Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis

Abstract

:1. Introduction

2. Establishment and Verification of the Meso-Model of RAC

2.1. Establishment of the Meso-Model of RAC

2.2. Constitutive Model

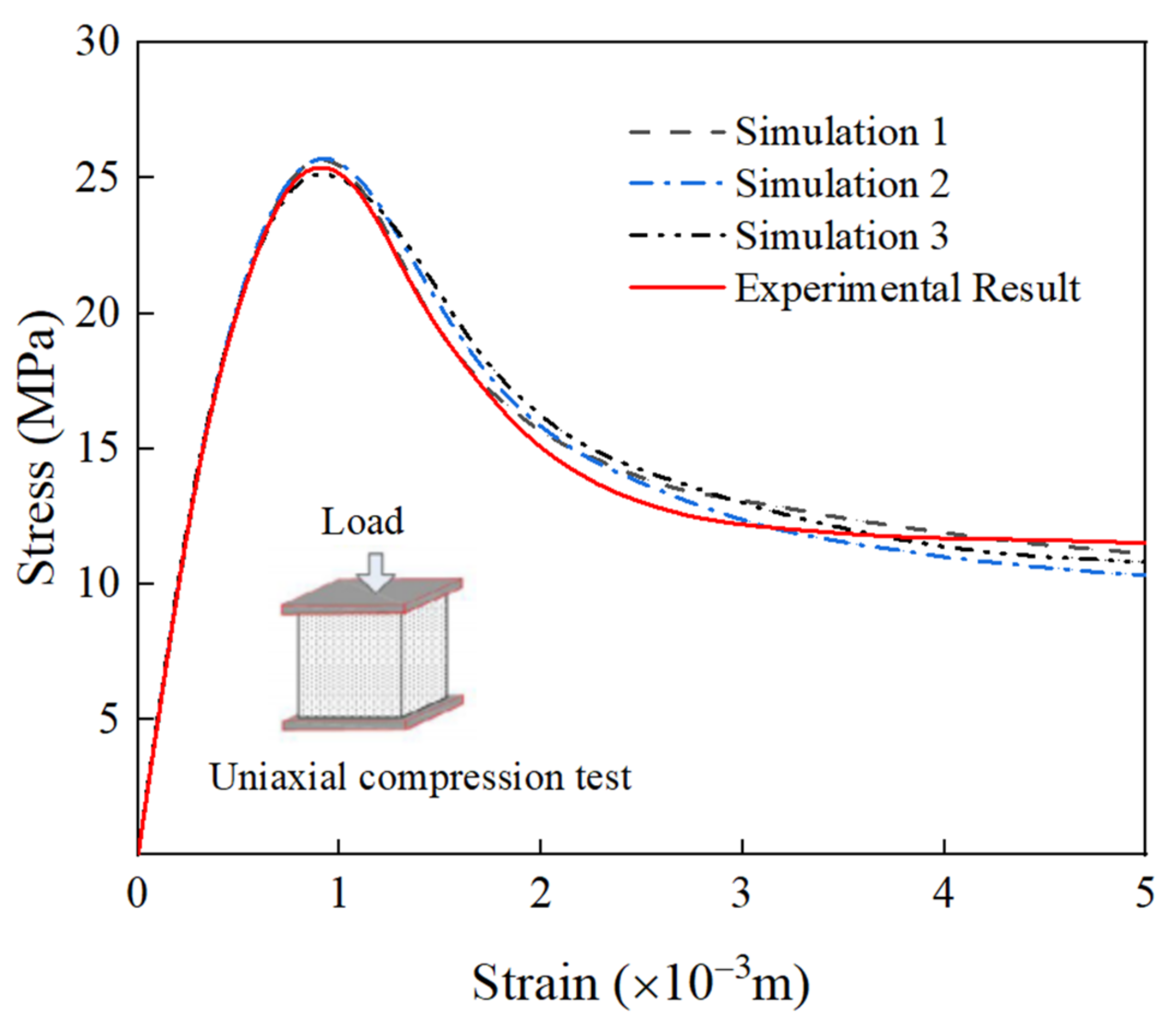

2.3. Verification of the Meso-Model

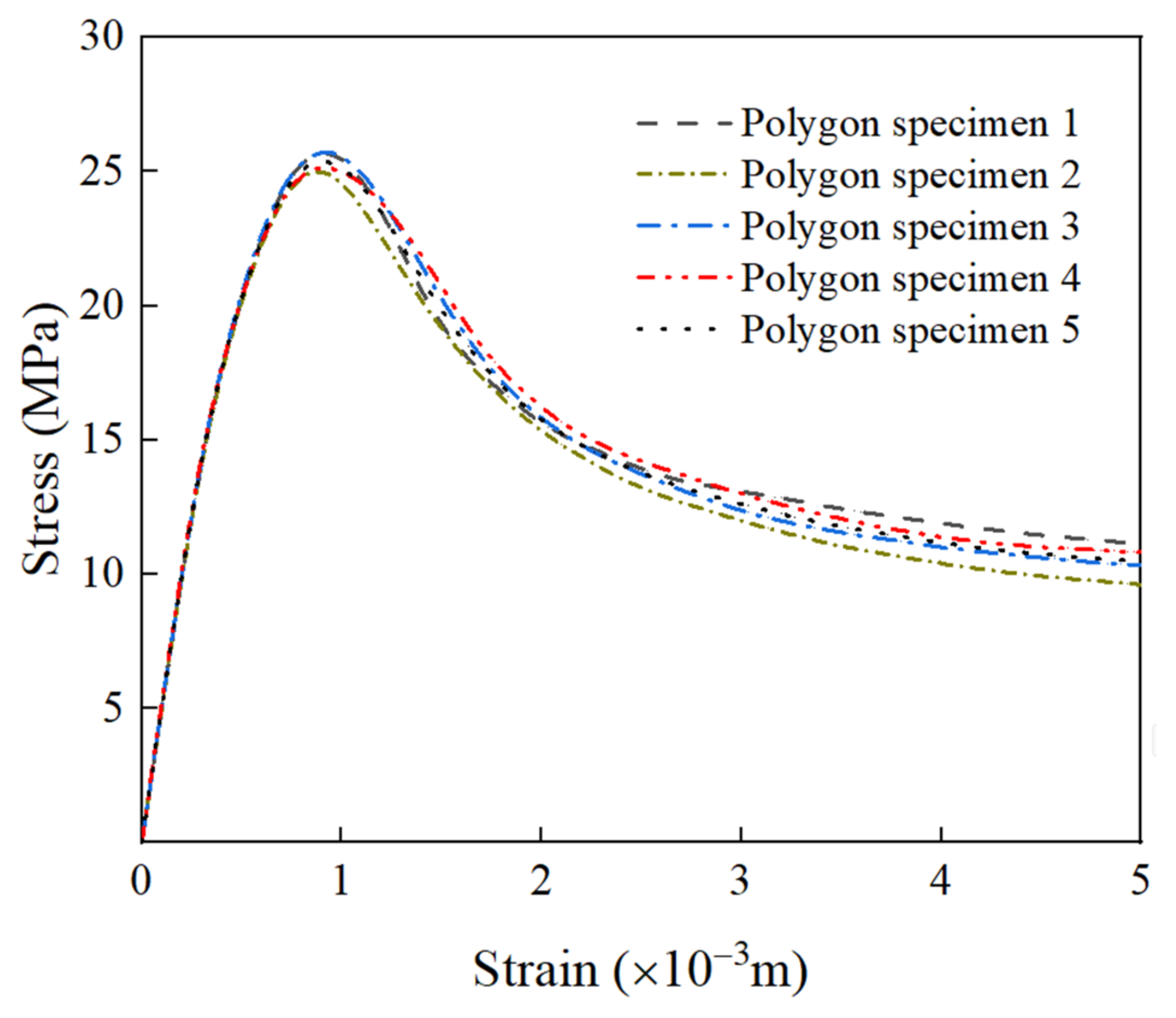

2.4. Analysis of the Boundary Conditions and Random Distribution of RAC

2.5. Study on Mesh-Dependence

3. The Effect of ITZ on the Compressive Properties of RAC

3.1. The Effect of the Strength of ITZ on the Compressive Properties of RAC

3.2. The Effect of ITZ Thickness on the Compressive Properties of RAC

4. The Size Effect of RAC under Uniaxial Compression under Different Maximum Aggregate Sizes

4.1. Compression Failure Mode of RAC under Different Maximum Aggregate Sizes

4.2. The Stress–Strain Relationship of RAC under Different Maximum Aggregate Sizes

4.3. The Effect of the Maximum Aggregate Size on the Peak Compressive Strength of RAC

5. Analysis of the Size Effect of RAC under Uniaxial Compression Based on the Maximum Aggregate Size

5.1. Analysis of Size Effect Degree of RAC

5.2. Theoretical Verification of the Size Effect of Bažant

5.3. Application of Meso-Numerical Simulation in Practical Engineering

- (1)

- The meso-mechanical analysis model of concrete is extended to the three-dimensional solid model, which can effectively predict the whole process of damage to fracture of concrete members under external load. At present, it is widely used in the long-term health monitoring of bridges and dams.

- (2)

- Through mesoscopic numerical simulation, the influence trend of fiber and other admixture materials on the mechanical properties and durability of concrete members can be accurately reflected, which has important guiding significance for the construction of practical projects. For example, the ultimate load of steel fiber reinforced concrete for bridge expansion joints and basalt fiber-reinforced concrete for structural toughening should be verified.

- (3)

- The meso-numerical analysis of concrete can be combined with the advanced 3D printing technology, which can effectively simulate the strength of 3D-printed concrete and other information. For practical projects, it can save a lot of manpower and material resources.

- (4)

- Meso-numerical analysis is the research basis of large-scale building components, such as seismic analysis of nuclear power plant and safety analysis of subway support design. Meso-analysis is the theoretical basis for the actual construction of mass concrete members.

6. Conclusions

- (1)

- With an increase in the ITZ strength, the compressive strength and elastic modulus of RAC linearly increase with the slope of 10.85 and 12.82, respectively, and the failure mode of RAC under uniaxial compression basically remains unchanged. With an increase in the ITZ thickness, the compressive strength and elastic modulus of RAC decrease linearly with the slope of −5.71 and −4.38, respectively, and the failure mode of RAC under uniaxial compression changes from a single macroscopic main crack to multiple macroscopic cracks.

- (2)

- The compressive strength of RAC has a size effect under different maximum aggregate sizes. The larger the specimen size, the greater the brittleness, and the size effect is more obvious. With an increase in the maximum aggregate size, the compressive strength of RAC with a size of 300 mm decreases by 19.06%, 17.72%, 16.78%, and 15.76%, respectively.

- (3)

- At the same size, with an increase in the maximum aggregate size, the curvature of the crack and the roughness of the failure surface of RAC increase; thus, the compressive strength increases. With an increase in the size, the compressive strength increases by 6% and 10%.

- (4)

- Increasing the maximum aggregate size (within the range of this study) can reduce the sensitivity of the compressive strength of RAC to size, thus weakening the size effect. Among them, when the maximum aggregate size reaches 30 mm, a decrease in the size effect degree tends to slow down compared with the maximum aggregate size of 20 mm.

- (5)

- The classical Bažant size effect law can accurately describe the simulation results under different maximum aggregate sizes, which is suitable for the size effect analysis on the compressive strength of RAC. In addition, it has a certain guiding significance for the prediction of the size effect of RAC in practical engineering.

- (1)

- Study on the meso-mechanical behavior of RAC under three-dimensional load;

- (2)

- Meso-numerical study on the axial tensile and fracture properties of RAC;

- (3)

- Study on the dynamic failure of RAC under different strain rates;

- (4)

- Meso-numerical study on the failure of RAC using a phase field method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bu, C.; Liu, L.; Lu, X. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Tam, V.W.; Le, K.N. Factors affecting the price of recycled concrete: A critical review. J. Build. Eng. 2022, 46, 103743. [Google Scholar] [CrossRef]

- Piccinali, A.; Diotti, A.; Plizzari, G. Impact of Recycled Aggregate on the Mechanical and Environmental Properties of Concrete: A Review. Materials 2022, 15, 1818. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W. Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. J. Sustain. Cem. Based Mater. 2022, 11, 41–61. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W.; Akbar, A. Influence of Elevated Temperatures on the Mechanical Performance of Sustainable-Fiber-Reinforced Recycled Aggregate Concrete: A Review. Buildings 2022, 12, 487. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Li, W.; Luo, Z.; Long, C. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater. Des. 2016, 112, 58–66. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Kazmi, S.M. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates–Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Klama, J.; Zawal, D. Modification of recycled concrete aggregate by calcium carbonate biodeposition. Constr. Build. Mater. 2012, 34, 145–150. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P. Mechanical properties and meso-microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete. J. Clean. Prod. 2022, 370, 133555. [Google Scholar] [CrossRef]

- Fang, S.; Hong, H.; Zhang, P. Mechanical Property Tests and Strength Formulas of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, S.; Hughes, P. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar]

- Wang, Y.; Hughes, P.; Niu, H. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nano-silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Pradhan, S.; Kumar, S.; Barai, S. Multi-scale characterisation of recycled aggregate concrete and prediction of its performance. Cem. Concr. Compos. 2020, 106, 103480. [Google Scholar] [CrossRef]

- Wu, C.; Hong, Z.; Zhang, J. Pore size distribution and ITZ performance of mortars prepared with different bio-deposition approaches for the treatment of recycled concrete aggregate. Cem. Concr. Compos. 2020, 111, 103631. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete. Constr. Build. Mater. 2021, 304, 124659. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, Y. Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol. Rev. 2022, 11, 2169–2189. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, Y.; Bie, Y. The prediction analysis of properties of recycled aggregate permeable concrete based on back-propagation neural network. J. Clean. Prod. 2020, 276, 124187. [Google Scholar] [CrossRef]

- Lian, S.; Ruan, S.; Zhan, S. Unlocking the role of pores in chloride permeability of recycled concrete: A multiscale and a statistical investigation. Cem. Concr. Compos. 2022, 125, 104320. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, B.; Ye, B. Mechanical behavior and constitutive relationship of the three types of recycled coarse aggregate concrete based on standard classification. J. Mater. Cycles Waste Manag. 2020, 22, 30–45. [Google Scholar] [CrossRef]

- Hrennikoff, A. Solution of problems of elasticity by the framework method. J. Appl. Mech. 1941, 8, A169–A175. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Li, K.; Li, D.; Li, P. Meso-mechanical investigations on the overall elastic properties of multi-phase construction materials using finite element method. Constr. Build. Mater. 2019, 228, 116727. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Hansen, W. Micromechanical modeling of concrete response under static loading—Part 1: Model development and validation. Mater. J. 1999, 96, 196–203. [Google Scholar]

- Bažant, Z.P.; Tabbara, M.R.; Kazemi, M.T. Random particle model for fracture of aggregate or fiber composites. J. Eng. Mech. 1990, 116, 1686–1705. [Google Scholar] [CrossRef]

- Schlangen, E.; Van Mier, J. Lattice model for numerical simulation of concrete fracture. In Proceedings of the International Conference on Dam Fracture, Denver, CO, USA, 11–13 September 1991. [Google Scholar]

- Xiong, Q.; Wang, X.; Jivkov, A.P. A 3D multi-phase meso-scale model for modelling coupling of damage and transport properties in concrete. Cem. Concr. Compos. 2020, 109, 103545. [Google Scholar] [CrossRef]

- Cusatis, G.; Mencarelli, A.; Pelessone, D. Lattice discrete particle model (LDPM) for failure behavior of concrete. II: Calibration and validation. Cem. Concr. Compos. 2011, 33, 891–905. [Google Scholar] [CrossRef]

- Nagai, K.; Sato, Y.; Ueda, T. Mesoscopic simulation of failure of mortar and concrete by 2D RBSM. J. Adv. Concr. Technol. 2004, 2, 359–374. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Corr, D.J. Simulation study on the stress distribution in modeled recycled aggregate concrete under uniaxial compression. J. Mater. Civ. Eng. 2013, 25, 504–518. [Google Scholar] [CrossRef]

- Peng, Y.; Chu, H.; Pu, J. Numerical simulation of recycled concrete using convex aggregate model and base force element method. Adv. Mater. Sci. Eng. 2016, 2016, 5075109. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Tam, V.W.; Gao, X.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Jayasuriya, A.; Adams, M.P.; Bandelt, M.J. Understanding variability in recycled aggregate concrete mechanical properties through numerical simulation and statistical evaluation. Constr. Build. Mater. 2018, 178, 301–312. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A. Microstructure analysis of hardened recycled aggregate concrete. Mag. Concr. Res. 2006, 58, 683–690. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Corr, D.J. Effects of interfacial transition zones on the stress–strain behavior of modeled recycled aggregate concrete. Cem. Concr. Res. 2013, 52, 82–99. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, Z. Experimental study on the failure mechanism of recycled concrete. Cem. Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Del Bosque, I.F.S.; Zhu, W.; Howind, T. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Kong, L.; Gao, L.; Du, Y. Effect of coarse aggregate on the interfacial transition zone of concrete based on grey correlation. Mag. Concr. Res. 2014, 66, 339–347. [Google Scholar] [CrossRef]

- Bazoant, Z.P. Size effect in blunt fracture: Concrete, rock, metal. J. Eng. Mech. 1984, 110, 518–535. [Google Scholar] [CrossRef]

- Bazoant, Z.P.; Xu, K. Size effect in fatigue fracture of concrete. ACI Mater. J. 1991, 88, 390–399. [Google Scholar]

- Bažant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials; Routledge: Abingdon, UK, 2019. [Google Scholar]

- Weibull, W. The phenomenon of rupture in solids. IVA Handl. 1939, 153, 1–55. [Google Scholar]

- Carpinteri, A.; Ferro, G. Size effects on tensile fracture properties: A unified explanation based on disorder and fractality of concrete microstructure. Mater. Struct. 1994, 27, 563–571. [Google Scholar] [CrossRef]

- Huang, W.; Cai, X.; Li, X. Influence of nominal maximum aggregate size and aggregate gradation on pore characteristics of porous asphalt concrete. Materials 2020, 13, 1355. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Yang, K.; Sim, J. Direct tensile strength of lightweight concrete with different specimen depths and aggregate sizes. Constr. Build. Mater. 2014, 63, 132–141. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Li, D. Numerical and theoretical investigation on the size effect of concrete compressive strength considering the maximum aggregate size. Int. J. Mech. Sci. 2021, 192, 106130. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X. Size effect on static splitting tensile strength of concrete: Experimental and numerical studies. J. Mater. Civ. Eng. 2020, 32, 4020308. [Google Scholar] [CrossRef]

- Wittmann, F.H.; Roelfstra, P.E.; Sadouki, H. Simulation and analysis of composite structures. Mater. Sci. Eng. 1985, 68, 239–248. [Google Scholar] [CrossRef]

- Walraven, J.C.; Reinhardt, H.W. Concrete mechanics. Part A: Theory and experiments on the mechanical behavior of cracks in plain and reinforced concrete subjected to shear loading. Nasa Sti/Recon Tech. Rep. N 1981, 82, 25417. [Google Scholar]

- Sadouki, H.; Wittmann, F.H. On the analysis of the failure process in composite materials by numerical simulation. Mater. Sci. Eng. A 1988, 104, 9–20. [Google Scholar] [CrossRef]

- Grassl, P.; Grégoire, D.; Solano, L.R. Meso-scale modelling of the size effect on the fracture process zone of concrete. Int. J. Solids Struct. 2012, 49, 1818–1827. [Google Scholar] [CrossRef]

- Pedersen, R.; Simone, A.; Sluys, L.J. Mesoscopic modeling and simulation of the dynamic tensile behavior of concrete. Cem. Concr. Res. 2013, 50, 74–87. [Google Scholar] [CrossRef]

- Yue, Q.; Wang, L.; Liu, F. Numerical study on damage process of recycled aggregate concrete by real meso-scale model. J. Build. Mater. 2016, 19, 221–228. [Google Scholar]

- Huang, Y.; Yang, Z.; Ren, W. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray Computed Tomography images using damage plasticity model. Int. J. Solids Struct. 2015, 67, 340–352. [Google Scholar] [CrossRef]

- Heukamp, F.; Lemarchand, E.; Ulm, F.J. The effect of interfacial properties on the cohesion of highly filled composite materials. Int. J. Solids Struct. 2005, 42, 287–305. [Google Scholar] [CrossRef]

- Kim, S.; Al-Rub, R. Meso-scale computational modeling of the plastic-damage response of cementitious composites. Cem. Concr. Res. 2011, 41, 339–358. [Google Scholar] [CrossRef]

- Wang, X.; Jacobsen, S.; He, J. Application of nanoindentation testing to study of the interfacial transition zone in steel fiber reinforced mortar. Cem. Concr. Res. 2009, 39, 701–715. [Google Scholar] [CrossRef]

- Zhu, W.; Sonebi, M.; Bartos, P. Bond and interfacial properties of reinforcement in self-compacting concrete. Mater. Struct. 2004, 37, 442–448. [Google Scholar] [CrossRef]

- Sorelli, L.; Constantinides, G.; Ulm, F. The nano-mechanical signature of ultra high performance concrete by statistical nanoindentation techniques. Cem. Concr. Res. 2008, 38, 1447–1456. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F. The effect of two types of CSH on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar] [CrossRef]

- Mondal, P.; Shah, S.P.; Marks, L.D. Nanoscale characterization of cementitious materials. ACI Mater. J. 2008, 105, 174. [Google Scholar]

- Yu, W.; Jin, L.; Du, X. Influence of pre-static loads on dynamic compression and corresponding size effect of concrete: Mesoscale analysis. Constr. Build. Mater. 2021, 300, 124302. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Mo, Y. Behavior of meso-scale heterogeneous concrete under uniaxial tensile and compressive loadings. Constr. Build. Mater. 2018, 178, 418–431. [Google Scholar] [CrossRef]

- Benkemoun, N.; Poullain, N.; Al Khazraji, H. Meso-scale investigation of failure in the tensile splitting test: Size effect and fracture energy analysis. Eng. Fract. Mech. 2016, 168, 242–259. [Google Scholar] [CrossRef]

- Li, W.; Guo, L. Meso-fracture simulation of cracking process in concrete incorporating three-phase characteristics by peridynamic method. Constr. Build. Mater. 2018, 161, 665–675. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X. Mesoscopic numerical simulation of dynamic size effect on the splitting-tensile strength of concrete. Eng. Fract. Mech. 2019, 209, 317–332. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X. Effect of initial static load and dynamic load on concrete dynamic compressive failure. J. Mater. Civ. Eng. 2020, 32, 4020351. [Google Scholar] [CrossRef]

- Song, Z.; Lu, Y. Mesoscopic analysis of concrete under excessively high strain rate compression and implications on interpretation of test data. Int. J. Impact Eng. 2012, 46, 41–55. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Wang, J. Parametric analysis on compressive strain rate effect of concrete using mesoscale modeling approach. Constr. Build. Mater. 2020, 246, 118375. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Liu, Q. Meso-level numerical simulation on mechanical properties of modeled recycled concrete under uniaxial compression. J. Tongji Univ. 2011, 39, 791–797. [Google Scholar]

- Bažant, Z.P. Size effect. Int. J. Solids Struct. 2000, 37, 69–80. [Google Scholar] [CrossRef]

- Griffith, A.A. VI. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. 1921, 221, 163–198. [Google Scholar]

| Group | Mixture Proportion (kg/m3) | ||||

|---|---|---|---|---|---|

| Water | Cement | Sand | RCA | Water Reducing Agent | |

| RAC | 210 | 420 | 639 | 1136 | 4.2 |

| Group | Compressive Strength (MPa) | σ | CV (%) | |

|---|---|---|---|---|

| Test Value | Average Value | |||

| RAC | 26.41 | 25.9 | 0.56 | 2.16 |

| 25.12 | ||||

| 26.17 | ||||

| Mortar | 28.42 | 29.0 | 0.62 | 2.14 |

| 29.87 | ||||

| 28.71 | ||||

| Materials | Mortar | Adhered Mortar | New-ITZ | Old-ITZ |

|---|---|---|---|---|

| Proportional strength | 1 | 1.1 | 0.7 | 0.75 |

| Materials | Elastic Modulus GPa | Poisson’s Ratio | Compressive Strength MPa | Tensile Strength MPa |

|---|---|---|---|---|

| NCA | 70 | 0.16 | 70 | 7.0 |

| Mortar | 20.0 | 0.22 | 29 | 2.9 |

| Adhered mortar | 22.5 | 0.22 | 32 | 3.2 |

| New-ITZ | 14.0 | 0.2 | 19 | 1.9 |

| Old-ITZ | 15.0 | 0.2 | 22 | 2.2 |

| Size of Mesh/mm | Number of Mesh | Number of Cell Nodes | Computation Time/min |

|---|---|---|---|

| 0.5 | 118,916 | 127,835 | 240 |

| 1 | 35,313 | 40,609 | 100 |

| 1.5 | 18,446 | 23,426 | 30 |

| Thickness of ITZ mm | Peak Stress MPa | Peak Strain | Residual Stress MPa | Elastic Modulus GPa |

|---|---|---|---|---|

| 0.02 | 27.71 | 0.001 | 10.13 | 26.41 |

| 0.05 | 26.51 | 0.00095 | 10.11 | 26.03 |

| 0.3 | 25.70 | 0.00095 | 8.90 | 24.41 |

| 0.7 | 24.07 | 0.001 | 7.78 | 21.90 |

| 1.0 | 22.92 | 0.001 | 8.05 | 20.91 |

| dmax/mm | A | B | C | D |

|---|---|---|---|---|

| 20 | 0.00264 | 0.7513 | 1.15 | 285 |

| 25 | 0.00239 | 0.7741 | 1.14 | 324 |

| 30 | 0.00223 | 0.79092 | 1.12 | 355 |

| 35 | 0.00205 | 0.80833 | 1.11 | 543 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuo, J.; Zhang, Y.; Ma, M.; Zhang, Y.; Zheng, Y. Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis. Materials 2022, 15, 5710. https://doi.org/10.3390/ma15165710

Zhuo J, Zhang Y, Ma M, Zhang Y, Zheng Y. Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis. Materials. 2022; 15(16):5710. https://doi.org/10.3390/ma15165710

Chicago/Turabian StyleZhuo, Jingbo, Yamin Zhang, Mei Ma, Yu Zhang, and Yuanxun Zheng. 2022. "Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis" Materials 15, no. 16: 5710. https://doi.org/10.3390/ma15165710

APA StyleZhuo, J., Zhang, Y., Ma, M., Zhang, Y., & Zheng, Y. (2022). Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis. Materials, 15(16), 5710. https://doi.org/10.3390/ma15165710