Development in Sustainable Concrete with the Replacement of Fume Dust and Slag from the Steel Industry

Abstract

:1. Introduction

2. Experimental Work

2.1. Materials

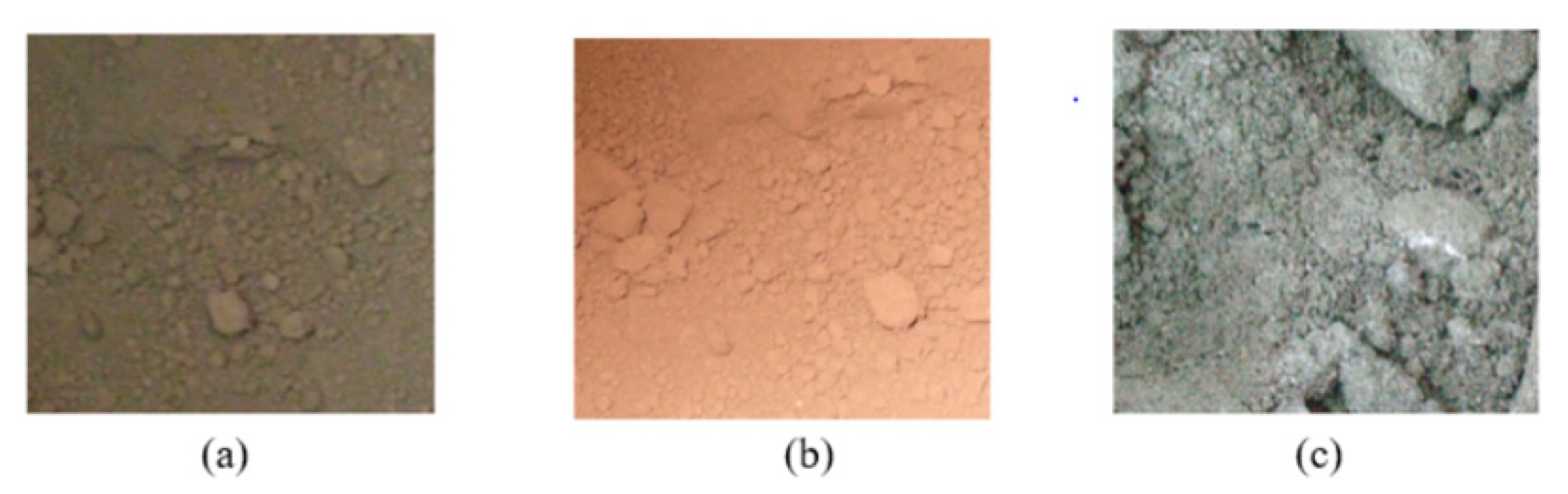

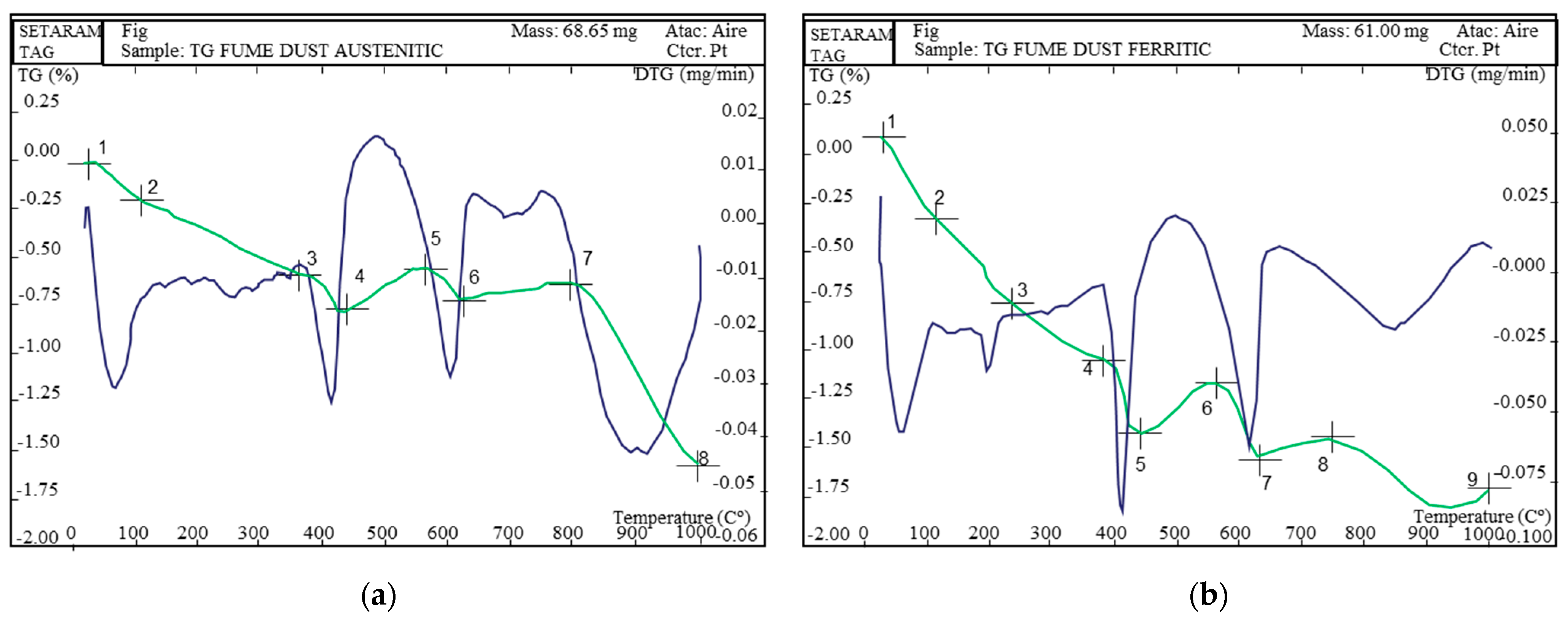

2.2. Morphology

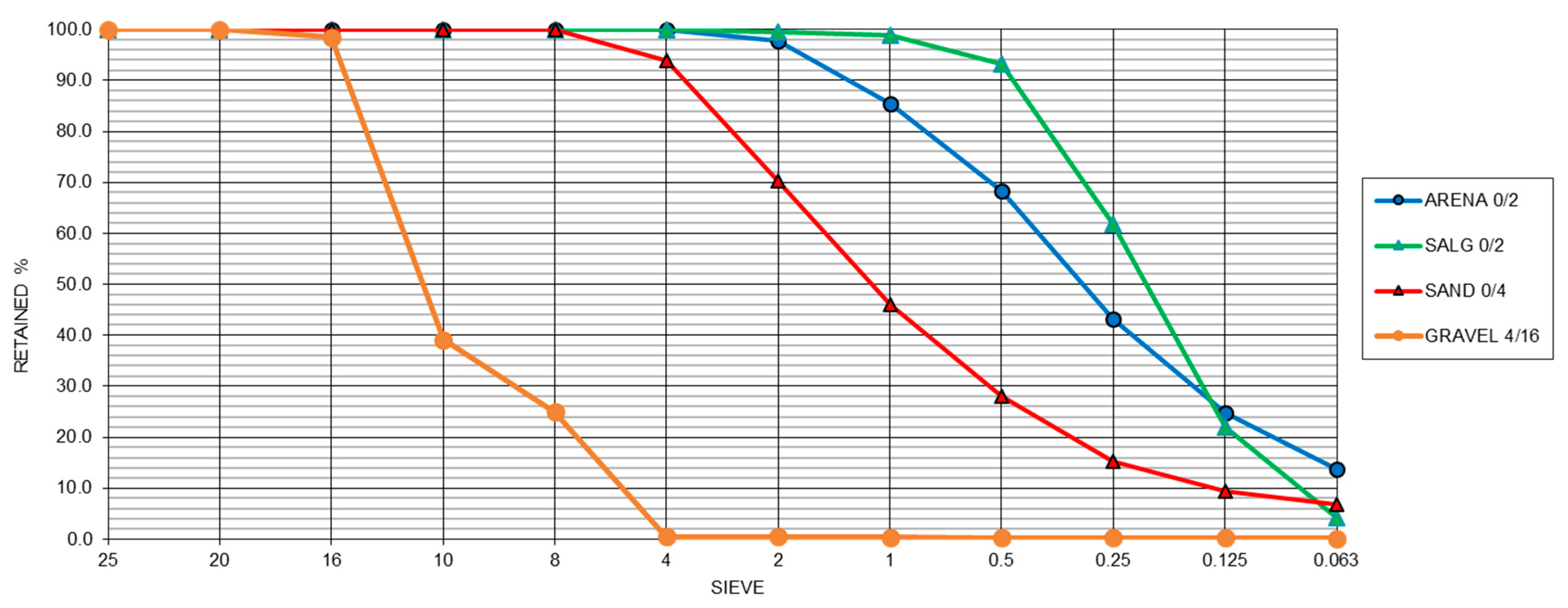

2.3. Description of the Type of Cement, Slag and Sand Used

2.4. Additive

2.5. Description of the Process

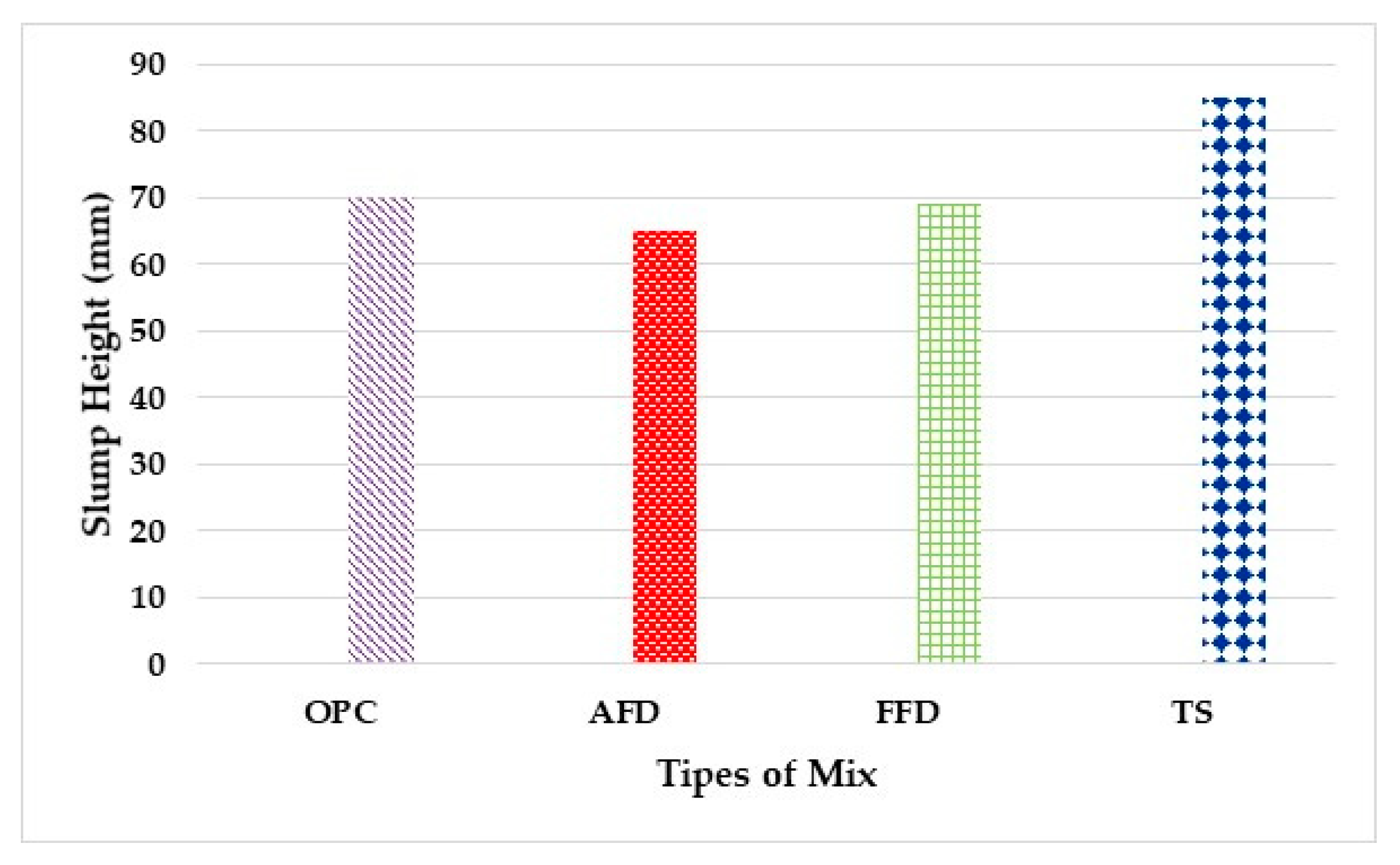

2.6. Workability

2.7. Geometry of Specimens

3. Result and Discussion

3.1. Workability

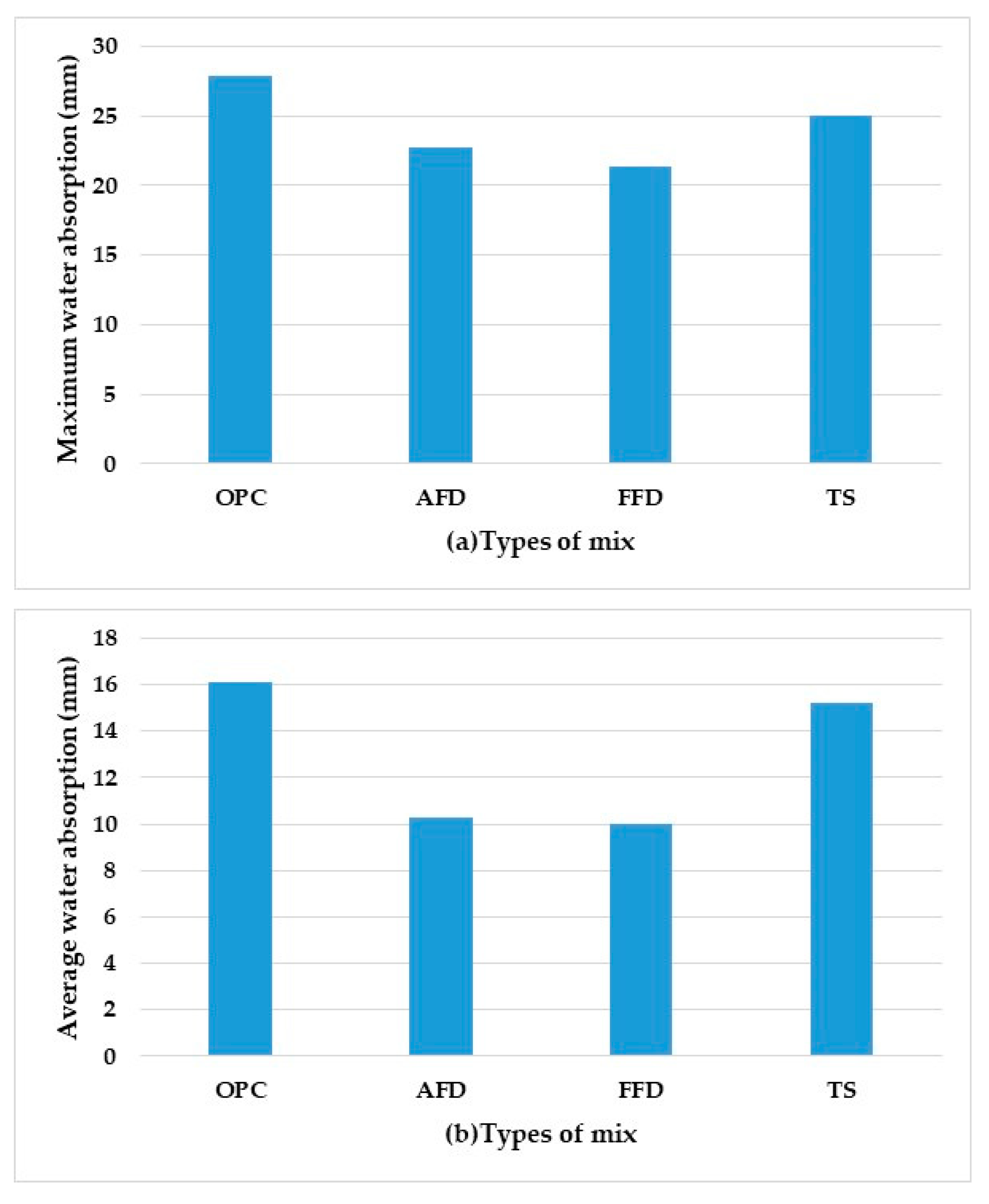

3.2. Water Absorption

3.3. Uniaxial Compression Tests

3.4. Flexural Strength of Specimens

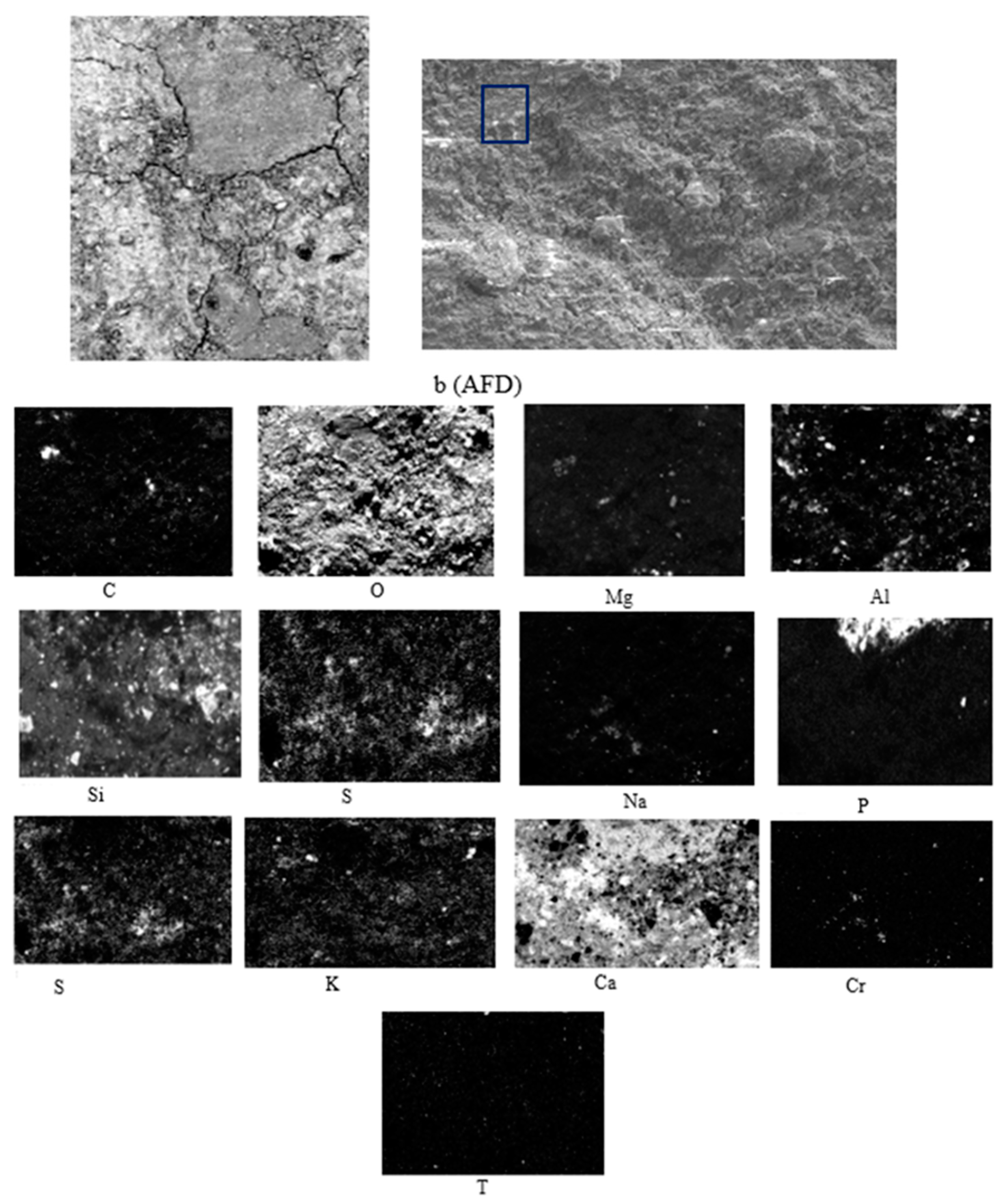

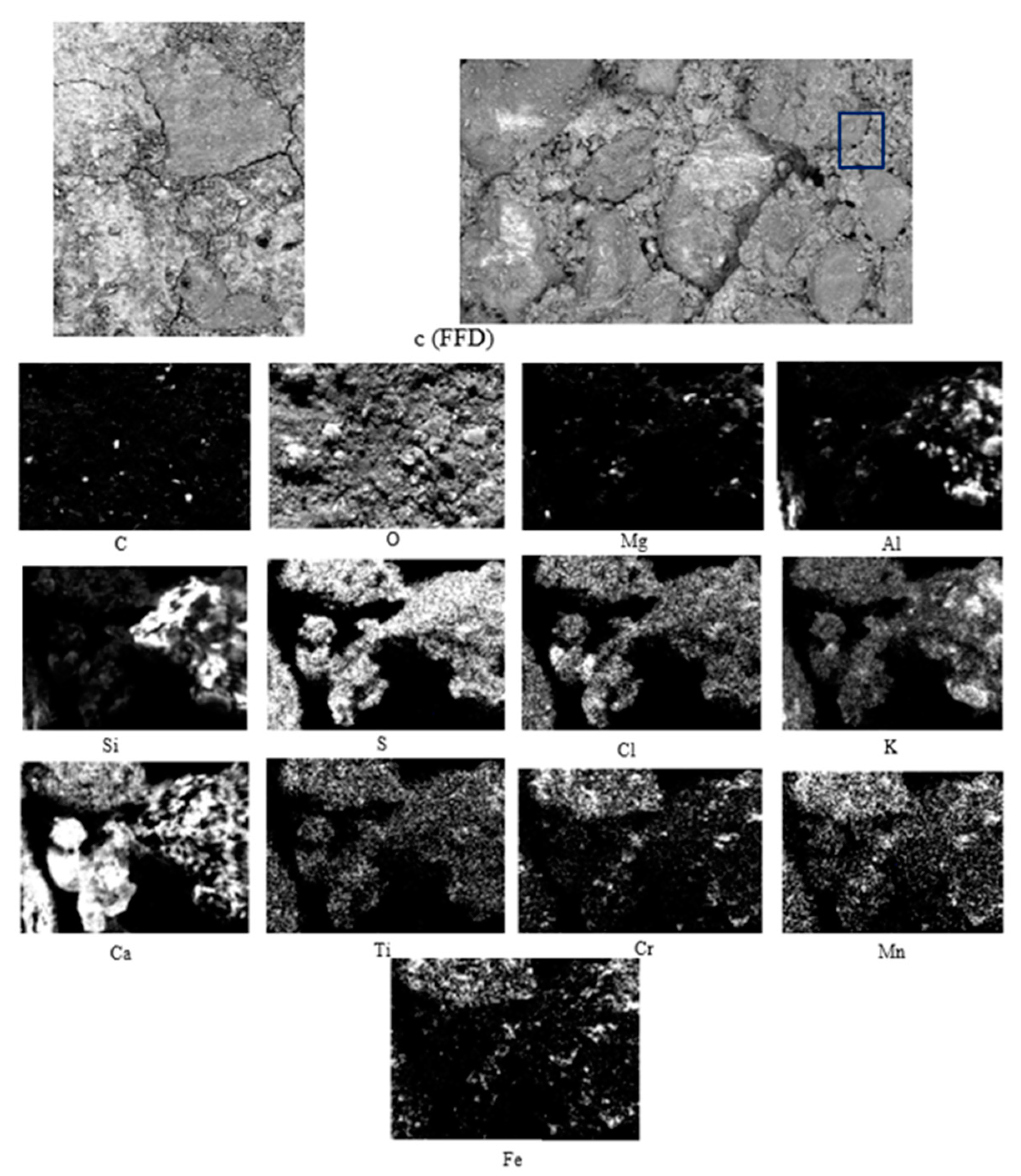

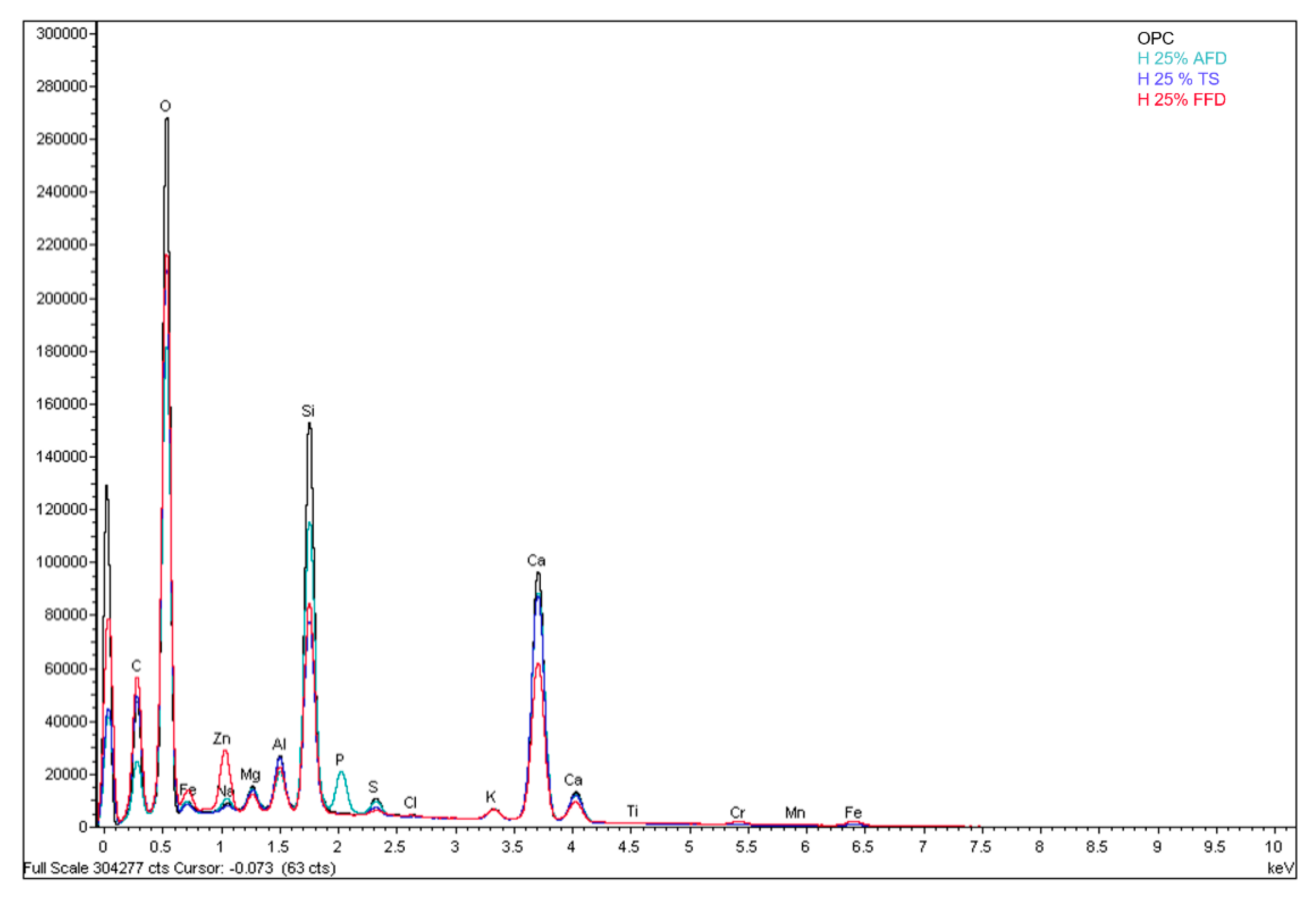

3.5. Scanning Electron Microscopy Study

3.6. Leachate Analysis

4. Conclusions

- The water absorption was lower by 23% and 37.8% in AFD and FFD, respectively, and by 5.6% in TS with respect to OPC, indicating that the pores decreased with the addition of AFD and FFD and remained practically the same in TS.

- The 20.5% increase in the compressive strength of concrete manufactured with AFD added and the 20% increase in FFD at 7 days maintained the same progression with respect to conventional concrete, with 12.3% in AFD and 21.7% in FFD at 28 days. At 90 days, hardening was 11% in AFD and 11.3% in FFD. Young’s modulus reached a range proportional to the resistance capacity of the addition.

- Regarding the resistance to flexotraction, the increase was practically equal to 64% in all tests, including the slag. A greater short-term hardening of the concrete made with both fume dust and slag was found, with around a 25% improvement in resistant behaviour. The data verify the success of the proposed experimental model.

- Steel residue at a substitution of 25% by weight of cement can solidify and stabilise safely, and it does not represent a threat to the environment, as the values of Cu, Pb, and Fe are below the allowed limits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, W.; Wang, Y.; Sun, J.; Tang, Y.; Wu, D.; Jiang, Z.; Wang, J.; Wang, X. Prediction of thermo-mechanical properties of rubber-modified recycled aggregate concrete, Constr. Build. Mater. 2022, 318, 125970. [Google Scholar] [CrossRef]

- Feng, W.; Tang, Y.; Zhang, Y.; Qi, C.; Ma, L.; Li, L. Partially fly ash and nano-silica incorporated recycled coarse aggregate based concrete: Constitutive model and enhancement mechanism. J. Mater. Res. Technol. 2022, 17, 192–210. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadistica (Spanish Statistical Office), (n.d.). Available online: https://www.ine.es/ (accessed on 29 November 2018).

- Palankar, N.; Shankar, A.U.R.; Mithun, B.M. Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J. Clean. Prod. 2016, 129, 437–448. [Google Scholar] [CrossRef]

- Fares, G.; Al-Zaid, R.Z.; Fauzi, A.; Alhozaimy, A.M.; Al-Negheimish, A.I.; Khan, M.I. Performance of optimized electric arc furnace dust-based cementitious matrix compared to conventional supplementary cementitious materials. Constr. Build. Mater. 2016, 112, 210–221. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Khalid, N.H.A.; Muhammad, B. Properties of concrete containing electric arc furnace steel slag and steel sludge. J. Build. Eng. 2020, 28, 101060. [Google Scholar] [CrossRef]

- Loaiza, A.; Cifuentes, S.; Colorado, H.A. Asphalt modified with superfine electric arc furnace steel dust (EAF dust) with high zinc oxide content. Constr. Build. Mater. 2017, 145, 538–547. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Awan, F.; Shameem, M.; Ibrahim, M.; Ali, M. Effect of electric arc furnace dust on the properties of OPC and blended cement concretes. Constr. Build. Mater. 2011, 25, 308–312. [Google Scholar] [CrossRef]

- Laforest, G.; Duchesne, J. Stabilization of electric arc furnace dust by the use of cementitious materials: Ionic competition and long-term leachability. Cem. Concr. Res. 2006, 36, 1628–1634. [Google Scholar] [CrossRef]

- Rubio-Cintas, M.; Parron-Rubio, M.; Perez-Garcia, F.; Ribeiro, A.B.; Oliveira, M. Influence of Steel Slag Type on Concrete Shrinkage. Sustainability 2020, 13, 214. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Shi, C.; Pan, S.-Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Özalp, F. Effects of electric arc furnace (EAF) slags on mechanical and permeability properties of paving stone, kerb and concrete pipes. Constr. Build. Mater. 2022, 329, 127159. [Google Scholar] [CrossRef]

- Perez-Garcia, F.; Parron-Rubio, M.E.; Garcia-Manrique, J.M.; Rubio-Cintas, M.D. Study of the Suitability of Different Types of Slag and Its Influence on the Quality of Green Grouts Obtained by Partial Replacement of Cement. Materials 2019, 12, 1166. [Google Scholar] [CrossRef]

- Parron-Rubio, M.E.; Perez-Garcia, F.; Gonzalez-Herrera, A.; Oliveira, M.J.; Rubio-Cintas, M.D. Slag Substitution as a Cementing Material in Concrete: Mechanical, Physical and Environmental Properties. Materials 2019, 12, 2845. [Google Scholar] [CrossRef]

- Parron-Rubio, M.E.; Perez-García, F.; Gonzalez-Herrera, A.; Rubio-Cintas, M.D. Concrete Properties Comparison When Substituting a 25% Cement with Slag from Different Provenances. Materials 2018, 11, 1029. [Google Scholar] [CrossRef] [PubMed]

- Perez-garcia, F.; Parrón-rubio, M.E.; Garcia-manrique, J.M.; Rubio-cintas, M.D. Analysis of cementitious grout mixtures incorporating GGBFS and LFS slags as partial cement replacement. Constr. Build. Mater. 2021, 310, 125174. [Google Scholar]

- De Domenico, D.; Faleschini, F.; Pellegrino, C.; Ricciardi, G. Structural behavior of RC beams containing EAF slag as recycled aggregate: Numerical versus experimental results. Constr. Build. Mater. 2018, 171, 321–337. [Google Scholar] [CrossRef]

- Azevedo, A.; de Matos, P.; Marvila, M.; Sakata, R.; Silvestro, L.; Gleize, P.; Brito, J. Rheology, Hydration, and Microstructure of Portland Cement Pastes Produced with Ground Açaí Fibers. Appl. Sci. 2021, 11, 3036. [Google Scholar] [CrossRef]

- Ahmad, S.; Al-Amoudi, O.S.B.; Khan, S.M.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Wang, H.; Sun, X.; Wang, J.; Monteiro, P.J. Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress. Materials 2016, 9, 252. [Google Scholar] [CrossRef]

- Sun, M.; Bennett, T.; Visintin, P. Plastic and early-age shrinkage of ultra-high performance concrete (UHPC): Experimental study of the effect of water to binder ratios, silica fume dosages under controlled curing conditions. Case Stud. Constr. Mater. 2022, 16, e00948. [Google Scholar] [CrossRef]

- Thermogravimetry and Carbonation of Cements and Concretes-Google Académico, (n.d.). Available online: https://scholar.google.es/scholar?hl=es&as_sdt=0%2C5&q=Thermogravimetry+and+carbonation+of+cements+and+concretes&btnG= (accessed on 11 June 2021).

- AENOR-Normas UNE-EN 933-2; Test to Determine the Geometric Properties of Aggregates. Part 2: Determination of the Granulometry of the Particles. Test Sieves, Nominal Size of the Openings. European Standards: Brussels, Belgium, 2020.

- Rubio-Cintas, M.D.; Fernandez-Ruiz, M.A.; Perez-García, F.; Parron-Rubio, M.E. Effect of the addition of electric arc furnace dust on the mechanical properties and carbonation performance of concrete. Eur. J. Environ. Civ. Eng. 2020, 26, 2767–2779. [Google Scholar] [CrossRef]

- Rubio-Cintas, M.D.; Barnett, S.; Perez-García, F.; Parron-Rubio, M. Mechanical-strength characteristics of concrete made with stainless steel industry wastes as binders. Constr. Build. Mater. 2019, 204, 675–683. [Google Scholar] [CrossRef]

- Rubio-Cintas, M.D.; Parrón-Vera, M.A.; Contreras-Villar, F. Method for Producing Cinder Concrete. Patente Nacional 201300758. ES2537256. Available online: http://www.oepm.es/ (accessed on 19 January 2016).

- UNE-EN 12390-2; Ensayos de Hormigón Endurecido, Parte 2: Fabricación y Curado de Probetas Para Ensayos de Resistencia. Spanish Association for Standardization and Certification: Madrid, Spain, 2001.

- UNE-EN 12390-4; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. European Standards: Brussels, Belgium, 2020.

- Ritchie, A.G.B. The triaxial testing of fresh concrete. Mag. Concr. Res. 1962, 14, 37–42. [Google Scholar] [CrossRef]

- AENOR-Normas UNE EN-12390-1; Hardened Concrete Tests. Part 1: Shape, Dimensions and Other Characteristics of Test Pieces and Molds. European Standards: Brussels, Belgium, 2021.

- Neville, A. Properties of Concrete. 1995. Available online: https://www.academia.edu/download/52236036/properties-of-concrete-by-am-neville.pdf (accessed on 28 January 2022).

- AENOR-Normas UNE On-Line, (n.d.). Available online: https://portal-aenormas-aenor-com.bibezproxy.uca.es/aenor/Suscripciones/Personal/pagina_per_buscador.asp (accessed on 6 May 2021).

- UNE-EN-12390-3; Norma Española Parte 3: Determinación de La Resistencia a Compresión de Probetas. Spanish Association for Standardization and Certification: Madrid, Spain, 2020; Volume 24.

- Kansal, C.M.; Goyal, R. Analysing mechanical properties of concrete with nano silica, silica fume and steel slag. Mater. Today Proc. 2021, 45, 4520–4525. [Google Scholar] [CrossRef]

- Odler, I.; Becker, T. Effect of some liquefying agents on properties and hydration of portland cement and tricalcium silicate pastes. Cem. Concr. Res. 1980, 10, 321–331. [Google Scholar] [CrossRef]

- UNE-EN12390-13; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. European Standards: Brussels, Belgium, 2022.

- UNE-EN 12350-5; Ensayos de Hormigón Fresco, Parte 5: Ensayo de La Masa de Sacudidas. Spanish Association for Standardization and Certification: Madrid, Spain, 2006.

- Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental analysis on partial replacement of cement with brick powder in concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [Google Scholar] [CrossRef]

- Massarweh, O.; Maslehuddin, M.; Al-Dulaijan, S.U.; Shameem, M.; Ahmad, S. Development of a concrete set retarder utilizing electric arc furnace dust. Constr. Build. Mater. 2020, 255, 119378. [Google Scholar] [CrossRef]

- Siddique, R.; Rajor, A. Use of cement kiln dust in cement concrete and its leachate characteristics. Resour. Conserv. Recycl. 2012, 61, 59–68. [Google Scholar] [CrossRef]

- Gomes, H.I.; Mayes, W.M.; Baxter, H.A.; Jarvis, A.P.; Burke, I.T.; Stewart, D.I.; Rogerson, M. Options for managing alkaline steel slag leachate: A life cycle assessment. J. Clean. Prod. 2018, 202, 401–412. [Google Scholar] [CrossRef]

- Vollpracht, A.; Lothenbach, B.; Snellings, R.; Haufe, J. The pore solution of blended cements: A review. Mater. Struct. 2015, 49, 3341–3367. [Google Scholar] [CrossRef] [Green Version]

| Element Oxide | Chemical Composition (%) |

|---|---|

| CaO | 35–60 |

| MgO | 4–12 |

| SiO2 | 27–37 |

| Al2O3 | 2–6 |

| Cr2O3 | 1–8 |

| MnO | 1–3 |

| FeO | 0.5–4 |

| TiO2 | 1–2 |

| P2O5 | 0–0.02 |

| Austenitic | Ferritic | |||

|---|---|---|---|---|

| % Metal | % Oxide | % Metal | % Oxide | |

| Zinc | 7.75 | 9.64 | 4.93 | 6.13 |

| Lead | 0.65 | 0.60 | 0.77 | 0.83 |

| Nickel | 2.43 | 3.18 | 2.48 | 3.25 |

| Silicon | 3.53 | 7.55 | 3.61 | 7.72 |

| Manganese | 3.12 | 3.99 | 3.47 | 4.44 |

| Iron | 27.01 | 38.62 | 26.26 | 37.55 |

| Chromium | 11.68 | 17.17 | 13.88 | 20.40 |

| Magnesium | 2.92 | 4.85 | 3.29 | 5.56 |

| Titanium | 0.10 | 0.17 | 0.11 | 0.18 |

| Aluminium | 0.43 | 0.81 | 0.45 | 0.85 |

| Calcium | 8.06 | 11.28 | 6.84 | 9.58 |

| Tin | 0.02 | 0.02 | 0.02 | 0.02 |

| Molybdenum | 0.38 | 0.57 | 0.20 | 0.30 |

| Phosphorus | 0.02 | 0.05 | 0.02 | 0.05 |

| Copper | 0.24 | 0.30 | 0.28 | 0.36 |

| Cadmium | 0.24 | 0.28 | 0.08 | 0.10 |

| Sodium | 0.70 | 0.95 | 0.73 | 0.98 |

| Potassium | 0.80 | 0.97 | 1.00 | 1.20 |

| Chloride | 0.62 | 0.68 | ||

| Fluoride | 0.17 | 0.06 | ||

| Carbon | 0.44 | 0.33 | ||

| Sulfur | 0.28 | 0.30 | ||

| Arsenic | 0.003 | 0.005 | 0.004 | 0.006 |

| Nitrogen | 0.069 | 0.053 | ||

| Binder | Aggregates | |||||||

|---|---|---|---|---|---|---|---|---|

| Mix | Water (w/c ratio) | Cement Dosage kg/m3 | Fume Dust and Slag % | Additive % | Dosage kg/m3 | Fine Sand 0–2% (mm) | Sand 0–4% (mm) | Gravel 4–16% (mm) |

| OPC | 0.5 | 325 | 0% | 1.2% | 2033.8 | 15% | 50% | 50% |

| AFD | 81.25 | 25% of AFD | ||||||

| FFD | 25% of FFD | |||||||

| TS | 25% of TS | |||||||

| Type of Concrete | fc (MPa) 7 Days | fc (MPa) 28 Days | fc (MPa) 90 Days | E (GPa) 28 Days |

|---|---|---|---|---|

| OPC | 36.8 | 55.7 | 58.3 | 34.21 |

| AFD | 48.2 | 62.6 | 66.9 | 40.6 |

| FFD | 48.23 | 67.8 | 68.5 | 42.3 |

| TS | 31.1 | 42.2 | 43.6 | 28.6 |

| Type of Concrete | Flexural Strength (Mpa) |

|---|---|

| OPC | 8.84 |

| AFD | 14.67 |

| FFD | 14.02 |

| TS | 14.44 |

| Components Test Tubes | AFD | FFD | TS | OPC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Leaching | 1ª | 2ª | 1ª | 2ª | 1ª | 2ª | 1ª | 2ª | 1ª | 2ª | 1ª | 2ª | 1ª | 2ª | ||

| Specimen Weight (gr) | 362.41 | 360.35 | 365.95 | 365.05 | 360.15 | 352.1 | 353.26 | |||||||||

| Detection limits (ppm) | 0.034 | As | <LD | <LD | 0.035 | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD |

| 0.1 | Ca | 1.77 | 1.08 | 1.20 | 1.09 | 1.59 | 0.90 | 1.32 | 1.13 | 1.88 | 1.48 | 1.72 | 1.25 | 1.56 | 1.76 | |

| 0.004 | Cr Total | 0.042 | 0.025 | 0.053 | 0.030 | 0.045 | 0.057 | 0.037 | 0.034 | 0.006 | 0.013 | 0.008 | 0.046 | 0.007 | 0.023 | |

| 0.003 | Cu | <LD | <LD | <LD | <LD | <LD | <LD | 0.0221 | <LD | <LD | <LD | <LD | <LD | <LD | <LD | |

| 0.042 | Fe | 0.071 | <LD | 0.079 | <LD | 0.062 | <LD | 0.070 | <LD | <LD | <LD | 0.054 | <LD | <LD | <LD | |

| 0.001 | Mn | 0.001 | <LD | 0.013 | 0.001 | 0.001 | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD | <LD | |

| 0.09 | SO4− | 10.09 | 2.78 | 11.59 | 3.16 | 6.91 | 2.17 | 4.68 | 2.05 | 9.00 | 5.98 | 11.13 | 5.29 | 17.90 | 14.15 | |

| 0.002 | Zn | 0.014 | <LD | 0.010 | 0.005 | 0.016 | 0.002 | 0.019 | 0.007 | 0.010 | 0.003 | 0.010 | 0.013 | 0.014 | <LD | |

| 1.9 | Na | 24.15 | 10.22 | 25.45 | 10.30 | 22.51 | 10.38 | 19.19 | 8.37 | 13.52 | 6.29 | 15.49 | 7.90 | 16.81 | 7.15 | |

| 0.014 | Al | 0.084 | 0.066 | 0.104 | 0.072 | 0.095 | 0.066 | 0.090 | 0.053 | 0.110 | 0.048 | 0.082 | 0.079 | 0.071 | 0.042 | |

| 0.056 | K | 48.46 | 22.88 | 52.11 | 22.80 | 37.27 | 18.62 | 28.52 | 14.91 | 23.60 | 14.59 | 31.75 | 18.46 | 28.15 | 17.87 | |

| 0.025 | Si | 2.48 | 1.89 | 2.63 | 2.03 | 2.18 | 1.76 | 2.03 | 1.72 | 2.88 | 2.09 | 3.59 | 2.40 | 2.75 | 1.90 | |

| TDS (ppm) | 117.53 | 63.67 | 124.13 | 63.84 | 101.00 | 57.46 | 82.36 | 48.16 | 72.05 | 44.57 | 82.99 | 52.21 | 82.59 | 54.09 | ||

| Conductivity (µS/cm) | 215.0 | 114.4 | 225.0 | 114.7 | 179.9 | 103.5 | 147.2 | 87.2 | 129.1 | 80.9 | 148.3 | 94.3 | 147.6 | 97.6 | ||

| pH | 9.300 | 8.620 | 9.370 | 8.730 | 9.250 | 8.680 | 9.140 | 8.320 | 8.960 | 8.220 | 9.180 | 8.530 | 8.990 | 8.160 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parron-Rubio, M.E.; Kissi, B.; Perez-García, F.; Rubio-Cintas, M.D. Development in Sustainable Concrete with the Replacement of Fume Dust and Slag from the Steel Industry. Materials 2022, 15, 5980. https://doi.org/10.3390/ma15175980

Parron-Rubio ME, Kissi B, Perez-García F, Rubio-Cintas MD. Development in Sustainable Concrete with the Replacement of Fume Dust and Slag from the Steel Industry. Materials. 2022; 15(17):5980. https://doi.org/10.3390/ma15175980

Chicago/Turabian StyleParron-Rubio, Maria Eugenia, Benaissa Kissi, Francisca Perez-García, and Maria Dolores Rubio-Cintas. 2022. "Development in Sustainable Concrete with the Replacement of Fume Dust and Slag from the Steel Industry" Materials 15, no. 17: 5980. https://doi.org/10.3390/ma15175980

APA StyleParron-Rubio, M. E., Kissi, B., Perez-García, F., & Rubio-Cintas, M. D. (2022). Development in Sustainable Concrete with the Replacement of Fume Dust and Slag from the Steel Industry. Materials, 15(17), 5980. https://doi.org/10.3390/ma15175980