Problems of HLAW Hybrid Welding of S1300QL Steel

Abstract

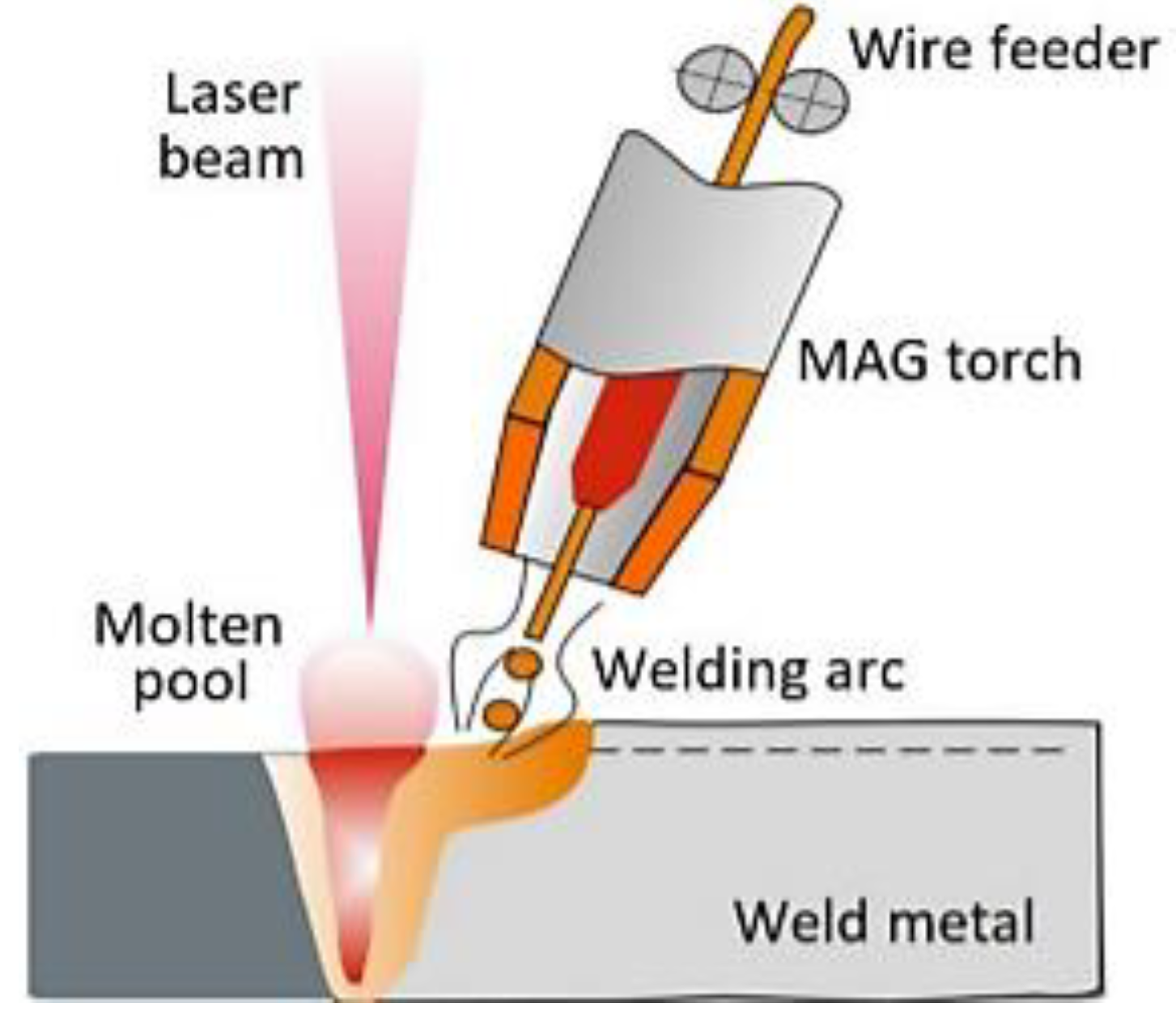

:1. Introduction

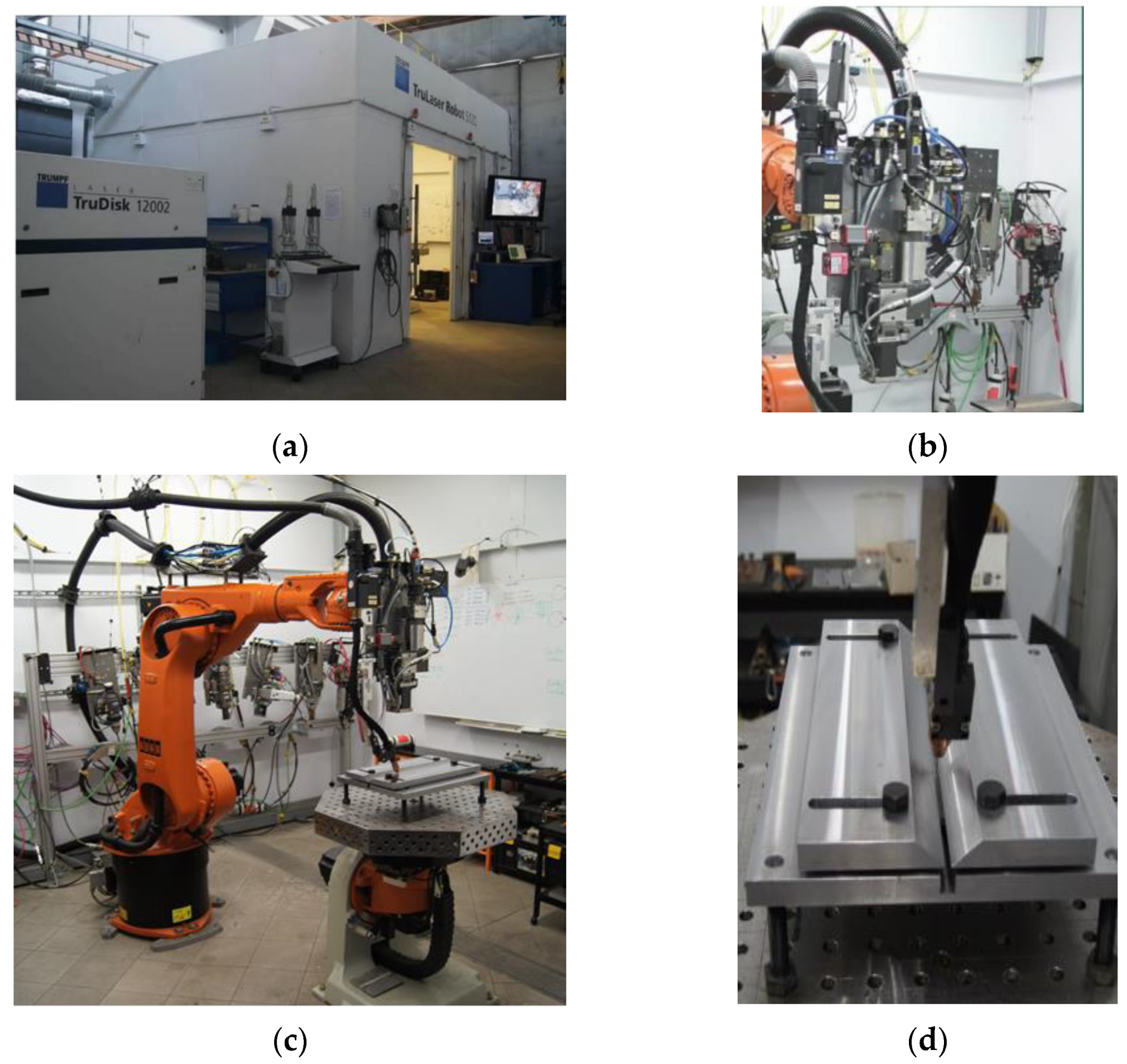

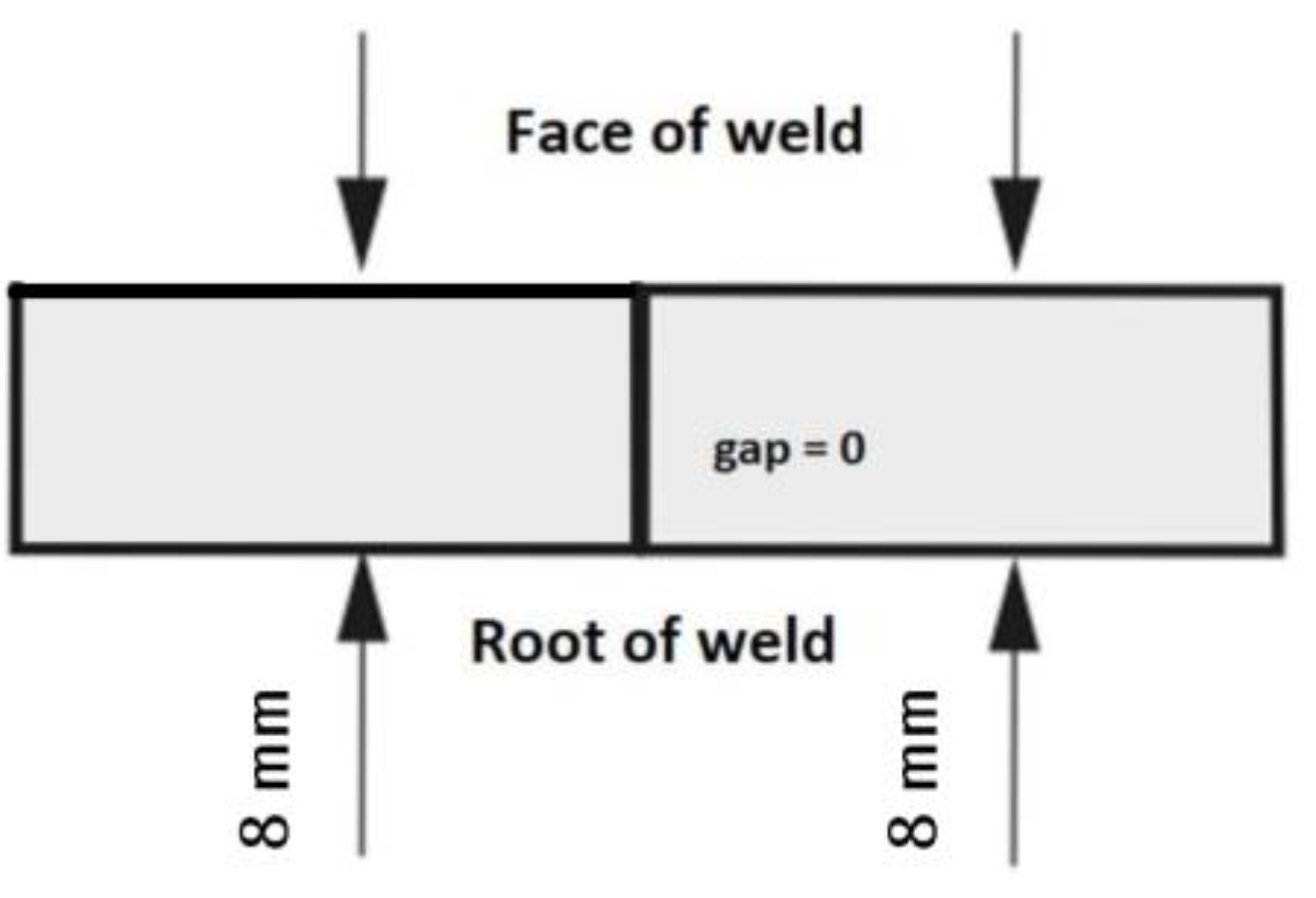

2. Materials and Methods

3. Results and Discussion

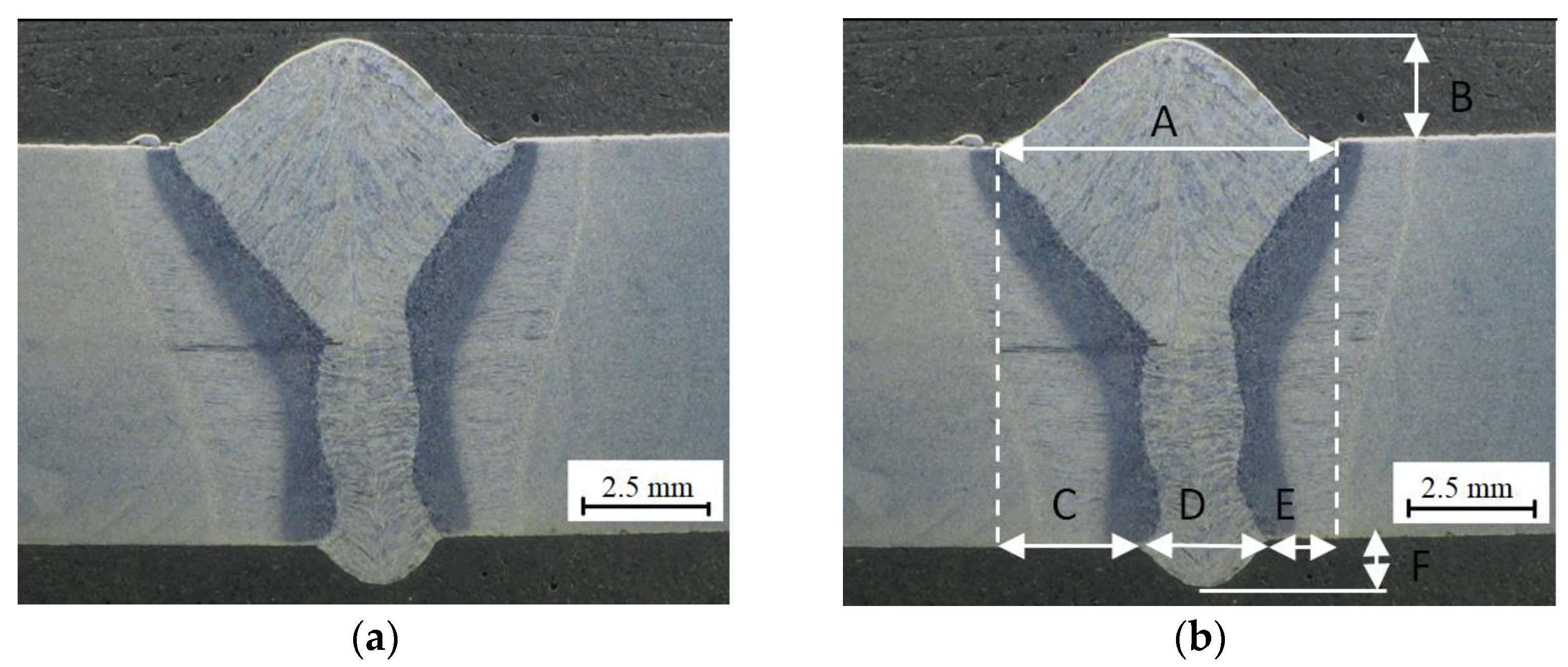

3.1. Visual and Macroscopic Examination

3.2. Radiographic Examinations

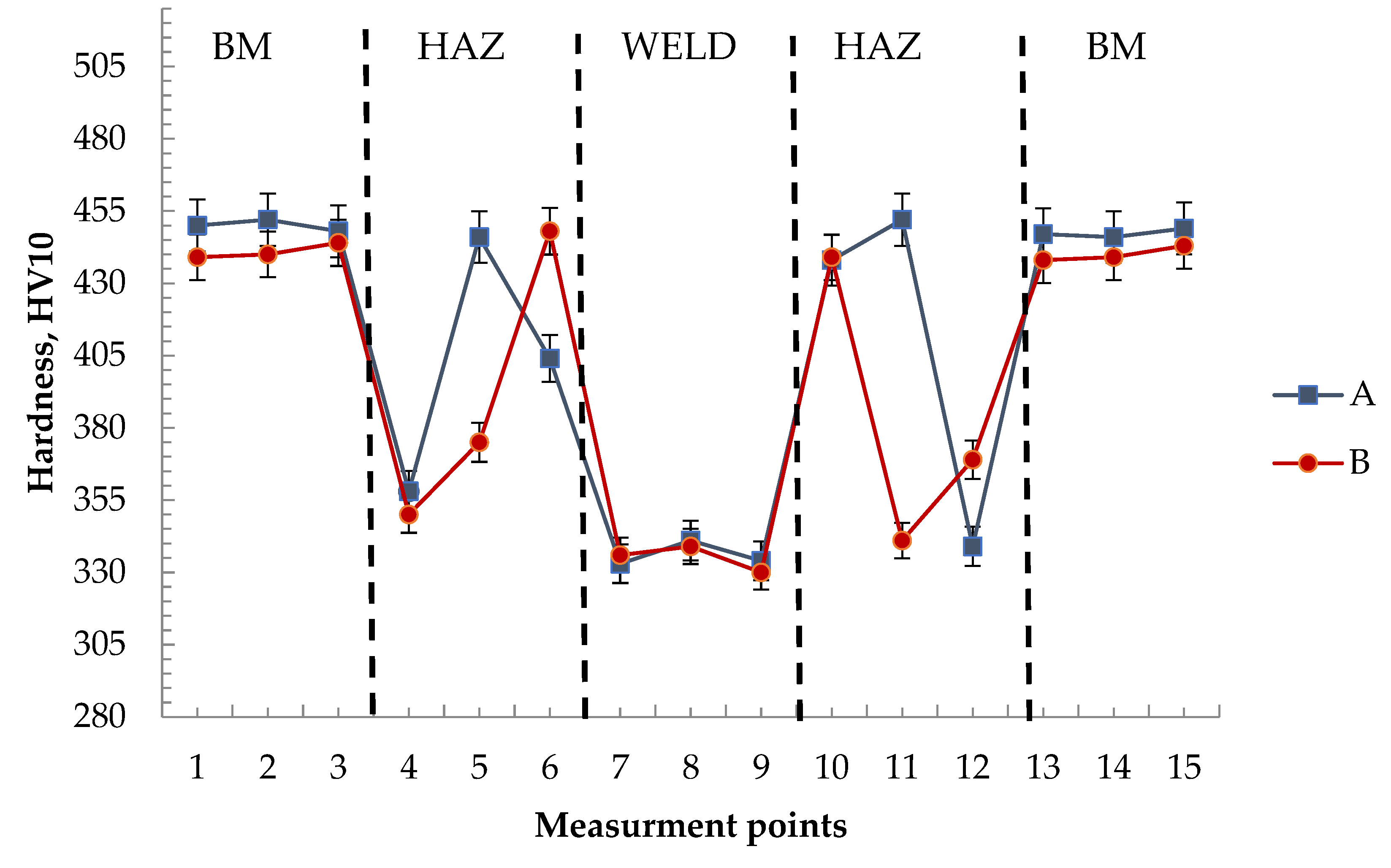

3.3. Hardness Distribution

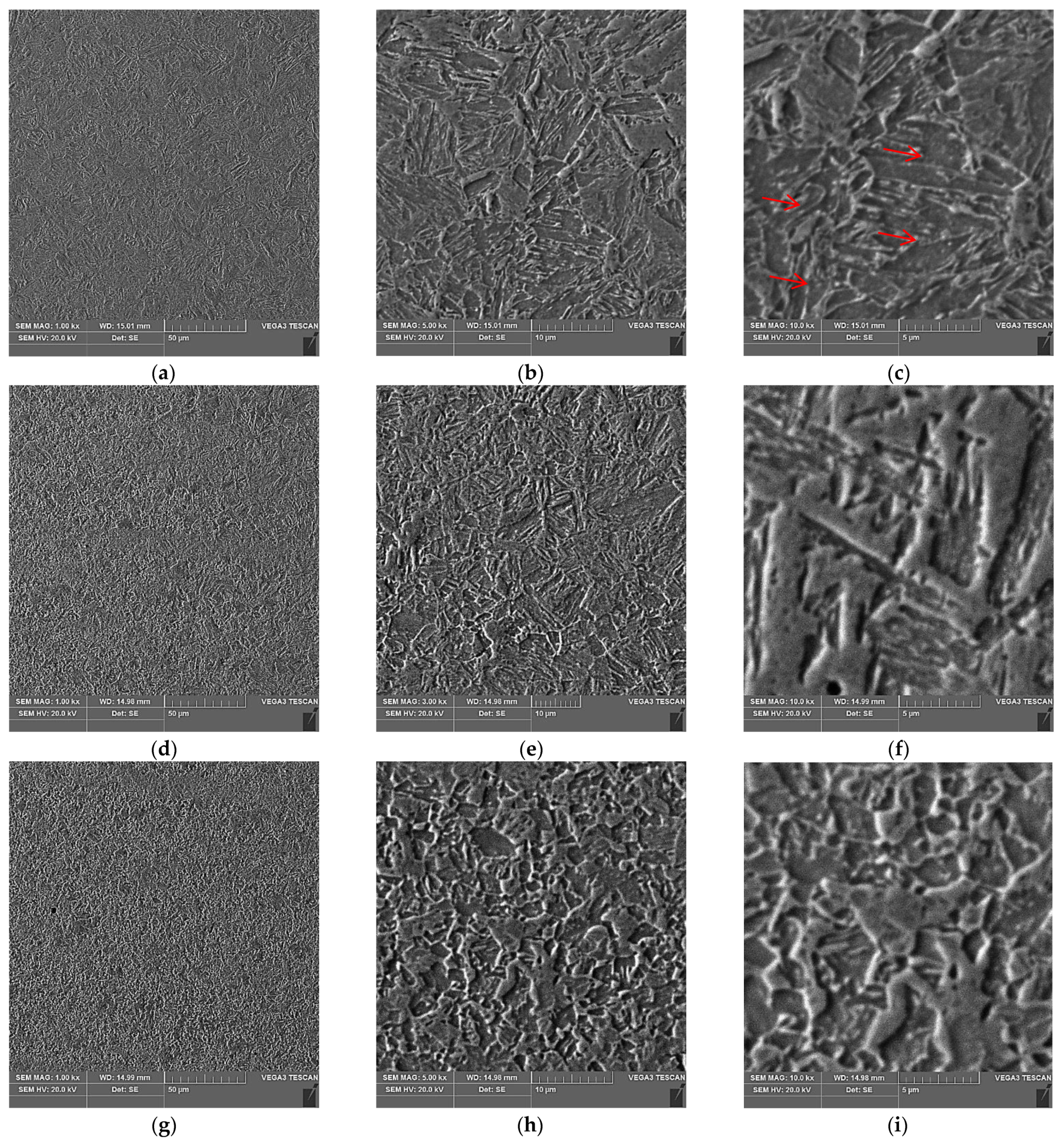

3.4. Welded Joint Microstructure

3.5. Static Tensile Test

3.6. Bending Test

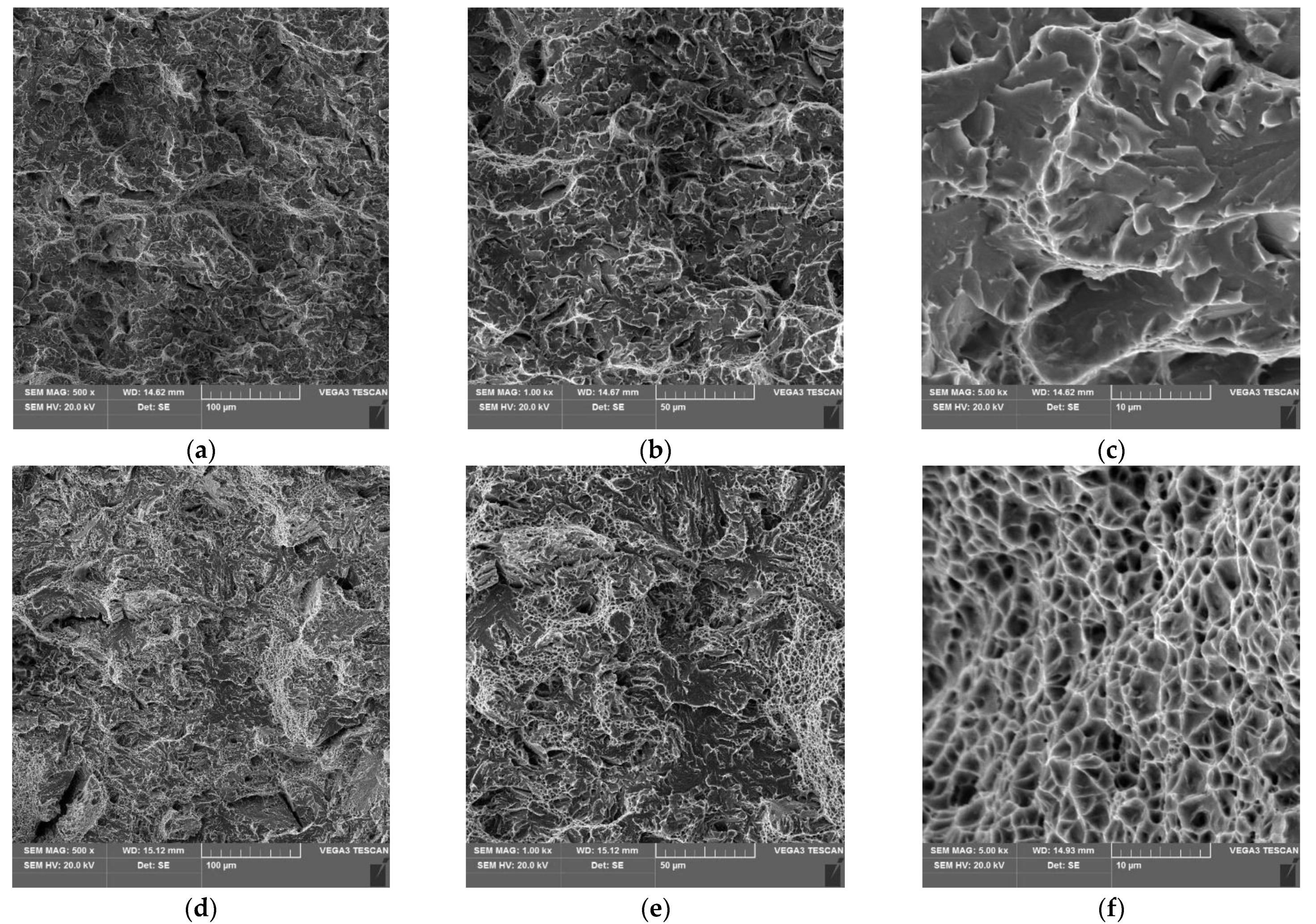

3.7. Impact Testing

4. Conclusions

- Qualification of the test joints was performed based on non-destructive testing and destructive testing.

- The welded joints were characterised by an even, smooth face with no visible spalling. The root was characterised by its correct formation.

- The visual and radiographic examination did not reveal the presence of surface defects.

- The metallographic examination showed that the weld is characterised by a martensitic structure. Columnar crystals are arranged from the fusion line to the weld axis. The heat-affected zone (HAZ) contains minor precipitates of martensite.

- The static tensile test showed that the produced joints were characterised by high strength but did not meet the accepted requirements. These joints failed to meet the minimum tensile strength requirements of the base material, i.e., Rm ≥ 1400 MPa.

- A maximum bending angle of 70° was found in the bending test, which did not meet the requirements stipulating that for S1300QL steel the required bending angle should be 90°.

- The impact tests showed that the condition for the required minimum value of breaking work was met for notched specimens in the HAZ. In the case of the specimens with a notch cut into the weld, the minimum breaking work was not achieved, which was the basis for the unsatisfactory impact test results.

- The analysis of the test results shows that obtaining a high-quality joint using S1300QL steel that meets the requirements of the standards is difficult and requires further research. The problem of achieving a proper welded joint is the formation of hard and brittle hardening products during welding, as well as the presence of spherical calcium aluminate particles (CaO-Al2O3), which have a detrimental effect on the strength properties of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ozgowicz, W.; Kalinowska-Ozgowicz, E. Investigations on the impact strength of constructional high-strength Weldox steel at lowered temperature. Arch. Mater. Sci. Eng. 2008, 32, 89–94. [Google Scholar]

- Grigorenko, G.M.; Kostin, W.A.; Poznjakow, W.D.; Żdanow, S.L.; Żukow, W.W. Features of structural transformation in metals HAZ high-strength steel WELDOX 1300 performed by MAG welding. Weld. Technol. Rev. 2015, 87, 42–46. [Google Scholar]

- High Strength and Ultra-High Strength Heavy Plates-Weight Savings Combined with Excellent Weldability, VoestAlpine Grobblech GmbH. 2012. Available online: https://www.yumpu.com/en/document/view/12574930/high-strength-and-ultra-high-strength-heavy-plates-voestalpine (accessed on 10 May 2022).

- PN-EN 10025-6; Hot Rolled Products of Structural Steels Part 6: Technical Delivery Conditions for Flat Products of High Yield Strength Structural Steels in the Quenched and Tempered Condition. Available online: https://standards.iteh.ai/catalog/standards/cen/8ecdc9d2-f50a-4bf8-8503-eb9fd8e0e276/en-10025-6-2004 (accessed on 12 May 2022).

- Berg, J.; Stranghöner, N. Fatigue behaviour of high frequency hammer peened ultra-high strength steels. Int. J. Fatigue 2016, 82, 35–48. [Google Scholar] [CrossRef]

- Kah, P.; Pirinen, M.; Suoranta, R.; Martikainen, J. Welding of Ultra High Strength Steels. Adv. Mater. Res. 2014, 849, 357–365. [Google Scholar] [CrossRef]

- Tümer, M.; Schneider-Bröskamp, C.; Enzinger, N. Fusion welding of ultra-high strength structural steels—A review. J. Manuf. Process. 2022, 82, 203–229. [Google Scholar] [CrossRef]

- SSAB Oxelösund. Offering List of the Original Firm SSAB Oxelösund; Company catalog in Printed Form, Collective Work; SSAB Oxelösund: Uxelsund, Sweden, 2007. [Google Scholar]

- Tyssen Krupp Steel. Promotional Materials Tyssen Krupp Steel; Promotional materials of ThyssenKrupp Steel, printed paper catalog, Collective Work; TyssenKrupp Steel: Essen, Germany, 2019. [Google Scholar]

- Tuz, L.; Rakoczy, Ł.; Pancikiewicz, K. Wpływ Podgrzewania Wstępnego na Twardość i Mikrostrukturę Niestopowych Stali Konstrukcyjnych o Wysokiej Wytrzymałości; Wydawnictwo Naukowe Tygiel: Lublin, Poland, 2017; pp. 7–19. ISBN 978-83-65598-97-4. [Google Scholar]

- Tuz, L.; Sulikowski, K. Evaluation of weldability of non-alloy high strenght heat-treated steel. Przegląd Spaw. 2018, 90, 9–13. [Google Scholar]

- Tuz, L.; Pancikiewicz, K.; Sulikowski, K.; Rakoczy, Ł. Evaluation of laser beam butt welded joints of high-strength steel. Przegląd Spaw. 2017, 89, 90–97. [Google Scholar] [CrossRef]

- Gogou, E. Use of High Strength Steel Grades for Economical Bridge Design. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2012. [Google Scholar]

- Tasak, E.; Ziewiec, A. Spawalność Materiałów Konstrukcyjnych Tom 1. Spawalność Stali; Wydawnictwo JAK: Kraków, Poland, 2009. [Google Scholar]

- Węglowski, M.S.; Zeman, M. Prevention of cold cracking in ultra-high strength steel Weldox 1300. Arch. Civ. Mech. Eng. 2014, 14, 417–424. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B.; Węgrzyn, T.; Piwnik, J.; Jurek, A. Welding of a mixed joint in the structure of mobile platforms made S690QL and S960 MC steel. Apar. Badaw. Dydakt. 2020, 1, 23–26. [Google Scholar]

- Shenghai, Z.; Yifu, S.; Huijuan, Q. The technology and welding joint properties of hybrid laser-TIG welding on thick plate. Opt. Laser Technol. 2013, 48, 381–388. [Google Scholar] [CrossRef]

- Macchietto, C. Hybrid Laser Arc Welding (HLAW); Valmont Industries: Omaha, NE, USA, 2011. [Google Scholar]

- Denney, P. Hybrid Laser Arc Welding Has Its Time Finally Arrived? Available online: http://www.lincolnelectric.com/assets/US/EN/literature/mc1129.pdf (accessed on 1 June 2022).

- Urbańczyk, M.; Adamiec, J. Hybrid welding (laser-electric arc MAG) of high yield Point steel S960QL. Materials 2021, 14, 5447. [Google Scholar] [CrossRef] [PubMed]

- Turichin, G.; Klimova-Korsmik, O.; Skylar, M.; Zhitenev, A.; Kurakin, A.; Pozdnyakov, A. Laser-arc hybrid welding perspective ultra-high strength steels: Influence of the chemical composition of weld metal on microstructure and mechanical properties. Procedia CIRP 2018, 74, 752–756. [Google Scholar] [CrossRef]

- Mazar Atabaki, M.; Ma, J.; Yang, G.; Kovacevic, R. Hybrid laser/arc welding of advanced high strength steel in different butt joint configurations. Mater Des. 2014, 64, 573–587. [Google Scholar] [CrossRef]

- Banasik, M.; Urbańczyk, M. Spawanie metodą hybrydową laser + MAG różnych rodzajów złączy. Biul. Inst. Spaw. 2017, 61, 20–25. [Google Scholar]

- Nielsen, S.E. High power laser hybrid welding—Challenges and perspectives. Phys. Procedia 2015, 78, 24–34. [Google Scholar] [CrossRef]

- Sajek, A. Application of FEM simulation method in area of the dynamics of cooling AHSS steel with a complex hybrid welding process. Weld. World 2019, 63, 1065–1073. [Google Scholar] [CrossRef] [Green Version]

- Łomzik, M. Mechanical properties of joints made in steel S1300QL using various welding methods. Biul. Inst. Spaw. Res. 2020, 3, 9–22. [Google Scholar] [CrossRef]

- Zimmer, P. Zur Bewertung der Kaltrisssicherheit von Schweissverbindungen aus hochfesten Feinkornbaustählen. Phys. Procedia 2007, 78, 24–34. [Google Scholar]

- Gaspar, M.; Balogh, A. Gmaw experiments for advanced (Q + T) high strength steels. Prod. Process. Syst. 2013, 6, 9–24. [Google Scholar]

- Gáspár, M.; Sisodia, R.P.S. Weldability analysis of Q + T and TMCP high strength steels by physical simulation. In Proceedings of the IIW 2017 International Conference: Green Welding Technologies for Effective and Reliable Manufacturing, Shanghai, China, 29–30 June 2017; Schaupp, T., Ernst, W., Spindler, H., Kannengiesser, T., Eds.; pp. 166–170. [Google Scholar]

- Thomas, S.; Wolfgang, E.; Helmut, S.; Thomas, K. Hydrogen-assisted cracking of GMA welded 960 MPa grade high-strength steels. Int. J. Hydrogen Energy 2020, 45, 20080–20093. [Google Scholar] [CrossRef]

- ISO 15614-1:2017; Specification and Qualification of Welding Procedures for Metallic Materials-Welding Procedure Test—Part 1: Arc and Gas Welding of Steels and Arc Welding of Nickel and Nickel Alloys. ISO: Geneva, Switzerland, 2017.

- ISO/TR 15608:2017; Welding—Guidelines for a Metallic Materials Grouping System. Przepisy Klasyfikacji Budowy Statków Morskich. Materiały i Spawanie. Część IX. Polski Rejestr Statków: Gdańsk, Poland, 2021.

| Chemical Composition, (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ti | Ni | Mo | Nb | V | Cu | |

| Standard | 0.25 | 0.50 | 1.40 | 0.80 | 0.02 | 2.0 | 0.70 | 0.04 | 0.08 | 0.10 |

| Certificate | 0.24 | 0.22 | 0.89 | 0.49 | 0.004 | 1.3 | 0.392 | 0.021 | 0.02 | 0.01 |

| Control test | 0.20 | 0.212 | 0.87 | 0.50 | 0.002 | 1.23 | 0.391 | 0.021 | 0.019 | 0.01 |

| Mechanical properties | ||||||||||

| Rm [MPa] 1400–1700 | Re [MPa] min. 1300 | A5 [%] min. 8 | ||||||||

| C | Si | Mn | Cr | Mo | Ni | |

|---|---|---|---|---|---|---|

| Certificate | 0.10 | 0.80 | 1.80 | 0.35 | 0.60 | 2.30 |

| Control test | 0.11 | 0.78 | 1.93 | 0.43 | 0.55 | 2.31 |

| P, kW | Vs, m/min | Vd, m/min | I, A | U, V | kor. U, V | Q, kJ/mm | Tp, °C |

|---|---|---|---|---|---|---|---|

| 4.5 | 1.2 | 8.5 | 275 | 27 | 3 | 0.59 | 200 |

| BM | HAZ | WELD | HAZ | BM | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| A | 450 | 452 | 448 | 358 | 446 | 404 | 333 | 341 | 334 | 438 | 452 | 339 | 447 | 446 | 449 |

| B | 439 | 440 | 444 | 350 | 375 | 448 | 336 | 339 | 330 | 439 | 341 | 369 | 438 | 439 | 443 |

| No. | Determination of Sample | Tensile Strength Rm, MPa | Comments |

|---|---|---|---|

| 1 | R1 | 1229 | rupture in HAZ |

| 2 | R2 | 1286 |

| Spot | C | O | Al | Ca | Fe | Si | Balance |

|---|---|---|---|---|---|---|---|

| 1 | 11.37 | 38.07 | 18.38 | 15.15 | 13.70 | 2.63 | 0.70 |

| 2 | 11.81 | 38.41 | 17.57 | 15.63 | 12.76 | 2.99 | 0.83 |

| No. | Designation of Sample | Angle of Bend, ° | Comments |

|---|---|---|---|

| 1 | FBB/I | 35 | Brittle cracking in HAZ |

| 2 | FBB/II | 70 | |

| 3 | RBB/I | 65 | |

| 4 | RBB/II | 70 |

| No. | Designation | Notch Type | Breaking Work, J | Impact Strength J/cm2 | Fracture Characteristics |

|---|---|---|---|---|---|

| 1 | VWT/I | Charpy V | 17 | 42.5 | Mixed fracture |

| 2 | VWT/II | 18 | 45.0 | ||

| 3 | VWT/III | 15 | 37.5 | ||

| 4 | VHT/I | 18 | 45.0 | ||

| 5 | VHT/II | 24 | 60.0 | ||

| 6 | VHT/III | 20 | 50.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupiec, B.; Urbańczyk, M.; Radoń, M.; Mróz, M. Problems of HLAW Hybrid Welding of S1300QL Steel. Materials 2022, 15, 5756. https://doi.org/10.3390/ma15165756

Kupiec B, Urbańczyk M, Radoń M, Mróz M. Problems of HLAW Hybrid Welding of S1300QL Steel. Materials. 2022; 15(16):5756. https://doi.org/10.3390/ma15165756

Chicago/Turabian StyleKupiec, Bogdan, Michał Urbańczyk, Magdalena Radoń, and Marek Mróz. 2022. "Problems of HLAW Hybrid Welding of S1300QL Steel" Materials 15, no. 16: 5756. https://doi.org/10.3390/ma15165756

APA StyleKupiec, B., Urbańczyk, M., Radoń, M., & Mróz, M. (2022). Problems of HLAW Hybrid Welding of S1300QL Steel. Materials, 15(16), 5756. https://doi.org/10.3390/ma15165756