Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes

Abstract

:1. Introduction

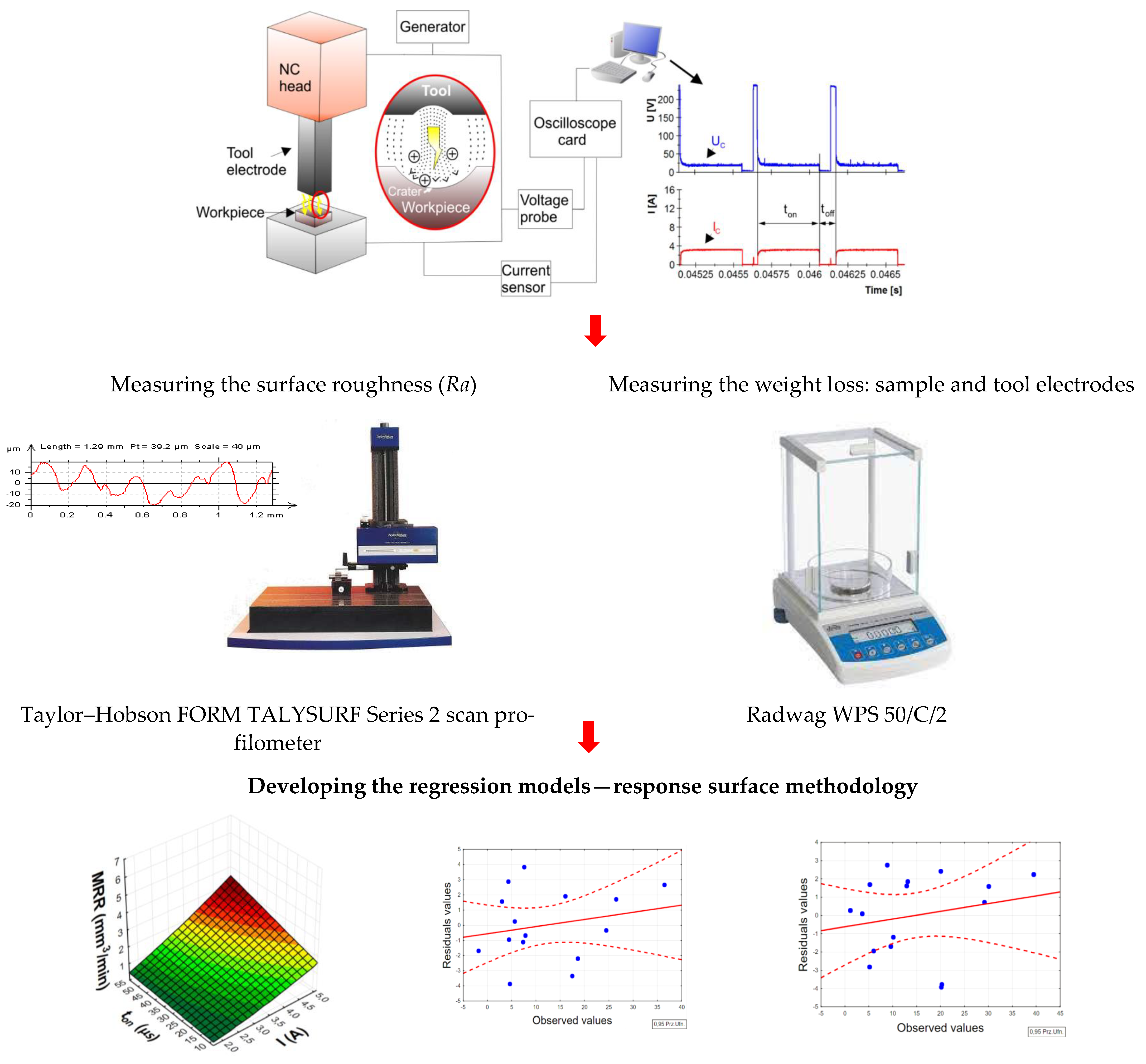

2. Materials and Method

Machining Parameters

3. Results and Discussion

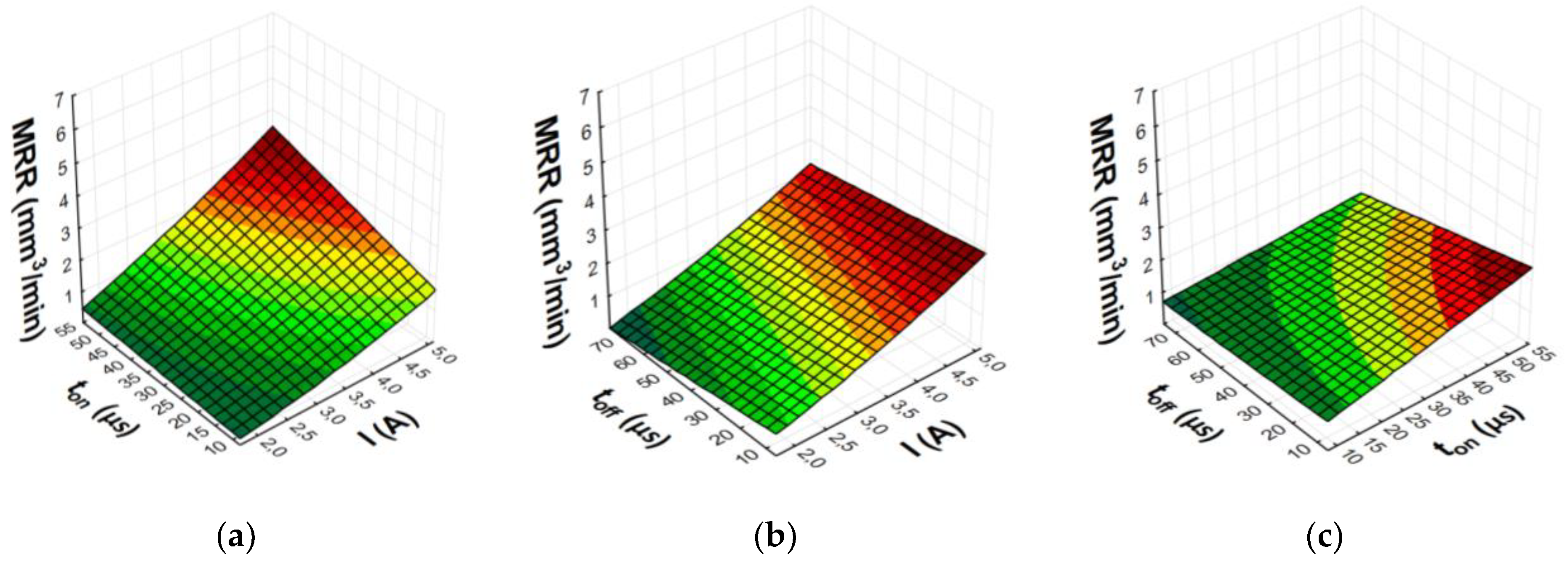

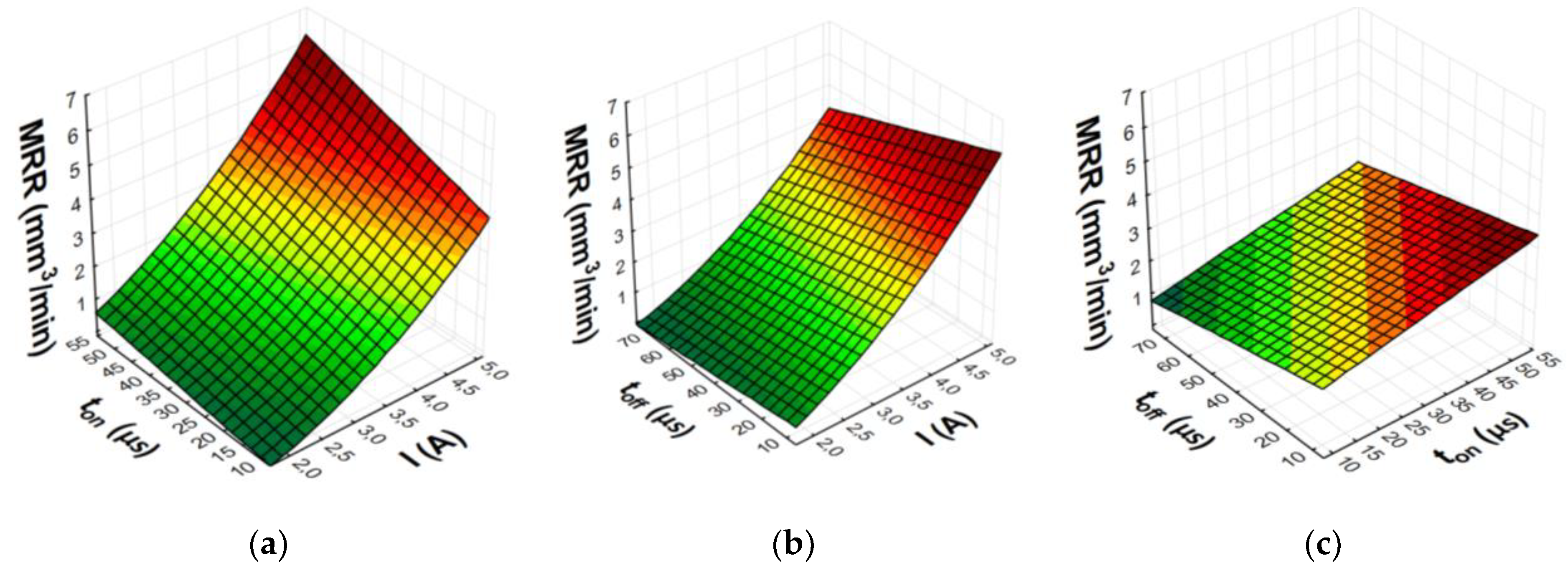

3.1. Material Removal and Tool Wear Rates

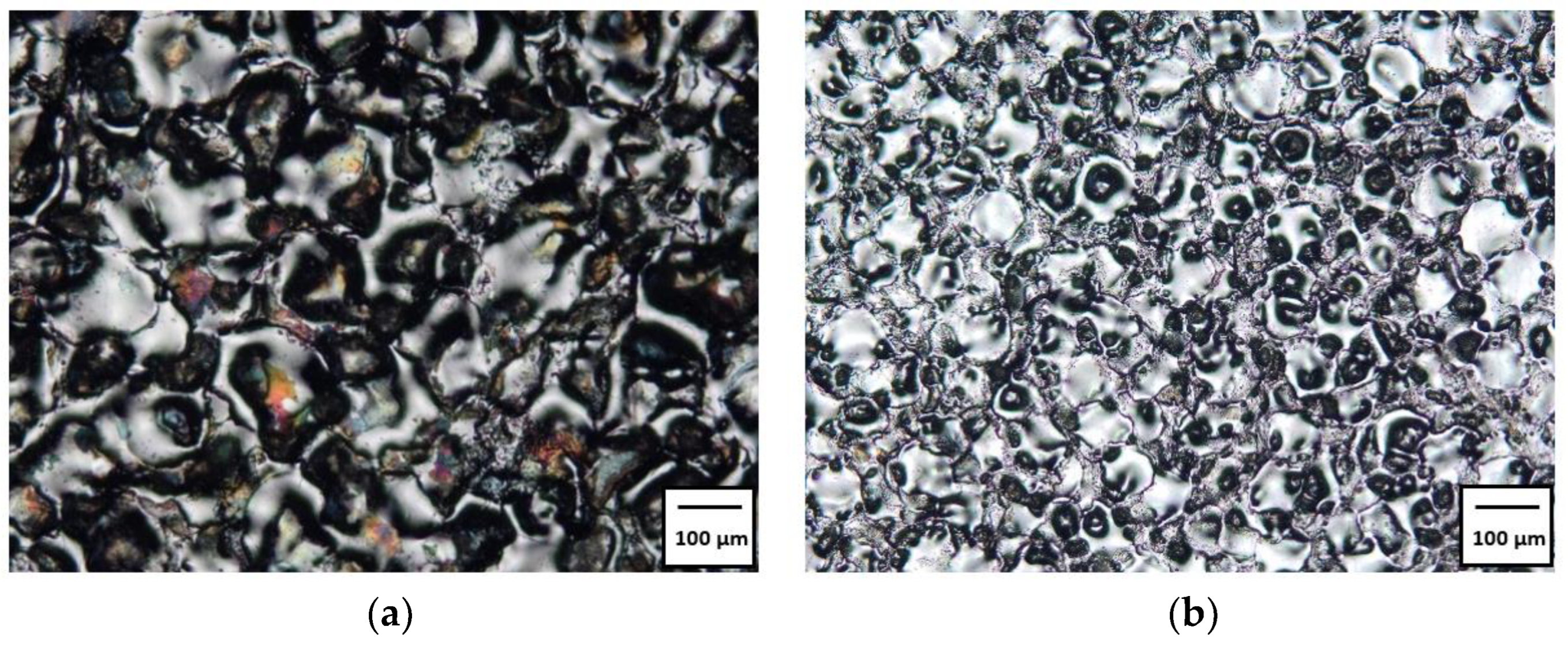

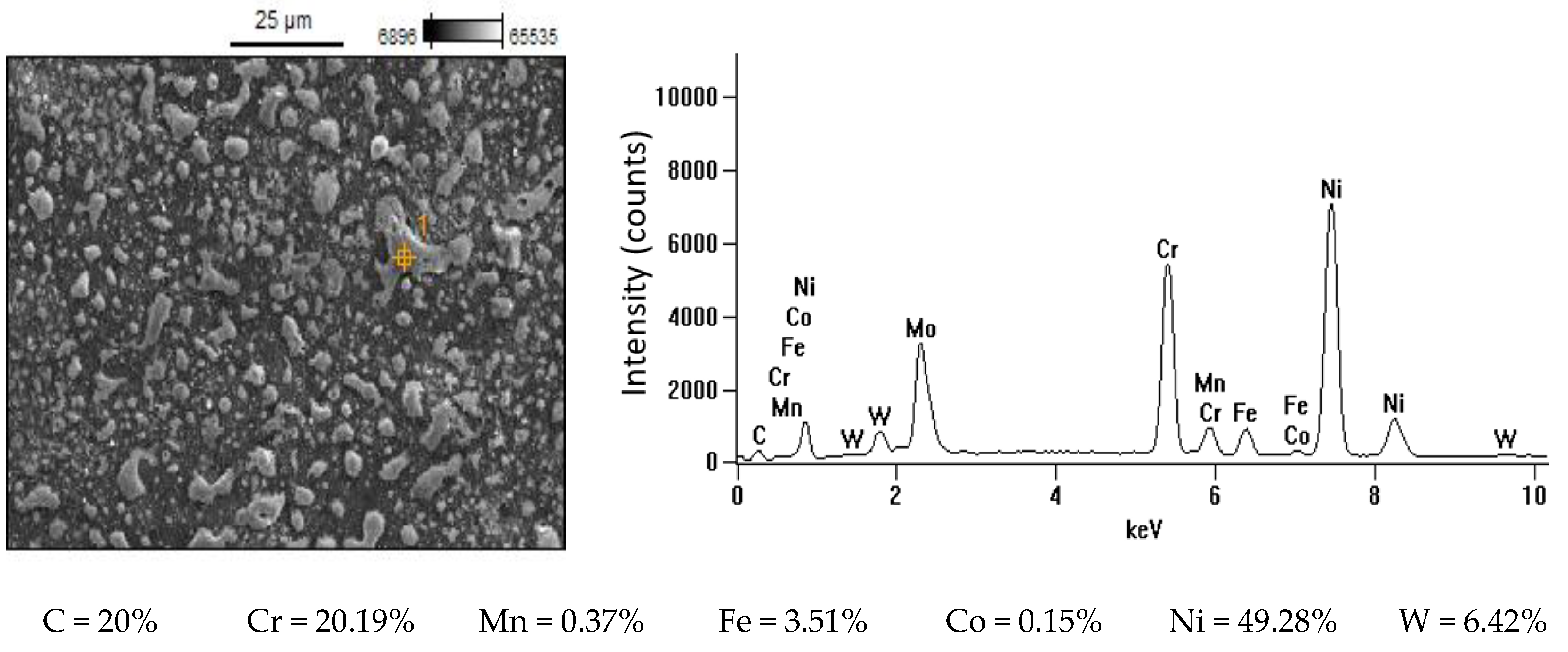

3.2. Analysis of Surface Integrity

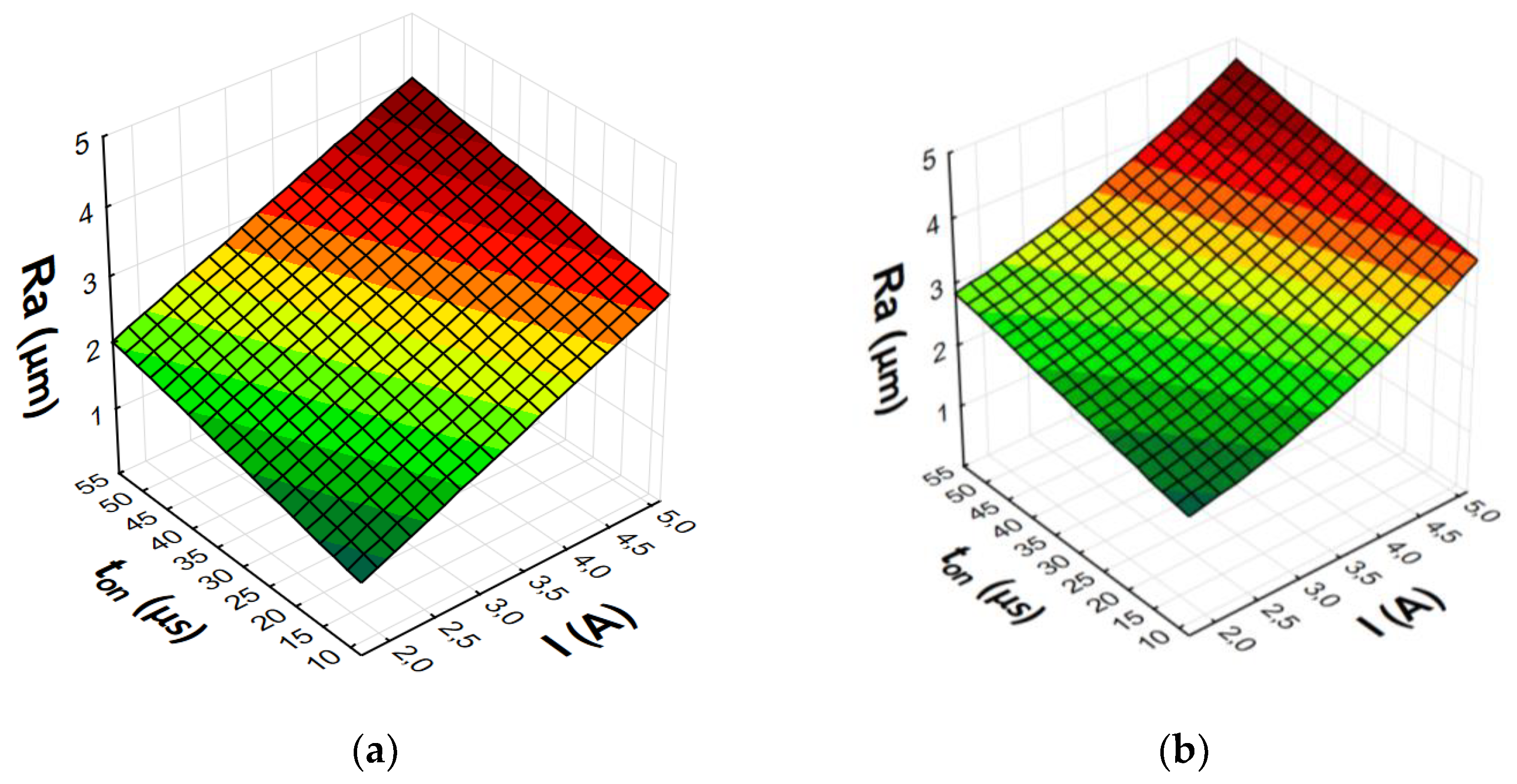

3.3. Statistical Models of MRR, TWR, and Ra

4. Summary

- Relative wear of the working electrode was greater for S-180 graphite due to the larger grain size, as well as lower resistivity and apparent density.

- POCO AF-5 graphite electrode obtained the lowest surface roughness after EDM. With low electrical discharge energy, the graphite electrode mapped its grain microstructure on the machining surface. Graphite with a smaller grain and low relative porosity provided lower surface roughness.

- The main determinants of MRR and Ra were discharge current I and, to a lesser extent, pulse duration ton. In the case of TWR, the most important parameters were pulse duration, followed by discharge current.

- A long pulse duration reduced TWR due to the deposition of carbon and elements of the workpiece on the electrode surface, providing a protective layer to prevent excessive wear of the tool.

- Increase of the discharge current I reduced the value of the relative tool wear for both the AF-5 and S-180 graphite electrodes.

- An increase in the value of the current intensity I and the pulse duration ton caused an increase in the roughness of the surface after EDM.

- The developed predictive models for EDM of Hastelloy C-22 using graphite electrodes can be implemented for the construction of technological tables in modern erosion machines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Torres, A.; Luis, C.J.; Puertas, I. Analysis of the Influence of EDM Parameters on Surface Finish, Material Removal Rate, and Electrode Wear of an INCONEL 600 Alloy. Int. J. Adv. Manuf. Technol. 2015, 80, 123–140. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Sethi, B.L. Surface Modification by Electrical Discharge Machining: A Review. J. Mater. Process. Technol. 2009, 209, 3675–3687. [Google Scholar] [CrossRef]

- Czelusniak, T.; Higa, C.F.; Torres, R.D.; Laurindo, C.A.H.; de Paiva Júnior, J.M.F.; Lohrengel, A.; Amorim, F.L. Materials Used for Sinking EDM Electrodes: A Review. J. Braz. Soc. Mech. Sci. Eng. 2018, 41, 14. [Google Scholar] [CrossRef]

- Wang, J.; Sánchez, J.A.; Izquierdo, B.; Ayesta, I. Experimental and Numerical Study of Crater Volume in Wire Electrical Discharge Machining. Materials 2020, 13, 577. [Google Scholar] [CrossRef] [PubMed]

- Ho, K.H.; Newman, S.T. State of the Art Electrical Discharge Machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Machno, M. Investigation of the Machinability of the Inconel 718 Superalloy during the Electrical Discharge Drilling Process. Materials 2020, 13, 3392. [Google Scholar] [CrossRef]

- Straka, Ľ.; Piteľ, J.; Čorný, I. Influence of the Main Technological Parameters and Material Properties of the Workpiece on the Geometrical Accuracy of the Machined Surface at Wedm. Int. J. Adv. Manuf. Technol. 2021, 115, 3065–3087. [Google Scholar] [CrossRef]

- Żyra, A.; Bogucki, R.; Skoczypiec, S. An Influence of Titanium Alloy Ti10V2Fe3Al Microstructure on the Electrodischarge Process Efficiency. Arch. Metall. Mater. 2019, 64, 1005–1010. [Google Scholar]

- Jithin, S.; Joshi, S.S. Surface Topography Generation and Simulation in Electrical Discharge Texturing: A Review. J. Mater. Process. Technol. 2021, 298, 117297. [Google Scholar] [CrossRef]

- Nowicki, R.; Świercz, R.; Oniszczuk-Świercz, D.; Dąbrowski, L.; Kopytowski, A. Influence of Machining Parameters on Surface Texture and Material Removal Rate of Inconel 718 after Electrical Discharge Machining Assisted with Ultrasonic Vibration. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 2017. [Google Scholar] [CrossRef]

- Buk, J. Surface Topography of Inconel 718 Alloy in Finishing WEDM. Adv. Sci. Technol. Res. J. 2022, 16, 47–61. [Google Scholar] [CrossRef]

- Rafaqat, M.; Mufti, N.A.; Ahmed, N.; Alahmari, A.M.; Hussain, A. EDM of D2 Steel: Performance Comparison of EDM Die Sinking Electrode Designs. Appl. Sci. 2020, 10, 7411. [Google Scholar] [CrossRef]

- Burek, J.; Babiarz, R.; Buk, J.; Sułkowicz, P.; Krupa, K. The Accuracy of Finishing WEDM of Inconel 718 Turbine Disc Fir Tree Slots. Materials 2021, 14, 562. [Google Scholar] [CrossRef] [PubMed]

- Jithin, S.; Bhandarkar, U.V.; Joshi, S.S. Three-Dimensional Topography Analysis of Electrical Discharge Textured SS304 Surfaces. J. Manuf. Process. 2020, 60, 384–399. [Google Scholar] [CrossRef]

- Straka, Ľ.; Hašová, S. Study of Tool Electrode Wear in EDM Process. Key Eng. Mater. 2016, 669, 302–310. [Google Scholar] [CrossRef]

- Oniszczuk-Swiercz, D.; Swiercz, R.; Chmielewski, T.; Salacinski, T. Experimental Investigation of Influence Wedm Parameters on Surface Roughness and Flatness Deviation. Metal 2020, 29, 611–617. [Google Scholar] [CrossRef]

- Żyra, A.; Bogucki, R.; Podolak-Lejtas, A.; Skoczypiec, S. Research on Influence of Heat Treatment Scheme of Ti10V2Fe3Al Alloy on Technological Surface Integrity after Electrodischarge Machining. J. Manuf. Process. 2021, 62, 47–57. [Google Scholar] [CrossRef]

- Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Osinnikov, I.V. Study of the Structure and Mechanical Properties after Electrical Discharge Machining with Composite Electrode Tools. Materials 2022, 15, 1566. [Google Scholar] [CrossRef]

- Le, V.T. Influence of Processing Parameters on Surface Properties of SKD61 Steel Processed by Powder Mixed Electrical Discharge Machining. J. Mater. Eng. Perform. 2021, 30, 3003–3023. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through Fundamental Insight into the Process. CIRP Ann. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Ozgedik, A.; Çoğun, C. An Experimental Investigation of Tool Wear in Electric Discharge Machining. Int. J. Adv. Manuf. Technol. 2006, 27, 488–500. [Google Scholar] [CrossRef]

- Mercer, J. Graphite vs. Copper. Available online: https://poco.entegris.com (accessed on 28 July 2022).

- Che Haron, C.H.; Ghani, J.A.; Burhanuddin, Y.; Seong, Y.K.; Swee, C.Y. Copper and Graphite Electrodes Performance in Electrical-Discharge Machining of XW42 Tool Steel. J. Mater. Process. Technol. 2008, 201, 570–573. [Google Scholar] [CrossRef]

- Torres, A.; Puertas, I.; Luis, C.J. EDM Machinability and Surface Roughness Analysis of INCONEL 600 Using Graphite Electrodes. Int. J. Adv. Manuf. Technol. 2016, 84, 2671–2688. [Google Scholar] [CrossRef]

- Aas, K.L. Performance of Two Graphite Electrode Qualities in EDM of Seal Slots in a Jet Engine Turbine Vane. J. Mater. Process. Technol. 2004, 149, 152–156. [Google Scholar] [CrossRef]

- Amorim, F.L.; Stedile, L.J.; Torres, R.D.; Soares, P.C.; Henning Laurindo, C.A. Performance and Surface Integrity of Ti6Al4V After Sinking EDM with Special Graphite Electrodes. J. Mater. Eng. Perform. 2014, 23, 1480–1488. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Bai, S.-L.; Zhao, Y.-H.; Liu, Z.-D. Effect of Mechanical Polishing on Corrosion Behavior of Hastelloy C22 Coating Prepared by High Power Diode Laser Cladding. Appl. Surf. Sci. 2014, 303, 312–318. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Zhang, Y.-F.; Bai, S.-L.; Liu, Z.-D. Microstructures, Mechanical Properties and Corrosion Resistance of Hastelloy C22 Coating Produced by Laser Cladding. J. Alloys Compd. 2013, 553, 253–258. [Google Scholar] [CrossRef]

- INCONEL® Alloy 22. Available online: https://www.bibusmetals.pl/alloys/inconel-alloy-22/ (accessed on 28 July 2022).

- Sameer, M.D.; Sai Kartheek Reddy, B.; Amrutha, N.; Srishma, K.; Samantha, K. Selection of Optimal EDM Process Parameters for Machining Maraging Steel Using Grey-Fuzzy Relational Analysis—An Experimental Approach; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 905–918. [Google Scholar] [CrossRef]

- Vagaská, A.; Gombár, M.; Straka, Ľ. Selected Mathematical Optimization Methods for Solving Problems of Engineering Practice. Energies 2022, 15, 2205. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; Al-Ahmari, A.M. Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses. Materials 2019, 12, 1940. [Google Scholar] [CrossRef]

- Świercz, R.; Oniszczuk-Świercz, D.; Chmielewski, T. Multi-Response Optimization of Electrical Discharge Machining Using the Desirability Function. Micromachines 2019, 10, 72. [Google Scholar] [CrossRef]

| Ni | Cr | Mo | Fe | W | Co | Mn | C |

|---|---|---|---|---|---|---|---|

| 56 Balance | 20.0–22.5 | 12.5–14.5 | 2.0–6.0 | 2.5–3.5 | 2.5 max | 0.5 max | 0.015 max |

| POCO Graphite | AF-5 | S-180 |

|---|---|---|

| Average grain size (µm) | 1 | 10 |

| Apparent density (g/cm3) | 1.8 | 1.78 |

| Electrical resistivity (µΩm) | 21.6 | 13 |

| Shore hardness | 87 | 66 |

| Flexural strength (MPa) | 117 | 58 |

| Material electrode | POCO AF-5 (1 µm), POCO S-180 (10 µm) |

| Workpiece material | Hastelloy C-22 |

| Discharge current I (A) | 1.7–5 |

| Pulse duration ton (µm) | 8–55 |

| Time interval toff (µm) | 6–75 |

| Discharge voltage Uc (V) | 25 |

| Open voltage U0 (V) | 225 |

| Tool polarity | Positive (+) |

| Machining depth ap (mm) | 0.5 |

| Dielectric | EDM fluid 108 MP-SE |

| Level | EDM Parameter | ||

|---|---|---|---|

| Discharge Current I (A) | Pulse Duration ton (µm) | Time Interval toff (µm) | |

| −1.68 | 1.7 | 8 | 6 |

| −1 | 2.7 | 17 | 19 |

| 0 | 3.8 | 30 | 37 |

| 1 | 4 | 41 | 51 |

| 1.68 | 5 | 55 | 75 |

| Ex. No. | EDM Parameters | Material of Electrode AF-5 | Material of Electrode S-180 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| I (A) | ton (µs) | toff (µs) | MRR (mm3/min) | TWR (%) | Ra (µm) | MRR (mm3/min) | TWR (%) | Ra (µm) | |

| 1 | 2.7 | 17 | 19 | 0.74 | 26.48 | 1.9 | 0.84 | 30.04 | 2.53 |

| 2 | 2.7 | 17 | 51 | 0.57 | 24.44 | 2.03 | 0.64 | 29.16 | 2.37 |

| 3 | 2.7 | 41 | 19 | 1.13 | 4.43 | 2.21 | 1.19 | 5.12 | 2.6 |

| 4 | 2.7 | 41 | 51 | 0.89 | 5.63 | 2.52 | 0.92 | 5.99 | 3.24 |

| 5 | 4 | 17 | 19 | 1.46 | 18.62 | 2.38 | 2.82 | 20.26 | 2.57 |

| 6 | 4 | 17 | 51 | 1.64 | 17.46 | 3.06 | 1.84 | 20.11 | 2.97 |

| 7 | 4 | 41 | 19 | 3.10 | 2.99 | 3.42 | 3.40 | 3.62 | 3.43 |

| 8 | 4 | 41 | 51 | 2.59 | 4.29 | 3.07 | 2.82 | 5.21 | 3.32 |

| 9 | 1.7 | 30 | 37 | 0.26 | 16.03 | 1.44 | 0.27 | 20.03 | 2.07 |

| 10 | 5.0 | 30 | 37 | 3.81 | 7.57 | 3.52 | 4.21 | 8.82 | 4.21 |

| 11 | 3.8 | 8 | 37 | 0.86 | 36.44 | 2.35 | 0.99 | 39.46 | 2.94 |

| 12 | 3.8 | 55 | 37 | 2.87 | −1.87 | 3.35 | 2.99 | 1.11 | 3.64 |

| 13 | 3.8 | 30 | 6 | 2.59 | 4.59 | 3.12 | 2.81 | 9.59 | 3.26 |

| 14 | 3.8 | 30 | 75 | 1.64 | 7.35 | 2.98 | 1.75 | 10.09 | 3.32 |

| 15 | 3.8 | 30 | 37 | 1.96 | 7.81 | 2.91 | 2.08 | 13.14 | 3.31 |

| 16 | 3.8 | 30 | 37 | 1.80 | 7.77 | 2.85 | 2.22 | 12.90 | 3.37 |

| POCO Graphite | Investigated Parameters | Calculated Regression Statistics | |

|---|---|---|---|

| Ratio R | F/Fkr | ||

| AF-5 | MRR | 0.98 | 25.9 |

| TWR | 0.98 | 25.0 | |

| Ra | 0.95 | 17.7 | |

| S-180 | MRR | 0.98 | 5.9 |

| TWR | 0.98 | 15.7 | |

| Ra | 0.92 | 9.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowicki, R.; Świercz, R.; Oniszczuk-Świercz, D.; Rozenek, M. Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes. Materials 2022, 15, 5631. https://doi.org/10.3390/ma15165631

Nowicki R, Świercz R, Oniszczuk-Świercz D, Rozenek M. Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes. Materials. 2022; 15(16):5631. https://doi.org/10.3390/ma15165631

Chicago/Turabian StyleNowicki, Rafał, Rafał Świercz, Dorota Oniszczuk-Świercz, and Marek Rozenek. 2022. "Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes" Materials 15, no. 16: 5631. https://doi.org/10.3390/ma15165631

APA StyleNowicki, R., Świercz, R., Oniszczuk-Świercz, D., & Rozenek, M. (2022). Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes. Materials, 15(16), 5631. https://doi.org/10.3390/ma15165631