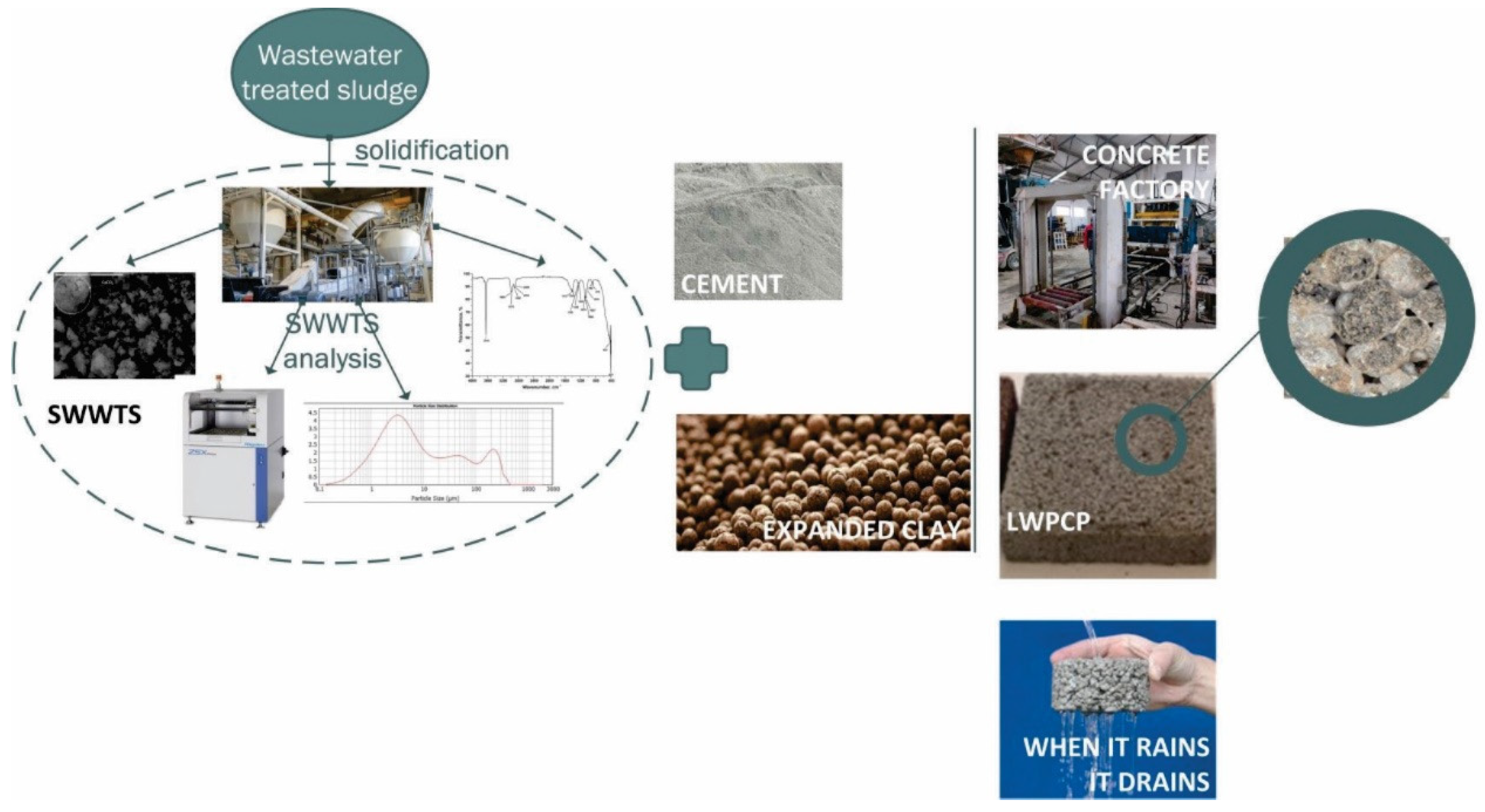

Evaluation of Solidified Wastewater Treatment Sludge as a Potential SCM in Pervious Concrete Pavements

Abstract

:1. Introduction

2. Supplementary Cementitious Materials in Concrete Mixtures

- “Extending the use of supplementary cementitious materials (SCMs) in cement to further reduce clinker content, chiefly by developing technology for the combined addition of calcined clay and limestone.

- Reducing concrete’s clinker content by improving mix designs that allow for increased filler content, which can be added either via the cement or directly during concrete mixing” [15].

2.1. Limestone Filler

2.2. Wastewater Treatment Sludge

3. Materials and Methods

3.1. Materials

3.2. Methods

4. Results

4.1. Chemical Composition of Wastewater Treatment Sludge (WWTS)

4.2. SWWTS Characterization

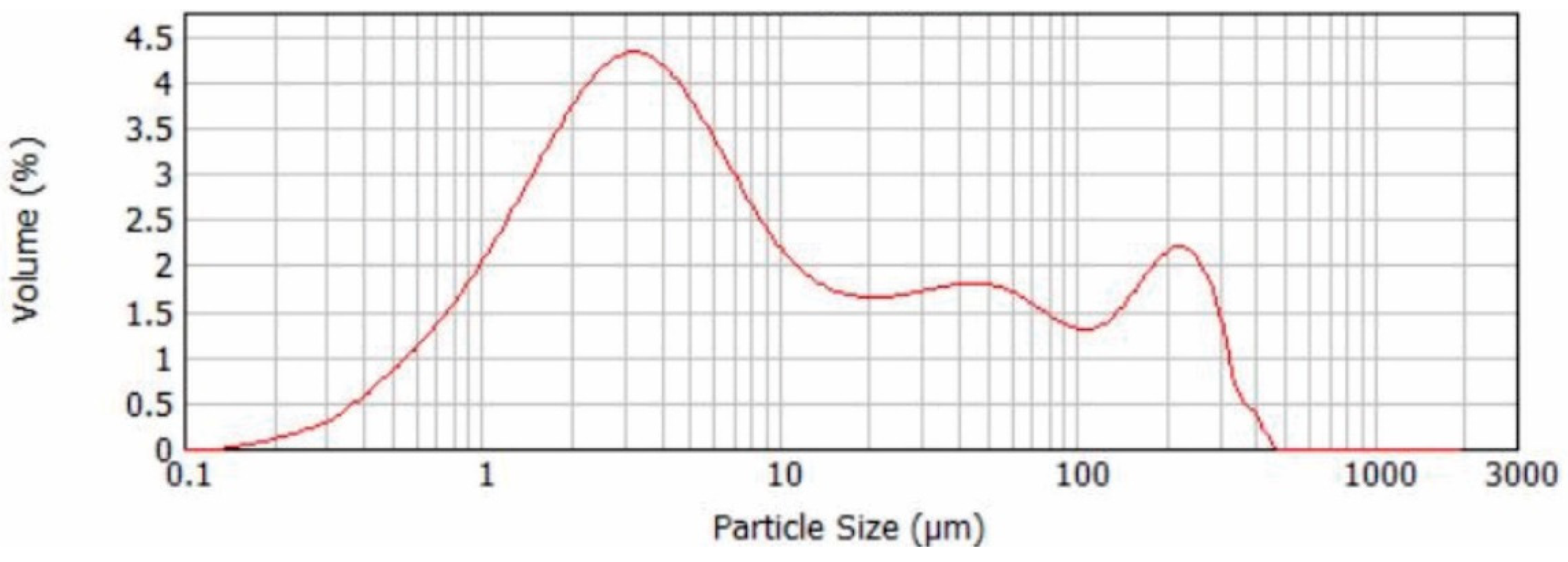

4.2.1. Particle Size Distribution

4.2.2. X-Ray Fluorescence (XRF)

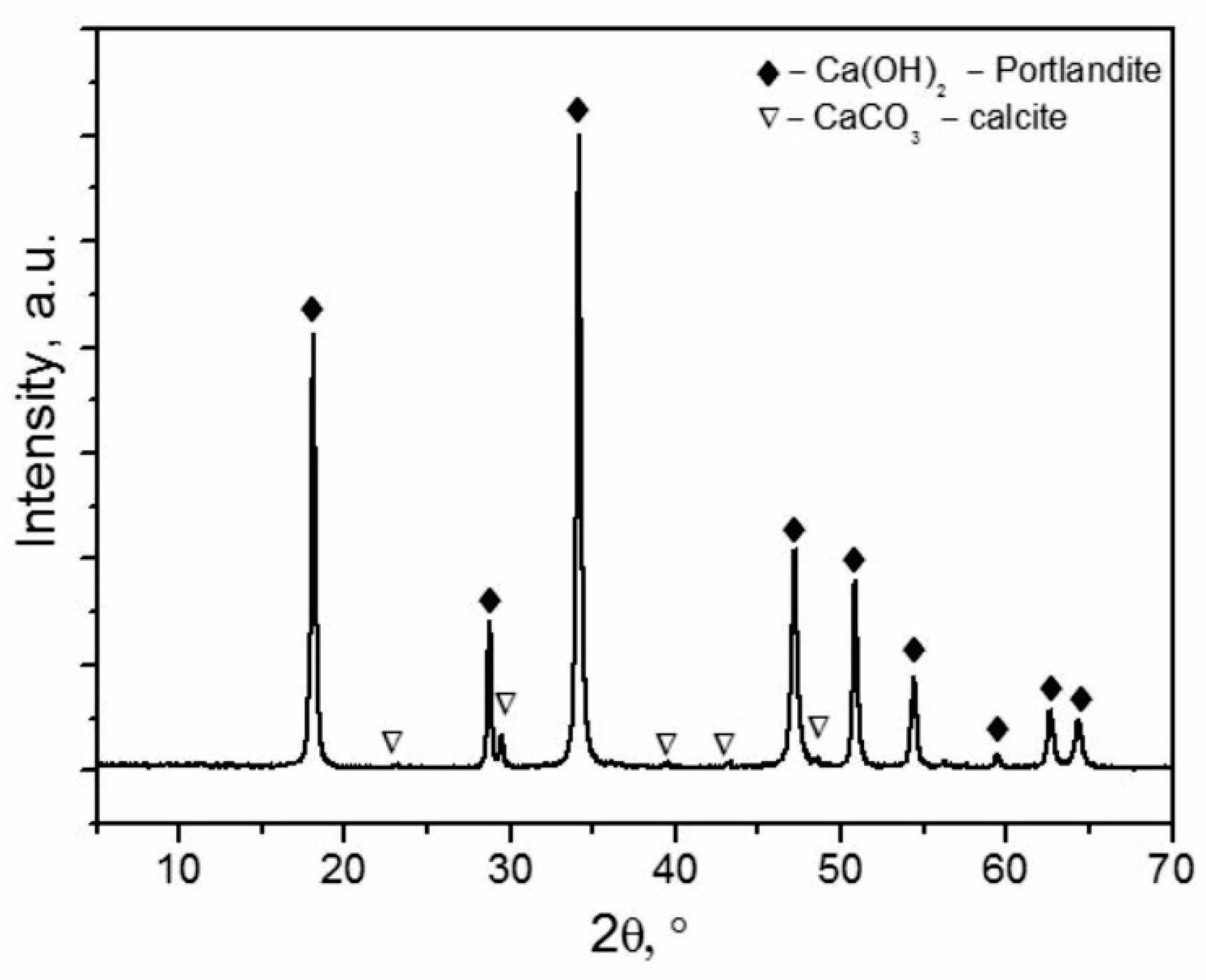

4.2.3. XRD Analysis

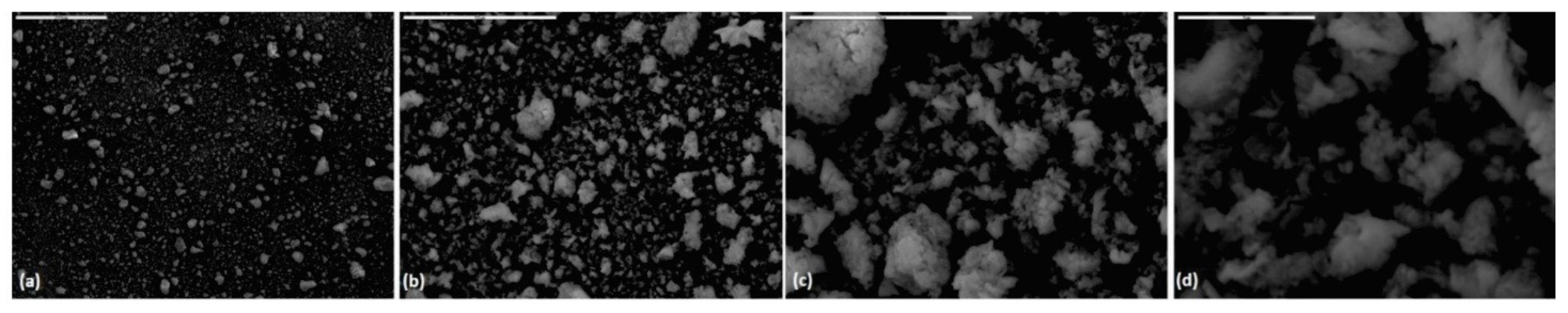

4.2.4. SEM

4.2.5. Fourier Transform Infrared Spectroscopy–FTIR

4.2.6. Chemical Titration

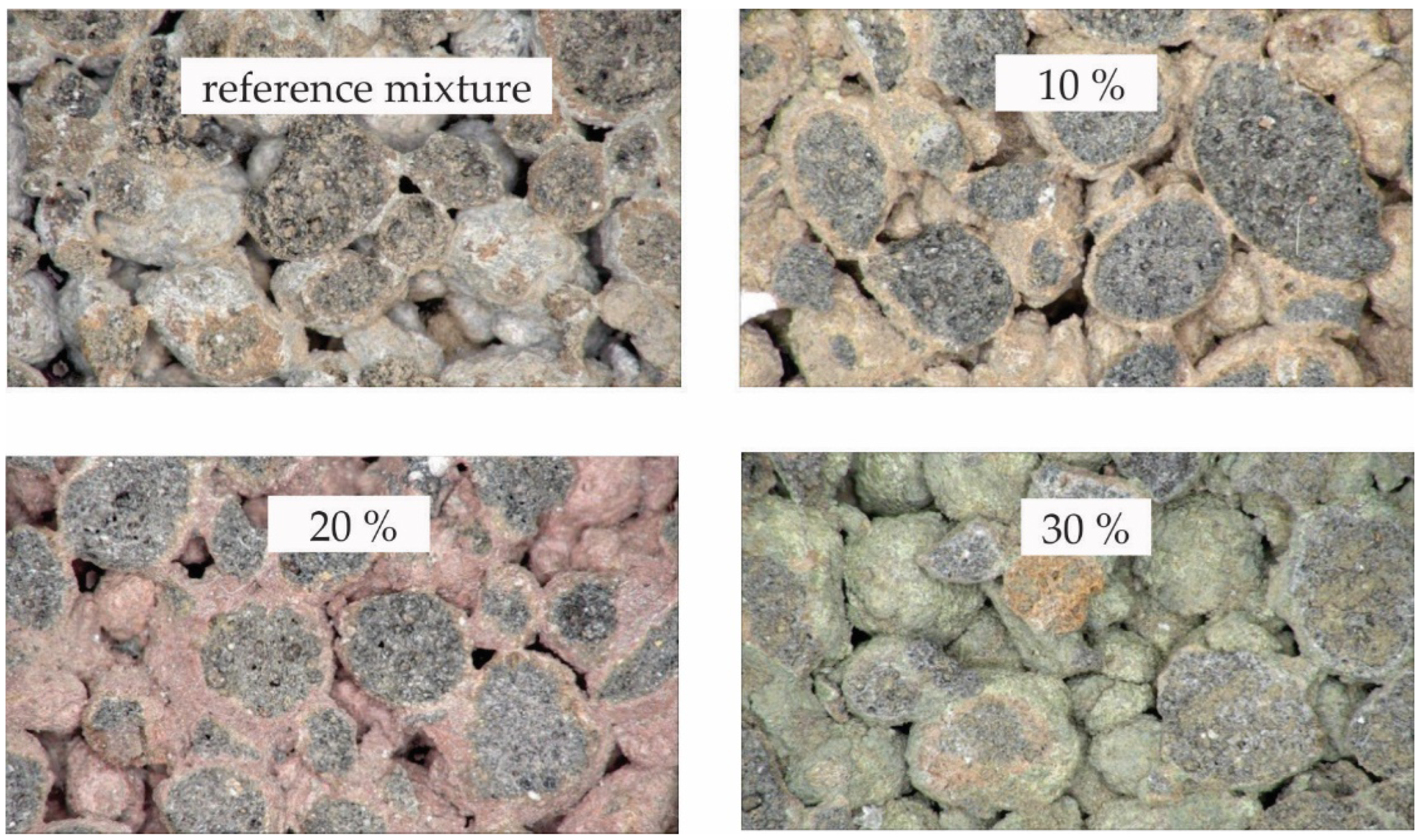

4.3. Physical and Mechanical Properties of LWPCPs

4.3.1. Bulk Density

4.3.2. Water Absorption

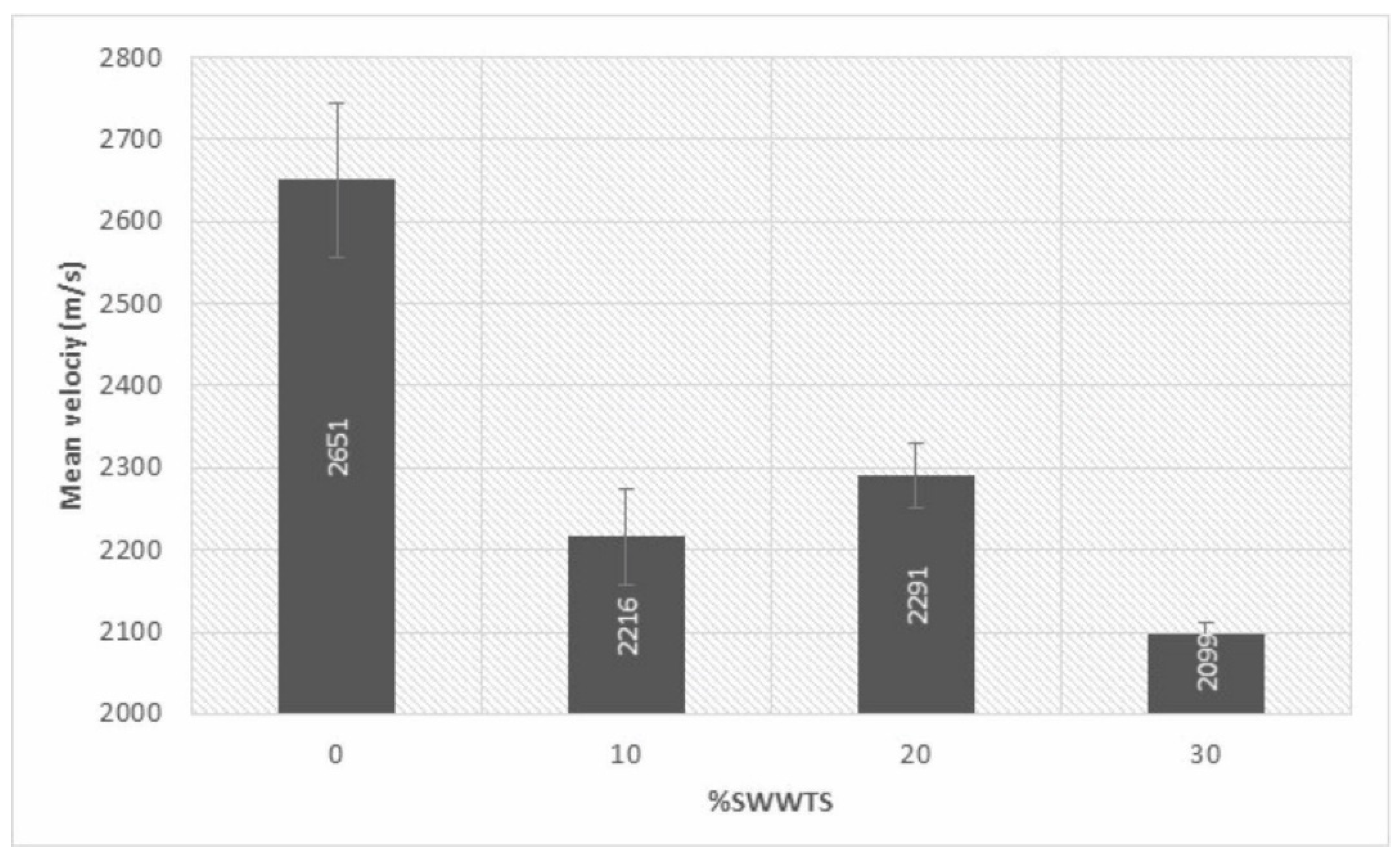

4.3.3. Ultrasonic Pulse Velocity

4.3.4. Mercury Intrusion Porosimetry (MIP)

4.3.5. Saturated Hydraulic Conductivity and Thermal Conductivity

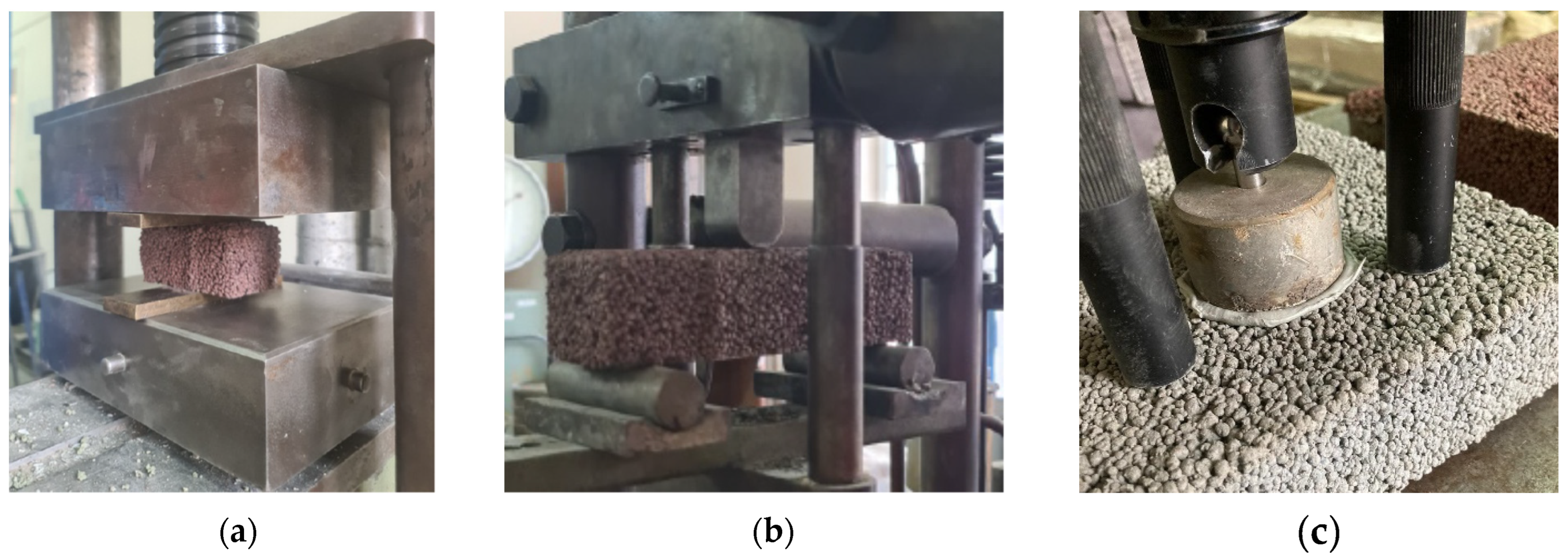

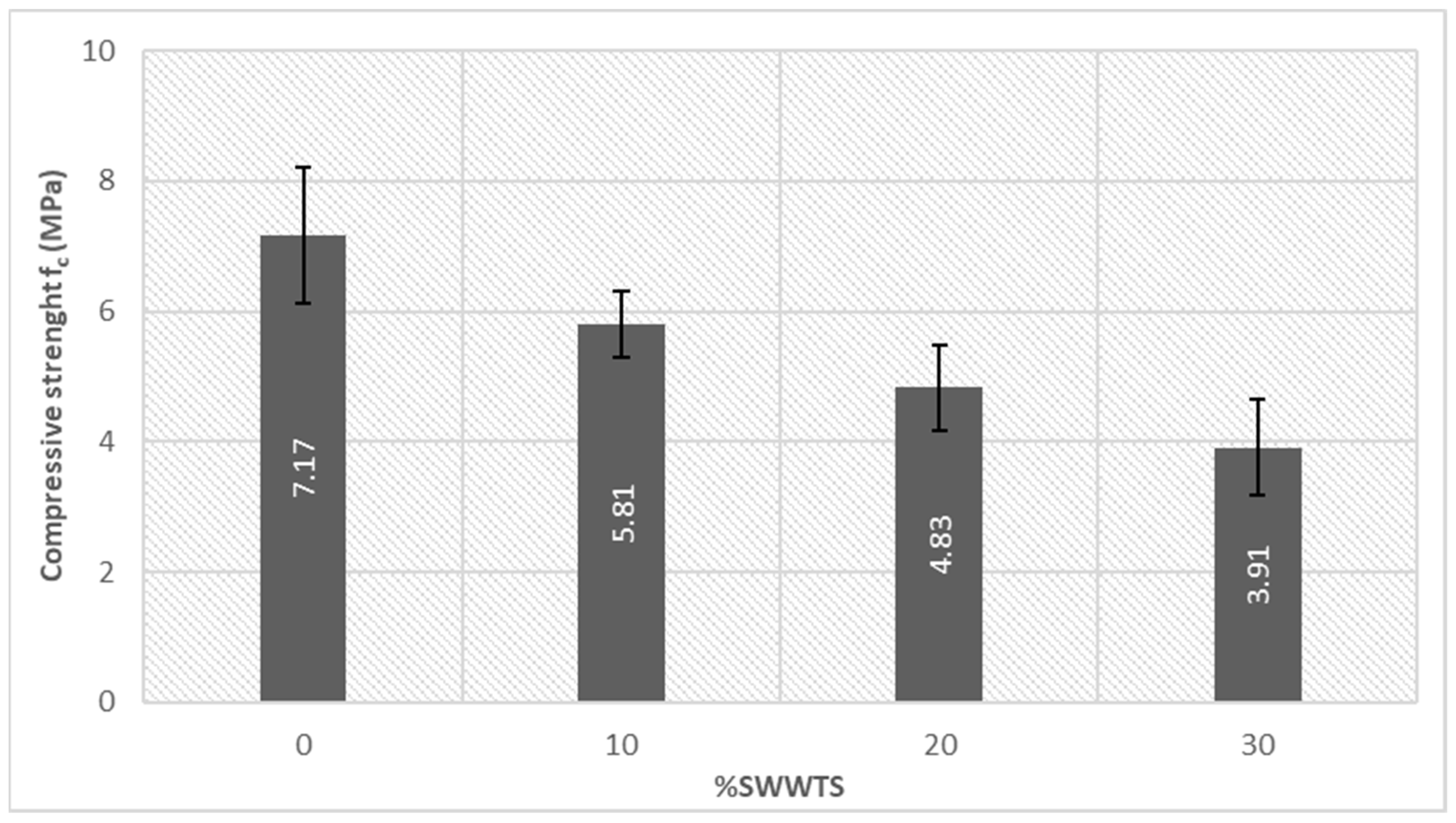

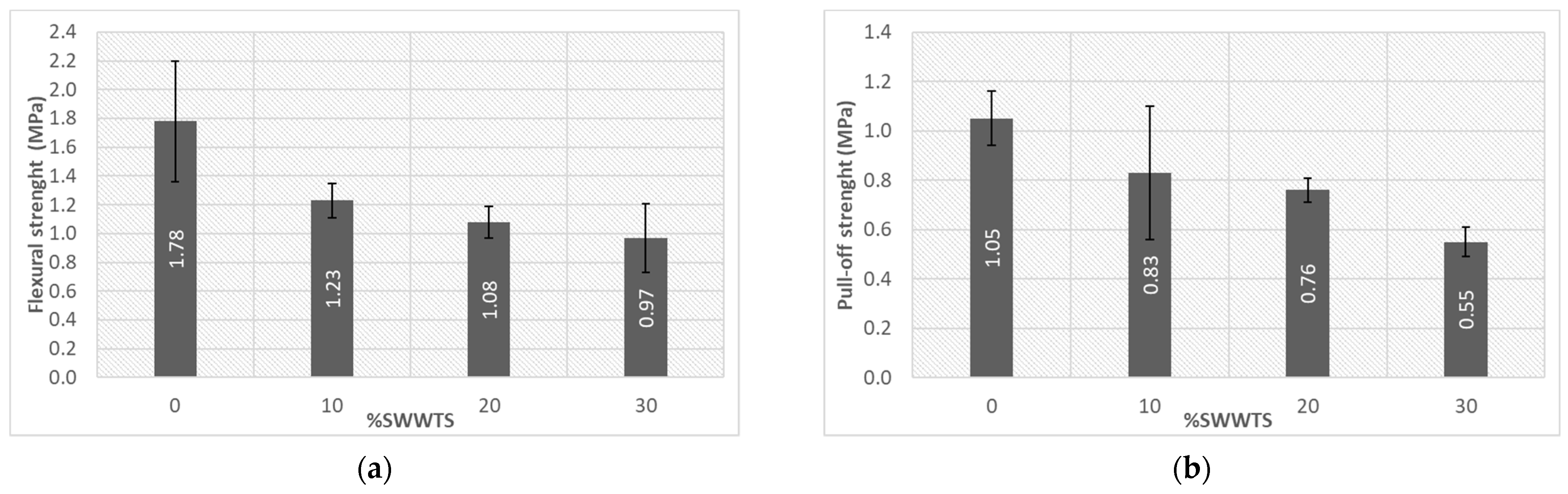

4.3.6. Mechanical Properties

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winston, R.J.; Arend, K.; Dorsey, J.D.; Hunt, W.F. Water Quality Performance of a Permeable Pavement and Stormwater Harvesting Treatment Train Stormwater Control Measure. Blue-Green Syst. 2020, 2, 91–111. [Google Scholar] [CrossRef] [Green Version]

- Sambito, M.; Severino, A.; Freni, G.; Neduzha, L. A Systematic Review of the Hydrological, Environmental and Durability Performance of Permeable Pavement Systems. Sustainability 2021, 13, 4509. [Google Scholar] [CrossRef]

- Djukić, A.; Lekić, B.; Rajaković-Ognjanović, V.; Veljović, D.; Vulić, T.; Djolić, M.; Naunović, Z.; Despotović, J.; Prodanović, D. Further Insight into the Mechanism of Heavy Metals Partitioning in Stormwater Runoff. J. Environ. Manag. 2016, 168, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Thives, L.P.; Ghisi, E.; Brecht, D.G.; Pires, D.M. Filtering Capability of Porous Pavements. Multidiscip. Digit. Publ. Inst. Proc. 2018, 2, 174. [Google Scholar] [CrossRef] [Green Version]

- Hammes, G.; Thives, L.P.; Ghisi, E. Application of Stormwater Collected from Porous Asphalt Pavements for Non-Potable Uses in Buildings. J. Environ. Manag. 2018, 222, 338–347. [Google Scholar] [CrossRef]

- Bhavana, T.D.; Koushik, S.; Kumar, K.U.M.; Srinath, R. Pervious Concrete Pavement: Integrated Laboratory and Field Study. Transp. Res. Rec. 2017, 8, 13–21. [Google Scholar] [CrossRef]

- Hung, V.V.; Seo, S.Y.; Kim, H.W.; Lee, G.C. Permeability and Strength of Pervious Concrete according to Aggregate Size and Blocking Material. Sustainability 2021, 13, 426. [Google Scholar] [CrossRef]

- Tang, C.W.; Cheng, C.K.; Tsai, C.Y. Mix Design and Mechanical Properties of High-Performance Pervious Concrete. Materials 2019, 12, 2577. [Google Scholar] [CrossRef] [Green Version]

- Önorm B 4710-1; Beton—Festlegung, Eigenschaften, Herstellung, Verwendung Und Konformität—Teil 1: Regeln Zur Umsetzung Der Önorm EN 206 Für Normal—Und Schwerbeton. Austrian Standard: Vienna, Austrian, 2018.

- Abdalla, E.M.H.; Selseth, I.; Muthanna, T.M.; Helness, H.; Alfredsen, K.; Gaarden, T.; Sivertsen, E. Hydrological Performance of Lined Permeable Pavements in Norway. Blue-Green Syst. 2021, 3, 107–118. [Google Scholar] [CrossRef]

- Horiguchi, I.; Mimura, Y.; Monteiro, P.J.M. Plant-Growing Performance of Pervious Concrete Containing Crushed Oyster Shell Aggregate. Clean. Mater. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Monteiro, C.M.; Santos, C.; Wood, J.R.; Rosenbom, K. Nature-Based Solutions Using LECA LWA to Increase Urban Sustainability and Support Stormwater Management. In Urban Green Spaces; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Guan, X.; Wang, J.; Xiao, F. Sponge City Strategy and Application of Pavement Materials in Sponge City. J. Clean. Prod. 2021, 303, 127022. [Google Scholar] [CrossRef]

- Alqam, M.; Jamrah, A.; Daghlas, H. Utilization of Cement Incorporated with Water Treatment Sludge. Jordan J. Civ. Eng. 2011, 5, 268–277. [Google Scholar]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Menéndez, G.; Cabrera, O.; Irassar, E.F. Limestone Filler Cement in Low W/c Concrete: A Rational Use of Energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Aqel, M.; Panesar, D. Physical and Chemical Effects of Limestone Filler on the Hydration of Steam Cured Cement Paste and Mortar. Rev. ALCONPAT 2020, 10, 191–205. [Google Scholar] [CrossRef]

- Hooton, R.D. Current Developments and Future Needs in Standards for Cementitious Materials. Cem. Concr. Res. 2015, 78, 165–177. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Sinthupinyo, S.; Chaipanich, A. Effect of Limestone Powders on Compressive Strength and Setting Time of Portland-Limestone Cement Pastes. Adv. Mater. Res. 2011, 343–344, 322. [Google Scholar] [CrossRef]

- Eurostat. Sewage Sludge Production and Disposal. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=env_ww_spd&lang=en (accessed on 2 May 2022).

- Chen, M.; Blanc, D.; Gautier, M.; Mehu, J.; Gourdon, R. Environmental and Technical Assessments of the Potential Utilization of Sewage Sludge Ashes (SSAs) as Secondary Raw Materials in Construction. Waste Manag. 2013, 33, 1268–1275. [Google Scholar] [CrossRef]

- Lopes, M.H.; Abelha, P.; Lapa, N.; Oliveira, J.S.; Cabrita, I.; Gulyurtlu, I. The Behaviour of Ashes and Heavy Metals during the Co-Combustion of Sewage Sludges in a Fluidised Bed. Waste Manag. 2003, 23, 859–870. [Google Scholar] [CrossRef]

- Yusuf, R.O.; Noor, Z.Z.; Din, M.F.M.; Abba, A.H. Use of Sewage Sludge Ash (SSA) in the Production of Cement and Concrete—A Review. Int. J. Glob. Environ. Issues 2012, 12, 214–228. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of Sewage Sludge in the Fabrication of Construction and Building Materials: A Review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Gastaldini, A.L.G.; Hengen, M.F.; Gastaldini, M.C.C.; Do Amaral, F.D.; Antolini, M.B.; Coletto, T. The Use of Water Treatment Plant Sludge Ash as a Mineral Addition. Constr. Build. Mater. 2015, 94, 513–520. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage Sludge Ash Characteristics and Potential for Use in Concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef] [Green Version]

- Nakic, D.; Vouk, D.; Serdar, M.; Cheeseman, C.R. Use of MID-MIX® Treated Sewage Sludge in Cement Mortars and Concrete. Eur. J. Environ. Civ. Eng. 2020, 24, 1483–1498. [Google Scholar] [CrossRef]

- Stowa. Stowa 2019-35 Slibverwerking Met Ongebluste Kalk Middels Het Mid Mix Proces Slibverwerking Met Ongebluste Kalk Middels Het Mid Mix Proces; Stowa Publicaties: Amersfoort, The Netherlands, 2019. [Google Scholar]

- Đeković-Šević, M.; Malešević, Z.; Jovović, M. Recycling of Waste Sludge From Wwtp “Gorić” Valjevo Using the Process of Stabilization and Solidification. Arch. Tech. Sci. 2021, 1, 59–64. [Google Scholar] [CrossRef]

- Garcés, P.; Pérez Carrión, M.; García-Alcocel, E.; Payá, J.; Monzó, J.; Borrachero, M.V. Mechanical and Physical Properties of Cement Blended with Sewage Sludge Ash. Waste Manag. 2008, 28, 2495–2502. [Google Scholar] [CrossRef]

- Monzó, J.; Payá, J.; Borrachero, M.V.; Peris-Mora, E. Mechanical Behavior of Mortars Containing Sewage Sludge Ash (SSA) and Portland Cements with Different Tricalcium Aluminate Content. Cem. Concr. Res. 1999, 29, 87–94. [Google Scholar] [CrossRef]

- Liang, C.; Le, X.; Fang, W.; Zhao, J.; Fang, L.; Hou, S. The Utilization of Recycled Sewage Sludge Ash as a Supplementary Cementitious Material in Mortar: A Review. Sustainability 2022, 14, 4432. [Google Scholar] [CrossRef]

- Peng, H.; Yin, J.; Song, W. Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag. Appl. Sci. 2018, 8, 859. [Google Scholar] [CrossRef] [Green Version]

- Hua, M.; Chen, B.; Liu, Y.; Liu, H.; Zhu, P.; Chen, C.; Wang, X. Durability and Abrasion Resistance of Innovative Recycled Pervious Concrete with Recycled Coarse Aggregate of Different Quality under Sulfate Attack. Appl. Sci. 2021, 11, 9647. [Google Scholar] [CrossRef]

- International Standard ISO 9276-2; Representation of Resuts of Particle Size Analysis—Part 2: Calculation of Average Particle Sizes/diameters and Moments from Particle Size Distributions. ISO: Geneva, Switzerland, 2014.

- Grimes, C.J.; Hardcastle, T.; Manga, M.S.; Mahmud, T.; York, D.W. Calcium Carbonate Particle Formation through Precipitation in a Stagnant Bubble and a Bubble Column Reactor. Cryst. Growth Des. 2020, 20, 5572–5582. [Google Scholar] [CrossRef]

- Khachani, M.; El Hamidi, A.; Halim, M.; Arsalane, S. Non-Isothermal Kinetic and Thermodynamic Studies of the Dehydroxylation Process of Synthetic Calcium Hydroxide Ca(OH)2. J. Mater. Environ. Sci. 2014, 5, 615–624. [Google Scholar]

- Huh, J.; Choi, Y.; Ramakrishna, C.; Cheong, S.H.; Ahn, J.W.; Corporation, H.C.; Resource, C.; Appropriate, R.; Resources, M. Use of Calcined Oyster Shell Powders as CO2 Adsorbents in Algae-Containing Water. J. Korean Ceram. Soc. 2016, 53, 429–434. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, C.; Xiao, B.; Bai, Z.; Jiang, C.; Yang, C.; Wu, Y.; Wang, X. Hierarchical CaCO3 Particles Self-Assembled from Metastable Vaterite and Stable Calcite during the Decomposition of Ca(HCO3)2. CrystEngComm 2017, 19, 7332–7338. [Google Scholar] [CrossRef]

- Afflerbach, S.; Trettin, R. A Fundamental Study on the Mechanistic Impact of Repeated de- and Rehydration of Ca(OH)2 on Thermochemical Cycling in Technical Scale. Adv. Mater. Lett. 2019, 10, 312–318. [Google Scholar] [CrossRef]

- Rajathi, K.; Sridhar, S. Synthesis and Characterization of Ca(OH)2 Nanoparticles in Different Media. J. Biol. Chem. Res. 2018, 35, 877–882. [Google Scholar]

- Xiang, J.; Liu, H.; Lu, H.; Gui, F. Degradation Mechanism and Numerical Simulation of Pervious Concrete under Salt Freezing-Thawing Cycle. Materials 2022, 15, 3054. [Google Scholar] [CrossRef]

| Material | Reference Mixture | 10% | 20% | 30% |

|---|---|---|---|---|

| Cement CEM I 52.5R | 300 | 270 | 240 | 210 |

| SWWTS | 0 | 30 | 60 | 90 |

| Expanded clay–1/4 mm | 720 | 720 | 720 | 720 |

| Water | 90 | 90 | 90 | 90 |

| Pigment | Gray | Brown | Red | Green |

| Air-entraining admixture, Accelerating admixture | ||||

| Parameter | SWWTS |

|---|---|

| Specific surface area (m2/g) | 2.190 |

| Surface Weighed mean D(3,2) | 2.740 |

| Volume Weighed mean D(4,3) | 41.282 |

| Span | 27.111 |

| D10 (µm) | 1.103 |

| D50 (µm) | 5.814 |

| D90 (µm) | 158.74 |

| Element | WWTS (mg/kg) | SWWTS (mg/kg) |

|---|---|---|

| Cl | No data | 387.10 |

| Ni | No data | 16.18 |

| Cu | 44.5 | 6.21 |

| Zn | 120 | 13.10 |

| As | 20.2 | 0.10 |

| Sr | No data | 121.90 |

| Mo | No data | 1.91 |

| Cd | <0.6 | 0.30 |

| Ba | 56.6 | 27.80 |

| Pb | 13.1 | 1.31 |

| Content (%) | |

|---|---|

| L.O.I. at 1000 °C | 26.93 |

| SiO2 | 0.14 |

| Al2O3 | 0.14 |

| Fe2O3 | 0.03 |

| CaO | 71.70 |

| MgO | 0.51 |

| Na2O | 0.01 |

| K2O | 0.07 |

| SO3 | 0.27 |

| Others | 0.20 |

| Content (%) | S1 | S2 | S3 | Average |

|---|---|---|---|---|

| O | 50.1 | 53.1 | 52.3 | 51.8 |

| Mg | 0.3 | 0.3 | 0.3 | 0.3 |

| Si | 0.1 | 0.2 | 0.2 | 0.2 |

| K | 0.1 | 0.1 | 0.2 | 0.1 |

| Ca | 45.7 | 43.2 | 43.6 | 44.2 |

| Others | 3.7 | 3.1 | 3.4 | 3.4 |

| Sample, % SWWTS | Porosity (%) | Cumulative Pore Volume (cm3/g) |

|---|---|---|

| 0 | 37.65 | 0.2761 |

| 10 | 34.85 | 0.2451 |

| 20 | 34.58 | 0.2476 |

| 30 | 36.78 | 0.2759 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Govedarica, O.; Aškrabić, M.; Hadnađev-Kostić, M.; Vulić, T.; Lekić, B.; Rajaković-Ognjanović, V.; Zakić, D. Evaluation of Solidified Wastewater Treatment Sludge as a Potential SCM in Pervious Concrete Pavements. Materials 2022, 15, 4919. https://doi.org/10.3390/ma15144919

Govedarica O, Aškrabić M, Hadnađev-Kostić M, Vulić T, Lekić B, Rajaković-Ognjanović V, Zakić D. Evaluation of Solidified Wastewater Treatment Sludge as a Potential SCM in Pervious Concrete Pavements. Materials. 2022; 15(14):4919. https://doi.org/10.3390/ma15144919

Chicago/Turabian StyleGovedarica, Ognjen, Marina Aškrabić, Milica Hadnađev-Kostić, Tatjana Vulić, Branislava Lekić, Vladana Rajaković-Ognjanović, and Dimitrije Zakić. 2022. "Evaluation of Solidified Wastewater Treatment Sludge as a Potential SCM in Pervious Concrete Pavements" Materials 15, no. 14: 4919. https://doi.org/10.3390/ma15144919

APA StyleGovedarica, O., Aškrabić, M., Hadnađev-Kostić, M., Vulić, T., Lekić, B., Rajaković-Ognjanović, V., & Zakić, D. (2022). Evaluation of Solidified Wastewater Treatment Sludge as a Potential SCM in Pervious Concrete Pavements. Materials, 15(14), 4919. https://doi.org/10.3390/ma15144919