Numerical Simulation of Dry Ice Compaction Process: Comparison of Drucker-Prager/Cap and Cam Clay Models with Experimental Results

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Powder

2.1.2. Compaction

2.1.3. Dry Ice Elastoplastic Properties in the Function of Density

2.2. Material Models

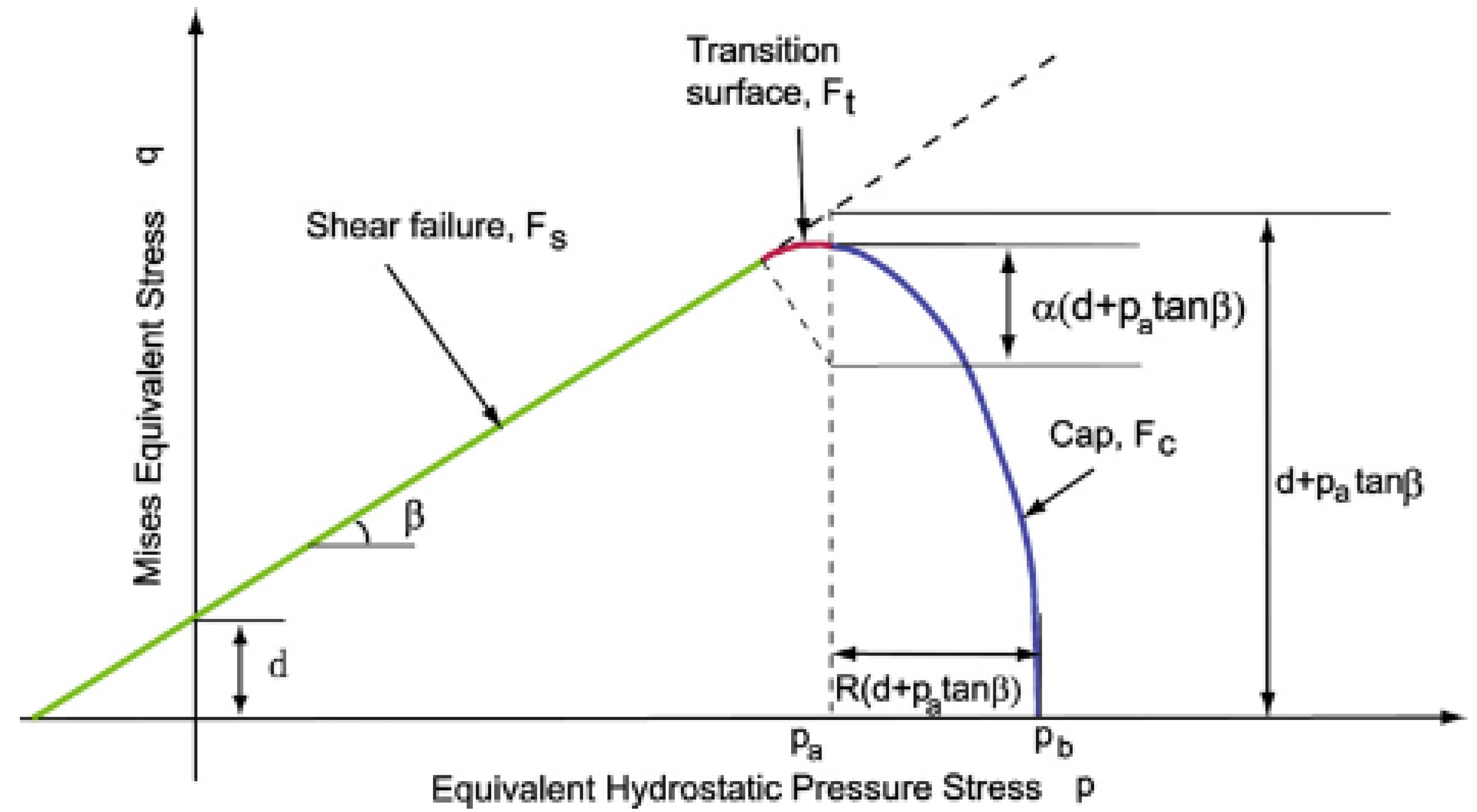

2.2.1. The Drucker-Prager Cap (DPC) Model

2.2.2. The modified Cam Clay (MCC) Model

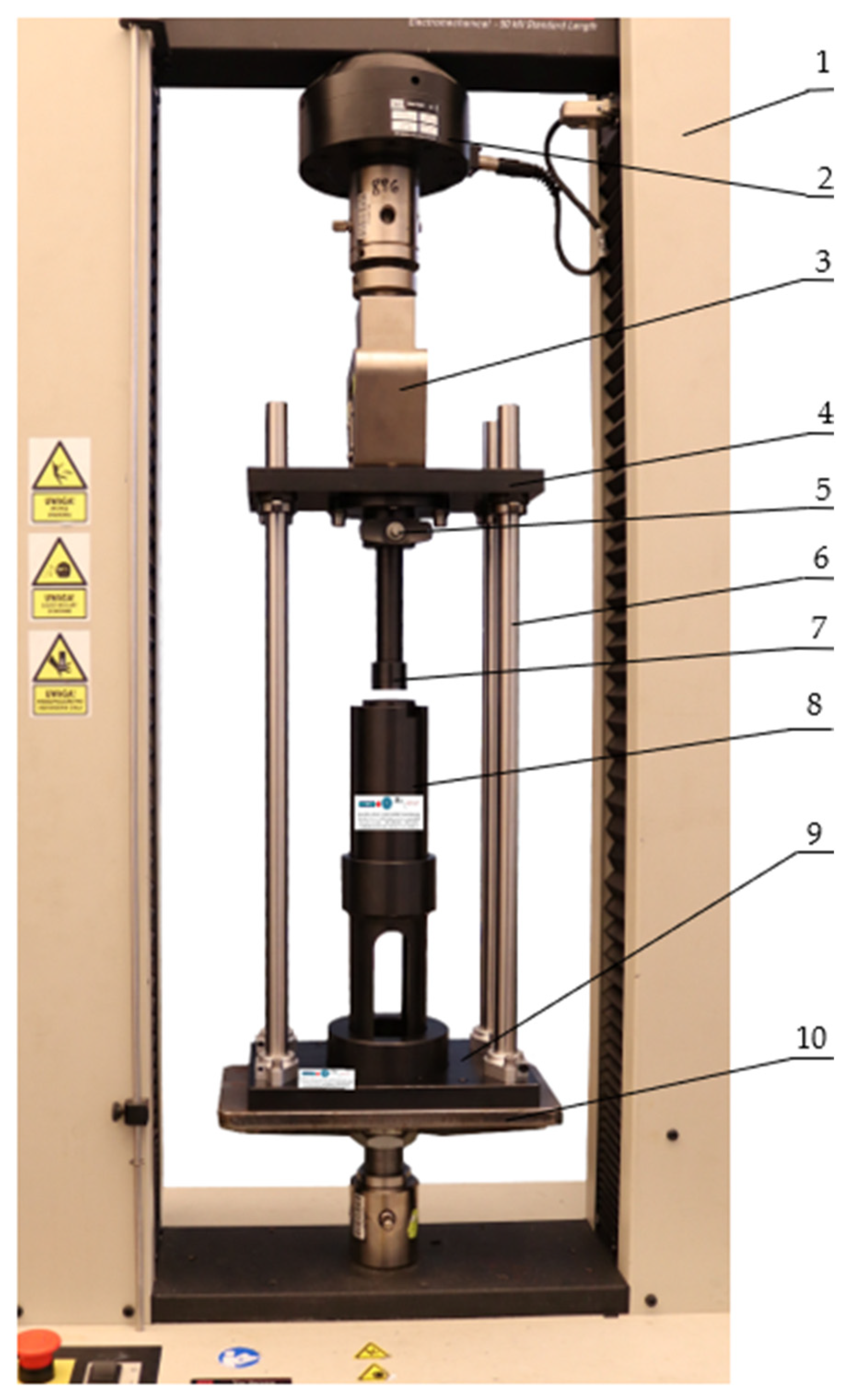

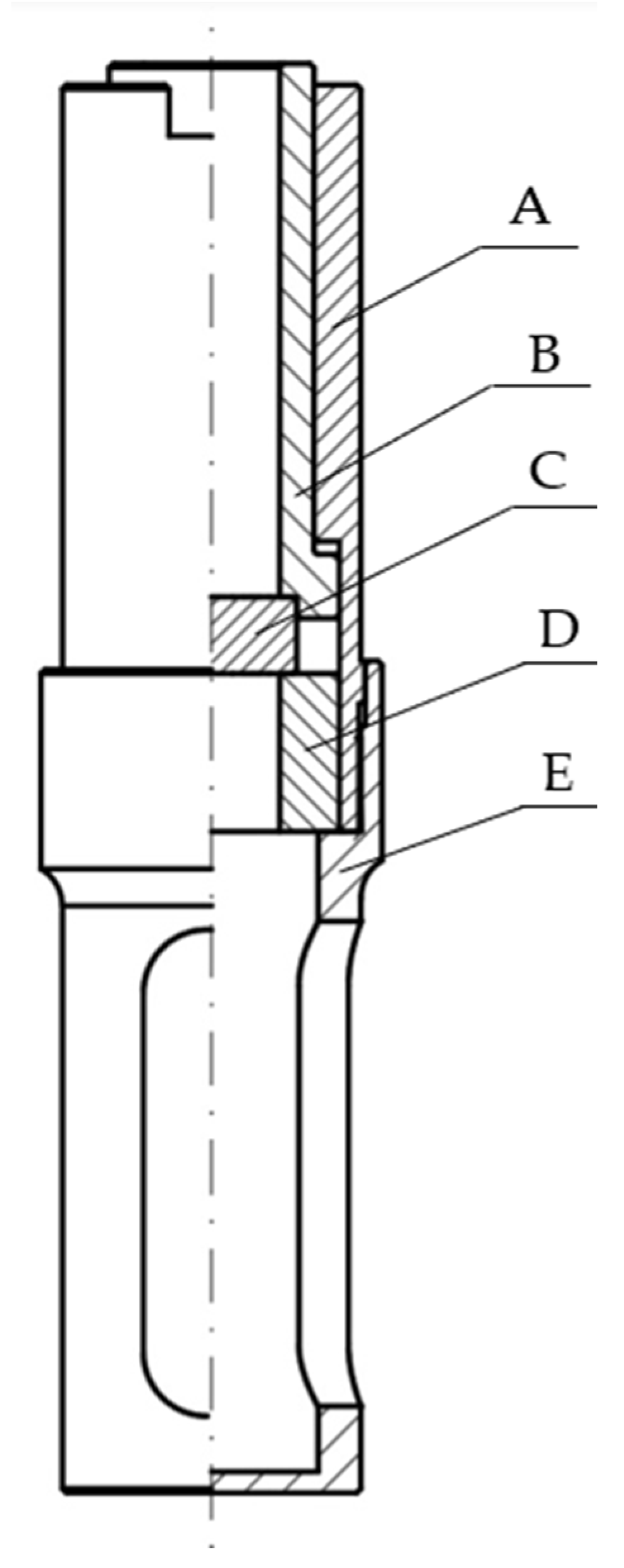

2.2.3. Methodology of Experimental Test

- The upper grip of the machine together with the piston arrived at the reference position with the initial velocity.

- Initial downward motion was performed (with 1 mm/s travel speed) until a resistance force value of 50 N was detected.

- The test was initiated. The machine grip moved downwards together with the mounted upper plate and the piston at a test speed of 5 mm/s until the specimen height of 24 ± 0.05 mm was reached.

- The assembly retracted with a speed of 5 mm/s until a force value of 0 N was obtained.

- The piston retracted with the final test speed to a height approximately 60 mm above the reference position to facilitate the removal of the sleeve and specimen for measurement.

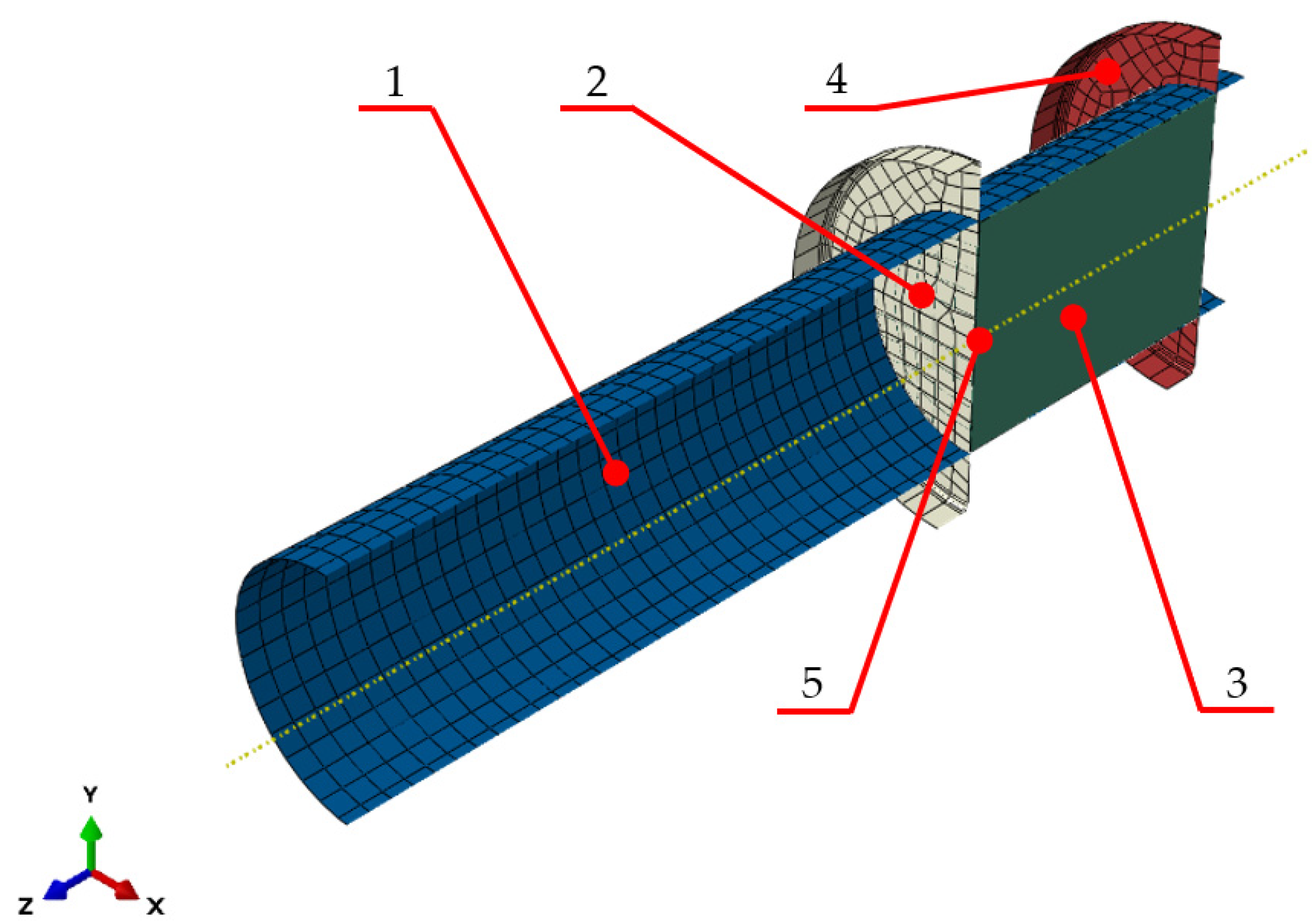

2.2.4. Compaction Simulation Model

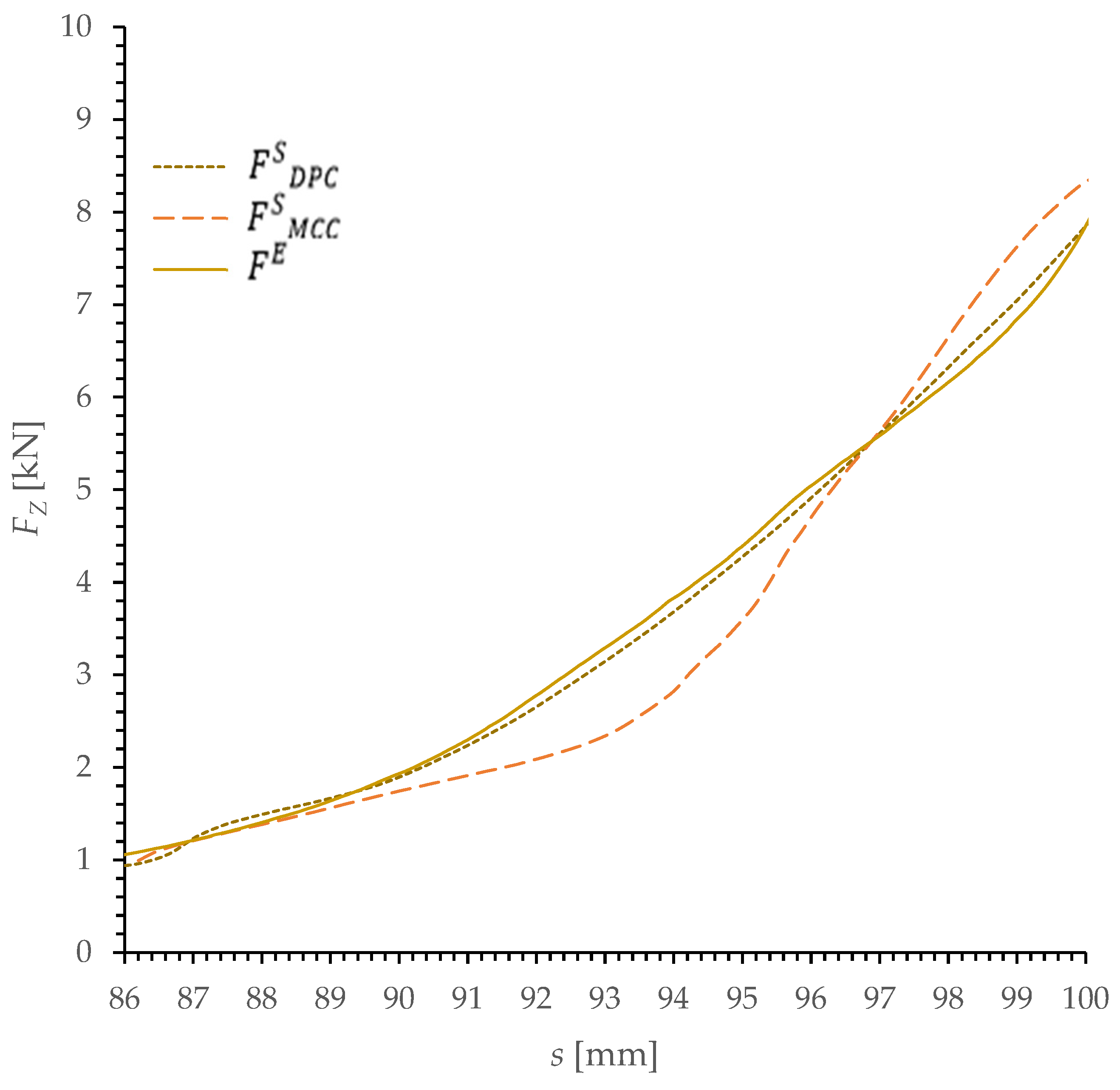

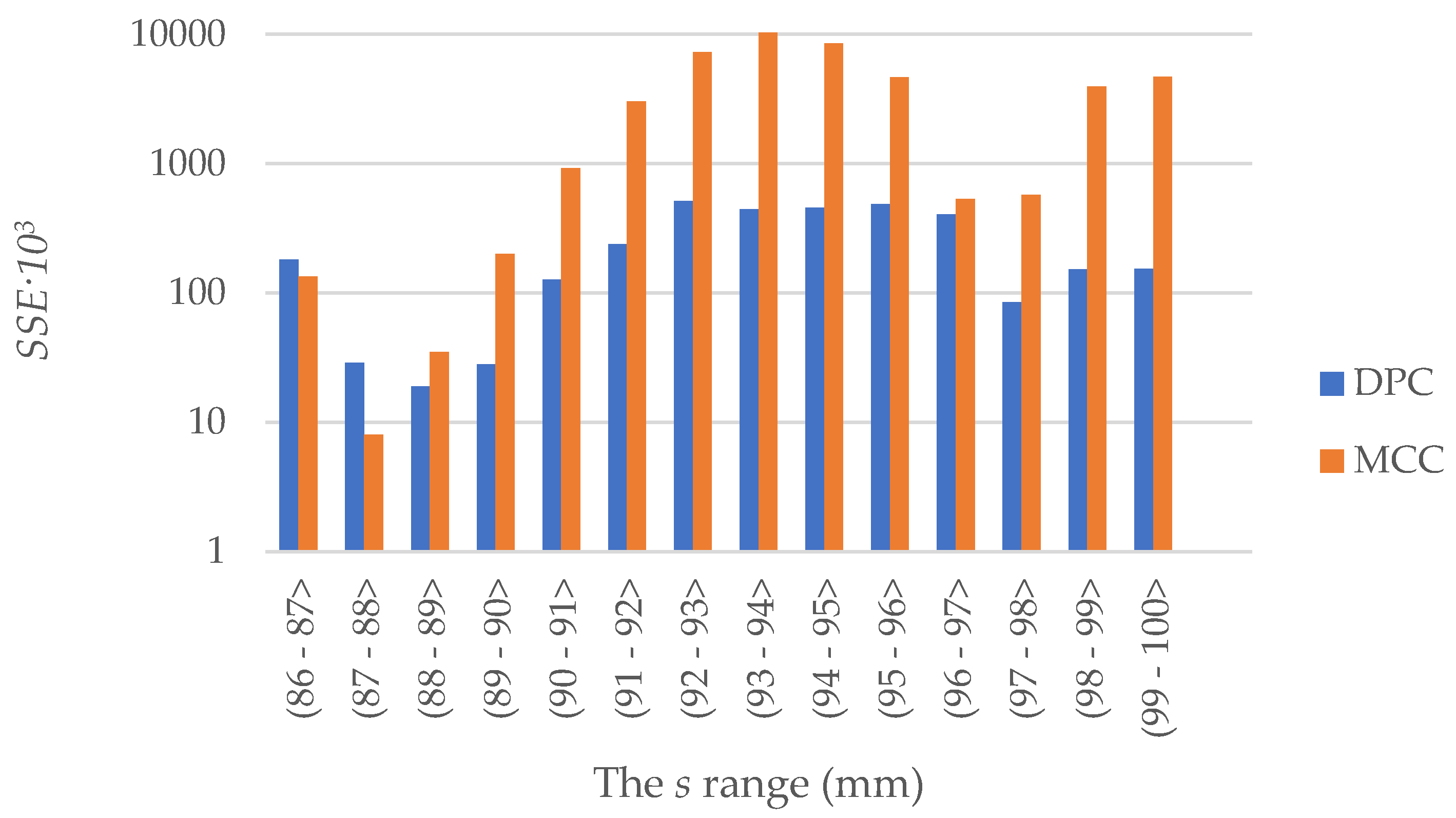

3. Results

4. Conclusions and Results Discussion

- both the MCC and the DPC model make it possible to determine an approximate Fz value, where the value of the difference as compared to the experimental test result does not exceed 15%;

- the results presented indicate that the computer simulations of the dry ice compaction process using the DPC model offer a better representation of the curve describing the change in the force value during compaction.

- Numerical simulation of the extrusion processes using the DPC and MCC material models, for the purpose of estimating the working load;

- Optimization of the geometric characteristics of the tools used in the compaction and extrusion of dry ice, to increase the process efficiency;

- Analysis of the energy consumption of the dry ice pelletization process with the use of a gravity roller press.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giannis, K.; Schilde, C.; Finke, J.H.; Kwade, A. Modeling of High-Density Compaction of Pharmaceutical Tablets Using Multi-Contact Discrete Element Method. Pharmaceutics 2021, 13, 2194. [Google Scholar] [CrossRef] [PubMed]

- Krok, A.; Peciar, M.; Fekete, R. Numerical investigation into the influence of the punch shape on the mechanical behavior of pharmaceutical powders during compaction. Particuology 2014, 16, 116–131. [Google Scholar] [CrossRef]

- Wilczyński, D.; Berdychowski, M.; Wojtkowiak, D.; Górecki, J.; Wałęsa, K. Experimental and numerical tests of the compaction process of loose material in the form of sawdust. MATEC Web Conf. 2019, 254, 02042. [Google Scholar] [CrossRef]

- Domek, G.; Talaśka, K. Model of the pressing and drying system of organic material. In Proceedings of the 26th International Slovak-Polish Scientific Conference on Machine Modelling and Simulations (MMS 2021), Bardejovské Kúpele, Slovak Republic, 13–15 September 2021; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1199. [Google Scholar] [CrossRef]

- Wojtkowiak, D.; Talaśka, K.; Wilczyński, D.; Górecki, J.; Wałęsa, K. Determinig the Power Consumption of the Atomatic Device for Belt Perforation Based on the Dynamic Model. Energies 2021, 14, 317. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Górecki, J.; Talaśka, K.; Wałęsa, K.; Wilczyński, D.; Wojtkowiak, D. Mathematical Model Describing the Influence of Geometrical Parameters of Multichannel Dies on the Limit Force of Dry Ice Extrusion Process. Materials 2020, 13, 3317. [Google Scholar] [CrossRef]

- Witte, A.K.; Bobal, M.; David, R.; Blättler, B.; Schoder, D.; Rossmanith, P. Investigation of the potential of dry ice blasting for cleaning and disinfection in the food production environment. LWT 2017, 75, 735–741. [Google Scholar] [CrossRef]

- Yamasaki, H.; Wakimoto, H.; Kamimura, T.; Hattori, K.; Nekså, P.; Yamaguchi, H. Visualization and Measurement of Swirling Flow of Dry Ice Particles in Cyclone Separator-Sublimator. Energies 2022, 15, 4128. [Google Scholar] [CrossRef]

- Dzido, A.; Krawczyk, P.; Badyda, K.; Chondrokostas, P. Operational parameters impact on the performance of dry-ice blasting nozzle. Energy 2021, 214, 118847. [Google Scholar] [CrossRef]

- Górecki, J.; Fierek, A.; Talaśka, K.; Wałęsa, K. The influence of the limit stress value on the sublimation rate during the dry ice densification process. In Proceedings of the 24th Slovak-Polish International Scientific Conference on Machine Modelling and Simulations—MMS 2019, Liptovský Ján, Slovakia, 3–6 September 2019; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 776. [Google Scholar] [CrossRef]

- Górecki, J. Development of a Testing Station for Empirical Verification of the Algebraic Model of Dry Ice Piston Extrusion. Acta Mech. et Autom. 2021, 15, 107–112. [Google Scholar] [CrossRef]

- Diarra, H.; Mazel, V.; Boillon, A.; Rehault, L.; Busignies, V.; Bureau, S.; Tchoreloff, P. Finite Element Method (FEM) modeling of the powder compaction of cosmetic products: Comparison between simulated and experimental results. Powder Technol. 2012, 224, 233–240. [Google Scholar] [CrossRef]

- Harthong, B.; Jérier, J.-F.; Dorémus, P.; Imbault, D.; Donzé, F.-V. Modeling of high-density compaction of granular materials by the Discrete Element Method. Int. J. Solids Struct. 2009, 46, 3357–3364. [Google Scholar] [CrossRef]

- Brewin, P.; Coube, O.; Doremus, P.; Tweed, J. Modeling of Powder Die Compaction; Springer-Verlag: London, UK, 2008. [Google Scholar]

- Wilczyński, D.; Berdychowski, M.; Talaśka, K.; Wojtkowiak, D. Experimental and numerical analysis of the effect of compaction conditions on briquette properties. Fuel 2021, 288, 119613. [Google Scholar] [CrossRef]

- Han, L.; Elliott, J.; Bentham, A.; Mills, A.; Amidon, G.; Hancock, B. A modified Drucker-Prager Cap model for die compaction simulation of pharmaceutical powders. Int. J. Solids Struct. 2008, 45, 3088–3106. [Google Scholar] [CrossRef]

- Cassiani, G.; Brovelli, A.; Hueckel, T. A strain-rate-dependent modified Cam-Clay model for the simulation of soil/rock compaction. Géoméch. Energy Environ. 2017, 11, 42–51. [Google Scholar] [CrossRef]

- Berdychowski, M.; Talaśka, K.; Malujda, I.; Kukla, M. Application of the Mohr-Coulomb model for simulating the biomass compaction process. Proceedings of the 24th Slovak-Polish International Scientific Conference on Machine Modelling and Simulations—MMS 2019, Liptovský Ján, Slovakia, 3–6 September 2019 2020, 776. [Google Scholar] [CrossRef]

- Gorecki, J.; Malujda, I.; Talaśka, K.; Tarkowski, P.; Kukla, M. Influence of the Value of Limit Densification Stress on the Quality of the Pellets During the Agglomeration Process of CO2. Procedia Eng. 2016, 136, 269–274. [Google Scholar] [CrossRef]

- Biszczanik, A.; Wałęsa, K.; Kukla, M.; Górecki, J. The Influence of Density on the Value of Young’s Modulus for Dry Ice. Materials 2021, 14, 7763. [Google Scholar] [CrossRef]

- Biszczanik, A.; Górecki, J.; Kukla, M.; Wałęsa, K.; Wojtkowiak, D. Experimental Investigation on the Effect of Dry Ice Compression on the Poisson Ratio. Materials 2022, 15, 1555. [Google Scholar] [CrossRef] [PubMed]

- Abaqus Documentation; Dassault Systemes: Paris, France, 2017.

- Talaśka, K. Study of Research and Modeling of the Compaction Processes of Loose and Disintegrated Materials; Politechnika Poznańska: Poznań, Poland, 2018. (In Polish) [Google Scholar]

- Zhang, B.; Jain, M.; Zhao, C.; Bruhis, M.; Lawcock, R.; Ly, K. Experimental calibration of density-dependent modified Drucker-Prager/Cap model using an instrumented cubic die for powder compact. Powder Technol. 2010, 204, 27–41. [Google Scholar] [CrossRef]

- Berdychowski, M.; Talaśka, K.; Wilczyński, D. Evaluation of the possibility of using the Drucker-Prager-Cap model in simulations of the densification process of shredded natural materials. MATEC Web Conf. 2019, 254, 02018. [Google Scholar] [CrossRef][Green Version]

- Devroye, L.; Schäfer, D.; Györfi, L.; Walk, H. The estimation problem of minimum mean squared error. Stat. Decis. 2009, 21, 15–28. [Google Scholar] [CrossRef]

- Bilal, M.; Masud, S.; Athar, S. FPGA Design for Statistics-Inspired Approximate Sum-of-Squared-Error Computation in Multimedia Applications. IEEE Trans. Circuits Syst. II Express Briefs 2012, 59, 506–510. [Google Scholar] [CrossRef]

| Material Cohesion [MPa] | Angle of Friction [deg] | Cap Eccentricity [Pa] | Init Yld Surf Pos [–] | Yield Stress [MPa] | Vol Plas Strain [–] | Young’s Modulus [MPa] | Poisson’s Ratio [–] |

|---|---|---|---|---|---|---|---|

| 1.07 | 25.92 | 0.68 | 0.02 | 1.24 | 0 | 136.94 | 0.023 |

| 1.75 | 21.46 | 0.76 | 0.02 | 1.57 | 0.048 | 194.18 | 0.059 |

| 2.22 | 20.51 | 0.78 | 0.02 | 1.92 | 0.095 | 251.42 | 0.102 |

| 2.53 | 20.59 | 0.79 | 0.02 | 3.20 | 0.139 | 308.66 | 0.150 |

| 2.73 | 21.05 | 0.80 | 0.02 | 4.50 | 0.182 | 365.9 | 0.200 |

| 2.85 | 21.59 | 0.81 | 0.02 | 6.54 | 0.223 | 423.14 | 0.249 |

| 2.93 | 22.08 | 0.83 | 0.02 | 7.92 | 0.262 | 480.38 | 0.295 |

| 3.00 | 22.43 | 0.84 | 0.02 | 10.25 | 0.300 | 537.62 | 0.335 |

| 3.07 | 22.61 | 0.87 | 0.02 | 13.1 | 0.336 | 594.86 | 0.370 |

| 3.14 | 22.64 | 0.90 | 0.02 | 16.57 | 0.371 | 652.1 | 0.399 |

| 3.23 | 22.60 | 0.93 | 0.02 | 21.51 | 0.405 | 709.34 | 0.422 |

| 3.32 | 22.63 | 0.98 | 0.02 | 27.22 | 0.438 | 766.58 | 0.441 |

| 3.40 | 22.88 | 1.03 | 0.02 | 32.06 | 0.470 | 823.82 | 0.456 |

| Stress Ratio | Flow Stress Ratio | Wet Yld Surf Size | Init Vol Plas Strain [–] | Yield Stress [MPa] | Vol Plas Strain [–] | Young’s Modulus [MPa] | Poisson’s Ratio [–] |

|---|---|---|---|---|---|---|---|

| 1.24 | 0 | 136.94 | 0.023 | ||||

| 1.54 | 0.048 | 194.18 | 0.059 | ||||

| 2.09 | 0.095 | 251.42 | 0.102 | ||||

| 2.20 | 0.139 | 308.66 | 0.150 | ||||

| 2.63 | 0.182 | 365.9 | 0.200 | ||||

| 3.54 | 0.223 | 423.14 | 0.249 | ||||

| 1 | 1 | 1 | 0.02 | 4.97 | 0.262 | 480.38 | 0.295 |

| 5.96 | 0.300 | 537.62 | 0.335 | ||||

| 7.32 | 0.336 | 594.86 | 0.370 | ||||

| 8.64 | 0.371 | 652.1 | 0.399 | ||||

| 9.53 | 0.405 | 709.34 | 0.422 | ||||

| 9.99 | 0.438 | 766.58 | 0.441 | ||||

| 8.45 | 0.470 | 823.82 | 0.456 |

| Range of s Value [mm] | SSEDPC | SSEMCC |

|---|---|---|

| 1.81 × 105 | 1.34 × 105 | |

| 2.9 × 104 | 8 × 103 | |

| 1.9 × 104 | 3.5 × 104 | |

| 2.8 × 104 | 2.01 × 105 | |

| 1.27 × 105 | 9.21 × 105 | |

| 2.38 × 105 | 3.027 × 106 | |

| 5.16 × 105 | 7.268 × 106 | |

| 4.42 × 105 | 1.0334 × 107 | |

| 4.56 × 105 | 8.474 × 106 | |

| 4.85 × 105 | 4.660 × 106 | |

| 4.07 × 105 | 5.31 × 105 | |

| 8.5 × 105 | 5.73 × 105 | |

| 1.53 × 105 | 3.962 × 106 | |

| 1.54 × 105 | 4.705 × 106 | |

| (86–100〉 | 3.32 × 106 | 4.4833 × 107 |

| κ[%] | ||

|---|---|---|

| 8.065 | 14.38 | |

| 8.328 | 11.59 | |

| 9.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berdychowski, M.; Górecki, J.; Biszczanik, A.; Wałęsa, K. Numerical Simulation of Dry Ice Compaction Process: Comparison of Drucker-Prager/Cap and Cam Clay Models with Experimental Results. Materials 2022, 15, 5771. https://doi.org/10.3390/ma15165771

Berdychowski M, Górecki J, Biszczanik A, Wałęsa K. Numerical Simulation of Dry Ice Compaction Process: Comparison of Drucker-Prager/Cap and Cam Clay Models with Experimental Results. Materials. 2022; 15(16):5771. https://doi.org/10.3390/ma15165771

Chicago/Turabian StyleBerdychowski, Maciej, Jan Górecki, Aleksandra Biszczanik, and Krzysztof Wałęsa. 2022. "Numerical Simulation of Dry Ice Compaction Process: Comparison of Drucker-Prager/Cap and Cam Clay Models with Experimental Results" Materials 15, no. 16: 5771. https://doi.org/10.3390/ma15165771

APA StyleBerdychowski, M., Górecki, J., Biszczanik, A., & Wałęsa, K. (2022). Numerical Simulation of Dry Ice Compaction Process: Comparison of Drucker-Prager/Cap and Cam Clay Models with Experimental Results. Materials, 15(16), 5771. https://doi.org/10.3390/ma15165771