Enhanced Energy-Storage Performances in Sodium Bismuth Titanate-Based Relaxation Ferroelectric Ceramics with Optimized Polarization by Tuning Sintering Temperature

Abstract

:1. Introduction

2. Materials and Methods

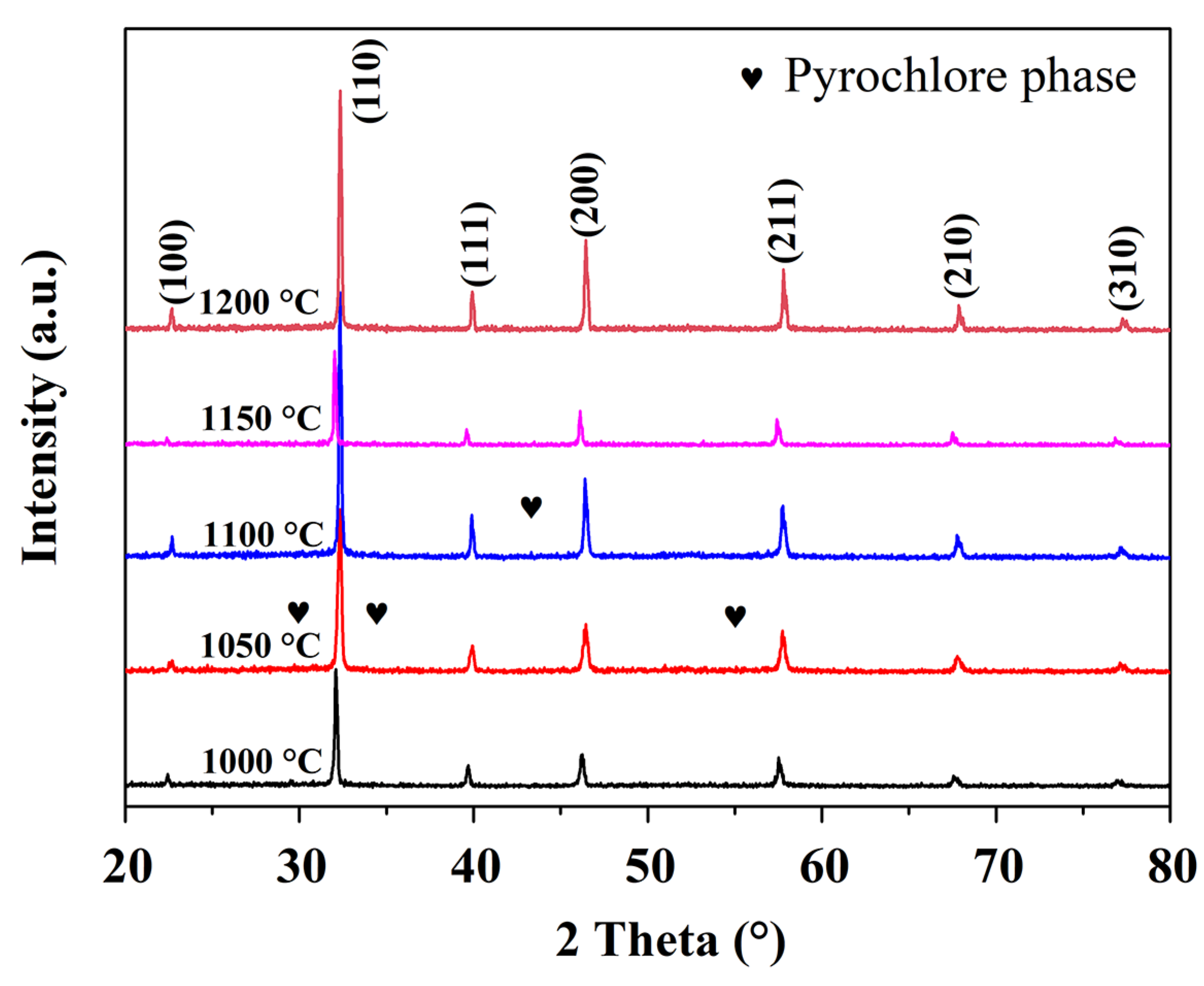

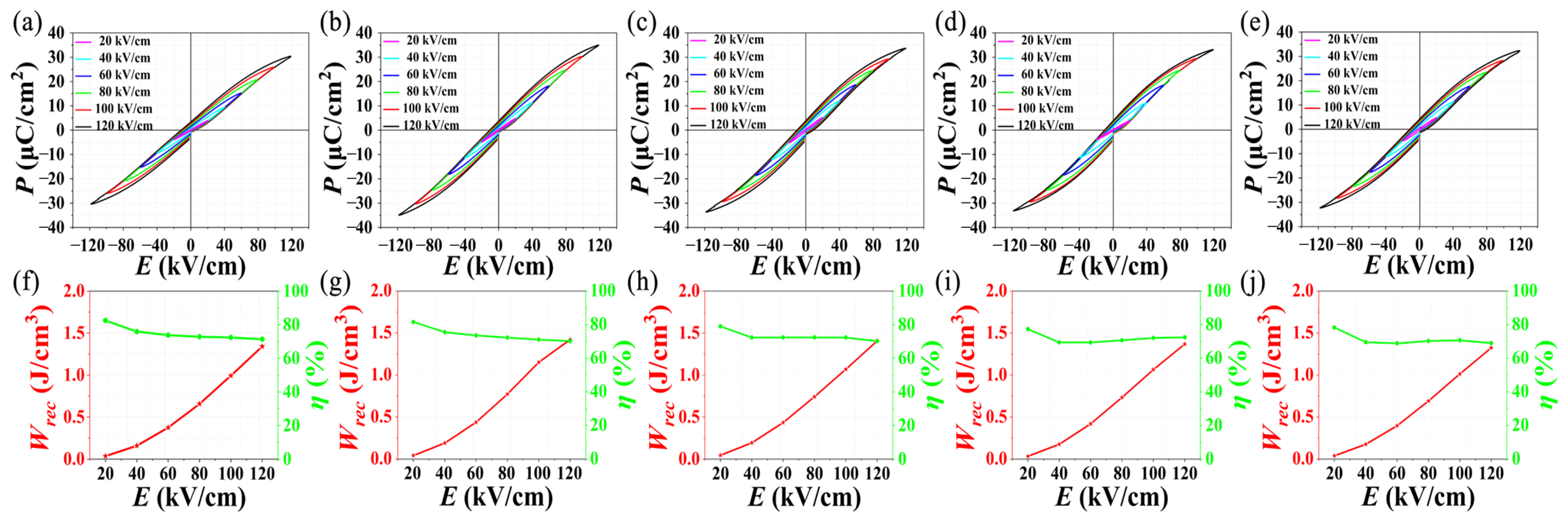

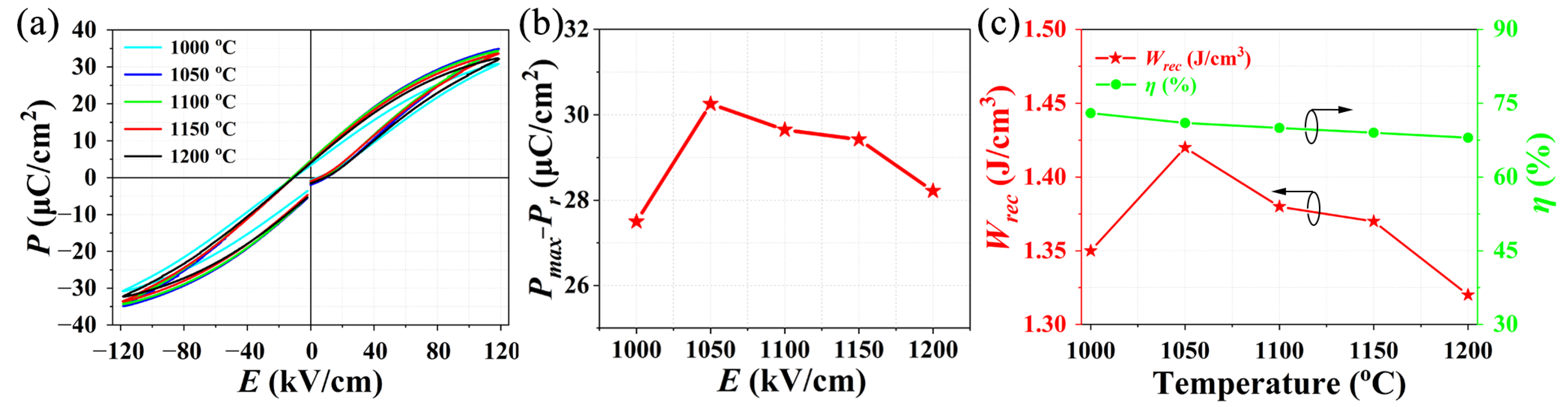

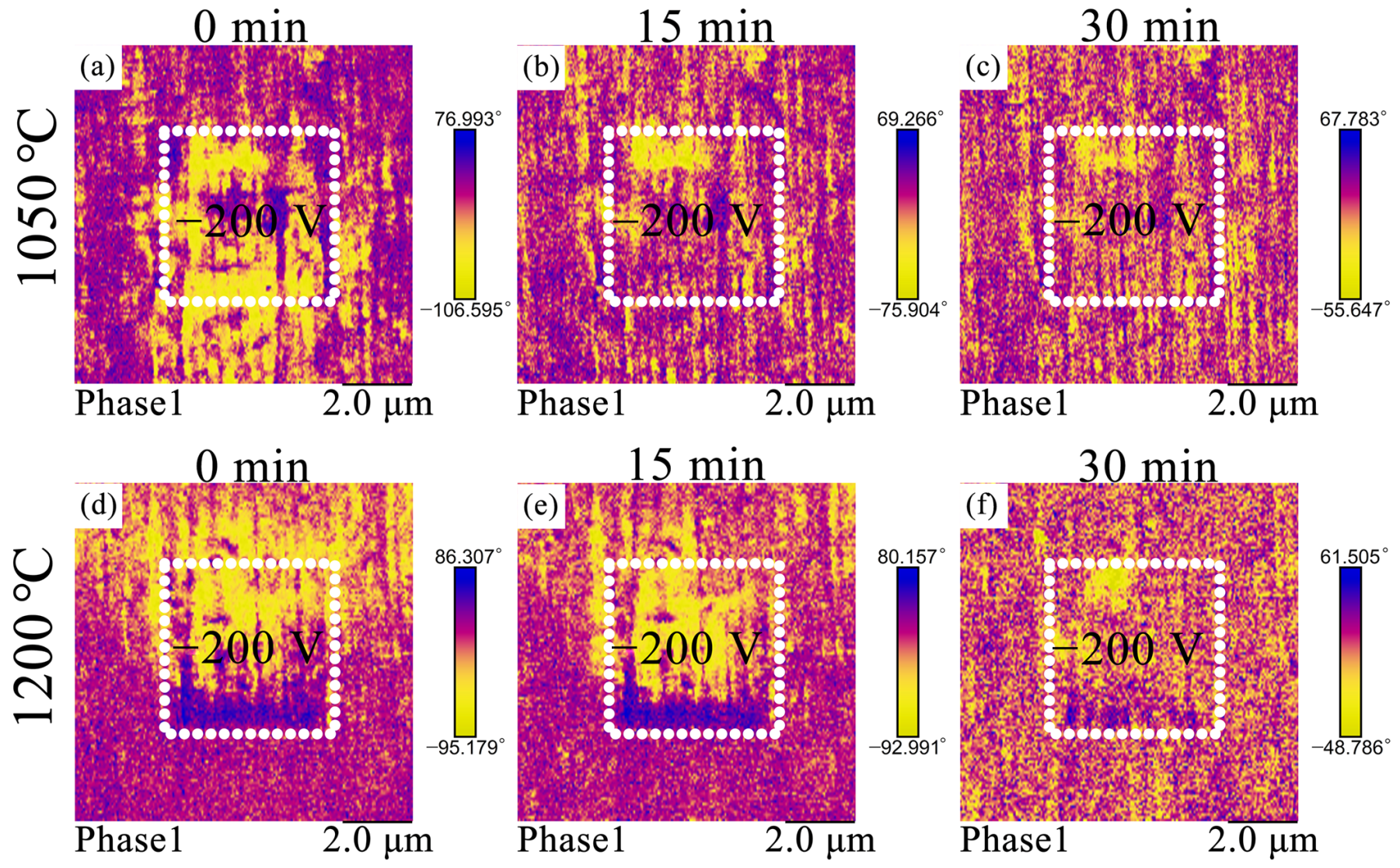

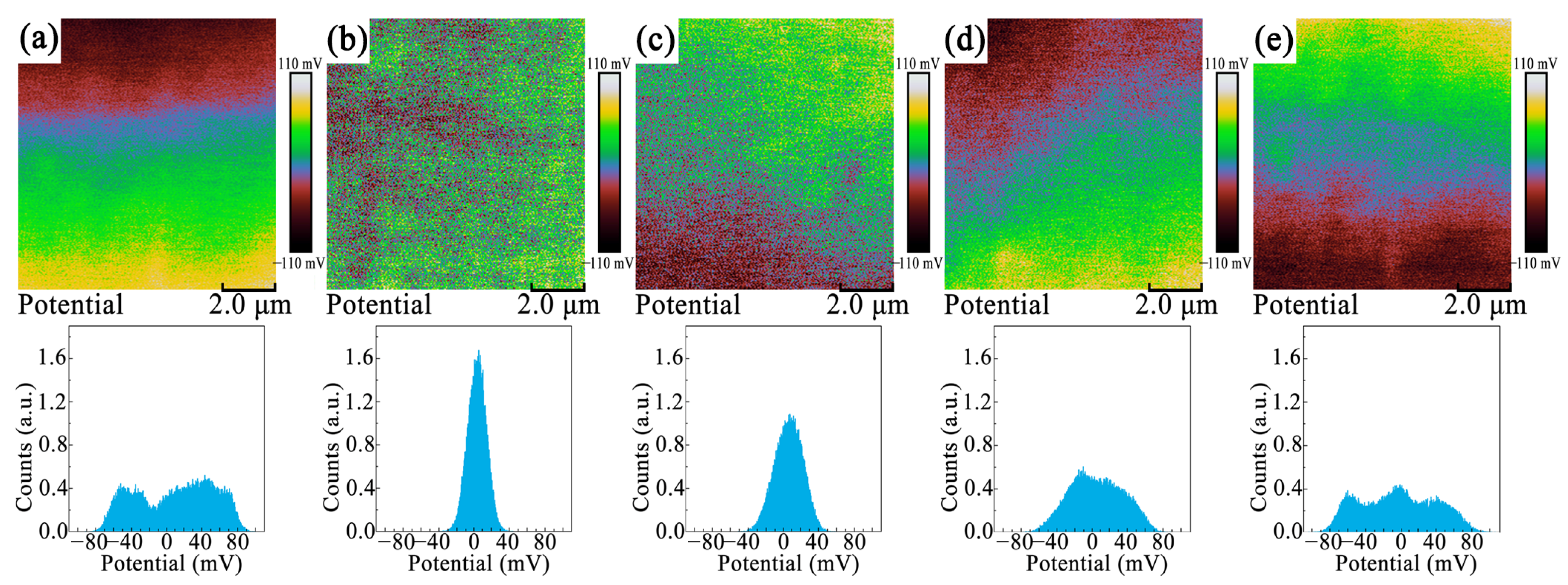

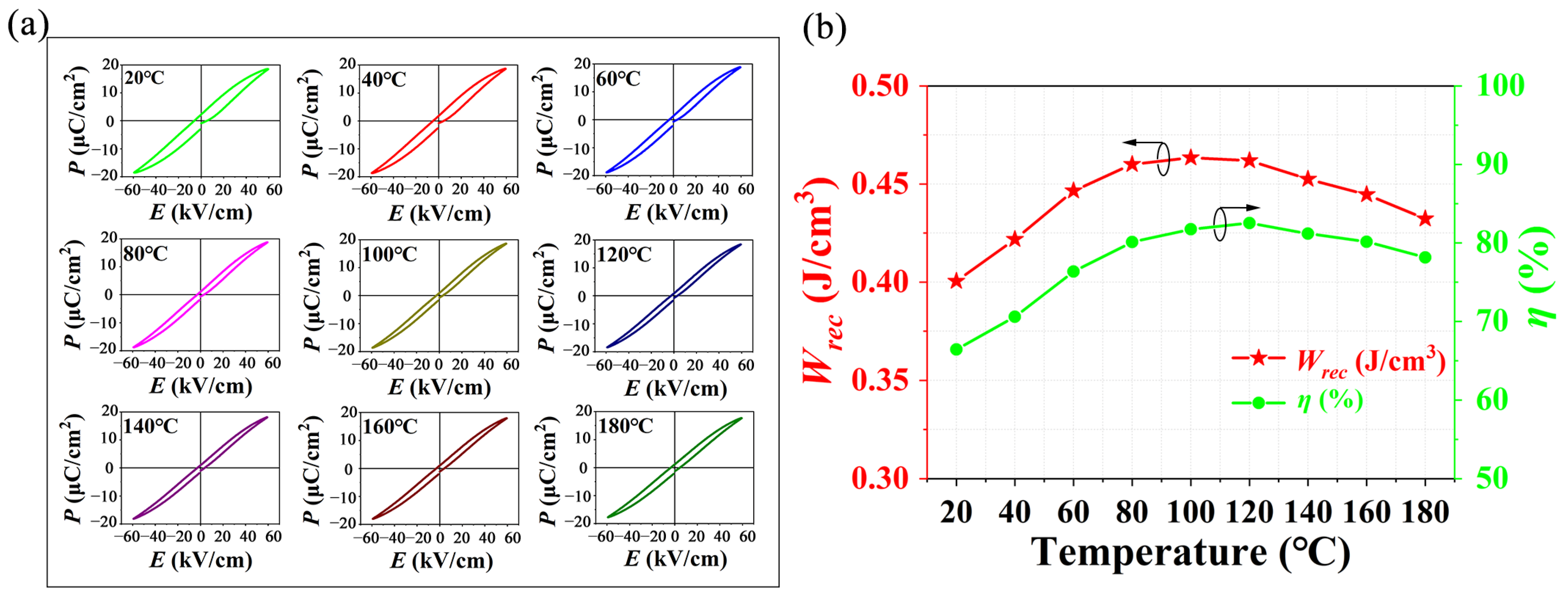

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, W.; Li, T.; Chen, P.; Wang, C. Outstanding Energy Storage Performance of Na0.5Bi0.5TiO3-BaTiO3-(Sr0.85Bi0.1)(Mg1/3Nb2/3)O3 Lead-Free Ceramics. ACS Appl. Energy Mater. 2021, 4, 9362–9367. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, G.; Bao, W.; Li, J.; Li, L.; Mostaed, A.; Yang, H.; Ji, H.; Li, D.; Feteira, A.; et al. Superior energy density through tailored dopant strategies in multilayer ceramic capacitors. Energy Environ. Sci. 2020, 13, 2938–2948. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, T.; Zhang, Q.; Ma, W.; Fan, P.; Salamon, D.; Zhang, S.-T.; Nan, B.; Tan, H.; Ye, Z.-G. A review on the development of lead-free ferroelectric energy-storage ceramics and multilayer capacitors. J. Mater. Chem. C 2020, 8, 16648–16667. [Google Scholar] [CrossRef]

- Ogihara, H.; Randall, C.A.; Trolier-McKinstry, S. High-Energy Density Capacitors Utilizing 0.7BaTiO3-0.3BiScO3 Ceramics. J. Am. Ceram. Soc. 2009, 92, 1719–1724. [Google Scholar] [CrossRef]

- Cao, W.; Li, W.; Zhang, T.; Sheng, J.; Hou, Y.; Feng, Y.; Yu, Y.; Fei, W. High-Energy Storage Density and Efficiency of (1−x)[0.94 NBT−0.06 BT]−xST Lead-Free Ceramics. Energy Technol. 2015, 3, 1198–1204. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy Rev. 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Lv, J.; Li, Q.; Li, Y.; Tang, M.; Jin, D.; Yan, Y.; Fan, B.; Jin, L.; Liu, G. Significantly improved energy storage performance of NBT-BT based ceramics through domain control and preparation optimization. Chem. Eng. J. 2021, 420, 129900. [Google Scholar] [CrossRef]

- Liu, N.; Liang, R.; Zhou, Z.; Dong, X. Designing lead-free bismuth ferrite-based ceramics learning from relaxor ferroelectric behavior for simultaneous high energy density and efficiency under low electric field. J. Mater. Chem. C 2018, 6, 10211–10217. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Zhang, X.; Fan, Z.; Yang, F.; Feteira, A.; Zhou, D.; Sinclair, D.C.; Ma, T.; Tan, X.; et al. Ultrahigh energy storage density lead-free multilayers by controlled electrical homogeneity. Energy Environ. Sci. 2019, 12, 582–588. [Google Scholar] [CrossRef]

- Xu, Q.; Li, T.; Hao, H.; Zhang, S.; Wang, Z.; Cao, M.; Yao, Z.; Liu, H. Enhanced energy storage properties of NaNbO3 modified Bi0.5Na0.5TiO3 based ceramics. J. Eur. Ceram. Soc. 2015, 35, 545–553. [Google Scholar] [CrossRef]

- Zannen, M.; Lahmar, A.; Khemakhem, H.; El Marssi, M. Energy storage property in lead free gd doped Na1/2Bi1/2TiO3 ceramics. Solid State Commun. 2016, 245, 1–4. [Google Scholar] [CrossRef]

- Gao, F.; Dong, X.; Mao, C.; Liu, W.; Zhang, H.; Yang, L.; Cao, F.; Wang, G.; Jones, J. Energy-Storage Properties of 0.89Bi0.5Na0.5TiO3-0.06BaTiO3-0.05K0.5Na0.5NbO3 Lead-Free Anti-ferroelectric Ceramics. J. Am. Ceram. Soc. 2011, 94, 4382–4386. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, F.; Du, H.; Jin, L.; Yan, L.; Hu, Q.; Yu, Y.; Qu, S.; Wei, X.; Xu, Z.; et al. Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties. Nano Energy 2019, 58, 768–777. [Google Scholar] [CrossRef]

- Hu, Q.; Tian, Y.; Zhu, Q.; Bian, J.; Jin, L.; Du, H.; Alikin, D.O.; Shur, V.Y.; Feng, Y.; Xu, Z.; et al. Achieve ultrahigh energy storage performance in BaTiO3-Bi(Mg1/2Ti1/2)O3 relaxor ferroelectric ceramics via nano-scale polarization mismatch and reconstruction. Nano Energy 2020, 67, 104264. [Google Scholar] [CrossRef]

- Bai, W.; Zhao, X.; Ding, Y.; Wang, L.; Zheng, P.; Hao, J.; Zhai, J. Giant Field-Induced Strain with Low Hysteresis and Boosted Energy Storage Performance under Low Electric Field in (Bi0.5Na0.5)TiO3-Based Grain Orientation-Controlled Ceramics. Adv. Electron. Mater. 2020, 6, 2000332. [Google Scholar] [CrossRef]

- Xu, C.; Su, R.; Wang, Z.; Wang, Y.; Zhang, D.; Wang, J.; Bian, J.; Wu, C.; Lou, X.; Yang, Y. Tuning the microstructure of BaTiO3@SiO2 core-shell nanoparticles for high energy storage composite ceramics. J. Alloys Compd. 2019, 784, 173–181. [Google Scholar] [CrossRef]

- Alkathy, M.S.; Hezam, A.; Manoja, K.S.D.; Wang, J.; Cheng, C.; Byrappa, K.; Raju, K.C.J. Effect of sintering temperature on structural, electrical, and ferroelectric properties of lanthanum and sodium co-substituted barium titanate ceramics. J. Alloys Compd. 2018, 762, 49–61. [Google Scholar] [CrossRef]

- Li, T.; Cao, W.; Chen, P.; Wang, J.; Wang, C. Effects of sintering method on the structural, dielectric and energy storage properties of AgNbO3 lead-free antiferroelectric ceramics. J. Mater. Sci. 2021, 56, 13499–13508. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, Z.; Liang, X.; Hu, K.; Li, S.; Zhang, Y. Dependence of dielectric and energy storage properties on sintering temperature in lead lanthanum zirconate titanate antiferroelectric ceramics. Mater. Res. Express 2019, 6, 126303. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, Z.; Su, Q.; Meng, X.; Zhao, Y.; Li, Y.; Hao, X. Enhanced energy-storage properties of lead-free Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramics by tuning sintering temperature. J. Mater. Sci. Mater. Electron. 2021, 32, 26258–26267. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Y.; Zhang, Y.; Li, H.; Zhang, Q.; Lu, Y.; He, Y. High-temperature energy storage performances in (1-x)(Na0.50Bi0.50TiO3)-xBaZrO3 lead-free relaxor ceramics. Ceram. Int. 2020, 46, 28652–28658. [Google Scholar] [CrossRef]

- Yan, F.; Shi, Y.; Zhou, X.; Zhu, K.; Shen, B.; Zhai, J. Optimization of polarization and electric field of bismuth ferrite-based ceramics for capacitor applications. Chem. Eng. J. 2021, 417, 127945. [Google Scholar] [CrossRef]

- Hu, B.; Fan, H.; Ning, L.; Wen, Y.; Wang, C. High energy storage performance of [(Bi0.5Na0.5)0.94Ba0.06]0.97La0.03Ti1-x(Al0.5Nb0.5)xO3 ceramics with enhanced dielectric breakdown strength. Ceram. Int. 2018, 44, 15160–15166. [Google Scholar] [CrossRef]

- Yao, Y.; Li, Y.; Sun, N.; Du, J.; Li, X.; Zhang, L.; Zhang, Q.; Hao, X. Enhanced dielectric and energy-storage properties in ZnO-doped 0.9(0.94Na0.5Bi0.5TiO3-0.06BaTiO3)-0.1NaNbO3 ceramics. Ceram. Int. 2018, 44, 5961–5966. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Phase diagrams and electrical properties of (Bi1/2Na1/2)TiO3-based solid solutions. J. Appl. Phys. 2008, 104, 124106. [Google Scholar] [CrossRef]

- Zhang, S.-T.; Kounga, A.B.; Aulbach, E.; Deng, Y. Temperature-Dependent Electrical Properties of 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 Ceramics. J. Am. Ceram. Soc. 2008, 91, 3950–3954. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, H.; Zhang, L.; Xie, J.; Hao, H.; Cao, M.; Yao, Z.; Lanagan, M.T. Structure and electrical properties of lead-free Bi0.5Na0.5TiO3-based ceramics for energy-storage applications. RSC Adv. 2016, 6, 59280–59291. [Google Scholar] [CrossRef]

- Ma, Z.; Su, Q.; Zhu, J.; Meng, X.; Zhao, Y.; Xin, G.; Li, Y.; Hao, X. Optimization of energy-storage properties for lead-free relaxor-ferroelectric (1-x)Na0.5Bi0.5TiO3-xSr0.7Nd0.2TiO3 ceramics. J. Mater. Sci. 2022, 57, 217–228. [Google Scholar] [CrossRef]

- Qi, H.; Xie, A.; Tian, A.; Zuo, R. Superior Energy-Storage Capacitors with Simultaneously Giant Energy Density and Efficiency Using Nanodomain Engineered BiFeO3-BaTiO3-NaNbO3 Lead-Free Bulk Ferroelectrics. Adv. Energy Mater. 2019, 10, 1903338. [Google Scholar] [CrossRef]

- Kang, R.; Wang, Z.; Lou, X.; Liu, W.; Shi, P.; Zhu, X.; Guo, X.; Li, S.; Sun, H.; Zhang, L.; et al. Energy storage performance of Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramics with superior temperature stability under low electric fields. Chem. Eng. J. 2021, 410, 128376. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.; Gong, A.; Zhang, S.; Liu, J.; Sun, N.; Hao, X. High-Performance Ferroelectric Electromagnetic Attenuation Materials with Multiple Polar Units Based on Nanodomain Engineering. Small 2022, 18, 2106302. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Liu, P.; Yan, F.; Lin, Y.; Wang, T. A novel lead-free ceramic with layered structure for high energy storage applications. J. Alloys Compd. 2019, 773, 244–249. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Ma, Z.; Yao, Y.; Sun, N.; Zhao, Y.; Li, Y.; Liu, R.; Hao, X. Enhanced Energy-Storage Performances in Sodium Bismuth Titanate-Based Relaxation Ferroelectric Ceramics with Optimized Polarization by Tuning Sintering Temperature. Materials 2022, 15, 4981. https://doi.org/10.3390/ma15144981

Wu J, Ma Z, Yao Y, Sun N, Zhao Y, Li Y, Liu R, Hao X. Enhanced Energy-Storage Performances in Sodium Bismuth Titanate-Based Relaxation Ferroelectric Ceramics with Optimized Polarization by Tuning Sintering Temperature. Materials. 2022; 15(14):4981. https://doi.org/10.3390/ma15144981

Chicago/Turabian StyleWu, Jianhua, Ziyue Ma, Yuan Yao, Ningning Sun, Ye Zhao, Yong Li, Runchang Liu, and Xihong Hao. 2022. "Enhanced Energy-Storage Performances in Sodium Bismuth Titanate-Based Relaxation Ferroelectric Ceramics with Optimized Polarization by Tuning Sintering Temperature" Materials 15, no. 14: 4981. https://doi.org/10.3390/ma15144981

APA StyleWu, J., Ma, Z., Yao, Y., Sun, N., Zhao, Y., Li, Y., Liu, R., & Hao, X. (2022). Enhanced Energy-Storage Performances in Sodium Bismuth Titanate-Based Relaxation Ferroelectric Ceramics with Optimized Polarization by Tuning Sintering Temperature. Materials, 15(14), 4981. https://doi.org/10.3390/ma15144981