Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu Alloy for Engine Cylinder Head Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Metal Matrix Composite

2.2. Density

2.3. Microstructure and Hardness Test

2.4. Tensile Test

3. Results and Discussions

3.1. Metallurgical Analysis

3.1.1. XRD Analysis

3.1.2. TEM Analysis for the Sample AF5

3.2. Mechanical Behavior of A354 Alloy and Stir Cast MMC

3.3. Ductility (Percentage Elongation)

3.4. Fractography

4. Conclusions

- The stir-casting technique fabricated sound castings of A354 alloy and composites.

- The microstructure of the composite specimen AF5 exhibited a homogeneous dispersion of FA particles and a fragmented eutectic Si phase. However, AF10 and AF15 specimens pronounced a greater agglomeration of FA particles. Furthermore, the AF15 sample had preferential segregation of eutectic Si and FA particles along the grain boundaries.

- The refined microstructure increased the microhardness (~20%), tensile strength (~25%), and yield strength (~25%) of the composite specimen AF5 than the A354 alloy. The specimens AF10 and AF15 had diminished mechanical properties because of heterogeneous microstructure.

- With an increase in the concentration of FA particles, the fracture mode transformed from a combined ductile-brittle mechanism to a predominantly brittle mechanism in the specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuchariková, L.; Tillová, E.; Bokuvka, O. Recycling and properties of recycled aluminium alloys used in the transportation industry. Transp. Probl. 2017, 11, 117–122. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, J.R. Recent development in aluminium for automotive applications. Trans. Nonferr. Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Henriksson, F.; Johansen, K. On Material Substitution in Automotive BIWs—From Steel to Aluminum Body Sides. Procedia CIRP 2016, 50, 683–688. [Google Scholar] [CrossRef] [Green Version]

- Pana, G.M.; Grigorie, L.D. The Issue of Car Body Manufacture in Unibody Aluminum Alloy Design. Appl. Mech. Mater. 2018, 880, 183–188. [Google Scholar] [CrossRef]

- Padmanaban, D.A.; Kurien, G. Silumins: The Automotive Alloys. Adv. Mater. Process. 2012, 170, 28–30. [Google Scholar]

- Camicia, G.; Timelli, G. Grain refinement of gravity die cast secondary AlSi7Cu3Mg alloys for automotive cylinder heads. Trans. Nonferr. Met. Soc. China 2016, 26, 1211–1221. [Google Scholar] [CrossRef]

- Molina, R.; Amalberto, P.; Rosso, M. Mechanical characterization of aluminium alloys for high temperature applications Part 2: Al-Cu, Al-Mg alloys. Metall. Sci. Technol. 2011, 29, 5–13. [Google Scholar]

- Fan, K.L.; He, G.; Liu, X.; Liu, B.; She, M.; Yuan, Y.; Yang, Y.; Lu, Q. Tensile and fatigue properties of gravity casting aluminum alloys for engine cylinder heads. Mater. Sci. Eng. A 2013, 586, 78–85. [Google Scholar] [CrossRef]

- Molina, R.; Amalberto, P.; Rosso, M. Mechanical characterization of aluminium alloys for high temperature applications Part 1: Al-Si-Cu alloys. Metall. Sci. Technol. 2011, 29, 5–15. [Google Scholar]

- Kaufman, J.G.; Rooy, E.L. Casting Properties, Processes, and Application; ASM International: Materials Park, OH, USA, 2004; pp. 27–31. [Google Scholar]

- Merchán, M.; Egizabal, P.; De Cortazar, M.G.; Irazustabarrena, A.; Galarraga, H. Development of an Innovative Low Pressure Die Casting Process for Aluminum Powertrain and Structural Components. Adv. Eng. Mater. 2018, 21, 1800105. [Google Scholar] [CrossRef]

- Castella, C. Self Hardening Aluminum Alloys for Automotive Applications. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2015. [Google Scholar]

- Köhler, E.; Klimesch, C.; Bechtle, S.; Stanchev, S. Cylinder head production with gravity die casting. MTZ Worldw. 2010, 71, 38–41. [Google Scholar] [CrossRef]

- Shankar, K.V.; Sellamuthu, R. Determination of optimum aging temperature and time, mechanical and wear properties for cu-9Ni-6Sn spinodal bronze alloy cast using permanent mould. Int. J. Mater. Eng. Innov. 2017, 8, 27–38. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Deepakaravind, V.; Gopal, P.; Azhagiri, P. Analysis the mechanical properties and material characterization on magnesium metal matrix nano composites through stir casting process. Mater. Today Proc. 2021, 46, 7436–7441. [Google Scholar] [CrossRef]

- Nanjan, S.; Muralia, J.G. Analysing the mechanical properties and corrosion phenomenon of reinforced metal matrix composite. Materials Res. 2020, 23, e20190681. [Google Scholar] [CrossRef]

- Alizadeh, A.; Khayami, A.; Karamouz, M.; Hajizamani, M. Mechanical properties and wear behavior of Al5083 matrix composites reinforced with high amounts of SiC particles fabricated by combined stir casting and squeeze casting; A comparative study. Ceramics Int. 2022, 48, 179–189. [Google Scholar] [CrossRef]

- Ramamoorthi, R.; Hillary, J.J.M.; Sundaramoorthy, R.; Joseph, J.D.J.; Kalidas, K.; Manickaraj, K. Influence of stir casting route process parameters in fabrication of aluminium matrix composites—A review. Mater. Today Proc. 2020, 45, 6660–6664. [Google Scholar] [CrossRef]

- Mohana Rao, D.; Bandam, B.R. Preparation and Characterization of Al-Fly Ash Metal Matrix Composite by Stir Casting Method. Int. J. Innov. Sci. Mod. Eng. 2014, 3, 1–5. [Google Scholar]

- De Oliveira, L.B.; de Azevedo, A.R.G.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards sustainable coal industry: Turning coal bottom ash into wealth. Sci. Total Environ. 2022, 804, 149985. [Google Scholar] [CrossRef]

- Zhao, H.; Zhou, F.; Evelina, L.M.A.; Liu, J.; Zhou, Y. A review on the industrial solid waste application in pelletizing additives: Composition, mechanism and process characteristics. J. Hazard. Mater. 2022, 423, 127056. [Google Scholar] [CrossRef]

- Sharma, D.K.; Badheka, V.; Patel, V.; Upadhyay, G. Recent developments in hybrid surface metal matrix composites produced by friction stir processing: A review. J. Tribol. 2021, 143, 1–58. [Google Scholar] [CrossRef]

- Ravikumar, K.S.; Ghanaraja, S.; Ramesh, M.R. Effect of milling on the hardness and wear behaviour of cast Al6061 reinforced with Al2O3 nanoparticles. J. Bio Tribo Corros. 2022, 8, 50801. [Google Scholar] [CrossRef]

- Révész, Á.; Gajdics, M. Improved h-storage performance of novel mg-based nanocomposites prepared by high-energy ball milling: A review. Energies 2021, 14, 6400. [Google Scholar] [CrossRef]

- Sathishkumar, A.; Soundararajan, R.; Siva Krishna, S.; Ranjan Prabakaran, B.R. Assessment of Tribological Characteristics of Stir Cum Squeeze Cast AlSi7Mg with x wt % flyash and 3wt % MoS2 Hybrid Composites; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2021; p. 173236. [Google Scholar] [CrossRef]

- Sharma, V.K.; Singh, R.C.; Chaudhary, R. Effect of fly ash and graphite addition on the tribological behavior of aluminium composites. Surf. Topogr. Metrol. Prop. 2021, 9, 25027. [Google Scholar] [CrossRef]

- Kumar, A.; Goyal, K.K.; Bhardwaj, A.; Sharma, N. Development and characterization of AA2024/SiC/Gr/Fly ash hybrid composite. J. Phys. Conf. Ser. 2021, 1854, 12022. [Google Scholar] [CrossRef]

- He, F.; Han, Q.; Chen, Y.C.; Xu, C.; Shao, L. Study on mechanical properties of al metal matrix nanocomposites processed using ultrasonic vibration. Proc. ASME Int. Manuf. Sci. Eng. Conf. 2009, 2, 285–288. [Google Scholar] [CrossRef]

- Javidani, M.; Larouche, D. Application of cast Al–Si alloys in internal combustion engine components. Int. Mater. Rev. 2014, 59, 132–158. [Google Scholar] [CrossRef]

- Aybarc, U.; Dispinar, D.; Seydibeyoglu, M.O. Aluminum Metal Matrix Composites with SiC, Al2O3 and Graphene–Review. Arch Foundry Eng. 2018, 2, 5–10. [Google Scholar]

- Li, R.; Pan, Z.; Zeng, Q.; Ye, X. Influence of the Interface of Carbon Nanotube-Reinforced Aluminum Matrix Composites on the Mechanical Properties—A Review. Arch Foundry Eng. 2022, 1, 23–36. [Google Scholar]

- Nemutlu, B.; Kahraman, O.; Demirel, K.B.; Erkul, I.; Cicek, M.; Sahin, H.; Dizdar, K.C.; Dispinar, D. Processing of Boron Nitride Nanotubes Reinforced Aluminum Matrix Composite. Arch Foundry Eng. 2022; accepted. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Mahesh, V.; Prabhu, R.T.; Patel, M.G.C.; Bontha, S. Free Vibration Analysis of A357 Alloy Reinforced with Dual Particle Size Silicon Carbide Metal Matrix Composite Plates Using Finite Element Method. Arch. Foundry Eng. 2021, 1, 101–112. [Google Scholar]

- Chaudhury, S.K.; Apelian, D.; Meyer, P.; Massinon, D.; Morichon, J. Fatigue Performance of Fluidized Bed Heat Treated 319 Alloy Diesel Cylinder Heads. Met. Mater. Trans. A 2015, 46, 3015–3027. [Google Scholar] [CrossRef]

- Torres, R.; Esparza, J.; Velasco, E.; Garcia-Luna, S.; Colás, R. Characterisation of an aluminium engine block. Int. J. Microstruct. Mater. Prop. 2006, 1, 129. [Google Scholar] [CrossRef]

- Kumar, L.; Jang, J.C.; Yu, H.; Shin, K.S. Effects of Cr and Ti Addition on Mechanical Properties and Thermal Conductivity of Al–7Si–3Mg Die-Casting Alloys. Met. Mater. Int. 2022, 1–11. [Google Scholar] [CrossRef]

- Wang, S.; Cui, X.; Xiao, A.; Zhang, L.; Zhao, P. Mechanical Properties and Microstructure Evolution of Pre-stretched Aluminum Alloy After Induced Electro-Pulsing Treatment. Met. Mater. Int. 2022, 1–11. [Google Scholar] [CrossRef]

- Kim, S.-B.; Jung, J.-G.; Cho, Y.-H.; Kim, S.-H.; Euh, K.; Lee, J.-M. Effect of Ultrasonic Melt Treatment on Solidification Microstructure of Al–5Ti–1B Alloy Containing Numerous Inoculant Particles. Met. Mater. Int. 2022, 28, 1549–1560. [Google Scholar] [CrossRef]

- Kim, S.B.; Kim, D.H.; Kang, J.W. Role of Ultrasonic Melt Treatment in the Improvement of Corrosion Resistance of Al–7Si–0.4Mg Cast Alloy. Met. Mater. Int. 2022; in press. [Google Scholar] [CrossRef]

- Biyikli, M.; Karagoz, T.; Calli, M.; Koo, T.M.; Lee, Y.S.; Lee, J.Y.; Cho, Y.H.; Lee, J.M. Single Track Geometry Prediction of Laser Metal Deposited 316L-Si Via Multi-Physics Modelling and Regression Analysis with Experimental Validation. Met. Mater. Int. 2022; in press. [Google Scholar] [CrossRef]

- Ganesh, M.R.S.; Reghunath, N.J.; Levin, M.; Prasad, A.; Doondi, S.; Shankar, K.V. Strontium in Al–Si–Mg Alloy: A Review. Met. Mater. Int. 2022, 28, 1–40. [Google Scholar] [CrossRef]

- Shankar, K.V.; Manu, K.; Raj, A.N.; Mukund, A.; Nair, A.S.; Nived, S.; Premkumar, A. Solutionising Temperature Influence on the Morphological and Mechanical Characteristics of Al–Si–Mg–Ni Hypoeutectic Alloys. J. Inst. Eng. India Ser. D 2021, 102, 131–148. [Google Scholar] [CrossRef]

- Shankar, K.V.; Ajay Ghosh, K.J.; Sudhin, C.B.; Pai, A.S.; Biju, A.; Sriram, K.R. Investigating the significance of SiC particle size on the mechanical properties of cu-6Sn-SiC composite. Int. J. Mater. Eng. Innov. 2020, 11, 323–337. [Google Scholar] [CrossRef]

| Elements | Al | Si | Cu | Mg |

|---|---|---|---|---|

| wt% | Rem. | 6.9 | 2.8 | 0.39 |

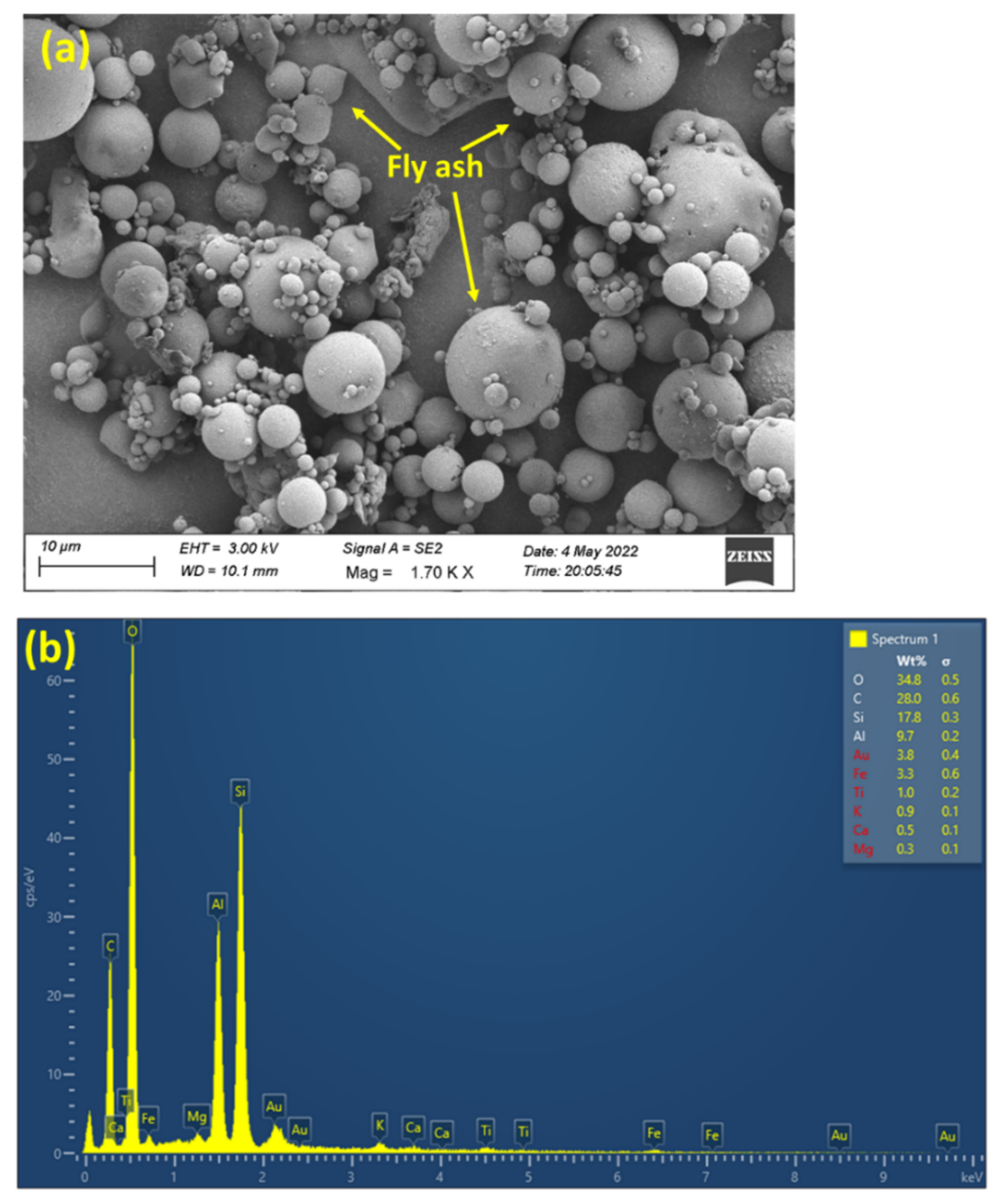

| Elements | Al | Si | O | C | Fe | Others (Na, Mg, K, P, Ca) |

|---|---|---|---|---|---|---|

| wt% | 9.7 | 17.8 | 34.8 | 2.8 | 3.3 | Rem. |

| Sample Code | Matrix | Reinforcement | Wt% Reinforcement |

|---|---|---|---|

| A | A354 | - | - |

| AF5 | A354 | Fly ash | 5 |

| AF10 | A354 | Fly ash | 10 |

| AF15 | A354 | Fly ash | 15 |

| Sl No | Samples | Density Values in g/cm3 | |

|---|---|---|---|

| Experimental | Theoretical | ||

| 1 | A | 2.75 ± 0.014 | 2.79 |

| 2 | AF5 | 2.45 ± 0.013 | 2.53 |

| 3 | AF10 | 2.42 ± 0.012 | 2.48 |

| 4 | AF15 | 2.39 ± 0.011 | 2.41 |

| Samples | Hardness (HV0.1) | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Ductility (%) |

|---|---|---|---|---|

| A | 143 ± 5.1 | 173± 2.1 | 104 ± 3.2 | 8.5 ± 0.25 |

| AF5 | 170 ± 5.6 | 216 ± 2.3 | 130 ± 2.2 | 6.5 ± 0.43 |

| AF10 | 164 ± 5.5 | 188 ± 2.2 | 113 ± 3.2 | 5.7 ± 0.38 |

| AF15 | 128 ± 5.6 | 181 ± 2.1 | 109 ± 2.1 | 4.9 ± 0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shankar, K.V.; Jezierski, J.; Ramalingam, V.V.; Padmakumar, D.; Leena, M.R.; Amal; Reghunath, G.; Krishnan, R. Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu Alloy for Engine Cylinder Head Application. Materials 2022, 15, 5462. https://doi.org/10.3390/ma15155462

Shankar KV, Jezierski J, Ramalingam VV, Padmakumar D, Leena MR, Amal, Reghunath G, Krishnan R. Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu Alloy for Engine Cylinder Head Application. Materials. 2022; 15(15):5462. https://doi.org/10.3390/ma15155462

Chicago/Turabian StyleShankar, Karthik Venkitraman, Jan Jezierski, Vaira Vignesh Ramalingam, Devaprasad Padmakumar, Midun Raj Leena, Amal, Gokul Reghunath, and Rakesh Krishnan. 2022. "Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu Alloy for Engine Cylinder Head Application" Materials 15, no. 15: 5462. https://doi.org/10.3390/ma15155462

APA StyleShankar, K. V., Jezierski, J., Ramalingam, V. V., Padmakumar, D., Leena, M. R., Amal, Reghunath, G., & Krishnan, R. (2022). Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu Alloy for Engine Cylinder Head Application. Materials, 15(15), 5462. https://doi.org/10.3390/ma15155462