Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cementitious Material

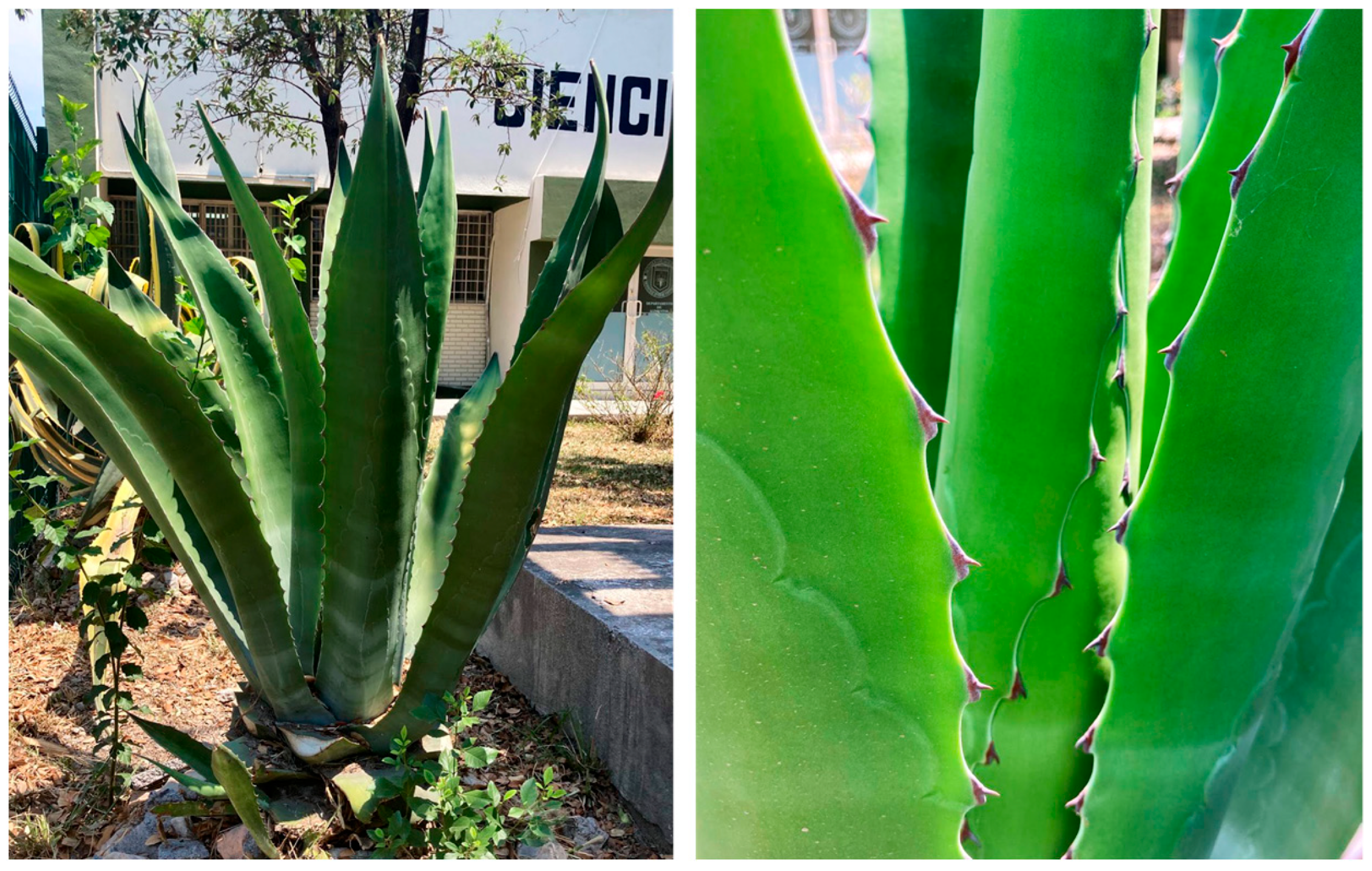

2.1.2. Plant Aggregate from Agave salmiana (AS)

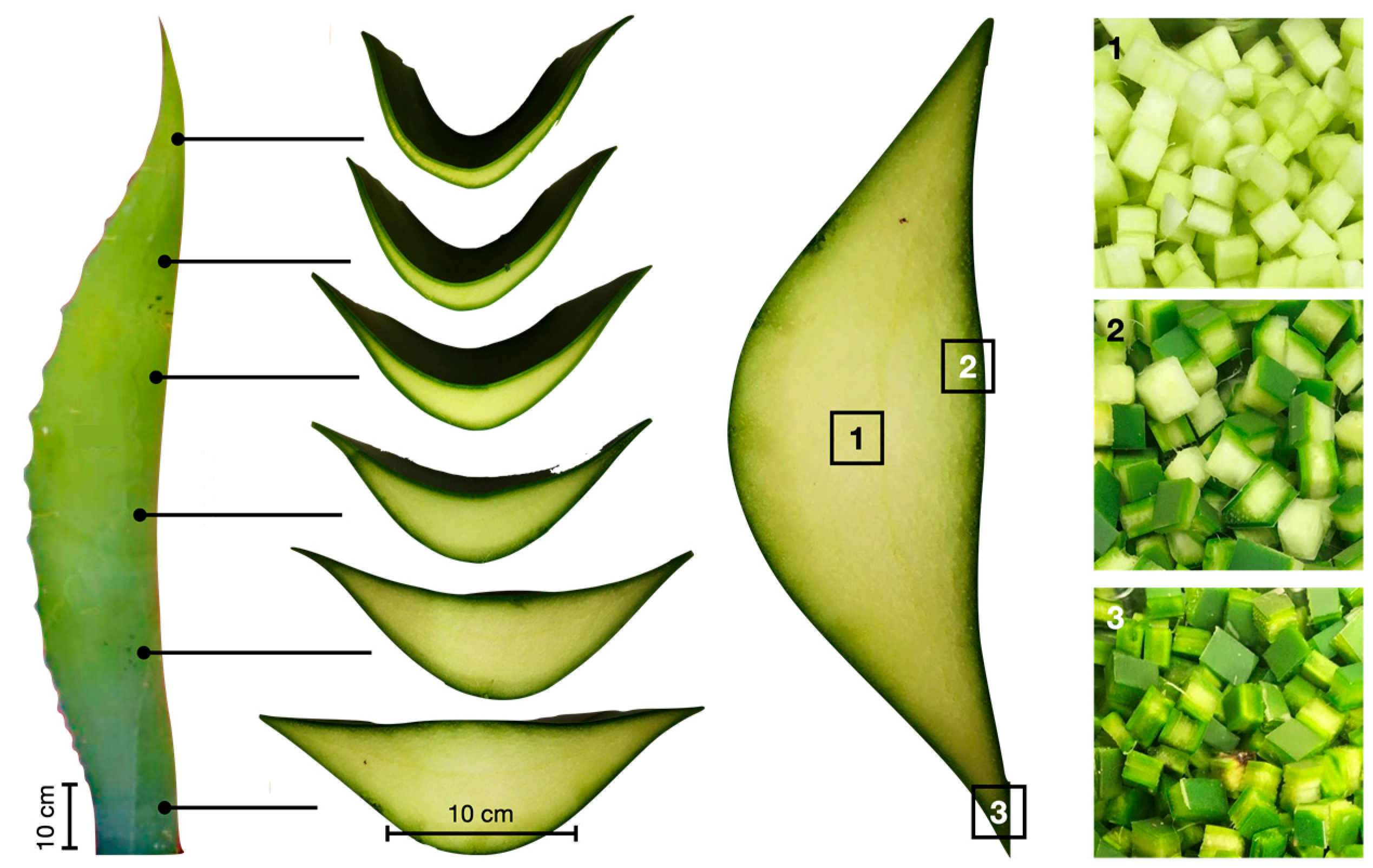

- Morphological characterization: The morphology of the AS used to produce distillates is shown in Figure 3, and its utilization is mainly focused on agave head distillation (i.e., leave base). This study worked with AS leaves, which are considered waste and therefore do not have well-defined disposal (Figure 3, right). To determine whether it was necessary to select some of the components of the leaf in the fabrication of the mortar, it was separated into three parts: pith (leaf medulla) [M], cuticle (leaf epidermis) [C], and pith with cuticle [MC].

- Chemical characterization: The chemical analysis of the fiber was performed according to TAPPI (Technical Association of the Pulp and Paper Industry) procedures and experimental methods, described by Wise L.E [19], and Rowell [20], to determine the ash content [21], ethanol-toluene extractable [22], acid-insoluble lignin content [23], holocellulose content [19], α-cellulose, and hemicellulose [20,24,25,26,27].

- Physical characterization:

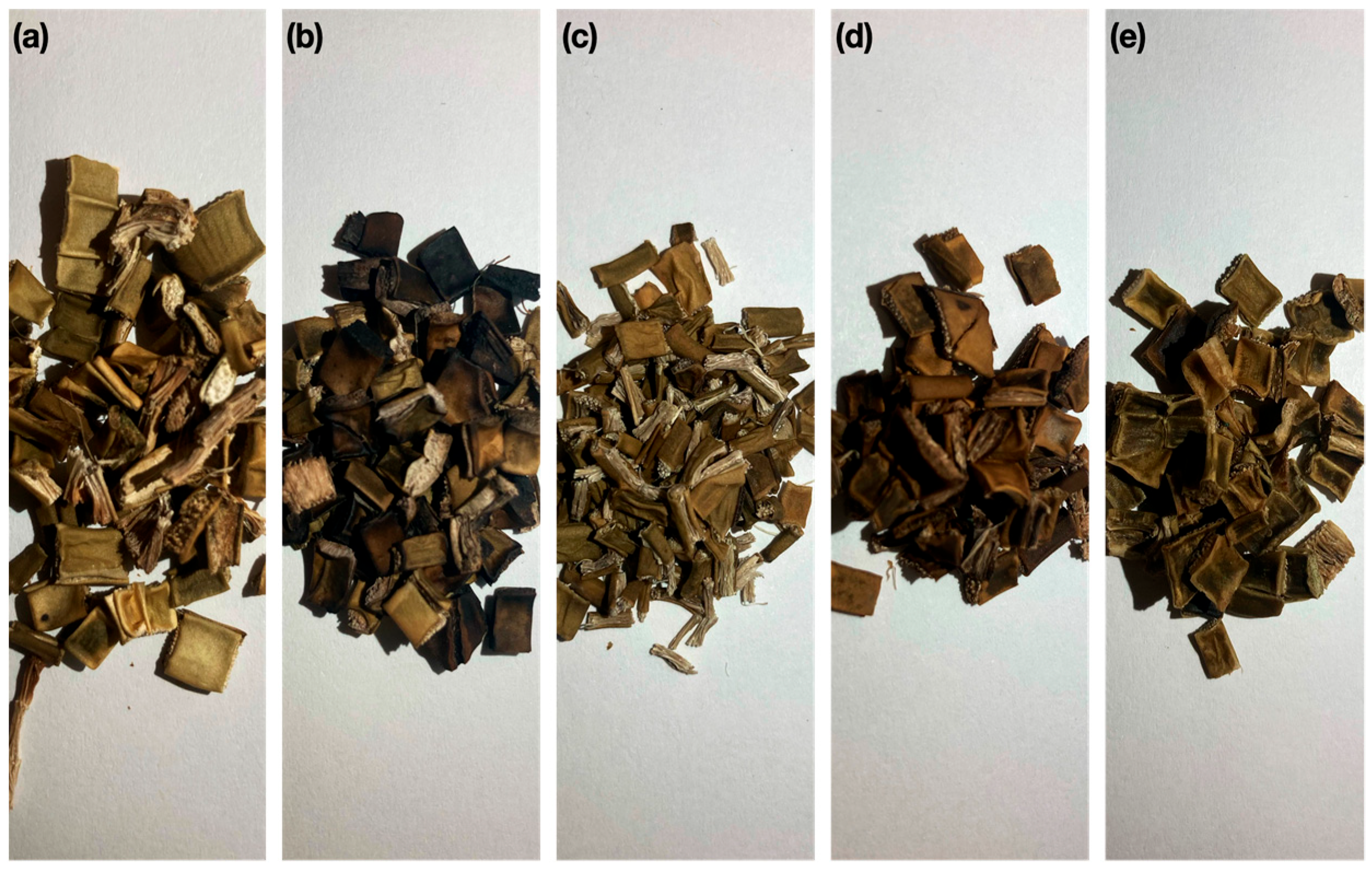

- Sample preparation: The procedure is shown in Figure 4. At this stage, the AS was manually cut (Figure 4a), then the pith (M), cuticle (C), and pith with cuticle (MC) were separated (Figure 4b) and dried in an oven with the air circulation at a temperature of 60 ± 5 °C until reaching a constant mass (variation of less than 0.1% between two readings at 24 h) (Figure 4c) [28]. Subsequently, the dried sample was sieved, leaving only the fraction retained between sieve No. 4 (4.75 mm) and No. 30 (0.6 mm) and stored in airtight bags (Figure 4d). After drying, the initial water content was determined in relation to the dry weight.

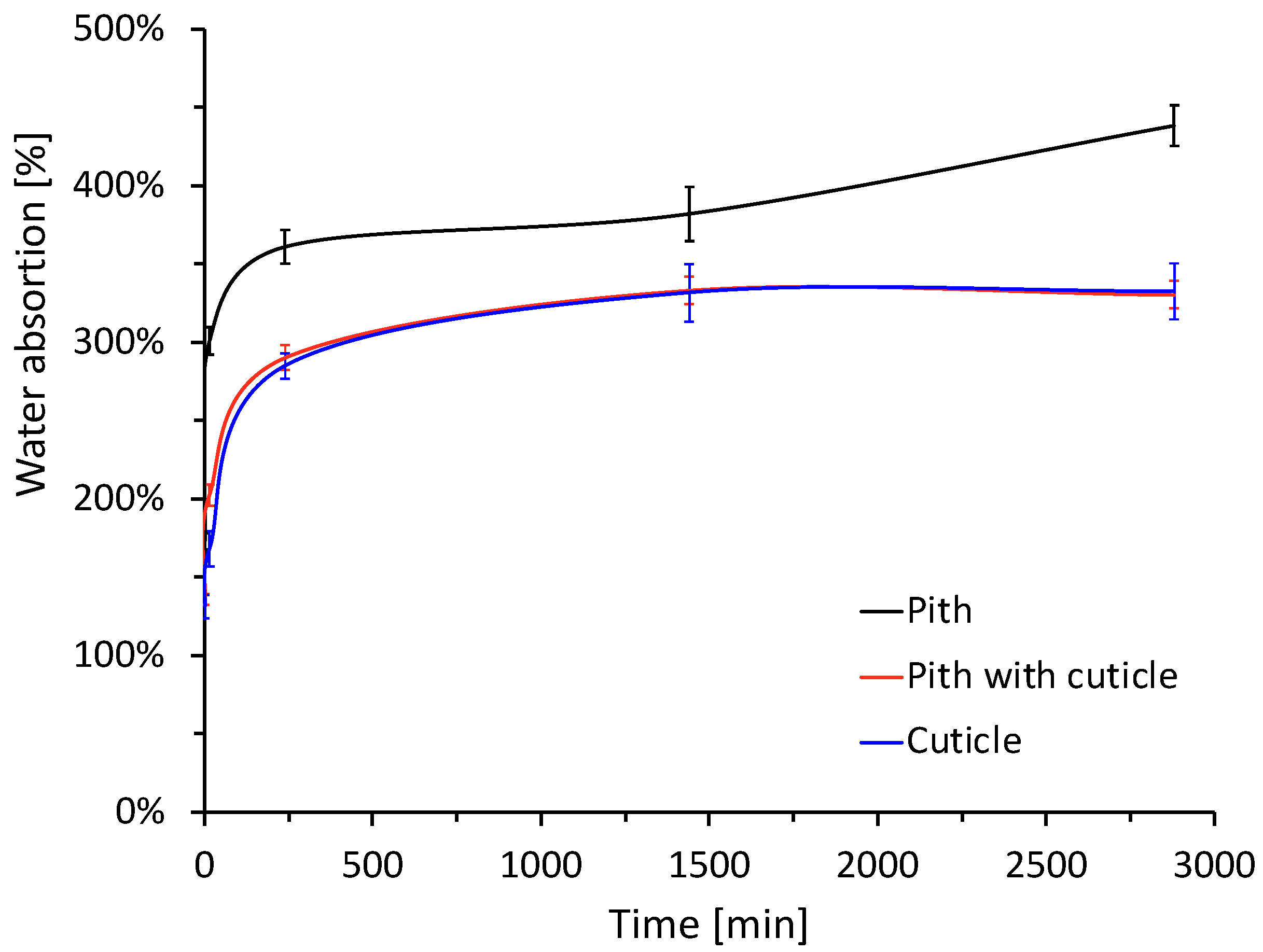

- Water absorption of the vegetable aggregate: 25 g of each AS sample (M, C, and MC) were weighed and immersed in distilled water for 1, 15, 240, 1440, and 2880 min. Subsequently, they were extracted and centrifuged at 120 RPM for 50 s [28,29]. The water absorption was calculated through Equation (1) [8]:where WW is the weight after water immersion and surface drying by centrifuge and WD is the initial weight after oven drying.

- 3.

- Bulk density of the vegetable aggregate: This was determined by placing a sample of each type (M, C, and MC) in a cylindrical container of known dimensions, which was shaken 10 times to subsequently determine the volume occupied by the fiber and its mass, thus obtaining the apparent density of the vegetable aggregate [28,30].

- 4.

- Thermal conductivity of the fiber: Thiswas performed using a Tempos, Meter Group brand, based on the hotwire technique that complies with the specifications of the IEEE 442-1981 standard and ASTM D5334-08. The data were collected in a 10 min test time using the KS-3 probe [28].

2.2. Treatments to AS Aggregate

2.2.1. Untreated Plant Aggregate [S/T]

2.2.2. Freezing Treatment [T/C]

2.2.3. Physical Treatment of Hornification [T/H]

2.2.4. Chemical Treatment of NaOH [T/NaOH]

2.2.5. Solid Paraffin-Based Coating Treatment [T/P]

2.2.6. Physical Characterization of Treated Aggregates

2.3. Plant-Based Concrete

2.3.1. Specimen Fabrication

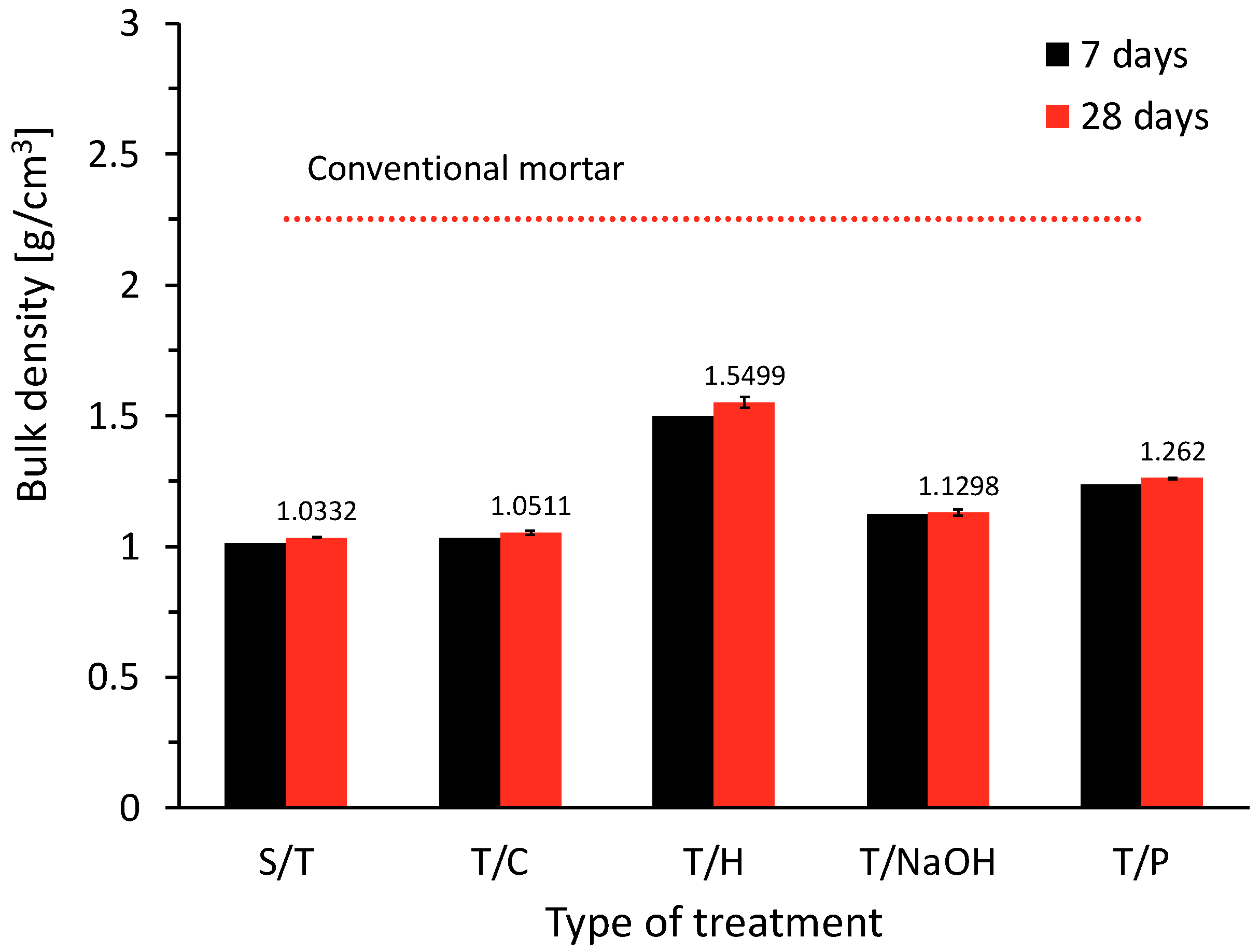

2.3.2. Bulk Density

2.3.3. Thermal Conductivity

2.3.4. Compressive Strength

2.3.5. Thermogravimetric Analysis of Cement Paste

2.3.6. Morphological Analysis

3. Results

3.1. Raw material Characterization

3.1.1. Morphological Characterization

3.1.2. Chemical Characterization of Plant Aggregate

3.1.3. Physical Properties

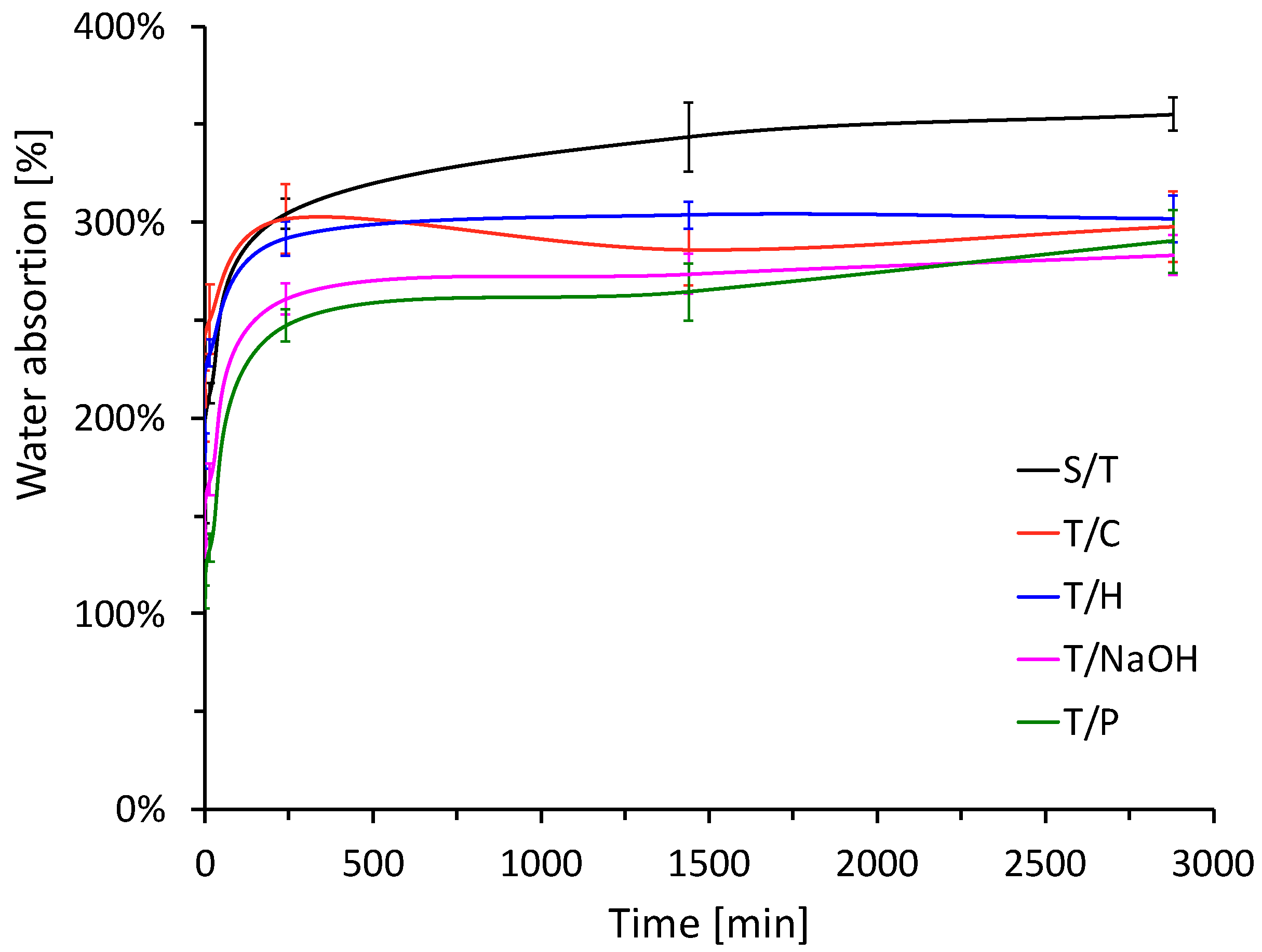

3.2. Characterization of the Vegetal Aggregate after Treatments

3.2.1. Water Absorption

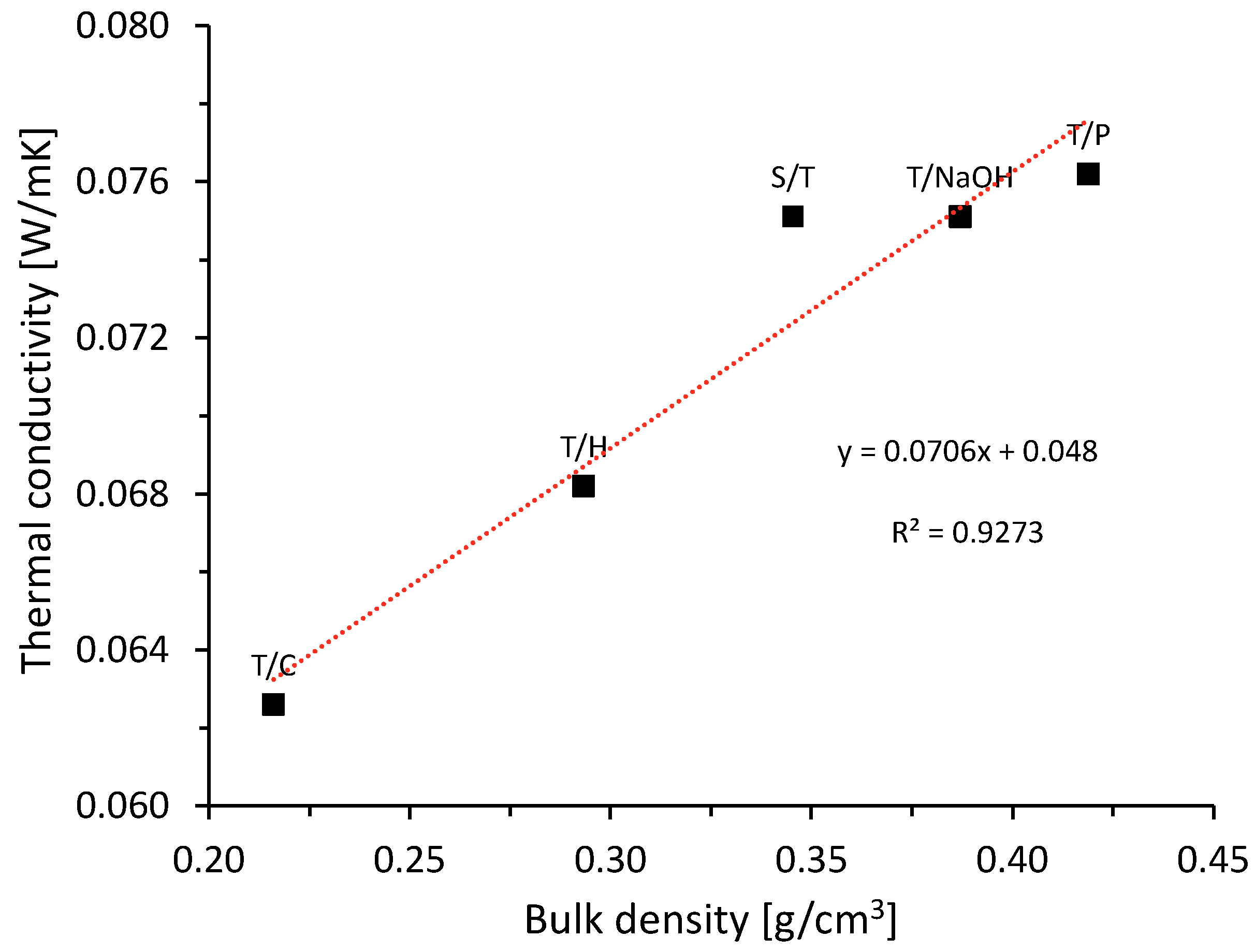

3.2.2. Thermal Conductivity and Bulk Density

3.3. Characterization of Vegetal Concrete

3.3.1. Bulk Density

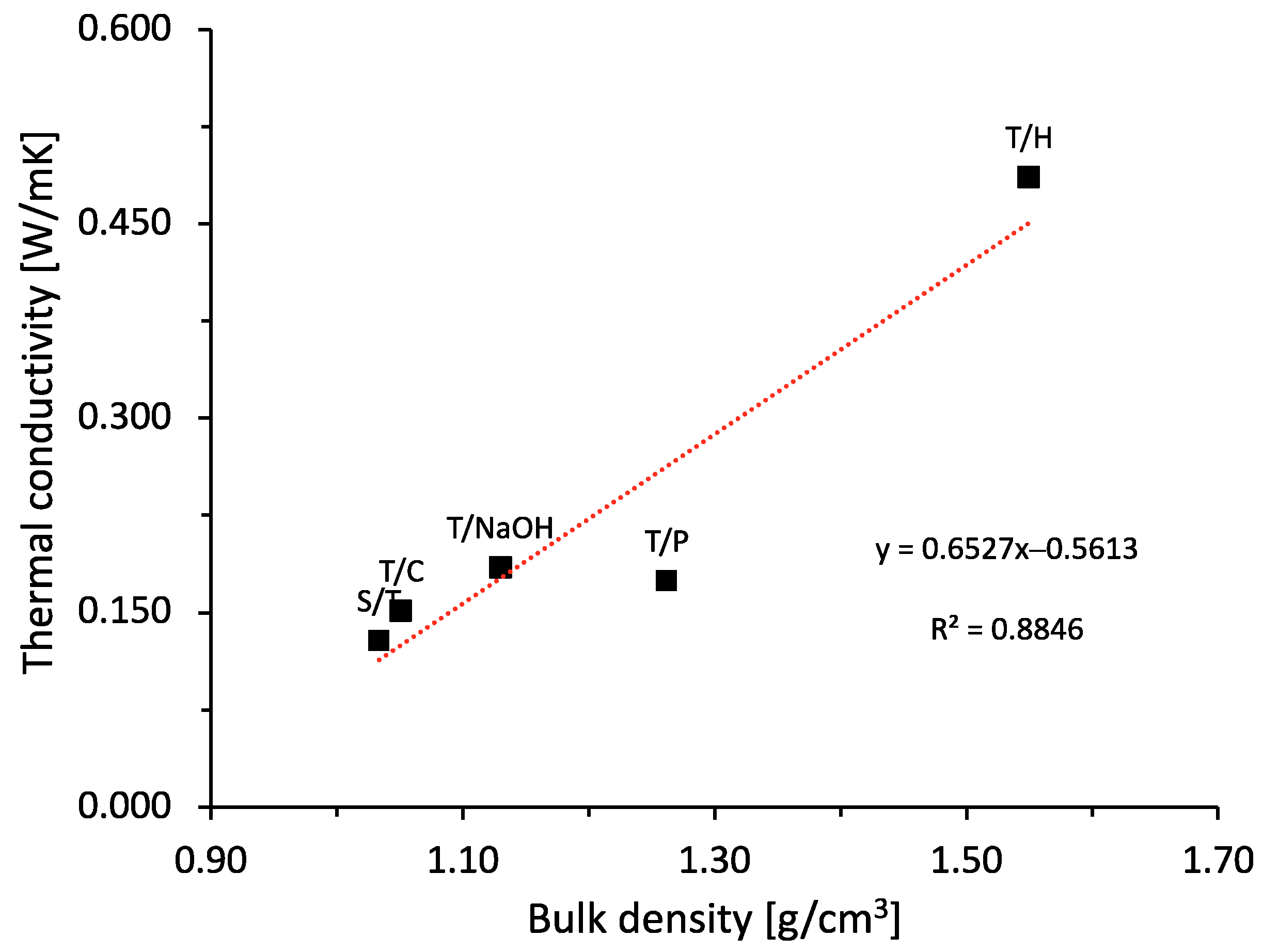

3.3.2. Thermal Conductivity

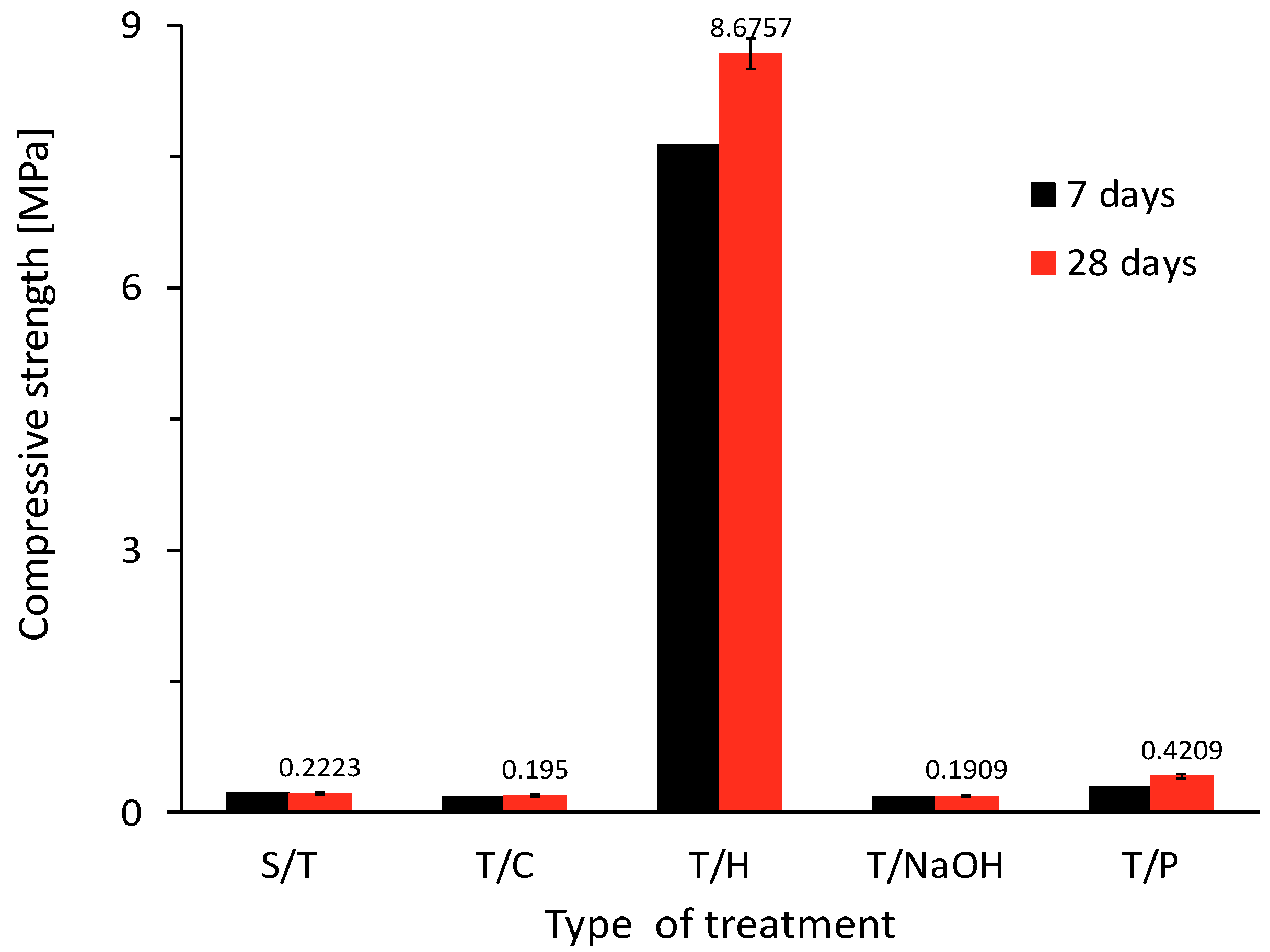

3.3.3. Compressive Strength

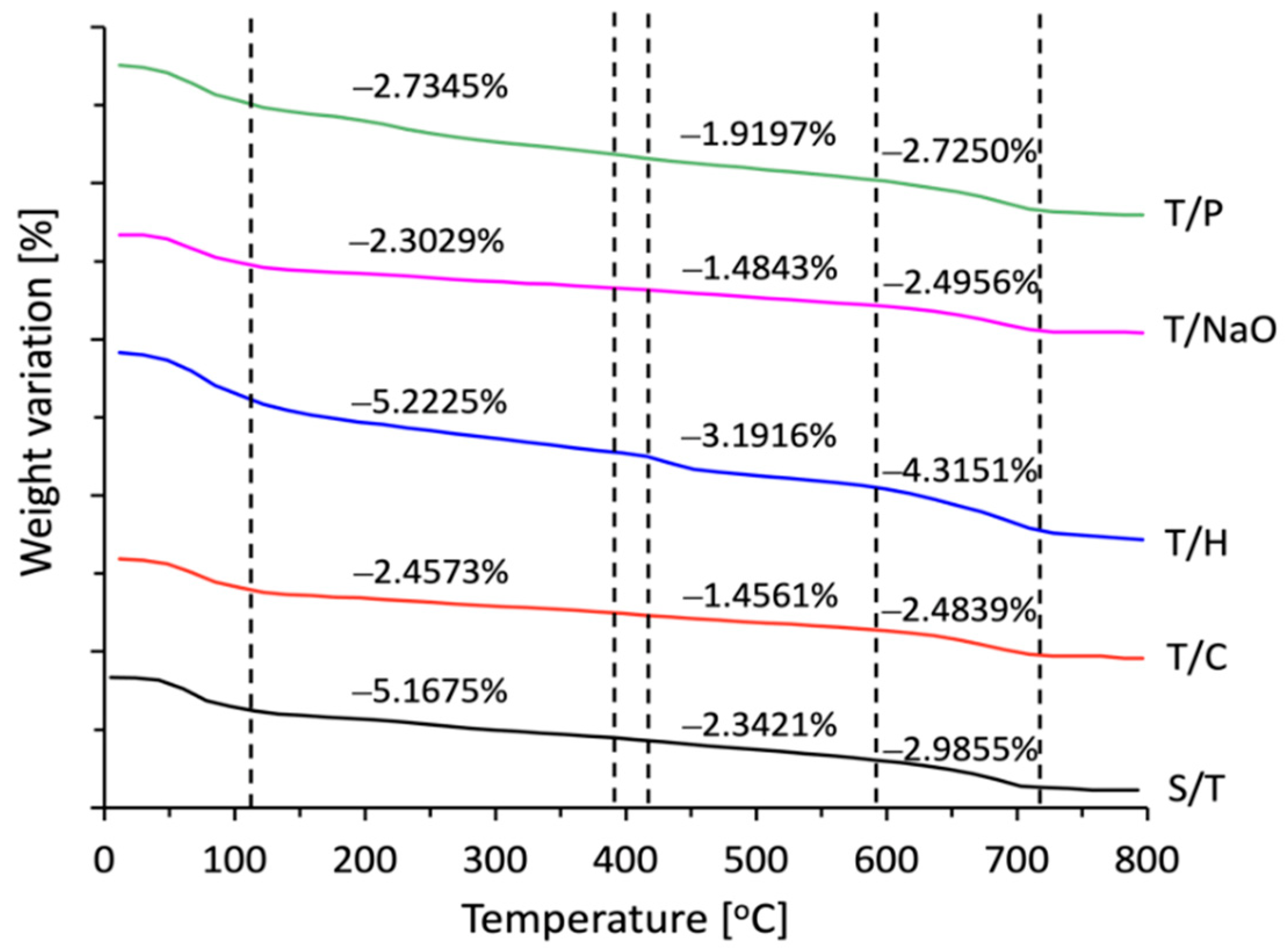

3.3.4. Thermo Gravimetric Analysis of the Cement Paste

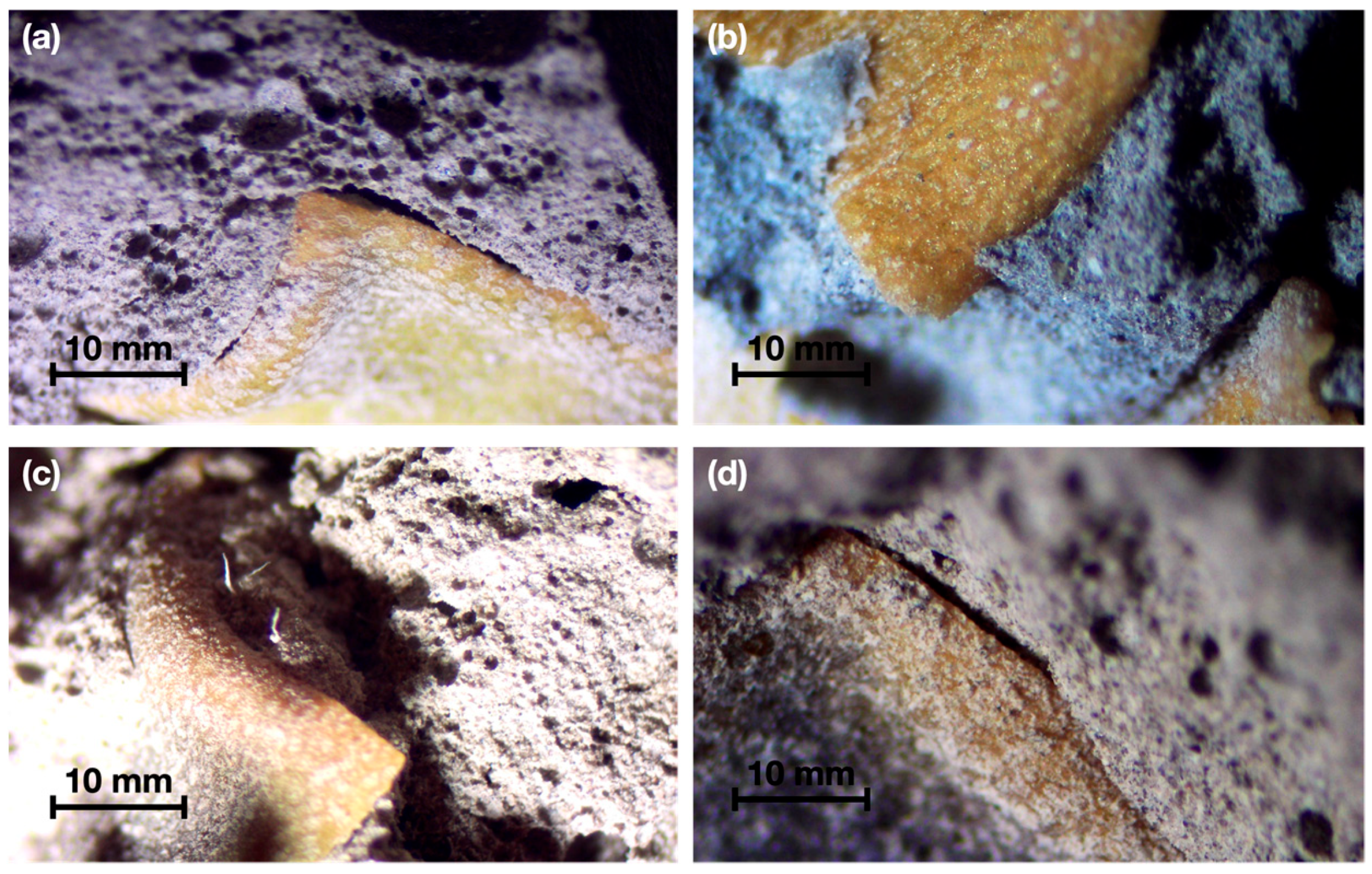

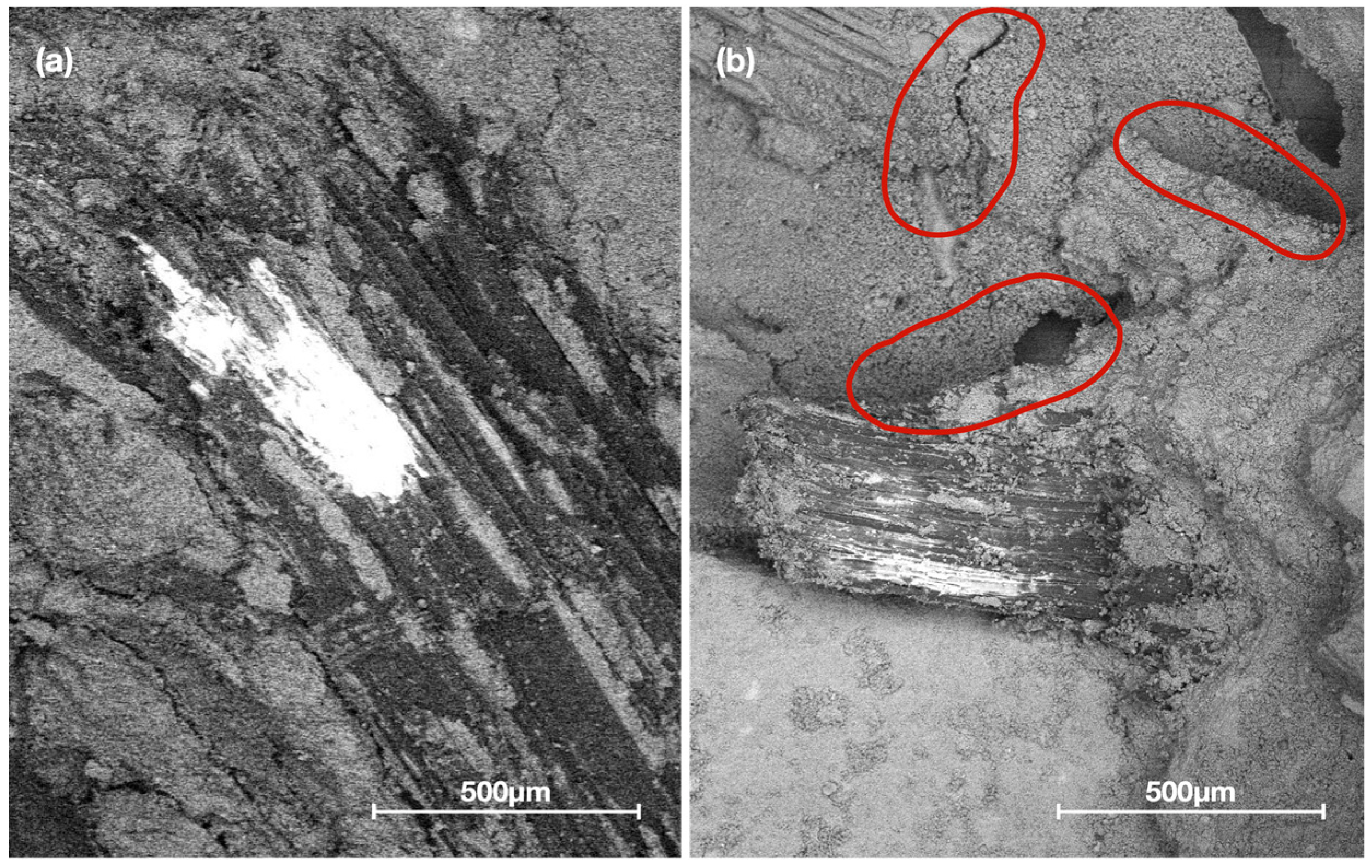

3.3.5. Morphological Observation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, B.R.; Hinrichsen, G. Natural fibers, biopolymers, and biocomposites. In Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 14–49. [Google Scholar]

- Acevedo, H.; Alejandro, A.; Hernández, V.; Alejandro, D.; Cardona, R. Sostenibilidad: Actualidad y necesidad en el sector de la construcción en Colombia. Gestión y Ambient. 2012, 15, 105–118. [Google Scholar]

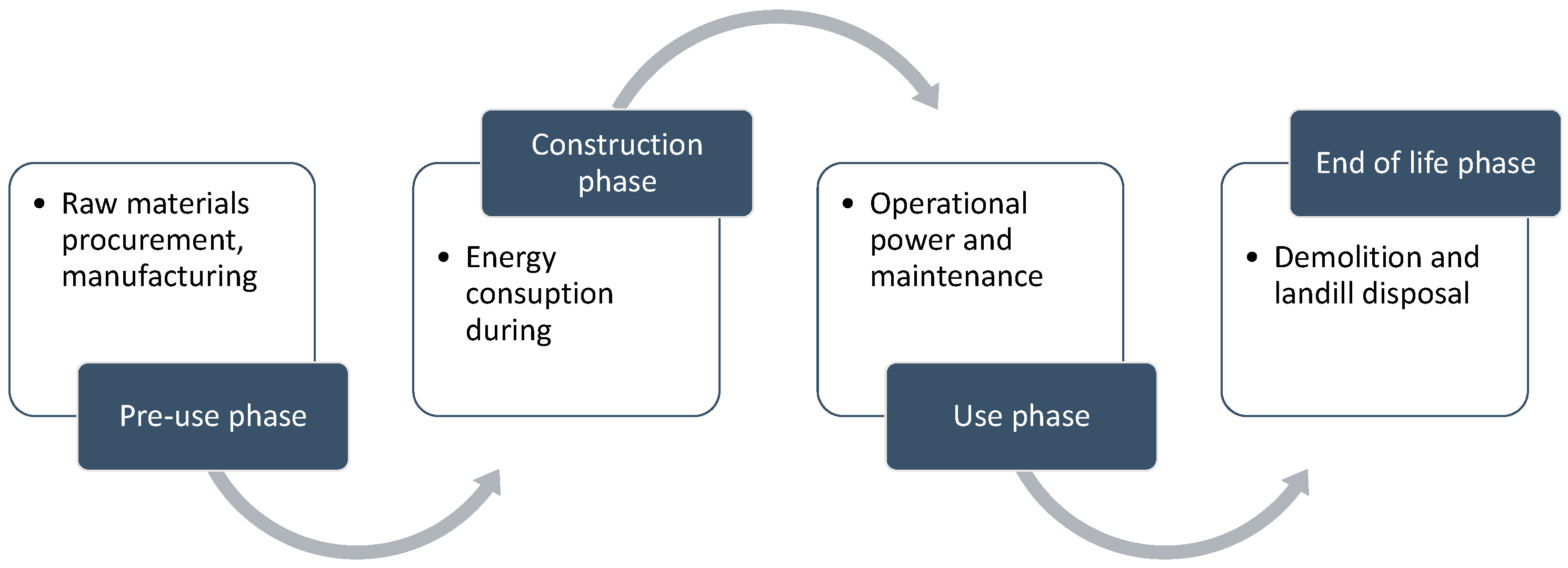

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Mora, E.P. Life cycle, sustainability and the transcendent quality of building materials. Build. Environ. 2007, 42, 1329–1334. [Google Scholar] [CrossRef]

- Arena, A.P.; de Rosa, C. Life cycle assessment of energy and environmental implications of the implementation of conservation technologies in school buildings in Mendoza—Argentina. Build. Environ. 2003, 38, 359–368. [Google Scholar] [CrossRef]

- IPCC, 2021: Summary for Policymakers. In Climate Change 2021: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V.P.; Zhai, A.; Pirani, S.L.; Connors, C.; Péan, S.; Berger, N.; Caud, Y.; Chen, L.; Goldfarb, M.I.; Gomis, M.; et al. (Eds.) Cambridge University Press: Cambridge, UK, 2021; in press. [Google Scholar]

- Sabathier, V.; Magniont, C.; Escadeillas, G.; Juarez, C.A. Flax and hemp fibre reinforced pozzolanic matrix: Evaluation of impact of time and natural weathering. Eur. J. Environ. Civ. Eng. 2017, 21, 1403–1417. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Filho, R.D.T. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Niyigena, C.; Amziane, S.; Chateauneuf, A.; Arnaud, L.; Bessette, L.; Collet, F.; Lanos, C.; Escadeillas, G.; Lawrence, M.; Magniont, C.; et al. Variability of the mechanical properties of hemp concrete. Mater. Today Commun. 2016, 7, 122–133. [Google Scholar] [CrossRef]

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental investigation of new biocomposite with low cost for thermal insulation. Energy Build. 2013, 66, 267–273. [Google Scholar] [CrossRef]

- Clemons, C.M. Natural Fibers. In Functional Fillers for Plastics; Xanthos, M., Ed.; Wiley-VCH: Weinheim, Germany, 2010; pp. 213–223. [Google Scholar]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. Constr. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. Sustain. Constr. Mater. Technol. 2016, 1, 31. [Google Scholar]

- Nehdi, M.L.; Suleiman, A.R.; Soliman, A.M. Investigation of concrete exposed to dual sulfate attack. Cem. Concr. Res. 2014, 64, 42–53. [Google Scholar] [CrossRef]

- Bentz, D.P.; Durán-Herrera, A.; Galvez-Moreno, D. Comparison of ASTM C311 strength activity index testing versus testing based on constant volumetric proportions. J. ASTM Int. 2012, 9, 1–7. [Google Scholar]

- Moreno, D.G. Robustez de un Concreto Autocompactable Producido con Materiales Disponibles en la Región de Monterrey, Nuevo León; Universidad Autónoma de Nuevo León: San Nicolás de Los Garza, Mexico, 2015. [Google Scholar]

- Wise, L.; Murphy, M.; Addieco, A.D. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Pap. Trade 1946, 122, 35–43. [Google Scholar]

- Rowell, R. The chemistry of solid wood. In Handbook of Wood Chemistry and Wood Composites; 1983; Volume 19, pp. 17–18. [Google Scholar]

- Technical Association for the Pulp and Paper Industries. Ash in Wood and Pulp; TAPPI Test Method T 211 om-85; TAPPI Press: Atlanta, GA, USA, 1998; 2p. [Google Scholar]

- Technical Association for the Pulp and Paper Industries. Solvent Extractives in Wood and Pulp; TAPPI Test Method T 204 om-88; TAPPI Press: Atlanta, GA, USA, 1998; 3p. [Google Scholar]

- Technical Association for the Pulp and Paper Industries. Acid-Insoluble Lignin in Wood and Pulp; TAPPI Test Method T 222 om-88; TAPPI Press: Atlanta, GA, USA, 1998; 3p. [Google Scholar]

- Flores-Sahagun, T.H.S.; Santos, L.P.D.; Santos, J.D.; Mazzaro, I.; Mikowski, A. Characterization of blue agave bagasse fibers of Mexico. Compos. Part A Appl. Sci. Manuf. 2013, 45, 153–161. [Google Scholar]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Carmona, J.E.; Morales-Martínez, T.K.; Mussatto, S.I.; Castillo-Quiroz, D.; Ríos-González, L.J. Propiedades químicas, estructurales y funcionales de la lechuguilla (Agave lechuguilla Torr.). Rev. Mex. Ciencias For. 2017, 8, 100–122. [Google Scholar]

- Ely, R.E.; Moore, L.A. The composition of holocellulose prepared from various forages and the corresponding feces. J. Dairy Sci. 1956, 39, 1706–1711. [Google Scholar] [CrossRef]

- Amziane, S.; Collet, F.; Lawrence, M.; Magniont, C.; Picandet, V.; Sonebi, M. Recommendation of the RILEM TC 236-BBM: Characterisation testing of hemp shiv to determine the initial water content, water absorption, dry density, particle size distribution and thermal conductivity. Mater. Struct. Constr. 2017, 50, 167. [Google Scholar] [CrossRef]

- Magniont, C.; Escadeillas, G.; Coutand, M.; Oms-Multon, C. Use of plant aggregates in building ecomaterials. Eur. J. Environ. Civ. Eng. 2012, 16, 37–41. [Google Scholar] [CrossRef]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; de Baynast, H. Design of green concrete made of plant-derived aggregates and a pumice-lime binder. Cem. Concr. Compos. 2012, 34, 231–241. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Lima, P.R.L.; Silva, F.A.; Filho, R.D.T. Effect of sisal fiber hornification on the fiber-matrix bonding characteristcs and bending behavior of cement based composites. Key Eng. Mater. 2014, 600, 421–432. [Google Scholar]

- Ferreira, S.R.; Lima, P.R.L.; Silva, F.A.; Filho, R.D.T. Influência de ciclos molhagem-secagem em fibras de sisal sobre a aderência com matrizes de cimento Portland. Rev. Mater. 2012, 17, 1024–1034. [Google Scholar] [CrossRef]

- Ferreira, S.S.R.; Lima, P.R.L.; Silva, F.A.; Filho, R.D.T. Effect of sisal fiber hornification on the adhesion with portland cement matrices. Rev. Mater. 2012, 17, 1024–1034. [Google Scholar]

- Juárez, C.M.A.; Rodríguez, P.; Rivera, R.; de Von Roth, R. Uso de fibras naturales de lechuguilla como refuerzo en concreto. Ingenierías 2004, 7, 7–19. [Google Scholar]

- Amziane, S.; Collet, F. Bio-Sggregates Based Building Materials: State-of-the-Art Report of the RILEM Technical Committee 236-BBM; Springer: Dordrecht, The Netherlands, 2017. [Google Scholar]

- Paulien, B.d.; Knut-Hakan, J.; Kenneth, S.; Christer, N. Mechanical properties of lime—hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar]

- Herrera, C.R.; Lemus, M.C.; Diaz, F.E.R.; Ramirez, J.P.C. Physical, chemical and mechanical characterization of a prototype insulating material based on eucalyptus bark fiber. IEEE Lat. Am. Trans. 2018, 16, 2441–2446. [Google Scholar] [CrossRef]

- Cérézo, V. Propriétés Mécaniques, Thermiques et Acoustiques d’un Matériau à Base de Particules Végétales: Approche Expérimentale et Modélisation Théorique; L’Institut National des Sciences Appliquées de Lyon: Lyon, France, 2005.

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian waste fibres as reinforcement for cement-based composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Lara, J.F.R. Activación de Sistemas Binarios y Ternarios Base Cemento Portland con Residuos Agroindustriales; Universidad Autónoma de Nuevo León: San Nicolás de Los Garza, Mexico, 2015. [Google Scholar]

- Khaloo, A.; Mobini, M.H.; Hosseini, P. Influence of different types of nano-SiO2 particles on properties of high-performance concrete. Constr. Build. Mater. 2016, 113, 188–201. [Google Scholar] [CrossRef]

- Gómez-Zamorano, L.Y.; Castillo-Linton, C.E. Modificación de las propiedades de matrices cementantes mediante la adición de partículas de nanosílice. Rev. Alconpat. 2016, 6, 101–115. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Scherer, G.W. Comparison of methods for arresting hydration of cement. Cem. Concr. Res. 2011, 41, 1024–1036. [Google Scholar] [CrossRef]

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (‘hempcrete’) manufactured by a projection process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Vidal, J. Desarrollo de Materiales Aislantes Basados en Fibras Naturales Residuales; Universidad de La Frontera: Temuco, Chile, 2016. [Google Scholar]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Fabiani, C.; Pisello, A.L.; Ubertini, F.; Materazzi, A.L.; Cotana, F. Innovative concretes for low-carbon constructions: A review. Int. J. Low-Carbon Technol. 2017, 12, 289–309. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M.A. Developments on vegetable fibre-cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Instituto Nacional de Normalización. NCh 853: Acondicionamiento Térmico—Envolvente Térmica de Eedificios—Cálculo de Resistencias y Transmitancias Térmicas; Instituto Nacional de Normalización: Santiago, Chile, 2007.

- Becchio, C.; Corgnati, S.P.; Kindinis, A.; Pagliolico, S. Improving environmental sustainability of concrete products: Investigation on MWC thermal and mechanical properties. Energy Build. 2009, 41, 1127–1134. [Google Scholar] [CrossRef]

- Krishna, N.K.; Prasanth, M.; Gowtham, R.; Karthic, S.; Mini, K.M. Enhancement of properties of concrete using natural fibers. Mater. Today Proc. 2018, 5, 23816–23823. [Google Scholar] [CrossRef]

- Traversa, L.P.; Iloro, F.H.; Benito, D. Determinación mediante ensayos térmicos del CO2 absorbido por morteros de cemento. Cienc. Tecnol. Mater. 2013, 3, 33–41. [Google Scholar]

| Advantages | Disadvantages |

|---|---|

| Low specific weight | Low mechanical resistance |

| Renewable resource | Variable fiber quality |

| Production with low investment and costs | Low moisture resistance |

| High electrical resistance | Low durability |

| Good thermal and acoustic insulation | Low fire resistance |

| Biodegradable | Low adhesion between fiber and matrix |

| Composite | MgO | Al2O3 | SiO2 | SO3 | K2O | CaO | TiO2 | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| % | 0.18 | 1.43 | 20.71 | 6.09 | 1.36 | 66.78 | 0.29 | 2.78 |

| Sample | AV [g] | AP [g] | OPC [g] | AR [g] |

|---|---|---|---|---|

| S/T | 46.6155 | 21.8120 | 546 | 191.1 |

| T/C | 29.1735 | 19.7192 | 546 | 191.1 |

| T/H | 39.6090 | 23.8059 | 546 | 191.1 |

| T/NaOH | 52.2315 | 23.0637 | 546 | 191.1 |

| T/P | 56.5515 | 20.1366 | 546 | 191.1 |

| Test | Average |

|---|---|

| Moisture analysis | 5.20 ± 0.03% |

| Ash analysis | 15.77 ± 1.90% |

| Ethanol-Toluene Extractables | 23.47 ± 2.45% |

| Acid insoluble lignin | 10.61 ± 0.24% |

| Holocellulose content | 42.64 ± 1.10% |

| Cellulose content | 49.64 ± 0.83% |

| Hemicellulose content | 50.36 ± 0.83% |

| Samples | ρ [g/cm3] | λ [W/mK] |

|---|---|---|

| Pith | 0.2994 | 0.0682 |

| Pith with Cuticle | 0.3350 | 0.0733 |

| Cuticle | 0.3771 | 0.0810 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosas-Díaz, F.; García-Hernández, D.G.; Mendoza-Rangel, J.M.; Terán-Torres, B.T.; Galindo-Rodríguez, S.A.; Juárez-Alvarado, C.A. Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate. Materials 2022, 15, 6000. https://doi.org/10.3390/ma15176000

Rosas-Díaz F, García-Hernández DG, Mendoza-Rangel JM, Terán-Torres BT, Galindo-Rodríguez SA, Juárez-Alvarado CA. Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate. Materials. 2022; 15(17):6000. https://doi.org/10.3390/ma15176000

Chicago/Turabian StyleRosas-Díaz, Felipe, David Gilberto García-Hernández, José M. Mendoza-Rangel, Bernardo T. Terán-Torres, Sergio Arturo Galindo-Rodríguez, and Cesar A. Juárez-Alvarado. 2022. "Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate" Materials 15, no. 17: 6000. https://doi.org/10.3390/ma15176000

APA StyleRosas-Díaz, F., García-Hernández, D. G., Mendoza-Rangel, J. M., Terán-Torres, B. T., Galindo-Rodríguez, S. A., & Juárez-Alvarado, C. A. (2022). Development of a Portland Cement-Based Material with Agave salmiana Leaves Bioaggregate. Materials, 15(17), 6000. https://doi.org/10.3390/ma15176000