Galvez, F. Effect of SPD processing on mechanical behavior and dynamic strain aging of an Al-Mg alloy in various deformation modes and wide strain rate range. Mater. Sci. Eng. A 2017, 696, 348–359. [Google Scholar] [CrossRef]

- Malekjani, S.; Hodgson, P.D.; Cizek, P.; Hilditch, T.B. Strain rate effect on the cyclic deformation response of UFG Al alloys. Mater. Sci. Eng. A 2012, 548, 69–74. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A. Development of equations for strain rate sensitivity of UFG aluminum as a function of strain rate. Int. J. Plast. 2017, 90, 167–176. [Google Scholar] [CrossRef]

- Liu, S.; Kent, D.; Zhan, H.; Doan, N.; Dargush, M.; Wang, G. Dynamic recrystallization of pure zinc during high strain-rate compression at ambient temperature. Mater. Sci. Eng. A 2020, 784, 139325. [Google Scholar] [CrossRef]

- Skiba, J.; Kossakowska, J.; Kulczyk, M.; Pachla, W.; Przybysz, S.; Smalc-Koziorowska, J.; Przybysz, M. The impact of severe plastic deformations obtained by hydrostatic extrusion on the machinability of ultrafine-grained AA5083 alloy. J. Manuf. Processes 2020, 58, 1232–1240. [Google Scholar] [CrossRef]

- Kulczyk, M.; Skiba, J.; Pachla, W.; Smalc-Koziorowska, J.; Przybysz, S.; Przybysz, M. The effect of high-pressure plastic forming on the structure and strength of AA5083 and AA5754 alloys intended for fasteners. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 903–911. [Google Scholar]

- Przybysz, S.; Kulczyk, M.; Pachla, W.; Skiba, J.; Wróblewska, M.; Mizera, J.; Moszczyńska, D. Anisotropy of mechanical and structural properties in the AA 6060 aluminium alloy after the hydrostatic extrusion process. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 709–717. [Google Scholar]

- Kulczyk, M.; Pachla, W.; Godek, J.; Smalc-Koziorowska, J.; Skiba, J.; Przybysz, S.; Wróblewska, M.; Przybysz, M. Improved compromise between the electrical conductivity and hardness of the thermo-mechanically treated CuCrZr alloy. Mater. Sci. Eng. A 2018, 724, 45–52. [Google Scholar] [CrossRef]

- Skiba, J.; Kulczyk, M.; Pachla, W.; Wiśniewski, T.; Smalc-Koziorowska, J.; Kubiś, M.; Wróblewska, M.; Przybysz, M. Effect of Severe Plastic Deformation Realized by Hydrostatic Extrusion on Heat Transfer in CP Ti Grade 2 and 316L Austenitic Stainless Steel. J. Nanomed. Nanotechnol. 2018, 9, 1000511. [Google Scholar] [CrossRef]

- Skowrońska, B.; Chmielewski, T.; Kulczyk, M.; Skiba, J.; Przybysz, S. Microstructural Investigation of a Friction-Welded 316L Stainless Steel with Ultrafine-Grained Structure Obtained by Hydrostatic Extrusion. Materials 2021, 14, 1537. [Google Scholar] [CrossRef] [PubMed]

- Pachla, W.; Przybysz, S.; Jarzębska, A.; Bieda, M.; Sztwiertnia, K.; Kulczyk, M.; Skiba, J. Structural and mechanical aspects of hypoeutectic Zn-Mg binary alloys for biodegradable vascular stent applications. Bioact. Mater. 2021, 6, 26–44. [Google Scholar] [CrossRef]

- Pachla, W.; Skiba, J.; Kulczyk, M.; Przybysz, M. High-pressure equipment for cold severe plastic deformation working of materials. Obróbka Plast. Met. 2015, XXVI, 283–306. [Google Scholar]

- Wejrzanowski, T.; Spychalski, W.L.; Różniatowski, K.; Kurzydłowski, K.J. Image based analysis of complex microstructures of engineering materials. Int. J. Appl. Math. Comput. Sci. 2008, 18, 33–39. [Google Scholar] [CrossRef]

- Srinivasarao, B.; Zhilyaev, A.P.; Langdon, T.G.; Perez-Prado, M.T. On the relation between the microstructure and the mechanical behavior of pure Zn processed by high pressure torsion. Mater. Sci. Eng. A 2013, 562, 196–202. [Google Scholar] [CrossRef]

- Pieła, K.; Wróbel, M.; Sztwiertnia, K.; Jaskowski, M.; Kawałko, J.; Bieda, M.; Kiper, M.; Jarzębska, A. Zinc subjected to plastic deformation by complex loading and conventional extrusion: Comparison of the microstructure and mechanical properties. Mater. Des. 2017, 117, 111–120. [Google Scholar] [CrossRef]

| Strain Rate | 0 | 0.04 s−1 | 0.13 s−1 | 0.53 s−1 | 7 s−1 | 50 s−1 | 170 s−1 |

|---|---|---|---|---|---|---|---|

| d2 [µm] | 15.3 +/−0.46 | 6.1 +/−0.36 | 5.4 +/−0.12 | 5.9 +/−0.31 | 7.1 +/−0.19 | 5.6 +/−0.20 | 5.5 +/−0.24 |

| CVd2 | 0.5 | 1.05 | 0.86 | 0.81 | 0.36 | 0.39 | 0.43 |

| Strain Rate | 0 | 0.04 s−1 | 0.13 s−1 | 0.53 s−1 | 7 s−1 | 50 s−1 | 170 s−1 |

|---|---|---|---|---|---|---|---|

| UTS[MPa] | 60 +/−6 | 148 +/−5.2 | 144 +/−3 | 148 +/−2.5 | 190 +/−1.43 | 192 +/−1.49 | 194 +/−2.48 |

| YS [MPa] | 30 +/−4.1 | 116 +/−1.43 | 118 +/−3.79 | 119 +/−2.48 | 130 +/−2.86 | 135 +/−1.43 | 145 +/−4.96 |

| A [%] | 2 +/−0.8 | 2 +/−1.3 | 2.9 +/−1.4 | 5.9 +/−0.9 | 42 +/−4.16 | 47 +/−2.79 | 49 +/−1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulczyk, M.; Skiba, J.; Skorupska, M.; Przybysz, S.; Smalc-Koziorowska, J. Influence of Strain Rates during Severe Plastic Strain Processes on Microstructural and Mechanical Evolution in Pure Zinc. Materials 2022, 15, 4892. https://doi.org/10.3390/ma15144892

Kulczyk M, Skiba J, Skorupska M, Przybysz S, Smalc-Koziorowska J. Influence of Strain Rates during Severe Plastic Strain Processes on Microstructural and Mechanical Evolution in Pure Zinc. Materials. 2022; 15(14):4892. https://doi.org/10.3390/ma15144892

Chicago/Turabian StyleKulczyk, Mariusz, Jacek Skiba, Monika Skorupska, Sylwia Przybysz, and Julita Smalc-Koziorowska. 2022. "Influence of Strain Rates during Severe Plastic Strain Processes on Microstructural and Mechanical Evolution in Pure Zinc" Materials 15, no. 14: 4892. https://doi.org/10.3390/ma15144892

APA StyleKulczyk, M., Skiba, J., Skorupska, M., Przybysz, S., & Smalc-Koziorowska, J. (2022). Influence of Strain Rates during Severe Plastic Strain Processes on Microstructural and Mechanical Evolution in Pure Zinc. Materials, 15(14), 4892. https://doi.org/10.3390/ma15144892