Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy

Abstract

:1. Introduction

2. Experimental Methods

3. Results and Discussions

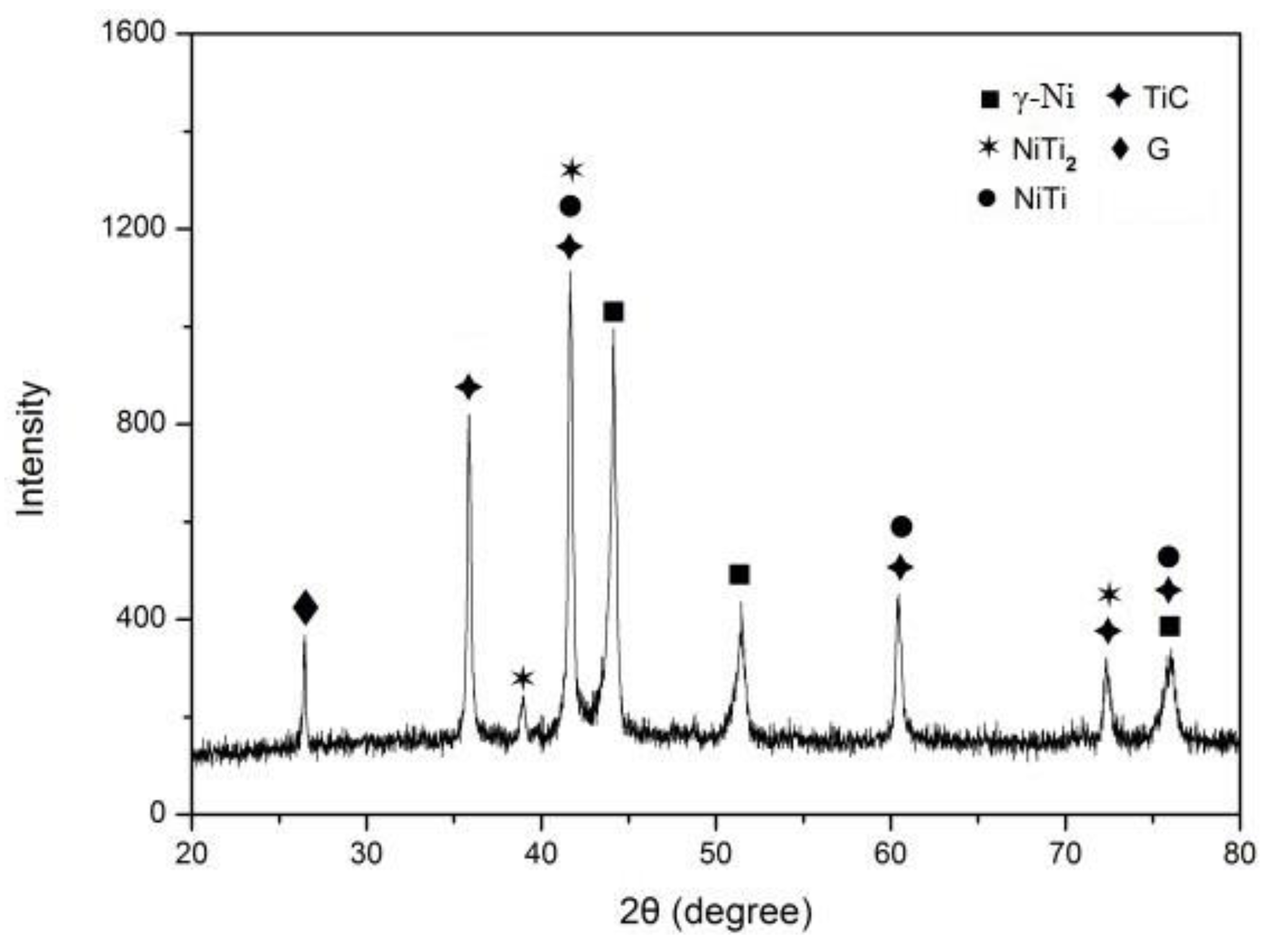

3.1. XRD Analysis

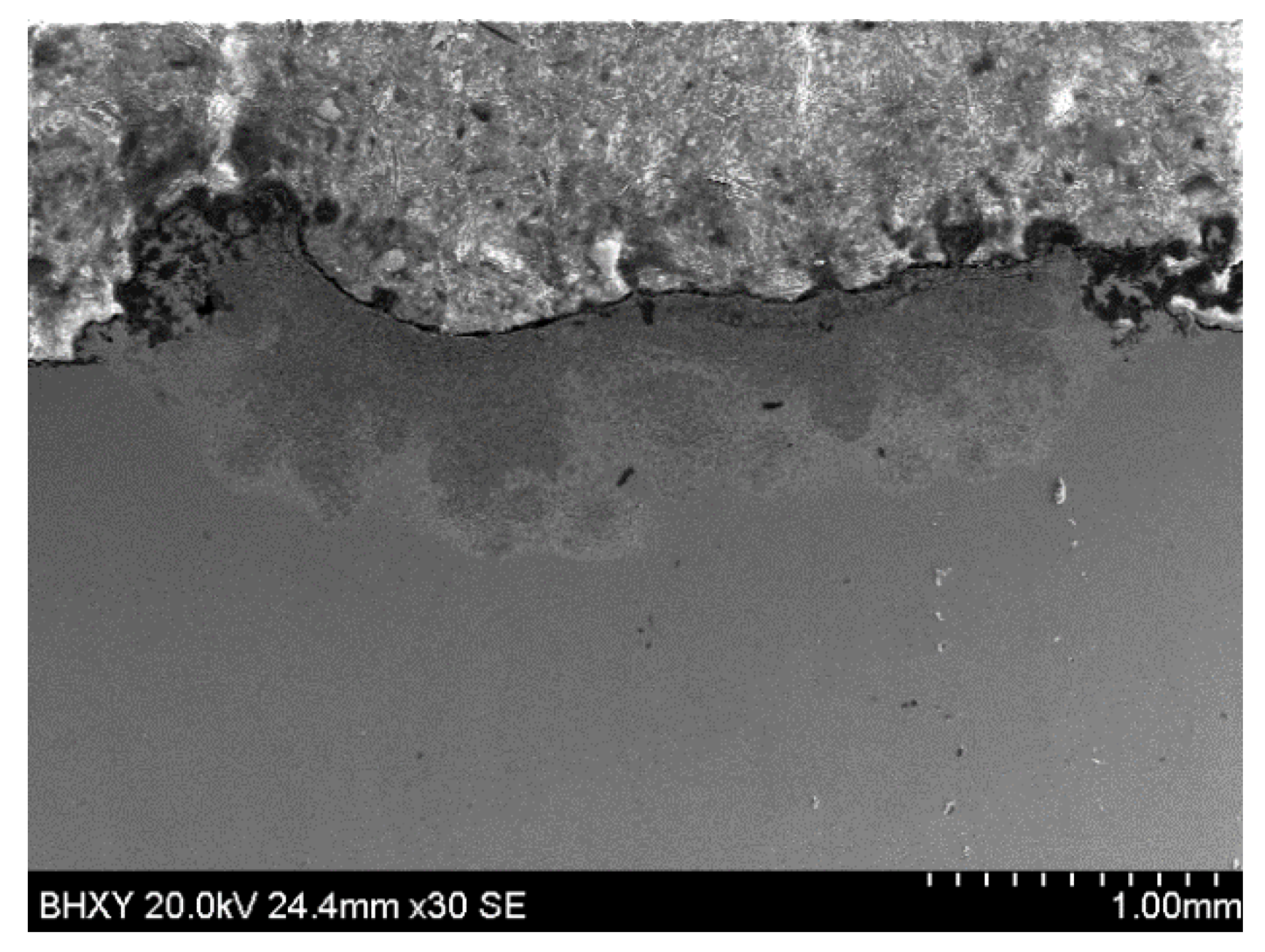

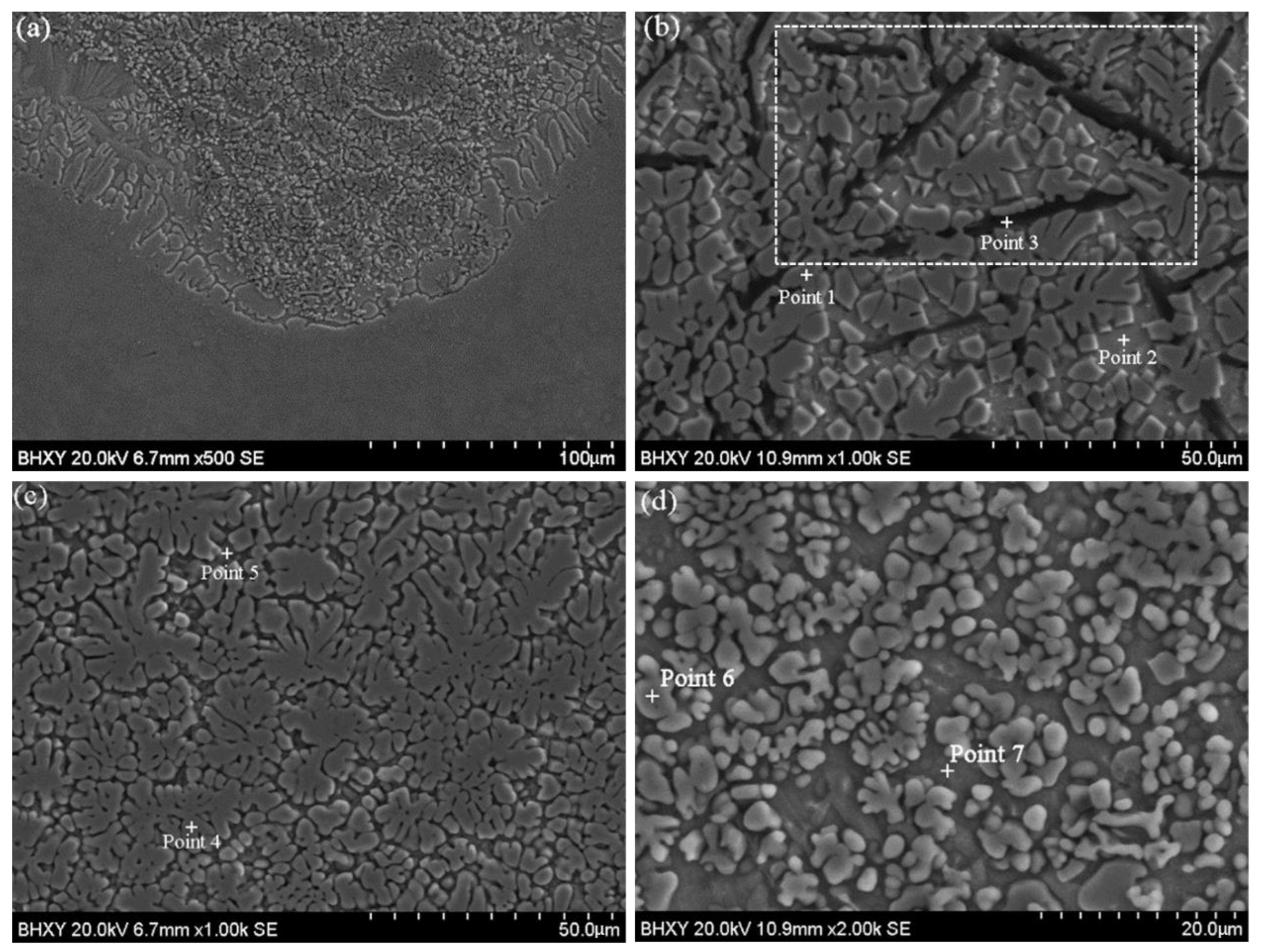

3.2. SEM Analysis

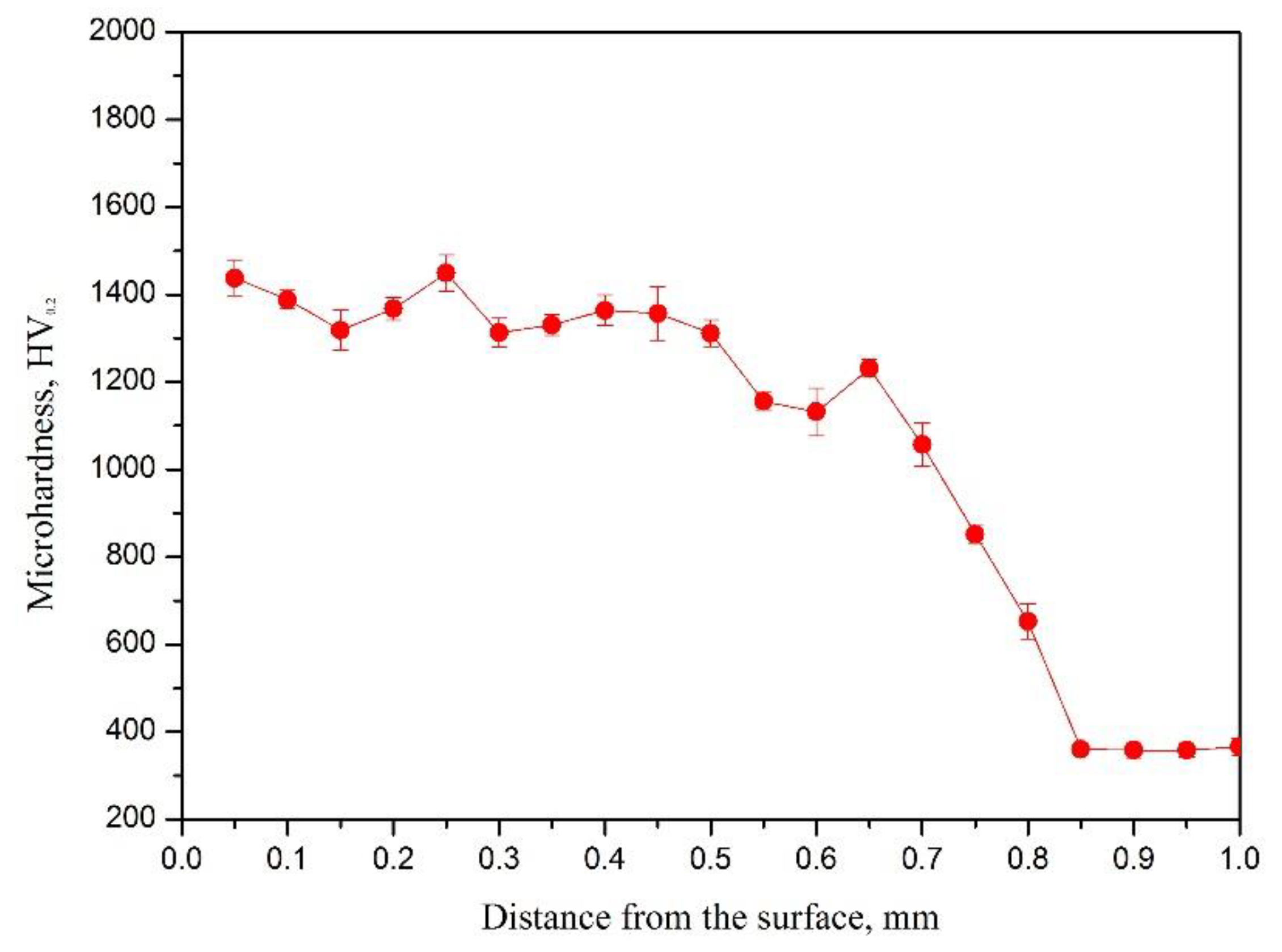

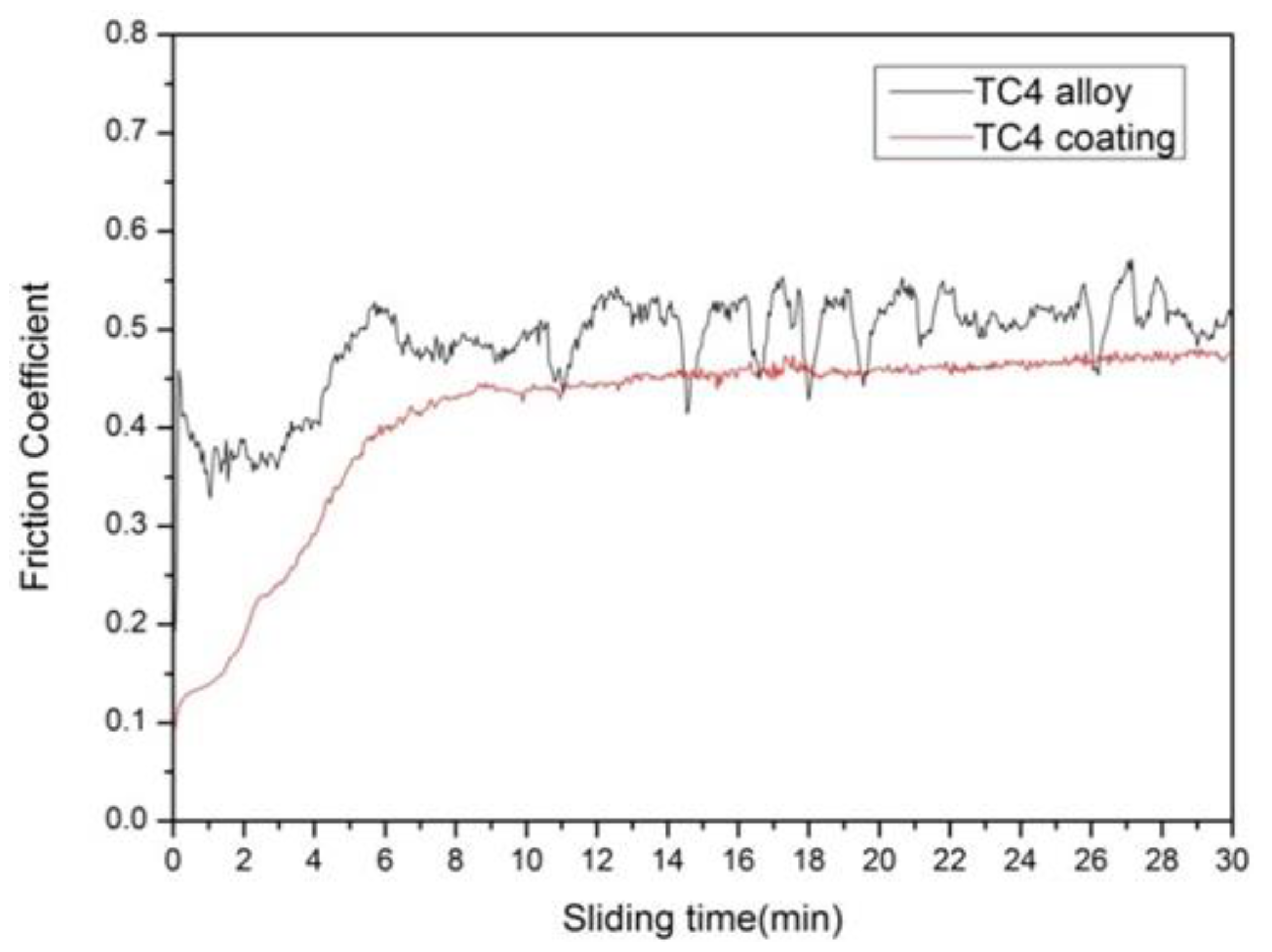

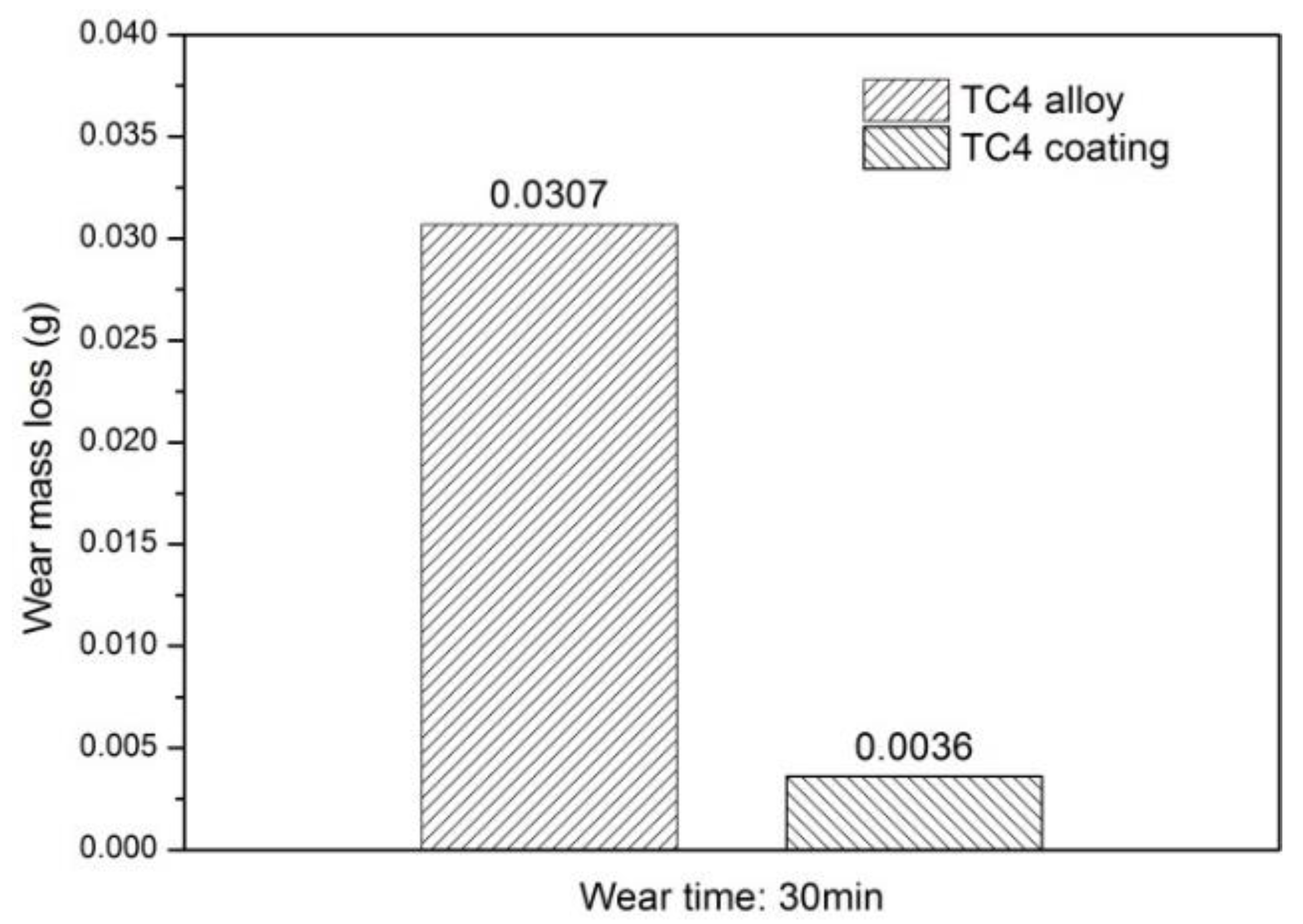

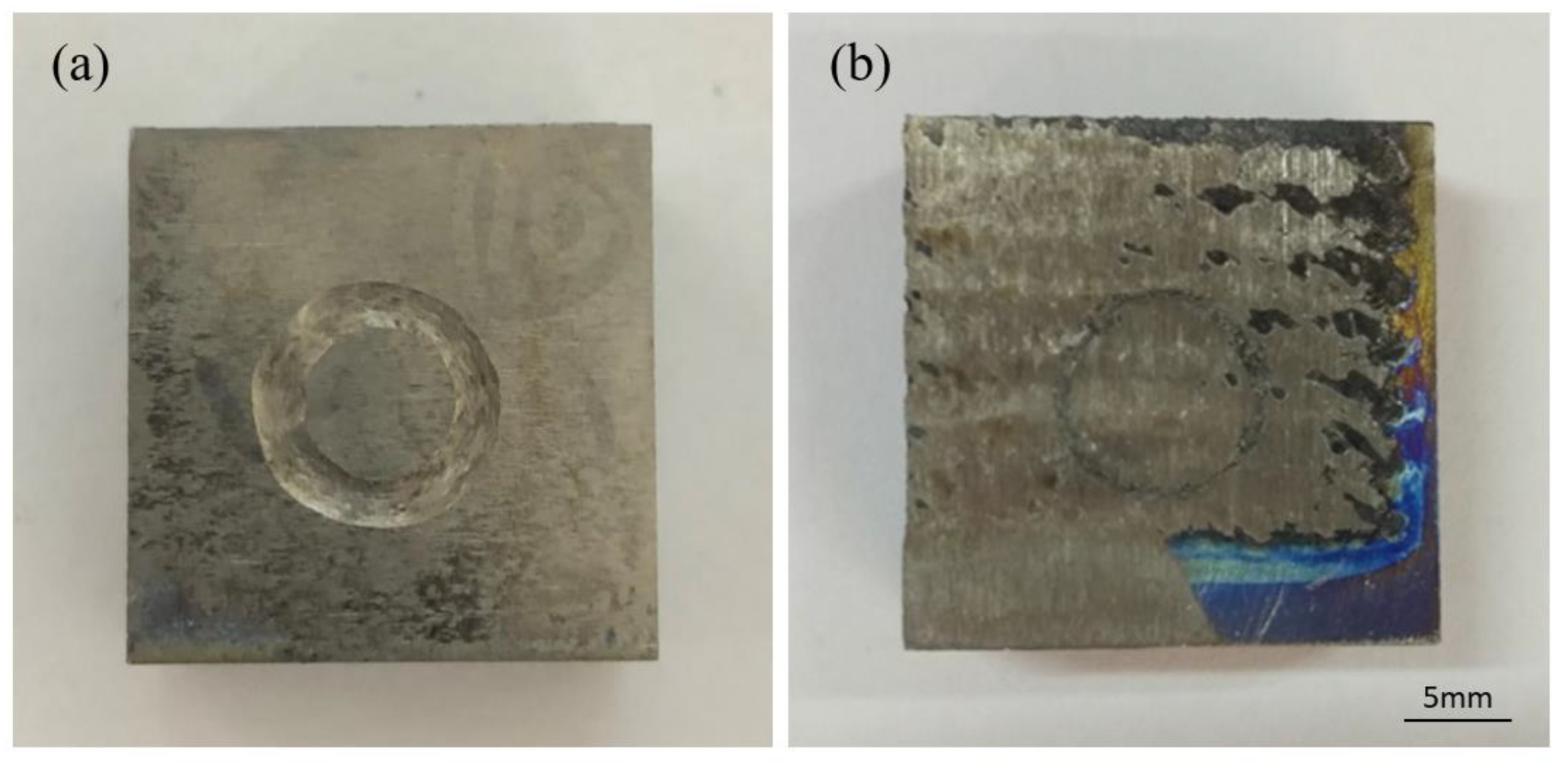

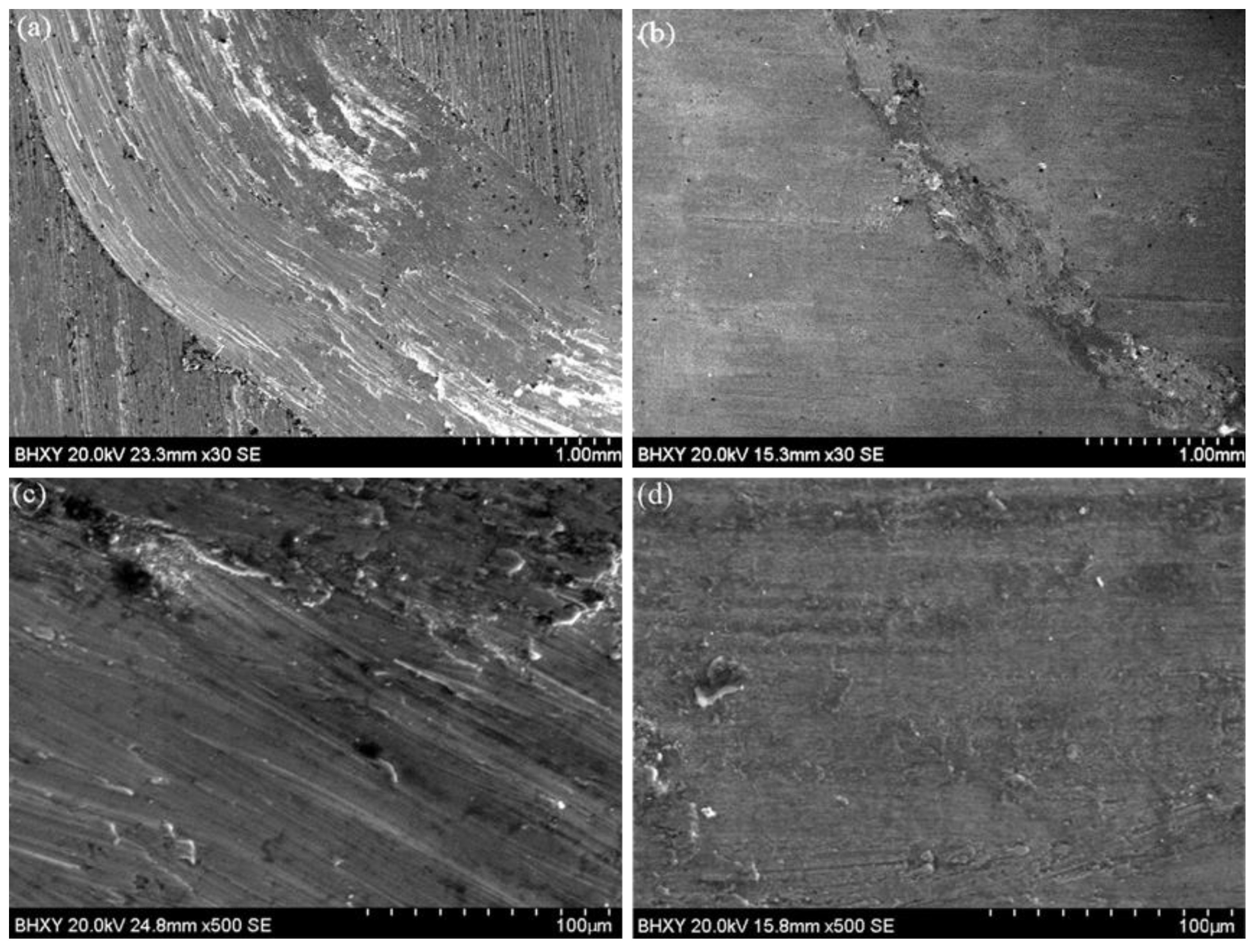

3.3. Micro-Hardness and Wear Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Attar, H.; Prashanth, K.G.; Chaubey, A.K.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Comparison of wear properties of commercially pure titanium prepared by selective laser melting and casting processes. Mater. Lett. 2015, 142, 38–41. [Google Scholar] [CrossRef]

- Alabort, E.; Tang, Y.T.; Barba, D.; Reed, R.C. Alloys-by-design: A low-modulus titanium alloy for additively manufactured biomedical implants. Acta Mater. 2022, 229, 117749. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Mordike, B.L.; Manna, I. Friction and wear behavior of Ti following laser surface alloying with Si, Al and Si+Al. Wear 2000, 242, 18–27. [Google Scholar] [CrossRef]

- DuttaMajumdar, J.; Li, L. Development of titanium boride (TiB) dispersed titanium (Ti) matrix composite by direct laser cladding. Mater. Lett. 2010, 64, 1010–1012. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.H.; Tseng, S.P. Characterization and tribological evaluation of NiCrMoNb and NiCrBSiC laser cladding on near-α titanium alloy. Int. J. Adv. Manuf. Technol. 2020, 106, 2347–2361. [Google Scholar] [CrossRef]

- Kim, T.S.; Park, Y.G.; Wey, M.Y. Characterization of Ti-6Al-4V alloy modified by plasma carburizing process. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2003, 361, 275–280. [Google Scholar] [CrossRef]

- Li, X.Y.; Taniguchi, S.; Zhu, Y.C.; Fujita, K.; Iwamoto, N.; Matsunaga, Y.; Nakagawa, K. Oxidation behavior of TiAl protected by Si plus Nb combined ion implantation. Intermetallics 2001, 9, 443–449. [Google Scholar] [CrossRef]

- Campanelli, L.C.; Duarte, L.T.; Carvalho, P.S.; Bolfarini, C. Fatigue behavior of modified surface of Ti-6Al-7Nb and CP-Ti by micro-arc oxidation. Mater. Des. 2014, 64, 393–399. [Google Scholar] [CrossRef]

- Meng, Q.W.; Geng, L.; Zhang, B.Y. Laser cladding of Ni-base composite coatings onto Ti–6Al–4V substrates with pre-placed B4C+NiCrBSi powders. Surf. Coat. Technol. 2006, 200, 4923–4928. [Google Scholar] [CrossRef]

- Ramani, R.; Saparia, A.; Markna, J. Effect of Nanocoating (CuO Nanoparticles) on the Performance of Solar Evacuated Tube. J. Sustain. Mater. Process. Manag. 2022, 2, 64–71. [Google Scholar] [CrossRef]

- Sadeq, F.O.; Sharifitabar, M.; Afarani, M.S. Synthesis of Ti–Si–Al coatings on the surface of Ti–6Al–4V alloy via hot dip siliconizing route. Surf. Coat. Technol. 2018, 337, 349–356. [Google Scholar] [CrossRef]

- Li, S.; Yamaguchi, T. High-temperature oxidation performance of laser-cladded amorphous TiNiSiCrCoAl high-entropy alloy coating on Ti-6Al-4V surface. Surf. Coat. Technol. 2022, 433, 128123. [Google Scholar] [CrossRef]

- Dai, J.; Zhang, F.; Wang, A.; Yu, H.; Chen, C. Microstructure and properties of Ti-Al coating and Ti-Al-Si system coatings on Ti-6Al-4V fabricated by laser surface alloying. Surf. Coat. Technol. 2017, 309, 805–813. [Google Scholar] [CrossRef]

- Saleh, A.F.; Abboud, J.H.; Benyounis, K.Y. Surface carburizing of Ti–6Al–4V alloy by laser melting. Opt. Lasers Eng. 2010, 48, 257–267. [Google Scholar] [CrossRef]

- Makuch, N.; Kulka, M.; Dziarski, P.; Przestacki, D. Laser surface alloying of commercially pure titanium with boron and carbon. Opt. Lasers Eng. 2014, 57, 64–81. [Google Scholar] [CrossRef]

- Filip, R.; Sieniawski, J.; Pleszakov, E. Formation of surface layers on Ti–6Al–4V titanium alloy by laser alloying. Surf. Eng. 2006, 22, 53–57. [Google Scholar] [CrossRef]

- Chehrghani, A.; Torkamany, M.J.; Hamedi, M.J.; Sabbaghzadeh, J. Numerical modeling and experimental investigation of TiC formation on titanium surface pre-coated by graphite under pulsed laser irradiation. Appl. Surf. Sci. 2012, 258, 2068–2076. [Google Scholar] [CrossRef]

- Dahotre, S.N.; Vora, H.D.; Pavani, K.; Banerjee, R. An integrated experimental and computational approach to laser surface nitriding of Ti–6Al–4V. Appl. Surf. Sci. 2013, 271, 141–148. [Google Scholar] [CrossRef]

- Kulka, M.; Makuch, N.; Dziarski, P.; Piasecki, A.; Miklaszewski, A. Microstructure and properties of laser-borided composite layers formed on commercially pure titanium. Opt. Laser Technol. 2014, 56, 409–424. [Google Scholar] [CrossRef]

- Lin, Y.; Yao, J.; Lei, Y.; Fu, H.; Wang, L. Microstructure and properties of TiB2–TiB reinforced titanium matrix composite coating by laser cladding. Opt. Lasers Eng. 2016, 86, 216–227. [Google Scholar] [CrossRef]

- Li, J.; Yu, Z.; Wang, H. Wear behaviors of an (TiB+TiC)/Ti composite coating fabricated on Ti6Al4V by laser cladding. Thin Solid Film. 2011, 519, 4804–4808. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Jiang, Y.; Zhou, R. Microstructure and high temperature oxidation resistance of in-situ synthesized TiN/Ti3Al intermetallic composite coatings on Ti6Al4V alloy by laser cladding process. J. Alloys Compd. 2016, 670, 268–274. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Akhtar, S.S.; Matthews, A.; Karatas, C.; Leyland, A. Microstructure and thermal stress distributions in laser carbonitriding treatment of Ti–6Al–4V alloy. J. Manuf. Sci. Eng. 2011, 133. [Google Scholar] [CrossRef]

- Li, W.; Yu, H.; Chen, C.; Wang, D. Microstructure characteristics of laser alloying composite coatings in nitrogen protective atmosphere. Sci. Eng. Compos. Mater. 2013, 20, 129–133. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A.; Ronkainen, H. Coatings tribology-contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar] [CrossRef]

- Peddiraju, V.C.; Pulapakura, K.K.; Jagadeesh, D.S.; Athira, K.S.; Gudur, S.; Suryakumar, S.; Chatterjee, S. Weld deposition of nickel on titanium for surface hardening with Ti-Ni-based intermetallic compounds. Mater. Today Proc. 2020, 27, 2096–2100. [Google Scholar] [CrossRef]

- Lou, M.; Alpas, A.T. High temperature wear mechanisms in thermally oxidized titanium alloys for engine valve applications. Wear 2019, 426, 443–453. [Google Scholar] [CrossRef]

- Gao, F.; Wang, H.M. Effect of TiNi in dry sliding wear of laser melt deposited Ti2Ni/TiNi alloys. Mater. Charact. 2008, 59, 1349–1354. [Google Scholar] [CrossRef]

- Sun, R.; Yang, X. Microstructure and wear resistance of laser clad TiC+Ti and TiC+NiCrBSi composite layers on Ti-6Al-4V alloy. Trans. Mater. Heat Treat. 2006, 27, 96–99. [Google Scholar] [CrossRef] [Green Version]

- Jin, Y.X.; Zhang, H.; Zeng, S.Y.; Zhang, E.L.; Li, Q.F. Study of Growth Habit of TiC in TiCp/Ti Composites. Acta Metall. Sin. 2002, 11, 1223–1227. [Google Scholar]

- Liu, Y.; Sun, R.; Zhang, T. Influence of Ni on TiC Growth in Rare Earth Laser Clad Layer on Titanium Alloy. Heat Treat. Met. 2018, 43, 16–21. [Google Scholar]

- Poondla, N.; Srivatsan, T.S.; Patnaik, A.; Petraroli, M. A study of the microstructure and hardness of two titanium alloys: Commercially pure and Ti–6Al–4V. J. Alloys Compd. 2009, 486, 162–167. [Google Scholar] [CrossRef]

- Li, D.M.; Sun, X.F.; Li, Z.M.; Wei, S.; Zhao, H.X.; Peng, S.; Zheng, B.J. Effect of TiC content on the microstructure and properties of large-area laser-cladded TiC Ni-based composite coatings. Mater. Res. Express 2021, 8, 026516. [Google Scholar]

| Materials | Density (g/cm3) | Melting Point (°C) |

|---|---|---|

| TI-6Al-4V | 4.5 | 1700 |

| Ni | 8.97 | 1455 |

| G | 2.62 | 3652 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Lu, L.; Wang, Z.; Chen, C. Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy. Materials 2022, 15, 5512. https://doi.org/10.3390/ma15165512

Yu H, Lu L, Wang Z, Chen C. Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy. Materials. 2022; 15(16):5512. https://doi.org/10.3390/ma15165512

Chicago/Turabian StyleYu, Huijun, Lu Lu, Zifan Wang, and Chuanzhong Chen. 2022. "Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy" Materials 15, no. 16: 5512. https://doi.org/10.3390/ma15165512

APA StyleYu, H., Lu, L., Wang, Z., & Chen, C. (2022). Microstructure and Wear Resistance of a Composite Coating Prepared by Laser Alloying with Ni-Coated Graphite on Ti-6Al-4V Alloy. Materials, 15(16), 5512. https://doi.org/10.3390/ma15165512