Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Statistical Analysis

2.2.2. Chemical Analysis of the Tested Biomass

2.2.3. Moisture Measurement

3. Results

3.1. Preliminary Study

3.2. Main Research

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hryniewicz, M.; Roman, K. Simulations of fuels consumption in the CHP system based on modernised GTD-350 tur-bine engine. J. Water Land Dev. 2021, 51, 250–255. [Google Scholar] [CrossRef]

- Hryniewicz, M.; Strzelczyk, M.; Helis, M.; Paszkiewicz-Jasińska, A.; Steinhoff-Wrzesniewska, A.; Ro-man, K. Mathematical models use to yield prognosis of perennials on marginal land according to fertilis-ers doses. J. Water Land Dev. 2021, 51, 233–242. [Google Scholar] [CrossRef]

- Journal of Law No 261, item 2187 of 19 December 2005 on a Detailed Scope of Obligations of Acquiring and Submitting the Certificates of Origin to Be Cancelled, Making a Compensatory Payment, Purchasing Electrical Energy and Heat Produced from Renewable Sources of Energy, §2 Clause 1. Available online: https://www.infor.pl/akt-prawny/DZU.2005.261.0002187,rozporzadzenie-ministra-gospodarki-w-sprawie-szczegolowego-zakresu-obowiazkow-uzyskania-i-przedstawienia-do-umorzenia-swiadectw-pochodzenia-uiszczenia-oplaty-zastepczej-oraz-zakupu-energii-elektryczne.html (accessed on 3 May 2022).

- Xu, J.; Chang, S.; Yuan, Z.; Jiang, Y.; Liu, S.; Li, W.; Ma, L. Regionalized techno-economic assessment and policy analysis for biomass molded fuel in China. Energies 2015, 8, 13846–13863. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubík, H.; Brožek, M.; Herák, D.; Šleger, V.; Mazancová, J. Potential of tropical fruit waste biomass for production of bio-briquette fuel: Using Indonesia as an example. Energies 2017, 10, 2119. [Google Scholar] [CrossRef]

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Rotella Junior, P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Mohammad, S.; Baidurah, S.; Kamimura, N.; Matsuda, S.; Bakar, N.A.S.A.; Muhamad, N.N.I.; Ahmad, A.H.; Dominic, D.; Kobayashi, T. Fermentation of Palm Oil Mill Effluent in the Presence of Lysinibacillus sp. LC 556247 to Produce Alternative Biomass Fuel. Sustainability 2021, 13, 11915. [Google Scholar] [CrossRef]

- Aherne, J.; MPosch Forsius, M.; Lehtonen, A.; Härkönen, K. Impacts of forest biomass removal on soil nutrient status under climate change: A catchment-based modelling study for Finland. Biogeochemistry 2012, 107, 471–488. [Google Scholar] [CrossRef]

- Forsius, M.; Akujarvi, A.; Mattsson, T.; Holmberg, M.; Punttila, P.; Posch, M.; Liski, J.; Virkkala, R.; Vihervaara, P. Modelling impacts of forest bioenergy use on ecosystem sustainability: Lammi LTER region, southern Finland. Ecol. Indic. 2016, 65, 66–75. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The impact of fractional composition on the mechanical properties of agglomerated logging residues. Sustainability 2020, 12, 6120. [Google Scholar] [CrossRef]

- Fiszer, A. Wpływ wilgotności słomy i temperatury procesu brykietowania na jakość aglomeratu. J. Res. Appl. Agric. Eng. 2009, 54, 69–73. [Google Scholar]

- Niedziółka, I.; Szymanek, M.; Zuchniarz, A. Ocena trwałości brykietów wytworzonych z masy roślinnej kukurydzy pastewnej. Inżynieria Rol. 2008, 9, 237–238. [Google Scholar]

- Dyjakon, A.; Sobol, Ł.; Krotowski, M.; Mudryk, K.; Kawa, K. The Impact of Particles Comminution on Mechanical Durability of Wheat Straw Briquettes. Energies 2020, 13, 6186. [Google Scholar] [CrossRef]

- Zhang, S.; Deng, M.; Shan, M.; Zhou, C.; Liu, W.; Xu, X.; Yang, X. Energy and environmental impact assessment of straw return and substitution of straw briquettes for heating coal in rural China. Energy Pol. 2019, 128, 654–664. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2019, 7, 1801011. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2019, 33, 337–359. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Brunerová, A.; Brožek, M.; Šleger, V.; Nováková, A. Energy Balance of Briquette Production from Various Waste Biomass. Sci. Agric. Bohem. 2018, 49, 236–243. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn cobs. Fuel Process. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Grochowicz, J.; Andrejko, D.; Mazur, J. Wpływ wilgotności i stopnia rozdrobnienia na energię zagęszczania i wytrzymałość brykietów łubinowych. MOTROL-Motoryz. I Energetyka Rol. 2004, 6, 96–103. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Specific Energy Requirement for Compacting Corn Stover. Bioresour. Technol. 2006, 97, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Gradziuk, P.; Gradziuk, B.; Trocewicz, A.; Jendrzejewski, B. Potential of Straw for Energy Purposes in Poland—Forecasts Based on Trend and Causal Models. Energies 2020, 13, 5054. [Google Scholar] [CrossRef]

- Asket. The Manufacturer’s Leaflet. Available online: https://zlotywegiel.pl/tag/zloty-wegiel/ (accessed on 21 January 2022).

- Rembowski, Ł. Brykieciarka Tłokowa (mimośrodowa), Stemplowa, Korbowodowa, Agroenergetyka, s. 1. 2007. Available online: http://agroenergetyka.pl/?a=article&id=199 (accessed on 7 December 2016).

- Wang, Y.; Wu, K.; Sun, Y. Effects of raw material particle size on the briquetting process of rice straw. J. Energy Inst. 2016, 91, 153–162. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Roman, K.; Roman, M.; Szadkowska, D.; Szadkowski, J.; Grzegorzewska, E. Evaluation of Physical and Chemical Pa-rameters According to Energetic Willow (Salix viminalis L.) Cultivation. Energies 2021, 14, 2968. [Google Scholar] [CrossRef]

- Roman, K.; Barwicki, J.; Hryniewicz, M.; Szadkowska, D.; Szadkowski, J. Production of Electricity and Heat from Bio-mass Wastes Using a Converted Aircraft Turbine AI-20. Processes 2021, 9, 364. [Google Scholar] [CrossRef]

- Thomas, M.; Vliet, T.; Poel AF, B. Physical quality of pelleted animal feed 3. Contribution of feedstuff components. Anim. Feed. Sci. Technol. 1998, 73, 59–78. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198, ISSN 0003-2670. [Google Scholar] [CrossRef]

- Kraszkiewicz, A. Analiza wybranych właściwości chemicznych drewna i kory robinii akacjowej (Robinia pseudoacacia L.). Inżynieria Rol. 2009, 8, 69–75. [Google Scholar]

- Prosiński, S. Chemia Drewna; PWRiL: Warszawa, Poland, 1984. [Google Scholar]

- Rybak, W. Spalanie i Współspalanie Biopaliw Stałych. Wyd; Politechniki Wrocławskiej: Wrocław, Poland, 2006; ISBN 8373859380. [Google Scholar]

- Roman, K. Dobór Parametrów Technicznych Procesu Brykietowania Biomasy Leśnej. Ph.D. Thesis, Warsaw University of Life, Warszawa, Poland, 2017. [Google Scholar]

- Kajda-Szcześniak, M. Evaluation of the basic properties of the wood waste and woodbased wastes. Arch. Waste Manag. Environ. Prot. 2013, 15, 1–10, ISSN 1733-4381. [Google Scholar]

- Bach, Q.; Chen, W.; Chu, Y.; Skreiberg, Ø. Predictions of biochar yield and elemental composition during torre-faction of forest residues. Bioresour. Technol. 2016, 215, 239–246. [Google Scholar] [CrossRef] [PubMed]

- Raslavičius, L.; Grzybek, A.; Dubrovin, V. Bioenergy in Ukraine—Possibilities of rural development and opportunities for local communities. Energy Policy 2011, 39, 3370–3379, ISSN 0301-4215. [Google Scholar] [CrossRef]

- Konieczna, A.; Roman, K.; Borek, K.; Grzegorzewska, E. GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study. Energies 2021, 14, 5574. [Google Scholar] [CrossRef]

| Material | Durability Factor (Ψ) | References |

|---|---|---|

| Twisted straw (0°) | 0.81 | [12] |

| Twisted straw (5°) | 0.93 | [12] |

| Twisted straw (10°) | 0.9 | [12] |

| Twisted straw (20°) | 0.8 | [12] |

| Fodder corn straw (15 tons, mounted forage harvester) | 0.75 | [13] |

| Fodder corn straw (20 tons, mounted forage harvester) | 0.81 | [13] |

| Fodder corn straw (15 tons, hammer mill) | 0.88 | [13] |

| Fodder corn straw (20 tons, hammer mill) | 0.88 | [13] |

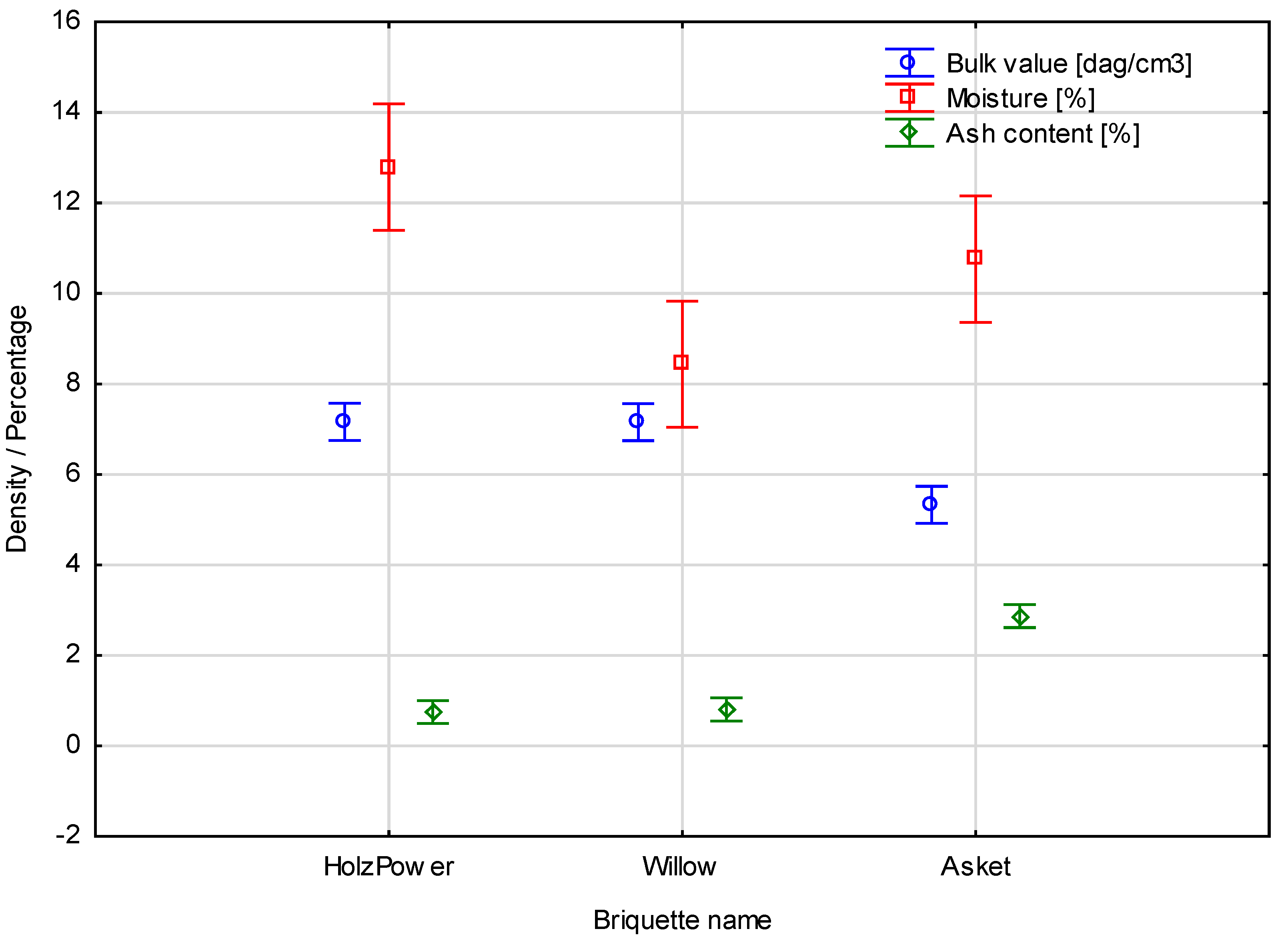

| Briquette Commercial Name | Bulk Value (dag/cm3) | Moisture (%) | Ash Content (%) |

|---|---|---|---|

| HolzPower (Straw) | 7.19 | 12.74 | 0.575 |

| 7.35 | 12.42 | 0.657 | |

| 6.96 | 13.22 | 1.020 | |

| Asket (Straw) | 5.84 | 12.25 | 2.790 |

| 4.94 | 8.97 | 2.864 | |

| 5.20 | 11.06 | 2.961 | |

| Willow | 7.18 | 8.33 | 0.673 |

| 7.12 | 8.42 | 1.019 | |

| 7.17 | 8.56 | 0.728 |

| Briquette Name | Bulk Value (dag/cm3) | Moisture (%) | Ash Content (%) |

|---|---|---|---|

| Mean | |||

| HolzPower | 7.17 a | 12.79 c | 0.75 f |

| Asket | 5.33 b | 10.76 d | 2.87 g |

| Willow | 7.16 a | 8.44 e | 0.81 f |

| Straw | Content of (%) | Ash Content (%) | ||||

|---|---|---|---|---|---|---|

| C | H | N | S | O | ||

| Rye | 44.14 | 6.38 | 0.63 | 0.16 | 44.38 | 4.31 |

| Rye | 44.96 | 6.22 | 0.57 | 0.17 | 43.79 | 4.29 |

| Rye | 45.25 | 6.29 | 0.62 | 0.18 | 43.38 | 4.28 |

| Rye | 44.52 | 6.27 | 0.58 | 0.15 | 44.20 | 4.28 |

| Rye | 44.02 | 6.33 | 0.52 | 0.12 | 44.75 | 4.26 |

| Rye | 46.55 | 6.21 | 0.37 | 0.13 | 42.48 | 4.26 |

| Rye | 46.71 | 6.16 | 0.46 | 0.17 | 42.26 | 4.24 |

| Rye | 46.43 | 6.18 | 0.57 | 0.15 | 42.45 | 4.22 |

| Rye | 46.71 | 6.12 | 0.48 | 0.12 | 42.36 | 4.21 |

| Triticale | 45.22 | 6.04 | 0.51 | 0.16 | 43.89 | 4.18 |

| Triticale | 45.32 | 6.04 | 0.48 | 0.17 | 43.81 | 4.18 |

| Triticale | 43.17 | 6.18 | 1.16 | 0.24 | 45.10 | 4.15 |

| Triticale | 43.47 | 6.16 | 0.56 | 0.16 | 45.50 | 4.15 |

| Triticale | 44.63 | 6.32 | 0.49 | 0.17 | 44.25 | 4.14 |

| Triticale | 44.14 | 6.32 | 0.57 | 0.16 | 44.68 | 4.13 |

| Triticale | 43.73 | 6.37 | 0.57 | 0.13 | 45.08 | 4.12 |

| Triticale | 44.76 | 6.32 | 0.61 | 0.12 | 44.07 | 4.12 |

| Triticale | 44.15 | 6.22 | 0.54 | 0.14 | 44.83 | 4.12 |

| Wheat | 45.83 | 6.01 | 0.53 | 0.12 | 43.50 | 4.01 |

| Wheat | 45.44 | 6.07 | 0.47 | 0.16 | 43.94 | 3.92 |

| Wheat | 45.64 | 6.01 | 0.42 | 0.14 | 43.90 | 3.89 |

| Wheat | 45.73 | 6.08 | 0.42 | 0.14 | 43.85 | 3.78 |

| Rapeseed | 41.75 | 6.14 | 0.89 | 0.47 | 47.03 | 3.72 |

| Rapeseed | 43.52 | 6.48 | 0.85 | 0.55 | 44.99 | 3.61 |

| Straw | Content of (%) | Ash Content (%) | ||||

|---|---|---|---|---|---|---|

| C | H | N | S | O | ||

| Rapeseed | 42.64 a | 6.31 c | 0.87 e | 0.51 g | 46,01 i | 3.67 k |

| Triticale | 44.29 b | 6.22 c | 0.61 e | 0.16 h | 44,58 j | 4.14 l |

| Rye | 45.48 b | 6.24 c | 0.53 e | 0.15 h | 43,34 k | 4.26 m |

| Wheat | 45.66 b | 6.04 d | 0.46 f | 0.14 h | 43,80 j, k | 3.90 n |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roman, K.; Grzegorzewska, E.; Zatoń, P.; Konieczna, A.; Oleńska, S.; Borek, K.; Świętochowski, A. Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy. Materials 2022, 15, 5235. https://doi.org/10.3390/ma15155235

Roman K, Grzegorzewska E, Zatoń P, Konieczna A, Oleńska S, Borek K, Świętochowski A. Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy. Materials. 2022; 15(15):5235. https://doi.org/10.3390/ma15155235

Chicago/Turabian StyleRoman, Kamil, Emilia Grzegorzewska, Patrycja Zatoń, Anita Konieczna, Sylwia Oleńska, Kinga Borek, and Adam Świętochowski. 2022. "Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy" Materials 15, no. 15: 5235. https://doi.org/10.3390/ma15155235

APA StyleRoman, K., Grzegorzewska, E., Zatoń, P., Konieczna, A., Oleńska, S., Borek, K., & Świętochowski, A. (2022). Dispersed Power Production in Terms of the Potential of Briquettes Made from Straw and Willow as Renewable Sources of Energy. Materials, 15(15), 5235. https://doi.org/10.3390/ma15155235