The Influence of Biofilm on Selected Properties of Thin-Coat Mineral-Based Plasters on EPS Substrate

Abstract

:1. Introduction

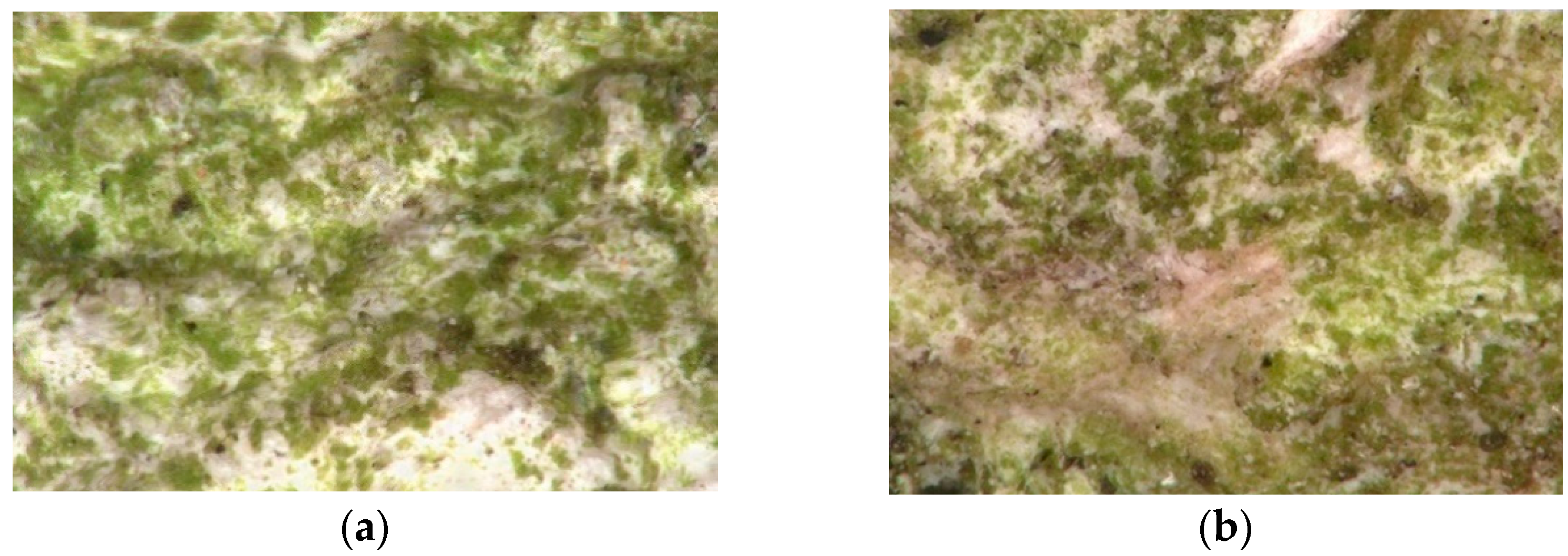

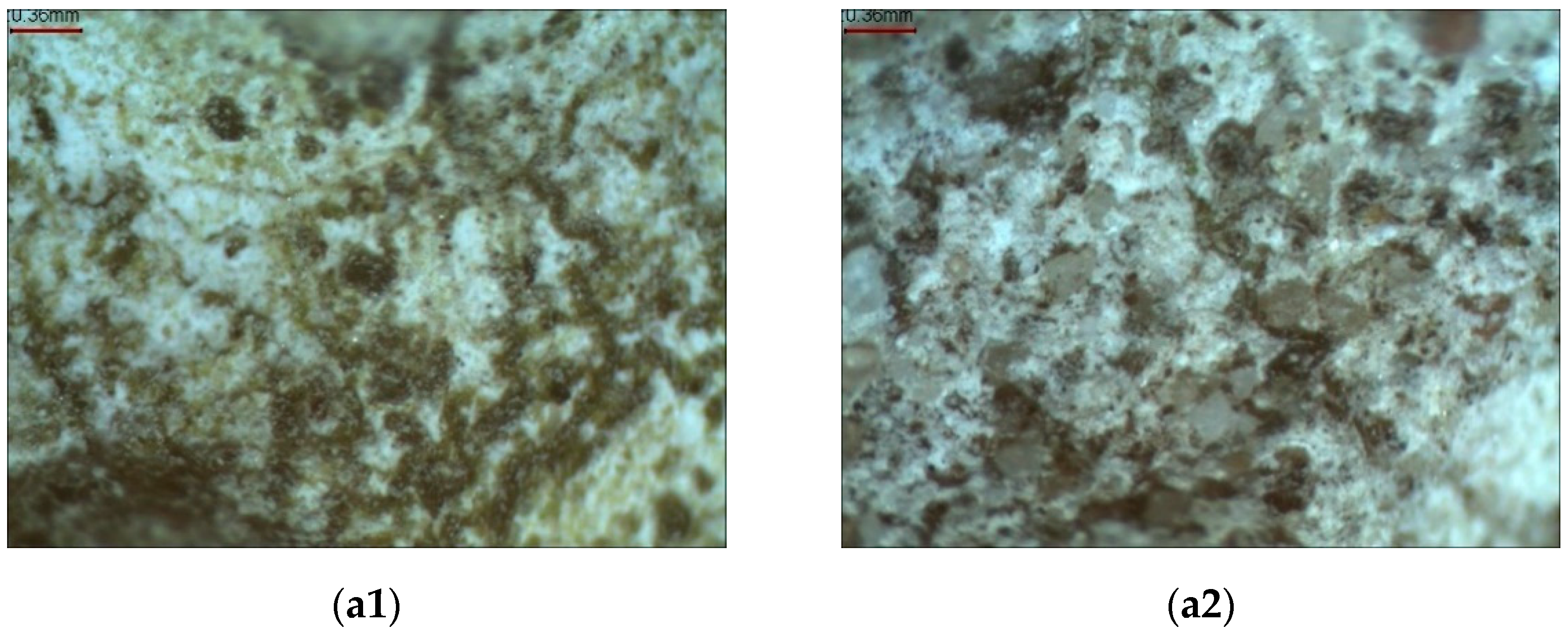

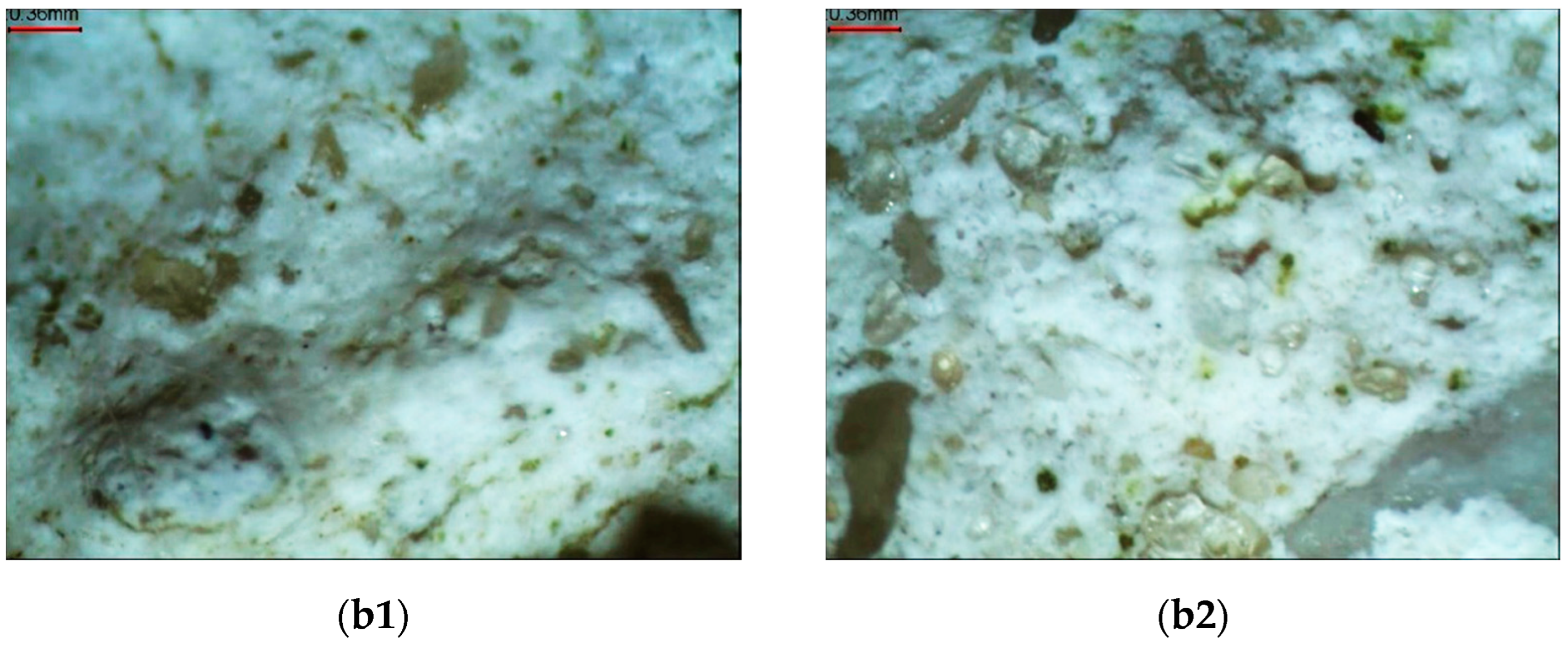

2. Test Material

- Initial laboratory samples (designated as group A);

- Initial laboratory samples after freeze–thaw cycles (designated as group B);

- Samples taken from the test bed subjected to a natural ageing process (designated as group C).

- Heating up to 60 °C at 80% humidity within 1 h and maintaining constant temperature and humidity for 3 h;

- Reducing temperature to –20 °C within 1 h and maintaining it for 3 h.

3. Test Methods

3.1. Water Absorption Test

- A system to maintain a constant water level with an accuracy of ±2 mm;

- A load to hold the sample in a particular position;

- Spacers to hold the sample at least 5 mm from the bottom (Figure 5).

- —a value of ∆m read from the timeline , in kg/m2;

- —a value of ∆m read from the timeline for = 0, in kg/m2;

- —test time, in seconds.

- —a value of ∆m read from the timeline , in kg/m2;

- —a value of ∆m read from the timeline for = 0, in kg/m2;

- —test time, in hours.

3.2. Microstructure Test Using Mercury Intrusion Porosimetry (MIP)

- Pores responsible for freeze–thaw durability:

- Pores responsible for capillary transport:

- IVfrost—pore volume in the diameter range from 100 to 1000 nm;

- IVcap—pore volume in the diameter range from 100 to 100,000 nm;

- TIV—total mercury intrusion;

- P—total porosity.

4. Test Results

4.1. Water Absorption

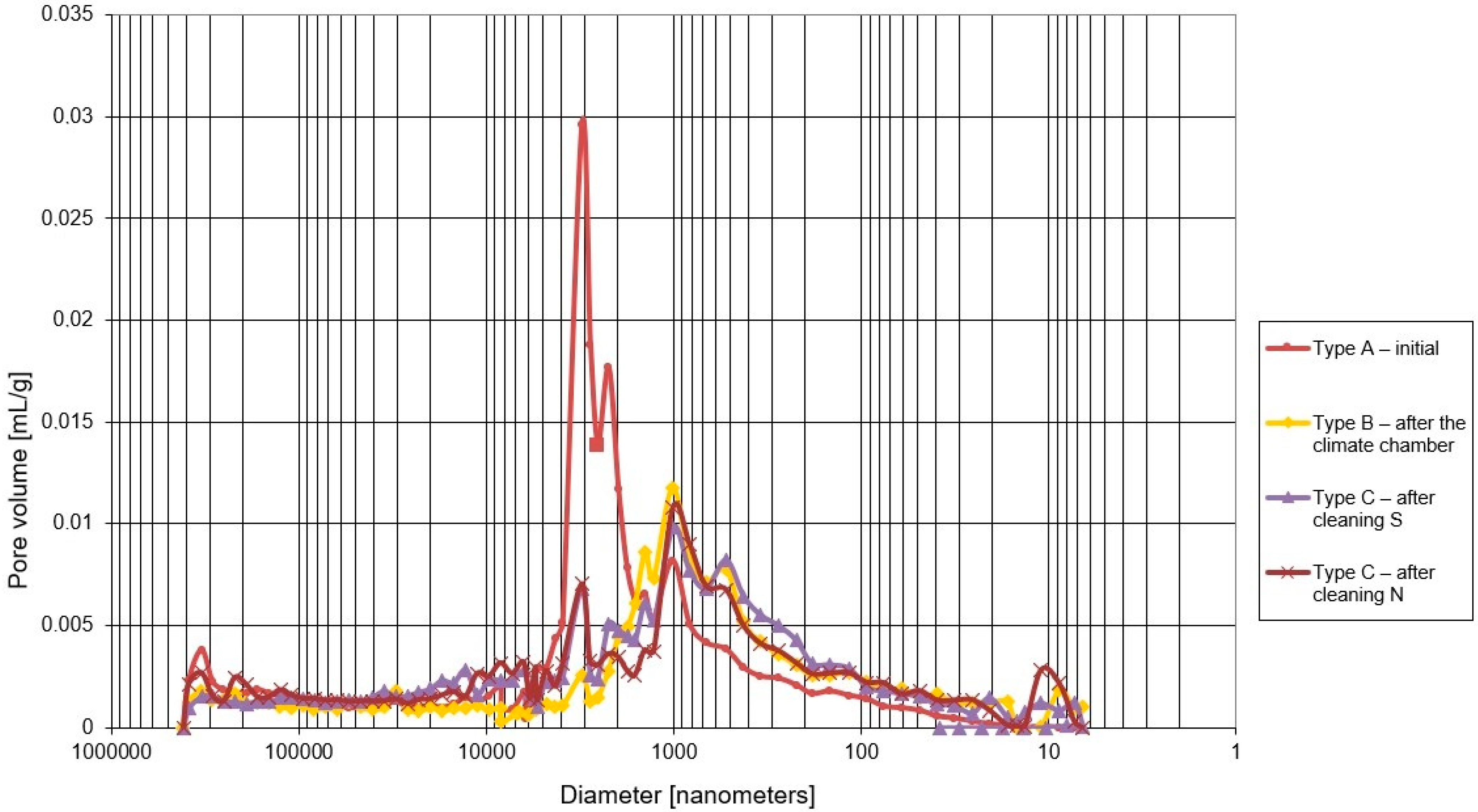

4.2. Microstructure

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EAD 040083-00-0404 External Thermal Insulation Composite Systems (ETICS) with Renderings. Available online: https://www.nlfnorm.cz/en/ehn/6669 (accessed on 6 June 2022).

- ETAG 004 External Thermal Insulation Composite Systems (ETICS) with Renderings. Available online: https://www.nlfnorm.cz/en/ehn/6705 (accessed on 6 June 2022).

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L.; Dionisio, A.; Gomes, M.; Faria, P. Performance parameters of ETICS: Correlating water resistance, bio-susceptibility and surface properties. Constr. Build. Mater. 2021, 272, 121956–121970. [Google Scholar] [CrossRef]

- Kukletova, I.; Chromkova, I. Testing of biocidal properties of thermal insulation system during material life cycle. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1205. [Google Scholar]

- Michałowski, B.; Marcinek, M.; Tomaszewska, J.; Czernik, S.; Piasecki, M.; Geryło, R.; Michalak, J. Influence of Rendering Type on the Environmental Characteristics of Expanded Polystyrene-Based External Thermal Insulation Composite System. Buildings 2020, 10, 47. [Google Scholar] [CrossRef]

- Künzel, H.; Künzel, H.M.; Sedlbauer, K. Long-Term Performance of External Thermal Insulation Systems (ETICS). Acta Sci. Pol. Archit. 2006, 1, 11–24. [Google Scholar]

- Johansson, S. Biological Growth on Rendered Facades. Ph.D. Thesis, Lund University, Division of Building Materials, Lund, Sweden, 2011. [Google Scholar]

- Fagerlund, G. Durability of Concrete Structures; Arkady: Warsaw, Poland, 1997. [Google Scholar]

- Stanaszek-Tomal, E. The Problem of Biological Destruction of Façades of Insulated Buildings—Causes and Effects. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 245. [Google Scholar]

- Wiejak, A.; Miklaszewska, J. Odporność na glony tynków cienkowarstwowych do stosowania na zewnątrz obiektów. Mater. Bud. 2012, 481, 28–29. [Google Scholar]

- Dylla, A.; Paczuska, B.; Wernerowska-Frąckiewicz, Z. Wstępne badania nad glonami aerofitycznymi porastającymi elewację budynków w Bydgoszczy ocieplonych metodą lekką-mokrą. Ochrona Przed Korozją 2008, 5, 47–50. [Google Scholar]

- Bochen, J.; Gil, S.; Szwabowski, J. Influence of ageing process on porosity changes of the external plasters. Cem. Concr. Compos. 2005, 27, 769–775. [Google Scholar] [CrossRef]

- Wilimzig, M. Biodeterioration od building materials. In Proceedings of the 8th International Congress on Deterioration and Conservation of Stone, Berlin/Heidelberg, Germany, 30 September–4 October 1996; Volume 18, pp. 579–583. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; Arkady: Cracow, Poland, 2000. [Google Scholar]

- Tran, T.; Govin, A.; Guyonnet, R.; Grosseau, P.; Lors, C.; Damidot, D.; Deves, O.; Ruot, B. Influence of the intrinsic characteristics of mortars on their biofouling by pigmented organisms: Comparison between laboratory and field scale experiments. Int. Biodeterior. Biodegrad. 2014, 86, 334–342. [Google Scholar] [CrossRef]

- Tada, S. Microstructural approach to frost resistance of highly porous materials. Durab. Build. Mater. Compon. 1996, 1, 299–308. [Google Scholar]

- Zhang, B. Relationship between pore structure and mechanical properties of ordinary concrete under bending fatigue. Cem. Concr. Res. 1998, 28, 699–711. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Zhihua, P.; Dongxu, L.; Jian, Y.; Yang, N. Properties and microstructure of the hardened alkali-activated red mud-slag cementitious material. Cem. Concr. Res. 2003, 33, 1437–1441. [Google Scholar]

- Moropoulou, A.; Polikreti, K.; Bakolas, A.; Michailidis, P. Correlation of physicochemical and mechanical properties of historical mortars and classification by multi variate statistics. Cem. Concr. Res. 2003, 33, 891–898. [Google Scholar] [CrossRef]

- Matusinović, T.; Šipušić, J.; Vrbos, N. Porosity–strength relation in calcium aluminate cement pastes. Cem. Concr. Res. 2003, 33, 1801–1806. [Google Scholar] [CrossRef]

- Martinez-Ramirez, S.; Puertas, F.; Blanco-Varela, M. Studies on degradation of lime mortars in atmospheric simulation chambers. Cem. Concr. Res. 1997, 27, 777–784. [Google Scholar] [CrossRef]

- Barberousse, H.; Brayner, R.; Do Rego, A.M.B.; Castaing, J.-C.; Beurdeley-Saudou, P.; Colombet, J.-F. Adhesion of facade coating colonisers, as mediated by physico-chemical properties. Biofouling 2007, 23, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Orazio, M.; Cursio, L.; Graziani, L. Effects of water absorption and surface roughness on the bioreceptivity of ETICS compared to clay bricks. Build. Environ. 2014, 77, 20–28. [Google Scholar] [CrossRef]

- EN ISO 15148:2004; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. ISO: London, UK, 2004.

| Sample Type | Orientation | Water Absorption Coefficient | |

|---|---|---|---|

| Aw (kg/(m2 × s0.5)) | Ww (kg/(m2 × h0.5)) | ||

| Initial (A) | - | 0.0023 | 0.1372 |

| After freeze–thaw cycles (B) | - | 0.0011 | 0.0656 |

| Taken from the field site (C) with biofilm | S | 0.0007 | 0.0433 |

| N | 0.0008 | 0.0466 | |

| Taken from the field site (C) after biocide cleaning | S | 0.0016 | 0.0969 |

| N | 0.0036 | 0.2177 | |

| Sample Type | General Porosity (%) | U Cap (%) (100 nm to 100,000 nm) | U Frost (%) (100 nm to 1000 nm) | Dominant Diameters (nm) |

|---|---|---|---|---|

| Initial (A) | 34.2 | 30.0 | 4.4 | 3000 |

| After freeze–thaw cycles (B) | 26.8 | 21.2 | 8.2 | 1000 |

| Taken from the field site (C), S orientation | 29.5 | 24.8 | 9.0 | 1000 |

| Taken from the field site (C), N orientation | 29.2 | 22.8 | 7.7 | 1000 3000 |

| Sample Type | Mercury Intrusion for a Given Range of Pores, mL/g | Volume Changes, mL/g | ||

|---|---|---|---|---|

| IVcap | IVfrost | IVcap | IVfrost | |

| 100 nm ÷ 100,000 nm | 100 nm ÷ 1000 nm | 100 nm ÷ 100,000 nm | 100 nm ÷ 1000 nm | |

| Initial (A) | 0.192562 | 0.02791 | – | – |

| After freeze–thaw cycles (B) | 0.121733 | 0.046944 | 36.8 | −68.2 |

| Taken from the field site (C), S orientation | 0.152485 | 0.054965 | 20.8 | −96.9 |

| Taken from the field site (C), N orientation | 0.137783 | 0.046643 | 28.4 | −67.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dybowska-Józefiak, M.; Wesołowska, M. The Influence of Biofilm on Selected Properties of Thin-Coat Mineral-Based Plasters on EPS Substrate. Materials 2022, 15, 5963. https://doi.org/10.3390/ma15175963

Dybowska-Józefiak M, Wesołowska M. The Influence of Biofilm on Selected Properties of Thin-Coat Mineral-Based Plasters on EPS Substrate. Materials. 2022; 15(17):5963. https://doi.org/10.3390/ma15175963

Chicago/Turabian StyleDybowska-Józefiak, Monika, and Maria Wesołowska. 2022. "The Influence of Biofilm on Selected Properties of Thin-Coat Mineral-Based Plasters on EPS Substrate" Materials 15, no. 17: 5963. https://doi.org/10.3390/ma15175963