Enhancement Properties of Zr Modified Porous Clay Heterostructures for Adsorption of Basic-Blue 41 Dye: Equilibrium, Regeneration, and Single Batch Design Adsorber

Abstract

:1. Introduction

2. Experimental Part

2.1. Materials

2.2. Preparation of Zr-Intercalated Clays and Zr-PCH Precursors

2.3. Adsorption Performance of Zr(X)-PCH

2.4. Regeneration and Reuse Experiments

2.5. Characterization Techniques

3. Results and Discussion

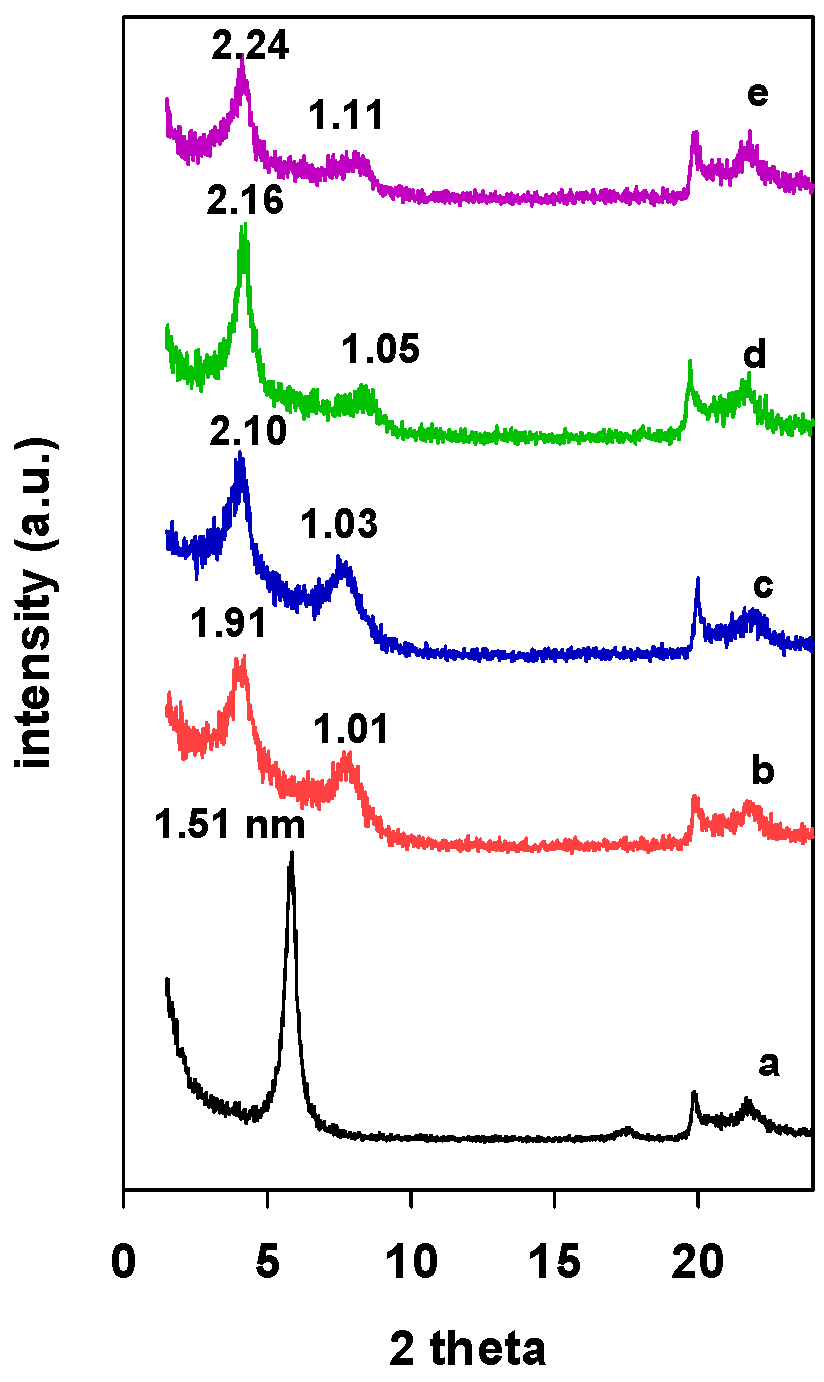

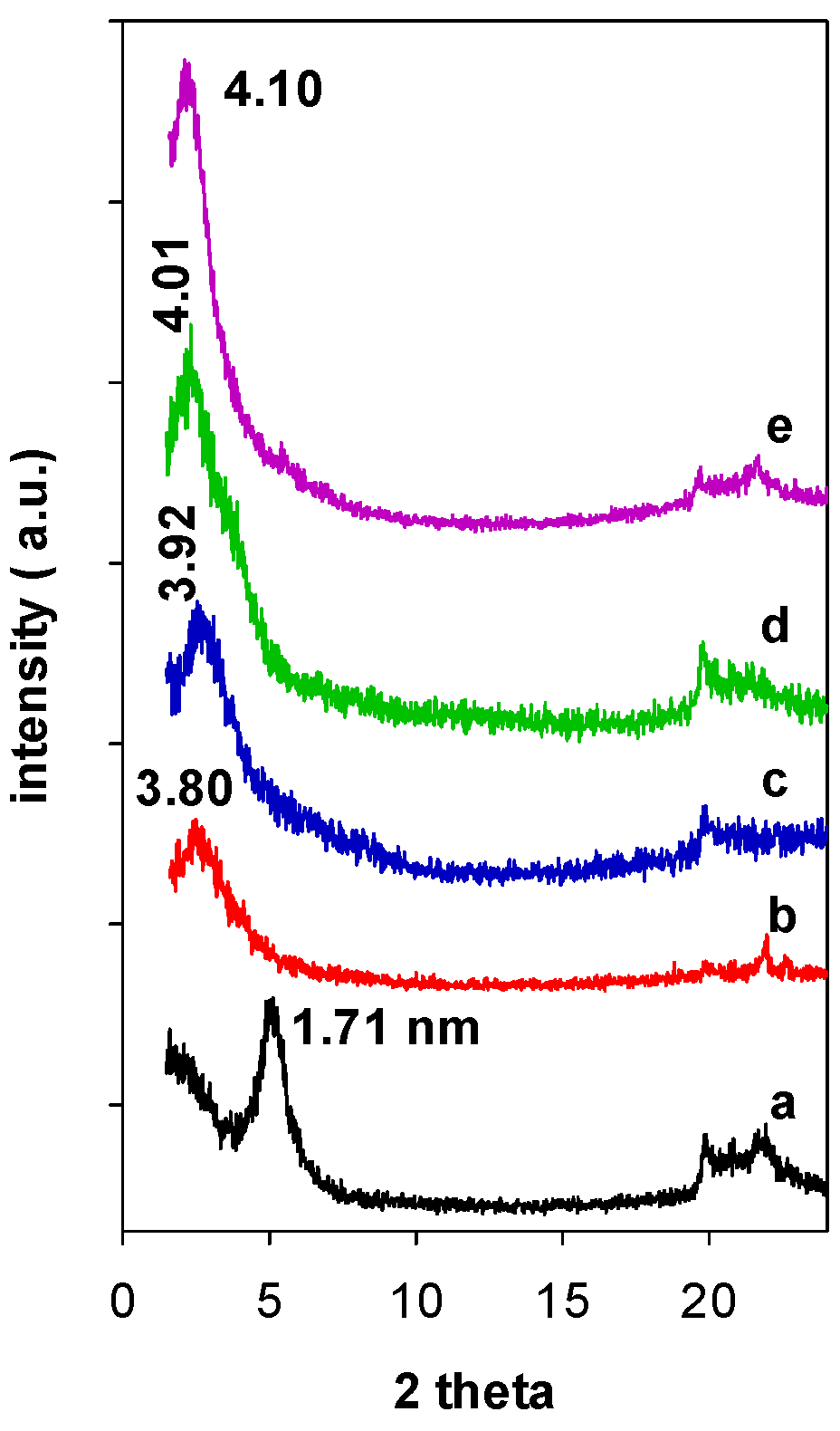

3.1. Characterization of Zr(X)-PCH Materials

3.2. Parametric Studies of Adsorption of Basic Blue-41

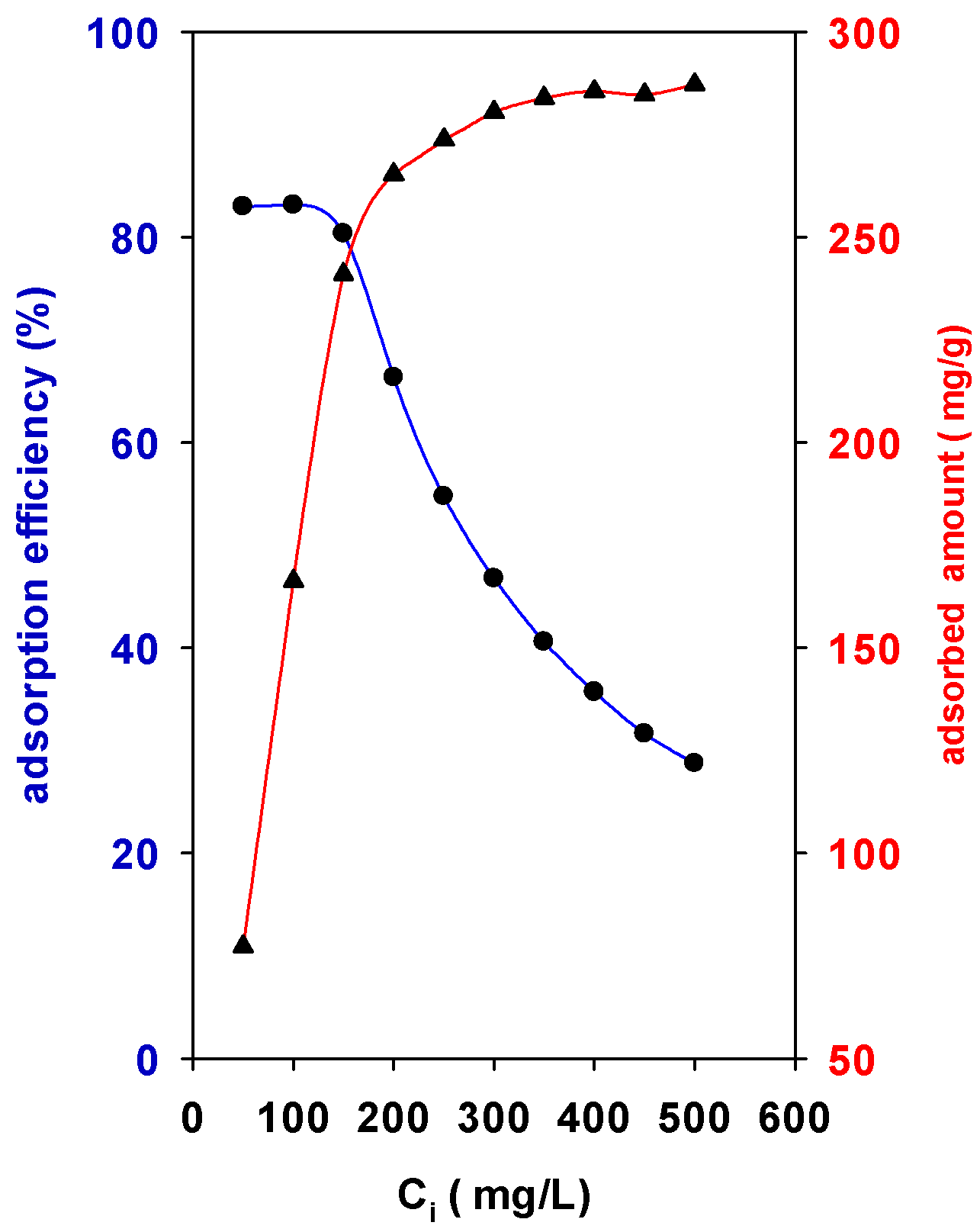

3.2.1. The Impact of Initial Concentration

3.2.2. Effect of Zr Contents

3.2.3. Effect of Solid Concentration

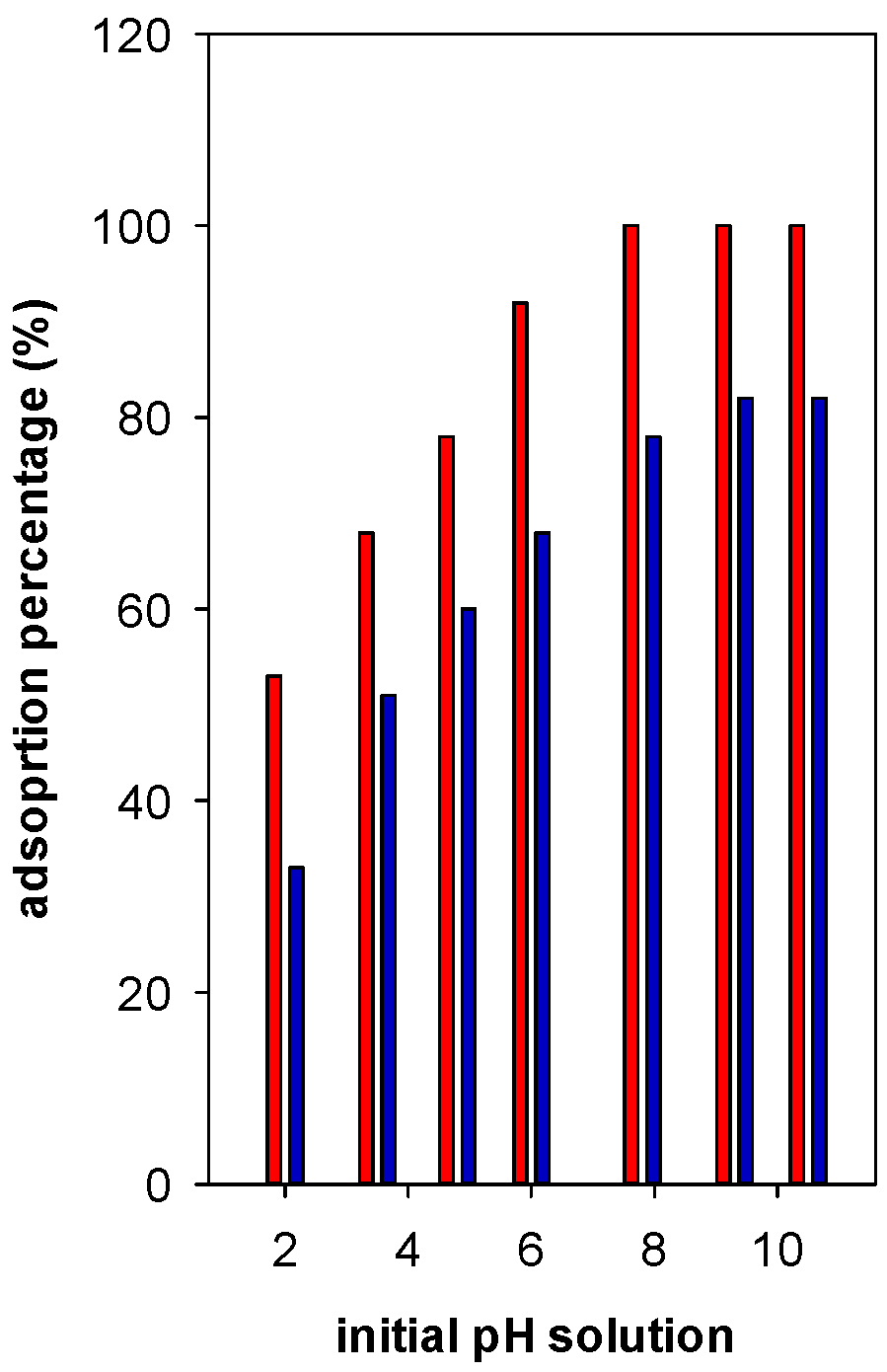

3.2.4. Effect of BB-41 pH Solution

3.2.5. Isotherm Modelling

3.2.6. Proposed Mechanism of Adsorption

3.2.7. Adsorption Thermodynamics

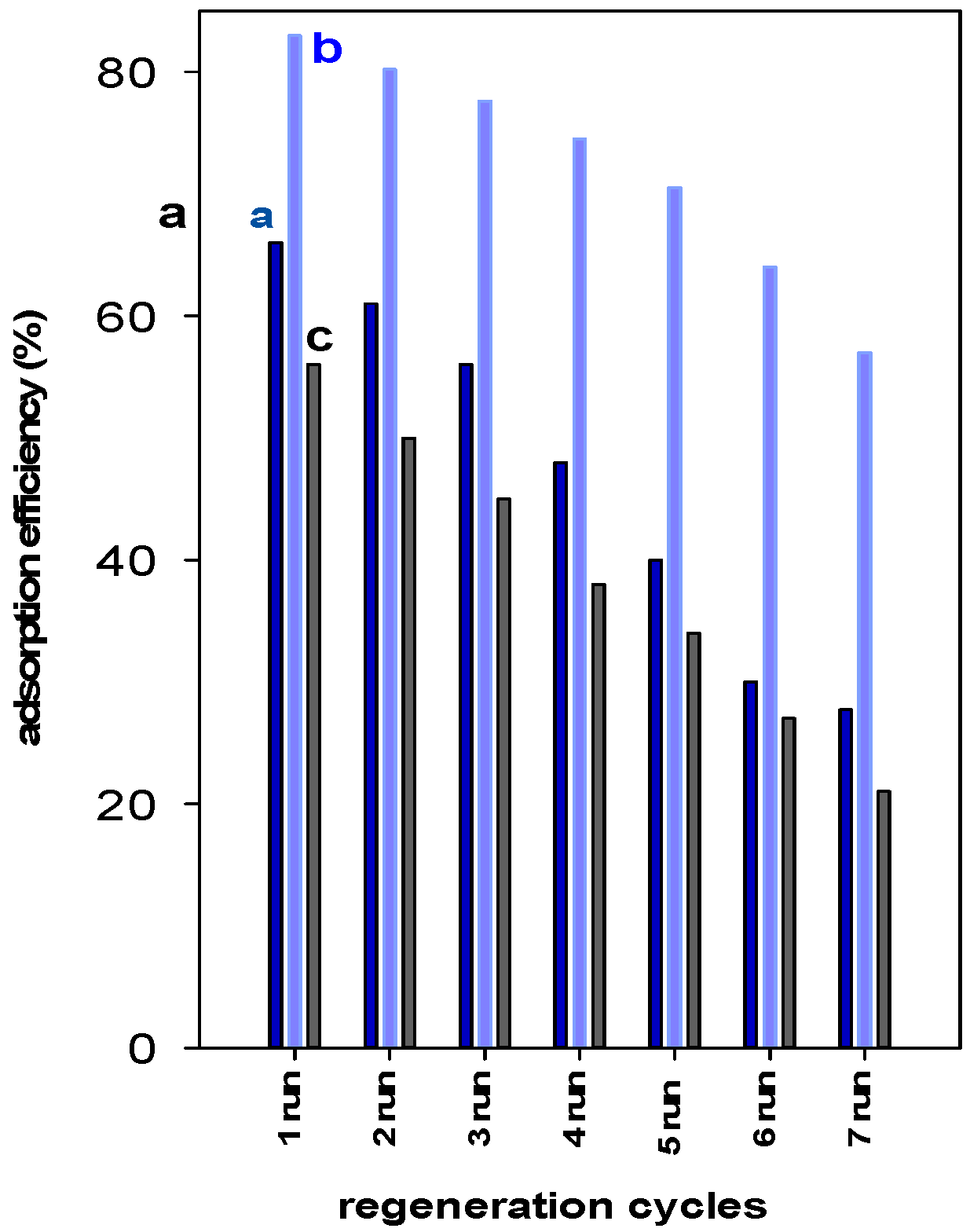

4. Zr(X)-PCH Reusability

5. Batch Design from Langmuir Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Galarneau, A.; Barodawalla, A.; Pinnavaia, T.J. Porous clay heterostructures formed by gallery-templated synthesis. Nature 1995, 374, 529–531. [Google Scholar] [CrossRef]

- Kooli, F.; Hian, P.; Weirong, Q.; Alshahateet, S.; Chen, F. Effect of the acid-activated clays on the properties of porous clay heterostructures. J. Porous Mater. 2006, 13, 319–324. [Google Scholar] [CrossRef]

- Cecilia, J.A.; García-Sancho, C.; Vilarrasa-García, E.; Jiménez-Jiménez, J.; Rodriguez-Castellón, E. Synthesis, characterization, uses and applications of porous clays heterostructures: A Review. Chem. Rec. 2018, 18, 1085–1104. [Google Scholar] [CrossRef] [PubMed]

- Gârea, S.A.; Mihai, A.I.; Vasile, E.; Nistor, C.; Sarbu, A.; Mitran, R. Synthesis of new porous clay heterostructures: The influence of co-surfactant type. Mater. Chem. Phys. 2016, 179, 17–26. [Google Scholar] [CrossRef]

- Chmielarz, L.; Kuśtrowski, P.; Drozdek, R.; Dziembaj, M.; Cool, P.; Vansant, E. Selective catalytic oxidation of ammonia into nitrogen over PCH modified with copper and iron species. Catal. Today 2006, 114, 319–325. [Google Scholar] [CrossRef]

- Chmielarz, L.; Piwowarska, Z.; Ku_strowski, P.; Gil, B.; Adamski, A.; Dudek, B.; Michalik, M. Porous clay heterostructures (PCHs) intercalated with silica-titania pillars and modified with transition metals as catalysts for the DeNOx process. Appl. Catal. B Environ. 2009, 91, 449–459. [Google Scholar] [CrossRef]

- Akkari, M.; Aranda, P.; Ben Haj Amara, A.; Ruiz-Hitzky, E. Organoclay hybrid materials as precursors of porous ZnO/silica-clay heterostructures for photocatalytic applications. Beilstein J. Nanotechnol. 2016, 7, 1971–1982. [Google Scholar] [CrossRef]

- Cecilia, A.; Garcia-Sancho, C.; Franco, F. Montmorillonite based porous clay heterostructures: Influence of Zr in the structure and acidic properties. Micropor. Mesopor. Mater. 2013, 176, 95–102. [Google Scholar] [CrossRef]

- Sanchis, R.; Cecilia, J.; Soriano, M.; Vázquez, M.; Dejoz, A.; Nieto, J. Porous clays heterostructures as supports of iron oxide for environmental catalysis. Chem. Eng. J. 2018, 223, 1159–1168. [Google Scholar] [CrossRef]

- Rubiyanto, D.; Prakoso, N.; Sahroni, I.; Nurillahi, R.; Fatimah, I. ZnO-porous clay heterostructure from saponite as green catalyst for citronellal cyclization. Bull. Chem. React. Eng. Catal. 2020, 15, 137–145. [Google Scholar] [CrossRef]

- Zimowska, M.; Gurgul, J.; Palkova, H.; Olejnicazak, Z.; Latka, K.; Litynska-Dobrzynska, L.; Matachowski, L. Structural rearrangements in Fe-porous clay heterostructures composites derived from Laponite- Influence of preparation methods and Fe source. Micropor. Mesopor. Mater. 2016, 231, 66–81. [Google Scholar] [CrossRef]

- Kooli, F. Porous clay heterostructures (PCHs) from Al13-intercalated and Al13-pillared montmorillonites: Properties and heptane hydro-isomerization catalytic activity. Microp. Mesop. Mater. 2014, 184, 184–192. [Google Scholar] [CrossRef]

- Kooli, F.; Liu, Y.; Hbaieb, K.; Al-Faze, R. Preparation and catalytic activities of porous clay heterostructures from aluminium-intercalated clays: Effect of aluminium content. Clay Miner. 2017, 52, 521–535. [Google Scholar] [CrossRef]

- Barakan, S.; Aghazadeh, V. Synthesis and characterization of hierarchical porous clay heterostructure from Al, Fe -pillared nano-bentonite using microwave and ultrasonic techniques. Microp. Mesopor. Mater. 2019, 278, 138–148. [Google Scholar] [CrossRef]

- Pires, J.; Bestilleiro, M.; Pinto, M.; Gil, A. Selective adsorption of carbon dioxide, methane and ethane by porous clays heterostructures. Sep. Purif. Technol. 2008, 61, 161–167. [Google Scholar] [CrossRef]

- Vilarrasa-Garcia, E.; Cecilia, J.; Rodriguez-Aguado, E.; Jimenez-Jimenez, J.; Cavalcante, C.; Azevedo, D.; Castellon, E.R. Amino-modified pillared adsorbent from water-treatment solid wastes applied to CO2/N2 separation. Adsorption 2017, 23, 405–421. [Google Scholar] [CrossRef]

- Qu, F.; Zhu, L.; Yang, K. Adsorption Behaviors of Volatile Organic Compounds (VOCs) on Porous Clay Heterostructures (PCH). J. Hazard. Mater. 2009, 170, 7–12. [Google Scholar] [CrossRef]

- Arellano-Cardenas, S.; Gallardo-Velasquez, T.; Osorio-Revilla, G.; Lopez-Cortez, M.D.; Perea, B.G. Adsorption of phenol and dichlorophenols from aqueous solutions by porous clay heterostructure (PCH). J. Mex. Chem. Soc. 2005, 49, 287–291. [Google Scholar]

- Mercier, L.; Pinnavaia, T. A functionalized porous clay heterostructure for heavy metal ion (Hg2+) trapping. Micropor. Mesopor. Mater. 1998, 20, 101–106. [Google Scholar] [CrossRef]

- Tchinda, A.J.; Ngameni, E.; Kenfack, I.T.; Walcarius, A. One-step preparation of thiol-functionalized porous clay heterostructures: Application to Hg(ii) binding and characterization of mass transport issues. Chem. Mater. 2009, 21, 4111–4121. [Google Scholar] [CrossRef]

- Diaz, M.; Cambier, P.; Brendle, J.; Prost, R. Functionalized clay heterostructures for reducing cadmium and lead uptake by plants in contaminated soils. Appl. Clay Sci. 2007, 37, 12–22. [Google Scholar] [CrossRef]

- Arellano-Cardenas, S.; Gallardo-Velazquez, T.; Osorio- Revilla, G.; Lopez-Cortez, M. Study of the surface charge of a porous clay heterostructure (pch) and its adsorption capacity of alkaline metals. J. Mex. Chem. Soc. 2010, 54, 92–97. [Google Scholar] [CrossRef]

- Al Dmour, H.; Kooli, F.; Mohmoud, A.; Liu, Y.; Popoola, S.A. Al and Zr porous clay heterostructures as removal agents of Basic Blue 41 dye from an artificially polluted solution: Regeneration properties and batch design. Materials 2020, 14, 2825. [Google Scholar] [CrossRef]

- Aguiar, J.F.; Cecilia, J.A.; Tavares, P.A.S.; Azevedo, D.C.S.; Rodriguez-Castellon, E.; Lucena, S.M.P.; SilvaJunior, I.J. Adsorption study of reactive dyes onto porous clay heterostructures. Appl. Clay Sci. 2017, 135, 35–44. [Google Scholar] [CrossRef]

- Daas, N.; Zaghouane-Boudiaf, H. Synthesis and characterization of porous bentonite adsorbent and its application to remove methylene blue dye from aqueous solutions. Desalin. Water Treat. 2022, 249, 271–280. [Google Scholar]

- Besghaier, S.; Cecilia, J.A.; Chouikhi, N.; Vilarrasa-Garcia, E.; Rodriguez-Castellon, E.; Chlendi, M.; Bagane, M. Glyphosate adsorption onto porous clay heterostructure (PCH): Kinetic and thermodynamic studies. Braz. J. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Arellano-Cardenas, S.; Gallardo- Velazquez, T.; Osorio-Revilla, G.; Lopez-Cortez, M. Preparation of a porous clay heterostructure and study of its adsorption capacity of phenol and chlorinated phenols from aqueous solutions. Water Environ. Res. 2008, 80, 60–67. [Google Scholar] [CrossRef]

- Benjelloun, M.; Cool, P.; Linssen, T.; Vansant, E. Template extraction from porous clay heterostructures: Influence on the porosity and the hydrothermal stability of the materials. Phys. Chem. Chem. Phys. 2002, 4, 2818–2823. [Google Scholar] [CrossRef]

- Pinto, M.; Pires, J. Porous and hybrid clay based materials for separation of hydrocarbons. Micropor. Mesopor. Mater. 2012, 151, 403–410. [Google Scholar] [CrossRef]

- Pinto, M.; Saini, V.; Guil, J.; Pires, J. Introduction of aluminum to porous clay heterostructures to modify the adsorption properties. Appl. Clay Sci. 2014, 101, 497–502. [Google Scholar] [CrossRef]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Int. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Kooli, F.; Liu, Y.; Hbaieb, K.; Al-Faze, R. Factors affecting the thermal stability and properties of Zr-Porous Clay heterostructures. J. Therm. Anal. Calorim. 2016, 126, 1143–1155. [Google Scholar] [CrossRef]

- Kooli, F.; Liu, Y.; Abboudi, M.; Oudghiri Hassani, H.; Rakass, S.; Ibrahim, S.M.; Al Wadaani, F. Waste bricks applied as removal agent of basic blue 41 from aqueous solutions: Base treatment and their regeneration efficiency. Appl. Sci. 2019, 9, 1237. [Google Scholar] [CrossRef]

- Mnasri-Ghnimia, S.; Frini-Srasraa, N. A comparison of single and mixed pillared clays for zinc and chromium cations removal. Appl. Clay Sci. 2018, 158, 150–157. [Google Scholar] [CrossRef]

- Qun, G.; Zhizhi, Z.; Xiwen, Z.; Fengxiang, L.; Wanfu, S.; Ruifeng, L.; Kechang, X. Preparation and characterization of mesoporous silica-pillared montmorillonite. J. Porous Mater. 2009, 16, 209–213. [Google Scholar]

- Essih, S.; Cecilia, J.A.; Jiménez-Gómez, C.P.; García-Sancho, C.; García-Mateos, F.J.; Rosas, J.M.; Moreno-Tost, R.; Franco, F.; Maireles-Torres, P. Synthesis of porous clay heterostructures modified with SiO2–ZrO2 nanoparticles for the valorization of furfural in one-pot process. Adv. Sustain. Syst. 2022, 6, 2100453. [Google Scholar] [CrossRef]

- Pálková, H.; Madejová, J.; Zimowska, M.; Bielańska, E.; Olejniczak, Z.; Lityńska-Dobrzyńska, L.; Serwicka, E.M. Laponite-derived porous clay heterostructures: I. Synthesis and physicochemical characterization. Micropor. Mesopor. Mater. 2010, 127, 228–236. [Google Scholar] [CrossRef]

- Kooli, F.; Liu, Y.; Hbaieb, K.; Al-Faze, R. Characterization and catalytic properties of porous clay heterostructures from zirconium intercalated clay and its pillared derivatives. Micropor. Mesopor. Mater. 2016, 226, 482–492. [Google Scholar] [CrossRef]

- Juang, L.; Wang, C.; Lee, C. Adsorption of basic dyes onto MCM-41. Chemosphere 2006, 64, 1920–1928. [Google Scholar] [CrossRef] [PubMed]

- Meissner, J.; Prause, A.; Bharti, B.; Findenegg, G.H. Characterization of protein adsorption onto silica nanoparticles: Influence of pH and ionic strength. Colloid Polym. Sci. 2015, 293, 3381–3391. [Google Scholar] [CrossRef] [PubMed]

- Lellou, S.; Kadi, S.; Ouadjenia, F.; Benhebal, H.; Schott, J.; Marouf, R. Reda Marouf. Synthesis and application of montmorillonite nanocomposites/phenolic resins for the elimination of Basic Blue 41. Desalin. Water Treat. 2021, 218, 389–400. [Google Scholar] [CrossRef]

- Aldegs, Y.; Elbarghouthi, M.; Elsheikh, A.; Walker, G. Effect of solution pH, ionic strength, and temperature on adsorption behavior of reactive dyes on activated carbon. Dyes Pigm. 2008, 77, 16–23. [Google Scholar] [CrossRef]

- Kosmulski, M. The pH dependent surface charging and points of zero charge. VIII. Update. Adv. Colloid Interface Sci. 2019, 275, 102064. [Google Scholar] [CrossRef] [PubMed]

- Gil, A.; Assis, F.; Albeniz, S.; Korili, S. Removal of dyes from wastewaters by adsorption on pillared clays. Chem. Eng. Technol. 2011, 168, 1032–1040. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Daana, D.A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383–122405. [Google Scholar] [CrossRef] [PubMed]

- Kooli, F.; Liu, Y.; Al-Faze, R.; Al Suhaimi, A. Effect of acid activation of Saudi local clay mineral on removal properties of basic blue 41 from an aqueous solution. Appl. Clay Sci. 2015, 116–117, 23–30. [Google Scholar] [CrossRef]

- Humelnicu, L.; Baiceanu, A.; Ignat, M.; Dulman, V. The Removal of Basic Blue 41 Textile Dye from Aqueous Solution by Adsorption onto Natural Zeolitic Tuff: Kinetics and Thermodynamics. Process Saf. Environ. Prot. 2017, 105, 274–287. [Google Scholar] [CrossRef]

- Zarezadeh-Mehrizi, M.; Badiei, A.R. Highly efficient removal of Basic Blue 41 with nanoporous silica. Water Resour. Ind. 2014, 5, 49–57. [Google Scholar] [CrossRef]

- Gougazeh, M.; Kooli, F.; Buhl, J.-C. Removal efficiency of basicblue41 by three zeolites prepared from natural Jordanian kaolinite. Clays Clay Miner. 2019, 67, 143–153. [Google Scholar] [CrossRef]

- Kul, A.R.; Aldemir, A.; Koyuncu, H. An investigation of natural and modified diatomite performance for adsorption of Basic Blue 41: Isotherm, kinetic, and thermodynamic studies. Desalination Water Treat. 2021, 229, 384–394. [Google Scholar] [CrossRef]

- Li, P.; Quinlivan, P.A.; Knappe, D.R.U. Effects of activated carbon surface chemistry and pore structure on the adsorption of organic contaminants from aqueous solution. Carbon 2002, 40, 2085–2100. [Google Scholar] [CrossRef]

- Gupta, V.; Suhas, V.; Mohan, D. Equilibrium uptake and sorption dynamics for the removal of a basic dye (basic red) using low-cost adsorbents. J. Colloid Interface Sci. 2003, 265, 257–264. [Google Scholar] [CrossRef]

- Huo, S.H.; Yan, X.P. Metal–organic framework MIL-100(Fe) for the adsorption of malachite green from aqueous solution. J. Mater. Chem. 2012, 22, 7449–7455. [Google Scholar] [CrossRef]

- Regti, A.; Laamari, R.; Stririba, S.E.; El Haddad, M. Removal of Basic Blue 41 dyes using Persea americana-activated carbon prepared by phosphoric acid action. Int. J. Ind. Chem. 2017, 8, 187–195. [Google Scholar] [CrossRef]

- Rápó, E.; Tonk, S. Factors Affecting Synthetic Dye Adsorption; Desorption Studies: A Review of Results from the Last Five Years (2017–2021). Molecules 2021, 26, 5419. [Google Scholar] [CrossRef]

- Kustov, A.L.; Tkachenko, O.P.; Kustov, L.M.; Romanovsky, B.V. Lanthanum cobaltite perovskite supported onto mesoporous zirconium dioxide: Nature of active sites of VOC oxidation. Environ. Int. 2011, 37, 1053–1056. [Google Scholar] [CrossRef]

- Khalilzadeh Shirazi, E.; Metzger, J.W.; Fischer, F.; Hassani, A.H. Design and cost analysis of batch adsorber systems for removal of dyes from contaminated groundwater using natural low-cost adsorbents. Int. J. Ind. Chem. 2020, 11, 101–110. [Google Scholar] [CrossRef]

- Mansour, R.A.; Simeda, M.G.; Zaatout, A.A. Removal of brilliant green dye from synthetic wastewater under batch mode using chemically activated date pit carbon. RSC Adv. 2021, 11, 7851–7861. [Google Scholar] [CrossRef] [PubMed]

| Samples | SiO2 | Al2O3 | MgO | ZrO2 | CaO | Zr/Clay + |

|---|---|---|---|---|---|---|

| Zr(0)-Mt | 66.4 | 14.5 | 2.97 | 0 | 1.66 | 0 |

| Zr(0)-PCH | 72.33 | 8.5 | 1.53 | 0 | 0.91 | 0 |

| Zr(3)-Mt | 54.5 | 11.7 | 2.03 | 6.23 | 0.03 | 0.57 |

| Zr(3)-PCH | 78.52 | 5.53 | 1.02 | 4.21 | 0.02 | N.C. |

| Zr(6)-Mt | 49.1 | 10.4 | 1.9 | 11 | 0.02 | 1.12 |

| Zr(6)-PCH | 81.02 | 5.54 | 0.66 | 6.83 | 0.02 | N.C. |

| Zr(12)-Mt | 46.7 | 10 | 1.69 | 12.8 | 0.01 | 1.38 |

| Zr(12)-PCH | 82.21 | 5.21 | 0.62 | 7.25 | 0.02 | N.C. |

| Zr(24)-Mt | 46.4 | 9.7 | 1.65 | 16.7 | 0 | 1.79 |

| Zr(24)-PCH | 83.01 | 4.69 | 0.58 | 8.12 | 0.02 | N.C. |

| Samples | SSA (m2/g) | µpore Volume (mL/g) | µpore SA (m2/g) | TPV (cm3/g) | APD (nm) | Acidity mmol H+/g |

|---|---|---|---|---|---|---|

| Zr(0)-Mt Zr(0)-PCH | 78 | 0.002 | 12 | 0.051 | 6.92 | 0.057 |

| 180 | 0.008 | 16 | 0.088 | 6.24 | 0.234 | |

| Zr(3)-Mt | 231 | 0.083 | 103 | 0.194 | 3.36 | 0.326 |

| Zr(3)-PCH | 445 | 0.063 | 50 | 0.394 | 3.53 | 1.031 |

| Zr(6)-Mt | 277 | 0.088 | 122 | 0.324 | 3.24 | 0.367 |

| Zr(6)-PCH | 950 | 0.101 | 142 | 0.804 | 3.02 | 0.993 |

| Zr(12)-Mt | 287 | 0.095 | 187 | 0.229 | 3.19 | 0.386 |

| Zr(12)-PCH | 933 | 0.105 | 135 | 0.818 | 2.95 | 0.973 |

| Zr(24)-Mt | 318 | 0.091 | 174 | 0.32 | 3.2 | 0.394 |

| Zr(24)-PCH | 908 | 0.101 | 145 | 0.736 | 2.84 | 0.953 |

| Samples | SSA (m2/g) | µpore Volume (mL/g) | TPV (cm3/g) | APD (nm) |

|---|---|---|---|---|

| Zr(6)-PCH | 401 | 0.067 | 0.287 | 2.87 |

| 550 °C * | 950 | 0.104 | 0.801 | 2.62 |

| 650 °C | 808 | 0.082 | 0.572 | 2.83 |

| 750 °C | 783 | 0.073 | 0.572 | 2.83 |

| 850 °C | 697 | 0.062 | 0.460 | 2.64 |

| 900 °C | 562 | 0.000 | 0.554 | 3.87 |

| Materials | qmax (mg/g) | KL (L/mg) | R2 | Γmax * (mg/m2) |

|---|---|---|---|---|

| Ca-Mt | 57 | 0.0289 | 0.9854 | 0.736 |

| Zr(3)-PCH | 224 | 0.0397 | 0.99710 | 0.505 |

| Zr(6)-PCH | 346 | 0.2124 | 0.9996 | 0.364 |

| Zr(12)-PCH | 301 | 0.0671 | 0.9997 | 0.322 |

| Zr(24)-PCH | 265 | 0.0408 | 0.99905 | 0.292 |

| Materials | qmax (mg/g) | Reference |

|---|---|---|

| Zr(X)-PCH | 224–346 | This study |

| Al-PCH material | 274 | [23] |

| Al-Pillared clays | 88 | [23] |

| Zr- Pillared clays | 114 | [23] |

| Nanoporous silica | 345 | [48] |

| Natural zeolite | 77 | [47] |

| Saudi Local clay | 50–70 | [46] |

| Brick waste materials | 60–70 | [33] |

| Sodalite zeolite | 39 | [49] |

| Zeolite X | 27 | [49] |

| bentonite -poly(p-hydroxybenzoic acid) composite | 173 | [41] |

| Mn modified diatomite | 62 | [50] |

| Materials | qmax (mg/g) | Estimated Volume (cc/g) | Experimental Percentage Occupation (%) | Calculated Pore Occupation (%) |

|---|---|---|---|---|

| Zr(3)-PCH | 224 | 0.2335 | 59.50 | 63.02 |

| Zr(6)-PCH | 346 | 0.360 | 44.77 | 43.02 |

| Zr(12)-PCH | 301 | 0.3135 | 38.50 | 45.12 |

| Zr(24)-PCH | 265 | 0.2765 | 37.56 | 48.68 |

| Parameter | Temperature | |||

|---|---|---|---|---|

| 298 K | 303 K | 313 K | 323 K | |

| ΔG° (kJ mol−1) | −3.988 | −4.391 | −4.878 | −5.192 |

| ΔS° (kJ mol−1 K) | 0.048 | |||

| ΔH° (kJ mol−1) | 10.082 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popoola, S.A.; Al Dmour, H.; Rakass, S.; Fatimah, I.; Liu, Y.; Mohmoud, A.; Kooli, F. Enhancement Properties of Zr Modified Porous Clay Heterostructures for Adsorption of Basic-Blue 41 Dye: Equilibrium, Regeneration, and Single Batch Design Adsorber. Materials 2022, 15, 5567. https://doi.org/10.3390/ma15165567

Popoola SA, Al Dmour H, Rakass S, Fatimah I, Liu Y, Mohmoud A, Kooli F. Enhancement Properties of Zr Modified Porous Clay Heterostructures for Adsorption of Basic-Blue 41 Dye: Equilibrium, Regeneration, and Single Batch Design Adsorber. Materials. 2022; 15(16):5567. https://doi.org/10.3390/ma15165567

Chicago/Turabian StylePopoola, Saheed A., Hmoud Al Dmour, Souad Rakass, Is Fatimah, Yan Liu, Ahmed Mohmoud, and Fethi Kooli. 2022. "Enhancement Properties of Zr Modified Porous Clay Heterostructures for Adsorption of Basic-Blue 41 Dye: Equilibrium, Regeneration, and Single Batch Design Adsorber" Materials 15, no. 16: 5567. https://doi.org/10.3390/ma15165567

APA StylePopoola, S. A., Al Dmour, H., Rakass, S., Fatimah, I., Liu, Y., Mohmoud, A., & Kooli, F. (2022). Enhancement Properties of Zr Modified Porous Clay Heterostructures for Adsorption of Basic-Blue 41 Dye: Equilibrium, Regeneration, and Single Batch Design Adsorber. Materials, 15(16), 5567. https://doi.org/10.3390/ma15165567