Influence of Annealing Time on Microstructure and Mechanical Properties of Al-14.5Si Alloy Prepared by Super-Gravity Solidification and Cold-Rolling

Abstract

:1. Introduction

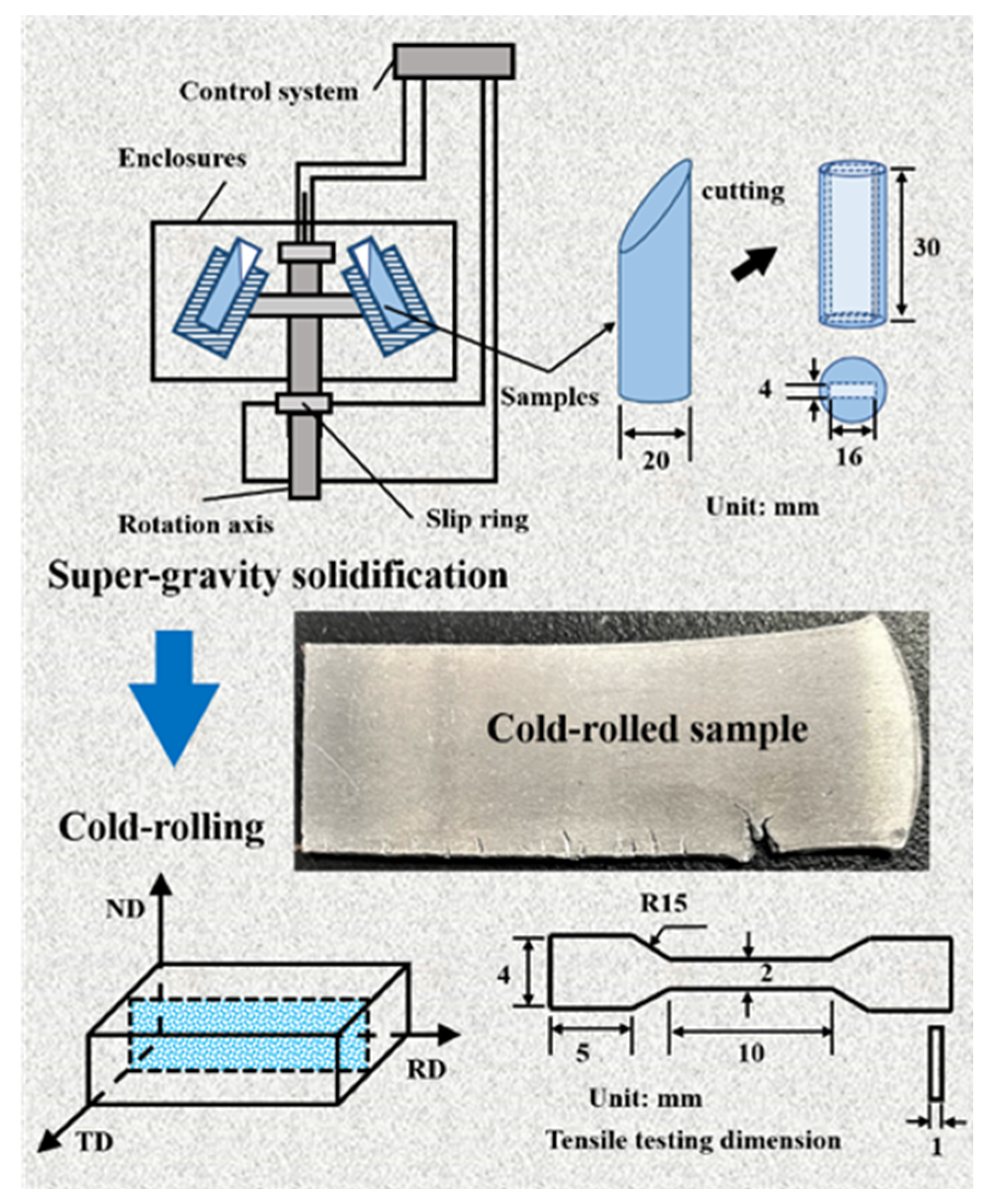

2. Experimental Processing

3. Results

3.1. X-ray Diffraction

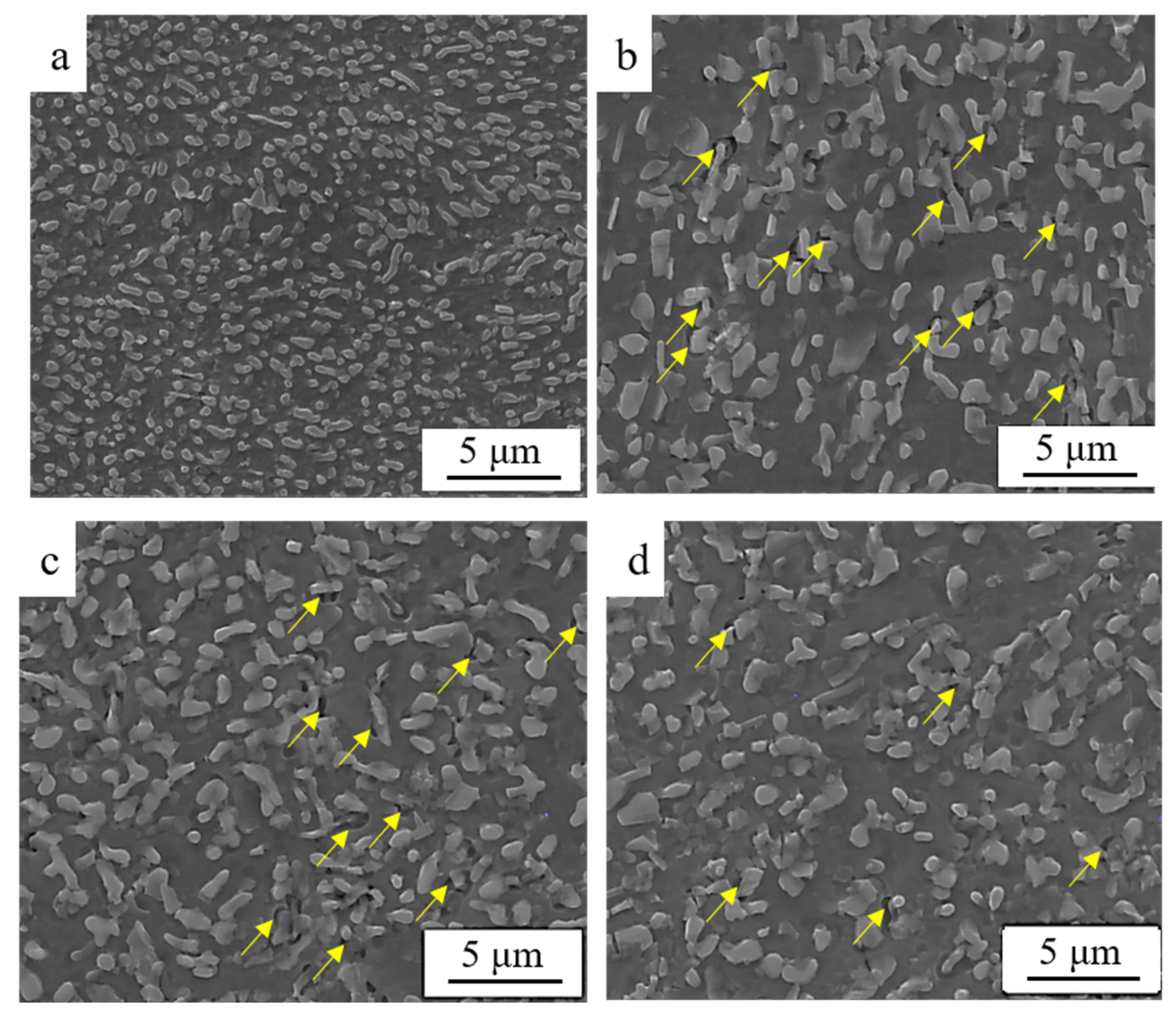

3.2. Microstructure Characterization

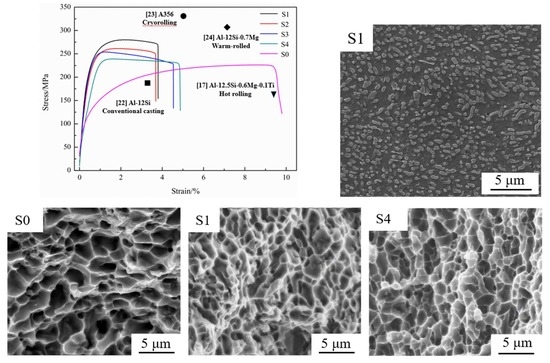

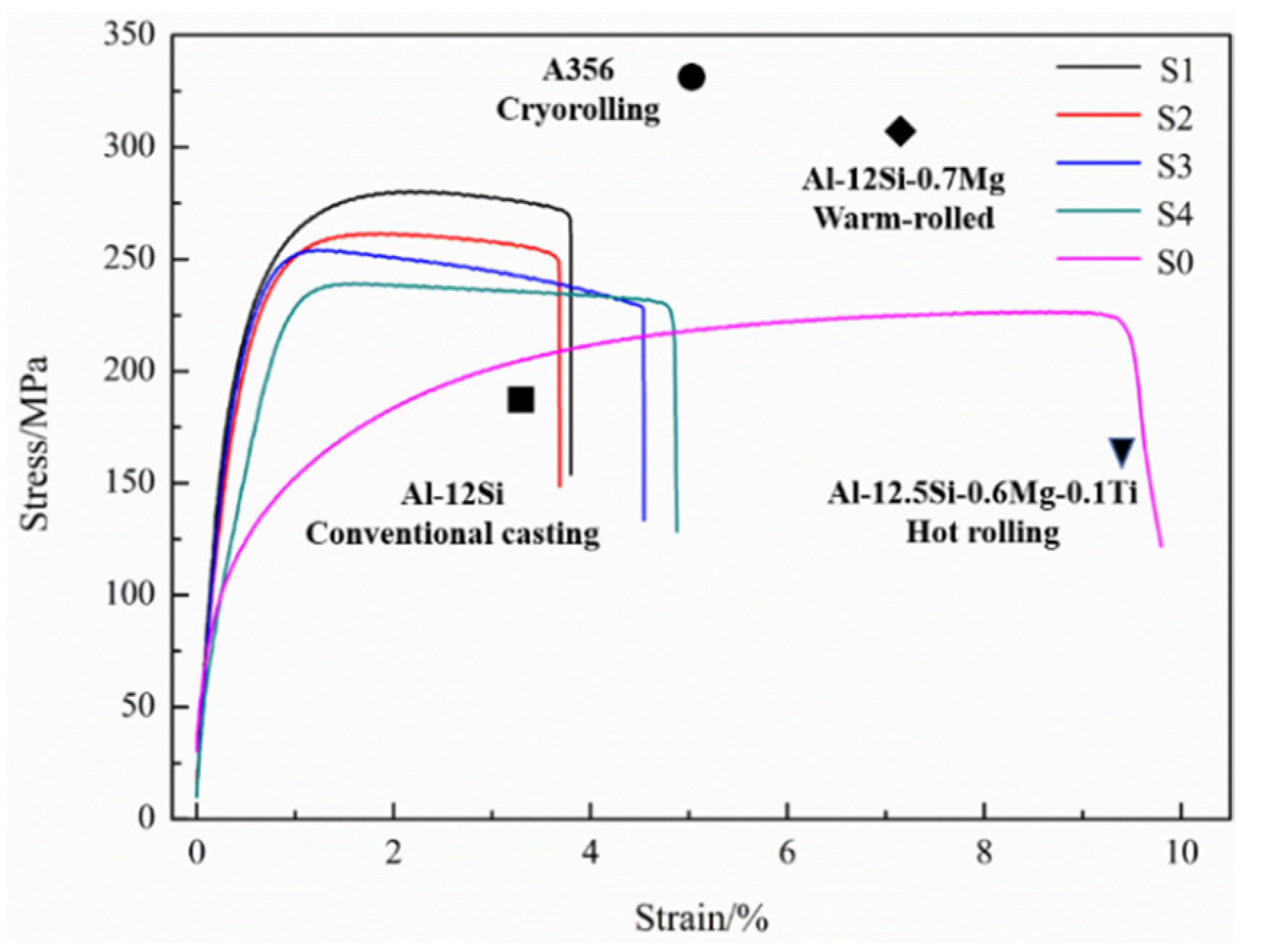

3.3. Mechanical Properties

3.4. Fractography

4. Discussion

4.1. Microstructure Evolution

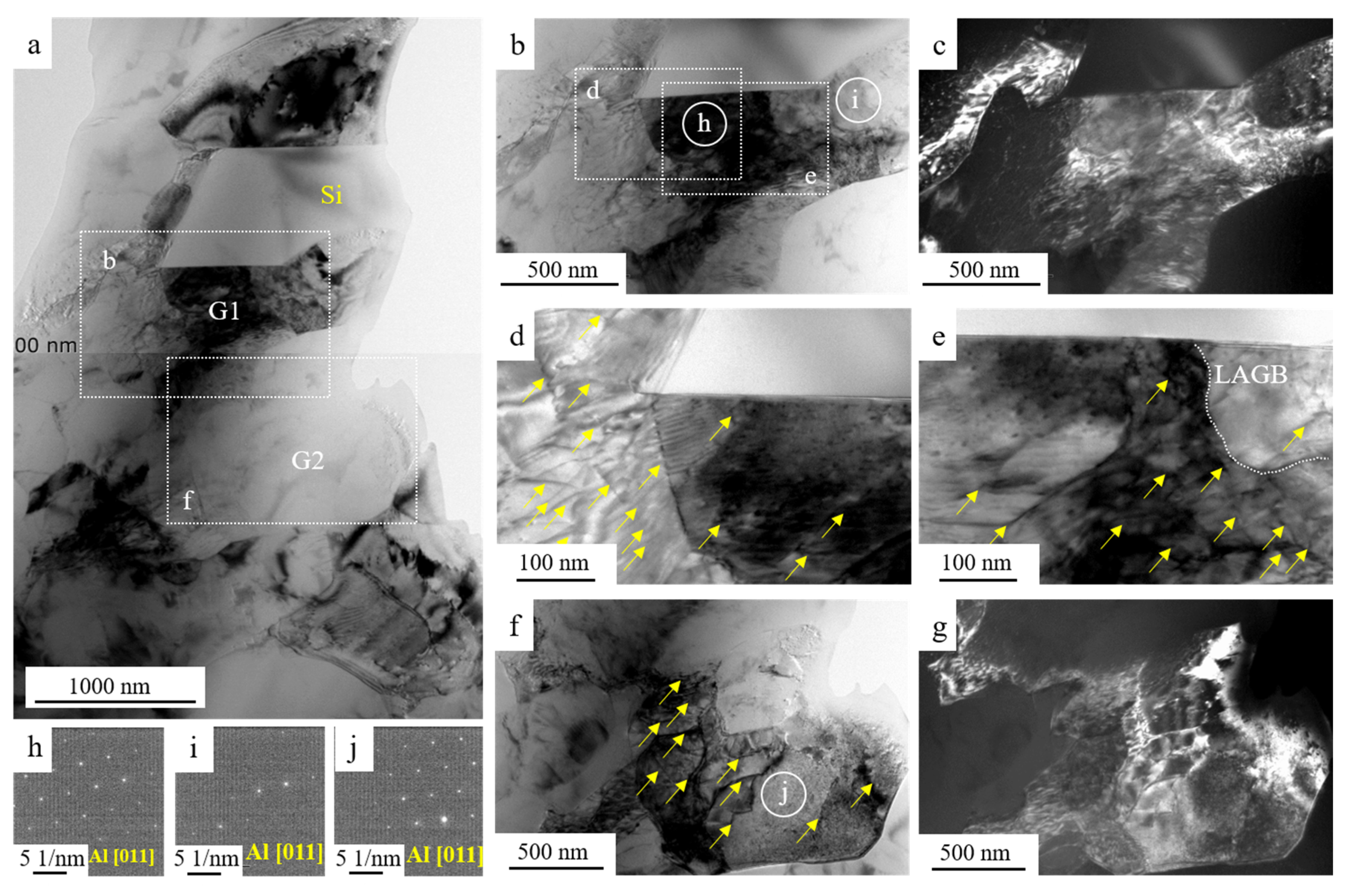

4.1.1. Microstructure Evolution during Cold-Rolling

4.1.2. Microstructure Evolution during Annealing

4.2. Fracture Behavior

5. Conclusions

- The grain of α-Al in S1 was severely elongated along the rolling direction during cold-rolling. A slight coarsening of eutectic Si was found during cold-rolling and annealing. The dislocation density in the vicinity of Si was higher than that far away from Si in the S1 sample. Compared with the S1 sample, lower dislocation density was observed in the S4 sample.

- Compared with the S0 sample (~127 ± 8 MPa), the higher yield strength (~214 ± 11 MPa) with limited elongation (~2.9 ± 0.5%) could be achieved after cold-rolling. After annealing for 1 h, the yield strength and elongation of the S3 sample were ~202 ± 8 MPa and ~3.7 ± 0.3%, respectively.

- Multiple micro-cracks/voids were detected beneath the fracture surface with an increase in annealing time and the internal stress and lattice distortion were eliminated, leading to a decrease in micro-cracks/voids.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guan, J.; Xie, K.; Liu, A.; Shi, Z.; Chen, G.; Boca, M. Study on the mechanism of Al-Si alloy preparation via aluminothermic reduction-molten salt electrolysis in KF-AlF3 molten salt. Mater. Today Commun. 2021, 29, 102959. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Zhang, S.; Wang, Y.; Tong, L.; Hong, W.; Chen, Z. Analysis of interface properties and associated void of nanoscale Al precipitates in Al-Si alloys: First-principles calculations and experiment. J. Alloys Compd. 2021, 873, 159598. [Google Scholar] [CrossRef]

- Soleymanpour, M.; Aval, H.J.; Jamaati, R. Achieving high strength and superior ductility in Al-Si alloy by cold rolling and friction stir processing. J. Alloys Compd. 2022, 896, 163102. [Google Scholar] [CrossRef]

- Gan, Z.; Hu, Z.; Su, Y.; Liu, Y.; Ni, Q.; Li, Y.; Wu, C.; Liu, J. Influence of super-gravity coefficient on spatial distribution of solidification structure in Al-14.5Si alloys. J. Mater. Res. Technol. 2021, 15, 4955–4969. [Google Scholar] [CrossRef]

- Zhuo, X.; Xu, H.; Wu, Y.; Hu, Z.; Jiang, J.; Ma, A. Effect of eutectic Si size on the flow behavior and hot processing map of near eutectic Al-Si alloys. J. Mater. Res. Technol. 2021, 15, 5694–5705. [Google Scholar] [CrossRef]

- Sharma, R.; Dwivedi, D.K. Influence of silicon (wt.%) and heat treatment on abrasive wear behaviour of cast Al-Si-Mg alloys. Mater. Sci. Eng. A 2005, 408, 274–280. [Google Scholar] [CrossRef]

- Ganesh, M.R.; Reghunath, N.; Levin, M.J.; Prasad, A.; Doondi, S.; Shankar, K.V. Strontium in Al-Si-Mg Alloy: A Review. Met. Mater. Int. 2022, 28, 1–40. [Google Scholar] [CrossRef]

- Gursoy, O.; Timelli, G. Lanthanides: A focused review of eutectic modification in hypoeutectic Al-Si alloys. J. Mater. Res. Technol. 2020, 9, 8652–8666. [Google Scholar] [CrossRef]

- Li, Y.; Yang, M.; Li, K.; Ma, C.; Yang, T.; Wang, J.; Lu, Q.; Zhang, Y.; Li, G.; Zhang, S.; et al. In-situ study of effects of heat treatments and loading methods on fracture behaviors of a cast Al-Si alloy. Mater. Today Commun. 2021, 28, 102680. [Google Scholar] [CrossRef]

- Li, M.; Omura, N.; Murakami, Y.; Matsui, I.; Tada, S. A comparative study of the primary phase formation in Al-7 wt% Si and Al-17 wt% Si alloys solidified by electromagnetic stirring processing. Mater. Today Commun. 2020, 24, 101146. [Google Scholar] [CrossRef]

- Haghayeghi, R.; Timelli, G. An investigation on primary Si refinement by Sr and Sb additions in a hypereutectic Al-Si alloy. Mater. Lett. 2020, 283, 128779. [Google Scholar] [CrossRef]

- Hou, L.G.; Cui, C.; Zhang, J.S. Optimizing microstructures of hypereutectic Al-Si alloys with high Fe content via spray forming technique. Mater. Sci. Eng. A 2010, 527, 6400–6412. [Google Scholar] [CrossRef]

- Zhang, Y.; Jie, J.; Gao, Y.; Lu, Y.; Li, T. Effects of ultrasonic treatment on the formation of iron-containing intermetallic compounds in Al-12%Si-2%Fe alloys. Intermetallics 2013, 42, 120–125. [Google Scholar] [CrossRef]

- Wu, H.; Wu, C.; Lu, Y.; Jiang, P.; Liu, J. Towards enhanced strength and ductility of Al-14.5Si alloy via solidification under super-gravity field. Adv. Eng. Mater. 2020, 22, 2000360. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, R.; Xiao, W.; Yu, X.; Peng, Q. Concurrent enhancement of strength and ductility for Al-Si binary alloy by refining Si phase to nanoscale. Mater. Sci. Eng. A 2019, 751, 303–310. [Google Scholar] [CrossRef]

- Liao, H.; Cai, M.; Jing, Q.; Ke, D. Effect of cold-rolling on mechanical properties and microstructure of an Al-12%Si-0.2%Mg alloy. J. Mater. Eng. Perform. 2011, 20, 1364–1369. [Google Scholar] [CrossRef]

- Wu, Y.; Liao, H.; Lü, C. Dynamic precipitation and recrystallization in Al-12.5 wt%Si-0.6 wt%Mg-0.1 wt%Ti alloy during hot-rolling and their impacts on mechanical properties. J. Alloys Compd. 2019, 788, 125–135. [Google Scholar] [CrossRef]

- Cepeda-Jimenez, C.; Garcia-Infanta, J.M.; Zhilyaev, A.P.; Ruano, O.A.; Carreo, F. Influence of the supersaturated silicon solid solution concentration on the effectiveness of severe plastic deformation processing in Al-7 wt.% Si casting alloy. Mater. Sci. Eng. A 2011, 528, 7938–7947. [Google Scholar] [CrossRef] [Green Version]

- Ma, A.; Takagi, M.; Saito, N.; Iwata, H.; Nishida, Y.; Suzuki, K.; Shigematsu, I. Tensile properties of an Al-11 mass%Si alloy at elevated temperatures processed by rotary-die equal-channel angular pressing. Mater. Sci. Eng. A 2005, 408, 147–153. [Google Scholar] [CrossRef]

- Ma, A.; Suzuki, K.; Nishida, Y.; Saito, N.; Shigematsu, I.; Takagi, M.; Iwata, H.; Watazu, A.; Imura, T. Impact toughness of an ultrafine-grained Al-11mass%Si alloy processed by rotary-die equal-channel angular pressing. Acta Mater. 2005, 53, 211–220. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, R.; Hanada, S.; Xiao, W.; Ma, C. Effect of hot extrusion and subsequent T6 treatment on the microstructure evolution and tensile properties of an Al-6Si-2Cu-0.5Mg alloy. Mater. Sci. Eng. A 2018, 710, 102–110. [Google Scholar] [CrossRef]

- Uludag, M. A statistical assessment of casting quality-tribological properties of eutectic Al-12Si alloy: Effect of Mg. J. Mater. Eng. Perform. 2020, 29, 7526–7543. [Google Scholar] [CrossRef]

- Immanuel, R.J.; Panigrahi, S.K. Influence of cryorolling on microstructure and mechanical properties of a cast hypoeutectic Al-Si alloy. Mater. Sci. Eng. A 2015, 640, 424–435. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, C.; Huang, H.; Zhang, L.; Zhang, B.; Shi, L. High strength and ductility of Al-Si-Mg alloys fabricated by deformation and heat treatment. Mater. Charact. 2021, 178, 111278. [Google Scholar] [CrossRef]

- Broek, D. The role of inclusions in ductile fracture and fracture toughness. Eng. Fract. Mech. 1973, 5, 55–66. [Google Scholar] [CrossRef]

- Van Stone, R.H.; Cox, T.B.; Low, J.R.; Psioda, J.A. Microstructural aspects of fracture by dimpled rupture. Int. Met. Rev. 1985, 30, 157–180. [Google Scholar]

- Garrett, G.G.; Knott, J.F. The influence of compositional and microstructural var-iations on the mechanism of static fracture in aluminum alloys. Metall. Trans. A 1978, 9, 1187–1201. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Muñoz-Morris, M.a.; Morris, D.G. Influence of cryorolling on microstructure and mechanical properties of a cast hypoeutectic Al-Si alloy. Mater. Sci. Eng. A 2007, 55, 1319. [Google Scholar]

- Cepeda-Jiménez, C.M.; García-Infanta, J.M.; Zhilyaev, A.P.; Ruano, O.A.; Carreño, F. Influence of the thermal treatment on the deformation-induced precipitation of a hypoeutectic Al-7 wt% Si casting alloy deformed by high-pressure torsion. J. Alloys Compd. 2011, 509, 636. [Google Scholar] [CrossRef] [Green Version]

- Cheng, W.; Liu, C.Y.; Ge, Z.J. Optimizing the mechanical properties of Al-Si alloys through friction stir processing and rolling. Mater. Sci. Eng. A 2021, 804, 140786. [Google Scholar] [CrossRef]

- Ujihara, T.; Fujiwara, K.; Sazaki, G.; Usami, N.; Nakajima, K. New method for measurement of interdiffusion coefficient in high temperature solutions based on Fick’s first law. J. Cryst. Growth 2002, 241, 387–394. [Google Scholar] [CrossRef]

- Samaras, S.N.; Haidemenopoulos, G.N. Modelling of microsegregation and homogenization of 6061 extrudable Al-alloy. J. Mater. Process. Technol. 2007, 194, 63–73. [Google Scholar] [CrossRef]

- Li, X.P.; Wang, X.J.; Saunders, M.; Suvorova, A.; Zhang, L.C.; Liu, Y.J.; Fang, M.H.; Huang, Z.H.; Sercombe, T.B. A selective laser melting and solution heat treatment refined Al-12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Hegde, S.; Prabhu, K.N. Modification of eutectic silicon in Al-Si alloys. J. Mater. Sci. 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, H.; Kang, S.B.; Cho, J.H.; Min, G.; Stetsenko, V.Y. Effect of fine-grained structural Al-12%Si materials on morphologies and crystal defects of eutectic Si in HCC Al-12%Si alloy billets. J. Alloys Compd. 2012, 541, 157–162. [Google Scholar] [CrossRef]

- Asta, M.; Beckermann, C.; Karma, A.; Kurz, W.; Napolitano, R.; Plapp, M.; Purdy, G.; Rappaz, M.; Trivedi, R. Solidification microstructures and solid-state parallels: Recent developments, future directions. Acta Mater. 2009, 57, 941–971. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Xu, C.; Zheng, R.; Guan, S.; Ma, C. Towards strength-ductility synergy through an optimized thermomechanical treatment in hypoeutectic Al-Si alloys. Mater. Lett. 2021, 295, 129850. [Google Scholar] [CrossRef]

| Sample | Annealing Time (h) | Width of Eutectic Si (μm) | Length of Eutectic Si (μm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|---|---|---|

| S0 | / | 0.30 ± 0.05 | 0.47 ± 0.06 | 127 ± 8 | 216 ± 12 | 8.4 ± 1.2 | 75 ± 3 |

| S1 | 0 | 0.38 ± 0.03 | 0.68 ± 0.07 | 214 ± 11 | 280 ± 15 | 2.9 ± 0.5 | 79 ± 5 |

| S2 | 0.5 | 0.42 ± 0.05 | 0.82 ± 0.06 | 202 ± 6 | 262 ± 11 | 2.8 ± 0.6 | 74 ± 2 |

| S3 | 1 | 0.45 ± 0.03 | 0.85 ± 0.09 | 202 ± 8 | 250 ± 9 | 3.7 ± 0.3 | 78 ± 5 |

| S4 | 2 | 0.50 ± 0.03 | 1.01 ± 0.12 | 162 ± 5 | 239 ± 11 | 3.9 ± 0.2 | 75 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, Z.; Ni, Q.; Huang, Y.; Su, Y.; Lu, Y.; Wu, C.; Liu, J. Influence of Annealing Time on Microstructure and Mechanical Properties of Al-14.5Si Alloy Prepared by Super-Gravity Solidification and Cold-Rolling. Materials 2022, 15, 5475. https://doi.org/10.3390/ma15165475

Gan Z, Ni Q, Huang Y, Su Y, Lu Y, Wu C, Liu J. Influence of Annealing Time on Microstructure and Mechanical Properties of Al-14.5Si Alloy Prepared by Super-Gravity Solidification and Cold-Rolling. Materials. 2022; 15(16):5475. https://doi.org/10.3390/ma15165475

Chicago/Turabian StyleGan, Zhanghua, Qian Ni, Yuanyuan Huang, Yin Su, Yuehui Lu, Chuandong Wu, and Jing Liu. 2022. "Influence of Annealing Time on Microstructure and Mechanical Properties of Al-14.5Si Alloy Prepared by Super-Gravity Solidification and Cold-Rolling" Materials 15, no. 16: 5475. https://doi.org/10.3390/ma15165475

APA StyleGan, Z., Ni, Q., Huang, Y., Su, Y., Lu, Y., Wu, C., & Liu, J. (2022). Influence of Annealing Time on Microstructure and Mechanical Properties of Al-14.5Si Alloy Prepared by Super-Gravity Solidification and Cold-Rolling. Materials, 15(16), 5475. https://doi.org/10.3390/ma15165475