A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials Used under the Qinghai–Tibet Railway Line

Abstract

1. Introduction

2. Materials and Methods

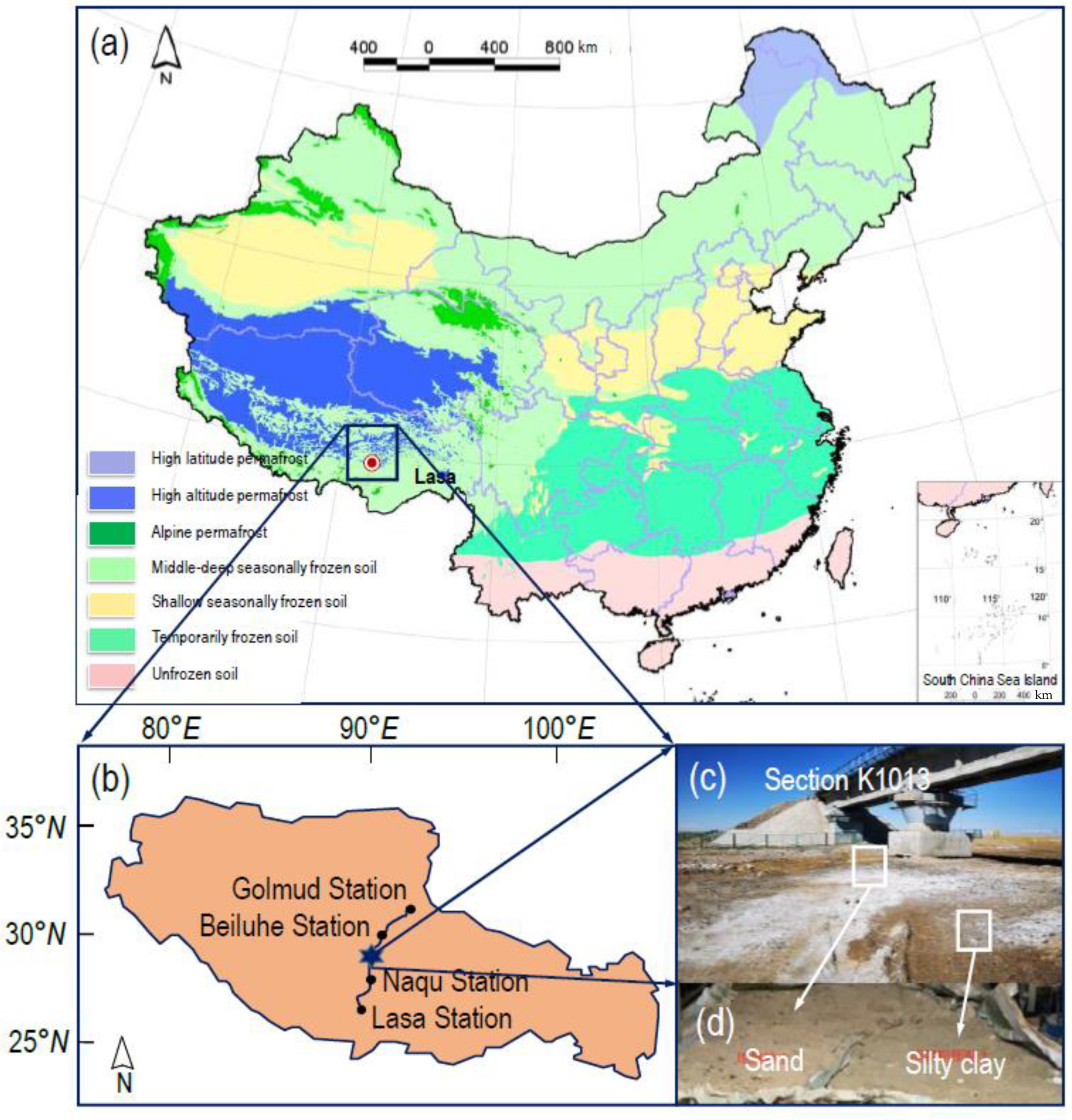

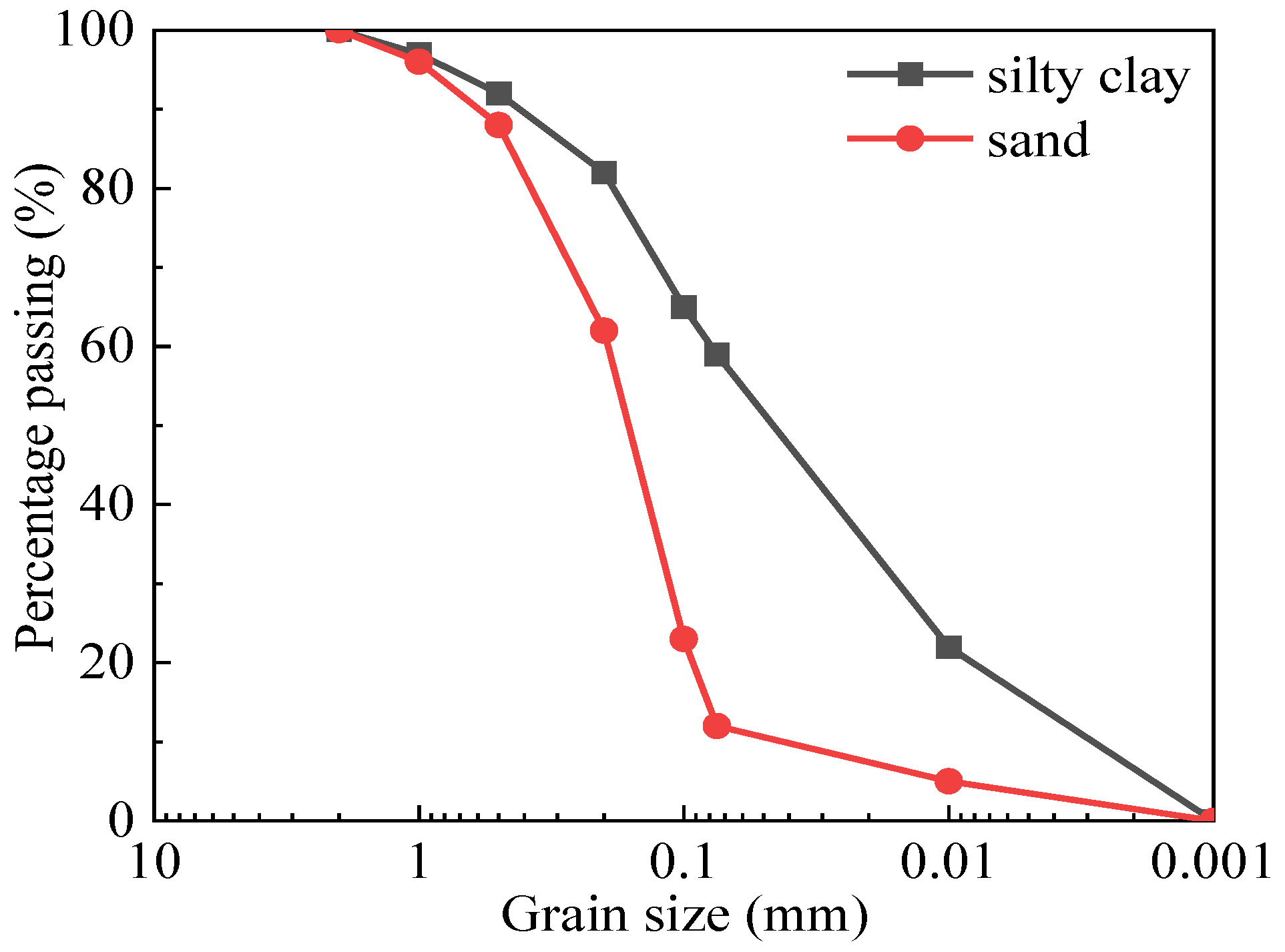

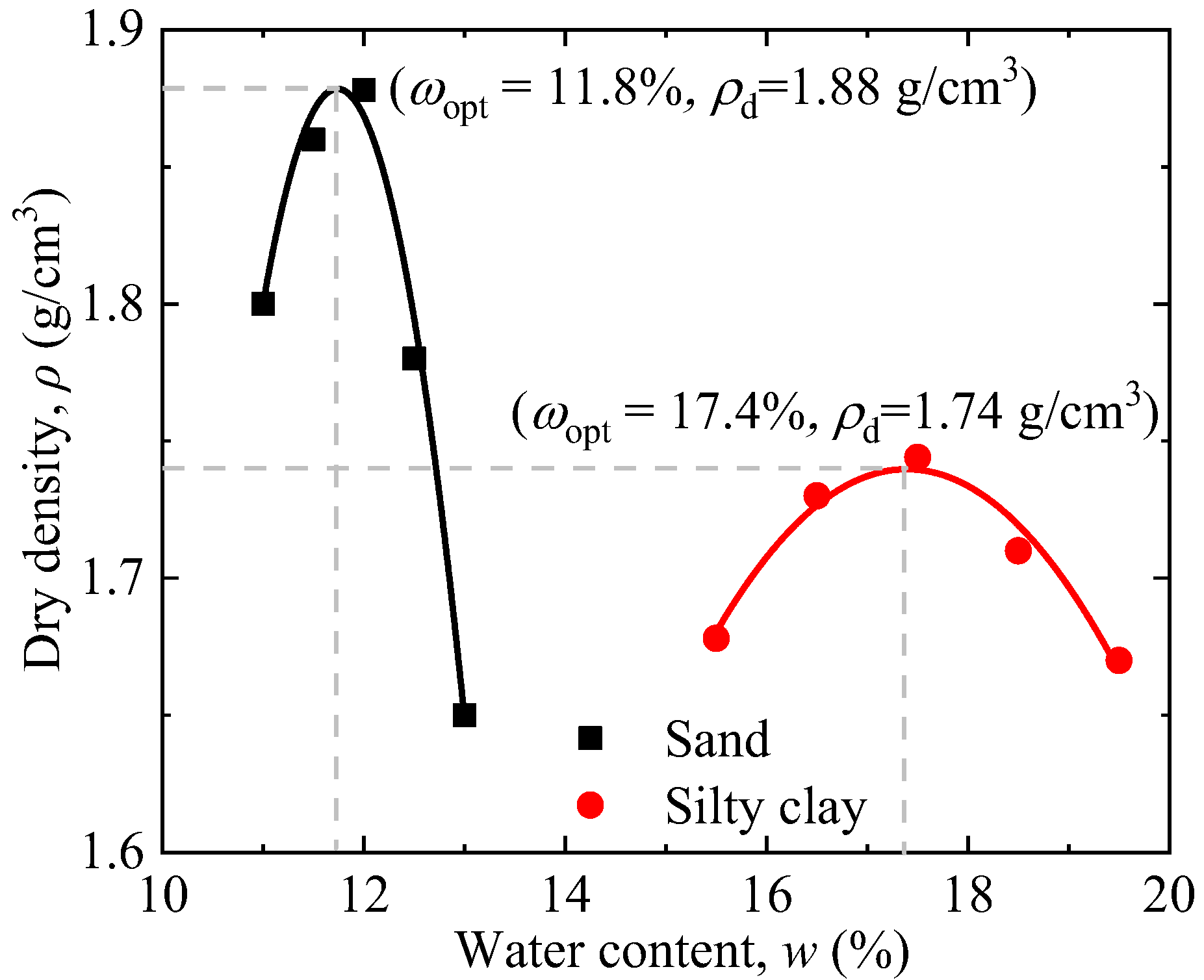

2.1. Study Area and Soil Properties

2.2. Sample Preparation

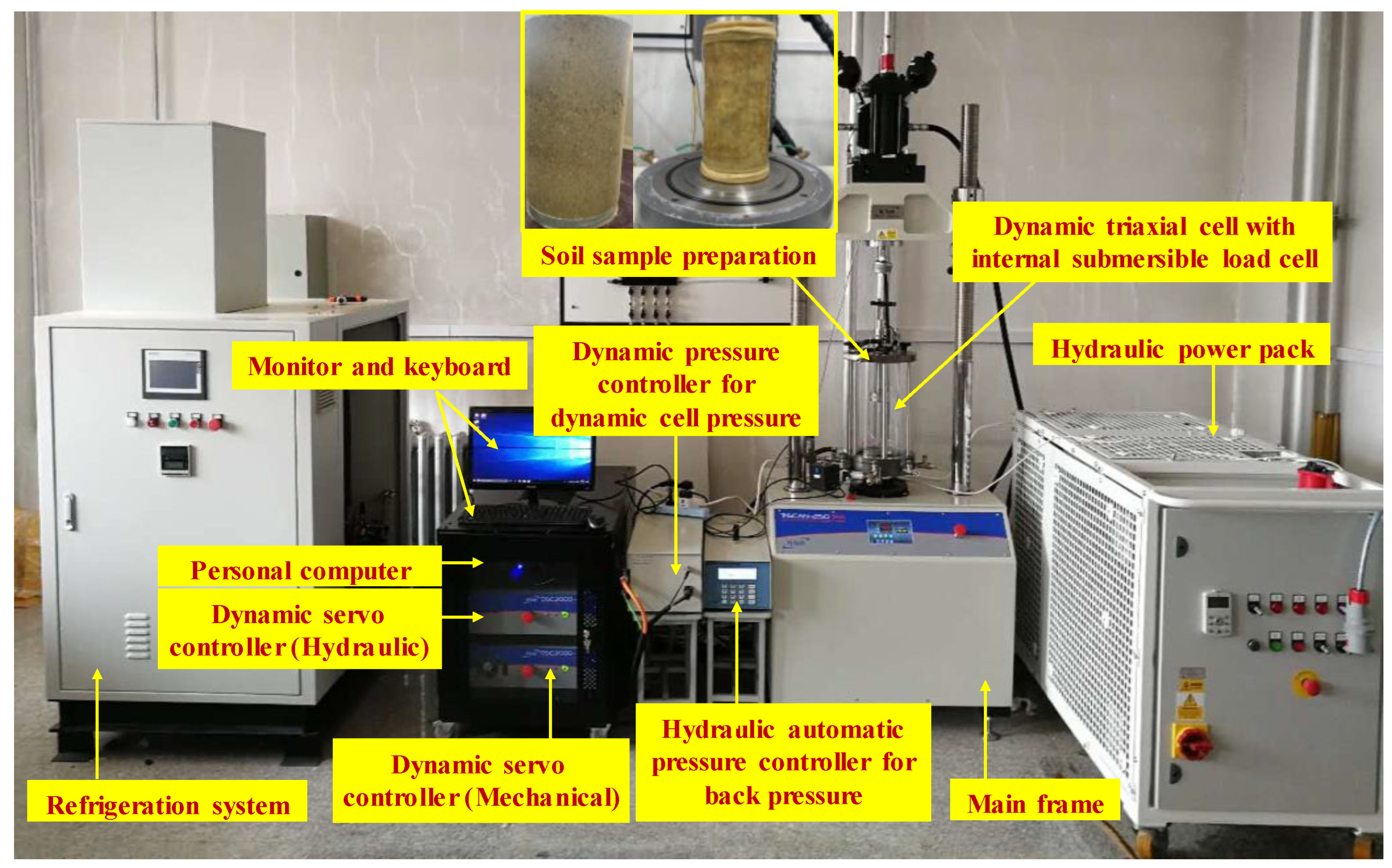

2.3. Test Procedures

3. Experiment Results and Analysis

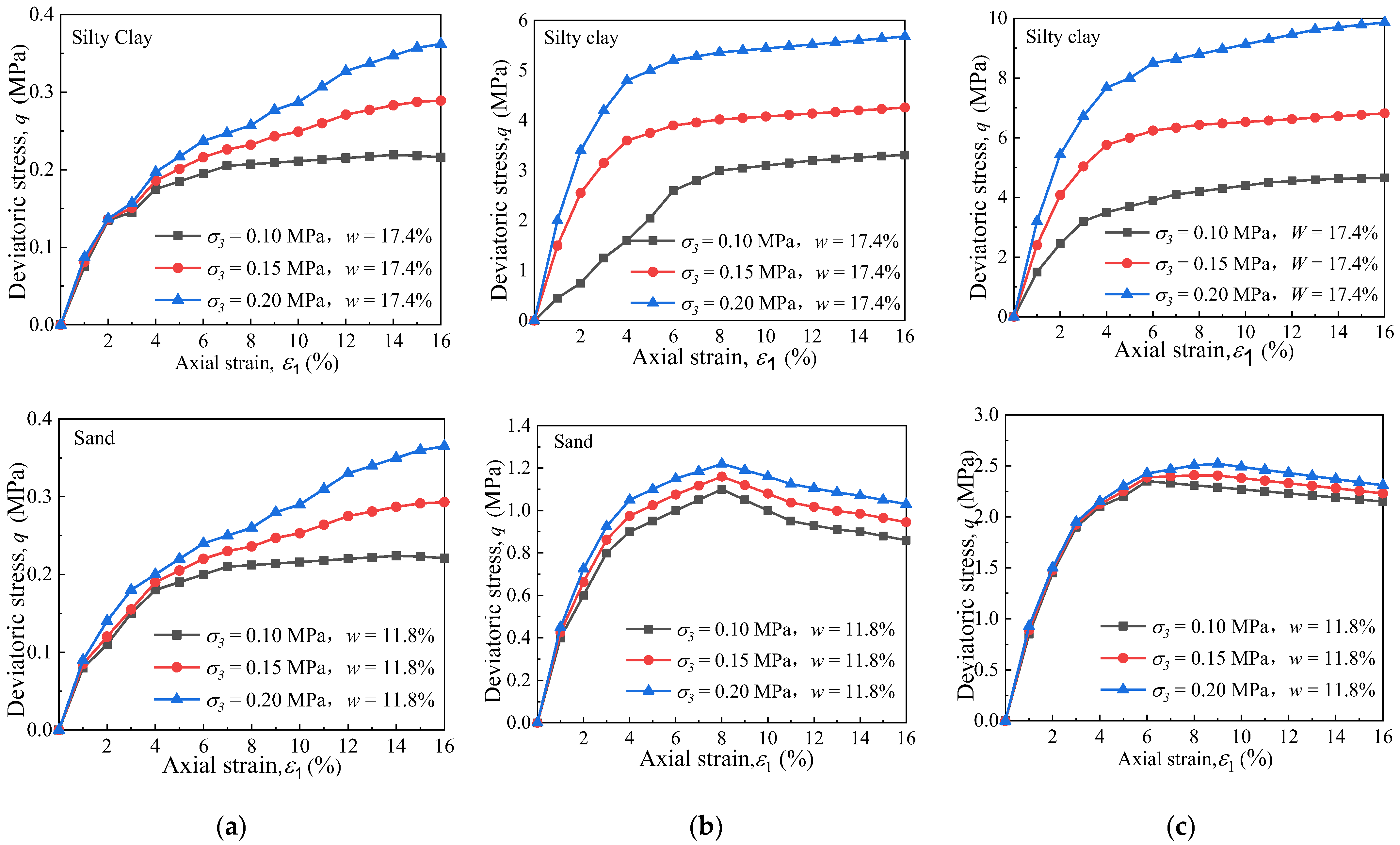

3.1. Stress–Strain Behaviour

3.2. Cohesion and Internal Friction Angle

3.3. Elastic Modulus

4. A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials

4.1. Establishment of the Model

- (1)

- Coefficient determination for Equation (1a).

- (2)

- Coefficients of determination for Equation (1b).

4.2. Determination of Model Parameters

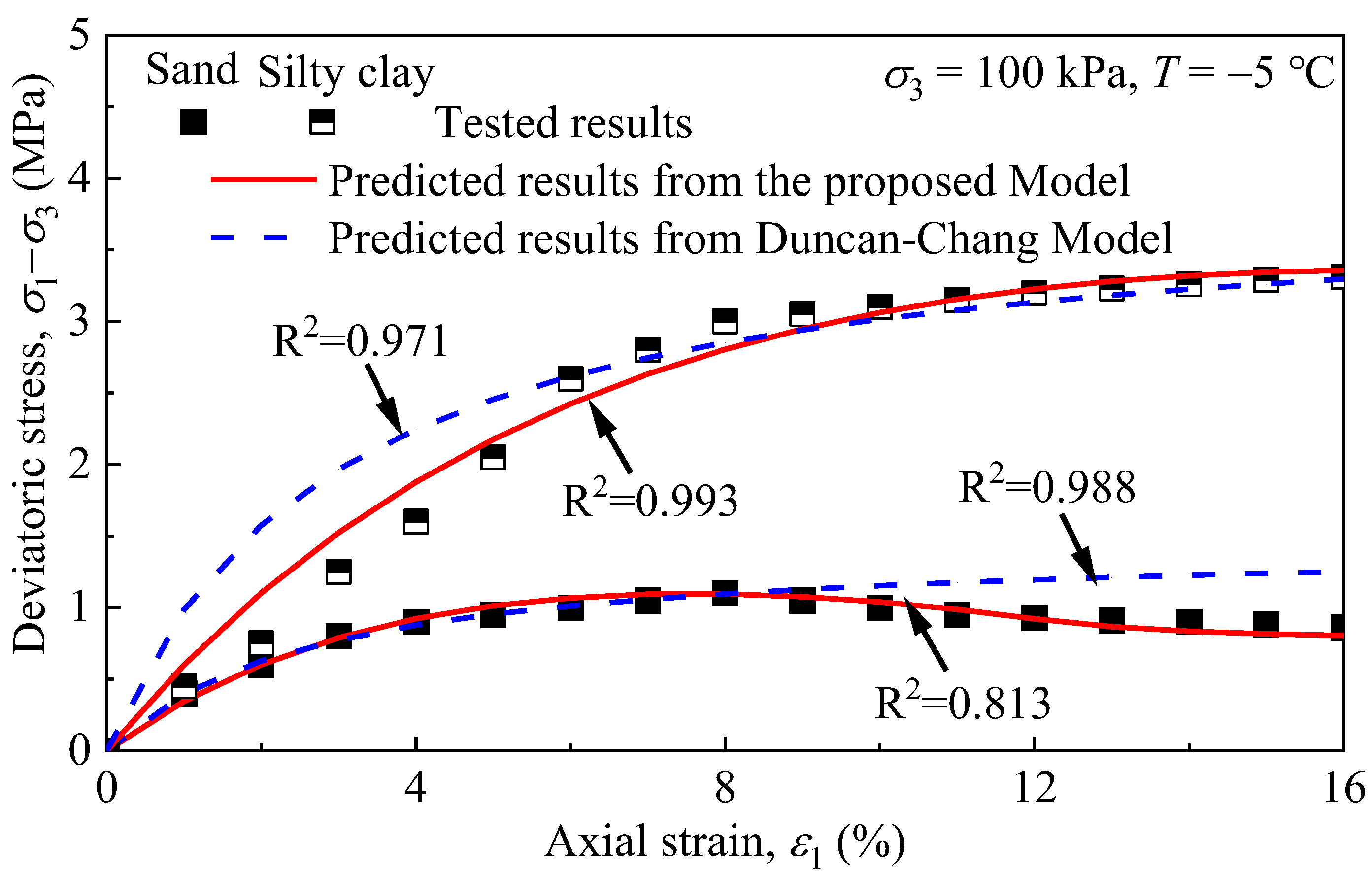

4.3. Model Verification

5. Discussion

5.1. Sensitivity Analysis of the Parameters

5.2. Comparison with the Existing Model

6. Conclusions

- (1)

- All the silty clay exhibited a strain-hardening type of stress–strain curve, but the sand under the temperatures of −5 °C and −10 °C showed strain-softening. Under the same test conditions, the shear strength of the silty clay was greater than that of the sand. In all cases, the cohesion (c) and angle of internal friction (φ) of the silty clay were greater than that of sand. Furthermore, the modulus of elasticity of the materials tested increased due to freezing and the temperature reduction.

- (2)

- A practical constitutive model was developed to represent the nonlinear, stress-dependent, and inelastic stress–strain behaviours of the fillers subjected to freezing and thawing. This model incorporated three important aspects of the stress–strain behaviour, including nonlinearity, strain-dependency softening, and inelasticity. A simple technique was used to interpret the test results and conveniently determine the six parameters in the model.

- (3)

- The triaxial test results of the remoulded fine-grained materials were employed to evaluate the reasonability of the proposed model established in this paper. A comparison of the predicted and test results showed that this model could well simulate the deviatoric stress–strain response in the failure process of the tested materials. In particular, it could reflect the residual deviatoric stress after materials’ failure.

- (4)

- This study analysed the behaviour of the fillers with optimum water content that were exposed to the freeze–thaw cycles to develop a constitutive model. If appropriate experimental results are available, the parameter values in the proposed model can be derived from the triaxial test results. Therefore, additional experiments should be conducted to investigate other parameters, such as the temperature, duration of freezing and thawing, and the moisture content and compactness of the fillers, which are important characteristics of fillers in regions that are subjected to seasonal freezing and thawing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, F.T.; Chang, L.J.; Zhang, W.Y. Experimental investigation of dynamic shear modulus and damping ratio of Qinghai-Tibet frozen silt under multi-stage cyclic loading. Cold Reg. Sci. Technol. 2020, 170, 102938. [Google Scholar] [CrossRef]

- Ma, D.D.; Ma, Q.Y.; Yao, Z.M.; Huang, K. Static-dynamic coupling mechanical properties and constitutive model of artificial frozen silty clay under triaxial compression. Cold Reg. Sci. Technol. 2019, 167, 102858. [Google Scholar] [CrossRef]

- Wu, Q.B.; Cheng, G.D.; Ma, W.; Niu, F.J.; Sun, Z.Z. Technical approaches on permafrost thermal stability for Qinghai–Xizang Railroad. Geomech. Geoeng. 2006, 1, 119–128. [Google Scholar] [CrossRef]

- Ma, W.; Cheng, G.D.; Wu, Q.B.; Wang, D.Y. Application on idea of dynamic design in Qinghai–Tibet Railway construction. Cold Reg. Sci. Technol. 2004, 41, 165–173. [Google Scholar] [CrossRef]

- Zu, Z.Y.; Ling, X.Z.; Chen, S.P.; Zhang, F.; Wang, L.N.; Wang, Z.Y.; Zou, Z.Y. Experimental investigation on the train-induced subsidence prediction model of Beiluhe permafrost subgrade along the Qinghai–Tibet Railway in China. Cold Reg. Sci. Technol. 2010, 62, 67–75. [Google Scholar] [CrossRef]

- Cheng, G.D. A roadbed cooling approach for the construction of Qinghai–Tibet Railway. Cold Reg. Sci. Technol. 2005, 42, 169–176. [Google Scholar] [CrossRef]

- Wang, C.; Li, S.; Zhang, T.; You, Z. Experimental Study on Mechanical Characteristics and Fracture Patterns of Unfrozen/Freezing Saturated Coal and Sandstone. Materials 2019, 12, 992. [Google Scholar] [CrossRef]

- Sobczyk, K.; Chmielewski, R.; Kruszka, L.; Rekucki, R. Strength Characterization of Soils’ Properties at High Strain Rates Using the Hopkinson Technique—A Review of Experimental Testing. Materials 2022, 15, 274. [Google Scholar] [CrossRef]

- Wei, X.; Ming, F.; Li, D.; Chen, L.; Liu, Y. Influence of Water Content on Mechanical Strength and Microstructure of Alkali-Activated Fly Ash/GGBFS Mortars Cured at Cold and Polar Regions. Materials 2020, 13, 138. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, G.; Wang, J. Deformation and strength behaviors of frozen clay with thermal gradient under uniaxial compression. Tunn. Undergr. Space Technol. 2013, 38, 550–558. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.J.; Wang, J. Unfrozen water content of permafrost during thawing by the capacitance technique. Cold Reg. Sci. Technol. 2018, 152, 15–22. [Google Scholar] [CrossRef]

- Török, Á.; Ficsor, A.; Davarpanah, M.; Vásárhelyi, B. Comparison of mechanical properties of dry, saturated and frozen porous rocks. In Proceedings of the IAEG/AEG Annual Meeting, San Francisco, CA, USA, 17–21 September 2018; Shakoor, A., Cato, K., Eds.; Springer International Publishing: New York, NY, USA, 2018; Volume 6, pp. 113–118. [Google Scholar]

- Esmaeili-Falak, M.; Katebi, H.; Javadi, A.A. Effect of Freezing on Stress–Strain Characteristics of Granular and Cohesive Soils. J. Cold Reg. Eng. 2020, 34, 05020001. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhu, Y.L.; Ma, W.; Niu, Y.H. Application of ultrasonic technology for physical–mechanical properties of frozen soils. Cold Reg. Sci. Technol. 2006, 44, 12–19. [Google Scholar] [CrossRef]

- Li, D.W.; Yang, X.; Chen, J.H. A study of Triaxial creep test and yield criterion of artificial frozen soil under unloading stress paths. Cold Reg. Sci. Technol. 2017, 141, 163–170. [Google Scholar] [CrossRef]

- Lai, Y.M.; Liao, M.K.; Hu, K. A constitutive model of frozen saline sandy soil based on energy dissipation theory. Int. J. Plast. 2016, 78, 84–113. [Google Scholar] [CrossRef]

- Xu, X.T.; Li, Q.L.; Lai, Y.; Pang, W.T.; Zhang, R.P. Effect of moisture content on mechanical and damage behavior of frozen loess under triaxial condition along with different confining pressures. Cold Reg. Sci. Technol. 2019, 157, 110–118. [Google Scholar] [CrossRef]

- Peng, W.; Wang, Q.; Liu, Y.F.; Sun, X.H.; Chen, Y.T.; Han, M.X. The Influence of Freeze-Thaw Cycles on the Mechanical Properties and Parameters of the Duncan-Chang Constitutive Model of Remolded Saline Soil in Nong’an County, Jilin Province, Northeastern China. Appl. Sci. 2019, 9, 4941. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Mao, C. Experimental and Theoretical Investigations of the Constitutive Relations of Artificial Frozen Silty Clay. Materials 2019, 12, 3159. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y. A Constitutive Relationship for Gravelly Soil Considering Fine Particle Suffusion. Materials 2017, 10, 1217. [Google Scholar] [CrossRef]

- Xu, P.; Sun, Z.; Shao, S.; Fang, L. Comparative Analysis of Common Strength Criteria of Soil Materials. Materials 2021, 14, 4302. [Google Scholar] [CrossRef]

- Fu, T.T.; Zhu, Z.W.; Zhang, D.; Liu, Z.J.; Xie, Q.J. Research on damage viscoelastic dynamic constitutive model of frozen soil. Cold Reg. Sci. Technol. 2019, 160, 209–221. [Google Scholar] [CrossRef]

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found Div. ASCE 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Duncan, J.M. Strength Stress-Strain and Bulk Modulus Parameters for Finite Element Analysis of Stresses and Movements in Soil Masses; VCB/GT/78-02; University of California, Berkeley: Berkeley, CA, USA, 1978.

- Liu, X.Q.; Liu, J.K.; Tian, Y.H.; Chang, D.; Hu, T.F. Influence of the Freeze-thaw Effect on the Duncan-Chang Model Parameter for Lean Clay. Transp. Geotech. 2019, 21, 100273. [Google Scholar] [CrossRef]

- Hu, T.F.; Liu, J.K.; Chang, D.; Fang, J.H.; Xu, A.H. Influence of Freeze-thaw Cycling on Mechanical Properties of Silty Clay and Ducan-Chang Constitutive Model. Zhongguo Gonglu Xuebao/China J. Highw. Transp. 2018, 31, 298–307. [Google Scholar]

- He, Y.; Chen, X. The Application of Improved Duncan-Chang Model in Unloading Soil. Open Civ. Eng. J. 2014, 8, 410–415. [Google Scholar] [CrossRef][Green Version]

- TB10102-2010; Code for Soil Test of Railway Engineering. China Railway First Survey and Design Institute Group: Beijing, China, 2010. (In Chinese)

- Wang, D.; Ma, W.; Niu, Y.; Chang, X.; Wen, Z. Effects of cyclic freezing and thawing on mechanical properties of Qinghai–Tibet clay. Cold Reg. Sci. Technol. 2007, 48, 34–43. [Google Scholar] [CrossRef]

- Yu, C.Y.; Tian, S.; Tang, L.; Ling, X.Z.; Zhou, G.Q. Finite element analysis on deformation of high embankment in heavy-haul railway subjected to freeze-thaw cycles. Sci. Cold Arid Reg. 2015, 7, 421–429. [Google Scholar] [CrossRef]

| Soil Type | Test No. | Confining Pressure (kPa) | Temperature (°C) | b1 | b2 | b3 | b4 | b5 | Dβ | The Patterns of the Stress–Strain Curves |

|---|---|---|---|---|---|---|---|---|---|---|

| Sand | S1 | 100 | −1 | 0.78 | 0.44 | 0.213 | - | - | 3.86 | Strain-hardening |

| S2 | 150 | 0.54 | 0.46 | 0.165 | - | - | 3.30 | Strain-hardening | ||

| S3 | 200 | 0.39 | 0.43 | 0.174 | - | - | 2.84 | Strain-hardening | ||

| S4 | 100 | −5 | 0.78 | 0.38 | 0.0036 | 1.41 | 5.93 | 2.91 | Strain-softening | |

| S5 | 150 | 0.54 | 0.25 | 0.0077 | 1.22 | 6.39 | 2.53 | Strain-softening | ||

| S6 | 200 | 0.39 | 0.33 | 0.0057 | 1.16 | 6.71 | 2.24 | Strain-softening | ||

| S7 | 100 | −10 | 0.78 | 0.25 | 0.0142 | 3.65 | 11.95 | 2.41 | Strain-softening | |

| S8 | 150 | 0.54 | 0.33 | 0.0192 | 2.60 | 9.43 | 2.35 | Strain-softening | ||

| S9 | 200 | 0.39 | 0.39 | 0.0446 | 1.83 | 8.44 | 2.40 | Strain-softening | ||

| Silty clay | SC1 | 100 | −1 | 1.26 | 0.42 | 0.19 | - | - | 4.67 | Strain-hardening |

| SC2 | 150 | 3.73 | 0.29 | 0.24 | - | - | 4.94 | Strain-hardening | ||

| SC3 | 200 | 4 | 0.02 | 0.16 | - | - | 4.28 | Strain-hardening | ||

| SC4 | 100 | −5 | 1.26 | 0.29 | 0.17 | - | - | 3.74 | Strain-hardening | |

| SC5 | 150 | 3.73 | 0.16 | 0.26 | - | - | 7.08 | Strain-hardening | ||

| SC6 | 200 | 4 | 0.14 | 0.12 | - | - | 6.54 | Strain-hardening | ||

| SC7 | 100 | −10 | 1.26 | 0.29 | 0.47 | - | - | 4.65 | Strain-hardening | |

| SC8 | 150 | 3.73 | 0.16 | 0.26 | - | - | 7.08 | Strain-hardening | ||

| SC9 | 200 | 4 | 0.17 | 0.14 | - | - | 6.82 | Strain-hardening |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, L.; Tian, S.; Yao, C.; Han, X.; Wang, K. A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials Used under the Qinghai–Tibet Railway Line. Materials 2022, 15, 5119. https://doi.org/10.3390/ma15155119

Dong L, Tian S, Yao C, Han X, Wang K. A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials Used under the Qinghai–Tibet Railway Line. Materials. 2022; 15(15):5119. https://doi.org/10.3390/ma15155119

Chicago/Turabian StyleDong, Liang, Shuang Tian, Changrui Yao, Xiao Han, and Ke Wang. 2022. "A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials Used under the Qinghai–Tibet Railway Line" Materials 15, no. 15: 5119. https://doi.org/10.3390/ma15155119

APA StyleDong, L., Tian, S., Yao, C., Han, X., & Wang, K. (2022). A Nonlinear Constitutive Model for Remoulded Fine-Grained Materials Used under the Qinghai–Tibet Railway Line. Materials, 15(15), 5119. https://doi.org/10.3390/ma15155119