Microstructures and Properties of Al-Mg Alloys Manufactured by WAAM-CMT

Abstract

:1. Introduction

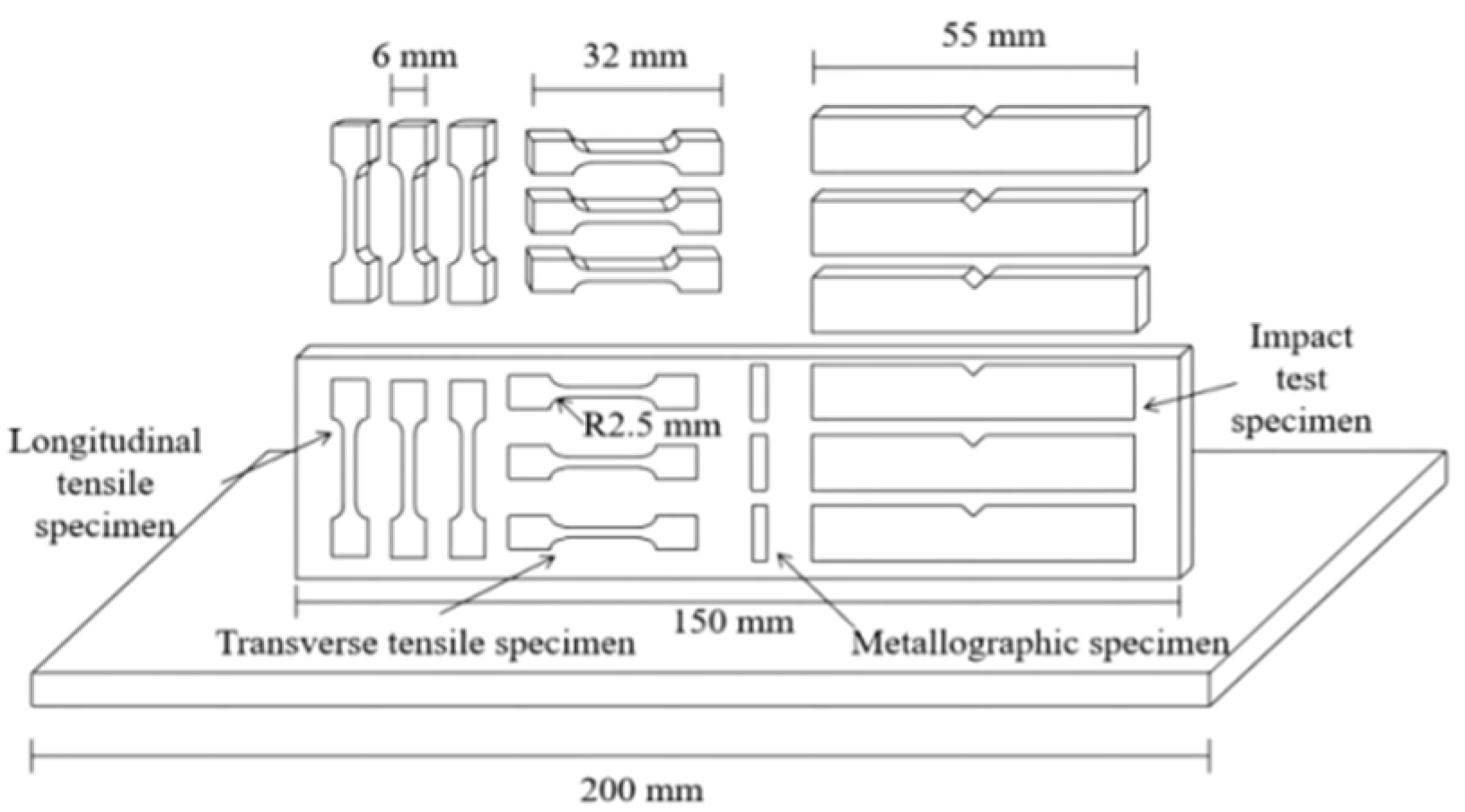

2. Materials and Methods

3. Results

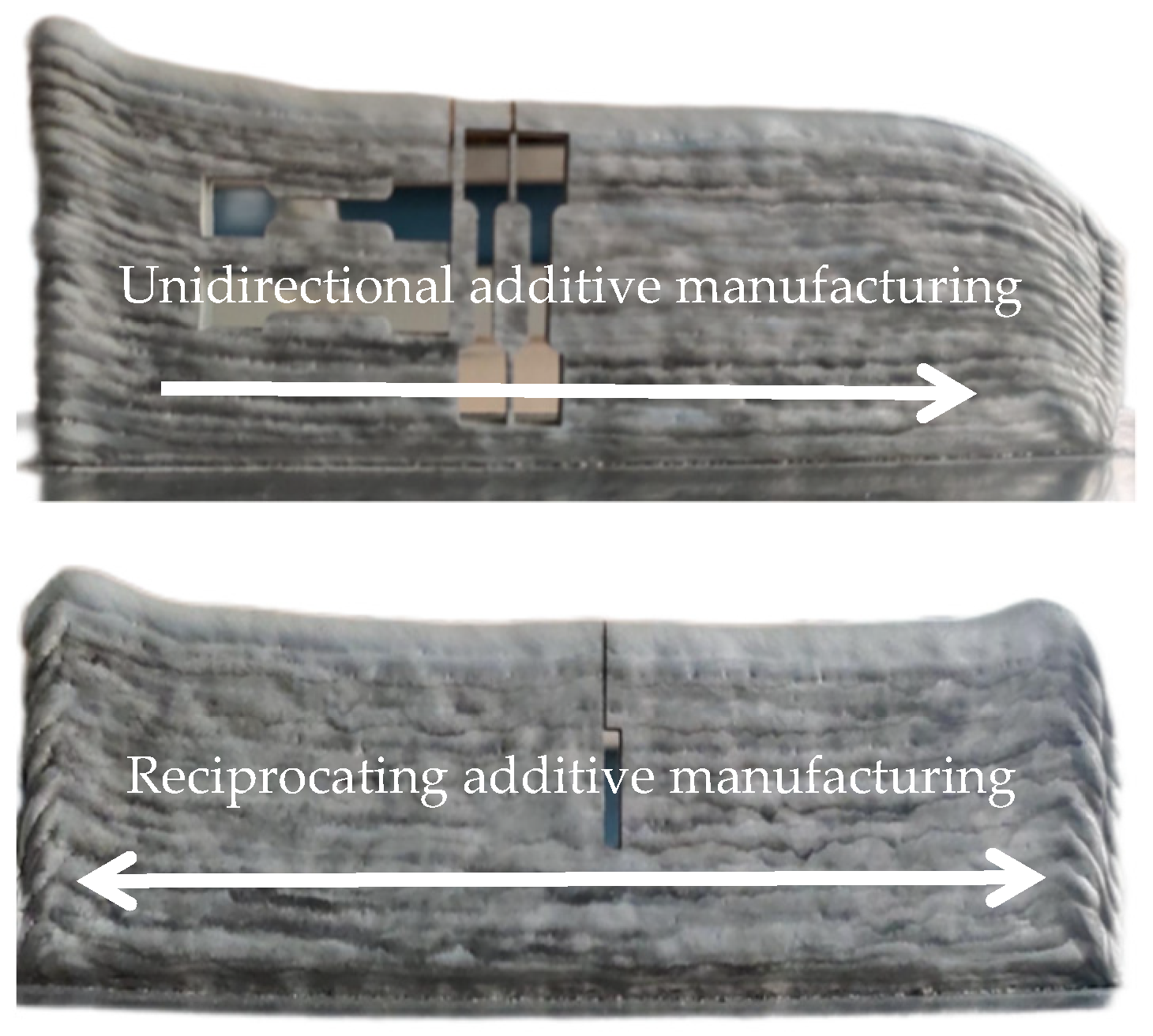

3.1. Effect of the Walking Path on Al-Mg Alloyed Additive

3.2. Optimal Process Parameters Based on Orthogonal Experiment

4. Discussion

4.1. Pore Analysis of Al-Mg Alloyed Additive under Orthogonal Experiment

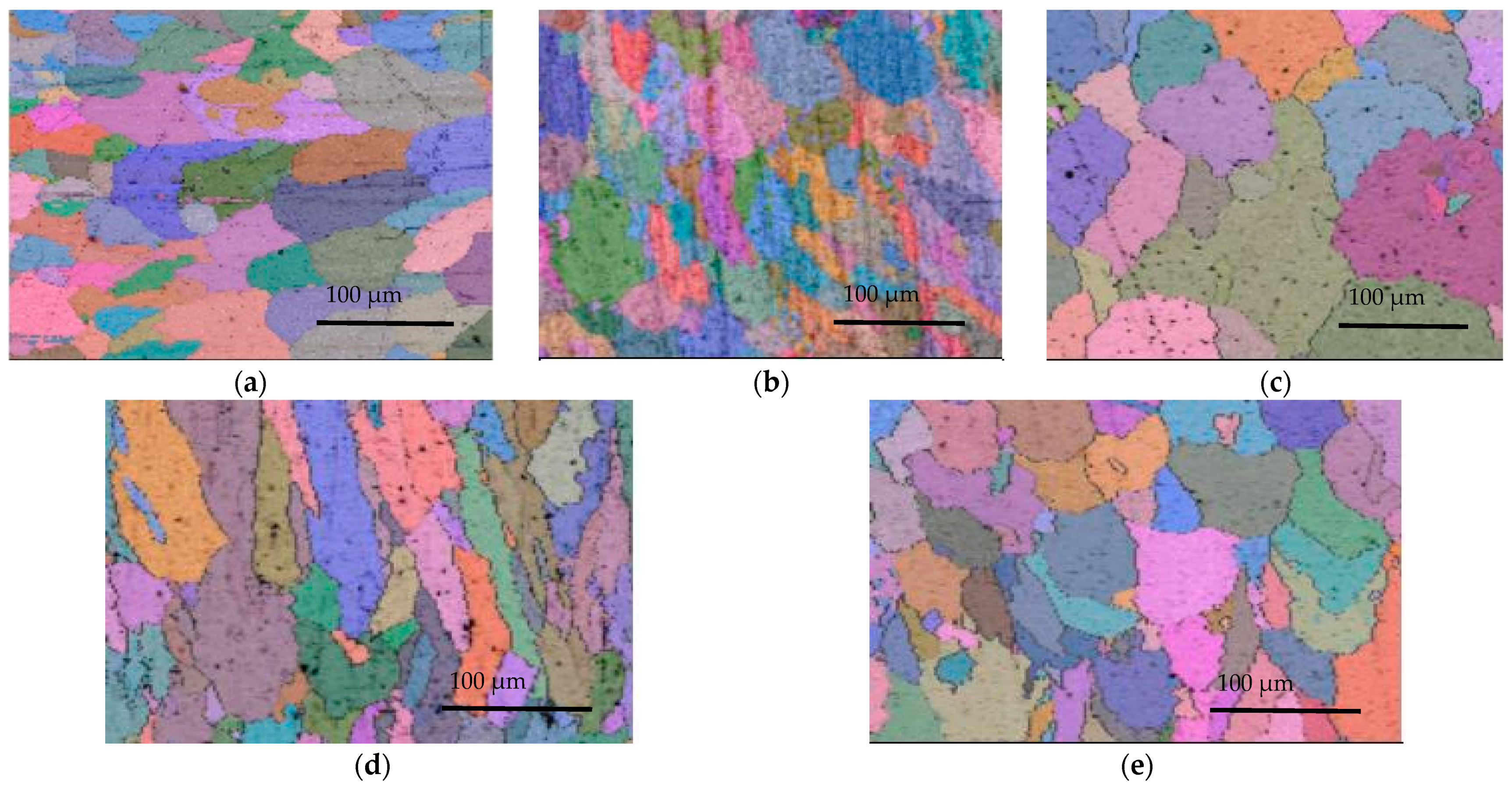

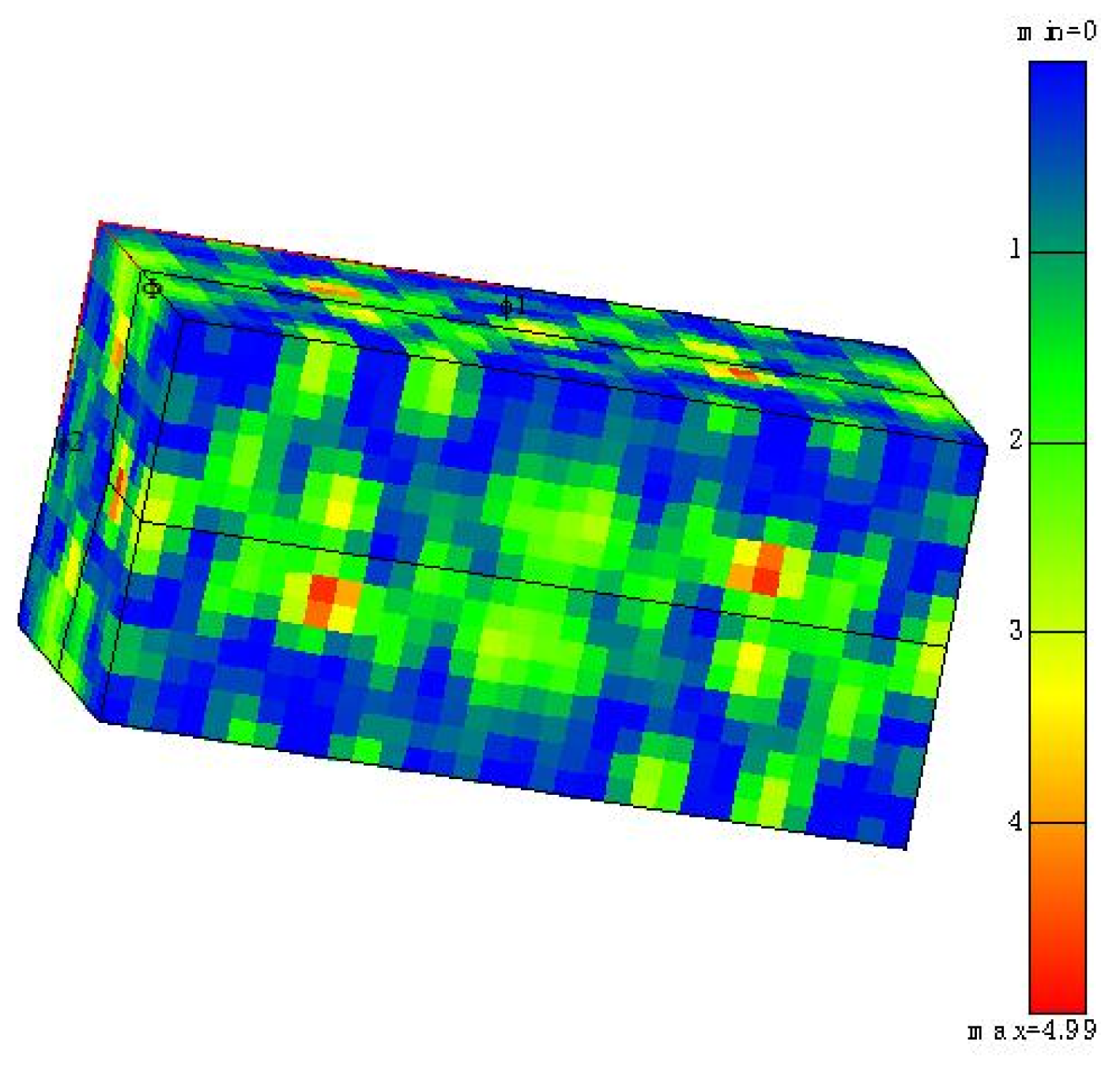

4.2. Grain Size Analysis of Al-Mg Alloyed Additive under Different Process Parameters

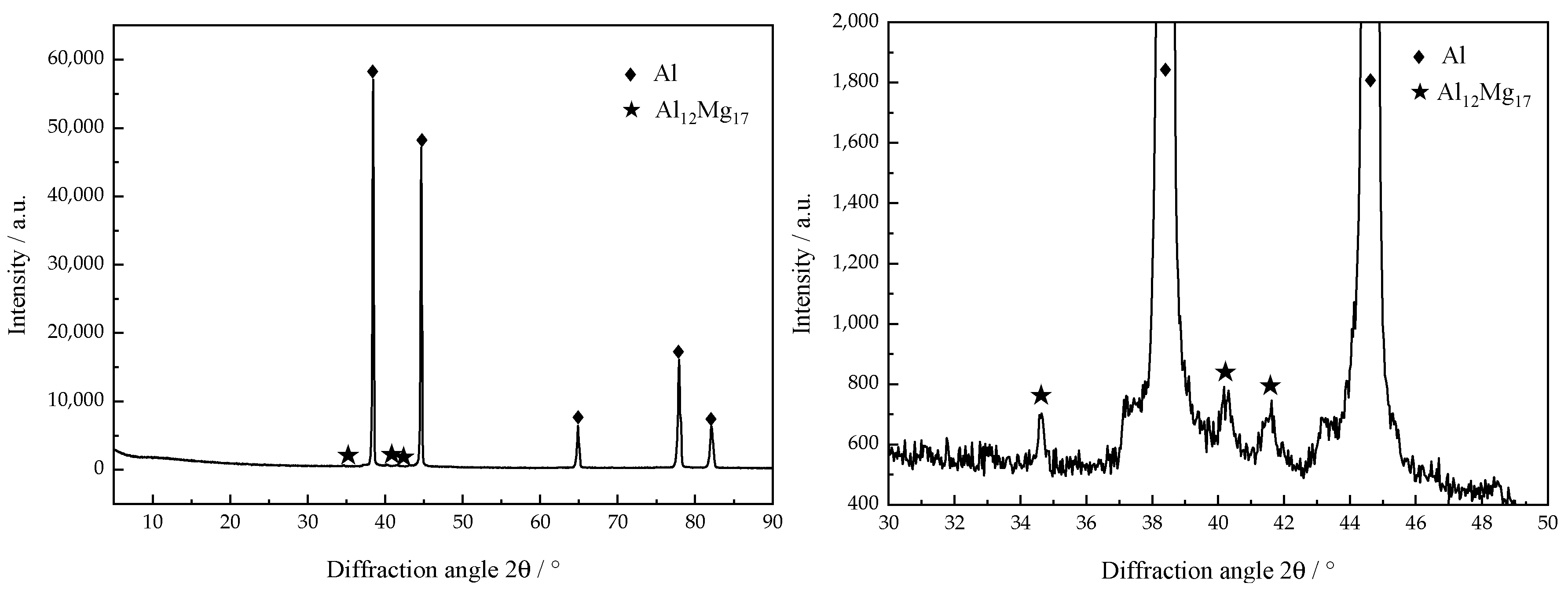

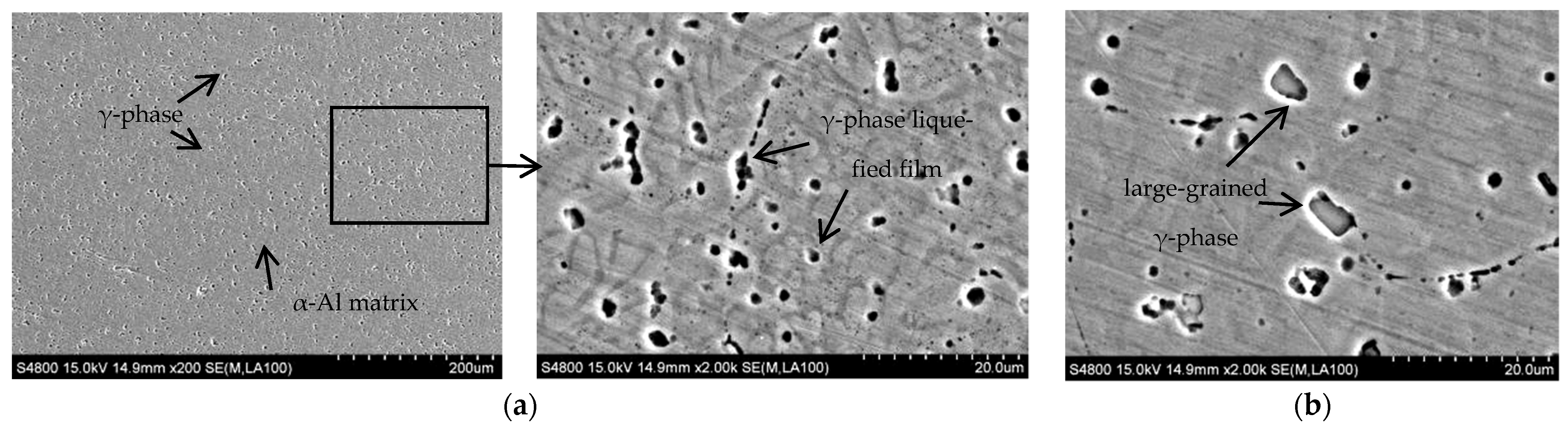

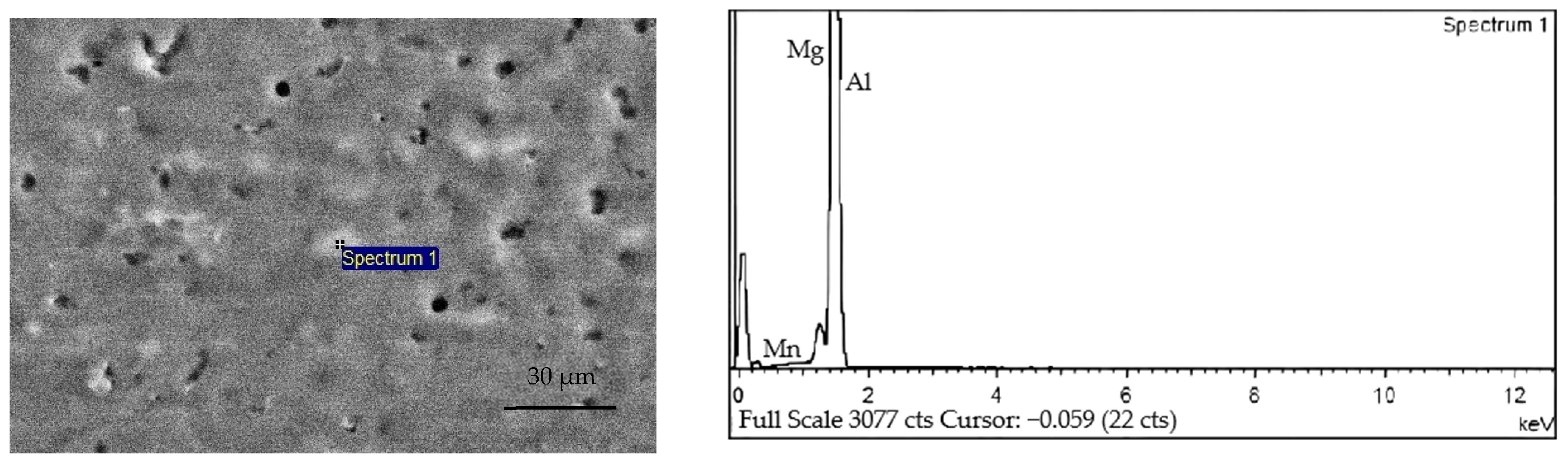

4.3. Phase Analysis of Al-Mg Alloyed Additive

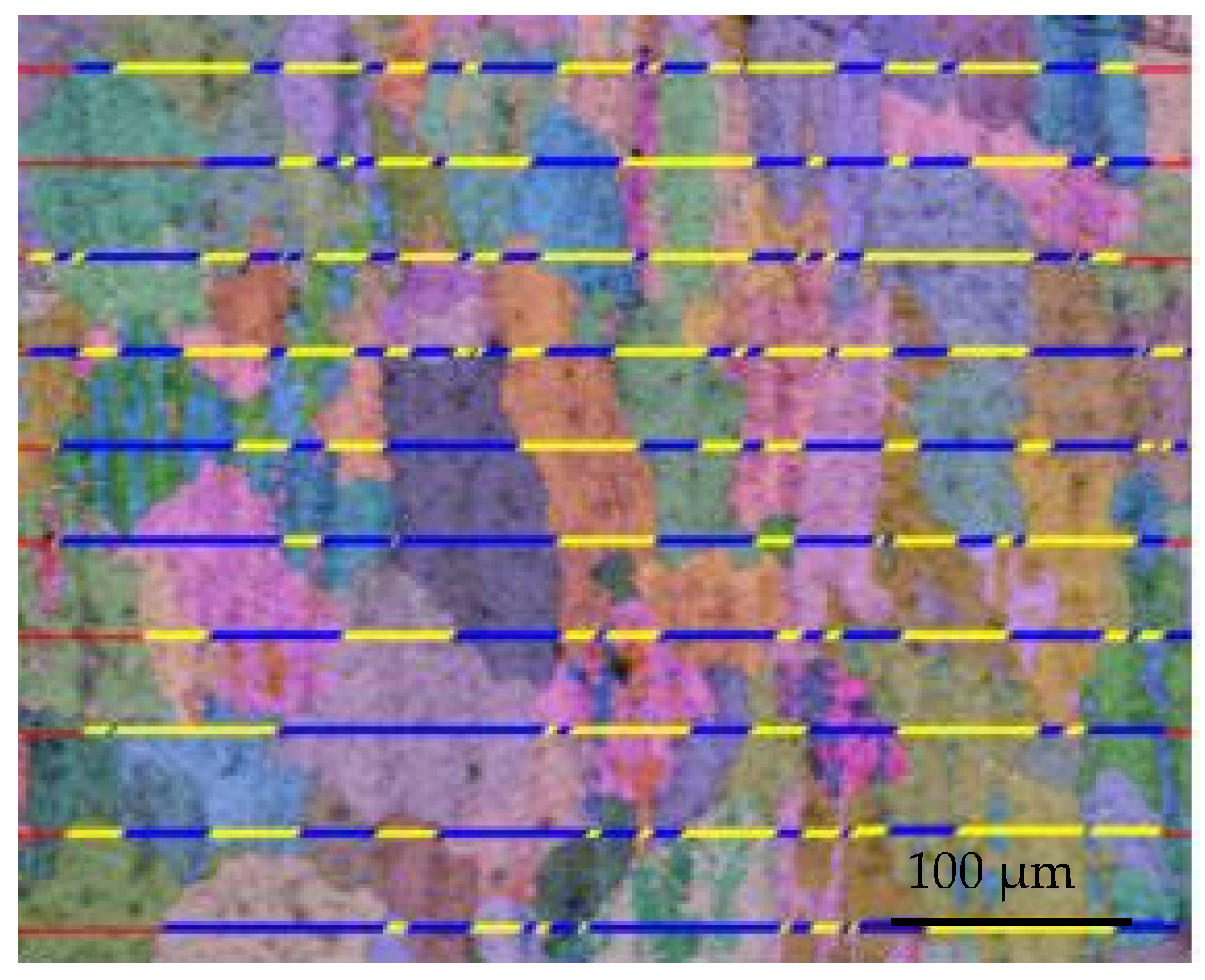

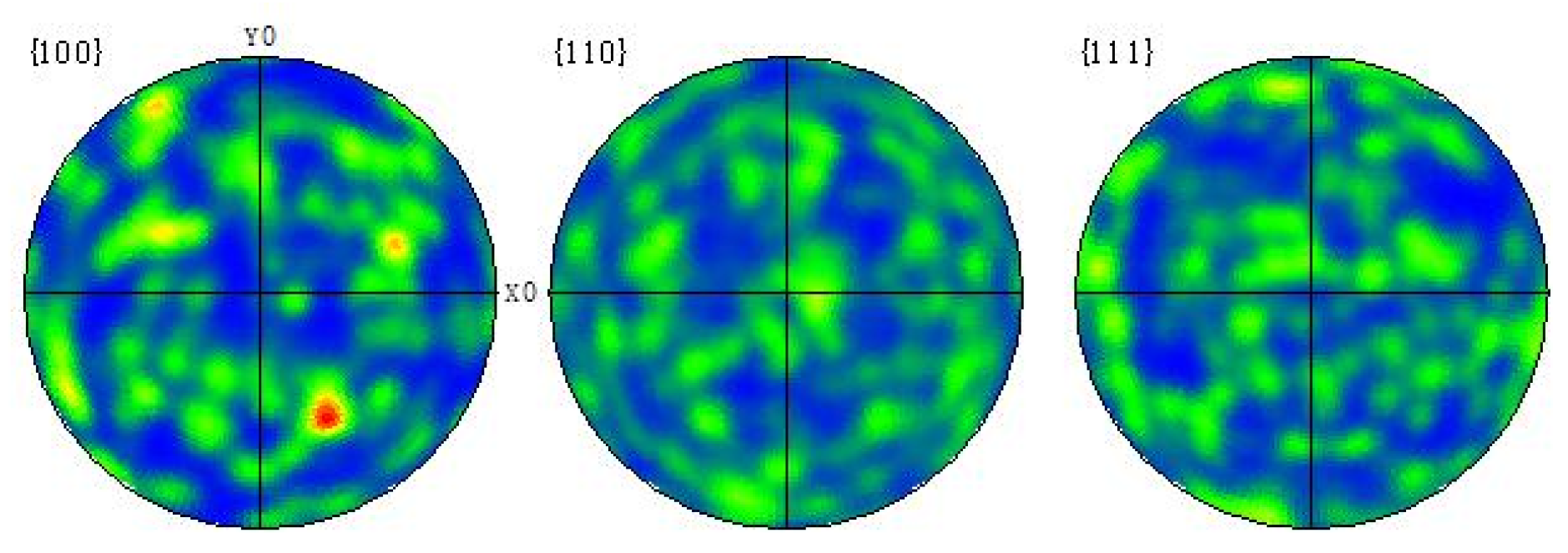

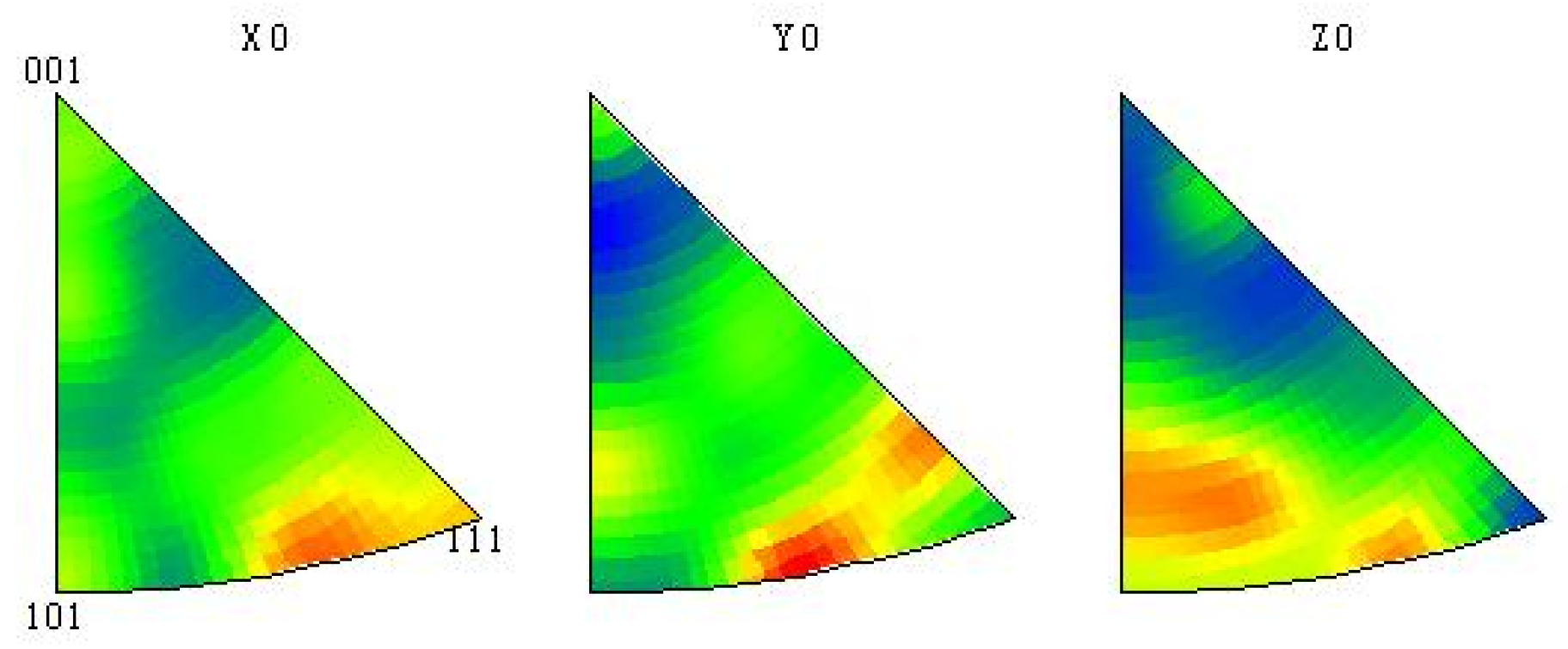

4.4. Crystal Orientation Analysis of Al-Mg Alloyed Additive

4.5. Performance Analysis of Al-Mg Alloyed Additive

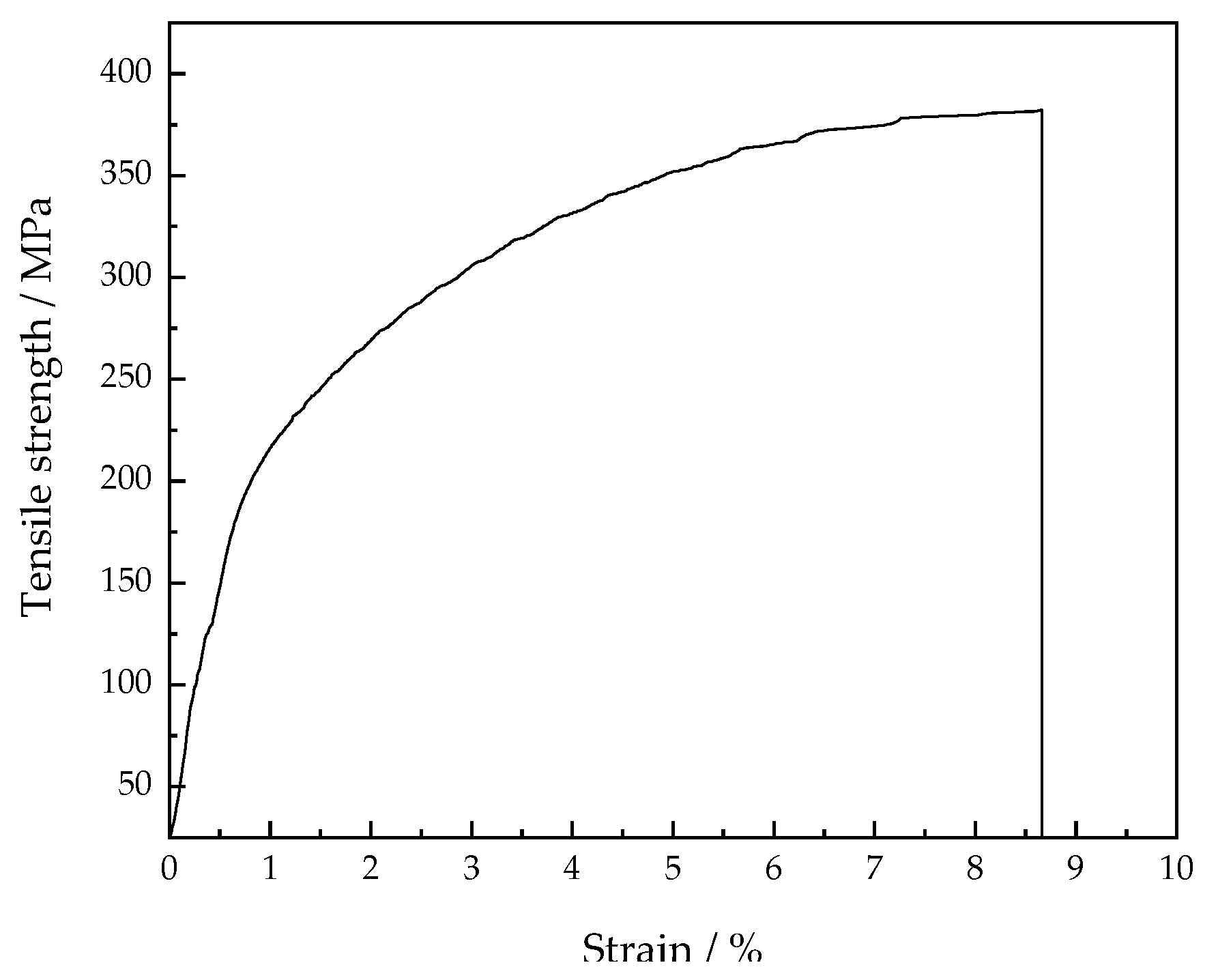

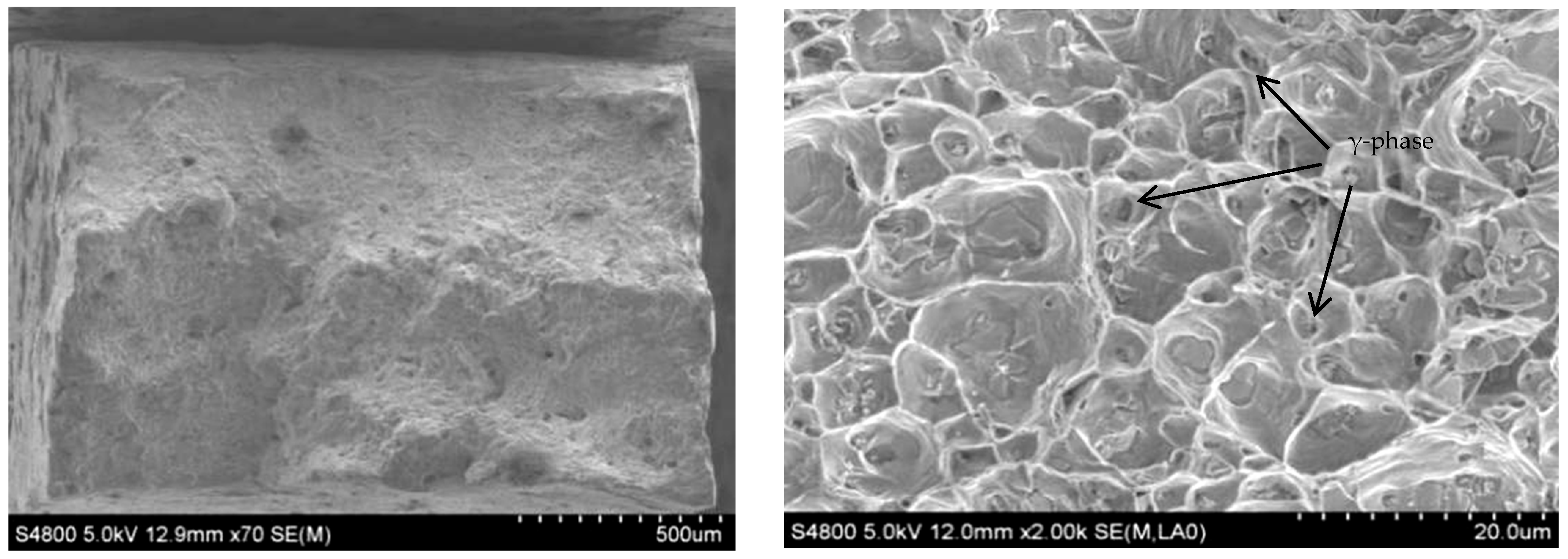

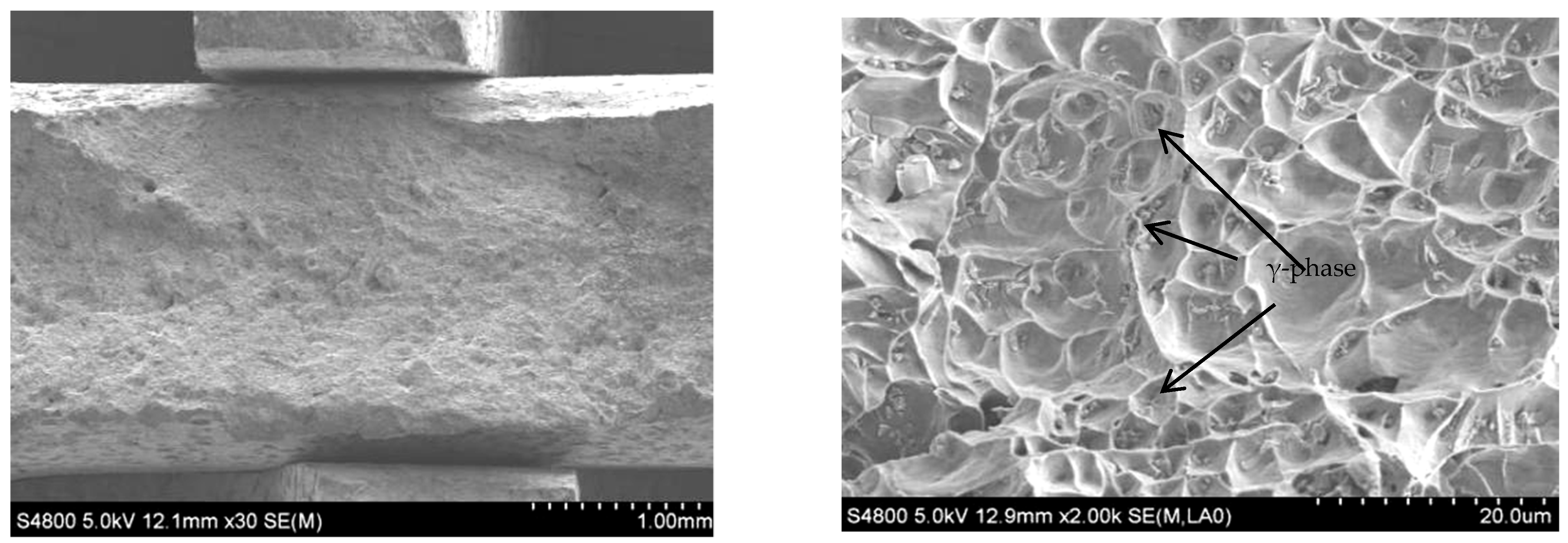

4.5.1. Analysis of Tensile Properties and Fracture Morphology

4.5.2. Analysis of Impact Properties and Fracture Morphology

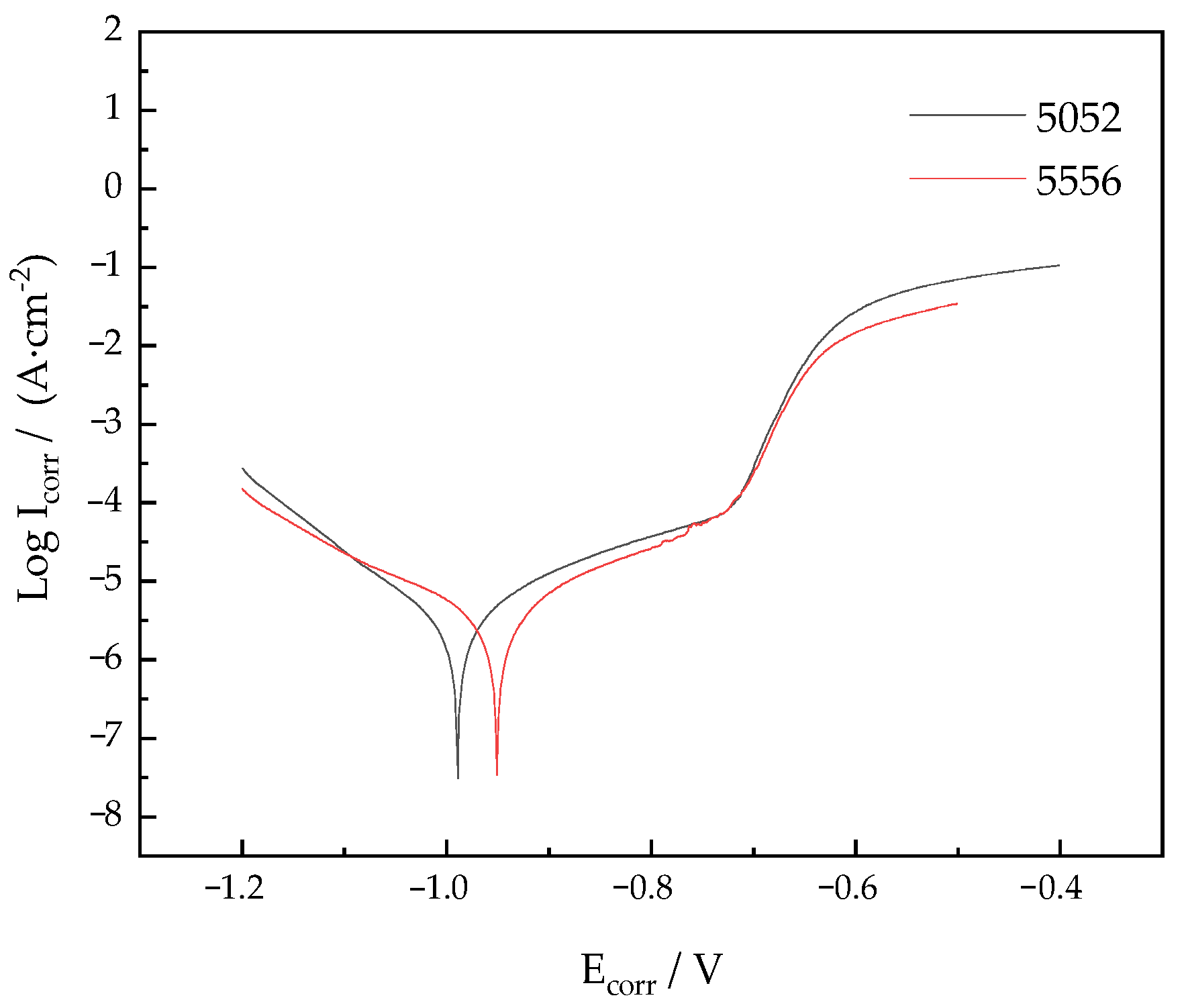

4.5.3. Corrosion Resistance Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Acta Aeronaut. Astronaut. Sin. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2017, 139, 565–586. [Google Scholar] [CrossRef]

- Tuan, D.; Alireza, K.; Gabriele, I.; Kate, T.Q.N.; David, H. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Chen, A.N.; Wu, J.M.; Liu, K.; Chen, J.Y.; Xiao, H.; Chen, P.; Li, C.H.; Shi, Y.S. High-performance ceramic parts with complex shape prepared by selective laser sintering: A review. Adv. Appl. Ceram. 2018, 117, 100–117. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Li, R.D.; Chen, H.; Zhu, H.B.; Wang, M.B.; Chen, C.; Yuan, T.C. Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting. Mater. Des. 2019, 168, 107668. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Pozdniakov, A.V.; Prosviryakov, A.S.; Loginova, I.S.; Daubarayte, D.K.; Ryabov, D.K.; Korolev, V.A.; Solonin, A.N.; Pavlov, M.D.; Valchuk, S.V. Microstructure and mechanical properties of a novel selective laser melted Al–Mg alloy with low Sc content. Mater. Res. Express 2019, 6, 126595. [Google Scholar] [CrossRef]

- Shen, X.F.; Cheng, Z.Y.; Wang, C.G.; Wu, H.F.; Yang, Q.; Wang, G.W.; Huang, S.K. Effect of heat treatments on the microstructure and mechanical properties of Al-Mg-Sc-Zr alloy fabricated by selective laser melting. Opt. Laser Technol. 2021, 143, 107312. [Google Scholar] [CrossRef]

- Li, S.W.; Gao, Q.W.; Zhao, J.; Liu, H.W.; Wang, P.F. Research progress and prospect of electron beam freeform fabrication. Mater. China 2021, 40, 130–138. [Google Scholar]

- Herawan, S.G.; Rosli, N.A.; Alkahari, M.R.; Abdollah, M.F.B.; Ramli, F.R. Review on effect of heat input for wire arc additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar]

- Cunningham, C.R.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Tawfik, M.M.; Nemat-Alla, M.M.; Dewidar, M.M. Enhancing the properties of aluminum alloys fabricated using wire + arc additive manufacturing technique—A review. J. Mater. Res. Technol. 2021, 13, 754–768. [Google Scholar] [CrossRef]

- Su, D.; Zhang, J.; Wang, B. The microstructure and weldability in welded joints for AA 5356 aluminum alloy after adding modified trace amounts of Sc and Zr. J. Manuf. Process. 2020, 57, 488–498. [Google Scholar] [CrossRef]

- Gaur, V.; Enoki, M.; Okada, T.; Yomogida, S. A study on fatigue behavior of MIG-welded Al-Mg alloy with different filler-wire materials under mean stress. Int. J. Fatigue 2018, 107, 119–129. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Wang, X.; Ding, H.; Zhao, J.; Zhang, F.; Ren, Z. Influence of tool pin eccentricity on microstructural evolution and mechanical properties of friction stir processed Al-5052 alloy. Mater. Sci. Eng. 2019, 739, 272–276. [Google Scholar] [CrossRef]

- Majeed, T.; Mehta, Y.; Siddiquee, A.N. Precipitation-dependent corrosion analysis of heat treatable aluminum alloys via friction stir welding, a review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 7600–7626. [Google Scholar] [CrossRef]

- Mari, D.; Oli, T.; Kondi, V.; Samardi, I. Statistical analysis of MAG-CMT welding parameters and their influence on the Ni-alloy weld overlay quality on 16Mo3 base material. Weld. World 2022, 66, 815–831. [Google Scholar] [CrossRef]

- Chen, X.; Su, C.; Wang, Y.; Arshad, N.S.; Konovalov, S.; Jayalakshmi, R.; Arvind, S. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Investig. X Ray Synchrotron Neutron Tech. 2018, 12, 1278–1284. [Google Scholar] [CrossRef]

- Han, S.; Zhang, Z.; Ruan, P.; Cheng, S.; Xue, D. Fabrication of circular cooling channels by cold metal transfer based wire and arc additive manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1715–1726. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Wang, Z.; Gou, J. Effects of ultrasonic vibration in the CMT process on welded joints of Al alloy. J. Mater. Process. Technol. 2018, 259, 282–291. [Google Scholar] [CrossRef]

- Nie, Y.P.; Zhang, P.L.; Xi, G.J.; Hua, Z. Rapid prototyping of 4043 Al-alloy parts by cold metal transfer. Sci. Technol. Weld. Join. 2018, 23, 527–535. [Google Scholar] [CrossRef]

- Kannan, A.R.; Shanmugam, N.S.; Vendan, S.A. Effect of cold metal transfer process parameters on microstructural evolution and mechanical properties of AISI 316L tailor welded blanks. Int. J. Adv. Manuf. Technol. 2019, 103, 4265–4282. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Konovalov, S.; Arvind, R.; Huang, L. Effect of deposition strategies on the microstructure and tensile properties of wire arc additive manufactured Al-5Si alloys. J. Mater. Eng. Perform. 2021, 30, 2136–2146. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, W.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric Limitation and Tensile Properties of Wire and Arc Additive Manufacturing 5A06 Aluminum Alloy Parts. J. Mater. Eng. Perform. 2017, 26, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Horgar, A.; Fostervoll, H.; Nyhus, B.; Ren, X.; Eriksson, M.; Akselsen, O.M. Additive manufacturing using WAAM with AA5183 wire. J. Mater. Process. Technol. 2018, 259, 68–74. [Google Scholar] [CrossRef]

- Gu, J.; Wang, X.; Bai, J.; Ding, J.; Williams, S.; Zhai, Y.; Kun, L. Deformation microstructures and strengthening mechanisms for the wire+arc additively manufactured Al-Mg4.5Mn alloy with inter-layer rolling. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostructure Process. 2018, 712, 292–301. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Gao, C.; Wang, Y. Effect of heat input on microstructure and mechanical properties of Al-Mg alloys fabricated by WAAM. Appl. Surf. Sci. 2019, 486, 431–440. [Google Scholar] [CrossRef]

- Ryan, E.M.; Sabin, T.J.; Watts, J.F.; Whiting, M.J. The influence of build parameters and wire batch on porosity of wire and arc additive manufactured aluminium alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Ortega, A.G.; Corona, G.L.; Salem, M.; Moussaoui, K.; Segonds, S.R.S.; Deschaux-Beaume, F. Characterisation of 4043 aluminium alloy deposits obtained by wire and arc additive manufacturing using a Cold Metal Transfer process. Sci. Technol. Weld. Join. 2019, 24, 538–547. [Google Scholar] [CrossRef] [Green Version]

- Klein, T.; Schnall, M. Control of macro-/microstructure and mechanical properties of a wire-arc additive manufactured aluminum alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 235–244. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, M.; Dai, T. Simulation of micropore formation in Al-7%Si alloy. J. Acta Metall. Sin. 2013, 49, 1032–1040. [Google Scholar] [CrossRef]

- Yuan, T.; Yu, Z.L.; Chen, S.J.; Xu, M.; Jiang, X.Q. Loss of elemental Mg during wire + arc additive manufacturing of Al-Mg alloy and its effect on mechanical properties. J. Manuf. Process. 2020, 49, 456–462. [Google Scholar] [CrossRef]

- Jiang, J.; Lai, S.; Lu, L.; Fang, J.; Liu, G.; Meng, S.; Jiang, F. Research progress of 5XXX series aluminum magnesium alloy. Manned Space 2019, 25, 411–418. [Google Scholar]

- Yan, X.; Zhao, G. Ac pulse plasma arc welding process of 5052 aluminum alloy. Welding 2018, 02, 30–34. [Google Scholar]

- Huang, B.Y.; Li, C.G.; Shi, L.K.; Qi, G.Z.; Zuo, T.L. Chinese Materials and Engineering Canon; Chemical Industry Press: Beijing, China, 2005; p. 88. [Google Scholar]

- Ren, L.L.; Gu, H.M.; Wang, W.; Wang, S.; Li, C.D.; Wang, Z.B.; Zhai, Y.C.; Ma, P.H. Effect of Mg content on microstructure and properties of Al-Mg alloy produced by the wire arc additive manufacturing method. Materials 2019, 12, 4160. [Google Scholar] [CrossRef] [Green Version]

| Materials | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2–2.8 | 0.15–0.35 | 0.10 | 0.01 | Bal. |

| ER5556 | 0.07 | 0.17 | 0.01 | 0.61 | 4.90 | 0.11 | 0.08 | 0.09 | Bal. |

| Factors | Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| WC/A | 90 | 100 | 110 | 120 | 130 |

| WS/mm·min−1 | 400 | 500 | 600 | 700 | 800 |

| GF/L·min−1 | 12.5 | 15.0 | 17.5 | 20.0 | 22.5 |

| IRT/min | 1 | 2 | 3 | 4 | 5 |

| No. | WC/A | WS/mm·min−1 | GF/L·min−1 | IRT/min | TTS/MPa | No. | WC/A | WS/mm·min−1 | GF/L·min−1 | IRT/min | TTS/MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 90 | 400 | 12.5 | 1 | 331 | 17 | 120 | 500 | 22.5 | 3 | 296 |

| 2 | 90 | 500 | 15.0 | 2 | 316 | 18 | 120 | 600 | 12.5 | 4 | 284 |

| 3 | 90 | 600 | 17.5 | 3 | 304 | 19 | 120 | 700 | 15.0 | 5 | 319 |

| 4 | 90 | 700 | 20.0 | 4 | 337 | 20 | 120 | 800 | 17.5 | 1 | 311 |

| 5 | 90 | 800 | 22.5 | 5 | 367 | 21 | 130 | 400 | 22.5 | 4 | 307 |

| 6 | 100 | 400 | 15.0 | 3 | 361 | 22 | 130 | 500 | 12.5 | 5 | 308 |

| 7 | 100 | 500 | 17.5 | 4 | 337 | 23 | 130 | 600 | 15.0 | 1 | 285 |

| 8 | 100 | 600 | 20.0 | 5 | 309 | 24 | 130 | 700 | 17.5 | 2 | 329 |

| 9 | 100 | 700 | 22.5 | 1 | 323 | 25 | 130 | 800 | 20.0 | 3 | 293 |

| 10 | 100 | 800 | 12.5 | 2 | 300 | ||||||

| 11 | 110 | 400 | 17.5 | 5 | 309 | k1 | 331.24 | 316.37 | 305.60 | 310.30 | |

| 12 | 110 | 500 | 20.0 | 1 | 315 | k2 | 326.15 | 314.40 | 310.56 | 310.56 | |

| 13 | 110 | 600 | 22.5 | 2 | 311 | k3 | 309.49 | 298.63 | 299.57 | 299.57 | |

| 14 | 110 | 700 | 12.5 | 3 | 304 | k4 | 296.71 | 322.48 | 305.68 | 319.57 | |

| 15 | 110 | 800 | 15.0 | 4 | 309 | k5 | 304.27 | 315.98 | 320.60 | 327.86 | |

| 16 | 120 | 400 | 20.0 | 2 | 274 | R | 34.53 | 23.85 | 21.03 | 28.29 |

| Al-Mg Metallographic Structure and Porosity under Orthogonal Experiment 1 200 Μm | ||||

|---|---|---|---|---|

|  |  |  |  |

| 0.7% | 1.6% | 1.0% | 0.7% | 0.5% |

|  |  |  |  |

| 1.9% | 1.9% | 0.9% | 0.8% | 1.3% |

|  |  |  |  |

| 2.0% | 1.2% | 0.8% | 2.0% | 1.7% |

|  |  |  |  |

| 5.4% | 1.8% | 1.3% | 1.1% | 1.1% |

|  |  |  |  |

| 2.0% | 0.5% | 0.4% | 0.8% | 3.0% |

| Materials | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | 0.25 | 0.39 | 0.11 | 0.10 | 2.54 | 0.21 | 0.09 | 0.01 | Bal. |

| 5556 | 0.08 | 0.18 | 0.01 | 0.63 | 4.68 | 0.12 | 0.07 | 0.10 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, Z.; Zhou, G.; He, C.; Zhang, J. Microstructures and Properties of Al-Mg Alloys Manufactured by WAAM-CMT. Materials 2022, 15, 5460. https://doi.org/10.3390/ma15155460

Liu Y, Liu Z, Zhou G, He C, Zhang J. Microstructures and Properties of Al-Mg Alloys Manufactured by WAAM-CMT. Materials. 2022; 15(15):5460. https://doi.org/10.3390/ma15155460

Chicago/Turabian StyleLiu, Yan, Zhaozhen Liu, Guishen Zhou, Chunlin He, and Jun Zhang. 2022. "Microstructures and Properties of Al-Mg Alloys Manufactured by WAAM-CMT" Materials 15, no. 15: 5460. https://doi.org/10.3390/ma15155460

APA StyleLiu, Y., Liu, Z., Zhou, G., He, C., & Zhang, J. (2022). Microstructures and Properties of Al-Mg Alloys Manufactured by WAAM-CMT. Materials, 15(15), 5460. https://doi.org/10.3390/ma15155460