Architected Materials for Additive Manufacturing: A Comprehensive Review

Abstract

:1. Introduction

2. Theoretical Background and Classification of Architected Materials

2.1. Theoretical Background of Architected Materials

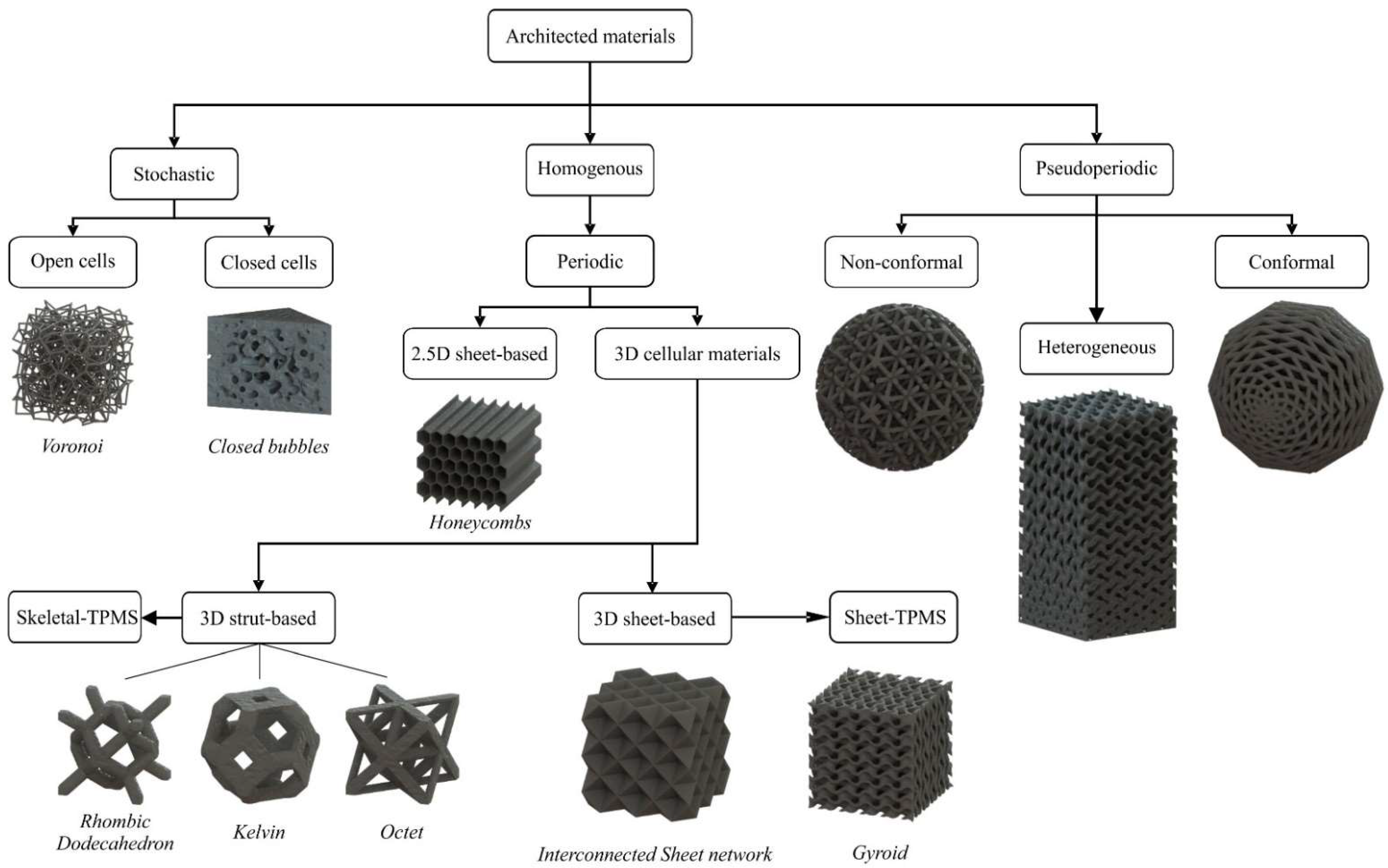

2.2. Classification of Architected Materials Based on the Geometry

2.3. Classification of Architected Materials Based on the Mechanical Response

3. Optimization of Architected Materials

4. Mechanical Properties of Architected Materials

5. Applications and Future Research of Architected Materials

5.1. Current Application of Architected Materials

5.2. Future Research in Architected Materials

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Navez, T.; Schmidt, M.P.; Sigmund, O.; Pedersen, C.B.W. Topology optimization guided by a geometrical pattern library. Struct. Multidisc. Optim. 2022, 65, 108. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. A case study on topology optimized design for additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 276, 12026. [Google Scholar] [CrossRef]

- Li, C.; Kim, I.Y.; Jeswiet, J. Conceptual and detailed design of an automotive engine cradle by using topology, shape, and size optimization. J. Struct. Multidiscip. Optim. 2015, 51, 547–564. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Wang, C.; Gong, P.; Shi, Y.; Yu, Y.; Liu, Z. Topology Optimization Design and Experimental Research of a 3D-Printed Metal Aerospace Bracket Considering Fatigue Performance. Appl. Sci. 2021, 11, 6671. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Lien, M.; Steinert, M. Optimization of Brake Calipers Using Topology Optimization for Additive Manufacturing. Appl. Sci. 2021, 11, 1437. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Finite Element Analysis of Orthopedic Hip Implant with Functionally Graded Bioinspired Lattice Structures. Biomimetics 2020, 5, 44. [Google Scholar] [CrossRef]

- Wu, P.-K.; Lee, C.-W.; Sun, W.-H.; Lin, C.-L. Biomechanical Analysis and Design Method for Patient-Specific Reconstructive Implants for Large Bone Defects of the Distal Lateral Femur. Biosensors 2022, 12, 4. [Google Scholar] [CrossRef]

- Michell, A.G.M. The limits of economy of material in frame-structures. Philos. Mag. 1904, 8, 589–597. [Google Scholar] [CrossRef]

- Prathyusha, A.L.R.; Raghu Babu, G. A review on additive manufacturing and topology optimization process for weight reduction studies in various industrial applications. Mater. Today Proc. 2022, 62, 109–117. [Google Scholar] [CrossRef]

- Rosen, D.W. Research supporting principles for design for additive manufacturing. J. Virtual Phys. Prototyp. 2014, 9, 225–232. [Google Scholar] [CrossRef]

- Larsen, S.D.; Sigmund, O.; Groen, J.P. Optimal truss and frame design from projected homogenization-based topology optimization. J. Struct. Multidiscip. Optim. 2018, 57, 1461–1474. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Steinert, M. Topology and Parametric Optimization-Based Design Processes for Lightweight Structures. Appl. Sci. 2020, 10, 4496. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Flem, D.T.; Steinert, M.; Olsen, A. State of the art of generative design and topology optimization and potential research needs. In Proceedings of the DS 91: NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Xie, Y.M.; Huang, X. Recent developments in evolutionary structural optimization (ESO) for continuum structures. IOP Conf. Ser. Mater. Sci. Eng. 2010, 10, 012196. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Hoang, V.N.; Tran, P.; Vu, V.T.; Nguyen-Xuan, H. Design of lattice structures with direct multiscale topology optimization. Compos. Struct. 2020, 252, 112718. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids. Structure and Properties; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Al-Rub, R.K.A. Topology-Mechanical Property Relationship of 3D Printed Strut, Skeletal, and Sheet Based Periodic Metallic Cellular Materials. J. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Mantovani, S.; Giacalone, M.; Merulla, A.; Bassoli, E.; Defanti, S. Effective Mechanical Properties of AlSi7Mg Additively Manufactured Cubic Lattice Structures. 3D Print. Addit. Manuf. 2021. ahead of print. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Abou-Ali, A.M.; Al-Ketan, O.; Rowshan, R.; Al-Rub, R.K.A. Mechanical Response of 3D Printed Bending-Dominated Ligament-Based Triply Periodic Cellular Polymeric Solids. J. Mater. Eng. Perform. 2019, 28, 2316–2326. [Google Scholar] [CrossRef]

- Ashby, M.F. The properties of foams and lattices. Phil. Trans. R. Soc. A 2006, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, M.S.A.; Pasini, D. Analysis of the elastostatic specific stiffness of 2D stretching-dominated lattice materials. Mech. Mater. 2010, 42, 709–725. [Google Scholar] [CrossRef]

- Gibson, L.J. Modelling the mechanical behavior of cellular materials. Mater. Sci. Eng. A 1989, 110, 1–36. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Effective Mechanical Properties of Additive Manufactured Strut-Lattice Structures: Experimental and Finite Element Study. Adv. Eng. Mater. 2021, 24, 2100879. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Effective mechanical properties of additive manufactured triply periodic minimal surfaces: Experimental and finite element study. Int. J. Adv. Manuf. Technol. 2022, 121, 7169–7189. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Pei, E.; Kabir, I.; Breški, T.; Godec, D.; Nordin, A. A review of geometric dimensioning and tolerancing (GD&T) of additive manufacturing and powder bed fusion lattices. Prog. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- Kanwar, S.; Al-Ketan, O.; Vijayavenkataraman, S. A novel method to design biomimetic, 3D printable stochastic scaffolds with controlled porosity for bone tissue engineering. Mater. Des. 2022, 220, 110857. [Google Scholar] [CrossRef]

- Groth, J.H.; Anderson, C.; Magnini, M.; Tuck, C.; Clare, A. Five simple tools for stochastic lattice creation. Addit. Manuf. 2022, 49, 102488. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; Hedayati, R.; Vena, P.; Vergani, L.; Strano, M.; Zadpoor, A.A. Rational design of soft mechanical metamaterials: Independent tailoring of elastic properties with randomness. Appl. Phys. Lett. 2017, 111, 051903. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Derveni, F.; Gross, A.J.; Peterman, K.D.; Gerasimidis, S. Postbuckling behavior and imperfection sensitivity of elastic–plastic periodic plate-lattice materials. Extrem. Mech. Lett. 2022, 50, 101510. [Google Scholar] [CrossRef]

- Dong, Z.; Zhao, X. Application of TPMS structure in bone regeneration. Eng. Regen. 2021, 2, 154–162. [Google Scholar] [CrossRef]

- Corona-Castuera, J.; Rodriguez-Delgado, D.; Henao, J.; Castro-Sandoval, J.C.; Poblano-Salas, C.A. Design and Fabrication of a Customized Partial Hip Prosthesis Employing CT-Scan Data and Lattice Porous Structures. ACS Omega 2021, 6, 6902–6913. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Zhao, Y.F. A survey of modeling of lattice structures fabricated by additive manufacturing. J. Mech Des. Trans. ASME 2017, 139, 100906. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Al-Rub, R.K.A. Multifunctional Mechanical Metamaterials Based on Triply Periodic Minimal Surface Lattices. Adv. Eng. Mater. 2019, 21, 1900524. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rezgui, R.; Rowshan, R.; Du, H.; Fang, N.X.; Abu Al-Rub, R.K. Microarchitected Stretching-Dominated Mechanical Metamaterials with Minimal Surface Topologies. Adv. Eng. Mater. 2018, 20, 1800029. [Google Scholar] [CrossRef]

- Farajzadeh Khosroshahi, S.; Tsampas, S.A.; Galvanetto, U. Feasibility study on the use of a hierarchical lattice architecture for helmet liners. Mater. Today Commun. 2018, 14, 312–323. [Google Scholar] [CrossRef]

- Ferro, C.G.; Varetti, S.; De Pasquale, G.; Maggiore, P. Lattice structured impact absorber with embedded anti-icing system for aircraft wings fabricated with additive SLM process. Mater. Today Commun. 2018, 15, 185–189. [Google Scholar] [CrossRef]

- Nasim, M.; Galvanetto, U. Mechanical characterisation of additively manufactured PA12 lattice structures under quasi-static compression. Mater. Today Commun. 2021, 29, 102902. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. J. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Zheng, X.; Guo, X.; Watanabe, I. A mathematically defined 3D auxetic metamaterial with tunable mechanical and conduction properties. Mater. Des. 2021, 198, 109313. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-responsive shape memory materials: A review. Mater. Des. 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Novak, N.; Al-Ketan, O.; Borovinšek, M.; Krstulović-Opara, L.; Rowshan, R.; Vesenjak, M.; Ren, Z. Development of novel hybrid TPMS cellular lattices and their mechanical characterization. J. Mater. Res. Technol. 2021, 15, 1318–1329. [Google Scholar] [CrossRef]

- Chen, Z.; Xie, Y.M.; Wu, X.; Wang, X.; Li, Q.; Zhou, S. On hybrid cellular materials based on triply periodic minimal surfaces with extreme mechanical properties. J. Mater. Des. 2019, 183, 108109. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Assad, M.A.; Al-Rub, R.K.A. Mechanical properties of periodic interpenetrating phase composites with novel architected microstructures. Compos. Struct. 2017, 176, 9–19. [Google Scholar] [CrossRef]

- Bauer, J.; Meza, L.R.; Schaedler, T.A.; Schwaiger, R.; Zheng, X.; Valdevit, L. Nanolattices: An Emerging Class of Mechanical Metamaterials. Adv. Mater. 2017, 29, 1701850. [Google Scholar] [CrossRef]

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Berhanu, S.; Tariq, F.; Jones, T.S.; McComb, D.W. Three-dimensionally interconnected organic nanocomposite thin films: Implications for donor–acceptor photovoltaic applications. J. Mater. Chem. 2010, 20, 8005–8009. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, D.L.; Jiang, S.L.; Li, S. Preparation and its cavitation performance of nickel foam/epoxy/SiC co-continuous composites. Wear 2015, 332–333, 979–987. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, F.; Deng, D.; Xin, T.; Sun, X.; Mousavian, R.T.; Peng, R.L.; Yang, Z.; Moverare, J. Cyclic response of additive manufactured 316L stainless steel: The role of cell structures. Scr. Mater. 2021, 205, 114190. [Google Scholar] [CrossRef]

- Sun, Z.P.; Guo, Y.B.; Shim, V.P.W. Characterisation and modeling of additively-manufactured polymeric hybrid lattice structures for energy absorption. Int. J. Mech. Sci. 2021, 191, 106101. [Google Scholar] [CrossRef]

- Yin, S.; Chen, H.; Li, J.; Yu, T.X.; Xu, J. Effects of architecture level on mechanical properties of hierarchical lattice materials. Int. J. Mech. Sci. 2019, 157–158, 282–292. [Google Scholar] [CrossRef]

- Al Hassanieh, S.; Alhantoobi, A.; Khan, K.A.; Khan, M.A. Mechanical Properties and Energy Absorption Characteristics of Additively Manufactured Lightweight Novel Re-Entrant Plate-Based Lattice Structures. Polymers 2021, 13, 3882. [Google Scholar] [CrossRef] [PubMed]

- Tancogne-Dejean, T.; Li, X.; Diamantopoulou, M.; Roth, C.C.; Mohr, D. High Strain Rate Response of Additively-Manufactured Plate-Lattices: Experiments and Modeling. J. Dyn. Behav. Mater. 2019, 5, 361–375. [Google Scholar] [CrossRef]

- Fischer, S.F. Energy absorption efficiency of open-cell pure aluminum foams. Mater. Lett. 2016, 184, 208–210. [Google Scholar] [CrossRef]

- Sychov, M.; Lebedev, L.; Dyachenko, S.; Nefedova, L. Mechanical properties of energy-absorbing structures with triply periodic minimal surface topology. Acta Astronaut. 2018, 150, 81–84. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.; Panesar, A.; Williams, C.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Zhang, L.; Feih, S.; Daynes, S.; Chang, S.; Wang, M.Y.; Wei, J.; Lu, W.F. Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading. Addit. Manuf. 2018, 23, 505–515. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef]

- Bobbert, F.S.L.; Lietaert, K.; Eftekhari, A.A.; Pouran, B.; Ahmadi, S.M.; Weinans, H.; Zadpoor, A.A. Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties. Acta Biomater. 2017, 53, 572–584. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Processing Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Montazerian, H.; Darabi, A.C.; Zargarian, A.; Schmauder, S. The relationships between deformation mechanisms and mechanical properties of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2017, 70, 28–42. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Fu, Z.; Du, K.; Wang, C.; Yi, Y. Minimal surface designs for porous materials: From microstructures to mechanical properties. J. Mater. Sci. 2018, 53, 10194–10208. [Google Scholar] [CrossRef]

- Dalaq, A.S.; Abueidda, D.W.; Al-Rub, R.K.A.; Jasiuk, I.M. Finite element prediction of effective elastic properties of interpenetrating phase composites with architectured 3D sheet reinforcements. Int. J. Solids Struct. 2016, 83, 169–182. [Google Scholar] [CrossRef]

- Yánez, A.; Cuadrado, A.; Martel, O.; Afonso, H.; Monopoli, D. Gyroid porous titanium structures: A versatile solution to be used as scaffolds in bone defect reconstruction. Mater. Des. 2018, 140, 21–29. [Google Scholar] [CrossRef]

- Abueidda, D.W.; Bakir, M.; Al-Rub, R.K.A.; Bergström, J.S.; Sobh, N.A.; Jasiuk, I. Mechanical properties of 3D printed polymeric cellular materials with triply periodic minimal surface architectures. Mater. Des. 2017, 122, 255–267. [Google Scholar] [CrossRef]

- Abueidda, D.W.; Elhebeary, M.; Shiang, C.S.A.; Pang, S.; Al-Rub, R.K.A.; Jasiuk, I.M. Mechanical properties of 3D printed polymeric Gyroid cellular structures: Experimental and finite element study. Mater. Des. 2019, 165, 107597. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Experimental and Computational Investigation of Lattice Sandwich Structures Constructed by Additive Manufacturing Technologies. J. Manuf. Mater. Process. 2021, 5, 95. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. J. Compos. Sci. 2021, 5, 58. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Chua, J.W.; Lee, H.P.; Ding, J.; Zhai, W. Microlattice Metamaterials with Simultaneous Superior Acoustic and Mechanical Energy Absorption. Small 2021, 17, 2100336. [Google Scholar] [CrossRef]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. J. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Chatzidai, N.; Karalekas, D. 3D printing-assisted design of scaffold structures. Int. J. Adv. Manuf Technol 2016, 82, 559–571. [Google Scholar] [CrossRef]

- Saleh, M.S.; Li, J.; Park, J.; Rahul, P. 3D printed hierarchically-porous microlattice electrode materials for exceptionally high specific capacity and areal capacity lithium ion batteries. J. Addit. Manuf. 2018, 23, 70–78. [Google Scholar] [CrossRef]

- Ouda, M.; Al-Ketan, O.; Sreedhar, N.; Ali, M.I.H.; Al-Rub, R.K.A.; Hong, S.; Arafat, H.A. Novel static mixers based on triply periodic minimal surface (TPMS) architectures. J. Environ. Chem. Eng. 2020, 8, 104289. [Google Scholar] [CrossRef]

- Carlson, S.W.; Goetz, D.D.; Liu, S.S.; Greiner, J.J.; Callaghan, J.J. Minimum 10-Year Follow-Up of Cementless Total Hip Arthroplasty Using a Contemporary Triple-Tapered Titanium Stem. J. Arthroplast. 2016, 31, 2231–2236. [Google Scholar] [CrossRef]

- Kousiatza, C.; Tzetzis, D.; Karalekas, D. In-situ characterization of 3D printed continuous fiber reinforced composites: A methodological study using fiber Bragg grating sensors. Compos. Sci. Technol. 2019, 174, 134–141. [Google Scholar] [CrossRef]

- Bogue, R. Smart materials: A review of recent developments. Assem. Autom. 2012, 32, 3–7. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4Dprinting with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Sundaram, S.; Kim, D.S.; Baldo, M.A.; Hayward, R.C.; Matusik, W. 3D-Printed Self-Folding Electronics. ACS Appl. Mater. Interfaces 2017, 9, 32290–32298. [Google Scholar] [CrossRef]

- Jiao, P.; Yang, Y.; Egbe, K.I.; He, Z.; Lin, Y. Mechanical Metamaterials Gyro-Structure Piezoelectric Nanogenerators for Energy Harvesting under Quasi-Static Excitations in Ocean Engineering. ACS Omega 2021, 6, 15348–15360. [Google Scholar] [CrossRef]

- Barri, K.; Jiao, P.; Zhang, Q.; Chen, J.; Wang, Z.L.; Alavi, A.H. Multifunctional meta-tribomaterial nanogenerators for energy harvesting and active sensing. Nano Energy 2021, 86, 106074. [Google Scholar] [CrossRef] [PubMed]

- Scheiner, B.; Schmitt, M.J.; Schmidt, D.; Goodwin, L.; Marshall, F.J. Two-photon polymerization printed lattices as support structures in multi-shell ICF targets: Platform development and initial assessment. Phys. Plasmas 2020, 27, 122702. [Google Scholar] [CrossRef]

| Study | Construction Material | Structure | Elastic Modulus | Strength | ||

|---|---|---|---|---|---|---|

| C | n | C | n | |||

| [62] | Photopolymer resin | Schwarz Primitive | 0.871 | 1.437 | 0.923 | 1.769 |

| Gyroid | 0.952 | 2.174 | 0.618 | 1.746 | ||

| Schwarz Diamond | 0.644 | 2.026 | 0.68 | 1.614 | ||

| IWP | 1.204 | 2.654 | 0.879 | 2.124 | ||

| [27,28] | Polyamide 12 (PA12) | Kelvin | 3.06 | 3.5 | 12.75 | 4.22 |

| Rhombic Dodecahedron | 0.76 | 2.63 | 2.12 | 2.83 | ||

| Waeire-Phelan | 0.3 | 1.7 | 0.76 | 1.79 | ||

| Octet | 0.13 | 1.11 | 0.62 | 1.6 | ||

| Schwarz Primitive | 0.4 | 2.01 | 1.61 | 2.55 | ||

| Gyroid | 0.16 | 1.22 | 0.34 | 1.14 | ||

| Schwarz Diamond | 0.43 | 1.2 | 0.37 | 0.91 | ||

| Neovius | 0.42 | 1.2 | 0.34 | 0.77 | ||

| [20] | Maraging steel | Kelvin | 0.15 | 1.56 | 1.375 | 1.83 |

| Octet | 0.1 | 1.23 | 0.615 | 1.32 | ||

| Gibson-Ashby | 0.15 | 1.62 | 1.185 | 1.76 | ||

| Skeletal-IWP | 0.19 | 2.01 | 0.153 | 2.17 | ||

| Skeletal-Diamond | 0.35 | 2.22 | 4.418 | 2.73 | ||

| Skeletal-Gyroid | 0.14 | 1.68 | 1.189 | 1.86 | ||

| Sheet-IWP | 0.08 | 1.15 | 2.354 | 2.13 | ||

| Sheet-Diamond | 0.037 | 0.522 | 0.933 | 1.39 | ||

| Sheet-Gyroid | 0.1 | 1.23 | 0.885 | 1.43 | ||

| Sheet-Primitive | 0.11 | 1.31 | 1.419 | 2.13 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kladovasilakis, N.; Tsongas, K.; Karalekas, D.; Tzetzis, D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials 2022, 15, 5919. https://doi.org/10.3390/ma15175919

Kladovasilakis N, Tsongas K, Karalekas D, Tzetzis D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials. 2022; 15(17):5919. https://doi.org/10.3390/ma15175919

Chicago/Turabian StyleKladovasilakis, Nikolaos, Konstantinos Tsongas, Dimitris Karalekas, and Dimitrios Tzetzis. 2022. "Architected Materials for Additive Manufacturing: A Comprehensive Review" Materials 15, no. 17: 5919. https://doi.org/10.3390/ma15175919