Anisotropy in the Tensile Properties of a Selective Laser Melted Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Treatment

Abstract

:1. Introduction

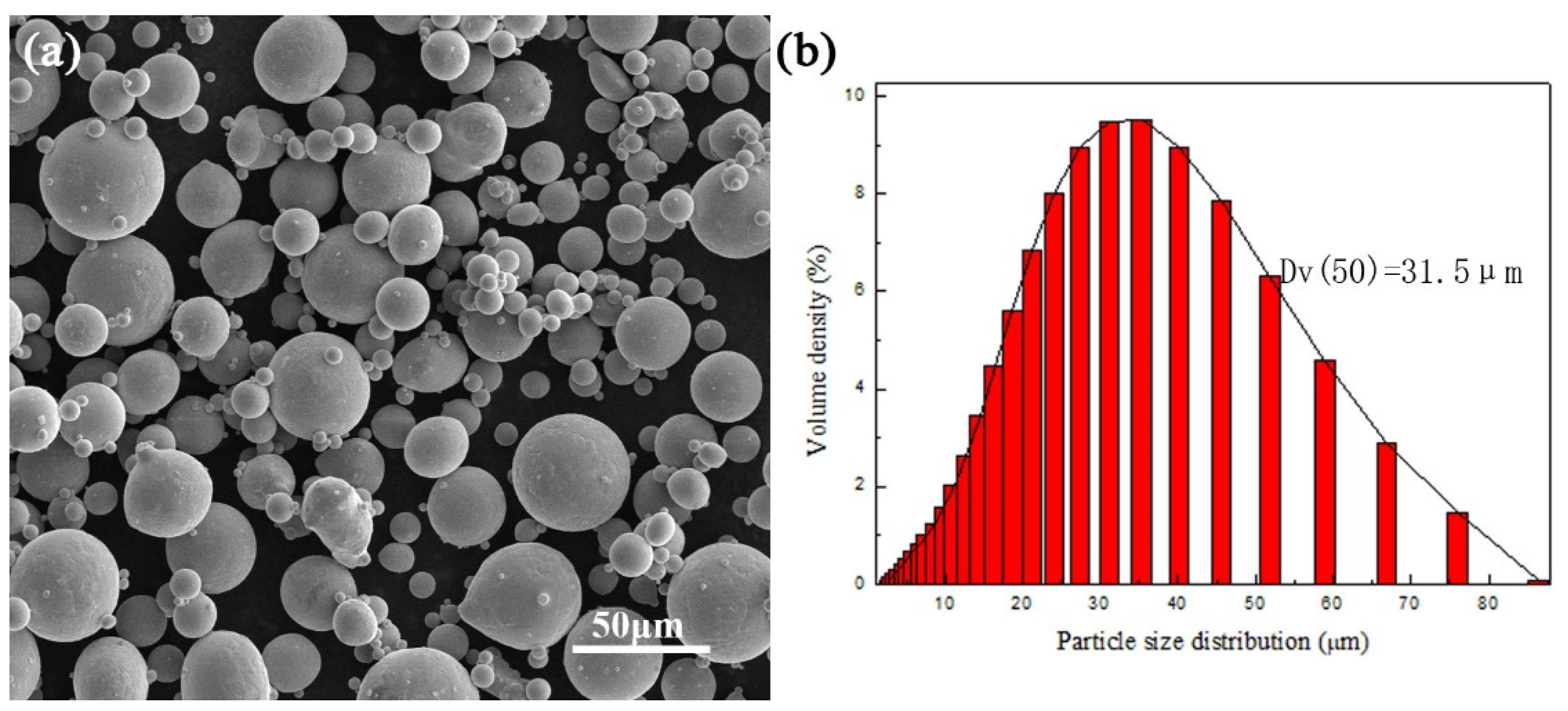

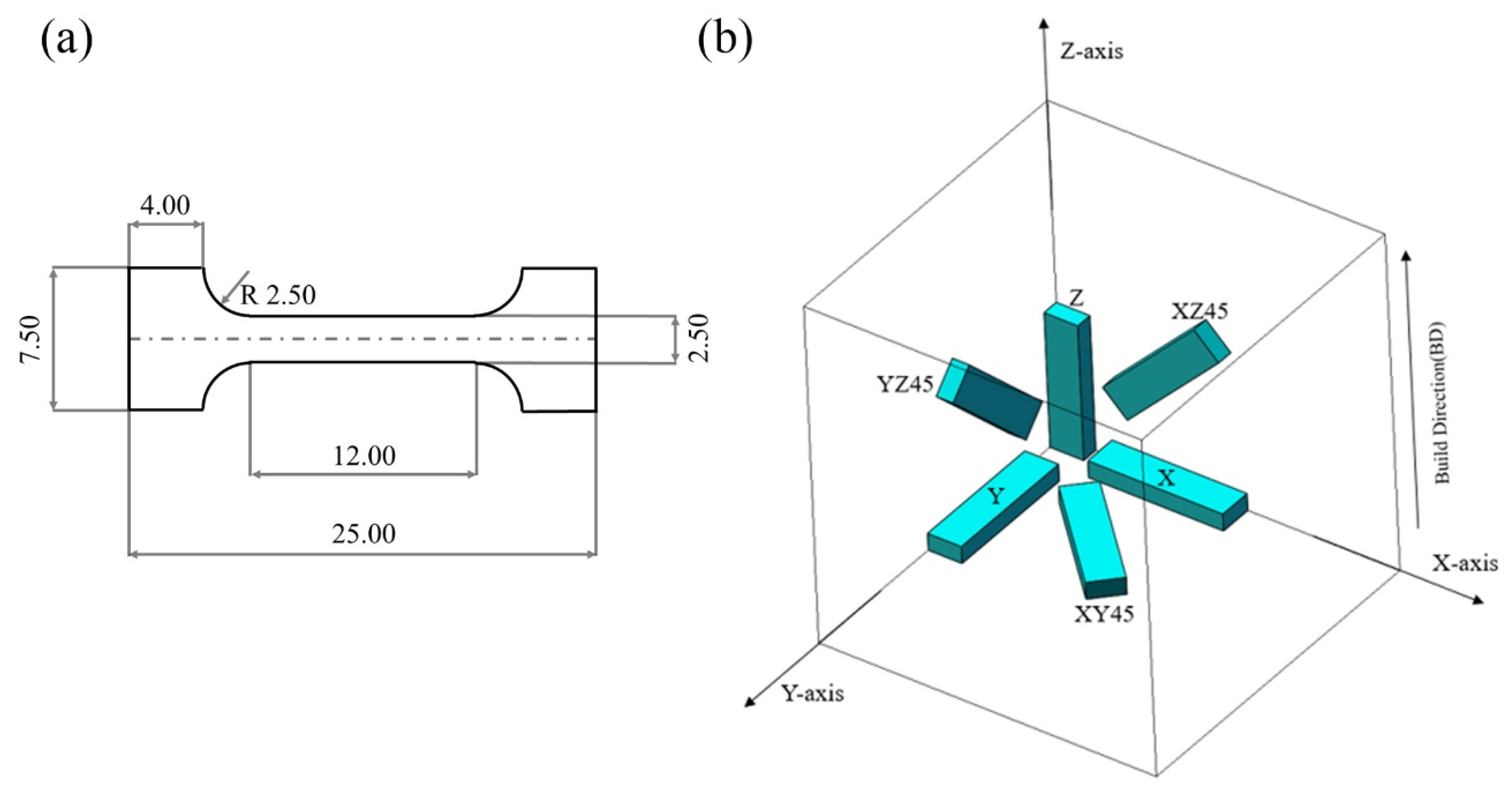

2. Experiments and Methods

3. Results and Discussion

3.1. Overview

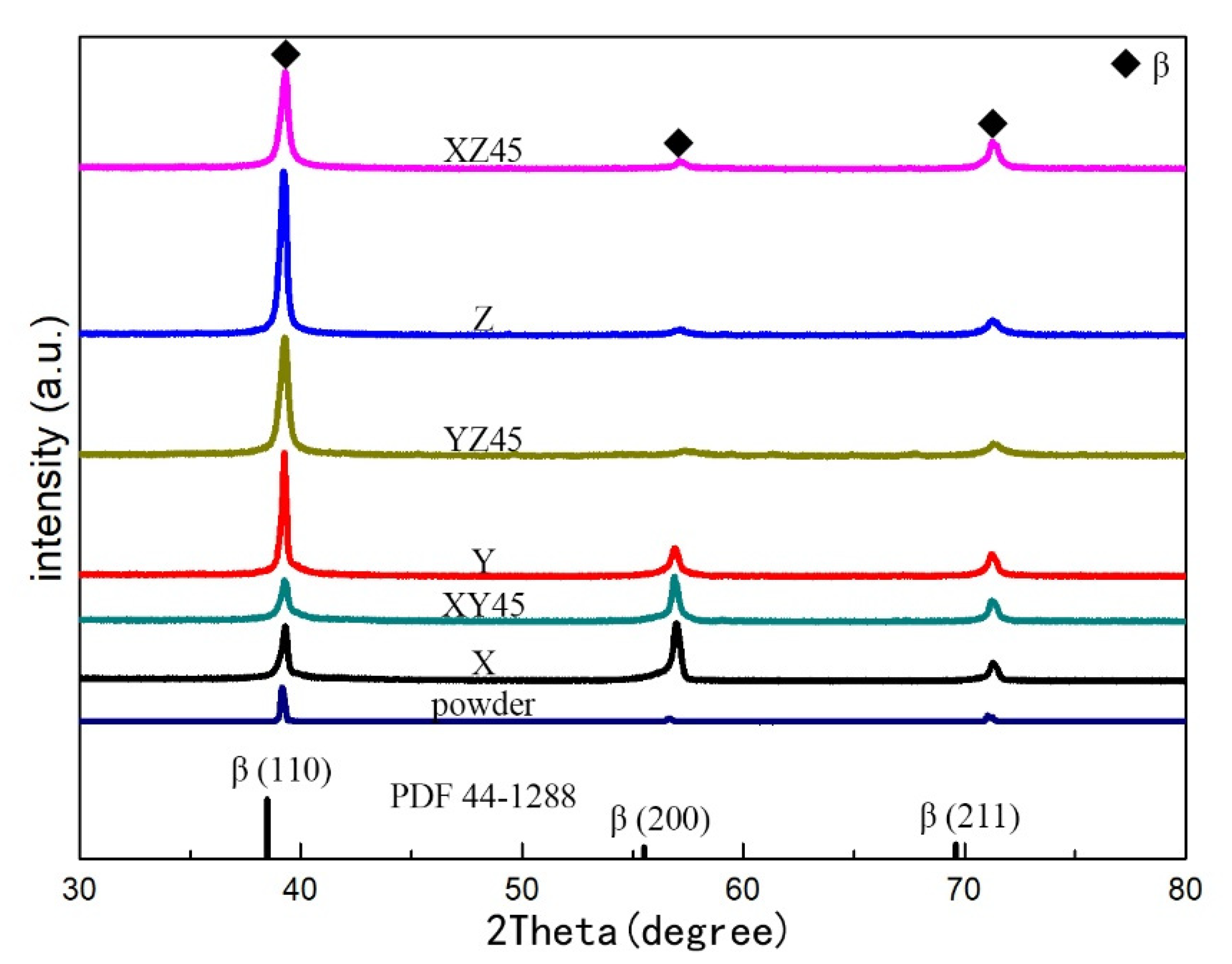

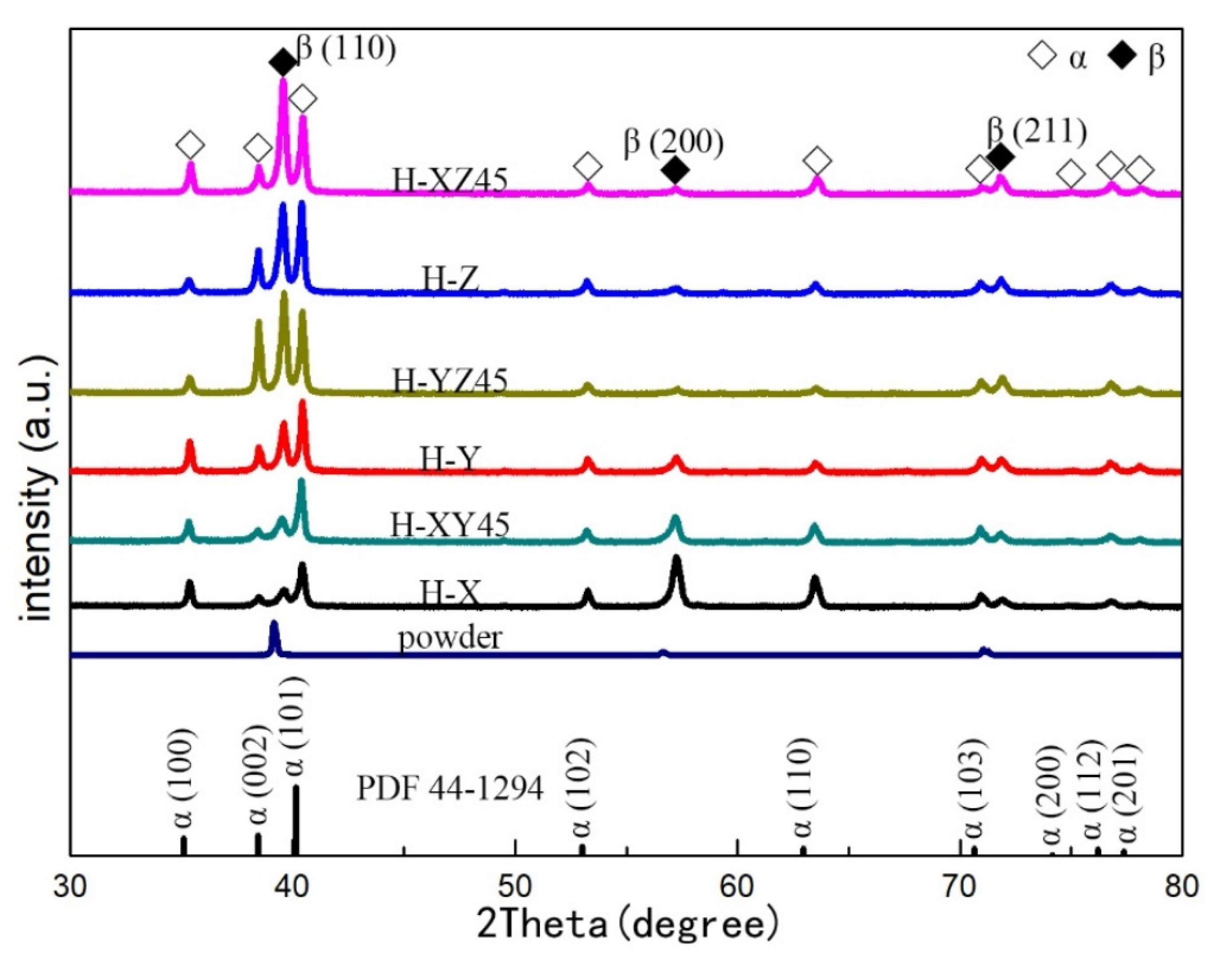

3.2. Phase Analysis

3.2.1. As-Fabricated Samples

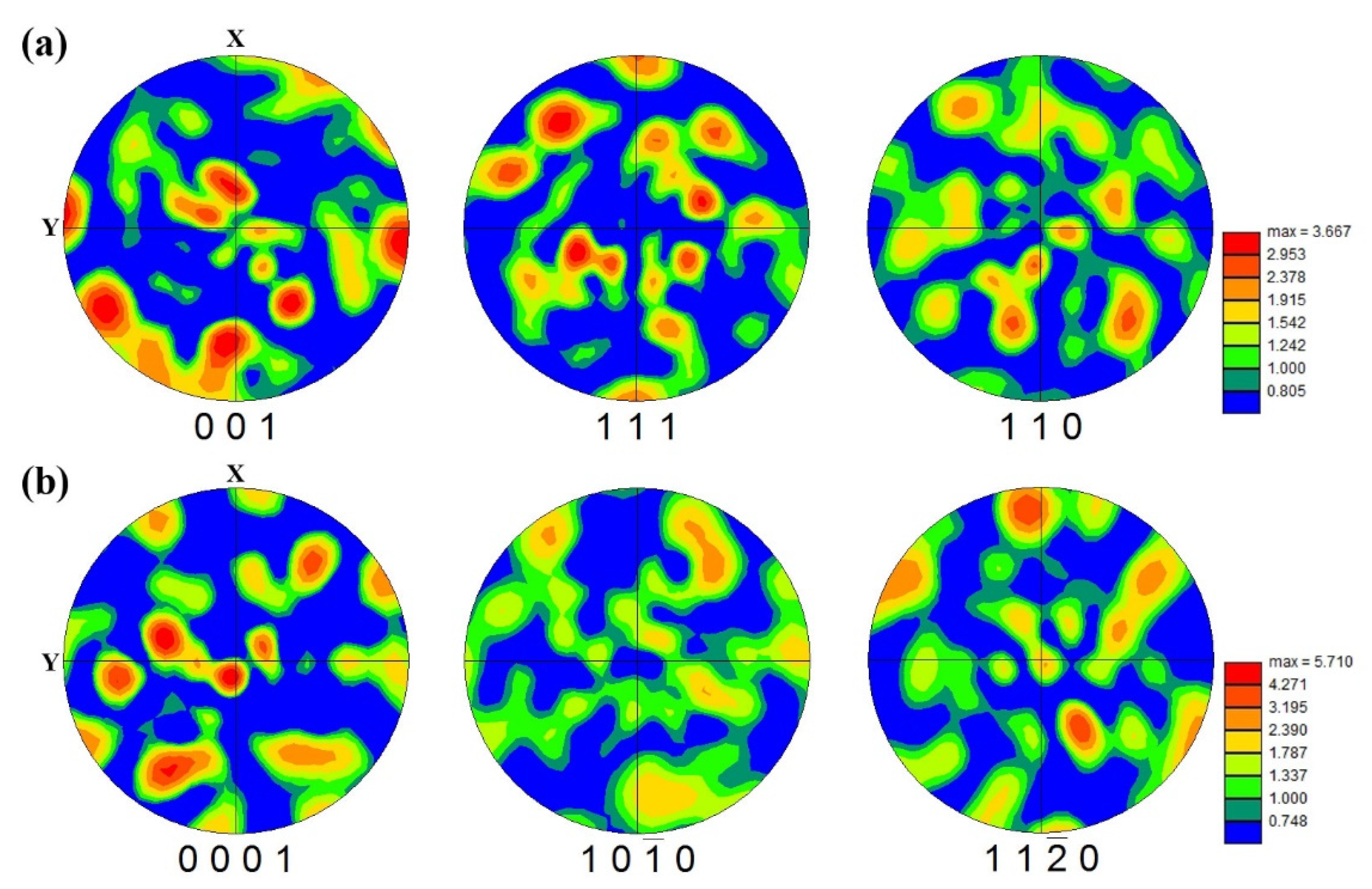

3.2.2. Aged Samples

3.3. Microstructural Characteristics

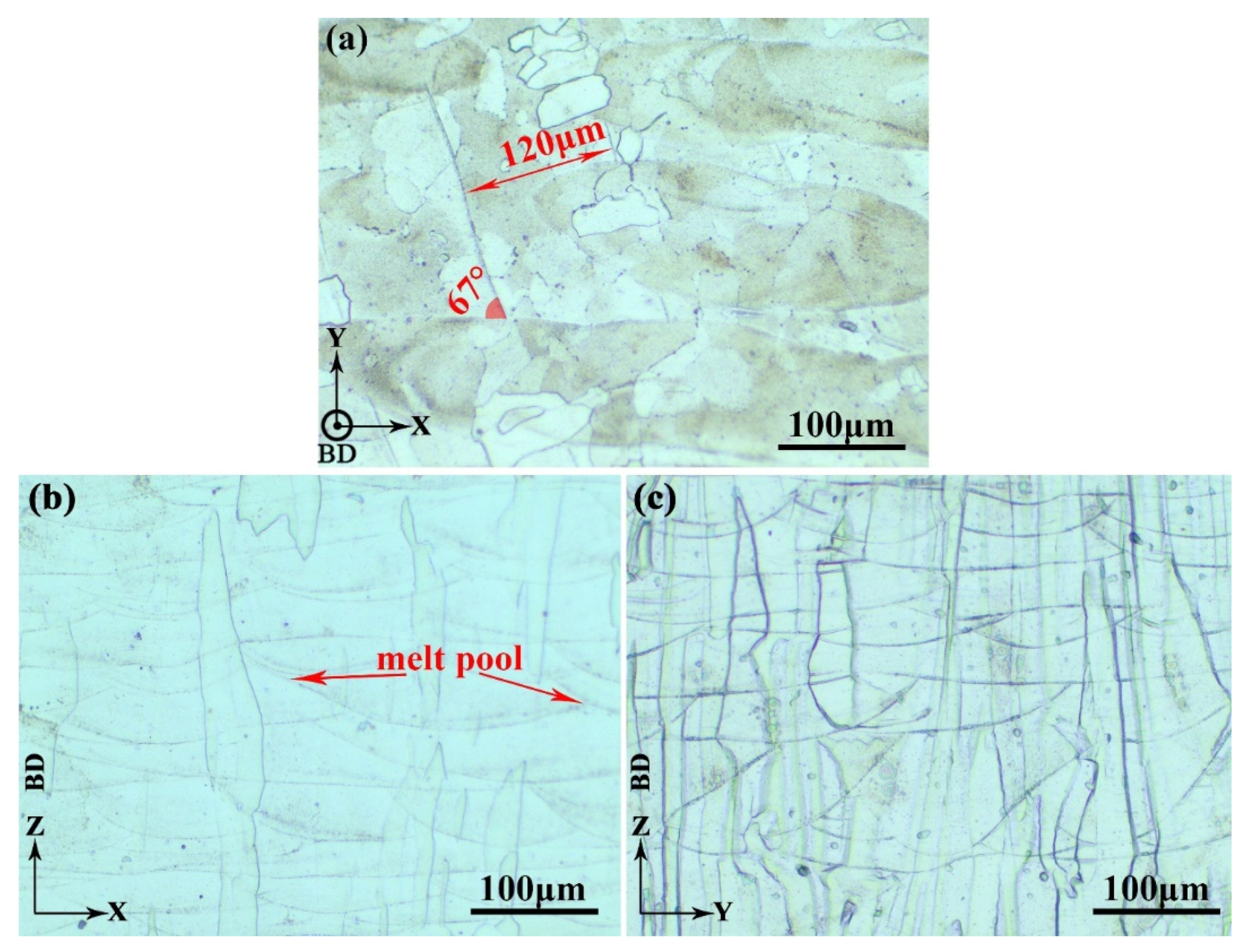

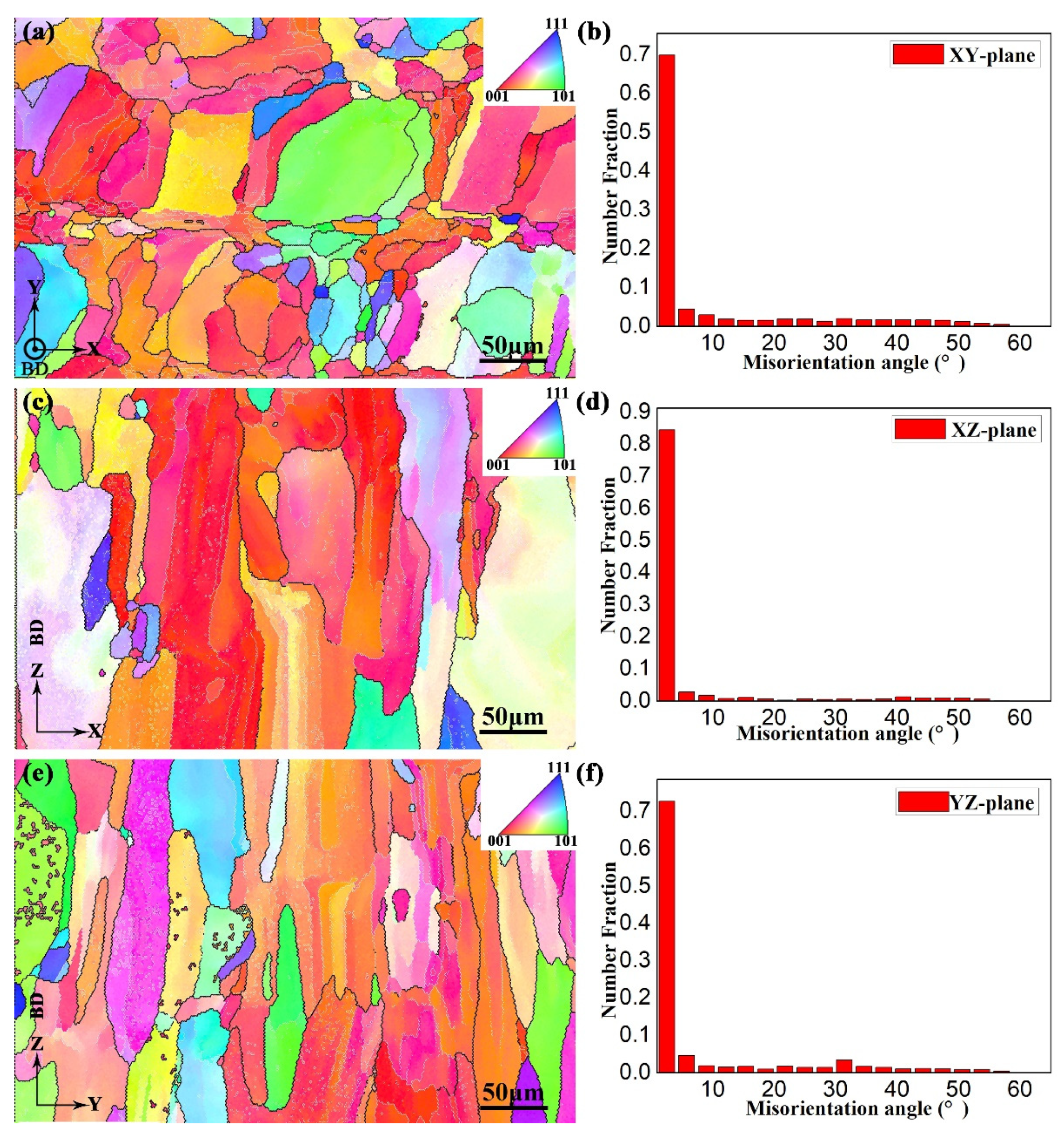

3.3.1. As-Fabricated Samples

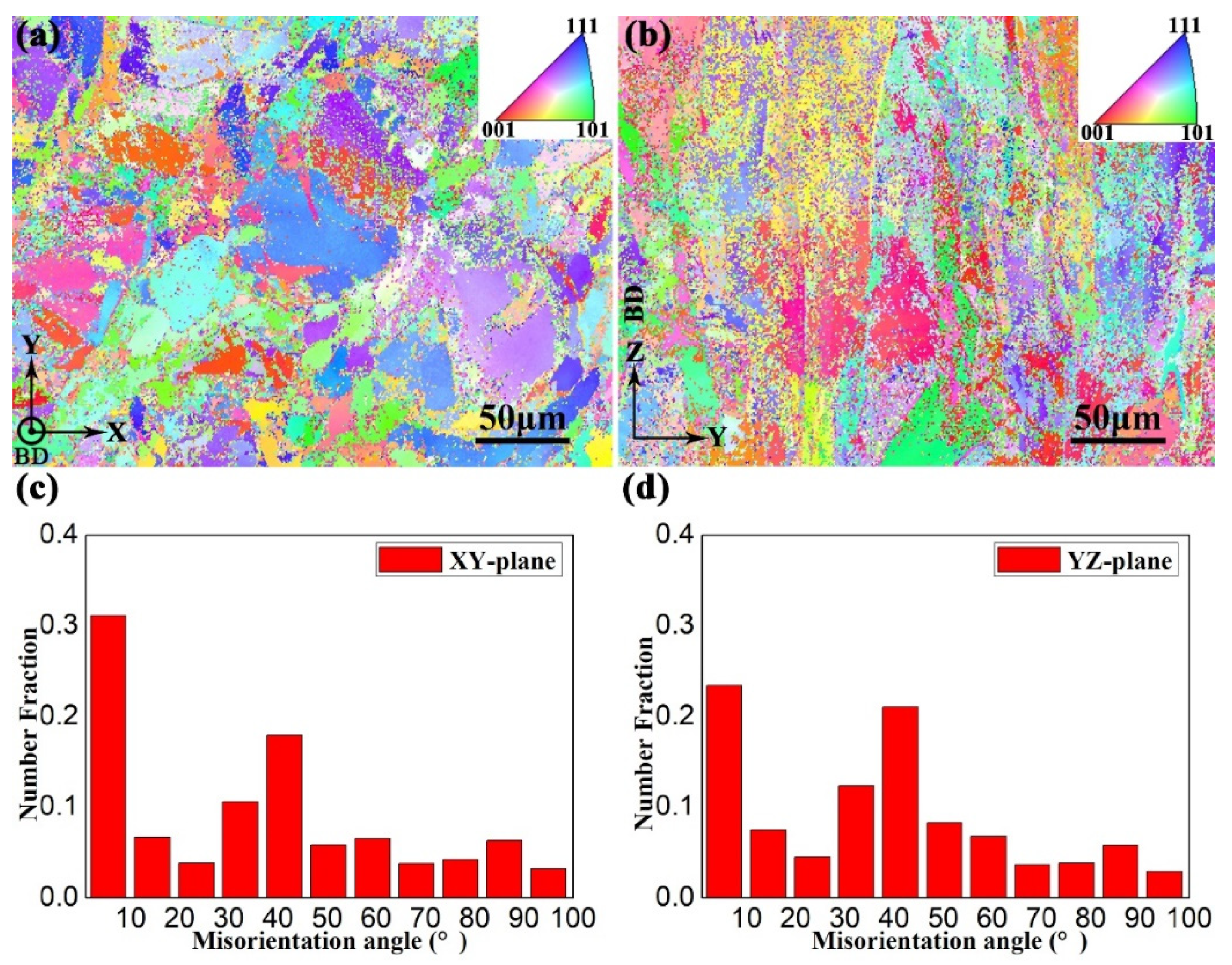

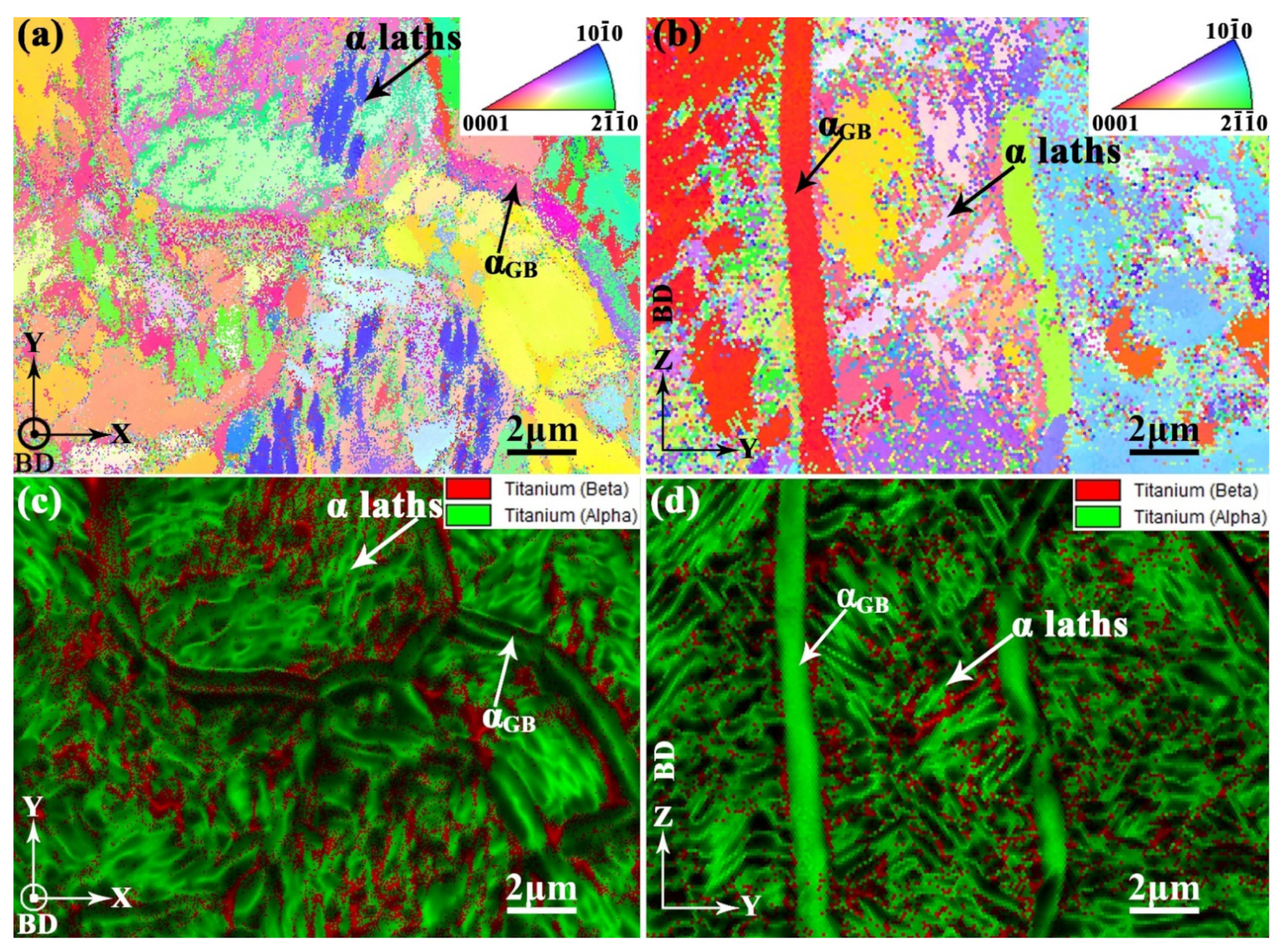

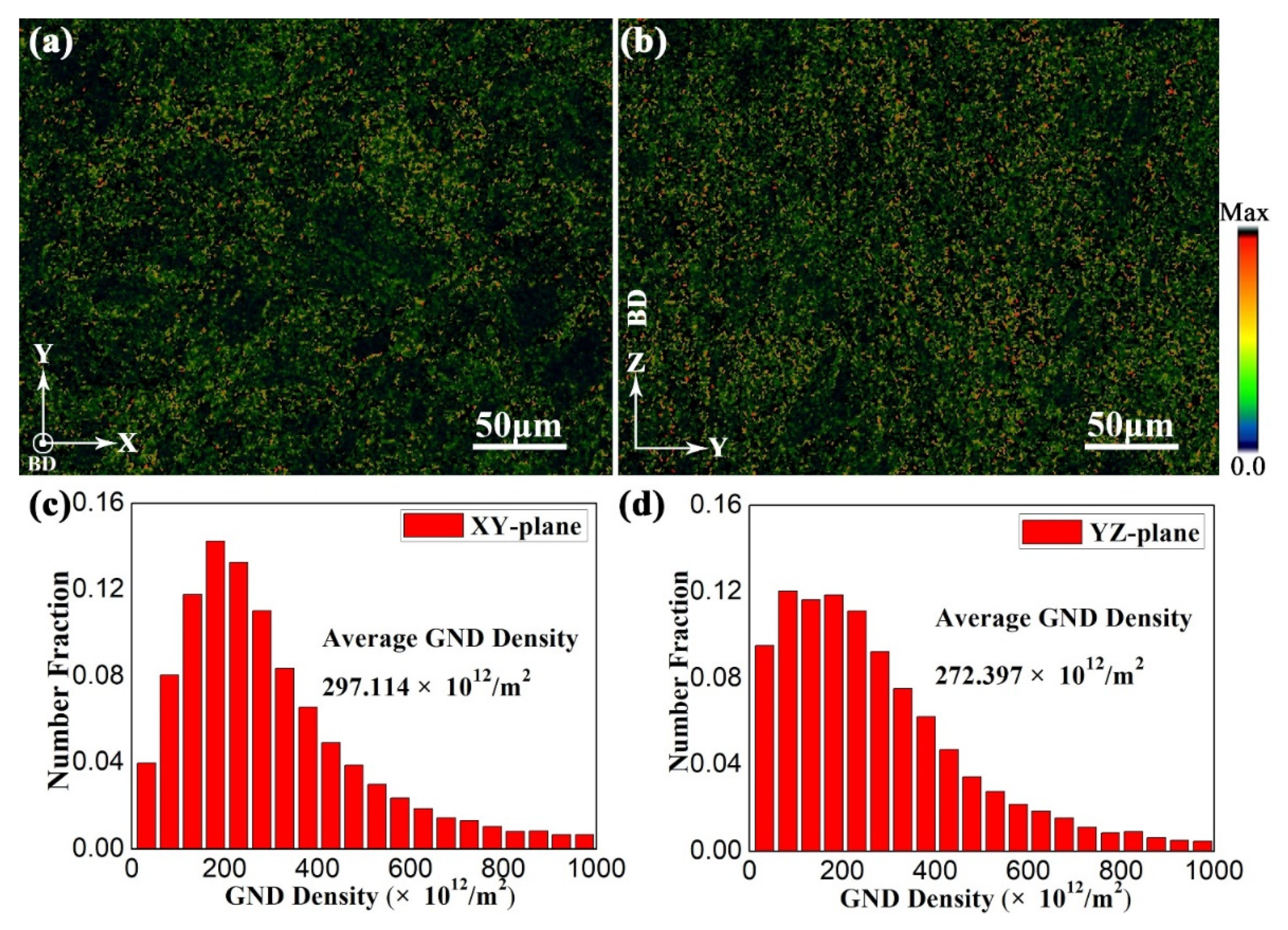

3.3.2. Aged Samples

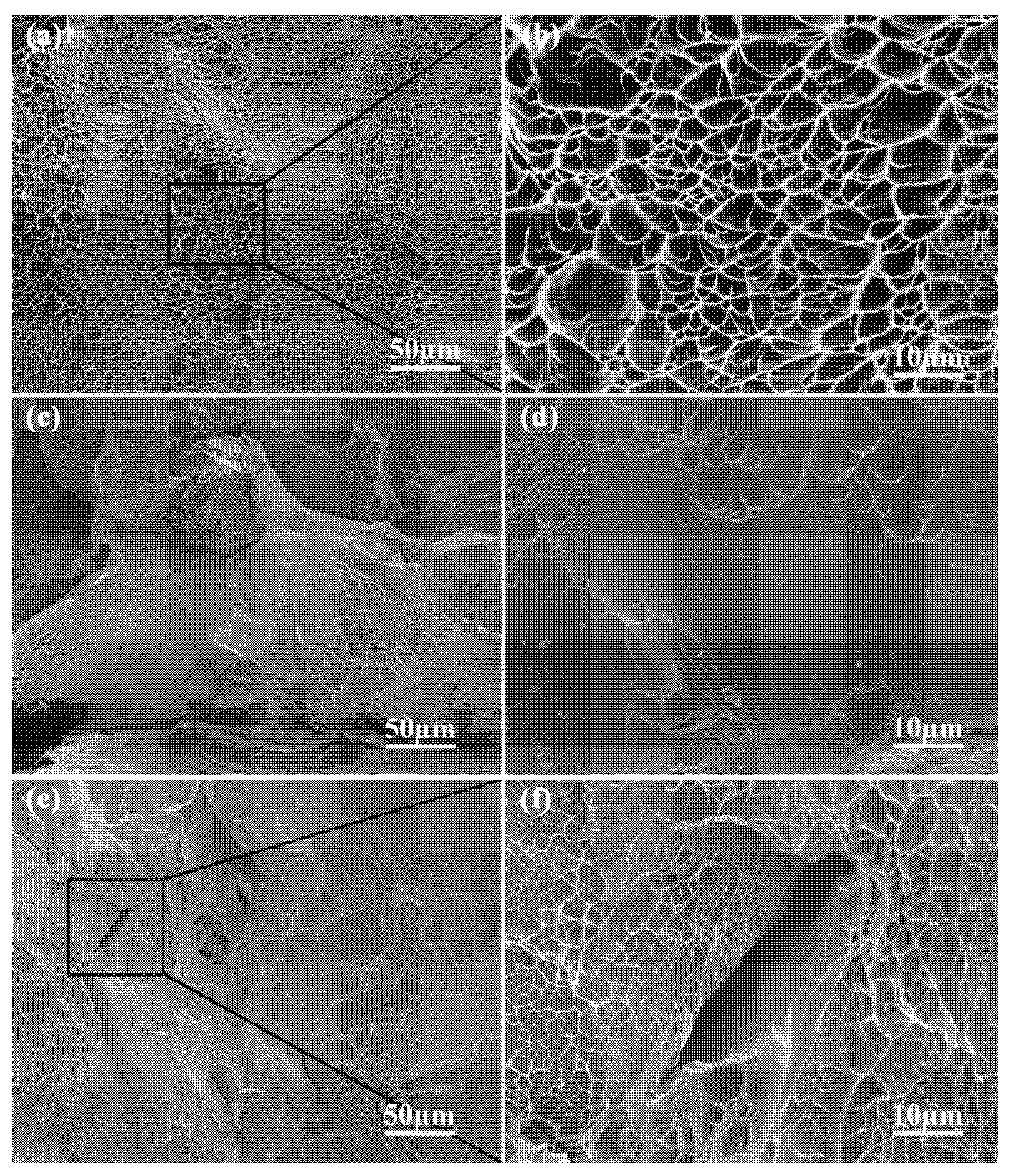

3.4. Tensile Properties

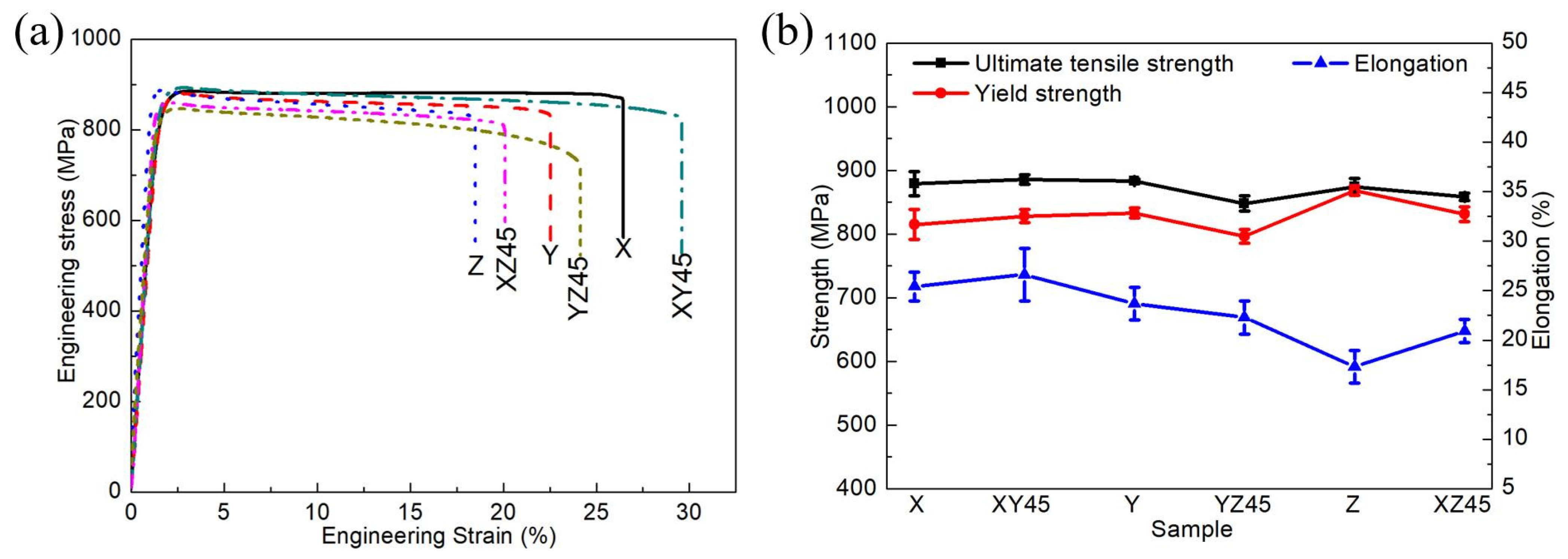

3.4.1. As-Fabricated Samples

3.4.2. Aged Samples

4. Conclusions

- The SLMed Ti-55511 alloy before the aging treatment exhibits slight anisotropy in its mechanical properties. The orientations within the XY-plane have a shallow effect on the mechanical properties. The yield strength of the vertical samples (868.2 ± 7.4 MPa) is slightly higher than that of the horizontal samples (815.0 ± 23.6 MPa); however, the vertical samples exhibit a similar ultimate tensile strength (874.5 ± 13.1 MPa) and lower ductility (17.3 ± 1.6%) compared with the horizontal samples (879.4 ± 19.2 MPa and 25.4 ± 1.5%).

- The anisotropy of the SLMed Ti-55511 alloy reduces after the aging treatment. The ultimate tensile strength and yield strength of the aged samples (1133~1166 MPa and 1093~1123 MPa) are significantly higher than those of as-fabricated samples (848~886 MPa and 797~868 MPa); however, the aged samples exhibit a lower ductility (13~16%) compared with the as-fabricated samples (17~27%). In the meantime, the mechanical properties of the aged samples meet the aerospace allowable specification well.

- The as-fabricated Ti-55511 alloy exhibits a single β columnar structure with {001} fiber texture. The vertical samples (3.1 × 1015 m−2) exhibit a higher total dislocation density compared with the horizontal samples (2.2 × 1015 m−2), which results in an enhancement of the yield strength. In addition, the weak ductility of the vertical samples may be due to the low bonding ability between neighboring layers.

- The aged Ti-55511 alloy exhibits α and prior-β structures with a weak texture. The total dislocation density of the aged samples (~134.8 × 1013 m−2) is significantly lower than that of the as-fabricated samples (~259.4 × 1013 m−2); however, the aged samples exhibit higher GND density (~28.5 × 1013 m−2) compared with the as-fabricated samples (~2.9 × 1013 m−2). Thus, a new approach to strengthening theory is proposed to explain the anisotropic mechanical properties of AM alloys, which was confirmed by the experimental investigations on the SLMed Ti-55511 alloy before and after the aging treatment.

Author Contributions

Funding

Conflicts of Interest

References

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 1: Distance from build plate and part size. Mater. Sci. Eng. A 2013, 573, 264–270. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Liu, J.; Wang, Q.; Gong, S. Effects of the crystallographic and spatial orientation of α lamellae on the anisotropic in-situ tensile behaviors of additive manufactured Ti–6Al–4V. J. Alloys Compd. 2021, 850, 156886. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- de Formanoir, C.; Michotte, S.; Rigo, O.; Germain, L.; Godet, S. Electron beam melted Ti–6Al–4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 652, 105–119. [Google Scholar] [CrossRef]

- Wang, K.; Baoa, R.; Liub, D. Plastic anisotropy of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe titanium alloy. Mater. Sci. Eng. A 2019, 746, 276–289. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmera, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Li, R.; Tang, J.; Wang, M. Anisotropic mechanical behavior of biomedical Ti–13Nb–13Zr alloy manufactured by selective laser melting. J. Alloys Compd. 2018, 762, 289–300. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, J.; Zhao, Z.; Wang, L.; Wang, Q.; Yang, R. Microstructure and tensile property of TC4 alloy produced via electron beam rapid manufacturing. Acta Metall. Sin. 2019, 55, 692–700. [Google Scholar]

- Liu, Z.; Zhao, Z.; Liu, J.; Wang, L.; Yang, R. Effect of α texture on the tensile deformation behavior of Ti–6Al–4V alloy produced via electron beam rapid manufacturing. Mater. Sci. Eng. A 2019, 742, 508–516. [Google Scholar] [CrossRef]

- Hicks, C.; Sivaswamy, G.; Konkova, T.; Blackwell, P. Anisotropic tensile properties and failure mechanism of laser metal deposited Ti–5Al–5Mo–5V–3Cr alloy before and after sub-transus heat-treatment. Mater. Sci. Eng. A 2021, 825, 141928. [Google Scholar] [CrossRef]

- Zhang, W.; Qin, P.; Wang, Z.; Yang, C.; Kollo, L.; Grzesiak, D.; Prashanth, K. Superior Wear Resistance in EBM-Processed TC4 Alloy Compared with SLM and Forged Samples. Materials 2019, 12, 782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jones, R.; Rans, C.; Iliopoulos, A.P.; Michopoulos, J.G.; Peng, D. Modelling the Variability and the Anisotropic Behaviour of Crack Growth in SLM Ti–6Al–4V. Materials 2021, 14, 1400. [Google Scholar] [CrossRef]

- Kabir, M.R.; Richter, H. Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti–6Al–4V Alloy. Materials 2017, 10, 145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xi, J.; Hu, Y.; Xing, H.; Han, Y.; Zhang, H.; Jiang, J.; Nikbin, K. The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti–6Al–4V Alloy with Different Heat Treatment Methods. Materials 2021, 14, 6276. [Google Scholar] [CrossRef]

- Phutela, C.; Aboulkhair, N.T.; Tuck, C.J.; Ashcroft, I. The Effects of Feature Sizes in Selectively Laser Melted Ti–6Al–4V Parts on the Validity of Optimised Process Parameters. Materials 2020, 13, 117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An Assessment of Subsurface Residual Stress Analysis in SLM Ti–6Al–4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.M.; Wang, H.M.; Tian, X.J.; Tang, H.B.; Liu, D. Microstructure and tensile properties of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near beta titanium alloy. Mater. Sci. Eng. A 2013, 586, 323–329. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Tian, X.J.; Tang, H.B. Subtransus triplex heat treatment of laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mater. Sci. Eng. A 2014, 590, 30–36. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Tian, X.J.; Liu, D. Development of a pre-heat treatment for obtaining discontinuous grain boundary α in laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Sci. Eng. A 2014, 604, 176–182. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Liu, J.; Wang, Q.; Gong, S. Anisotropy in microstructure and tensile properties of Ti–5Al–5Mo–5V–1Cr–1Fe produced via additive manufacturing. Mater. Sci. Eng. A 2020, 798, 140093. [Google Scholar] [CrossRef]

- Madeja, M.; Karoluk, M.; Smolina, I. Welding of Ti–5Al–5Mo–5 V–1Cr–1Fe parts manufactured in the electron beam melting. Mater. Des. 2020, 195, 108969. [Google Scholar] [CrossRef]

- Li, D.; Huang, H.; Chen, C.; Liu, S.; Liu, X.; Zhang, X.; Zhou, K. Additive manufacturing of high strength near β titanium alloy Ti–55511 by engineering nanoscale secondary α laths via in-situ heat treatment. Mater. Sci. Eng. A 2021, 814, 141245. [Google Scholar] [CrossRef]

- Huang, H.; Li, D.; Chen, C.; Li, R.; Zhou, K. Selective laser melted near-beta titanium alloy Ti–5Al–5Mo–5V–1Cr–1Fe: Microstructure and mechanical properties. J. Cent. South Univ. 2021, 28, 1601–1614. [Google Scholar] [CrossRef]

- Qi, M.; Huang, S.; Ma, Y.; Youssef, S.S.; Zhang, R.; Qiu, J.; Lei, J.; Yang, R. Columnar to equiaxed transition during β heat treatment in a near β alloy by laser additive manufacture. J. Mater. Res. Technol. 2021, 13, 1159–1168. [Google Scholar] [CrossRef]

- Bai, H.J.; Deng, H.; Chen, L.Q.; Liu, X.; Cui, X. Effect of heat treatment on the microstructure and mechanical properties of selective laser-melted Ti64 and Ti–5Al–5Mo–5V–1Cr–1Fe. Metals—Open Access Metall. J. 2021, 11, 534. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, H.; Hosseini, S.R.E.; Chen, W.; Li, F.; Chen, C.; Zhou, K. Obtaining heterogeneous α laths in selective laser melted Ti–5Al–5Mo–5V–1Cr–1Fe alloy with high strength and ductility. Mater. Sci. Eng. A 2022, 835, 142624. [Google Scholar] [CrossRef]

- Shevel’kov, V.V.; Kratovich, L.F. Design strength of VT22 titanium alloy in different structural conditions. Sov. Mater. Sci. A Transl. Fiz.-Khimicheskaya Mekhanika Mater./Acad. Sci. Ukr. SSR 1991, 26, 687–691. [Google Scholar] [CrossRef]

- Cui, L.; Yu, C.H.; Jiang, S.; Sun, X.; Peng, R.L.; Lundgren, J.E.; Moverare, J. A new approach for determining GND and SSD densities based on indentation size effect: An application to additive-manufactured Hastelloy X. J. Mater. Sci. Technol. 2022, 96, 295–307. [Google Scholar] [CrossRef]

- Wang, L.; Song, Z.; Zhang, X.; Park, J.S.; Almer, J.; Zhu, G.; Chen, Y.; Li, Q.; Zeng, X.; Li, Y. Developing ductile and isotropic Ti alloy with tailored composition for laser powder bed fusion. Addit. Manuf. 2022, 52, 102656. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Wang, X.; Wang, P.; Li, R.; Zhang, X.; Zhou, K. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. A 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Chen, W.; Chen, C.; Zi, X.; Cheng, X.; Zhang, X.; Lin, Y.C.; Zhou, K. Controlling the microstructure and mechanical properties of a metastable β titanium alloy by selective laser melting. Mater. Sci. Eng. A 2018, 726, 240–250. [Google Scholar] [CrossRef]

- Sangid, M.D.; Book, T.A.; Naragani, D.; Naragani, D.; Rotella, J. Role of heat treatment and build orientation in the microstructure sensitive deformation characteristics of IN718 produced via SLM additive manufacturing. Addit. Manuf. 2018, 22, 479–496. [Google Scholar] [CrossRef]

- Aslan, E.; Zarbali, M. Tuning of photosensitivity and optical parameters of ZnO based photodetectors by co-Sn and Ti doping. Opt. Mater. 2022, 125, 112030. [Google Scholar] [CrossRef]

- Yang, X.; Ma, W.; Zhang, Z.; Liu, S.; Tang, H. Ultra-high specific strength Ti6Al4V alloy lattice material manufactured via selective laser melting. Mater. Sci. Eng. A 2022, 840, 142956. [Google Scholar] [CrossRef]

- Franz, S.; Perego, D.; Marchese, O.; Lucotti, A.; Bestetti, M. Photoactive TiO2 coatings obtained by Plasma Electrolytic Oxidation in refrigerated electrolytes. Appl. Surf. Sci. 2016, 385, 498–505. [Google Scholar] [CrossRef]

- Lekoui, F.; Amrani, R.; Filali, W.; Garoudja, E.; Sebih, L.; Bakouk, I.E.; Akkari, H.; Hassani, S.; Saoula, N.; Oussalah, S. Investigation of the effects of thermal annealing on the structural, morphological and optical properties of nanostructured Mn doped ZnO thin films. Opt. Mater. 2021, 118, 111236. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Chi, J.; Sun, R.; Che, Z.; Lin, L.; Peng, P.; Zhang, H.; Guo, W. Gradient microstructure evolution in laser shock peened Ti6Al4V titanium alloy. Surf. Coat. Technol. 2022, 437, 128378. [Google Scholar] [CrossRef]

- Nagase, T.; Hori, T.; Todai, M.; Sun, S.H.; Nakano, T. Additive manufacturing of dense components in beta-titanium alloys with crystallographic texture from a mixture of pure metallic element powders. Mater. Des. 2019, 173, 107771. [Google Scholar] [CrossRef]

- Zhao, G.H.; Liang, X.Z.; Kim, B.; Rivera-Diaz-Del-Castillo, P.E.J. Modelling strengthening mechanisms in beta-type Ti alloys. Mater. Sci. Eng. A 2019, 756, 156–160. [Google Scholar] [CrossRef]

- de Formanoir, C.; Martin, G.; Prima, F.; Allain, S.; Dessolier, T.; Sun, F.; Vivès, S.; Hary, B.; Bréchet, Y.; Godet, S. Micromechanical behavior and thermal stability of a dual-phase α+α′ titanium alloy produced by additive manufacturing. Acta Mater. 2019, 162, 149–162. [Google Scholar] [CrossRef] [Green Version]

- Dean, J. Lange’s Handbook of Chemistry, 16th ed.; Lange, N.A., Ed.; McGraw-Hill Education: New York, NY, USA, 2005. [Google Scholar]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Li, Y.; Ou, X.; Ni, S.; Min, S. Deformation behaviors of a hot rolled near-β Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Sci. Eng. A 2019, 742, 390–399. [Google Scholar] [CrossRef]

- Kaschel, F.R.; Vijayaraghavan, R.K.; Shmeliov, A.; McCarthy, E.K.; Canavan, M.; McNally, P.J.; Dowling, D.P.; Nicolosi, V.; Celikin, M. Mechanism of Stress Relaxation and Phase Transformation in Additively Manufactured Ti–6Al–4V via in situ High Temperature XRD and TEM Analyses. Acta Mater. 2020, 188, 720–732. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti–6Al–4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti–6Al–4V. Metall. Mater. Trans. 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Clark, D.; Whittaker, M.T.; Bache, M.R. Microstructural characterization of a prototype titanium alloy structure processed via direct laser deposition (DLD). Metall. Mater. Trans. B 2011, 43, 388–396. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Fanning, J.C. Properties of TIMETAL 555 (Ti–5Al–5Mo–5V–3Cr–0.6Fe). J. Mater. Eng. Perform. 2005, 14, 788–791. [Google Scholar] [CrossRef]

- Delincé, M.; Bréchet, Y.; Embury, J.D.; Geers, M.G.D.; Jacques, P.J.; Pardoen, T. Structure–property optimization of ultrafine-grained dual-phase steels using a microstructure-based strain hardening model. Acta Mater. 2007, 55, 2337–2350. [Google Scholar] [CrossRef]

- Bahador, A.; Issariyapat, A.; Umeda, J.; Yamanoglu, R.; Kondoh, K. Strength–ductility balance of powder metallurgy Ti–2Fe–2W alloy extruded at high-temperature. J. Mater. Res. Technol. 2021, 14, 677–691. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; da Silva, M.R.; Pardal, J.M.; Abreu, H.F.G.; Gomes, A.M. Microstructural changes produced by plastic deformation in the UNS S31803 duplex stainless steel. J. Mater. Process. Technol. 2006, 180, 318–322. [Google Scholar] [CrossRef]

- Kubin, L.; Devincre, B.; Hoc, T. Toward a physical model for strain hardening in fcc crystals. Mater. Sci. Eng. A 2008, 483–484, 19–24. [Google Scholar] [CrossRef]

- Zhu, C.; Harrington, T.; Gray, G.T., III; Vecchio, K.S. Dislocation-type evolution in quasi-statically compressed polycrystalline nickel. Acta Mater. 2018, 155, 104–116. [Google Scholar] [CrossRef]

- Cui, L.; Yu, J.; Liu, J.; Tao, J.; Sun, X. The creep deformation mechanisms of a newly designed nickel-base superalloy. Mater. Sci. Eng. A 2018, 710, 309–317. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, J.; Wei, H.; Gui, W.; Su, H.; Jin, T.; Liu, L. A phase-field model for creep behavior in nickel-base single-crystal superalloy: Coupled with creep damage. Scr. Mater. 2018, 147, 16–20. [Google Scholar] [CrossRef]

- Zhao, J.; Pan, X.; Li, J.; Huang, Z.; Kan, Q.; Kang, G.; Zhou, L.; Zhang, X. Laser shock peened Ti–6Al–4V alloy: Experiments and modeling. Int. J. Mech. Sci. 2022, 213, 106874. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density–induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, Y.J.; Sun, J.Q.; Guo, J.; Kan, X.F.; Yang, D.C. Mechanism of high yield strength and yield ratio of 316 L stainless steel by additive manufacturing. Mater. Sci. Eng. A 2019, 744, 773–777. [Google Scholar] [CrossRef]

- Dai, G.; Niu, J.; Guo, Y.; Sun, Z.; Dan, Z.; Chang, H.; Zhou, L. Microstructure evolution and grain refinement behavior during hot deformation of Fe micro-alloyed Ti–6Al–4V. J. Mater. Res. Technol. 2021, 15, 1881–1895. [Google Scholar] [CrossRef]

- Fang, M.; Hu, F.; Han, Y.; Le, J.; Xi, J.; Song, J.; Ke, L.; Xiao, M.; Lu, W. Controllable mechanical anisotropy of selective laser melted Ti6Al4V: A new perspective into the effect of grain orientations and primary grain structure. Mater. Sci. Eng. A 2021, 827, 142031. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Wang, D. A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 2016, 87, 647–656. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti–6Al–4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

| Type of AM Process | Condition | Specimen Orientation | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Reference |

| LMD | As-built | Vertical | - | 1178 ± 20 | 5 ± 0.8 | Liu et al., 2013 [19] |

| LMD | Heat treatment | Vertical | 1036 ± 15 | 1135 ± 7 | 10.7 ± 1.2 | Liu et al., 2014 [20] |

| LMD | Heat treatment | Vertical | 1067 ± 6 | 1111 ± 7 | 12.3 ± 0.6 | Liu et al., 2014 [21] |

| LMD | Heat treatment | Horizontal | 957.1 ± 0.007 | 994.0 ± 0.023 | 4.7 ± 0.367 | Wang et al., 2019 [7] |

| Angled (45°) | 1045.7 ± 0.011 | 1101.3 ± 0.010 | 4.7 ± 0.308 | |||

| Vertical | 924.2 ± 0.005 | 1004.2 ± 0.006 | 12.0 ± 0.075 | |||

| LMD | As-built | Horizontal | - | ~1010 | ~9.9 | Liu et al., 2020 [22] |

| Angled (45°) | - | ~1095 | ~4.9 | |||

| Vertical | - | ~980 | ~16.3 | |||

| EBM | As-built | Horizontal | 929 ± 23 | 1024 ± 21 | 14 ± 1 | Madeja et al., 2020 [23] |

| Angled (45°) | 994 ± 27 | 1059 ± 30 | 8 ± 2 | |||

| Vertical | 978 ± 26 | 1027 ± 31 | 7 ± 1 | |||

| EBM | As-built | Horizontal | - | 1042–1230 | 8–19 | Li et al., 2021 [24] |

| SLM | As-built | Horizontal | 801 ± 16 | 938 ± 4 | 18.5 ± 1.0 | Huang et al., 2021 [25] |

| SLM | As-built | Vertical | 789 ± 1.9 | 799 ± 2.5 | 15.9 ± 0.3 | |

| Heat treatment | 1195 ± 10.3 | 1245 ± 9.9 | 7.8 ± 0.5 | Bai et al., 2021 [27] | ||

| Heat treatment | 1295 ± 8.7 | 1320 ± 7.5 | 5.5 ± 0.1 | |||

| SLM | As-built | Horizontal | 853.1 ± 16.2 | 889.1 ± 18.7 | 19.4 ± 1.8 | Zhang et al., 2022 [28] |

| Heat treatment | Horizontal | 1235.1 ± 9.4 | 1264.3 ± 18.7 | 9.3 ± 0.7 |

| Element | Al | Mo | V | Cr | Fe | Si | Zr | C | O | N | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 5.20 | 4.93 | 5.0 | 1.10 | 0.96 | 0.02 | 0.01 | 0.01 | 0.1389 | 0.0152 | Bal. |

| Sample | UTS (MPa) | YS (MPa) | E (GPa) | Elongation (%) |

|---|---|---|---|---|

| X | 879.4 ± 19.2 | 815.0 ± 23.6 | 59.4 ± 8.6 | 25.4 ± 1.5 |

| Y | 883.3 ± 3.8 | 833.3 ± 7.6 | 61.3 ± 2.3 | 23.7 ± 1.7 |

| Z | 874.5 ± 13.1 | 868.2 ± 7.4 | 78.5 ± 7.9 | 17.3 ± 1.6 |

| XY45 | 885.9 ± 7.3 | 828.3 ± 10.4 | 62.7 ± 1.2 | 26.6 ± 2.6 |

| XZ45 | 858.7 ± 5.7 | 831.7 ± 11.6 | 69.7 ± 1.1 | 20.9 ± 1.2 |

| YZ45 | 848.1 ± 12.1 | 796.7 ± 10.4 | 64.7 ± 6.2 | 22.3 ± 1.7 |

| Sample | UTS (MPa) | YS (MPa) | E (GPa) | Elongation (%) |

|---|---|---|---|---|

| H-X | 1141.7 ± 11.6 | 1113.3 ± 15.3 | 104.4 ± 3.8 | 14.2 ± 0.9 |

| H-Y | 1145.5 ± 14.4 | 1110.0 ± 10.0 | 104.4 ± 1.8 | 13.3 ± 2.0 |

| H-Z | 1145.1 ± 26.4 | 1100.7 ± 26.9 | 110.7 ± 7.1 | 15.9 ± 1.7 |

| H-XY45 | 1132.5 ± 11.5 | 1093.3 ± 11.6 | 98.3 ± 2.2 | 13.4 ± 1.9 |

| H-XZ45 | 1152.1 ± 21.3 | 1116.7 ± 15.3 | 100.5 ± 4.2 | 15.4 ± 1.4 |

| H-YZ45 | 1165.6 ± 12.9 | 1123.3 ± 5.8 | 99.8 ± 2.6 | 15.6 ± 0.9 |

| Sample | 2θ° for (110) | a (Å) | FWHM for (110) | Average Crystallite Size (nm) | Average Strain (10−3) | Average Dislocation Density (1015 Line/m2) | Intensity Ratio f (%) |

|---|---|---|---|---|---|---|---|

| Powder | 39.160 | 3.251 | 0.201 | 37.242 | 2.067 | 0.684 | 76.047 |

| X | 39.280 | 3.241 | 0.382 | 21.109 | 3.677 | 2.164 | 38.522 |

| Y | 39.241 | 3.244 | 0.347 | 20.711 | 3.709 | 2.222 | 71.272 |

| Z | 39.240 | 3.244 | 0.355 | 18.004 | 4.332 | 3.138 | 89.574 |

| XY45 | 39.280 | 3.241 | 0.420 | 20.838 | 3.752 | 2.249 | 33.711 |

| XZ45 | 39.300 | 3.239 | 0.414 | 18.218 | 4.237 | 2.894 | 71.185 |

| YZ45 | 39.260 | 3.243 | 0.413 | 18.305 | 4.317 | 2.897 | 88.354 |

| Sample | 2θ° for (110) | a (Å) | FWHM for (110) | Average Crystallite Size (nm) | Average Strain (10−3) | Average Dislocation Density (1015 Line/m2) | Intensity Ratio f (%) |

|---|---|---|---|---|---|---|---|

| H-X | 39.619 | 3.214 | 0.294 | 25.950 | 2.991 | 1.461 | 18.268 |

| H-Y | 39.599 | 3.216 | 0.286 | 26.131 | 3.009 | 1.502 | 58.364 |

| H-Z | 39.560 | 3.219 | 0.279 | 25.848 | 3.128 | 1.679 | 80.540 |

| H-XY45 | 39.539 | 3.221 | 0.309 | 26.420 | 3.009 | 1.487 | 31.095 |

| H-XZ45 | 39.580 | 3.217 | 0.262 | 26.663 | 3.256 | 1.578 | 80.734 |

| H-YZ45 | 39.601 | 3.216 | 0.251 | 25.658 | 3.026 | 1.543 | 81.184 |

| Sample | 2θ° for (002) | c (Å) | FWHM for (101) | c/a | Average Crystallite Size (nm) | Average Strain (10−3) | Average Dislocation Density (1015 Line/m2) | Intensity Ratio f (%) |

|---|---|---|---|---|---|---|---|---|

| H-X | 38.421 | 4.682 | 0.326 | 1.597 | 29.670 | 2.917 | 1.241 | 28.387 |

| H-Y | 38.480 | 4.675 | 0.303 | 1.596 | 29.152 | 2.956 | 1.265 | 37.782 |

| H-Z | 38.500 | 4.673 | 0.29 | 1.597 | 28.204 | 3.064 | 1.357 | 46.695 |

| H-XY45 | 38.441 | 4.680 | 0.298 | 1.598 | 29.980 | 2.896 | 1.232 | 41.101 |

| H-XZ45 | 38.420 | 4.682 | 0.304 | 1.598 | 28.741 | 3.050 | 1.318 | 41.201 |

| H-YZ45 | 38.480 | 4.675 | 0.281 | 1.597 | 29.182 | 3.013 | 1.328 | 37.104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Zhang, T.; Chen, C.; Hosseini, S.R.E.; Zhang, J.; Zhou, K. Anisotropy in the Tensile Properties of a Selective Laser Melted Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Treatment. Materials 2022, 15, 5493. https://doi.org/10.3390/ma15165493

Huang H, Zhang T, Chen C, Hosseini SRE, Zhang J, Zhou K. Anisotropy in the Tensile Properties of a Selective Laser Melted Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Treatment. Materials. 2022; 15(16):5493. https://doi.org/10.3390/ma15165493

Chicago/Turabian StyleHuang, Hualong, Taomei Zhang, Chao Chen, Seyed Reza Elmi Hosseini, Jiaqi Zhang, and Kechao Zhou. 2022. "Anisotropy in the Tensile Properties of a Selective Laser Melted Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Treatment" Materials 15, no. 16: 5493. https://doi.org/10.3390/ma15165493