Experimental Study on the Slip Behaviour of Stainless Steel High-Strength Bolted Connections with a New Surface Treatment

Abstract

:1. Introduction

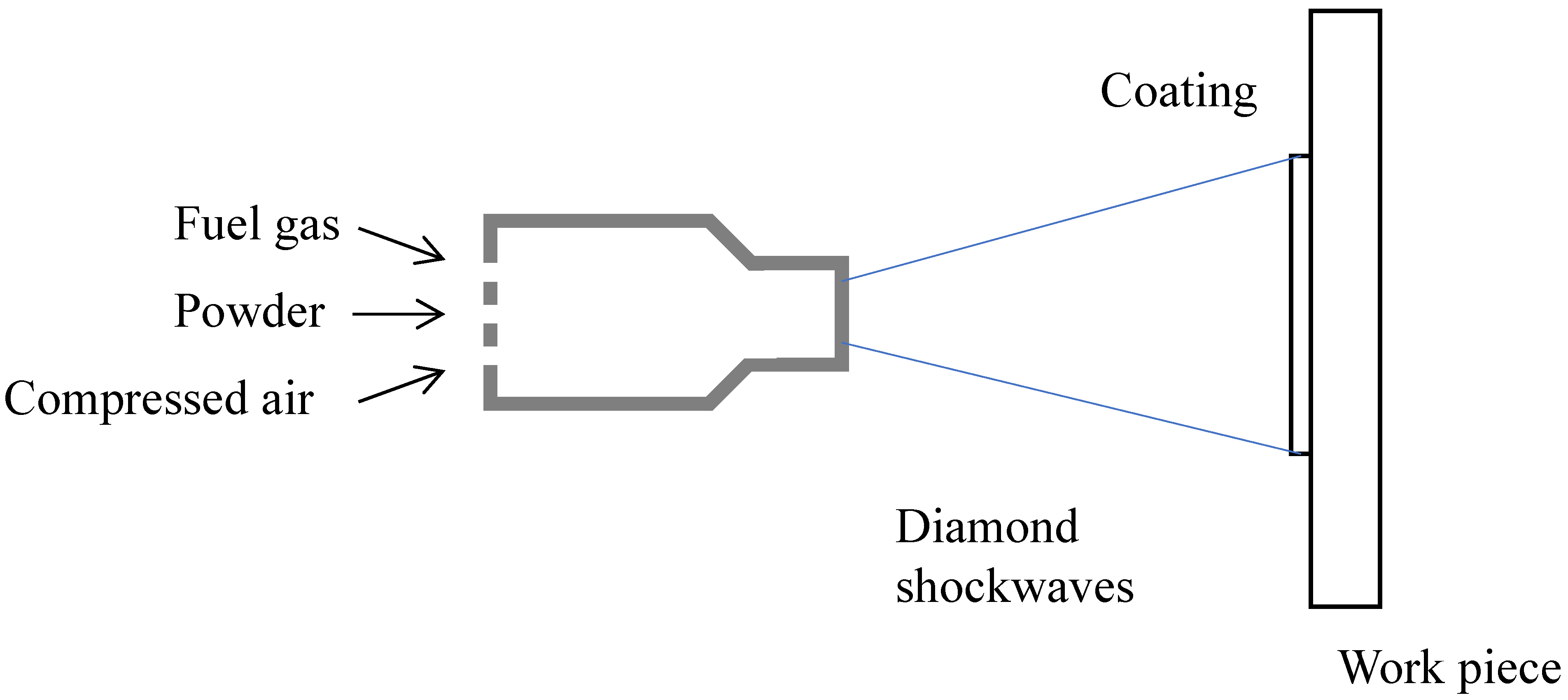

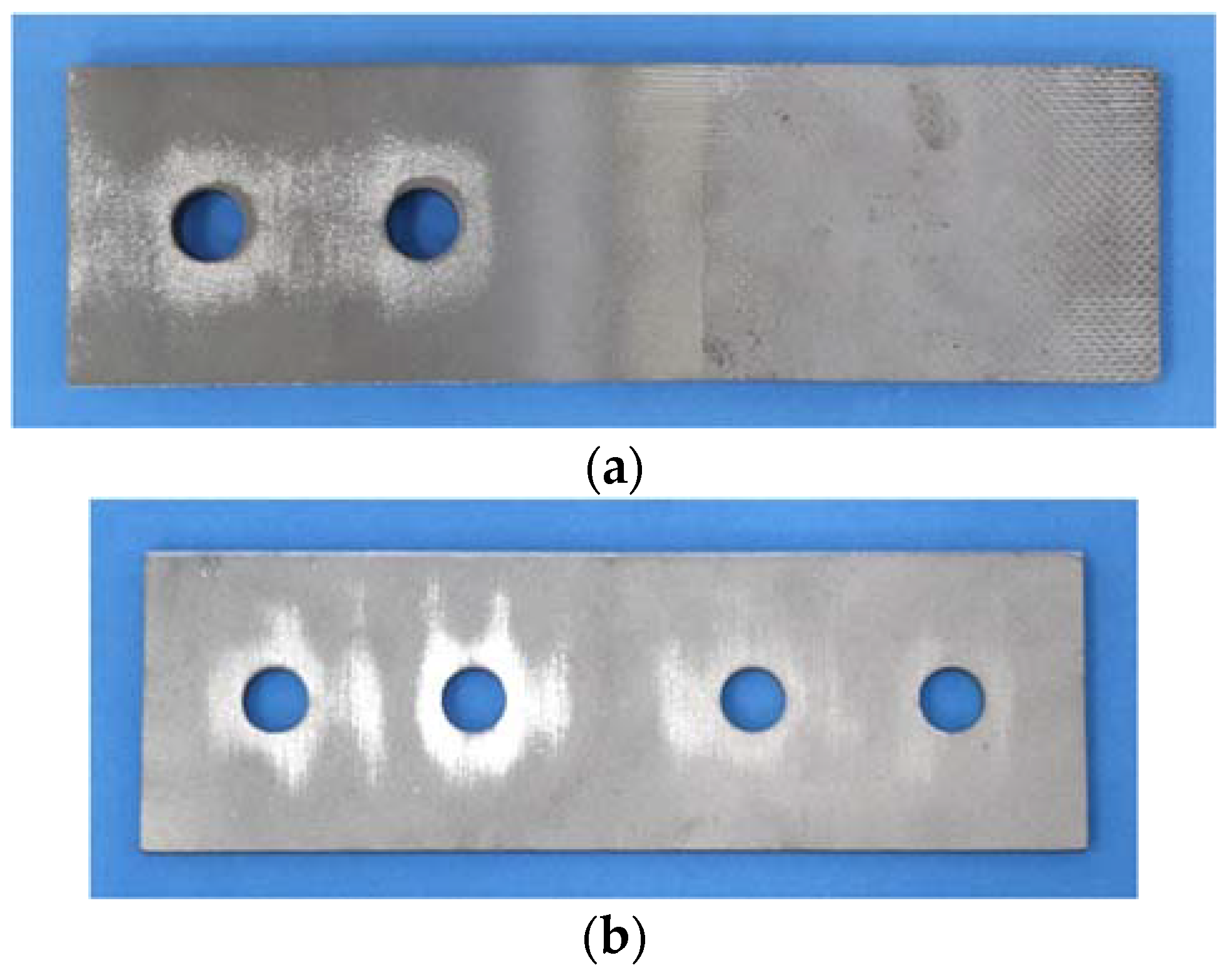

2. New Surface Treatment Method and Stainless Steel High-Strength Bolts

3. Experimental Investigations on Slip Factors

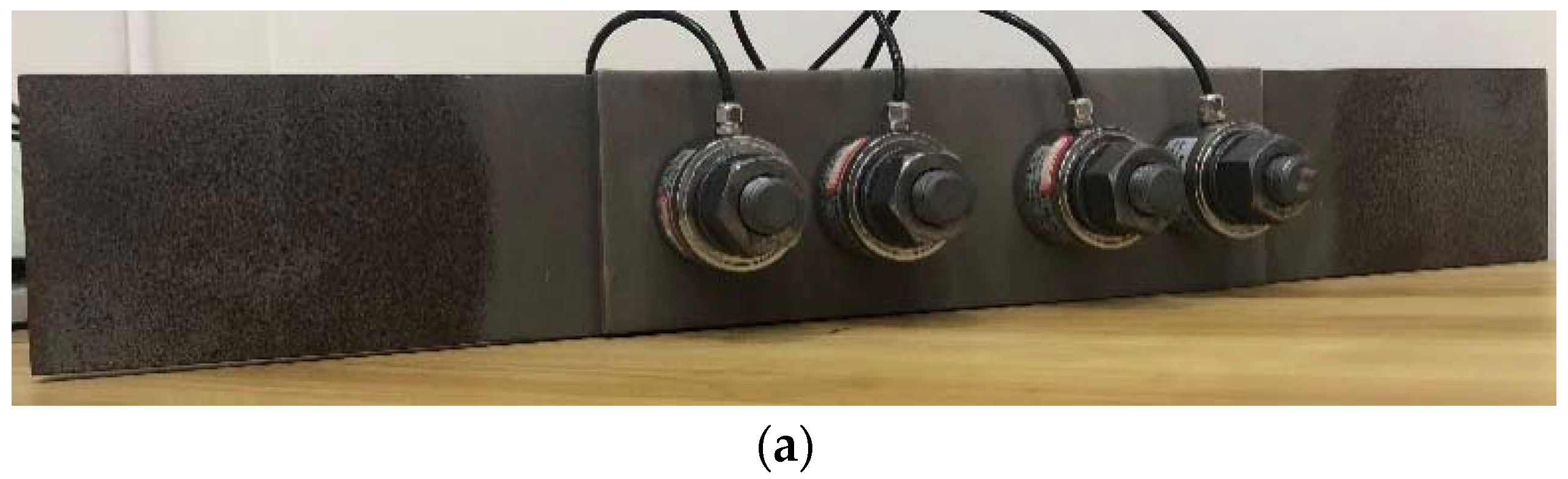

3.1. Specimens Design

3.2. Roughness and Hardness Measurements

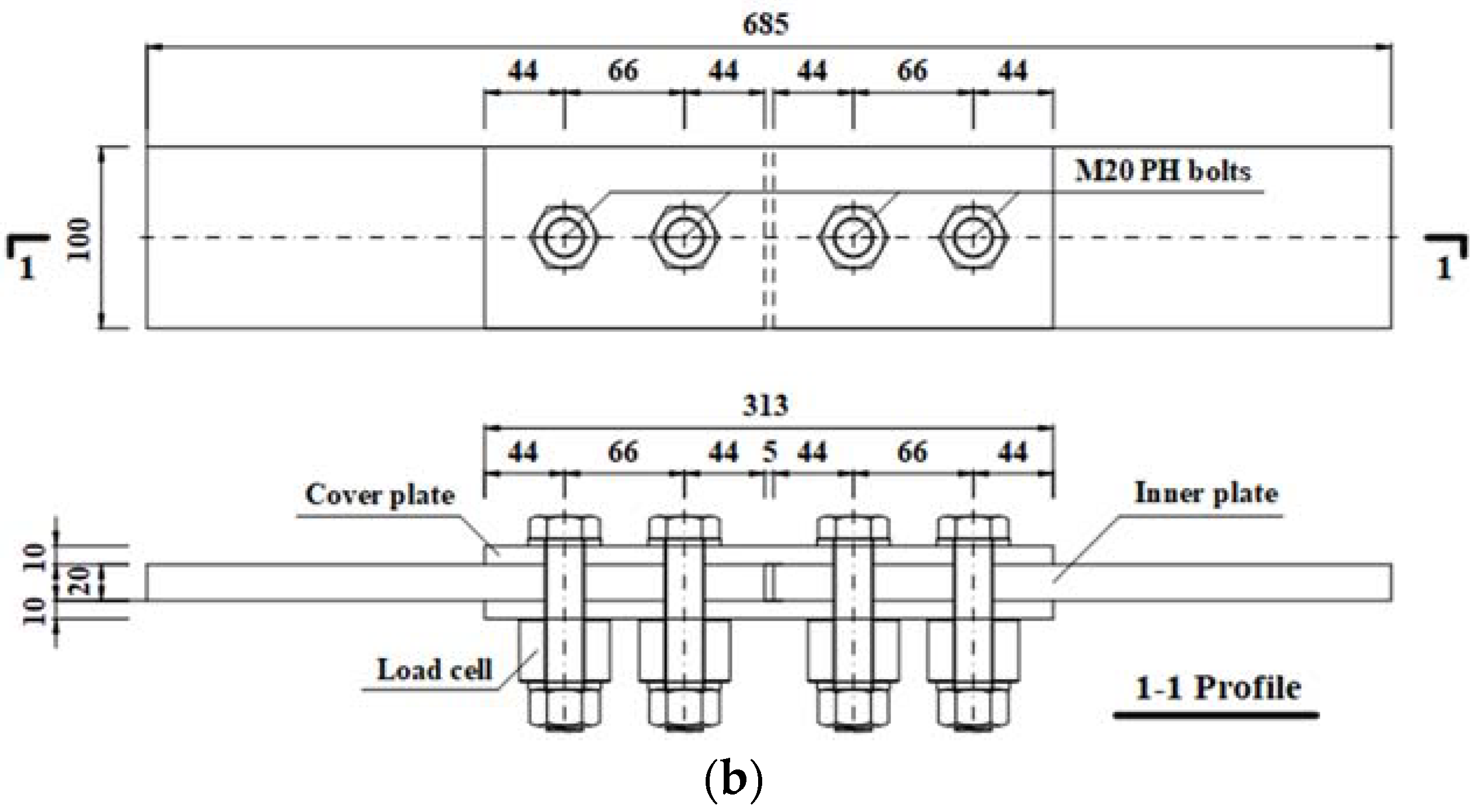

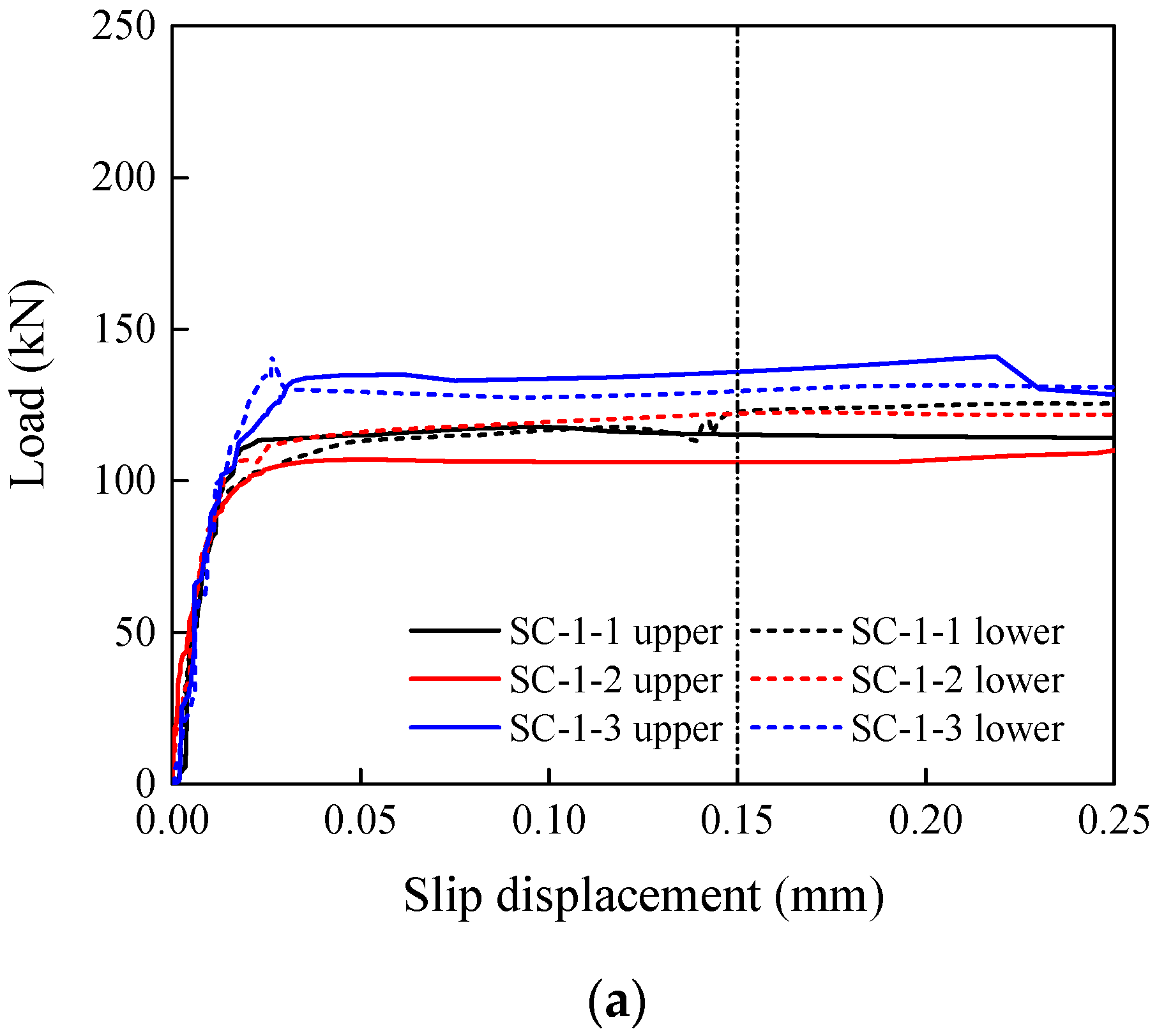

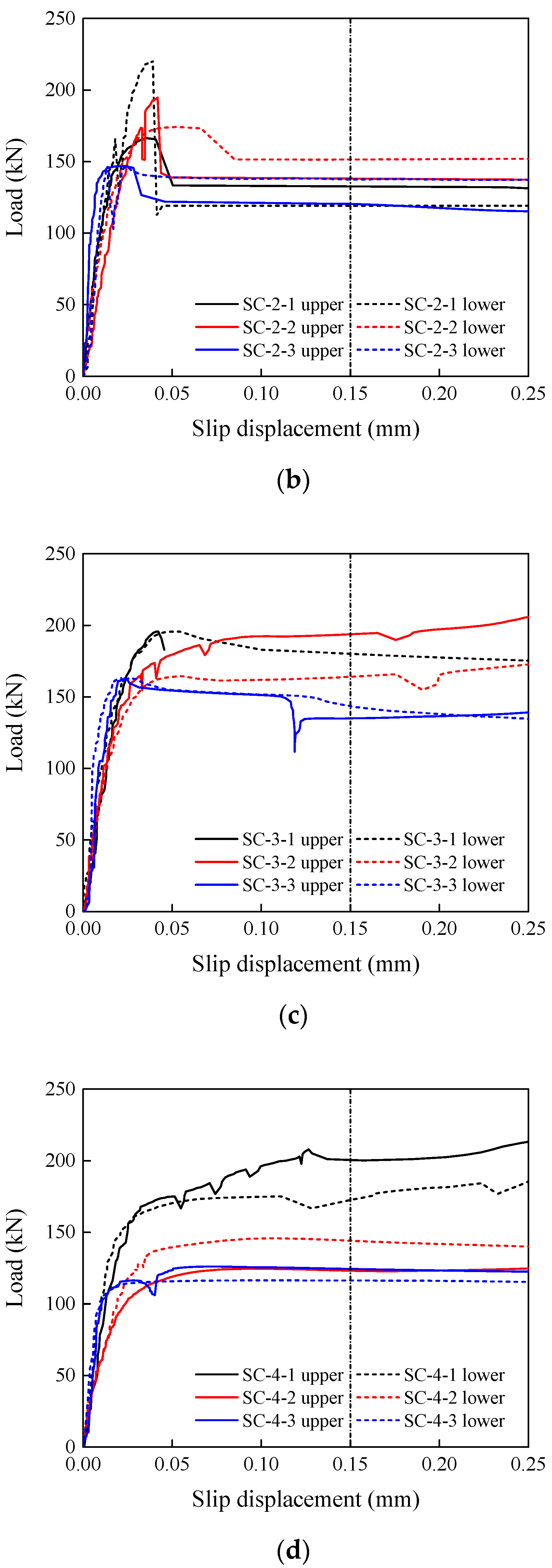

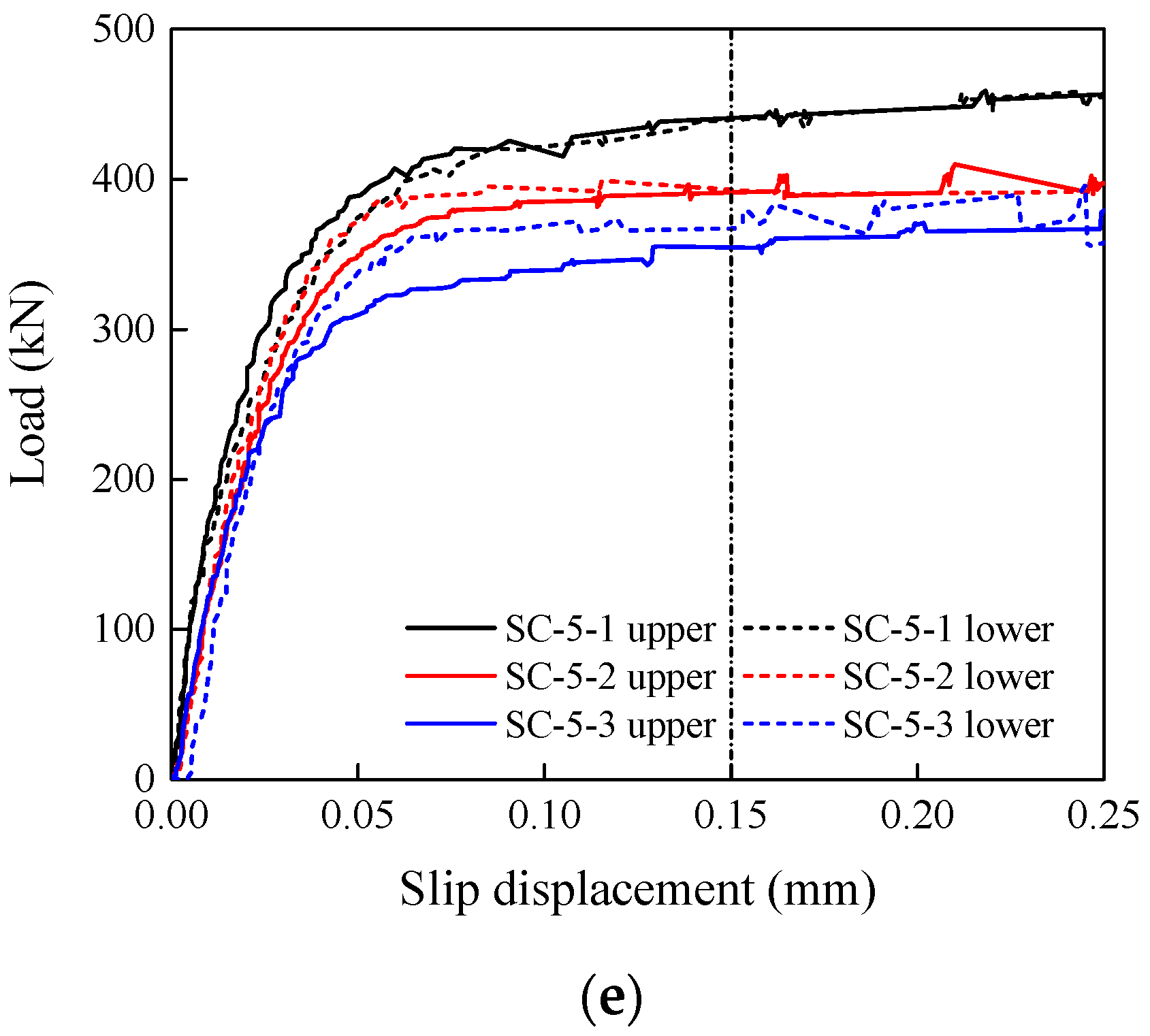

3.3. Static Tests

3.4. Creep Tests

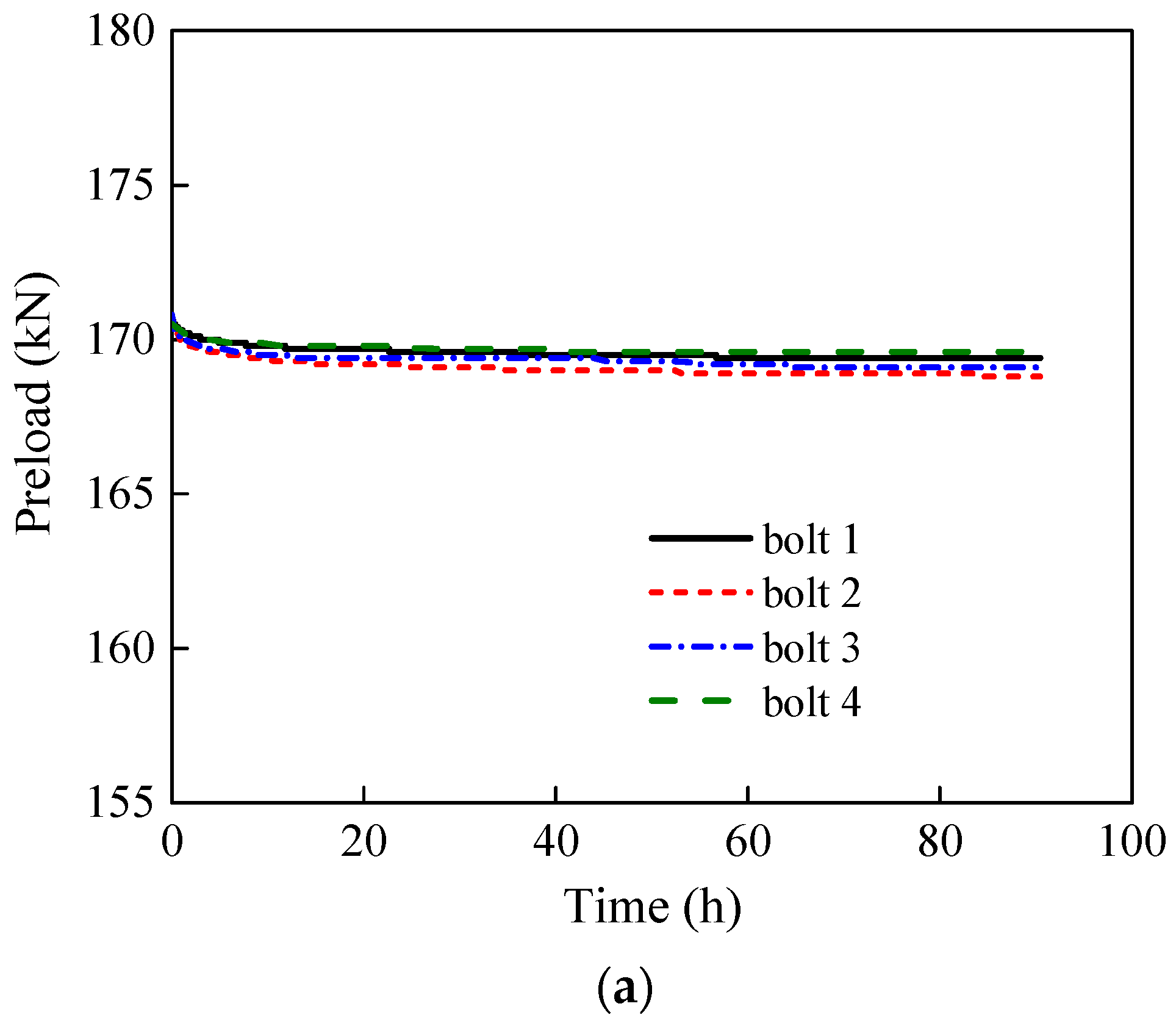

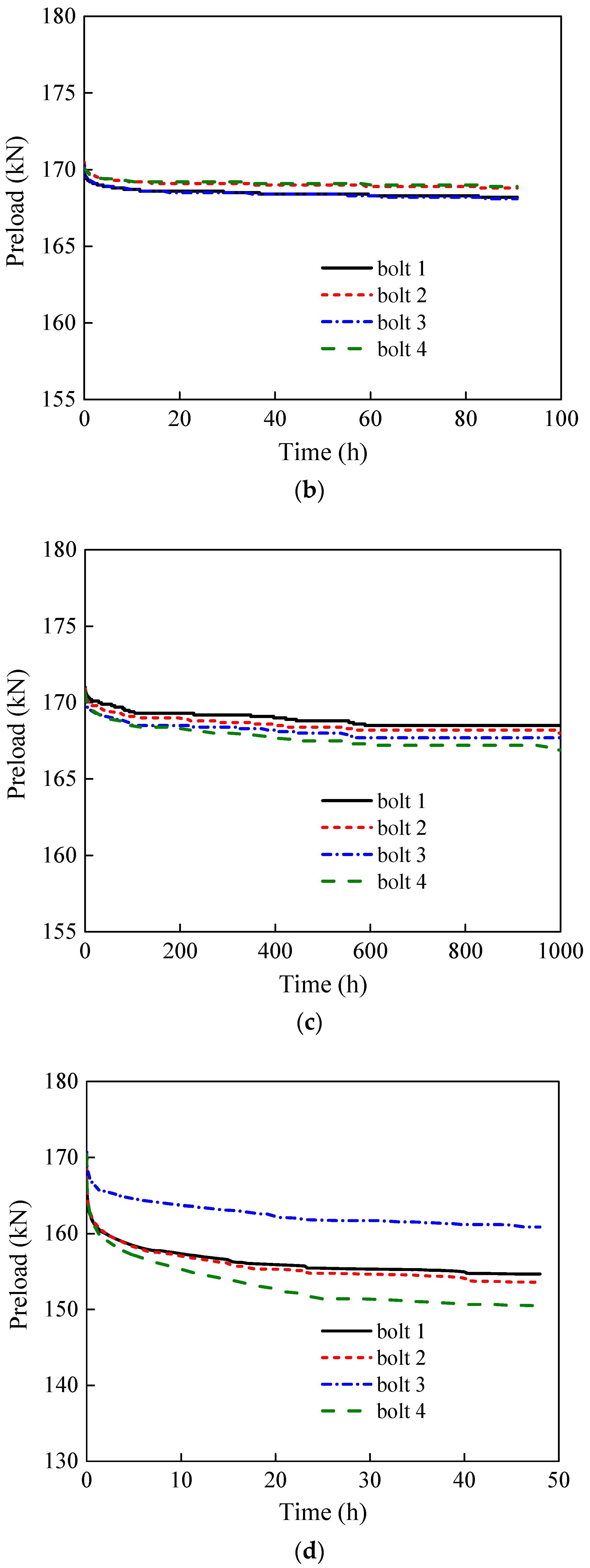

4. Preload Relaxation Monitoring

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- EN1993-1-4:2016/A1:2015; Eurocode 3: Design of Steel Structures-Part 1.4: General Rules-Supplementary Rules for Stainless Steels. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- Steel Design Guide 27 Structural Stainless Steel; American Institute of Steel Construction: Chicago, IL, USA, 2013.

- AS/NZS (Australian/New Zealand-Standard). AS/NZS 4673:2001; Cold-Formed Stainless Steel Structures. Standards Australia: Sydney, Australia, 2001.

- SEI/ASCE-8-02; Specification for the Design of Cold-Formed Stainless Steel Structural Members. American Society of Civil Engineers: Reston, VA, USA, 2002.

- CECS 410:2015; Technical Specification for Stainless Steel Structures. China Planning Press: Beijing, China, 2015. (In Chinese)

- Stainless Steel Building Structures Association. Japanese Standard for Design of Stainless Steel Building Structures, 2nd ed.; Tashiro Press: Kagoshima, Japan, 2001. (In Japanese) [Google Scholar]

- EN 1090-2:2008+A1; Execution of Steel Structures and Aluminium Structures—Part 2: Technical Requirements for Steel Structures. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- RCSC. Specification for Structural Joints Using High-Strength Bolts, 2009; Research Council on Structural Connections: Chicago, IL, USA, 2009.

- Wang, Y.; Guan, J.; Zhang, Y.; Yang, L. Experimental Research on Slip Factor in Bolted Connection with Stainless Steel. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2013, 29, 769–774. (In Chinese) [Google Scholar]

- Stranghöner, N.; Afzali, N.; de Vries, P.; Schedin, E.; Phihagen, J. Slip factors for slip resistant connections made of stainless steel. J. Constr. Steel Res. 2019, 152, 235–245. [Google Scholar] [CrossRef]

- Stranghöner, N.; Afzali, N.; de Vries, P.; Schedin, E.; Pilhagen, J.; Cardwell, S. Slip resistant bolted connections of stainless steel. Steel Constr. 2017, 10, 333–343. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, J.; Gu, Y.; Shu, G.; Xie, J.; Jiang, Q. Experimental study on stainless steel high-strength bolted slip-resistant connections. Eng. Struct. 2021, 231, 111778. Available online: https://www.sciencedirect.com/science/article/pii/S0141029620343790 (accessed on 14 August 2022). [CrossRef]

- Zhang, Y.; Wang, Y.; Zhi, X.; Li, B.; Ouyang, Y. Experimental study on slip resistant behaviours of aluminium alloy-stainless steel faying surfaces. SSRN 2022, 4069238. [Google Scholar] [CrossRef]

- Peng, Y.; Chen, W.; Wu, Z.; Zhao, J.; Dong, J. Experimental Study on the performance of GFRP–GFRP slip-critical connections with and without stainless-steel cover plates. Appl. Sci. 2020, 10, 4393. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Wang, Z.; Chen, S.; Du, X.; Zhang, T.; Guo, Z.; Yuan, H. Design and analysis of a 1-ton prototype of the Jinping Neutrino Experiment. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2017, 855, 81–87. [Google Scholar] [CrossRef]

- Afzali, N.; Pilhagen, J.; Manninen, T.; Schedin, E.; Stranghöner, N. Preload losses in stainless steel bolting assemblies. Steel Constr. 2017, 10, 310–318. [Google Scholar] [CrossRef]

- Afzali, N.; Stranghöner, N.; Pilhagen, J.; Manninen, T.; Schedin, E. Viscoplastic deformation behaviour of preloaded stainless steel connections. J. Constr. Steel Res. 2019, 152, 225–234. [Google Scholar] [CrossRef]

- Hasan, S. Design of Experiment Analysis of High Velocity Oxy-Fuel Coating of Hydroxyapatite. Doctoral Dissertation, Dublin City University, Dublin, Ireland. 2009. Available online: http://doras.dcu.ie/14876/ (accessed on 14 August 2022).

- GB/T 1228-2006; High Strength Bolts with Large Hexagon Head for Steel Structures. Standards Press of China: Beijing, China, 2006. (In Chinese)

- GB/T 1229-2006; High Strength Large Hexagon Nuts for Steel Structures. Standards Press of China: Beijing, China, 2006. (In Chinese)

- Zhang, T.; Wang, Y.; Chen, Z.; Bu, Y.; He, W.; Heng, Y. Experimental Study on Mechanical Properties and Tightening Methods of Stainless Steel High Strength Bolts. Industrial Construction:1-12. Available online: http://kns.cnki.net/kcms/detail/11.2068.TU.20220802.0930.014.html. (accessed on 14 August 2022). (In Chinese).

- EN ISO 898-1:2013; Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel—Part 1: Bolts, Screws and Studs with Specified Property Classes—Coarse Thread and Fine Pitch Thread. Technical Committee ISO/TC2: Milan, Italy, 2013.

- GB 50205-2001; Standard for Acceptance of Construction Quality of Steel Structures. China Planning Press: Beijing, China, 2002. (In Chinese)

- GB/T 10610-2009 (ISO 4288:1996); Geometrical Product Specification (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. Standards Press of China: Beijing, China, 2009. (In Chinese)

- GB/T 230.1-2018; Metallic Materials—Rockwell Hardness Test—Part 1: Test Method. Standards Press of China: Beijing, China, 2018. (In Chinese)

- EN ISO 4017:2014; Fasteners—Hexagon Head Screws—Product Grades A and B. European Committee for Standardization: Brussels, Belgium, 2014.

- JGJ 82-2011; Technical Specification for High Strength Bolt Connections of Steel Structures. Standards Press of China: Beijing, China, 2011. (In Chinese)

| Surface Treatment | Number of Specimens |

|---|---|

| Polishing | 3 |

| Brushing | 3 |

| Grit blasting | 3 |

| Shot blasting | 3 |

| Grit blasting–HVOF coating | 18 |

| Surface Treatment | Specimen ID | Pi (kN) | Slip Load Nv (kN) | Slip Factor µ | Average Slip Factor µ | Roughness Ra (µm) | Hardness (HRB) | Sound | |

|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | ||||||||

| Polishing | SC-1-1 | 171.1 | 170.8 | 117.8 | 0.17 | 0.18 | 1.10 | 98.5 | No |

| SC-1-2 | 171.5 | 170.3 | 106.9 | 0.16 | No | ||||

| SC-1-3 | 172.6 | 171.8 | 135.7 | 0.20 | No | ||||

| Brushing | SC-2-1 | 168.7 | 168.2 | 166.4 | 0.25 | 0.24 | 5.22 | 94.3 | No |

| SC-2-2 | 170.7 | 170.3 | 174.3 | 0.26 | No | ||||

| SC-2-3 | 169.9 | 170.2 | 146.9 | 0.22 | No | ||||

| Grit blasting | SC-3-1 | 169.4 | 170.1 | 195.7 | 0.29 | 0.26 | 5.93 | 93.6 | No |

| SC-3-2 | 168.8 | 169.5 | 164.8 | 0.24 | No | ||||

| SC-3-3 | 169.5 | 170.2 | 163.2 | 0.24 | No | ||||

| Shot blasting | SC-4-1 | 171.8 | 169.3 | 175.5 | 0.26 | 0.20 | 4.46 | 97.0 | No |

| SC-4-2 | 171.4 | 171.5 | 124.6 | 0.18 | No | ||||

| SC-4-3 | 170.6 | 169.3 | 116.5 | 0.17 | No | ||||

| Grit blasting–HVOF coating | SC-5-1 | 171.6 | 169.9 | 442.0 | 0.65 | 0.61 | 8.75 | 95.0 | Yes |

| SC-5-2 | 170.5 | 170.3 | 397.1 | 0.58 | Yes | ||||

| SC-5-3 | 171.1 | 170.5 | 355.2 | 0.52 | Yes | ||||

| SC-5-4 | 170.2 | 169.4 | 378.9 | 0.56 | Yes | ||||

| SC-5-5 | 170.0 | 169.9 | 383.2 | 0.56 | Yes | ||||

| SC-5-6 | 170.2 | 171.8 | 380.2 | 0.56 | Yes | ||||

| SC-5-7 | 172.4 | 170.8 | 449.6 | 0.66 | Yes | ||||

| SC-5-8 | 171.3 | 170.6 | 461.4 | 0.67 | Yes | ||||

| SC-5-9 | 170.5 | 172.1 | 417.9 | 0.61 | Yes | ||||

| SC-5-10 | 171.4 | 171.1 | 391.8 | 0.57 | Yes | ||||

| SC-5-11 | 170.9 | 170.2 | 395.0 | 0.58 | Yes | ||||

| SC-5-12 | 169.2 | 170.4 | 336.5 | 0.50 | Yes | ||||

| SC-5-13 | 170.5 | 169.1 | 393.0 | 0.58 | Yes | ||||

| SC-5-14 | 172.2 | 170.1 | 467.7 | 0.68 | Yes | ||||

| SC-5-15 | 171.6 | 168.7 | 458.5 | 0.67 | Yes | ||||

| SC-5-16 | 170.7 | 170.9 | 451.7 | 0.66 | Yes | ||||

| SC-5-17 | 171.2 | 169.7 | 450.8 | 0.66 | Yes | ||||

| SC-5-18 | 170.9 | 170.4 | 450.3 | 0.66 | Yes | ||||

| Bolt Type | Bolt Number | Preload (kN) | |||||

|---|---|---|---|---|---|---|---|

| 0 h | 2 h | 24 h | 48 h | 90 h | 1000 h | ||

| SS 10.9 Group 1 | 1 | 170.7 | 170.1 | 169.6 | 169.5 | 169.4 | - |

| 2 | 170.8 | 169.8 | 169.2 | 169.0 | 168.8 | - | |

| 3 | 170.8 | 169.9 | 169.4 | 169.3 | 169.1 | - | |

| 4 | 170.5 | 170.1 | 169.8 | 169.6 | 169.6 | - | |

| SS 10.9 Group 2 | 1 | 170.2 | 169.1 | 168.6 | 168.4 | 168.2 | - |

| 2 | 170.5 | 169.6 | 169.1 | 169.0 | 168.8 | - | |

| 3 | 170.3 | 169.2 | 168.5 | 168.4 | 168.1 | - | |

| 4 | 170.1 | 169.5 | 169.2 | 169.1 | 168.9 | - | |

| SS 10.9 Group 3 | 1 | 171.0 | 170.6 | 170.1 | 169.9 | 169.5 | 168.5 |

| 2 | 170.9 | 170.4 | 169.8 | 169.5 | 169.2 | 168.0 | |

| 3 | 170.5 | 170.0 | 169.3 | 169.1 | 168.7 | 167.7 | |

| 4 | 170.7 | 170.1 | 169.4 | 169.1 | 168.6 | 166.9 | |

| Class 10.9 | 1 | 170.6 | 160.0 | 155.5 | 154.7 | - | - |

| 2 | 170.5 | 160.1 | 154.8 | 153.6 | - | - | |

| 3 | 170.7 | 165.5 | 161.8 | 160.9 | - | - | |

| 4 | 170.4 | 159.2 | 151.6 | 150.5 | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Bu, Y.; Wang, Y.; Chen, Z.; He, W. Experimental Study on the Slip Behaviour of Stainless Steel High-Strength Bolted Connections with a New Surface Treatment. Materials 2022, 15, 5672. https://doi.org/10.3390/ma15165672

Zhang T, Bu Y, Wang Y, Chen Z, He W. Experimental Study on the Slip Behaviour of Stainless Steel High-Strength Bolted Connections with a New Surface Treatment. Materials. 2022; 15(16):5672. https://doi.org/10.3390/ma15165672

Chicago/Turabian StyleZhang, Tianxiong, Yidu Bu, Yuanqing Wang, Zhihua Chen, and Wei He. 2022. "Experimental Study on the Slip Behaviour of Stainless Steel High-Strength Bolted Connections with a New Surface Treatment" Materials 15, no. 16: 5672. https://doi.org/10.3390/ma15165672

APA StyleZhang, T., Bu, Y., Wang, Y., Chen, Z., & He, W. (2022). Experimental Study on the Slip Behaviour of Stainless Steel High-Strength Bolted Connections with a New Surface Treatment. Materials, 15(16), 5672. https://doi.org/10.3390/ma15165672