Environmental Benefit Assessment of Blended Cement with Modified Granulated Copper Slag

Abstract

:1. Introduction

2. Methodology

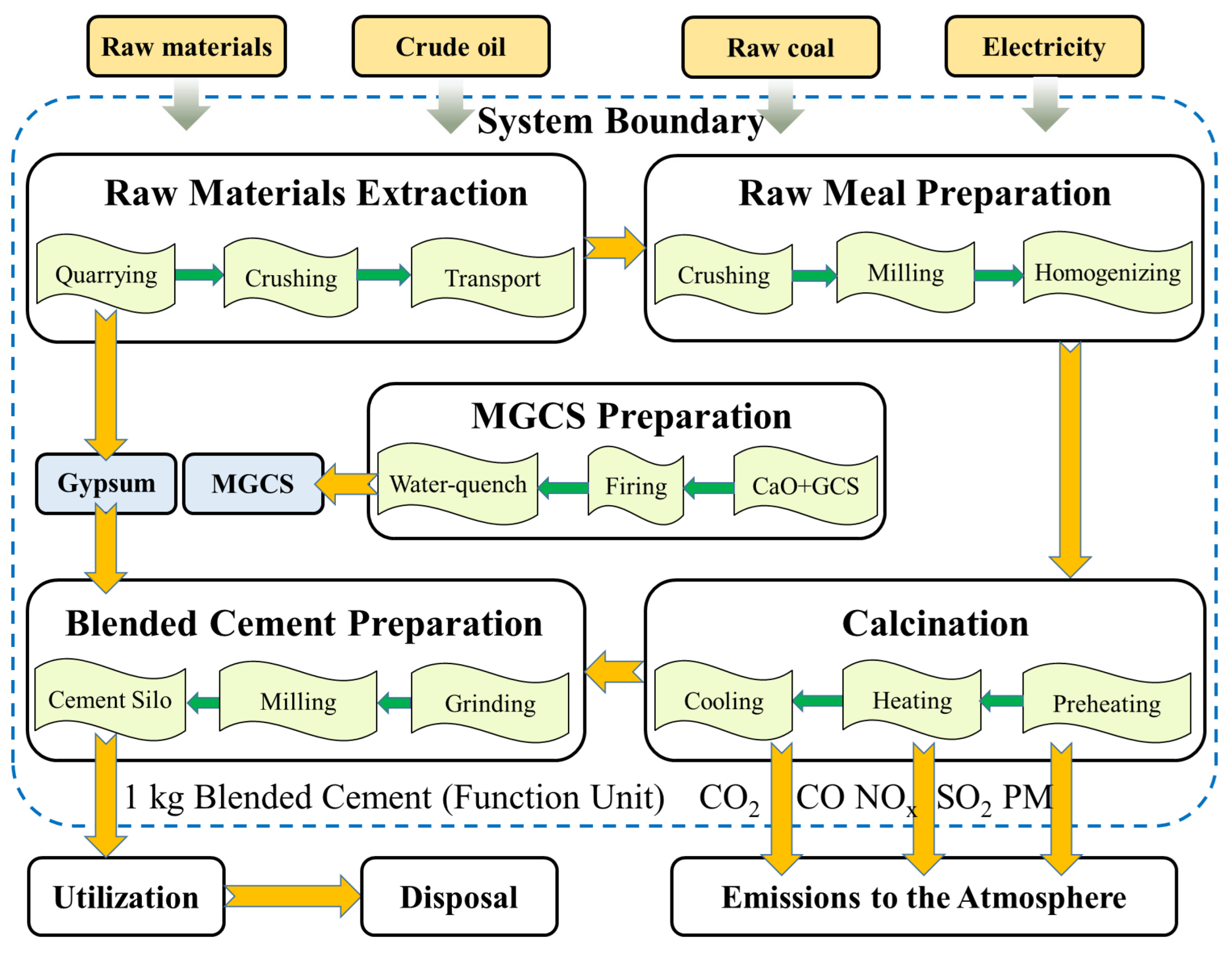

2.1. Blended Cement Production

2.2. Goal and Scope Definition

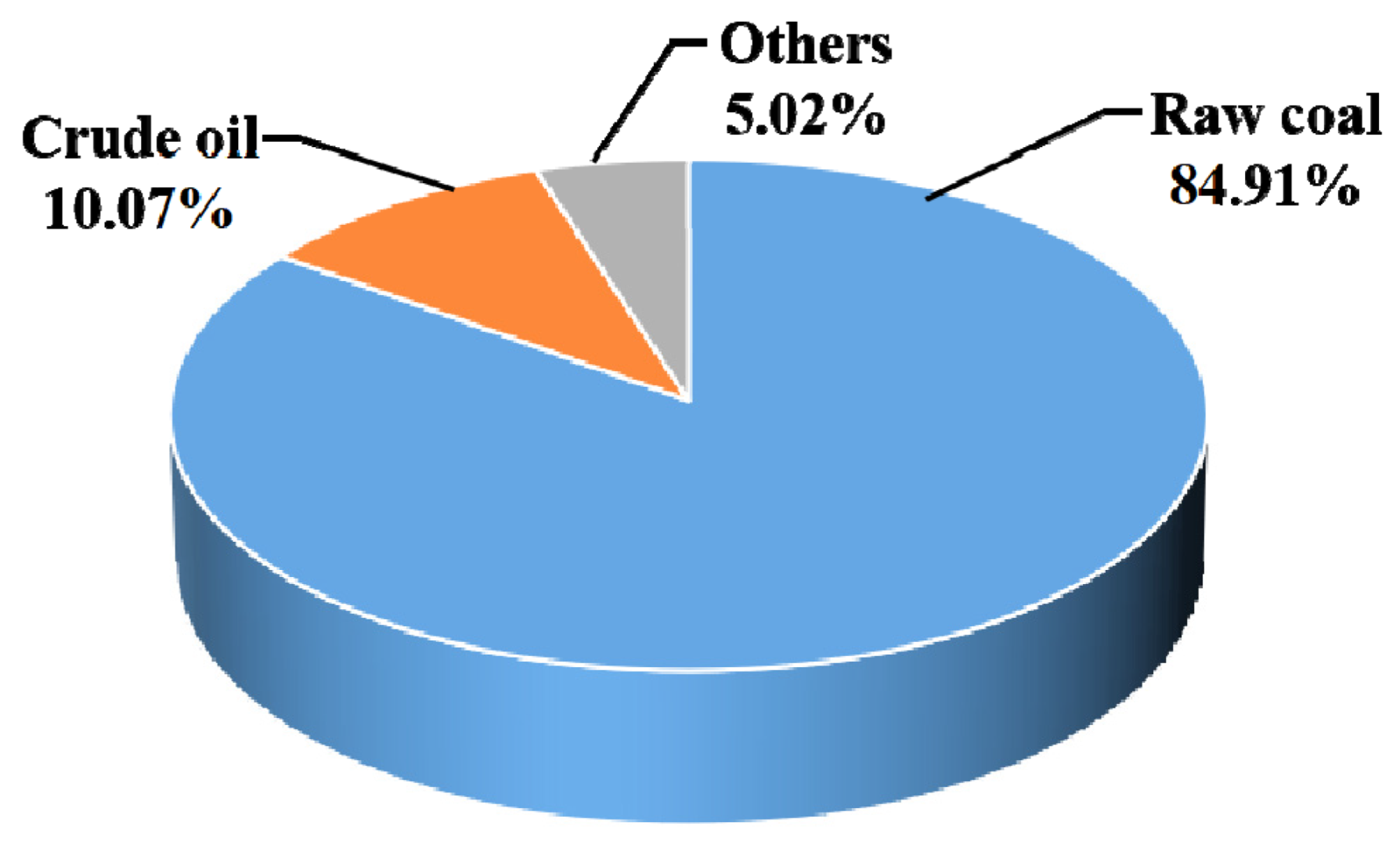

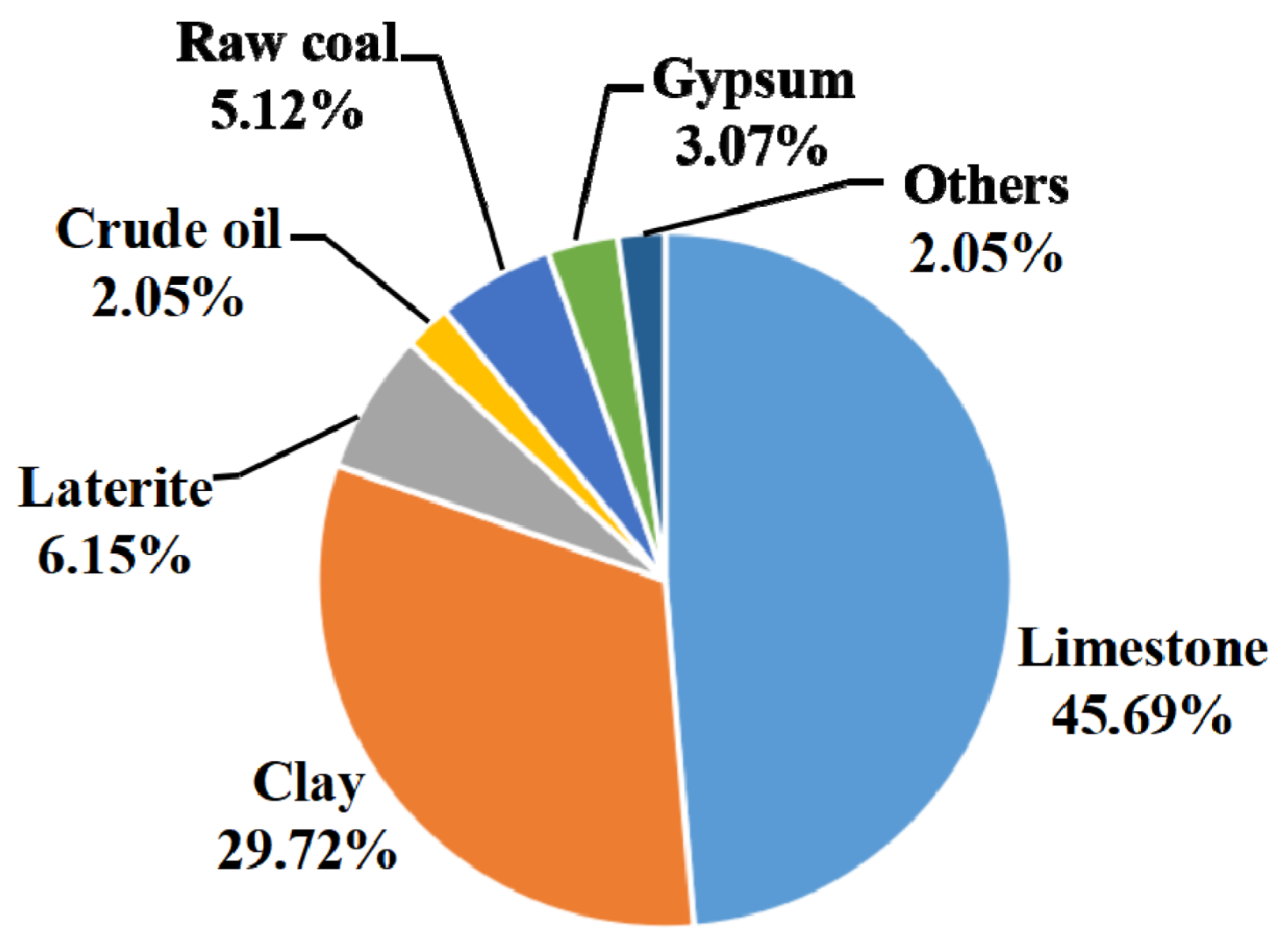

2.3. Life Cycle Inventory

2.4. Life Cycle Impact Assessment

3. Results and Discussion

3.1. LCIA Results

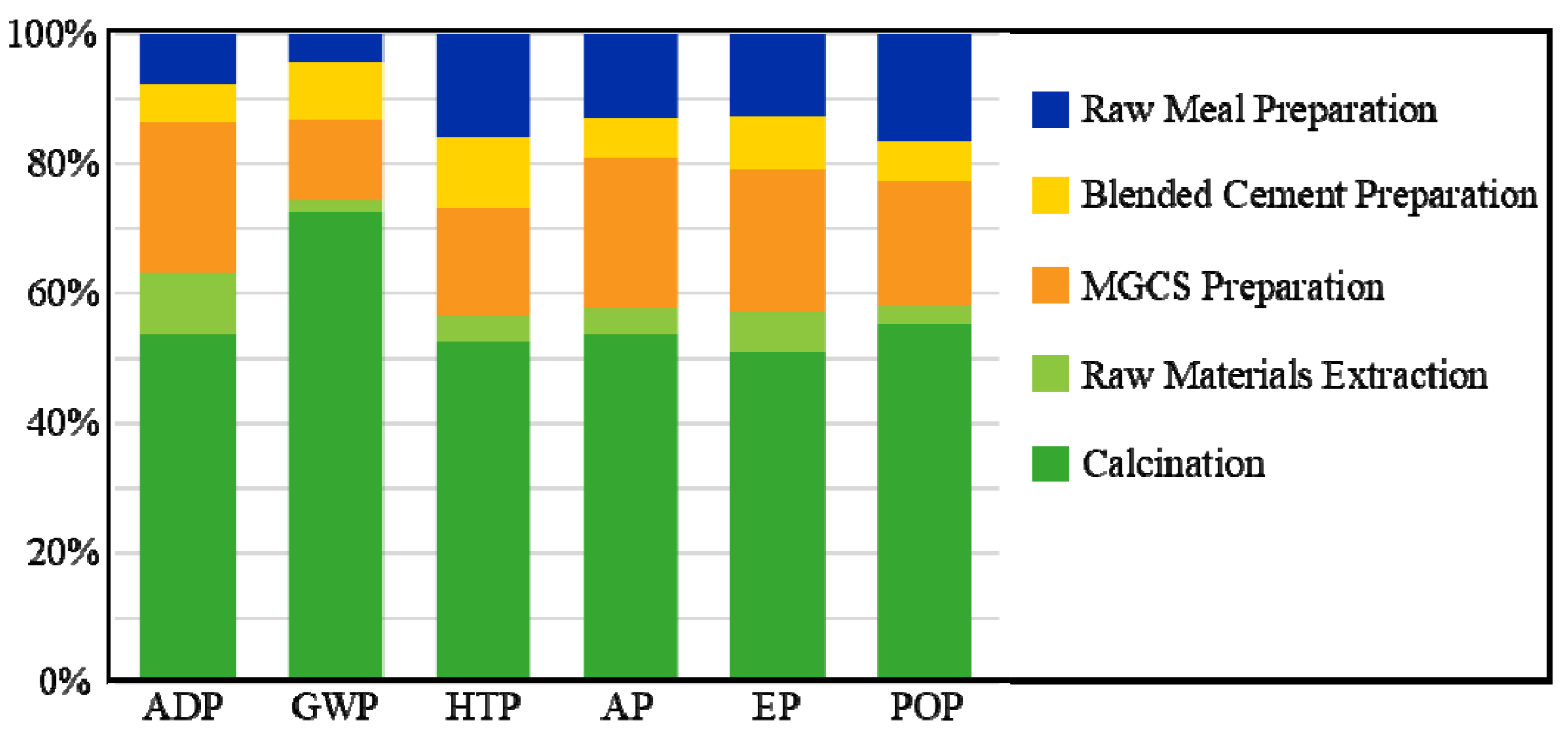

3.1.1. Characterization Results

3.1.2. Normalization Results

3.2. Sensitivity Analysis

3.2.1. Sensitivity Analysis for Substance Input Items

3.2.2. Sensitivity Analysis for the LCIA Model

3.3. Comparison with Other Studies

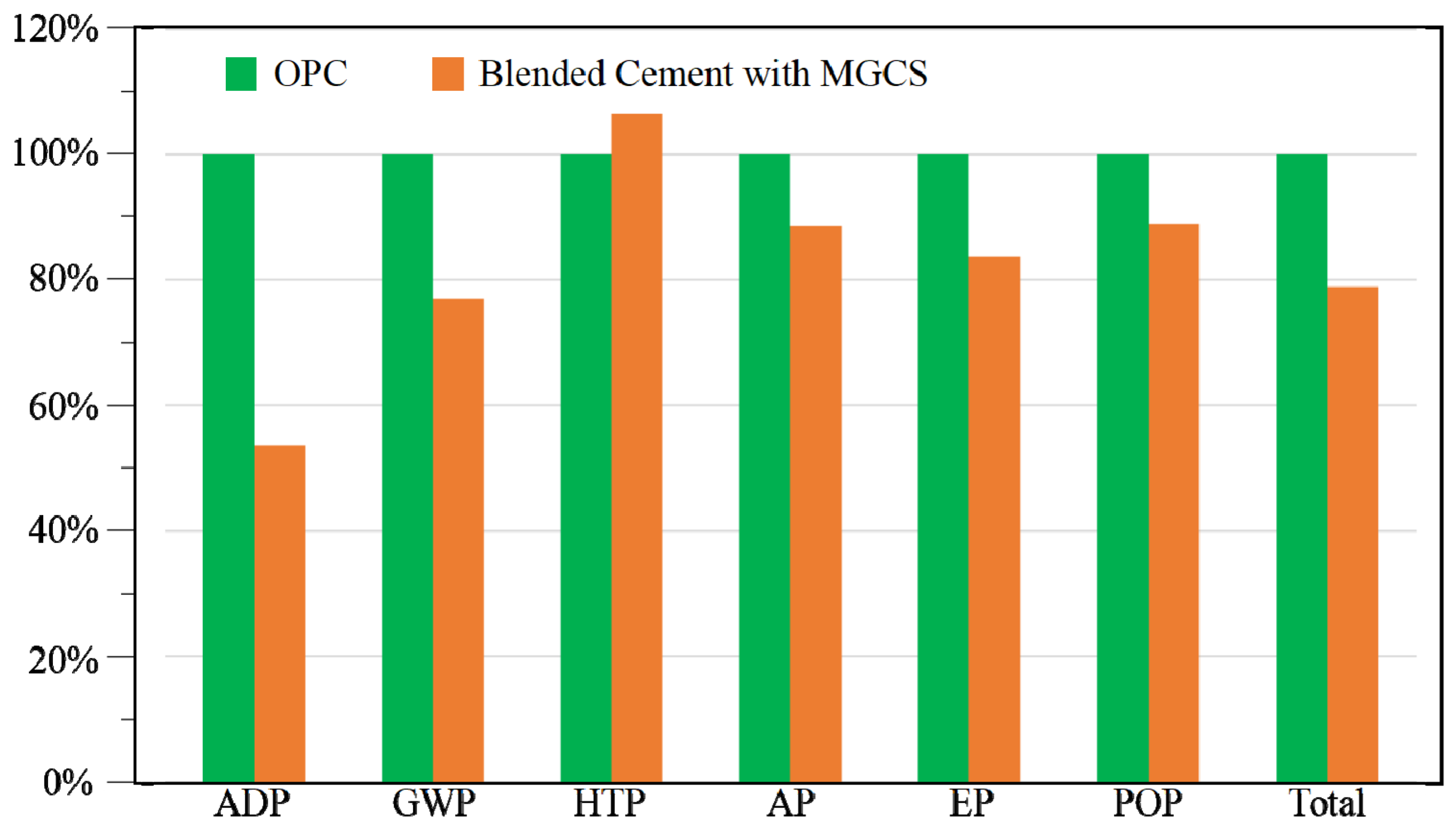

3.4. Comparison of Environmental Impact between Blended Cement and OPC

3.4.1. Comparison of Resource and Energy Depletion

3.4.2. Comparison of LCIA Results

3.5. Engineering Recommendation and Future Work

4. Conclusions

- Calcination had the largest contribution in all impact categories, significantly promoting GWP (93.67%) and the other categories.

- Using MGCS as a replacement for cement led to lower CO2 emissions and had a positive effect on all the impact categories. The intensive depletion of raw materials and raw coal mostly affected ADP. The burning of raw coal contributed significantly to AP and EP. Due to the fossil fuel usage during its generation, electricity was a non-negligible contribution to AP.

- The environmental effect of the production of blended cement was sensitive to the consumption of limestone and energy, as well as the selected LCIA model.

- Comparisons between LCA studies show that the production of blended cement with MGCS can markedly decrease environmental impacts for all impact categories. Positive mitigation effects were obtained for most impact categories in comparison to OPC production. The adoption of MGCS in blended cement can therefore reduce the comprehensive environmental impact (13.95%).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Oliveira, F.C.; Fernandes, J.; Galindo, J.; Rodríguez, J.; Cañadas, I.; Vermelhudo, V.; Nunes, A.; Rosa, L. Portland cement clinker production using concentrated solar energy—A proof-of-concept approach. Solar Energy 2019, 183, 677–688. [Google Scholar] [CrossRef] [Green Version]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schloemer, S.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Wang, L.; Li, G.; Li, X.; Guo, F.; Tang, S.; Lu, X.; Hanif, A. Influence of reactivity and dosage of MgO expansive agent on shrinkage and crack resistance of face slab concrete. Cem. Concr. Compos. 2022, 126, 104333. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, B.; Chen, Q.; Wang, D.; Gao, X. Safety Analysis of Synergetic Operation of Backfilling the Open Pit Using Tailings and Excavating the Ore Deposit Underground. Minerals 2021, 11, 818. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Damgaard, A.; Comans, R.N.J. Life cycle assessment of the reuse of fly ash from biomass combustion as secondary cementitious material in cement products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- Li, X.; Peng, J.; Xie, Y.; Li, Q.; Zhou, T.; Wang, J.; Zheng, W. Influence of High-Temperature Treatment on Strength and Failure Behaviors of a Quartz-Rich Sandstone under True Triaxial Condition. Lithosphere 2022, 2022, 3086647. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Taha, R.; Al-Hashmi, A.; Al-Harthy, A. Effect of copper slag and cement by-pass dust addition on mechanical properties of concrete. Constr. Build. Mater. 2006, 20, 322–331. [Google Scholar] [CrossRef]

- Shi, C.; Meyer, C.; Behnood, A. Utilization of copper slag in cement and concrete. Resour. Conserv. Recycl. 2008, 52, 1115–1120. [Google Scholar] [CrossRef]

- Mussapyrova, L.; Baláž, R.N.P.; Rajňák, M.; Bureš, R.; Baláž, M. Selective room-temperature leaching of copper from mechanically activated copper smelter slag. J. Mater. Res. Technol. 2021, 12, 2011–2025. [Google Scholar] [CrossRef]

- Zhang, T.; Zhi, S.; Li, T.; Zhou, Z.; Li, M.; Han, J.; Li, W.; Zhang, D.; Guo, L.; Wu, Z. Alkali Activation of Copper and Nickel Slag Composite Cementitious Materials. Materials 2020, 13, 1155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, Y.; Yang, Q.; Chen, Q.; Kero, J.; Andersson, A.; Ahmed, H.; Engström, F.; Samuelsson, C. Characterization and evaluation of the pozzolanic activity of granulated copper slag modified with CaO. J. Clean. Prod. 2019, 232, 1112–1120. [Google Scholar] [CrossRef]

- Zhu, J.; Li, Q.; Li, X.; Zhou, Y.; Liu, F.; Song, J. Effect of Coupled Mechanical-Chemical Activation on Hydration Activity of Copper Slag Powder. Appl. Sci. 2022, 12, 6018. [Google Scholar] [CrossRef]

- Galvez-Martos, J.-L.; Schoenberger, H. An analysis of the use of life cycle assessment for waste co-incineration in cement kilns. Resour. Conserv. Recycl. 2014, 86, 118–131. [Google Scholar] [CrossRef]

- Supino, S.; Malandrino, O.; Testa, M.; Sica, D. Sustainability in the EU cement industry: The Italian and German experiences. J. Clean. Prod. 2016, 112, 430–442. [Google Scholar] [CrossRef]

- Kua, H.W. The Consequences of Substituting Sand with Used Copper Slag in Construction. J. Ind. Ecol. 2013, 17, 869–879. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Malacarne, C.S.; da Silva, M.R.C.; Danieli, S.; Maciel, V.G.; Kirchheim, A.P. Environmental and technical assessment to support sustainable strategies for limestone calcined clay cement production in Brazil. Constr. Build. Mater. 2021, 310, 125261. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Teng, L.; Yang, S. Evolution characteristics of mining fissures in overlying strata of stope after converting from open-pit to underground. Arab. J. Geosci. 2021, 14, 2795. [Google Scholar] [CrossRef]

- Pardo, N.; Moya, J.A.; Mercier, A. Prospective on the energy efficiency and CO2 emissions in the EU cement industry. Energy 2011, 36, 3244–3254. [Google Scholar] [CrossRef]

- Thwe, E.; Khatiwada, D.; Gasparatos, A. Life cycle assessment of a cement plant in Naypyitaw, Myanmar. Clean. Environ. Syst. 2021, 2, 100007. [Google Scholar] [CrossRef]

- Wang, L.; Song, X.; Yang, H.; Wang, L.; Tang, S.; Wu, B.; Mao, W. Pore Structural and Fractal Analysis of the Effects of MgO Reactivity and Dosage on Permeability and F–T Resistance of Concrete. Fractal Fract. 2022, 6, 113. [Google Scholar] [CrossRef]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C.-Q. An analytical review on application of life cycle assessment in circular economy for built environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Chen, Q.; Peng, J.; Xie, Y.; Wang, J. Study on Three-Dimensional Dynamic Stability of Open-Pit High Slope under Blasting Vibration. Lithosphere 2022, 2021, 6426550. [Google Scholar] [CrossRef]

- IEA. Technology Roadmap: Low Carbon Transition in Cement Industry; International Energy Agency: Paris, France, 2018.

- Li, Y.; Liu, Y.; Gong, X.; Nie, Z.; Cui, S.; Wang, Z.; Chen, W. Environmental impact analysis of blast furnace slag applied to ordinary Portland cement production. J. Clean. Prod. 2016, 120, 221–230. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); European Parliament, Council of the European Union: Strasbourg, France, 2008.

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The ecoinvent Database: Overview and Methodological Framework (7 pp). Int. J. Life Cycle Assess. 2004, 10, 3–9. [Google Scholar] [CrossRef]

- Josa, A.; Aguado, A.; Cardim, A.; Byars, E. Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem. Concr. Res. 2007, 37, 781–788. [Google Scholar] [CrossRef] [Green Version]

- Stafford, F.N.; Dias, A.C.; Arroja, L.; Labrincha, J.; Hotza, D. Life cycle assessment of the production of Portland cement: A Southern Europe case study. J. Clean. Prod. 2016, 126, 159–165. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P. Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process. Sci. Total Environ. 2018, 659, 41–52. [Google Scholar] [CrossRef]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part I: Utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Peiffer, S.; Liao, X.; Yang, Z.; Ma, X.; He, D. Sulfidation of ferric (hydr)oxides and its implication on contaminants transformation: A review. Sci. Total Environ. 2021, 816, 151574. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Wang, J.; Tao, Z.; Ren, D.; Zhang, G.; Li, X.; Xie, L. 3D Nonlinear Analysis of Stilling Basin in Complex Fractured Dam Foundation. Lithosphere 2022, 2021, 2738130. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Yang, S.; Liu, Z.; Liu, Z.; Liu, Y.; Drewniak, L.; Jiang, C.; Li, Q.; Li, W.; et al. Life cycle assessment and cost analysis for copper hydrometallurgy industry in China. J. Environ. Manag. 2022, 309, 114689. [Google Scholar] [CrossRef] [PubMed]

- Clavreul, J.; Guyonnet, D.; Christensen, T.H. Quantifying uncertainty in LCA-modelling of waste management systems. Waste Manag. 2012, 32, 2482–2495. [Google Scholar] [CrossRef] [Green Version]

- Tao, M.; Zhang, X.; Wang, S.; Cao, W.; Jiang, Y. Life cycle assessment on lead–zinc ore mining and beneficiation in China. J. Clean. Prod. 2019, 237, 117833. [Google Scholar] [CrossRef]

- Li, Y.; Chiu, Y.H.; Lin, T.Y. Coal production efficiency and land destruction in China’s coal mining industry. Resour. Policy 2019, 63, 1. [Google Scholar] [CrossRef]

- Habert, G.; Arribe, D.; Dehove, T.; Espinasse, L.; Le Roy, R. Reducing environmental impact by increasing the strength of concrete: Quantification of the improvement to concrete bridges. J. Clean. Prod. 2012, 35, 250–262. [Google Scholar] [CrossRef]

- Gao, F.; Nie, Z.; Wang, Z.; Gong, X.; Zuo, T. Characterization and normalization factors of abiotic resource depletion for life cycle impact assessment in China. Sci. China Technol. Sci. 2009, 52, 215–222. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Valderrama, C.; Granados, R.; Cortina, J.L.; Gasol, C.M.; Guillem, M.; Josa, A. Implementation of best available techniques in cement manufacturing: A life-cycle assessment study. J. Clean. Prod. 2012, 25, 60–67. [Google Scholar] [CrossRef]

- Ali, M.; Saidur, R.; Hossain, M. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Muñoz-Cáceres, O.; Raposeiras, A.C.; Movilla-Quesada, D.; Castro-Fresno, D.; Lagos-Varas, M.; Andrés-Valeri, V.C.; Valdés-Vidal, G. Mechanical performance of sustainable asphalt mixtures manufactured with copper slag and high percentages of reclaimed asphalt pavement. Constr. Build. Mater. 2021, 304, 124653. [Google Scholar] [CrossRef]

- Boesch, M.E.; Hellweg, S. Identifying Improvement Potentials in Cement Production with Life Cycle Assessment. Environ. Sci. Technol. 2010, 44, 9143–9149. [Google Scholar] [CrossRef] [PubMed]

- Son, H.; Austbø, B.; Gundersen, T.; Hwang, J.; Lim, Y. Techno-economic versus energy optimization of natural gas liquefaction processes with different heat exchanger technologies. Energy 2022, 245, 123232. [Google Scholar] [CrossRef]

- Stafford, F.N.; Raupp-Pereira, F.; Labrincha, J.; Hotza, D. Life cycle assessment of the production of cement: A Brazilian case study. J. Clean. Prod. 2016, 137, 1293–1299. [Google Scholar] [CrossRef]

- Caronge, M.A.; Tjaronge, M.; Rahim, I.R.; Irmawaty, R.; Lapian, F.E. Feasibility study on the use of processed waste tea ash as cement replacement for sustainable concrete production. J. Build. Eng. 2022, 52, 104458. [Google Scholar] [CrossRef]

- Wu, C.; Guan, P.; Zhong, L.; Lv, J.; Hu, X.; Huang, G.; Li, C. An optimized low-carbon production planning model for power industry in coal-dependent regions—A case study of Shandong, China. Energy 2020, 192, 116636. [Google Scholar] [CrossRef]

- Hakkim, H.; Kumar, A.; Sinha, B.; Sinha, V. Air pollution scenario analyses of fleet replacement strategies to accomplish reductions in criteria air pollutants and 74 VOCs over India. Atmospheric Environ. X 2022, 13, 100150. [Google Scholar] [CrossRef]

- Strazza, C.; Del Borghi, A.; Gallo, M. Resource productivity enhancement as means for promoting cleaner production: Analysis of co-incineration in cement plants through a life cycle approach. J. Clean. Prod. 2011, 19, 1615–1621. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, B.; Feng, Y.; Qi, C.; Chen, Q.; Xiao, C. Hydration development of blended cement paste with granulated copper slag modified with CaO and Al2O3. J. Mater. Res. Technol. 2022, 18, 909–920. [Google Scholar] [CrossRef]

- Bae, J.-H.; Kim, S.; Amr, I.T.; Seo, J.; Jang, D.; Bamagain, R.; Fadhel, B.A.; Abu-Aisheh, E.; Lee, H. Evaluation of physicochemical properties and environmental impact of environmentally amicable Portland cement/metakaolin bricks exposed to humid or CO2 curing condition. J. Build. Eng. 2021, 47, 103831. [Google Scholar] [CrossRef]

| Inputs | Unit | Amount (Blended) | Amount (OPC) | Outputs | Unit | Amount (Blended) | Amount (OPC) |

|---|---|---|---|---|---|---|---|

| Raw Materials Extraction | |||||||

| Explosives | kg | 2.73 × 10−4 | 3.90 × 10−4 | PM | g | 2.61 × 10−3 | 3.73 × 10−3 |

| Crude oil a | L | 1.13 × 10−3 | 1.61 × 10−3 | CO | g | 1.22 × 10−4 | 1.74 × 10−4 |

| Electricity b,c | kWh | 1.09 × 10−2 | 1.56 × 10−2 | NOx | g | 5.25 × 10−3 | 7.50 × 10−3 |

| SO2 | g | 1.09 × 10−4 | 1.56 × 10−4 | ||||

| Raw Meal Preparation | |||||||

| Limestone | kg | 9.20 × 10−1 | 1.02 × 100 | PM | g | 2.84 × 100 | 4.06 × 100 |

| Clay | kg | 1.32 × 10−2 | 1.86 × 10−1 | CO2 | g | 1.86 × 10−3 | 2.66 × 10−3 |

| Laterite | kg | 4.38 × 10−2 | 6.26 × 10−2 | CO | g | 1.05 × 10−5 | 1.50 × 10−5 |

| Crude oil a | L | 1.01 × 10−3 | 1.44 × 10−3 | NOx | g | 1.84 × 10−5 | 2.63 × 10−5 |

| Electricity b,c | kWh | 1.87 × 10−2 | 2.67 × 10−2 | ||||

| MGCS Preparation | |||||||

| CaO | kg | 5.92 × 10−2 | / | PM | g | 3.65 × 10−1 | / |

| GCS | kg | 2.96 × 10−1 | / | ||||

| Electricity b,c,d | kWh | 1.55 × 10−1 | / | ||||

| Calcination | |||||||

| Raw meal | kg | 9.77 × 10−1 | 1.27 × 100 | PM | g | 5.21 × 10−4 | 7.44 × 10−4 |

| Raw coal | MJ | 4.49 × 100 | 5.21 × 100 | CO2 | g | 5.91 × 10−1 | 8.44 × 10−1 |

| Electricity b, c | kWh | 4.21 × 10−1 | 6.01 × 10−1 | CO | g | 3.22 × 10−4 | 4.60 × 10−4 |

| NOx | g | 1.58 × 10−3 | 2.26 × 10−3 | ||||

| SO2 | g | 1.77 × 10−4 | 2.53 × 10−4 | ||||

| Blended Cement Production | |||||||

| Clinker | kg | 6.57 × 10−1 | 9.38 × 10−1 | PM | g | 1.69 × 10−5 | 2.41 × 10−5 |

| Gypsum | kg | 4.73 × 10−2 | 6.76 × 10−2 | ||||

| MGCS | kg | 3.10 × 10−1 | / | ||||

| Electricity b,c | KWh | 7.22 × 10−2 | 6.83 × 10−2 |

| Category | Unit | Raw Materials Extraction | Raw Meal Preparation | MGCS Preparation | Calcination | Blended Cement Preparation | Total |

|---|---|---|---|---|---|---|---|

| ADP | kg Sb eq | 2.61 × 10−8 | 2.09 × 10−8 | 6.20 × 10−8 | 1.45 × 10−7 | 1.64 × 10−8 | 2.70 × 10−7 |

| GWP | kg CO2 eq | 8.90 × 10−3 | 1.99 × 10−2 | 5.98 × 10−2 | 3.49 × 10−1 | 4.37 × 10−2 | 4.81 × 10−1 |

| HTP | kg 1,4-DB eq | 1.69 × 10−3 | 7.06 × 10−3 | 7.39 × 10−3 | 2.33 × 10−2 | 4.92 × 10−3 | 4.44 × 10−2 |

| AP | kg SO2 eq | 1.54 × 10−5 | 4.90 × 10−5 | 8.80 × 10−5 | 2.02 × 10−4 | 2.28 × 10−5 | 3.77 × 10−4 |

| EP | kg PO4 eq | 9.91 × 10−6 | 2.03 × 10−5 | 3.55 × 10−5 | 8.13 × 10−5 | 1.28 × 10−5 | 1.60 × 10−4 |

| POP | kg C2H4 eq | 6.03 × 10−7 | 3.34 × 10−6 | 3.83 × 10−6 | 1.11 × 10−5 | 1.26 × 10−6 | 2.02 × 10−5 |

| Category | Raw Materials Extraction | Raw Meal Preparation | MGCS Preparation | Calcination | Blended Cement Preparation | Total |

|---|---|---|---|---|---|---|

| ADP | 1.21 × 10−15 | 9.67 × 10−16 | 2.87 × 10−15 | 6.71 × 10−15 | 7.59 × 10−16 | 1.25 × 10−14 |

| GWP | 2.43 × 10−16 | 5.43 × 10−16 | 1.63 × 10−15 | 9.52 × 10−15 | 1.19 × 10−15 | 1.31 × 10−14 |

| HTP | 2.60 × 10−16 | 1.09 × 10−15 | 1.14 × 10−15 | 3.59 × 10−15 | 7.58 × 10−16 | 6.83 × 10−15 |

| AP | 7.37 × 10−17 | 2.35 × 10−16 | 4.21 × 10−16 | 9.67 × 10−16 | 1.09 × 10−16 | 1.81 × 10−15 |

| EP | 1.27 × 10−16 | 2.60 × 10−16 | 4.54 × 10−16 | 1.04 × 10−15 | 1.64 × 10−16 | 2.04 × 10−15 |

| POP | 7.12 × 10−17 | 3.94 × 10−16 | 4.52 × 10−16 | 1.31 × 10−15 | 1.49 × 10−16 | 2.38 × 10−15 |

| Parameters | Limestone | MGCS | Raw Coal | Electricity |

|---|---|---|---|---|

| Consumption (kg/FU) | 9.20 × 10−1 | 3.55 × 10−1 | 4.49 × 100 | 6.53 × 10−1 * |

| Variation coefficient (input) | 5% | 5% | 5% | 5% |

| Change ratio (output) | 1.47% | 0.14% | 1.56% | 1.29% |

| Sensitivity | 29.4% | 2.8% | 31.2% | 25.8% |

| Impact Category | Unit | Chen, et al. (2010) | This Study |

|---|---|---|---|

| ADP | kg Sb eq | 2.43 × 10−3 | 2.70 × 10−7 |

| GWP | kg CO2 eq | 7.82 × 10−1 | 4.81 × 10−1 |

| HTP | kg 1,4-DB eq | 7.60 × 10−2 | 4.44 × 10−2 |

| AP | kg SO2 eq | 3.49 × 10−3 | 3.77 × 10−4 |

| EP | kg PO4 eq | 5.04 × 10−4 | 1.60 × 10−4 |

| POP | kg C2H4 eq | 1.11 × 10−4 | 2.02 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhang, B.; Wang, D. Environmental Benefit Assessment of Blended Cement with Modified Granulated Copper Slag. Materials 2022, 15, 5359. https://doi.org/10.3390/ma15155359

Zhang Q, Zhang B, Wang D. Environmental Benefit Assessment of Blended Cement with Modified Granulated Copper Slag. Materials. 2022; 15(15):5359. https://doi.org/10.3390/ma15155359

Chicago/Turabian StyleZhang, Qinli, Bingyi Zhang, and Daolin Wang. 2022. "Environmental Benefit Assessment of Blended Cement with Modified Granulated Copper Slag" Materials 15, no. 15: 5359. https://doi.org/10.3390/ma15155359

APA StyleZhang, Q., Zhang, B., & Wang, D. (2022). Environmental Benefit Assessment of Blended Cement with Modified Granulated Copper Slag. Materials, 15(15), 5359. https://doi.org/10.3390/ma15155359