An Investigation into a Miniature Saltless Solar Pond

Abstract

:1. Introduction

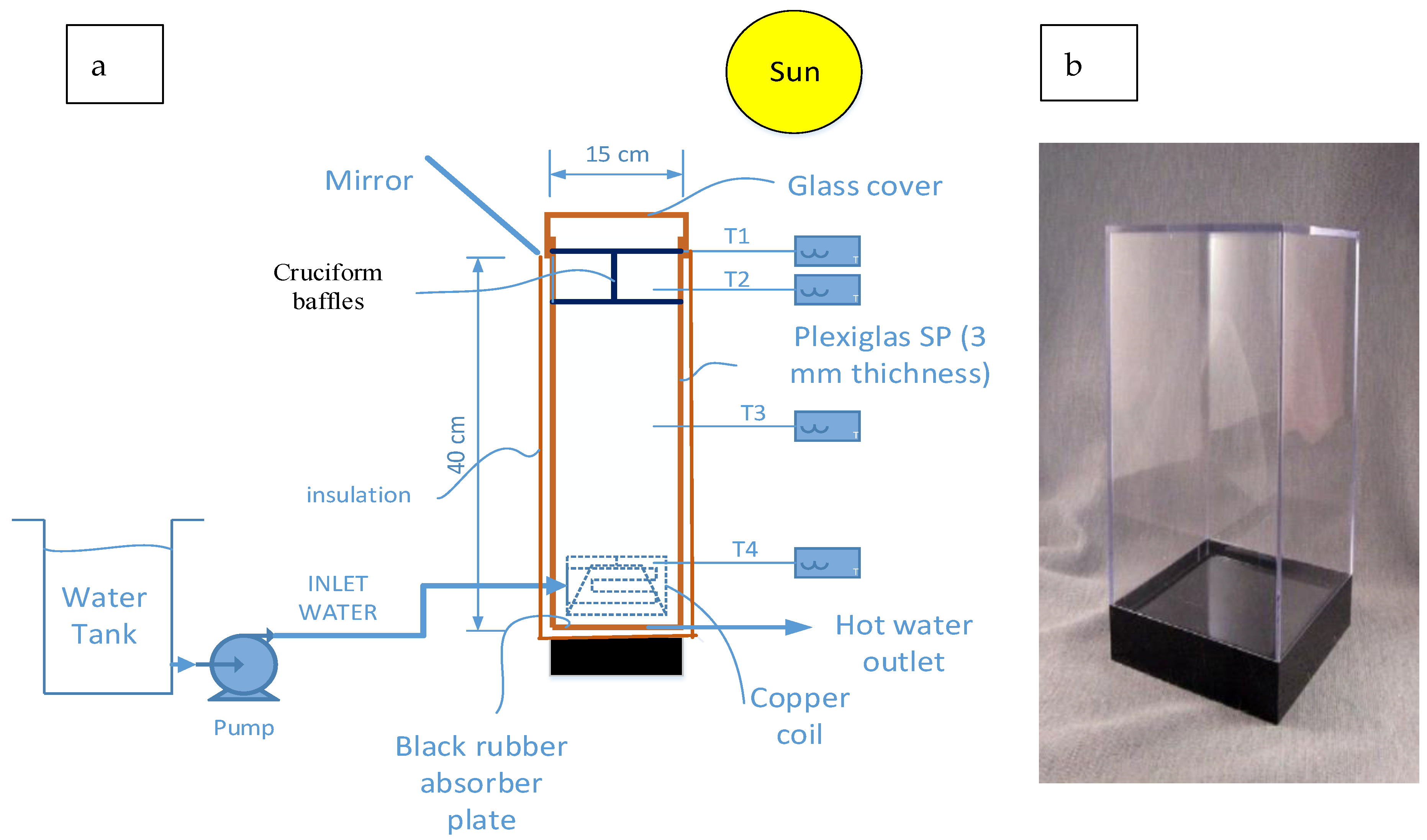

2. Experimental Section

2.1. Materials

2.2. Methods

2.3. Procedure

2.4. Variables Investigated

2.5. Computation of Thermal Efficiency of the SP

2.6. Uncertainty Analysis

3. Results and Discussions

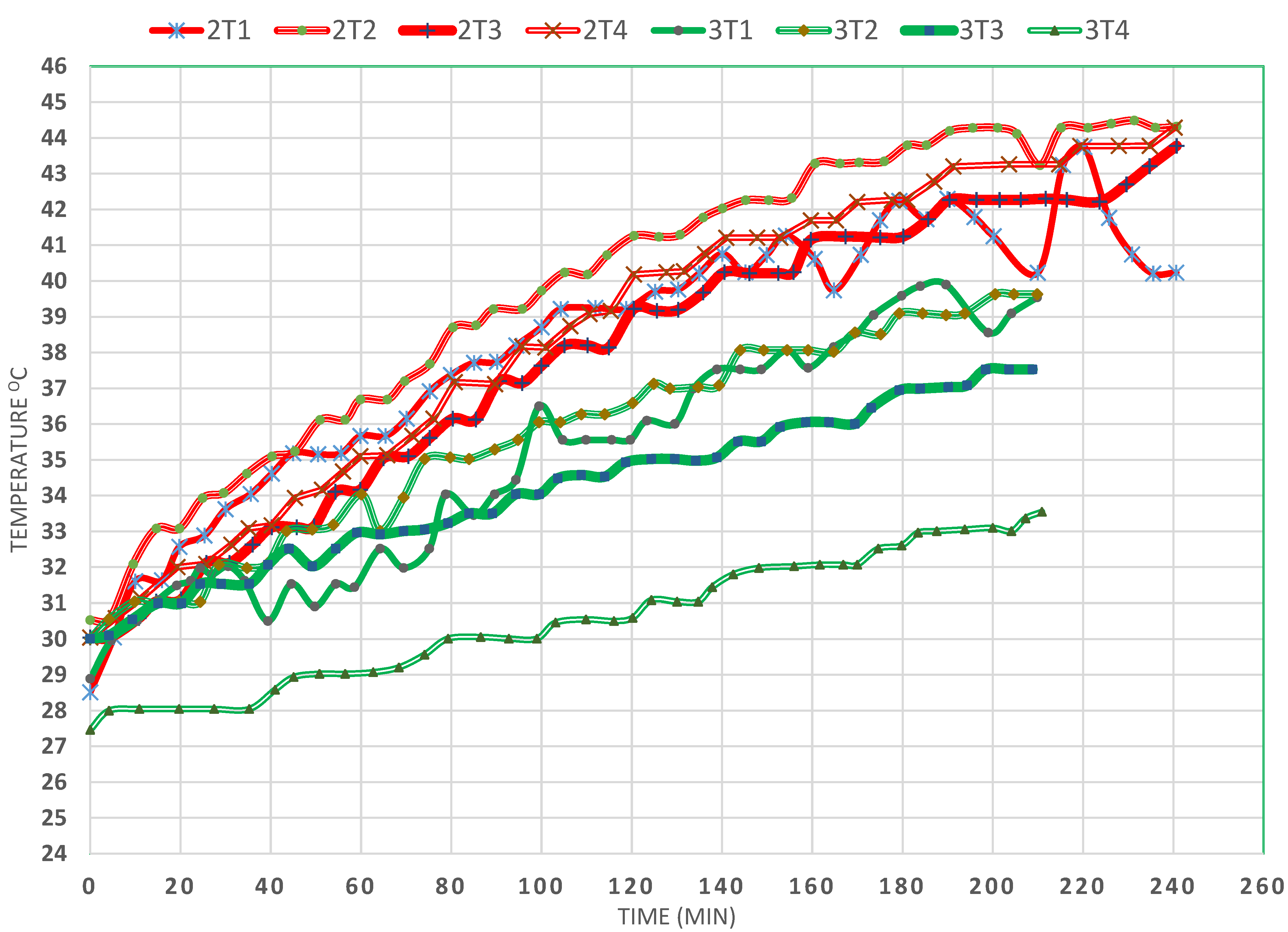

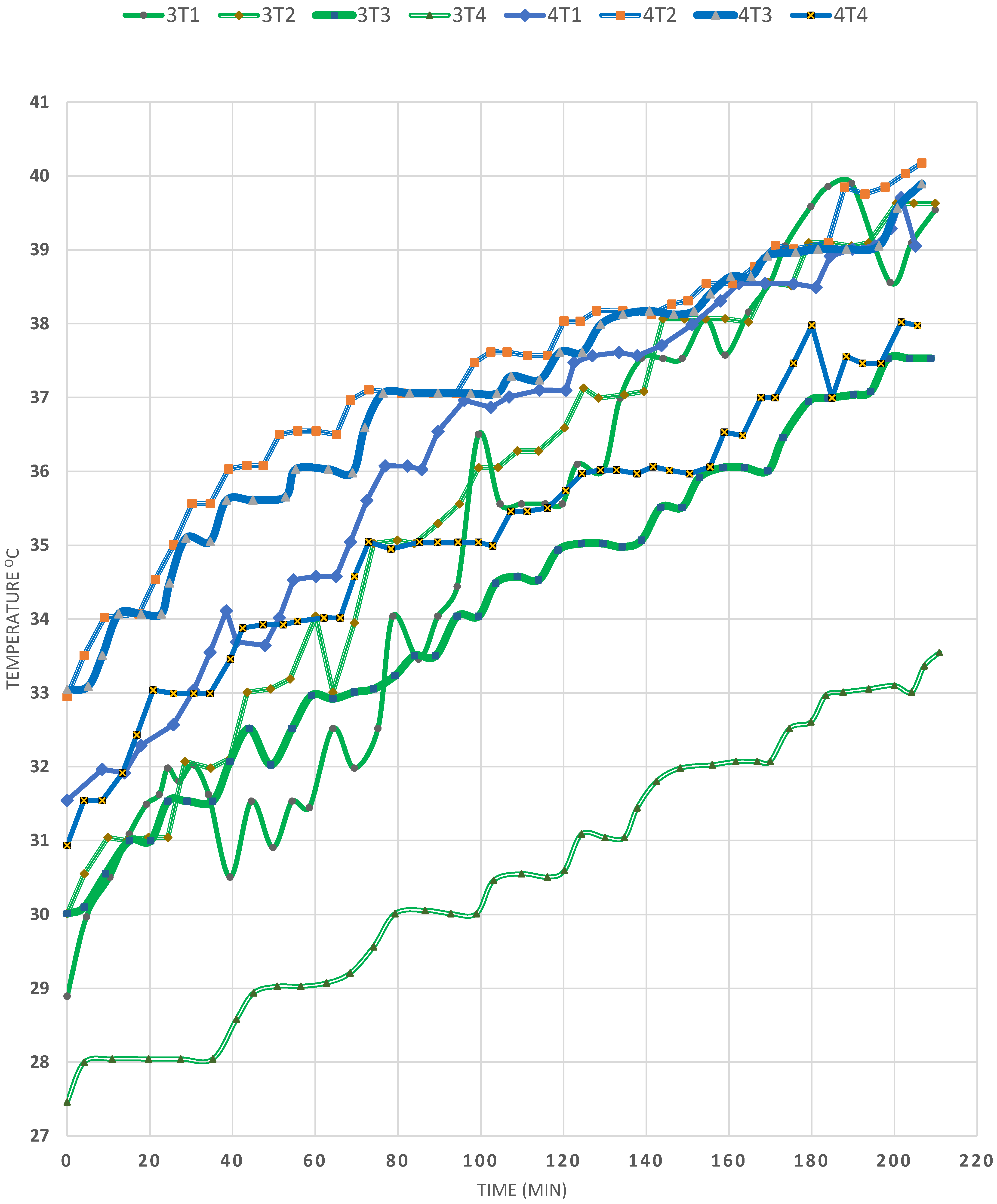

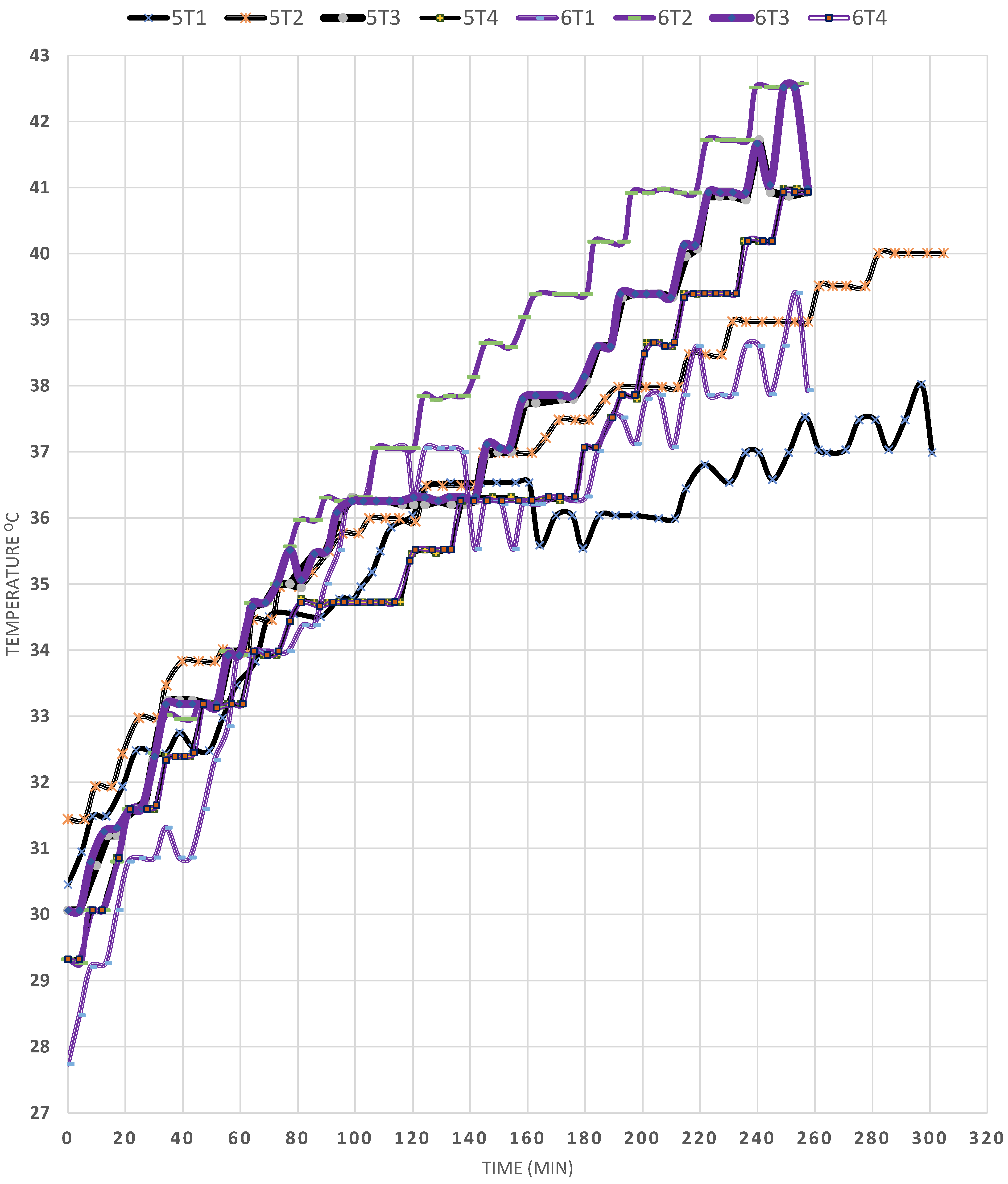

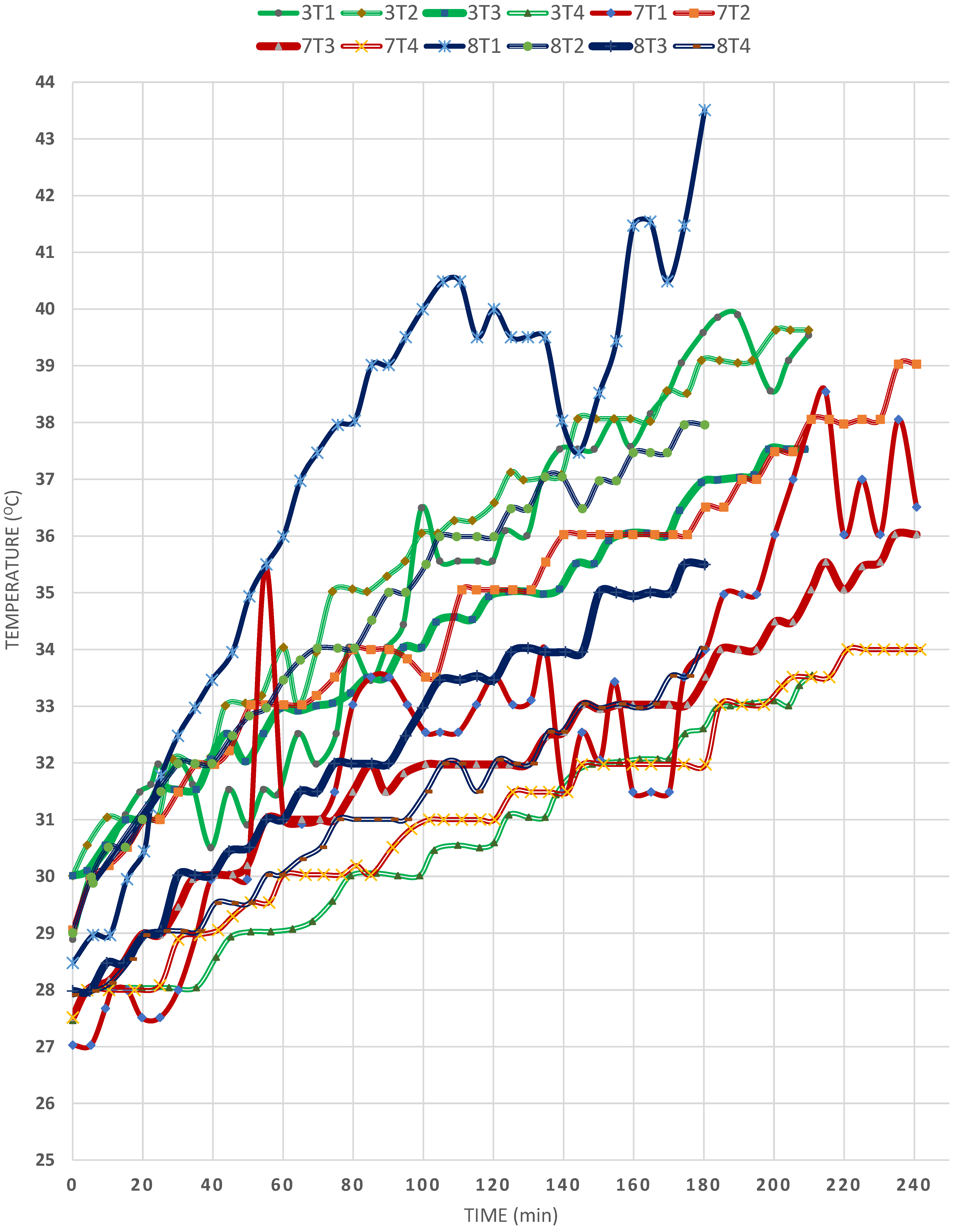

3.1. Effect of Mirror Slop

3.2. Effect of Glass Wool

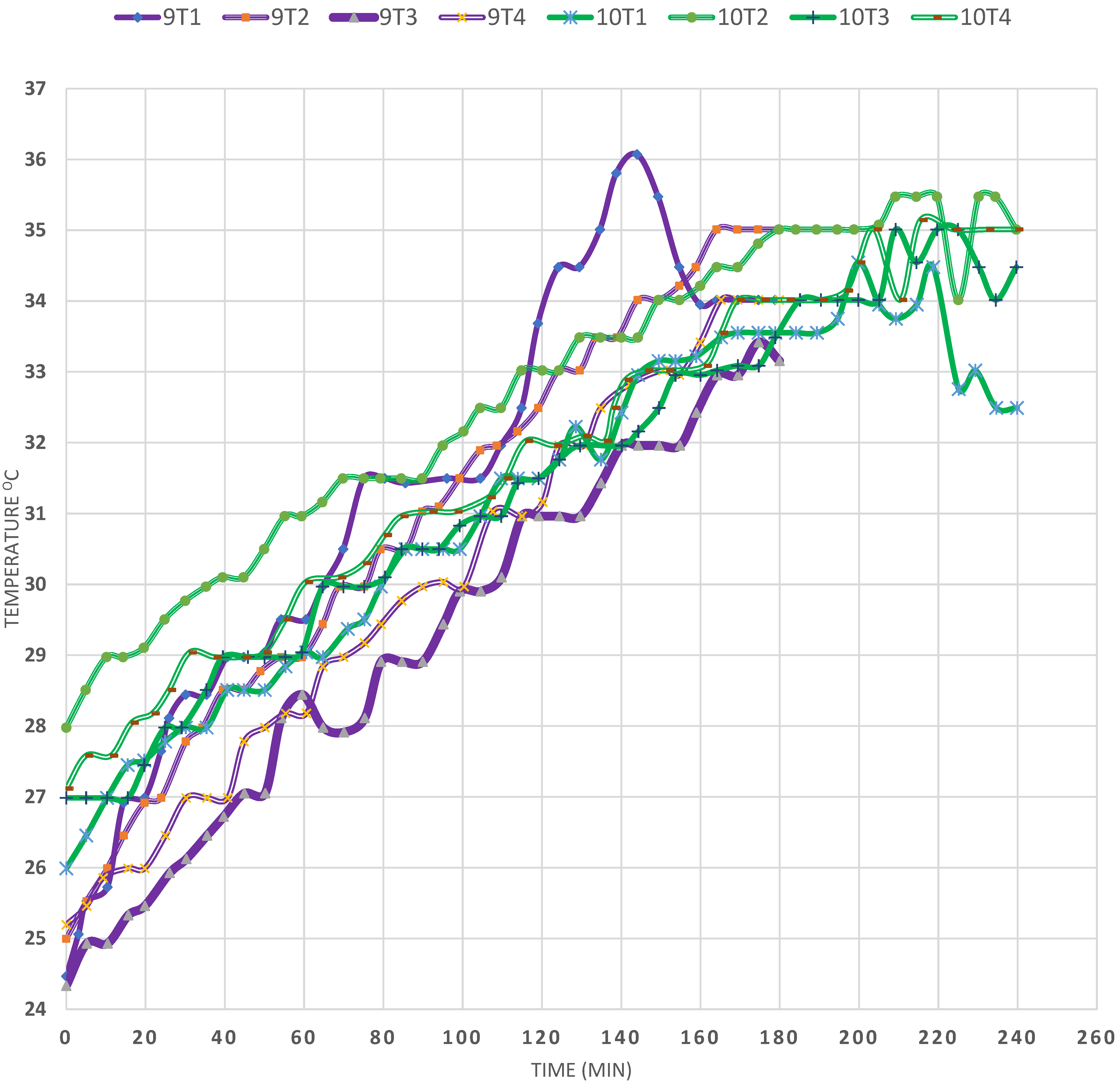

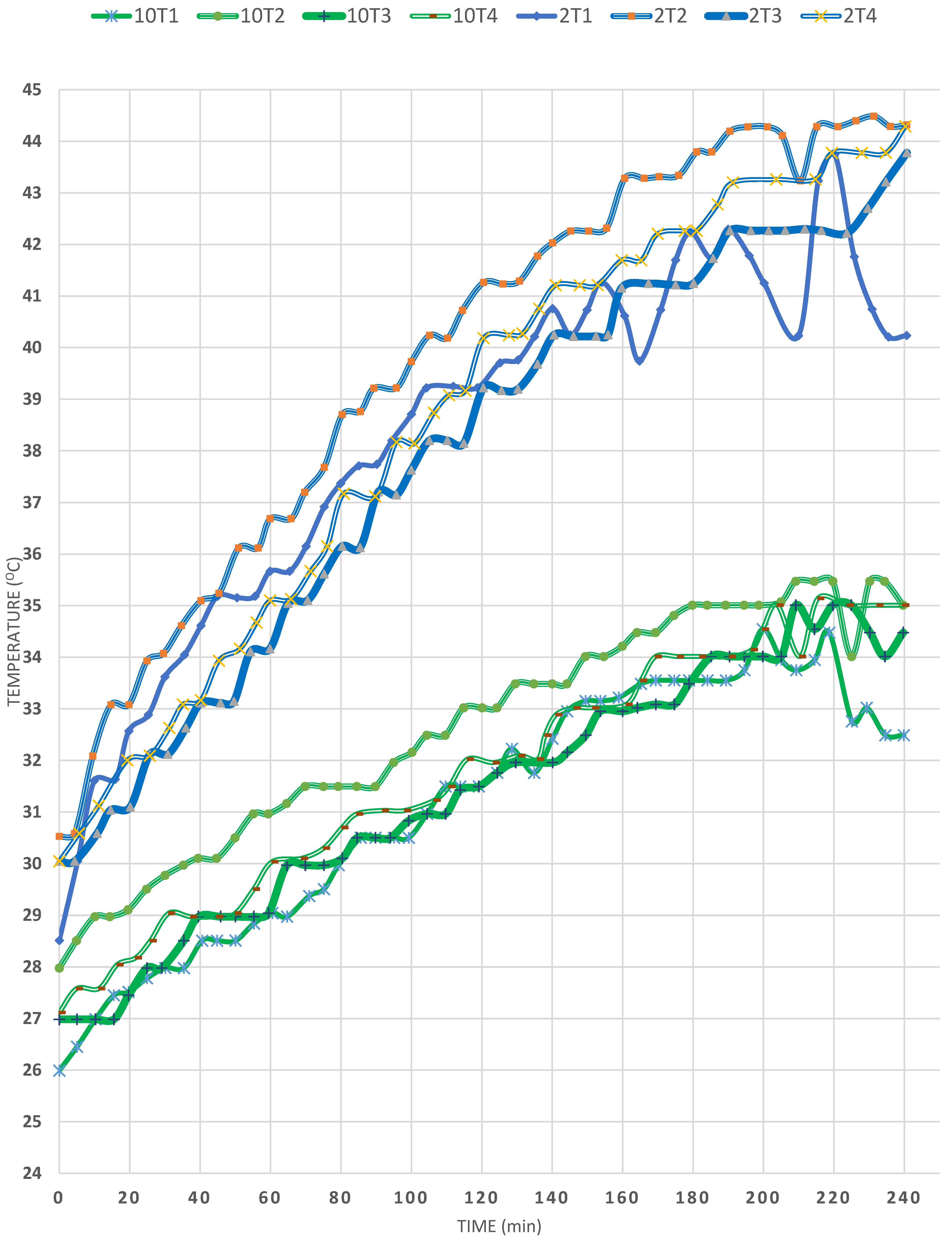

3.3. Effect of Climatic Conditions

3.4. Reproducibility

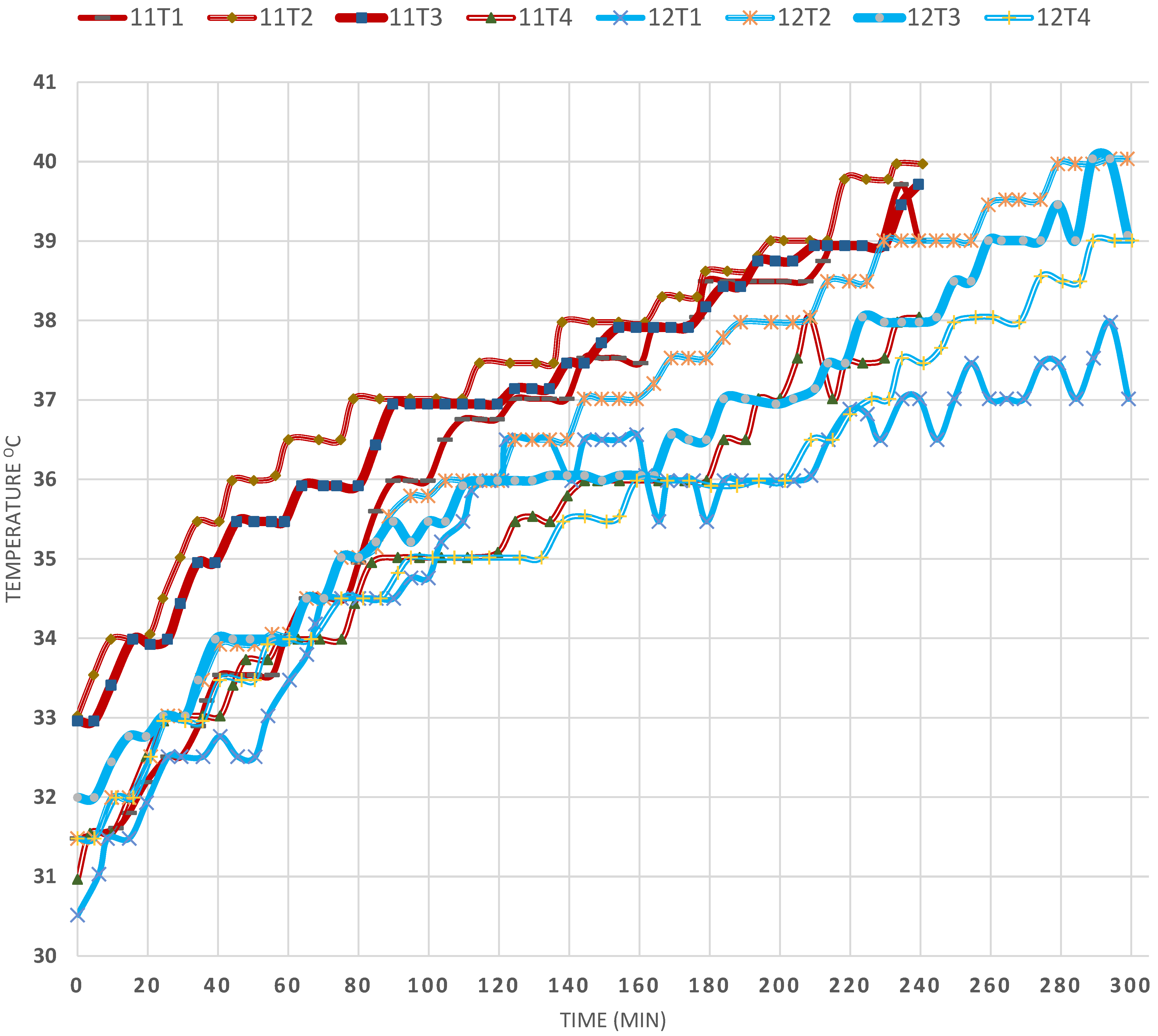

3.5. Effect of the Presence of Thickening Material

3.6. Effect of Ambient Temperature

3.7. Thermal Efficiency of the Pond

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suárez, F.; Ruskowitz, J.A.; Tyler, S.W.; Childress, A.E. Renewable water: Direct contact membrane distillation coupled with solar ponds. Appl. Energy 2015, 158, 532–539. [Google Scholar] [CrossRef]

- Mehdi, S. Solar Desalination. In Alternative Energy Sources; Veziroglu, T.N., Ed.; Hemisphere Publishing: London, UK, 1986; pp. 317–321. ISBN 0080325734. [Google Scholar]

- Naim, M.M.; Abd El Kawi, M.A. Non-conventional solar stills. Part 1. Non-conventional solar stills with charcoal particles as absorber medium. Desalination 2003, 153, 55–64. [Google Scholar] [CrossRef]

- Gawade, T.; Shinde, V.; Gawade, K.; Mumbai, N. Non Conventional Energy Sources: Solar Pond. Int. J. Stud. Res. Technol. Manag. 2013, 1, 156–162. [Google Scholar]

- Saxena, A.; Varun; Pandey, S.P.; Srivastav, G. A thermodynamic review on solar box type cookers. Renew. Sustain. Energy Rev. 2011, 15, 3301–3318. [Google Scholar] [CrossRef]

- Saxena, A.; Varun; El-Sebaii, A.A. A thermodynamic review of solar air heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- González, D.; Amigo, J.; Suárez, F. Membrane distillation: Perspectives for sustainable and improved desalination. Renew. Sustain. Energy Rev. 2017, 80, 238–259. [Google Scholar] [CrossRef]

- Sayer, A.H.; Al-Hussaini, H.; Campbell, A.N. New comprehensive investigation on the feasibility of the gel solar pond, and a comparison with the salinity gradient solar pond. Appl. Therm. Eng. 2018, 130, 672–683. [Google Scholar] [CrossRef]

- Pirvaram, A.; Talebzadeh, N.; Leung, S.N.; O’Brien, P.G. Radiative cooling for buildings: A review of techno-enviro-economics and life-cycle assessment methods. Renew. Sustain. Energy Rev. 2022, 162, 112415. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Saxena, A.; Guclu, T.; Besir, A.B. Performance analysis of a novel solar desalination system—Part 1: The unit with sensible energy storage and booster reflector without thermal insulation and cooling system. Sustain. Energy Technol. Assess. 2020, 37, 100566. [Google Scholar] [CrossRef]

- Mandal, J.; Yang, Y.; Yu, N.; Raman, A.P. Paints as a Scalable and Effective Radiative Cooling Technology for Buildings. Joule 2020, 4, 1350–1356. [Google Scholar] [CrossRef]

- Saxena, A.; Agarwal, N.; Norton, B. Design and performance characteristics of an innovative heat sink structure with phase change material for cooling of photovoltaic system. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–25. [Google Scholar] [CrossRef]

- Al-Nimr, M.A.; Dawahdeh, A.I.; Ali, H.A. Power generation by integrating a thermally regenerative electrochemical cycle (TREC) with a solar pond and underground heat exchanger. Renew. Energy 2022, 189, 663–675. [Google Scholar] [CrossRef]

- Dincer, I.; Yapicioglu, A. Solar Ponds. In Comprehensive Energy Systems; Dincer, I.B.T.-C.E.S., Ed.; Elsevier: Oxford, UK, 2018; Volume 4–5, pp. 659–691. ISBN 9780128095973. [Google Scholar]

- Deniz, S.; Bozkurt, I.; Karakilcik, M.; Dincer, I. Performance assessment of a small solar pond stratified with magnesium chloride water. In Progress in Exergy, Energy, and the Environment; Springer: Berlin/Heidelberg, Germany, 2014; pp. 243–250. ISBN 9783319046815. [Google Scholar]

- Abdulsalam, A.; Idris, A.; Mohamed, T.A.; Ahsan, A. The development and applications of solar pond: A review. Desalin. Water Treat. 2015, 53, 2437–2449. [Google Scholar] [CrossRef]

- Kreider, J.F.; Kreith, F. Solar Energy Handbook; McGraw-Hill Book Company: New York, NY, USA, 1981; Volume 103. [Google Scholar]

- Nielson, C.E. Solar Energy Technology Handbook, Part A, Engineering Fundamentals; Dickinson, W.C., Cheremisinoff, P.N., Eds.; Marcel Dekker Inc.: New York, NY, USA; Basel Sowie Butterworth: London, UK, 1980; Volume 11. [Google Scholar]

- Tabor, H. Non-Convecting Solar Ponds. Sol. Energy 1980, 295, 423–433. [Google Scholar] [CrossRef]

- Arulanantham, M.; Avanti, P.; Kaushika, N.D. Technical note: Solar pond with honeycomb surface insulation system. Renew. Energy 1997, 12, 435–443. [Google Scholar] [CrossRef]

- Tabor, H. Solar ponds. In Solar Energy; Elsevier: Amsterdam, The Netherlands, 1981; Volume 27, pp. 181–194. [Google Scholar]

- Hull, J.R. Membrane stratified solar ponds. Sol. Energy 1980, 25, 317–325. [Google Scholar] [CrossRef]

- Shaffer, L.H. Viscosity Stabilized Solar Ponds. In Sun: Mankind’s Future Source of Energy; Elsevier: Amsterdam, The Netherlands, 1978; pp. 1171–1175. [Google Scholar]

- Wilkins, E.S.; Lee, T.K. Development of the gel pond technology. Sol. Energy 1987, 39, 33–51. [Google Scholar] [CrossRef]

- Ortabasi, U.; Dyksterhuis, F.H.; Kaushika, N.D. Honeycomb stabilised saltless solar pond. Sol. Energy 1983, 31, 229–231. [Google Scholar] [CrossRef]

- Ortabasi, U.; Dyksterhuis, F. Experiences With Honeycomb Stabilized Solar Ponds for Heat and Power Generation; Pergamon: Oxford, UK, 1986; Volume 3, pp. 1484–1488. [Google Scholar]

- Sharma, M.S.; Kaushika, N.D. Design and performance characteristics of honeycomb solar pond. Energy Convers. Manag. 1987, 27, 111–116. [Google Scholar] [CrossRef]

- Kamiuto, K.; Iwamoto, M.; Koga, K.; Sata, S. Thermal behavior of a small, saltless solar pond with the semitransparent multilayer surface insulation system. Sol. Energy 1988, 41, 141–146. [Google Scholar] [CrossRef]

- Appadurai, M.; Raj, E.F.I.; Jenish, I. Application of Aluminium Oxide–Water Nanofluids to Augment the Performance of Shallow Pond: A Numerical Study. Process Integr. Optim. Sustain. 2022, 6, 211–222. [Google Scholar] [CrossRef]

- Selvakumar, B.; Shanmugapriya, V.; Amudha, K.; Periasamy, P. Enhanced Thermophysical Properties and Productive Yield of Pyramid Solar Still Combined with Shallow Solar Pond by Incorporating ZnO/Al2O3 Nanocomposites; Sengodan, T., Murugappan, M., Misra, S., Eds.; Springer Nature: Singapore, 2022; pp. 1121–1135. [Google Scholar]

- Ting, S.Y.Y.; Liaw, K.L.; Kurnia, J.C. Investigation on the Effect of Nanoparticle Diameter and Concentration on the Performance of Nanofluid Solar Pond. ECS Trans. 2022, 107, 151–162. [Google Scholar] [CrossRef]

- Sharma, P.; Said, Z.; Kumar, A.; Nižetić, S.; Pandey, A.; Hoang, A.T.; Huang, Z.; Afzal, A.; Li, C.; Le, A.T.; et al. Recent Advances in Machine Learning Research for Nanofluid-Based Heat Transfer in Renewable Energy System. Energy Fuels 2022, 36, 6626–6658. [Google Scholar] [CrossRef]

- Machine, S.V.; Sharma, P.; Elavarasan, R.M.; Tiawari, A.K.; Rathod, M.K.; Jamei, M.; Kumar, R. Journal of Energy Storage Exploring the specific heat capacity of three distinct water-based hybrid nanofluids for solar energy applications: A comparative evaluation of modern ensemble machine learning techniques. J. Energy Storage 2022, 54, 105230. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Experimental investigation and optical visualization of a salt gradient solar pond integrated with PCM. Sol. Energy Mater. Sol. Cells 2022, 234, 111425. [Google Scholar] [CrossRef]

- Assari, M.R.; Jafar Gholi Beik, A.; Eydi, R.; Basirat Tabrizi, H. Thermal-salinity performance and stability analysis of the pilot salt-gradient solar ponds with phase change material. Sustain. Energy Technol. Assess. 2022, 53, 102396. [Google Scholar] [CrossRef]

- Sakthivadivel, D.; Balaji, K.; Dsilva Winfred Rufuss, D.; Iniyan, S.; Suganthi, L. Solar energy technologies: Principles and applications. In Renewable-Energy-Driven Future; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–42. [Google Scholar]

- Wheatley, G.; Rubel, R.I. Design improvement of a laboratory prototype for efficiency evaluation of solar thermal water heating system using phase change material (PCMs). Results Eng. 2021, 12, 100301. [Google Scholar] [CrossRef]

- Khodabandeh, E.; Safaei, M.R.; Akbari, S.; Akbari, O.A.; Alrashed, A.A.A.A. Application of nanofluid to improve the thermal performance of horizontal spiral coil utilized in solar ponds: Geometric study. Renew. Energy 2018, 122, 1–16. [Google Scholar] [CrossRef]

- Al-Nimr, M.A.; Al-Dafaie, A.M.A. Using nanofluids in enhancing the performance of a novel two-layer solar pond. Energy 2014, 68, 318–326. [Google Scholar] [CrossRef]

- Saxena, A.; Cuce, E.; Kabeel, A.E.; Abdelgaied, M.; Goel, V. A thermodynamic review on solar stills. Sol. Energy 2022, 237, 377–413. [Google Scholar] [CrossRef]

- Bozkurt, I.; Atiz, A.; Karakilcik, M.; Dincer, I. Performance analysis of a solar pond. In Progress in Exergy, Energy, and the Environment; Springer International Publishing: Cham, Switzerland, 2014; pp. 783–790. ISBN 9783319046815. [Google Scholar]

- Bozkurt, I.; Karakilcik, M. The effect of sunny area ratios on the thermal performance of solar ponds. Energy Convers. Manag. 2015, 91, 323–332. [Google Scholar] [CrossRef]

- Valderrama, C.; Cortina, J.L.; Akbarzadeh, A.; Bawahab, M.; Faqeha, H.; Date, A. Solar ponds. In Storing Energy: With Special Reference to Renewable Energy Sources; Elsevier: Amsterdam, The Netherlands, 2022; pp. 537–558. ISBN 9780128245101. [Google Scholar]

- Kreith, F.; Kreider, J.F. Principles of Solar Engineering; Hemisphere Publishing Corporation: Washington, DC, USA, 1978. [Google Scholar]

- Spyridonos, A.V.; Argiriou, A.A.; Nickoletatos, J.K. Thermal storage efficiencies of two solar saltless water ponds. Sol. Energy 2003, 75, 207–216. [Google Scholar] [CrossRef]

- Kurt, H.; Halici, F.; Binark, A.K. Solar pond conception—Experimental and theoretical studies. Energy Convers. Manag. 2000, 41, 939–951. [Google Scholar] [CrossRef]

- Assari, M.R.; Basirat Tabrizi, H.; Kavoosi Nejad, A.; Parvar, M. Experimental investigation of heat absorption of different solar pond shapes covered with glazing plastic. Sol. Energy 2015, 122, 569–578. [Google Scholar] [CrossRef]

- Dineshkumar, P.; Raja, M. An experimental study on trapezoidal salt gradient solar pond using magnesium sulfate (MgSO4) salt and coal cinder. J. Therm. Anal. Calorim. 2022, 147, 10525–10532. [Google Scholar] [CrossRef]

| EXP No. | Variables Investigated | ||||||

|---|---|---|---|---|---|---|---|

| Ambient Temperature, Ta, °C | Presence or Absence of Baffles | Presence of GC | Slope of the Mirror at the Top of SP | Presence of GW Inside SP and Its Quantity, g | Wind Speed, km/h | Presence of Thickening Gel Material | |

| 1 | 31.5 | Yes | Yes | 80° | No | 3–7 | No |

| 2 | 30 | Yes | Yes | 45° | No | 7 | No |

| 3 | 30.5 | Yes | Yes | 80° | 344 | 11 | No |

| 4 | 26.5 | Yes | Yes | No | 170 | 16 | No |

| 5 | 28.5 | Yes | Yes | 45° | No | 21 | No |

| 6 | 30 | Yes | Yes | 45° | No | 3–7 | No |

| 7 | 30 | Yes | Yes | 80° | 344 | 24 | No |

| 8 | 31 | Yes | Yes | 80° | 344 | 26 | No |

| 9 | 29.5 | Yes | Yes | 45° | No | 13 | No |

| 10 | 30 | Yes | Yes | 45° | No | 12 | No |

| 11 | 32 | Yes | Yes | No | No | 3–7 | No |

| 12 | 32 | Yes | Yes | No | No | 3–7 | Yes |

| EXP No. | Ambient Temp., Ta, °C | T1 | ΔT1 | R2 | T2 | ΔT2 | R2 | T3 | ΔT3 | R2 | T4 | ΔT4 | R2 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Start | End | Start | End | Start | End | Start | End | ||||||||||

| 2 | 30 | 28.5 | 40.2 | 11.7 | 0.964 | 30.5 | 44.5 | 14 | 0.994 | 30 | 43.7 | 13.7 | 0.994 | 30 | 44.5 | 14.5 | 0.996 |

| 10 | 30 | 26 | 32.5 | 6.5 | 0.961 | 28 | 35 | 7 | 0.982 | 27 | 34.5 | 7.5 | 0.991 | 27 | 35 | 8 | 0.987 |

| EXP No. | Ambient Temperature, Ta, °C | LCZ Temperature | % Max Thermal Pond Efficiency |

|---|---|---|---|

| 1 | 31.5 | 43.3 | 27.25 |

| 2 | 30 | 44.5 | 32.58 |

| 3 | 30.5 | 33.5 | 8.96 |

| 4 | 26.5 | 38 | 30.26 |

| 5 | 28.5 | 41 | 30.49 |

| 6 | 30 | 41 | 26.83 |

| 7 | 30 | 34 | 11.76 |

| 8 | 31 | 34 | 8.82 |

| 9 | 29.5 | 34 | 13.24 |

| 10 | 30 | 35 | 14.29 |

| 11 | 32 | 38 | 15.79 |

| 12 | 32 | 39 | 17.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Batouti, M.; Naim, M.M.; Al Harby, N.F.; Elewa, M.M. An Investigation into a Miniature Saltless Solar Pond. Materials 2022, 15, 5974. https://doi.org/10.3390/ma15175974

El-Batouti M, Naim MM, Al Harby NF, Elewa MM. An Investigation into a Miniature Saltless Solar Pond. Materials. 2022; 15(17):5974. https://doi.org/10.3390/ma15175974

Chicago/Turabian StyleEl-Batouti, Mervette, Mona M. Naim, Nouf F. Al Harby, and Mahmoud M. Elewa. 2022. "An Investigation into a Miniature Saltless Solar Pond" Materials 15, no. 17: 5974. https://doi.org/10.3390/ma15175974

APA StyleEl-Batouti, M., Naim, M. M., Al Harby, N. F., & Elewa, M. M. (2022). An Investigation into a Miniature Saltless Solar Pond. Materials, 15(17), 5974. https://doi.org/10.3390/ma15175974