A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation

2.3. Materials Characterization

3. Results and Discussion

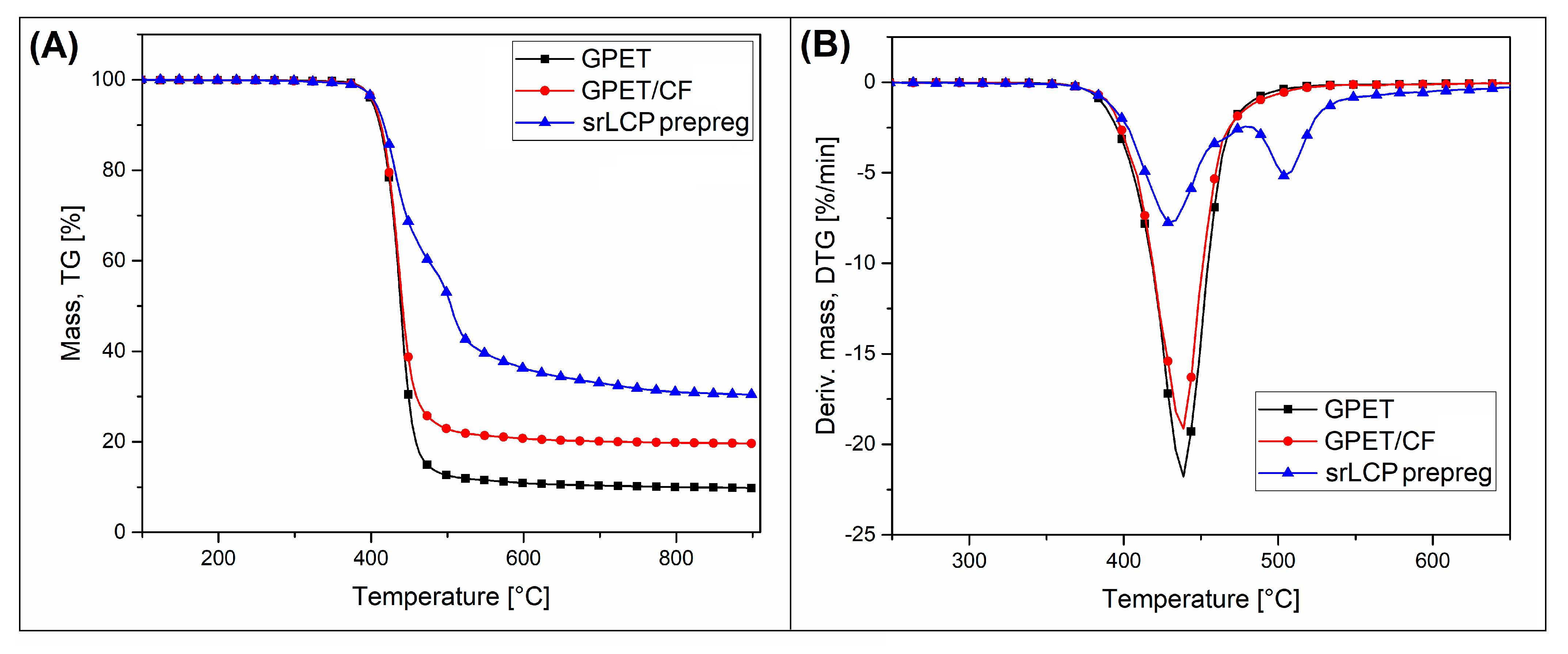

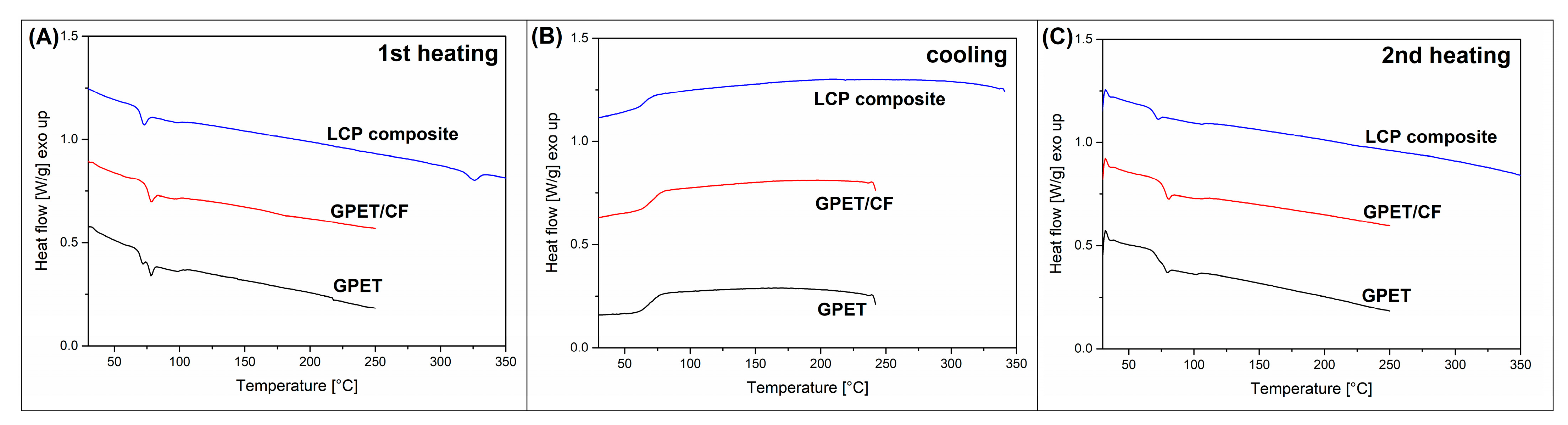

3.1. Thermal Properties-TGA and DSC Thermal Analysis

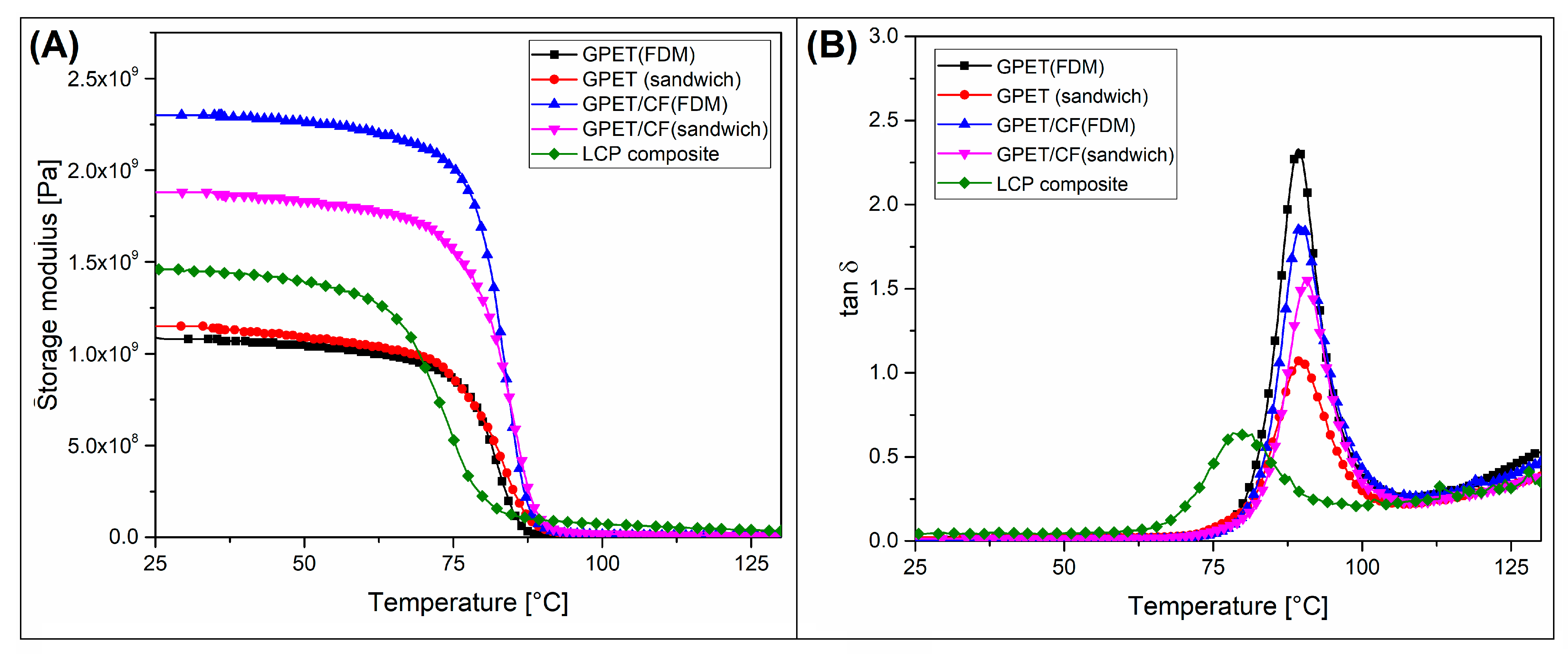

3.2. Thermomechanical Properties HDT and DMTA

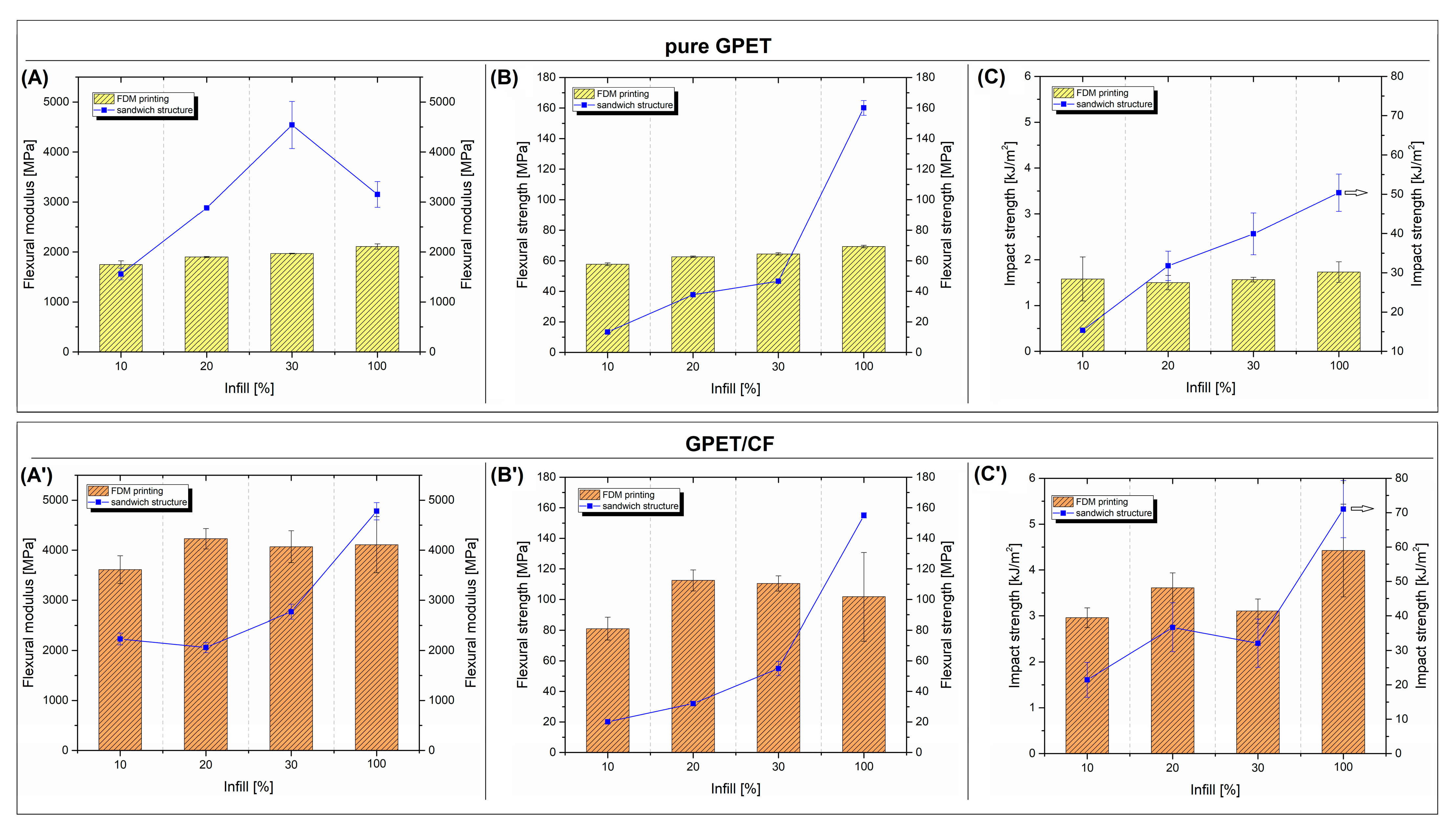

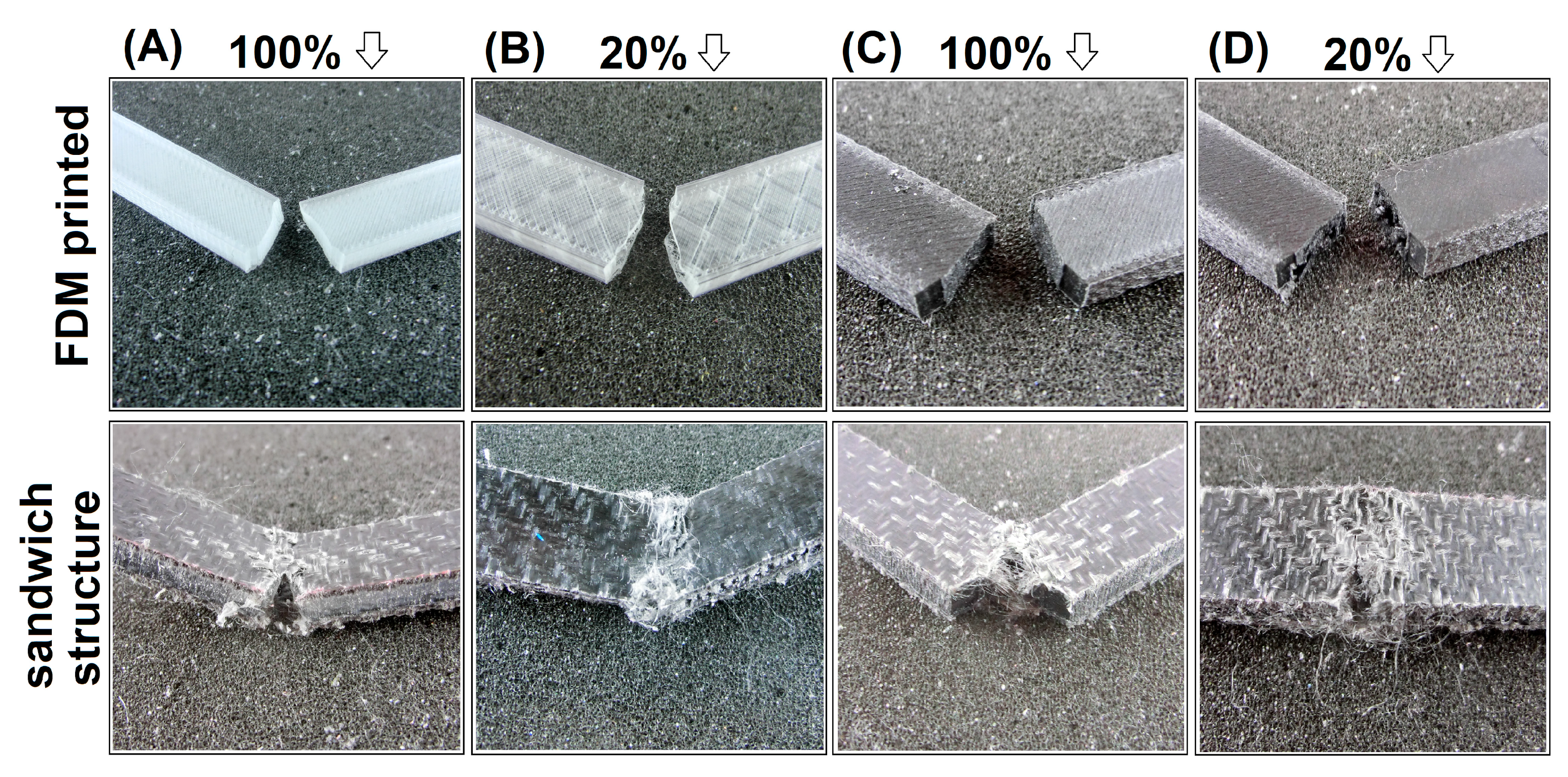

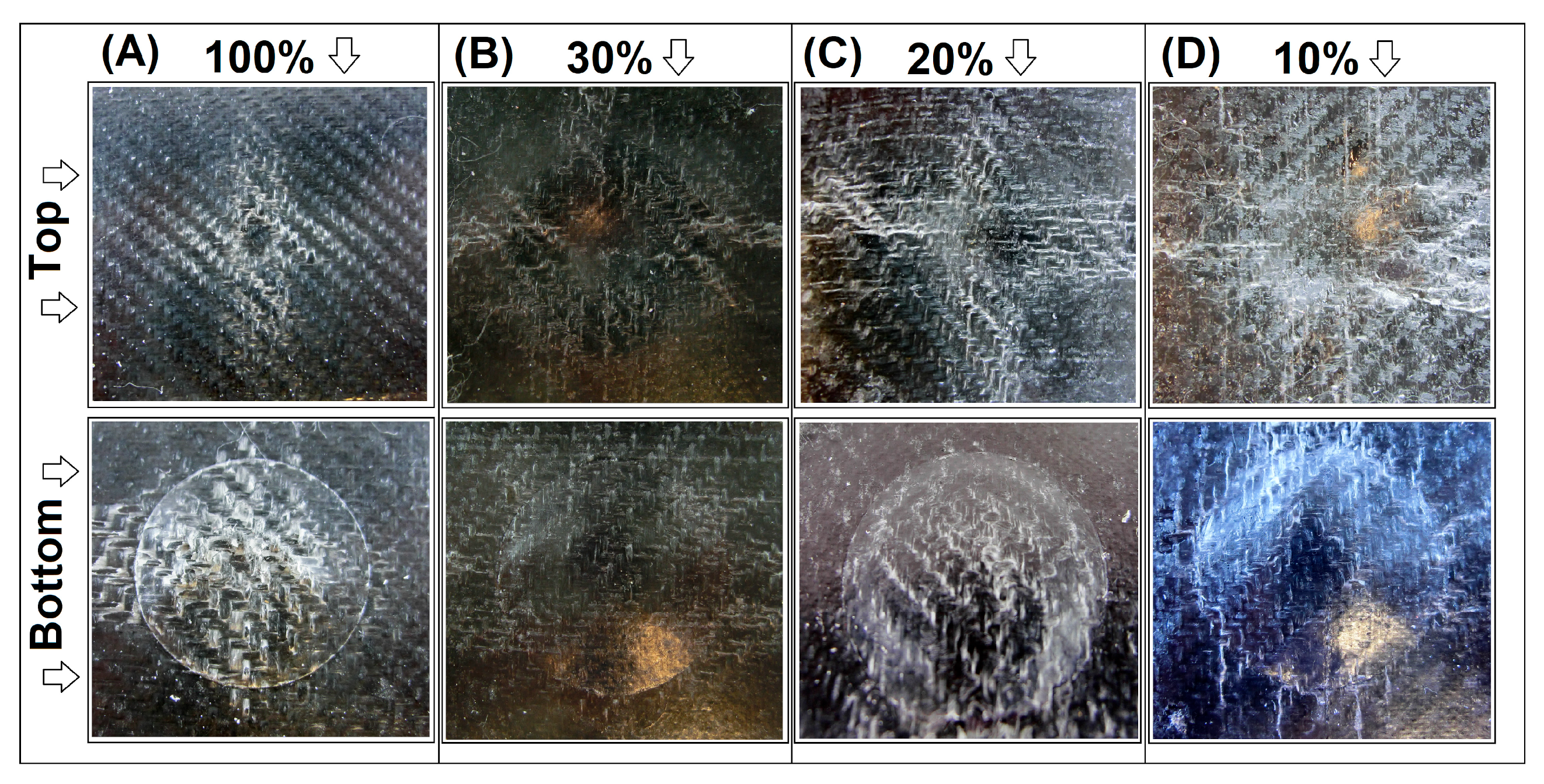

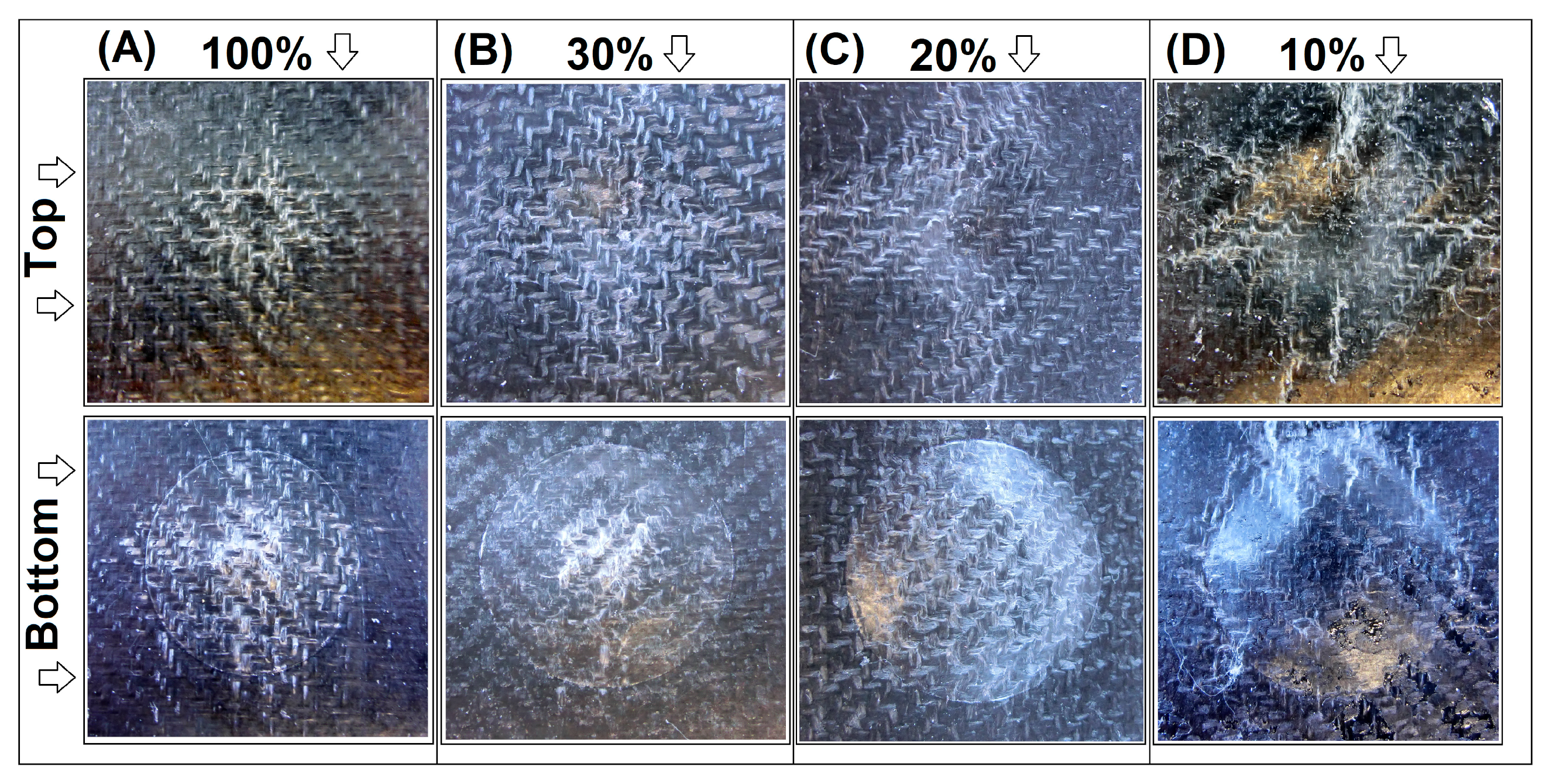

3.3. Mechanical Properties-Flexural Tests and Charpy Impact Resistance Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdallah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a Better Understanding of the Extrusion Process in Fused Filament Fabrication 3D Printing: A Review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291. [Google Scholar] [CrossRef]

- Donate, R.; Monzón, M.; Alemán-Domínguez, M.E. Additive Manufacturing of PLA-Based Scaffolds Intended for Bone Regeneration and Strategies to Improve Their Biological Properties. E-Polymers 2020, 20, 571–599. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Kochesfahani, S.H. Improving PLA-Based Material for FDM 3D-Printers Using Minerals (Principles and Method Development). In Proceedings of the Society of Plastics Engineers Annual Technical Conference, Indianapolis, IN, USA, 23–25 May 2016; pp. 1598–1614. [Google Scholar]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Kanagaraj, G.; Idris, M.S. 3D Printing: Overview of ABS Evolvement. AIP Conf. Proc. 2019, 2059, 20041. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS With Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Basurto-Vázquez, O.; Sánchez-Rodríguez, E.P.; McShane, G.J.; Medina, D.I. Load Distribution on PET-G 3D Prints of Honeycomb Cellular Structures under Compression Load. Polymers 2021, 13, 1983. [Google Scholar] [CrossRef]

- Tezel, T.; Ozenc, M.; Kovan, V. Impact Properties of 3D-Printed Engineering Polymers. Mater. Today Commun. 2021, 26, 102161. [Google Scholar] [CrossRef]

- Nagarajan, V.; Zhang, K.; Misra, M.; Mohanty, A.K. Overcoming the Fundamental Challenges in Improving the Impact Strength and Crystallinity of PLA Biocomposites: Influence of Nucleating Agent and Mold Temperature. ACS Appl. Mater. Interfaces 2015, 7, 11203–11214. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) Based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the Effect of Additives to ABS on the Mechanical Property Anisotropy of Specimens Fabricated by Material Extrusion 3D Printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of Polypropylene/Short Glass Fiber Composite as Fused Deposition Modeling (FDM) Filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of Short CF/GF Reinforced PEEK Composite Filaments and Their Comprehensive Properties Evaluation for FDM-3D Printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Li, J.H.; Huang, X.D.; Durandet, Y.; Ruan, D. A Review of the Mechanical Properties of Additively Manufactured Fiber Reinforced Composites. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012105. [Google Scholar] [CrossRef]

- Silva, M.; Pinho, I.S.; Covas, J.A.; Alves, N.M.; Paiva, M.C. 3D Printing of Graphene-Based Polymeric Nanocomposites for Biomedical Applications. Funct. Compos. Mater. 2021, 2, 8. [Google Scholar] [CrossRef]

- Sezer, H.K.; Eren, O. FDM 3D Printing of MWCNT Re-Inforced ABS Nano-Composite Parts with Enhanced Mechanical and Electrical Properties. J. Manuf. Process. 2019, 37, 339–347. [Google Scholar] [CrossRef]

- Jain, S.K. Fabrication of Polylactide/Carbon Nanopowder Filament Using Melt Extrusion and Filament Characterization for 3D Printing. Int. J. Nanosci. 2018, 17, 1850026. [Google Scholar] [CrossRef] [Green Version]

- Dorez, Y.; Lacrampe, M.-F.; Soulestin, J. Improved Tool for Depositing Material in Three Dimensions by Extrusion. Patent EP3740372-A1, 25 November 2020. [Google Scholar]

- Justino Netto, J.M.; Idogava, H.T.; Frezzatto Santos, L.E.; de Castro Silveira, Z.; Romio, P.; Alves, J.L. Screw-Assisted 3D Printing with Granulated Materials: A Systematic Review. Int. J. Adv. Manuf. Technol. 2021, 115, 2711–2727. [Google Scholar] [CrossRef] [PubMed]

- Tseng, J.W.; Liu, C.Y.; Yen, Y.K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.J.; Wang, A.B. Screw Extrusion-Based Additive Manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Pignatelli, F.; Percoco, G. An Application- and Market-Oriented Review on Large Format Additive Manufacturing, Focusing on Polymer Pellet-Based 3D Printing. Prog. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.F.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar Bonding Performance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Mei, H.; Ali, Z.; Ali, I.; Cheng, L. Tailoring Strength and Modulus by 3D Printing Different Continuous Fibers and Filled Structures into Composites. Adv. Compos. Hybrid Mater. 2019, 2, 312–319. [Google Scholar] [CrossRef]

- Chang, B.P.; Abdelwahab, M.A.; Kiziltas, A.; Mielewski, D.F.; Mohanty, A.K.; Misra, M. Effect of a Small Amount of Synthetic Fiber on Performance of Biocarbon-Filled Nylon-Based Hybrid Biocomposites. Macromol. Mater. Eng. 2021, 306, 202000680. [Google Scholar] [CrossRef]

- Zhang, D.; He, M.; Qin, S.; Yu, J. Effect of Fiber Length and Dispersion on Properties of Long Glass Fiber Reinforced Thermoplastic Composites Based on Poly(Butylene Terephthalate). RSC Adv. 2017, 7, 15439–15454. [Google Scholar] [CrossRef] [Green Version]

- Arslan, C.; Dogan, M. The Mechanical and Thermal Properties of Chopped Basalt Fiber-Reinforced Poly (Butylene Terephthalate) Composites: Effect of Fiber Amount and Length. J. Compos. Mater. 2019, 53, 2465–2475. [Google Scholar] [CrossRef]

- Karakaya, N.; Papila, M.; Özkoç, G. Overmolded Hybrid Composites of Polyamide-6 on Continuous Carbon and Glass Fiber/Epoxy Composites: ‘An Assessment of the Interface’. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105771. [Google Scholar] [CrossRef]

- Boros, R.; Rajamani, P.K.; Kovács, J.G. Thermoplastic Overmolding onto Injection-Molded and in Situ Polymerization-Based Polyamides. Materials 2018, 11, 2140. [Google Scholar] [CrossRef] [Green Version]

- Andrzejewski, J.; Przyszczypkowski, P.; Szostak, M. Development and Characterization of Poly(Ethylene Terephthalate) Based Injection Molded Self-Reinforced Composites. Direct Reinforcement by Overmolding the Composite Inserts. Mater. Des. 2018, 153, 273–286. [Google Scholar] [CrossRef]

- Wis, A.A.; Kodal, M.; Ozturk, S.; Ozkoc, G. Overmolded Polylactide/Jute-Mat Eco-Composites: A New Method to Enhance the Properties of Natural Fiber Biodegradable Composites. J. Appl. Polym. Sci. 2019, 137, 48692. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M. Preparation of Hybrid Poly(Lactic Acid)/Flax Composites by the Insert Overmolding Process: Evaluation of Mechanical Performance and Thermomechanical Properties. J. Appl. Polym. Sci. 2021, 138, 49646. [Google Scholar] [CrossRef]

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Mirbolghasemi, A.; Hermenean, K. 3D Printed Meta-Sandwich Structures: Failure Mechanism, Energy Absorption and Multi-Hit Capability. Mater. Des. 2018, 160, 179–193. [Google Scholar] [CrossRef]

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. 3D Printed Architected Polymeric Sandwich Panels: Energy Absorption and Structural Performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Hou, S.; Li, T.; Jia, Z.; Wang, L. Mechanical Properties of Sandwich Composites with 3d-Printed Auxetic and Non-Auxetic Lattice Cores under Low Velocity Impact. Mater. Des. 2018, 160, 1305–1321. [Google Scholar] [CrossRef]

- Antony, S.; Cherouat, A.; Montay, G. Fabrication and Characterization of Hemp Fibre Based 3D Printed Honeycomb Sandwich Structure by FDM Process. Appl. Compos. Mater. 2020, 27, 935–953. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D Printing of Composite Sandwich Structures Using Continuous Carbon Fiber and Fiber Tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 114–121. [Google Scholar] [CrossRef]

- Li, T.; Wang, L. Bending Behavior of Sandwich Composite Structures with Tunable 3D-Printed Core Materials. Compos. Struct. 2017, 175, 46–57. [Google Scholar] [CrossRef]

- Austermann, J.; Redmann, A.J.; Dahmen, V.; Quintanilla, A.L.; Mecham, S.J.; Osswald, T.A. Fiber-Reinforced Composite Sandwich Structures by Co-Curing with Additive Manufactured Epoxy Lattices. J. Compos. Sci. 2019, 3, 53. [Google Scholar] [CrossRef] [Green Version]

- Buican, G.R.; Zaharia, S.-M.; Pop, M.A.; Chicos, L.-A.; Lancea, C.; Stamate, V.; Pascariu, I.S. Fabrication and Characterization of Fiber-Reinforced Composite Sandwich Structures Obtained by Fused Filament Fabrication Process. Coatings 2021, 11, 601. [Google Scholar] [CrossRef]

- Kmetty, Á.; Bárány, T.; Karger-Kocsis, J. Self-Reinforced Polymeric Materials: A Review. Prog. Polym. Sci. 2010, 35, 1288–1310. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Bárány, T. Single-Polymer Composites (SPCs): Status and Future Trends. Compos. Sci. Technol. 2014, 92, 77–94. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.; Kazemahvazi, S.; Russell, B.P.; Zenkert, D.; Deshpande, V.S. Impact Response of Ductile Self-Reinforced Composite Corrugated Sandwich Beams. Compos. Part B Eng. 2016, 99, 121–131. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.; Kazemahvazi, S.; Åkermo, M.; Zenkert, D. Compression and Tensile Properties of Self-Reinforced Poly(Ethylene Terephthalate)-Composites. Polym. Test. 2013, 32, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Romhány, G.; Wu, C.M.; Lai, W.Y.; Karger-Kocsis, J. Fracture Behavior and Damage Development in Self-Reinforced PET Composites Assessed by Located Acoustic Emission and Thermography: Effects of Flame Retardant and Recycled PET. Compos. Sci. Technol. 2016, 132, 76–83. [Google Scholar] [CrossRef] [Green Version]

- Pegoretti, A.; Zanolli, A.; Migliaresi, C. Preparation and Tensile Mechanical Properties of Unidirectional Liquid Crystalline Single-Polymer Composites. Compos. Sci. Technol. 2006, 66, 1970–1979. [Google Scholar] [CrossRef]

- Komorek, A.; Szczepaniak, R.; Przybylek, P.; Krzyzak, A.; Godzimirski, J.; Roskowicz, M.; Seremak, D. Properties of Multi-Layered Polymer Composites with Vectran Fiber Reinforcement. Compos. Struct. 2021, 256, 113045. [Google Scholar] [CrossRef]

- Abdullah, S.I.B.S.; Iannucci, L.; Greenhalgh, E.S. On the Translaminar Fracture Toughness of Vectran/Epoxy Composite Material. Compos. Struct. 2018, 202, 566–577. [Google Scholar] [CrossRef]

- Jerpdal, L.; Schuette, P.; Ståhlberg, D.; Åkermo, M. Influence of Temperature during Overmolding on the Tensile Modulus of Self-reinforced Poly(Ethylene Terephthalate) Insert. J. Appl. Polym. Sci. 2020, 137, 48334. [Google Scholar] [CrossRef]

- Jin, X.; Chung, T.S. Thermal Decomposition Behavior of Main-Chain Thermotropic Liquid Crystalline Polymers, Vectra A-950, B-950, and Xydar SRT-900. J. Appl. Polym. Sci. 1999, 73, 2195–2207. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Dorigato, A.; Conti, T.; Vanzetti, L.; Bersani, M.; Pegoretti, A. Liquid Crystalline Polymer Nanocomposites Reinforced with In-Situ Reduced Graphene Oxide. Express Polym. Lett. 2015, 9, 709–720. [Google Scholar] [CrossRef]

- Naffakh, M.; Ellis, G.; Gómez, M.A.; Marco, C. Thermal Decomposition of Technological Polymer Blends. 1. Poly(Aryl Ether Ether Ketone) with a Thermotropic Liquid Crystalline Polymer. Polym. Degrad. Stab. 1999, 66, 405–413. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Marciniak-Podsadna, L. Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Materials 2020, 13, 2057. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Ozcan, S.; Ragauskas, A.J. Terephthalic Acid Copolyesters Containing Tetramethylcyclobutanediol for High-Performance Plastics. ChemistryOpen 2021, 10, 830–841. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Szymczyk, A.; Pawlikowska, D.; Irska, I.; Taraghi, I.; Pilawka, R.; Gu, J.; Li, X.; Tu, Y.; Piesowicz, E. Synthesis and Characterization of Poly(Ethylene Terephthalate-: Co -1,4-Cyclohexanedimethylene Terephtlatate)- Block -Poly(Tetramethylene Oxide) Copolymers. RSC Adv. 2017, 7, 41745–41754. [Google Scholar] [CrossRef] [Green Version]

- Kröger, H.; Mock, S.; Greb, C.; Gries, T. Damping Properties of Hybrid Composites Made from Carbon, Vectran, Aramid and Cellulose Fibers. J. Compos. Sci. 2022, 6, 13. [Google Scholar] [CrossRef]

- Liu, X.; Wu, J.; Xi, J.; Yu, Z. Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch. Materials 2019, 12, 1655. [Google Scholar] [CrossRef] [Green Version]

- Shi, S.S.; Sun, Z.; Hu, X.Z.; Chen, H.R. Carbon-Fiber and Aluminum-Honeycomb Sandwicah Composites with and without Kevlar-Fiber Interfacial Toughening. Compos. Part A Appl. Sci. Manuf. 2014, 67, 102–110. [Google Scholar] [CrossRef]

- Lin, Y.; Min, J.; Teng, H.; Lin, J.; Hu, J.; Xu, N. Flexural Performance of Steel–FRP Composites for Automotive Applications. Automot. Innov. 2020, 3, 280–295. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, S.; Hu, X.; Chen, H.; Wong, Z. Adhesive Joints between Carbon Fiber and Aluminum Foam Reinforced by Surface-Treated Aramid Fibers. Polym. Compos. 2015, 36, 192–197. [Google Scholar] [CrossRef]

- Sun, Z.; Jeyaraman, J.; Shi, S.; Sun, S.; Hu, X.; Chen, H. Processing and Property of Carbon-Fiber Aluminum-Foam Sandwich with Aramid-Fiber Composite Adhesive Joints. J. Adhes. Sci. Technol. 2014, 28, 1835–1845. [Google Scholar] [CrossRef]

- CASTANIE, B.; BOUVET, C.; Ginot, M. Review of Composite Sandwich Structure in Aeronautic Applications. Compos. Part C Open Access 2020, 1, 100004. [Google Scholar] [CrossRef]

- Jędral, A. Review of Testing Methods Dedicated for Sandwich Structures with Honeycomb Core. Trans. Aerosp. Res. 2019, 2019, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Basso, M.; Mingazzini, C.; Scafè, M.; Leoni, E.; Benco, E.; Garcia-Etxabe, R.; Gondra, K.; Pullini, D. Design of a Bonnet of a Sport Vehicle Realized with an Innovative Recyclable Polymeric Matrix Composite and Virtual Characterization of the Related Sandwich Structure. MATEC Web Conf. 2021, 349, 01011. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of Automotive Structural Composites Technology Developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Syed Abdullah, S.I.B.; Iannucci, L.; Greenhalgh, E.S.; Ahmad, Z. The Impact Performance of Vectran/Epoxy Composite Laminates with a Novel Non-Crimp Fabric Architecture. Compos. Struct. 2021, 265, 113784. [Google Scholar] [CrossRef]

- Jhou, S.Y.; Hsu, C.C.; Yeh, J.C. The Dynamic Impact Response of 3d-Printed Polymeric Sandwich Structures with Lattice Cores: Numerical and Experimental Investigation. Polymers 2021, 13, 4032. [Google Scholar] [CrossRef] [PubMed]

- Dou, H.; Ye, W.; Zhang, D.; Cheng, Y.; Huang, K.; Yang, F.; Rudykh, S. Research on Drop-Weight Impact of Continuous Carbon Fiber Reinforced 3D Printed Honeycomb Structure. Mater. Today Commun. 2021, 29, 102869. [Google Scholar] [CrossRef]

| Infill Density | Pure GPET | GPET/CF | ||

|---|---|---|---|---|

| FDM Printed | Sandwich Structure | FDM Printed | Sandwich Structure | |

| 10% | 68.4 (±0.9) | 66.9 (±0.3) | 72.1 (±0.2) | 65.1 (±2.8) |

| 20% | 69.8 (±1.3) | 65.5 (±4.1) | 73.7 (±0.5) | 67.5 (±3.3) |

| 30% | 72.1 (±1.3) | 66.4 (±3.2) | 74.6 (±0.8) | 68.9 (±2.1) |

| 100% | 71.5 (±0.3) | 68.2 (±1.3) | 73.1 (±0.2) | 69.5 (±2.3) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrzejewski, J.; Gronikowski, M.; Aniśko, J. A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core. Materials 2022, 15, 5405. https://doi.org/10.3390/ma15155405

Andrzejewski J, Gronikowski M, Aniśko J. A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core. Materials. 2022; 15(15):5405. https://doi.org/10.3390/ma15155405

Chicago/Turabian StyleAndrzejewski, Jacek, Marcin Gronikowski, and Joanna Aniśko. 2022. "A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core" Materials 15, no. 15: 5405. https://doi.org/10.3390/ma15155405

APA StyleAndrzejewski, J., Gronikowski, M., & Aniśko, J. (2022). A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core. Materials, 15(15), 5405. https://doi.org/10.3390/ma15155405