Valorization of Polypropylene Waste in the Production of New Materials with Adequate Mechanical and Thermal Properties for Environmental Protection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis and Characterization of SBSBC and SISBC

2.3. Processing of PPW/SBSBC/n-Clay and PPW/SISBC/n-Clay Composites

2.4. Investigation Methods

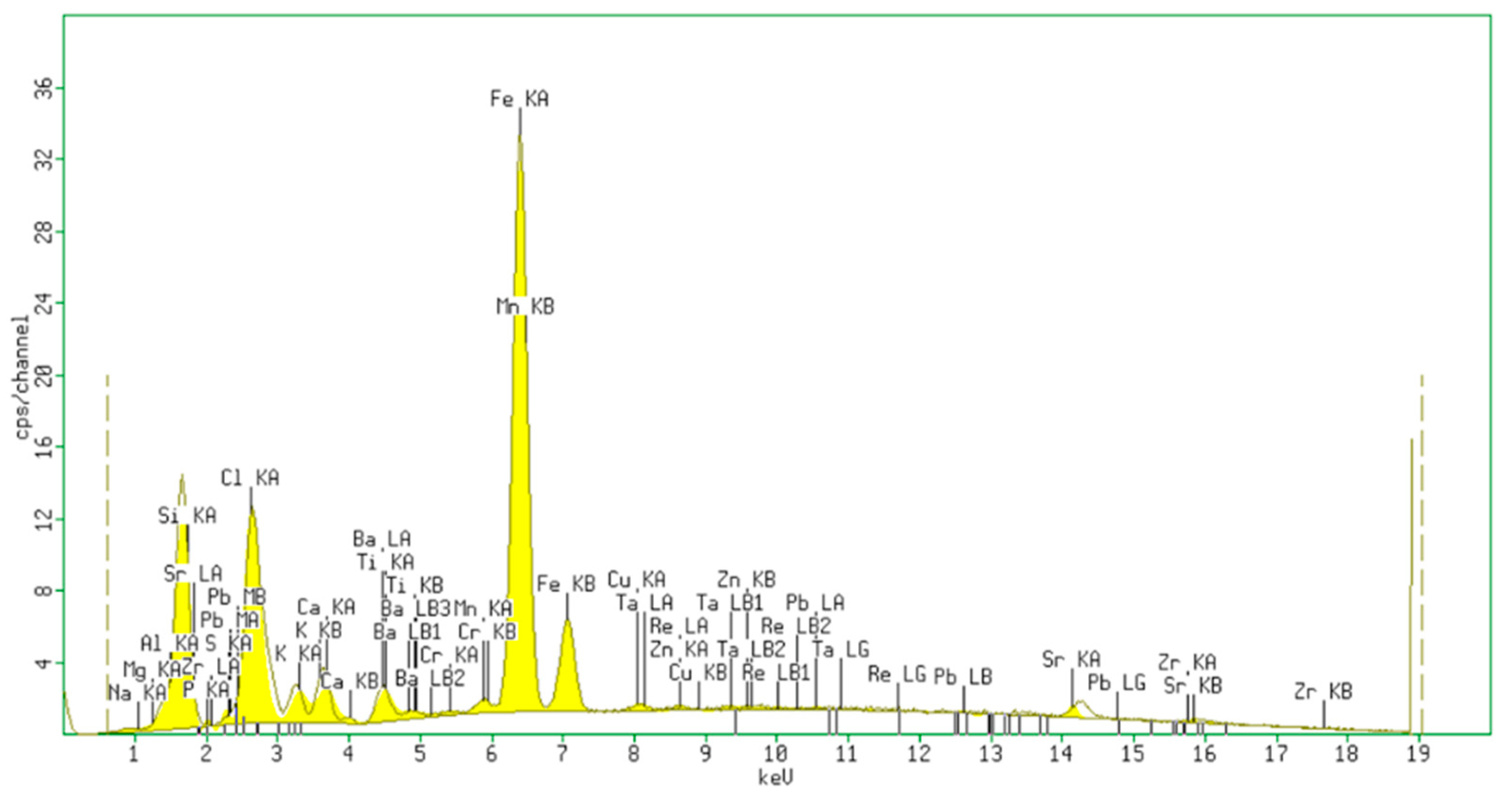

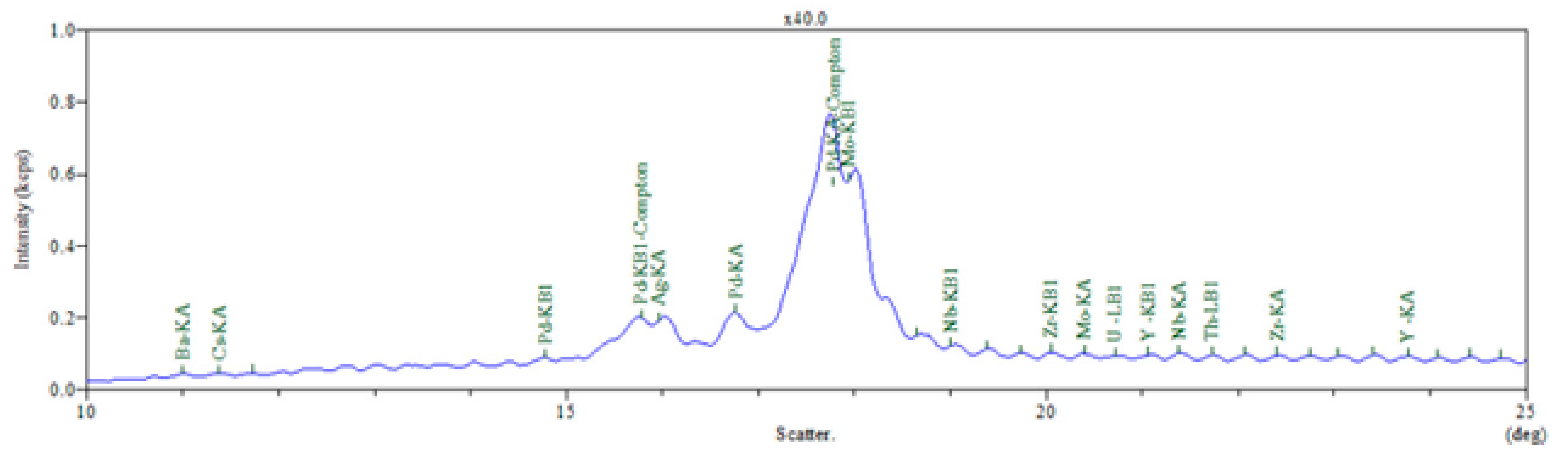

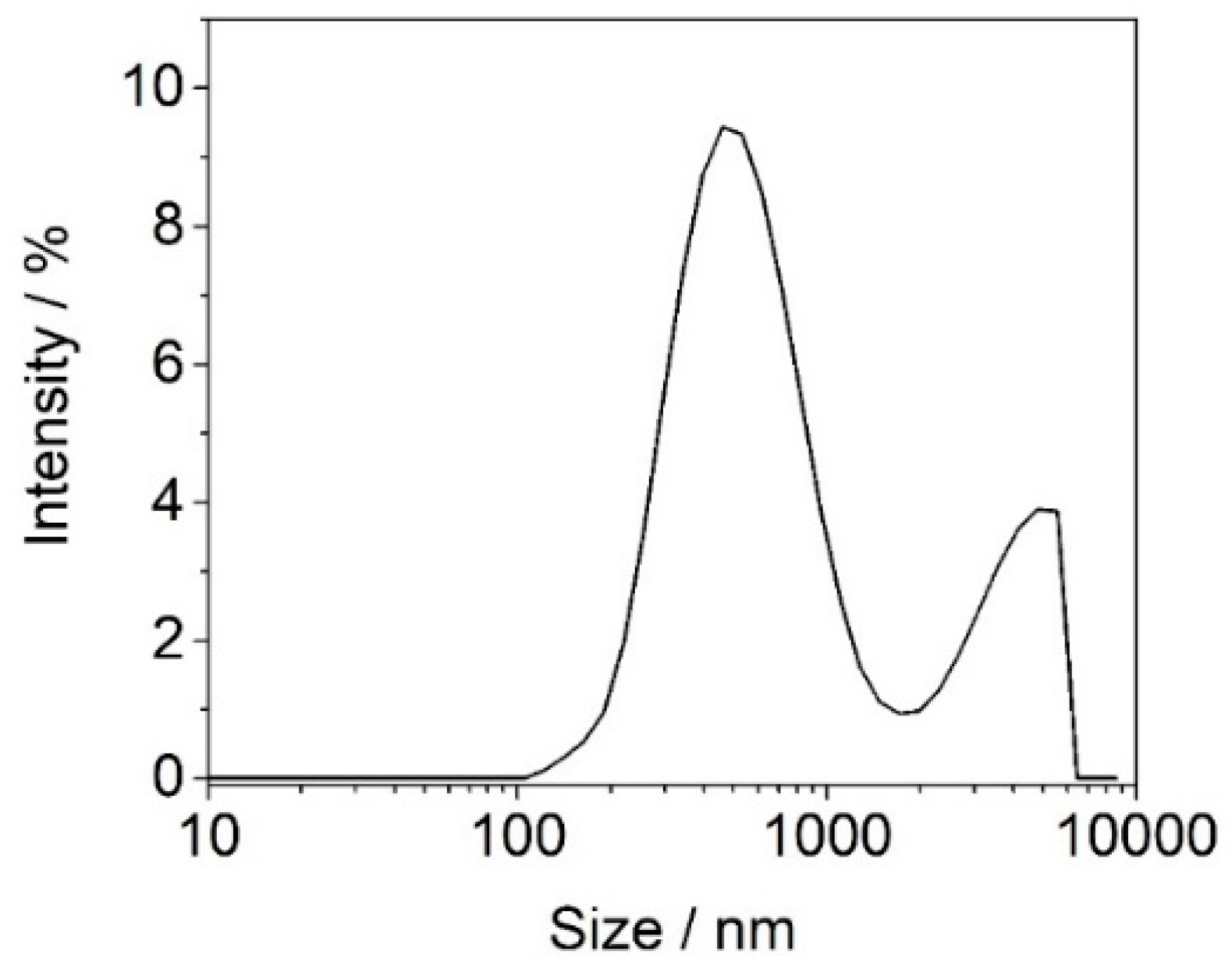

2.4.1. X-ray Fluorescence and Particle Size Distribution

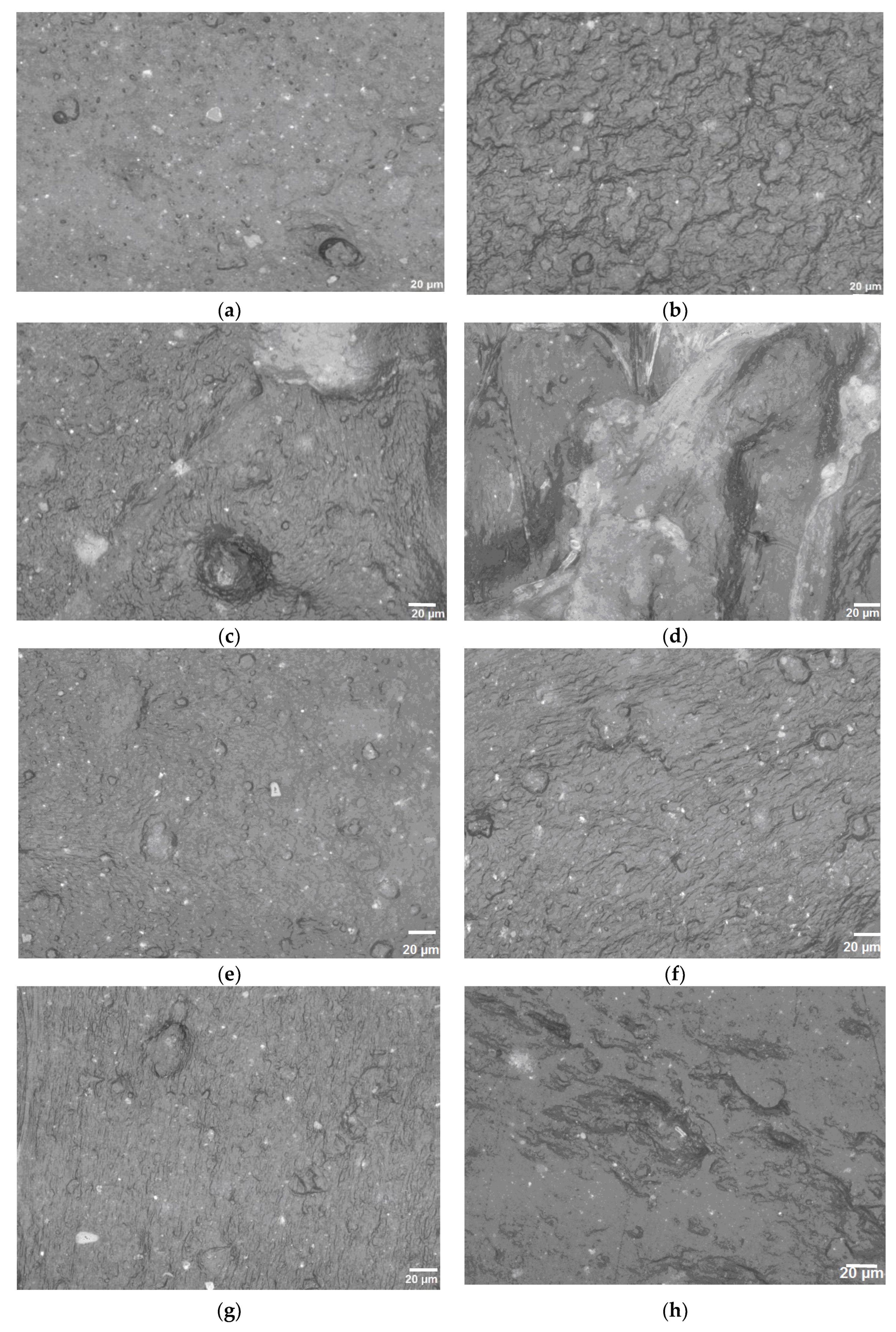

2.4.2. Microscopic Observation

2.4.3. ATR-FT-IR Analysis

2.4.4. Differential Scanning Calorimetry (DSC)

2.4.5. X-ray Diffraction (XRD)

2.4.6. TGA

2.4.7. Mechanical Properties

2.4.8. Dynamic Mechanical Analysis (DMA)

3. Results

3.1. Characterization of n-Clay and PPW

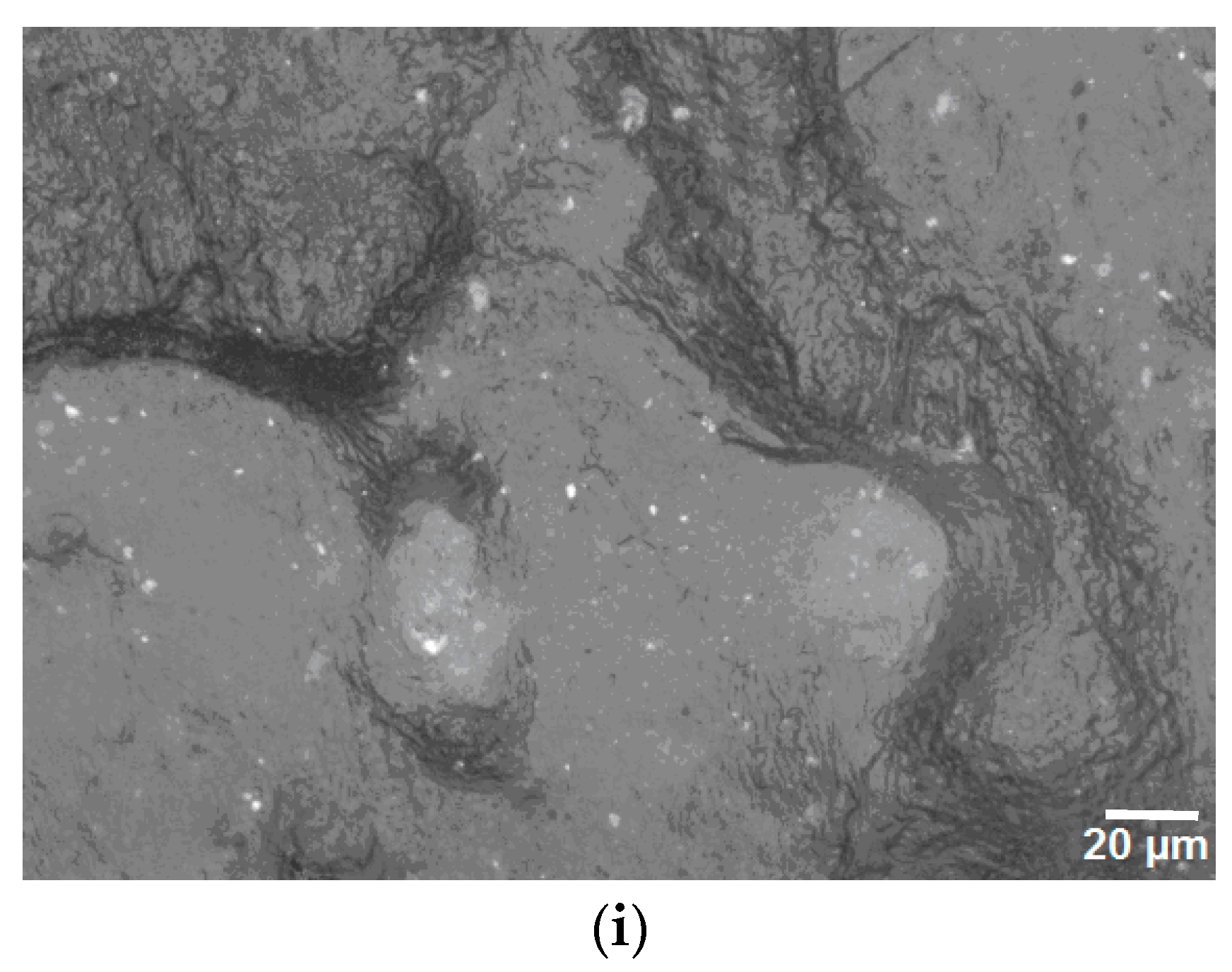

3.2. Optical Microscopy

3.3. ATR-FT-IR Analysis

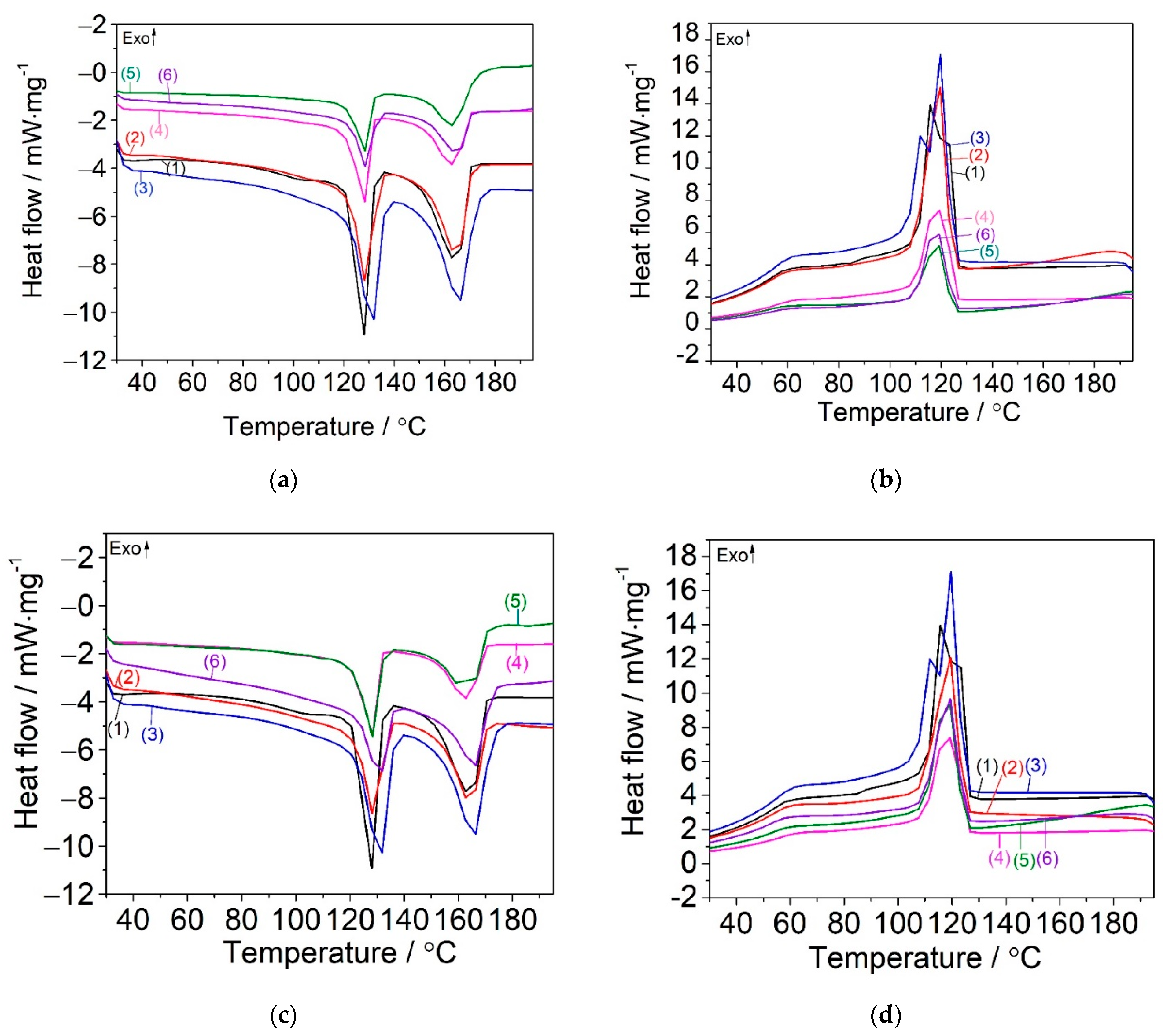

3.4. Differential Scanning Calorimetry (DSC)

3.5. X-ray Diffraction

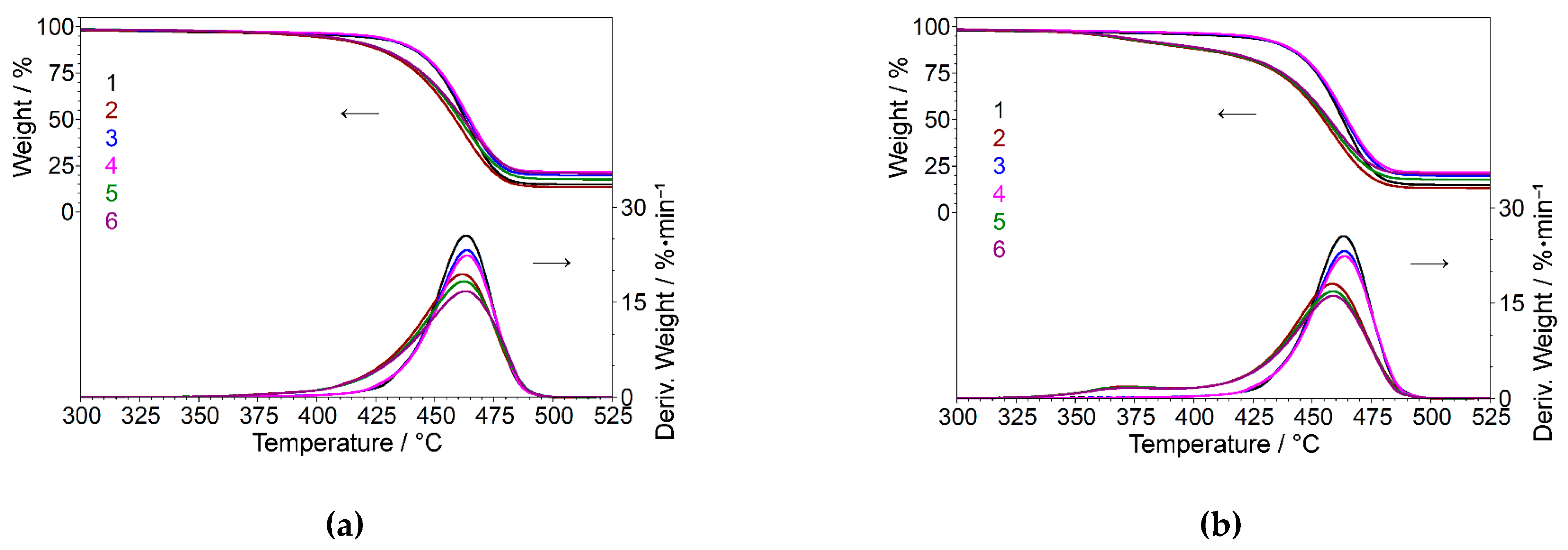

3.6. Thermogravimetric Analysis (TGA)

3.7. Mechanical Properties

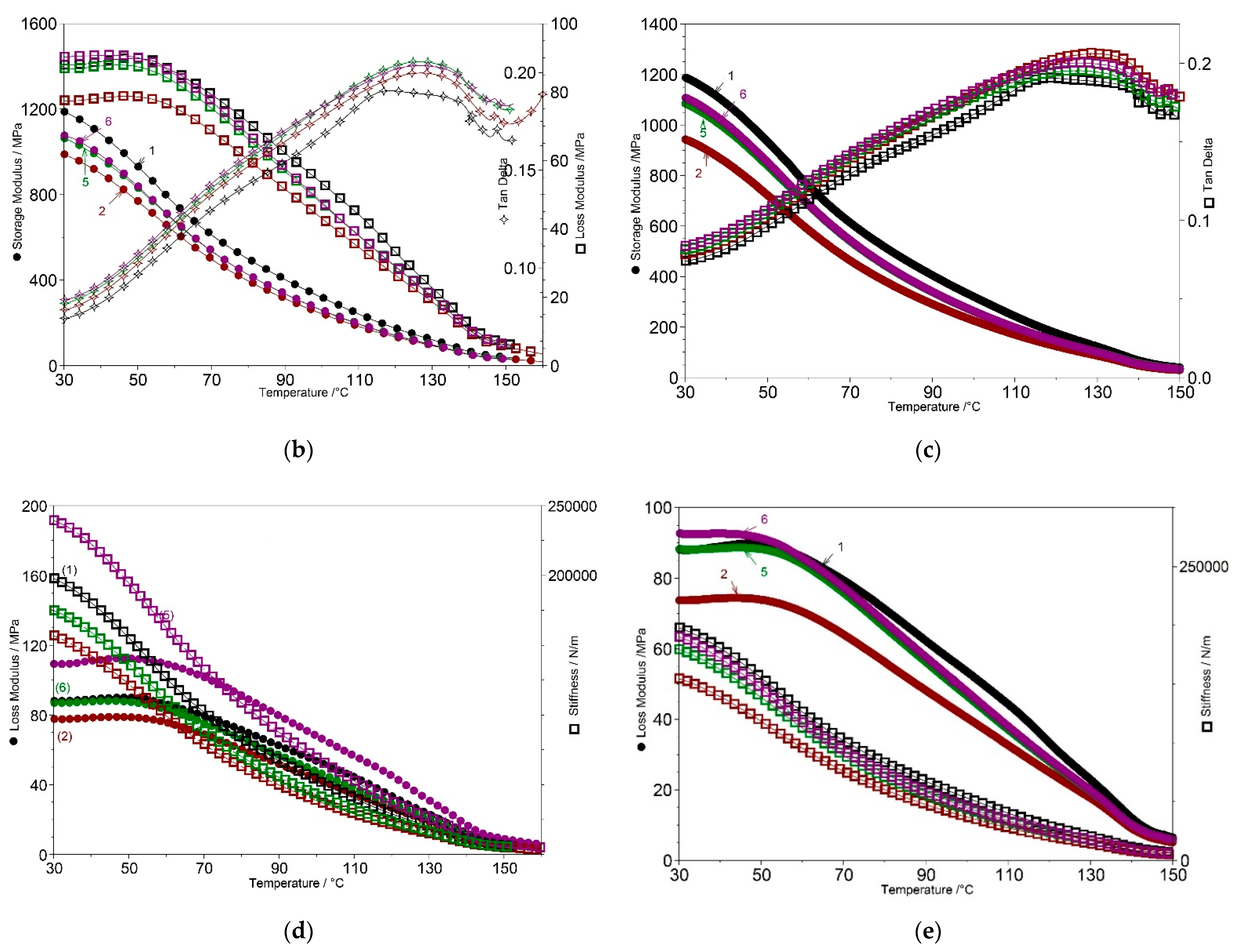

3.8. Dynamic Mechanical Analysis (DMA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Penca, J. European Plastics Strategy: What promise for global marine litter? Mar. Policy 2018, 97, 197–201. [Google Scholar] [CrossRef]

- Buch, R.; Marseille, A.; Williams, M.; Aggarwal, R.; Sharma, A. From Waste Pickers to Producers: An Inclusive Circular Economy Solution through Development of Cooperatives in Waste Management. Sustainability 2021, 13, 8956. [Google Scholar] [CrossRef]

- Lombardi, M.; Rana, R.; Fellner, J. Material flow analysis and sustainability of the Italian plastic packaging management. J. Clean. Prod. 2021, 287, 125573. [Google Scholar] [CrossRef]

- Knappe, H.; Schmidt, O. Future-Proofing Capitalism: The Paradox of the Circular Economy for Plastics. Glob. Environ. Politics 2021, 21, 121–142. [Google Scholar] [CrossRef]

- Kaur, G.; Uisan, K.; Ong, K.L.; Lin, C.S.K. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a circular economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Sustainability design of plastic packaging for the Circular Economy. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef]

- Tramis, O.; Garnier, C.; Yus, C.; Irusta, S.; Chabert, F. Enhancement of the fatigue life of recycled PP by incorporation of recycled opaque PET collected from household milk bottle wastes. Waste Manag. 2021, 125, 49–57. [Google Scholar] [CrossRef]

- Verstraeten, S.B.C.; van Muyden, A.; Bobbink, F.D. Towards a Plastic Circular Economy: Bio-derived Plastics and their End-of-life Strategies. Chimia 2021, 75, 744–751. [Google Scholar] [CrossRef]

- Anwar, M.K.; Shah, S.A.R.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef]

- Srikaanth, G.V.; Yeli, S. Effect of Different Fibers on Mechanical Properties of Polypropylene. J. Polym. Compos. 2017, 5, 50–56. [Google Scholar]

- Echeverrigaray, S.G.; Cruz, R.C.D.; Oliveira, R.V.B. Reactive processing of a non-additivated isotactic polypropylene: Mechanical and morphological properties on molten and solid states. Polym. Bull. 2013, 70, 1237–1250. [Google Scholar] [CrossRef]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef] [PubMed]

- Clancy, C.; Jordan, P.; Ridgway, P.F. Polypropylene mesh and systemic side effects in inguinal hernia repair: Current evidence. Ir. J. Med. Sci. 2019, 188, 1349–1356. [Google Scholar] [CrossRef] [PubMed]

- Macedo, K.R.M.; Cestari, S.P.; Mendes, L.C.; Albitres, G.A.V.; Rodrigues, D.C. Sustainable hybrid composites of recycled polypropylene and construction debris. J. Compos. Mater. 2018, 52, 2949–2959. [Google Scholar] [CrossRef]

- Gao, X.D.; Yang, W.M.; Tan, J.; Song, L.J.; Cheng, L.S.; Tian, X.L. Structural, electrical, and electromagnetic shielding properties of nanocarbon-coated glass fiber-reinforced polypropylene. Polym. Compos. 2022, 43, 2796–2802. [Google Scholar] [CrossRef]

- Sakthipriya, N. Plastic waste management: A road map to achieve circular economy and recent innovations in pyrolysis. Sci. Total Environ. 2022, 809, 151160. [Google Scholar] [CrossRef]

- Kazemi, Y.; Kakroodi, A.R.; Rodrigue, D. Compatibilization Efficiency in Post-Consumer Recycled Polyethylene/Polypropylene Blends: Effect of Contamination. Polym. Eng. Sci. 2015, 55, 2368–2376. [Google Scholar] [CrossRef]

- Michalska-Pozoga, I.; Rydzkowski, T.; Mazur, P.; Sadowska, O.; Thakur, V.K. A study on the thermodynamic changes in the mixture of polypropylene (PP) with varying contents of technological and post-user recyclates for sustainable nanocomposites. Vacuum 2017, 146, 641–648. [Google Scholar] [CrossRef]

- Brachet, P.; Hoydal, L.T.; Hinrichsen, E.L.; Melum, F. Modification of mechanical properties of recycled polypropylene from post-consumer containers. Waste Manag. 2008, 28, 2456–2464. [Google Scholar] [CrossRef]

- Lazim, N.H.; Samat, N. Effects of Irradiated Recycled Polypropylene Compatibilizer on the Mechanical Properties of Microcrystalline Cellulose Reinforced Recycled Polypropylene Composites. Adv. Mater. Processing Technol. Conf. 2017, 184, 538–543. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Kulsetthanchalee, C.; Bunmee, K.; Kliaklom, N.; Roddouyboon, W. Improvement Properties of Recycled Polypropylene by Reinforcement of Coir Fiber. Adv. Mater. Res. 2009, 79–82, 2027–2030. [Google Scholar] [CrossRef]

- Kim, J.; Cho, D. Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites. Polymers 2020, 12, 2578. [Google Scholar] [CrossRef] [PubMed]

- Phuong, N.T.; Chuong, B.; Guinault, A.; Sollogoub, C. Morphology and properties of recycled polypropylene/bamboo fibers composites. In Proceedings of the 14th International Conference on Material Forming ESAFORM, Belfast, UK, 27–29 April 2011; pp. 732–737. [Google Scholar]

- Yuan, Q.H.; Yang, W.; Ma, Z.W.; Huang, Z.R.; Cao, L.; Lin, Z.D.; Zhang, P. Tobacco Stalk Flour/Magnesium Oxysulfate Whiskers Reinforced Hybrid Composites of Recycled Polypropylene: Mechanical and Thermal and Antibacterial Properties. Polymers 2022, 14, 815. [Google Scholar] [CrossRef] [PubMed]

- Delva, L.; Ragaert, K.; Degrieck, J.; Cardon, L. The Effect of Multiple Extrusions on the Properties of Montmorillonite Filled Polypropylene. Polymers 2014, 6, 2912–2927. [Google Scholar] [CrossRef]

- Belviso, C.; Montano, P.; Lettino, A.; Toschi, F.; Lambertini, V.G.; Veca, A.D.; Moschetto, E.; Cavalcante, F.; Guarnaccio, A. Determining the role of the method used to recycle polypropylene waste materials from automotive industry using sepiolite and zeolite fillers. J. Mater. Cycles Waste Manag. 2021, 23, 965–975. [Google Scholar] [CrossRef]

- Li, Y.C.; Jia, S.; Du, S.L.; Wang, Y.F.; Lv, L.D.; Zhang, J.B. Improved properties of recycled polypropylene by introducing the long chain branched structure through reactive extrusion. Waste Manag. 2018, 76, 172–179. [Google Scholar] [CrossRef]

- Cincu, C.; Ecaterina, M.; Gardu, R.; Ghioca, P.N.; Grigorescu, R.M.; Iancu, L.; Pica, A.; Predescu, A.; Predescu, C.; Rapa, M.; et al. Process for Preparing Shock-Proof Composites of Recovered Polypropylene with Improved Impact Strength. RO132386-A2; RO132386-A8; RO132386-B1, 1 August 2016. [Google Scholar]

- Ghioca, P.; Iancu, L.; Spurcaciu, B.; Coserea, R.M.; Cincu, C.; Gardu, R. Modification of Waste Polypropylene by Styrene-isoprene Block-copolymers. Mater. Plast. 2013, 50, 32–35. [Google Scholar]

- Ghioca, P.; Iancu, L.; Grigorescu, R.M.; Spurcaciu, B.; Rapa, M.; Cincu, C.; Pica, A.; Matei, E. Recovered Polypropylene Composites with High Impact Strength. Mater. Plast. 2017, 54, 18–21. [Google Scholar] [CrossRef]

- Rapa, M.; Spurcaciu, B.N.; Coman, G.; Nicolae, C.A.; Gabor, R.A.; Ghioca, P.N.; Berbecaru, A.C.; Matei, E.; Predescu, C. Effect of Styrene-Diene Block Copolymers and Glass Bubbles on the Post-Consumer Recycled Polypropylene Properties. Materials 2020, 13, 543. [Google Scholar] [CrossRef]

- Rapa, M.; Matei, E.; Ghioca, P.N.; Grosu, E.; Iancu, L.; Spurcaciu, B.; Trifoi, A.R.; Gherman, T.; Pica, A.; Predescu, A.M.; et al. Improvement of Some Post-Consumer Polypropylene (rPP) by Melt Modification with Styrene-Diene Block Copolymers. Environ. Eng. Manag. J. 2017, 16, 2615–2624. [Google Scholar]

- Ghioca, P.; Spurcaciu, B.; Iancu, L.; Grigorescu, R.M.; Rapa, M.; Grosu, E.; Matei, E.; Berbecaru, C.; Pica, A.; Gardu, R.; et al. Composite of Waste Polypropylene by Styrene-Isoprene Block-copolymers Blending. Mater. Plast. 2015, 52, 281–285. [Google Scholar]

- Premphet, K.; Horanont, P. Phase structure and property relationships in ternary polypropylene/elastomer/filler composites: Effect of elastomer polarity. J. Appl. Polym. Sci. 2000, 76, 1929–1939. [Google Scholar] [CrossRef]

- Grigorescu, R.M.; Ghioca, P.; Iancu, L.; David, M.E.; Andrei, E.R.; Filipescu, M.I.; Ion, R.M.; Vuluga, Z.; Anghel, I.; Sofran, I.E.; et al. Development of thermoplastic composites based on recycled polypropylene and waste printed circuit boards. Waste Manag. 2020, 118, 391–401. [Google Scholar] [CrossRef] [PubMed]

- Phanthong, P.; Miyoshi, Y.; Yao, S. Development of Tensile Properties and Crystalline Conformation of Recycled Polypropylene by Re-Extrusion Using a Twin-Screw Extruder with an Additional Molten Resin Reservoir Unit. Appl. Sci. 2021, 11, 1707. [Google Scholar] [CrossRef]

- Elamri, A.; Hamdaoui, M.; Harzallah, O. Preparation and Characterization of Recycled PP/Organo-Clay Filter for Dyeing Ability. Fibers Polym. 2021, 22, 1145–1152. [Google Scholar] [CrossRef]

- Velasquez, E.; Espinoza, S.; Valenzuela, X.; Garrido, L.; Galotto, M.J.; Guarda, A.; de Dicastillo, C.L. Effect of Organic Modifier Types on the Physical-Mechanical Properties and Overall Migration of Post-Consumer Polypropylene/Clay Nanocomposites for Food Packaging. Polymers 2021, 13, 1502. [Google Scholar] [CrossRef]

- Hassanabadi, H.M.; Rodrigue, D. Effect of Particle Size and Shape on the Reinforcing Efficiency of Nanoparticles in Polymer Nanocomposites. Macromol. Mater. Eng. 2014, 299, 1220–1231. [Google Scholar] [CrossRef]

- Haq, S.; Srivastava, R. Wood Polypropylene (PP) Composites Manufactured by Mango Wood Waste with Virgin or Recycled PP: Mechanical, Morphology, Melt Flow Index and Crystalline Behaviour. J. Polym. Environ. 2017, 25, 640–648. [Google Scholar] [CrossRef]

- Phuong, N.T.; Gilbert, V.; Chuong, B. Preparation of Recycled Polypropylene/Organophilic Modified Layered Silicates Nanocomposites Part I: The Recycling Process of Polypropylene and the Mechanical Properties of Recycled Polypropylene/Organoclay Nanocomposites. J. Reinf. Plast. Compos. 2008, 27, 1983–2000. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.; Han, T.; Yuan, Y.Q.; Huang, S.H.; Liu, Y. Temperature and trap distribution dependence of electrical tree growth characteristics in polypropylene/elastomer blends for recyclable cable insulation. Iet Sci. Meas. Technol. 2019, 13, 755–765. [Google Scholar] [CrossRef]

- Song, Z.; Gao, Y.; Li, J.; Peng, J.J.; Du, B.X.; IEEE. Variation in Charge Transport Behavior of Polypropylene/Elastomer Blends Exposed to Thermal Cycling. In Proceedings of the 2020 3rd IEEE International Conference on Dielectrics (Icd 2020), Valencia, Spain, 5–31 July 2020; pp. 475–478. [Google Scholar] [CrossRef]

- Darie, R.N.; Brebu, M.; Vasile, C.; Kozlowski, M. On the compatibility of the IPP/PA6/EPDM blends with and without functionalized IPPI. Thermo-oxidative behaviour. Polym. Degrad. Stab. 2003, 80, 551–566. [Google Scholar] [CrossRef]

- Chen, W.C.; Lai, S.M.; Chen, C.M. Preparation and properties of styrene-ethylene-butylene-styrene block copolymer/clay nanocomposites: I. Effect of clay content and compatibilizer types. Polym. Int. 2008, 57, 515–522. [Google Scholar] [CrossRef]

- Onuegbu, G.C.; Onyedika, G.O.; Ogwuegbu, M.O.C. Mechanical and Thermal Behaviour of Clay Filled Recycled Low Density Polyethylene. In Green Materials Engineering; Springer: Cham, Switzerland, 2019; pp. 13–21. [Google Scholar] [CrossRef]

- Ghioca, P.; Buzdugan, E.; Cerchez, I.; Stancu, R.; Stanga, F.; Ionescu, P.; Corciovei, M.; Serban, S.; Anastasiu, V.; Vintan, L.; et al. Polymerisation of linear styrene!-butadiene! tri:block copolymers-using chain modifier comprising ether having active centre to reduce energy consumption during polymerisation. RO109850-B1, 24 August 1994. [Google Scholar]

- Ramos, F.; Mendes, L.C. Recycled high-density polyethylene/gypsum composites: Evaluation of the microscopic, thermal, flammability, and mechanical properties. Green Chem. Lett. Rev. 2014, 7, 199–208. [Google Scholar] [CrossRef]

- Patel, A.K.; Bajpai, R.; Keller, J.M. On the crystallinity of PVA/palm leaf biocomposite using DSC and XRD techniques. Microsyst. Technol.-Micro-Nanosyst.-Inf. Storage Process. Syst. 2014, 20, 41–49. [Google Scholar] [CrossRef]

- Milev, A.; Wilson, M.; Kannangara, G.S.K.; Tran, N. X-ray diffraction line profile analysis of nanocrystalline graphite. Mater. Chem. Phys. 2008, 111, 346–350. [Google Scholar] [CrossRef]

- Chaqmaqchee, F.A.I.; Baker, A.G.; Salih, N.F. Comparison of Various Plastics Wastes Using X-ray Fluorescence. Am. J. Mater. Synth. Process. 2017, 2, 24–27. [Google Scholar] [CrossRef]

- da Silva, D.J.; Wiebeck, H. ATR-FTIR Spectroscopy Combined with Chemometric Methods for the Classification of Polyethylene Residues Containing Different Contaminants. J. Polym. Environ. 2022, 30, 3031–3044. [Google Scholar] [CrossRef]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez, C.V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.J.; et al. Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef]

- Suman, T.Y.; Li, W.G.; Alif, S.; Faris, V.R.P.; Amarnath, D.J.; Ma, J.G.; Pei, D.S. Characterization of petroleum-based plastics and their absorbed trace metals from the sediments of the Marina Beach in Chennai, India. Environ. Sci. Eur. 2020, 32, 110. [Google Scholar] [CrossRef]

- Shang-Guan, Y.; Chen, F.; Zheng, Q. Microstructure, morphology, crystallization and rheological behavior of impact polypropylene copolymer. Sci. China-Chem. 2012, 55, 698–712. [Google Scholar] [CrossRef]

- Martins, A.F.; Pereira, R.A.; Mano, E.B. Recycled car bumpers’ impact resistance investigated by wide-angle X-ray diffraction. J. Appl. Polym. Sci. 2000, 75, 999–1004. [Google Scholar] [CrossRef]

- Mano, E.B.; Martins, A.F.; Mendes, L.C. Thermal analysis applied to discarded car bumpers. J. Therm. Anal. Calorim. 2000, 59, 425–432. [Google Scholar] [CrossRef]

- Kukaleva, N.; Simon, G.P.; Kosior, E. Binary and ternary blends of recycled high-density polyethylene containing polypropylenes. Polym. Eng. Sci. 2003, 43, 431–443. [Google Scholar] [CrossRef]

- Madi, N.K. Thermal and mechanical properties of injection molded recycled high density polyethylene blends with virgin isotactic polypropylene. Mater. Des. 2013, 46, 435–441. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, Q.; ClemonS, C.M.; Yao, F.; Xu, Y. Influence of nanoclay on properties of HDPE/Wood composites. J. Appl. Polym. Sci. 2007, 106, 3958–3966. [Google Scholar] [CrossRef]

- Sui, G.; Fuqua, M.A.; Ulven, C.A.; Zhong, W.H. A plant fiber reinforced polymer composite prepared by a twin-screw extruder. Bioresour. Technol. 2009, 100, 1246–1251. [Google Scholar] [CrossRef] [PubMed]

- Qiu, F.; Wang, M.; Hao, Y.B.; Guo, S.Y. The effect of talc orientation and transcrystallization on mechanical properties and thermal stability of the polypropylene/talc composites. Compos. Part A-Appl. Sci. Manuf. 2014, 58, 7–15. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, W.S.; Teng, C.Y.; Meng, S.X. Mechanical properties and space charge behavior of thermally aged polypropylene/elastomer blends. J. Electrost. 2022, 115, 103673. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.; Li, Y.; Yuan, Y.Q.; Huang, S.H.; Du, B.X. Effect of Elastomer Type on Electrical and Mechanical Properties of Polypropylene/Elastomer Blends. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017; pp. 574–577. [Google Scholar]

- Jose, J.; Nag, A.; Nando, G.B. Processing and Characterization of Recycled Polypropylene and Acrylonitrile Butadiene Rubber Blends. J. Polym. Environ. 2010, 18, 155–166. [Google Scholar] [CrossRef]

- Barreto Luna, C.B.; Barbosa Ferreira, E.D.S.; Medeiros Dantas da Silva, L.J.; da Silva, W.A.; Araujo, E.M.; Costa Agra de Melo, J.B. Blends with technological potential of copolymer polypropylene with polypropylene from post-consumer industrial containers. Mater. Res. Express 2019, 6, 125319. [Google Scholar] [CrossRef]

- Bikiaris, D. Microstructure and Properties of Polypropylene/Carbon Nanotube Nanocomposites. Materials 2010, 3, 2884–2946. [Google Scholar] [CrossRef]

- Majka, T.M.; Bartyzel, O.; Raftopoulos, K.N.; Pagacz, J.; Pielichowski, K. Examining the Influence of Re-Used Nanofiller-Pyrolyzed Montmorillonite, on the Thermal Properties of Polypropylene-Based Engineering Nanocomposites. Materials 2019, 12, 2636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Robin, R.S.; Purvaja, R.; Ganguly, D.; Hariharan, G.; Paneerselvam, A.; Sundari, R.T.; Karthik, R.; Neethu, C.S.; Saravanakumar, C.; Semanti, P.; et al. COVID-19 restrictions and their influences on ambient air, surface water and plastic waste in a coastal megacity, Chennai, India. Mar. Pollut. Bull. 2021, 171, 112739. [Google Scholar] [CrossRef] [PubMed]

| Characteristic | SBSBC | SISBC |

|---|---|---|

| PS content (wt%) | 30.2 | 30.5 |

| PS block molecular weight (g/mol) | 12,650 | 18,700 |

| PB block molecular weight (g/mol) | 118,500 | |

| PI block molecular weight (g/mol) | 85,000 | |

| Molecular mass (g/mol) | 180,500 | 122,500 |

| Tensile strength (MPa) | 19.80 | 7.60 |

| Elongation at break (%) | 840 | 1440 |

| Hardness (°Sh A) | 42.5 | 38.5 |

| Melt flow index at 190 °C, 5 kg (g/10 min) | 7.4 | 8.6 |

| Tg for PB phase (°C) | −76 | |

| Tg for PI phase (°C) | −60 | |

| Tg of PS phase (°C) | 86 | 90 |

| Element | % | Oxide | % |

|---|---|---|---|

| Silicon (Si) | 44.40 | SiO2 | 51.10 |

| Phosphorus (P) | 19.60 | P2O5 | 19.00 |

| Chloride (Cl) | 8.43 | SO3 | 7.93 |

| Sulphur (S) | 8.19 | Na2O | 7.00 |

| Natrium (Na) | 7.00 | Al2O3 | 6.30 |

| Aluminum (Al) | 5.50 | MgO | 4.10 |

| Magnesium (Mg) | 3.70 | Fe2O3 | 0.90 |

| Iron (Fe) | 1.85 |

| Element | % | Oxide | % |

|---|---|---|---|

| Titanium (Ti) | 2.86 | TiO2 | 0.17 |

| Calcium (Ca) | 2.64 | SiO2 | 0.12 |

| Silicon (Si) | 1.02 | Al2O3 | 0.11 |

| Aluminum (Al) | 0.84 | CaO | 0.05 |

| Bromine (Br) | 0.63 | MgO | 0.04 |

| Chloride (Cl) | 0.43 | P2O5 | 0.01 |

| Magnesium (Mg) | 0.40 | SO3 | 0.01 |

| Potassium (K) | 0.25 | ||

| Iodine (I) | 0.24 | ||

| Sulphur (S) | 0.22 | ||

| Iron (Fe) | 0.20 | ||

| Phosphorus (P) | 0.05 | ||

| Iron (Fe) | 1.85 |

| Sample | ΔHm1 (J g−1) | Tm1 (°C) | ΔHm2 (J g−1) | Tm2 (°C) | Tc1 (°C) | Tc2 (°C) | 1 (%) | 2 (%) |

|---|---|---|---|---|---|---|---|---|

| PPW | −29.5 | 127.9 | −33.3 | 164.6 | 115.6 | 121.7 | 10.1 | 24.1 |

| PPW/SBSBC | −25.5 | 129.3 | −28.3 | 164.0 | 114.8 | 120.4 | 8.4 | 19.5 |

| PPW/n-Clay 5% | −24.4 | 130.8 | −30.7 | 165.7 | 113.5 | 120.1 | 8.3 | 22.0 |

| PPW/n-Clay 10% | −25.7 | 129.7 | −28.2 | 165.3 | 114.7 | 120.8 | 8.9 | 20.4 |

| PPW/SBSBC/n-Clay 5% | −23.7 | 128.2 | −39.9 | 165.0 | 114.3 | 120.0 | 7.8 | 27.5 |

| PPW/SBSBC/n-Clay 10% | −22.7 | 129.5 | −25.7 | 165.2 | 115.0 | 120.4 | 7.1 | 17.0 |

| PPW/SISBC | −25.6 | 129.6 | −28.5 | 164.4 | 114.3 | 120.6 | 8.8 | 20.6 |

| PPW/SISBC/n-Clay 5% | −24.0 | 128.1 | −26.4 | 165.0 | 114.8 | 120.4 | 7.9 | 18.2 |

| PPW/SISBC/n-Clay 10% | −19.8 | 130.7 | −31.6 | 165.5 | 114.6 | 120.4 | 6.2 | 20.8 |

| Sample | Average Crystallite Size (nm) |

|---|---|

| PWP | 42.24 |

| PPW/SBSBC | 32.58 |

| PPW/SBSBC/n-Clay 5% | 26.98 |

| PPW/SBSBC/n-Clay 10% | 32.38 |

| PPW/SISBC | 25.41 |

| PPW/SISBC/n-Clay 5% | 16.12 |

| PPW/SISBC/n-Clay 10% | 25.14 |

| Weight Loss (%) | Weight Loss (%) | Tmax1 (°C) | Tmax2 (°C) | Weight Loss (%) | Tmax3 (°C) | Residue (%) | Temp. (°C) | Weight Loss (%) | |

|---|---|---|---|---|---|---|---|---|---|

| 25–310 °C | 310–560 °C | 560–700 °C | 700 °C (N2) | Onset degradation | |||||

| n-Clay | 1.90 | 6.48 | 488.6 | - | 1.21 | - | 90.26 | 431.0 | 97.91 |

| PPW | 1.96 | 83.42 | 463.2 | - | 5.01 | 631.5 | 9.58 | 446.5 | 96.04 |

| SBSBC | 0.25 | 99.24 | 452.4 | - | 0.22 | - | 0.21 | 415.5 | 99.63 |

| PPW/SBSBC | 1.58 | 85.15 | 461.9 | - | 4.50 | 641.9 | 8.73 | 435.0 | 96.73 |

| PPW/n-Clay 5% | 1.37 | 79.07 | 463.5 | - | 4.63 | 645.8 | 14.93 | 444.4 | 96.87 |

| PPW/n-Clay 10% | 1.26 | 77.49 | 463.6 | - | 4.59 | 649.2 | 16.66 | 444.3 | 97.04 |

| PPW/SBSBC/n-Clay 5% | 1.21 | 81.42 | 462.4 | - | 4.33 | 652.3 | 13.04 | 435.2 | 97.14 |

| PPW/SBSBC/n-Clay 10% | 1.25 | 78.11 | 463.0 | - | 4.19 | 647.5 | 16.44 | 434.2 | 97.20 |

| SISBC | 0.92 | 98.61 | 375.2 | 423.7 | 0.03 | - | 0.45 | 351.0 | 96.85 |

| PWP/SISBC | 1.45 | 85.43 | 370.7 | 458.3 | 4.46 | 641.4 | 8.65 | 429.4 | 95.95 |

| PPW/SISBC/n-Clay 5% | 1.28 | 81.15 | 376.7 | 458.7 | 4.27 | 649.7 | 13.31 | 428.9 | 96.26 |

| PPW/SISBC/n-Clay 10% | 1.26 | 78.30 | 375.5 | 458.9 | 4.09 | 651.1 | 16.35 | 428.8 | 96.42 |

| Sample | Tensile Strength at Break (MPa) | Elongation at Break (%) | Hardness (Sh D) | VST A50 (°C) | HDT (°C) | Izod Impact (kJ m−2) |

|---|---|---|---|---|---|---|

| PPW | 24.12 ± 2.4 | 28.30 ± 3.1 | 63.5 ± 1 | 138 ± 2 | 168 ± 3 | 1.35 ± 0.5 |

| PPW/SBSBC | 19.62 ± 1.2 | 64.32 ± 4.5 | 61.5 ± 1 | 136 ± 2 | 167 ± 2 | 2.65 ± 0.3 |

| PPW/n-Clay 5% | 22.78 ± 2.0 | 25.00 ± 5.0 | 62.0 ± 1 | 130 ± 2 | 165 ± 2 | 1.15 ± 0.4 |

| PPW/n-Clay 10% | 22.56 ± 3.1 | 15.92 ± 2.4 | 62.5 ± 1 | 132 ± 2 | 166 ± 2 | 1.10 ± 0.2 |

| PPW/SBSBC/n-Clay 5% | 19.45 ± 0.9 | 35.22 ± 4.7 | 61.5 ± 2 | 110 ± 1 | 165 ± 2 | 2.19 ± 0.2 |

| PPW/SBSBC/n-Clay 10% | 18.25 ± 1.2 | 31.30 ± 4.4 | 62.0 ± 2 | 113 ± 2 | 163 ± 5 | 1.78 ± 0.3 |

| PPW/SISBC | 20.12 ± 1.9 | 70.14 ± 3.7 | 60.5 ± 1 | 135 ± 2 | 166 ± 5 | 3.89 ± 0.7 |

| PPW/SISBC/n-Clay 5% | 19.62 ± 0.5 | 64.32 ± 4.7 | 61.5 ± 1 | 136 ± 2 | 167 ± 4 | 3.25 ± 1.0 |

| PPW/SISBC/n-Clay 10% | 22.78 ± 0.7 | 35.40 ± 6.0 | 62.0 ± 2 | 130 ± 1 | 165 ± 6 | 2.15 ± 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Râpă, M.; Spurcaciu, B.N.; Ion, R.-M.; Grigorescu, R.M.; Darie-Niță, R.N.; Iancu, L.; Nicolae, C.-A.; Gabor, A.R.; Matei, E.; Predescu, C. Valorization of Polypropylene Waste in the Production of New Materials with Adequate Mechanical and Thermal Properties for Environmental Protection. Materials 2022, 15, 5978. https://doi.org/10.3390/ma15175978

Râpă M, Spurcaciu BN, Ion R-M, Grigorescu RM, Darie-Niță RN, Iancu L, Nicolae C-A, Gabor AR, Matei E, Predescu C. Valorization of Polypropylene Waste in the Production of New Materials with Adequate Mechanical and Thermal Properties for Environmental Protection. Materials. 2022; 15(17):5978. https://doi.org/10.3390/ma15175978

Chicago/Turabian StyleRâpă, Maria, Bogdan Norocel Spurcaciu, Rodica-Mariana Ion, Ramona Marina Grigorescu, Raluca Nicoleta Darie-Niță, Lorena Iancu, Cristian-Andi Nicolae, Augusta Raluca Gabor, Ecaterina Matei, and Cristian Predescu. 2022. "Valorization of Polypropylene Waste in the Production of New Materials with Adequate Mechanical and Thermal Properties for Environmental Protection" Materials 15, no. 17: 5978. https://doi.org/10.3390/ma15175978

APA StyleRâpă, M., Spurcaciu, B. N., Ion, R.-M., Grigorescu, R. M., Darie-Niță, R. N., Iancu, L., Nicolae, C.-A., Gabor, A. R., Matei, E., & Predescu, C. (2022). Valorization of Polypropylene Waste in the Production of New Materials with Adequate Mechanical and Thermal Properties for Environmental Protection. Materials, 15(17), 5978. https://doi.org/10.3390/ma15175978