Influence of Mechanical Grinding on Particle Characteristics of Coal Gasification Slag

Abstract

:1. Introduction

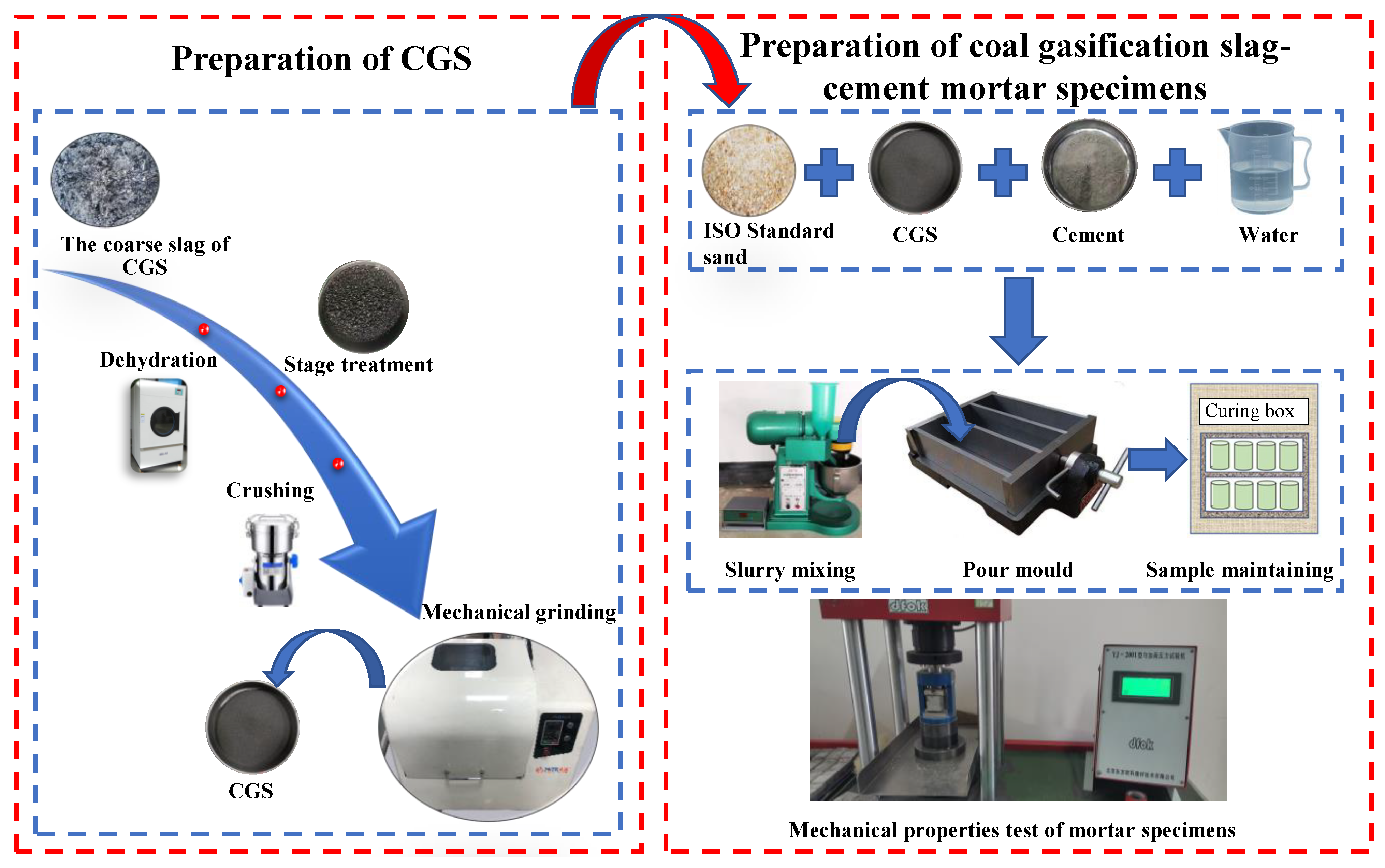

2. Materials and Methods

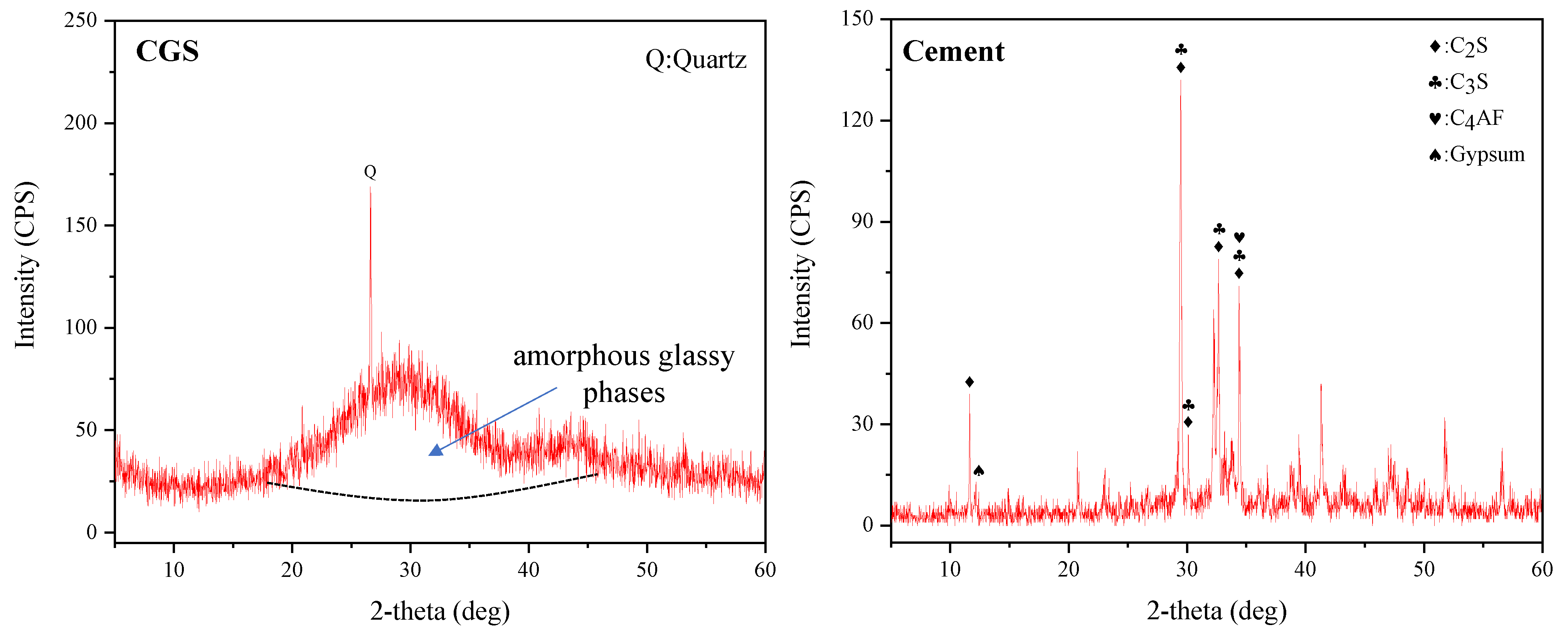

2.1. Raw Materials

2.2. Test Methods

2.3. Mathematical Model

2.3.1. Kinetic Equation of CGS Powder

2.3.2. RRB Model

3. Results and Discussion

3.1. PSD and Microstructure of CGS with Different Grinding Time

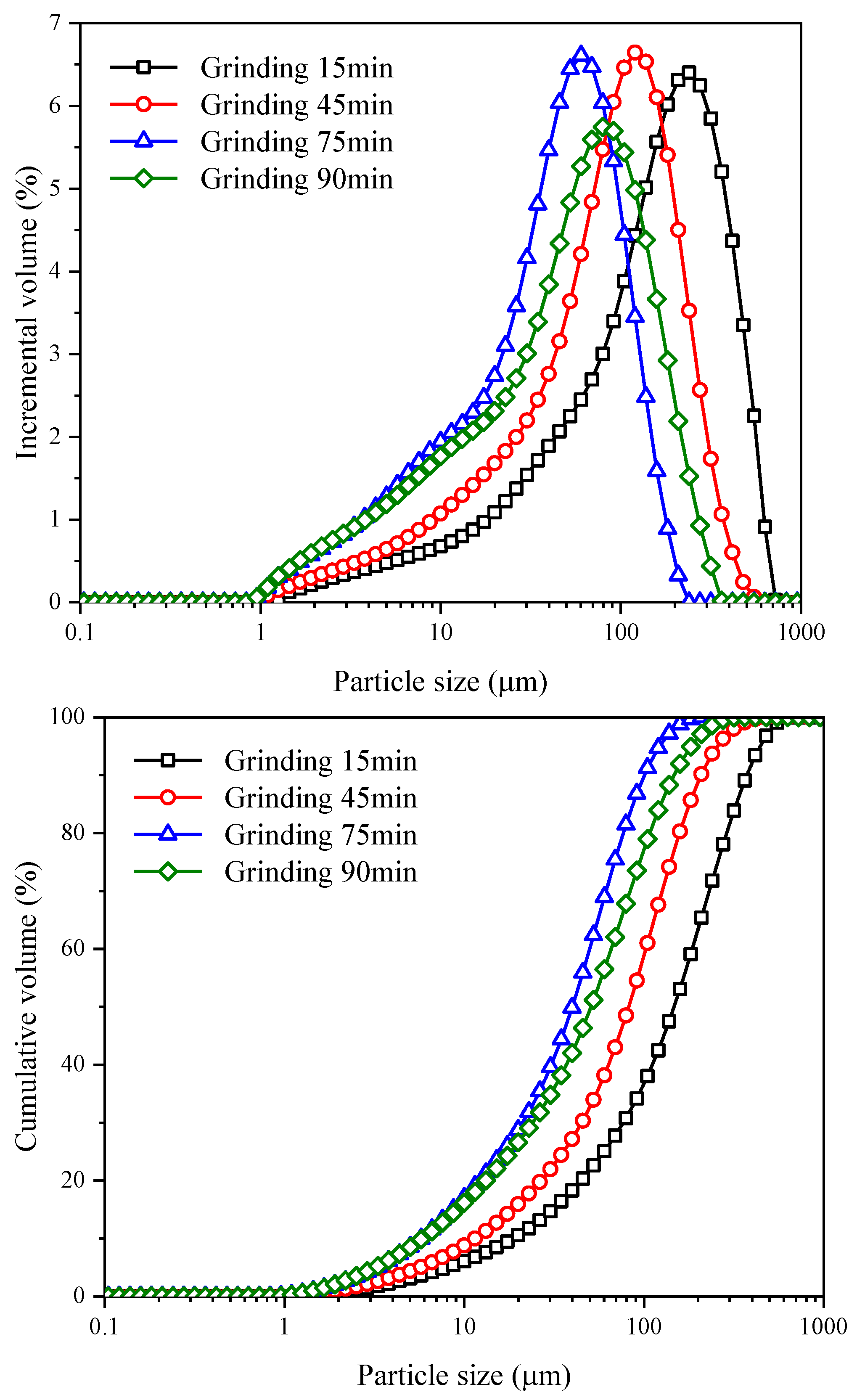

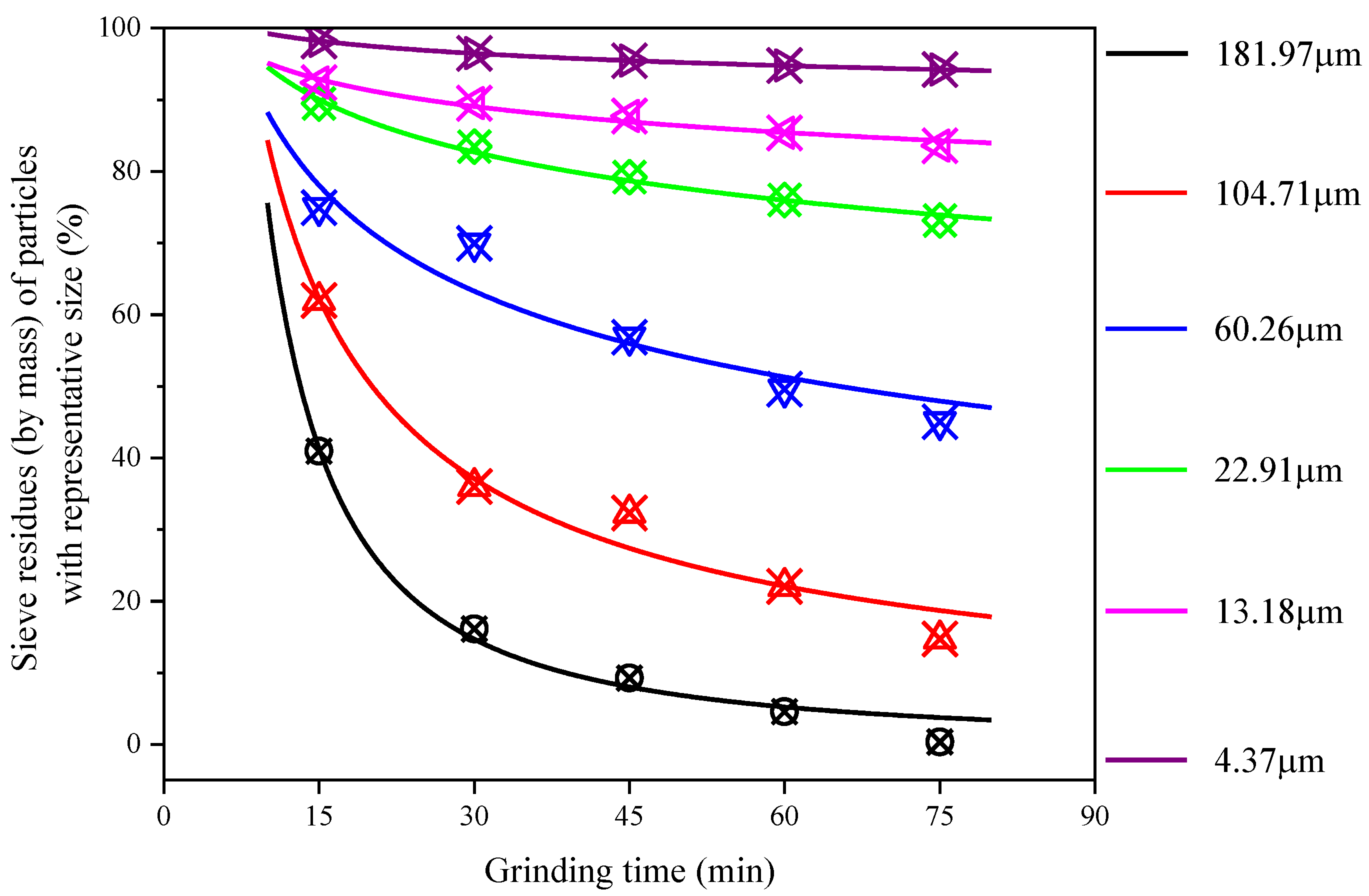

3.1.1. PSD Characteristics

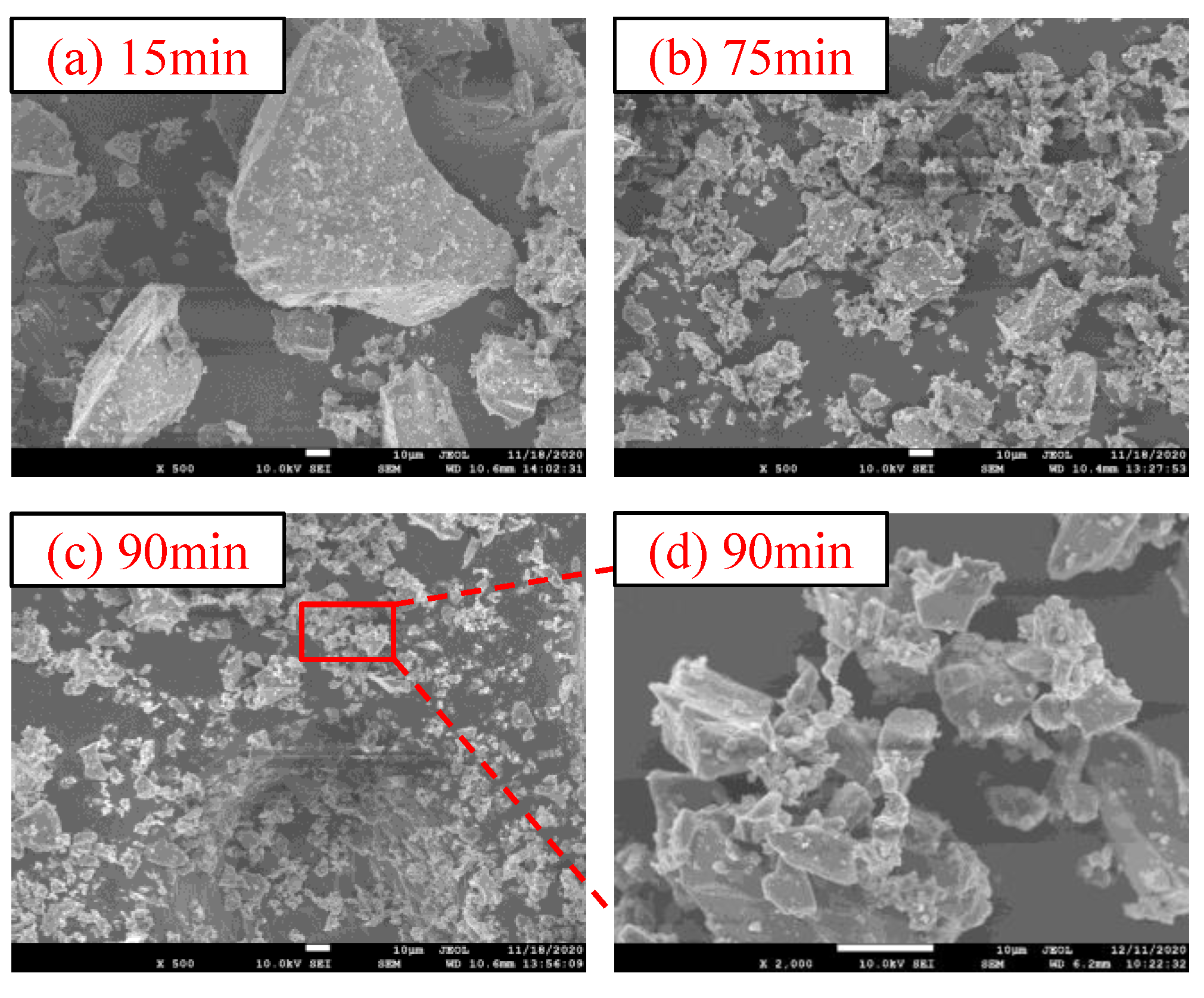

3.1.2. Microstructure Characteristics

- (1)

- Particle stress refinement stage: Due to the high-speed operation of the grinding ball in the ball mill, the CGS particles are subjected to the collision stress of the grinding ball, and the particles are cracked and refined under impact. At this stage, the SSA of the CGS is linear with the grinding time. Since the whole process belongs to sealed grinding, a large amount of internal energy is generated during the operation of the system, which leads to the decline of the crystallization degree of the CGS particle crystal, the decrease in the bond energy of the internal chemical bond and the gradual increase in the surface-free energy in the system.

- (2)

- Stable stage: In this stage, the CGS gradually tends to the grinding limit, and the crystallization degree, chemical bond energy and surface free energy of CGS particles gradually tend to be stable.

- (3)

- Agglomeration stage: At this stage, due to the high surface free energy of CGS particles, they are more active and absorb a certain amount of water from the surrounding environment, forming a hydroxyl layer on the surface. The formation of hydroxyl layer reduces the electrostatic repulsion effect due to the relaxation phenomenon on the particle surface, and the formation of van der Waals force and hydrogen bond between hydroxyl groups leads to the agglomeration of CGS particles. After that, continuing the mechanical grinding of CGS leads the particle state gradually into reversible equilibrium.

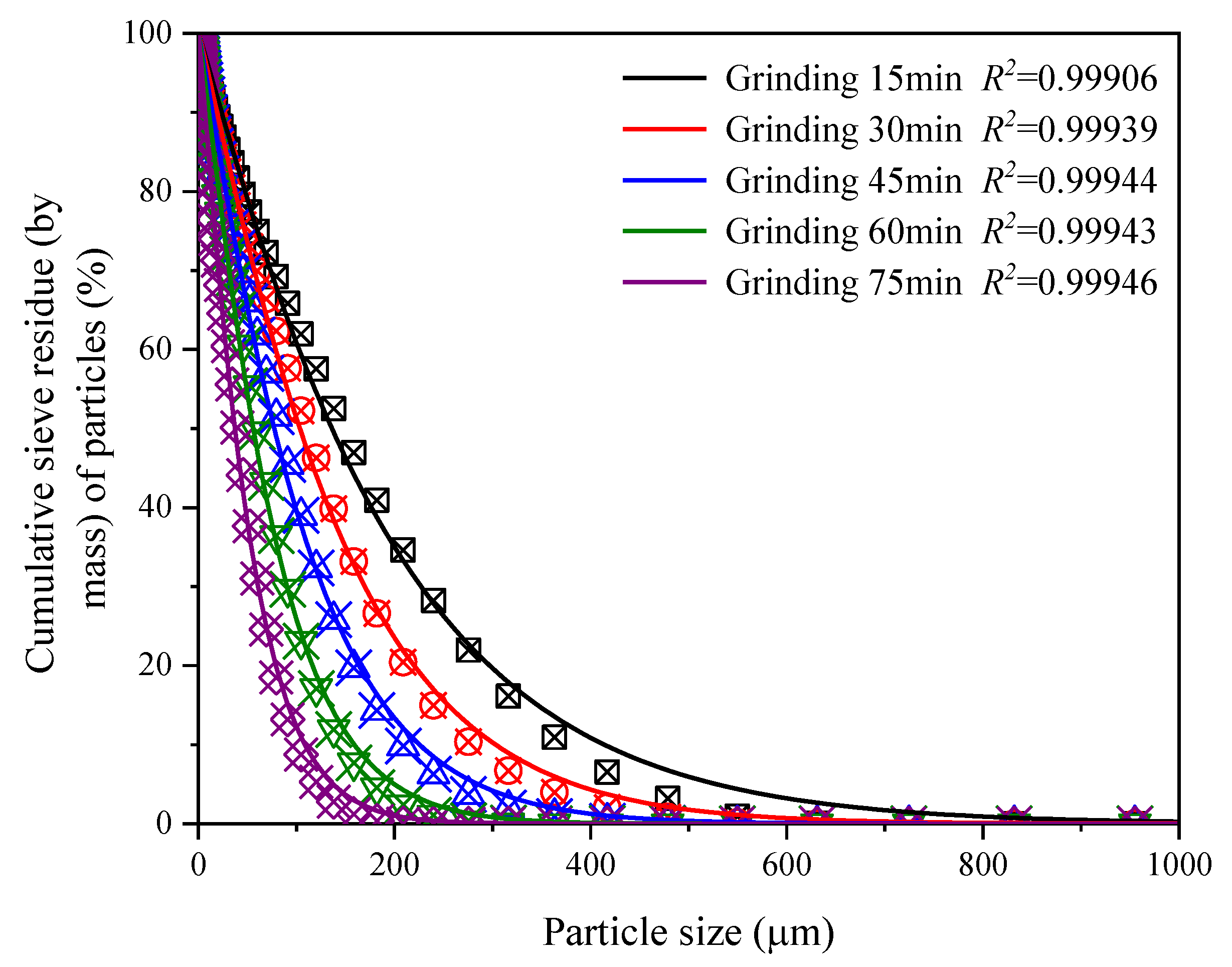

3.2. Grinding Kinetics and RRB Model of CGS

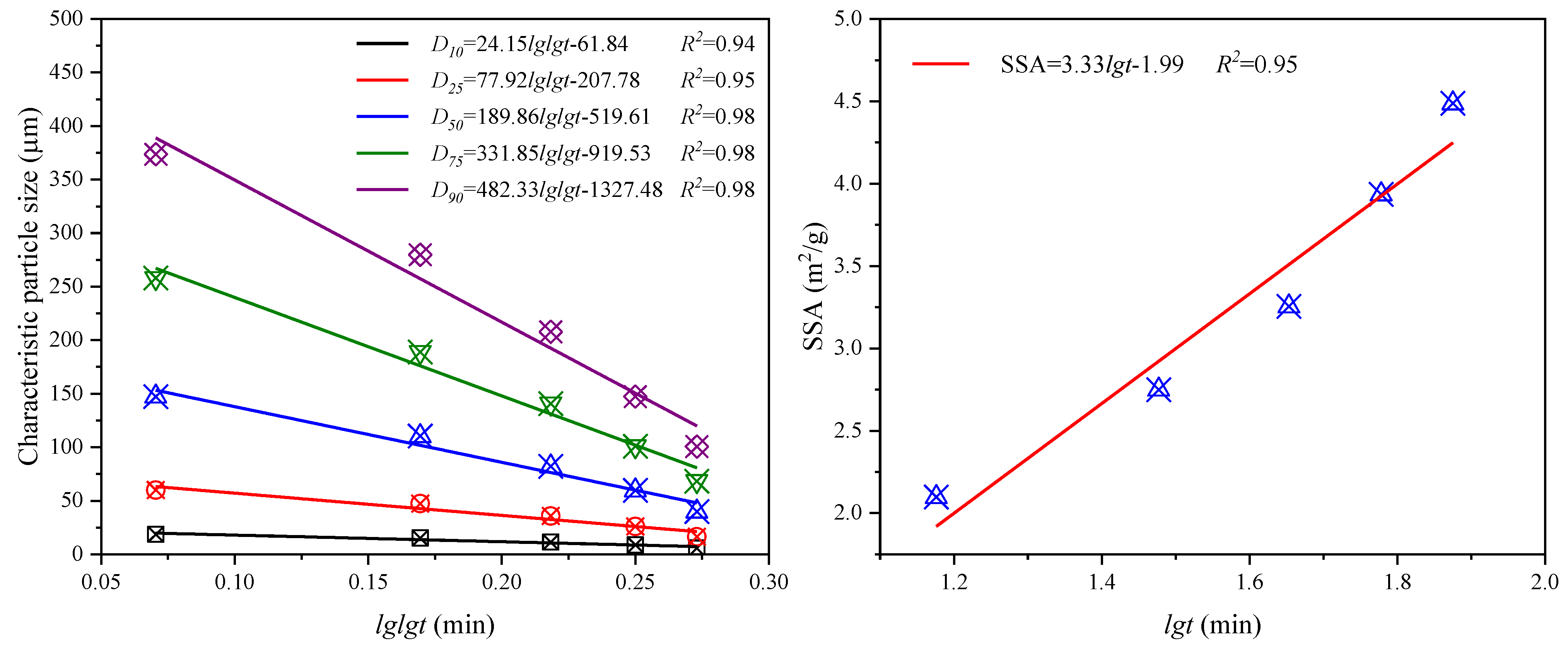

3.3. Characteristic Particle Size and SSA of CGS with Different Grinding Time

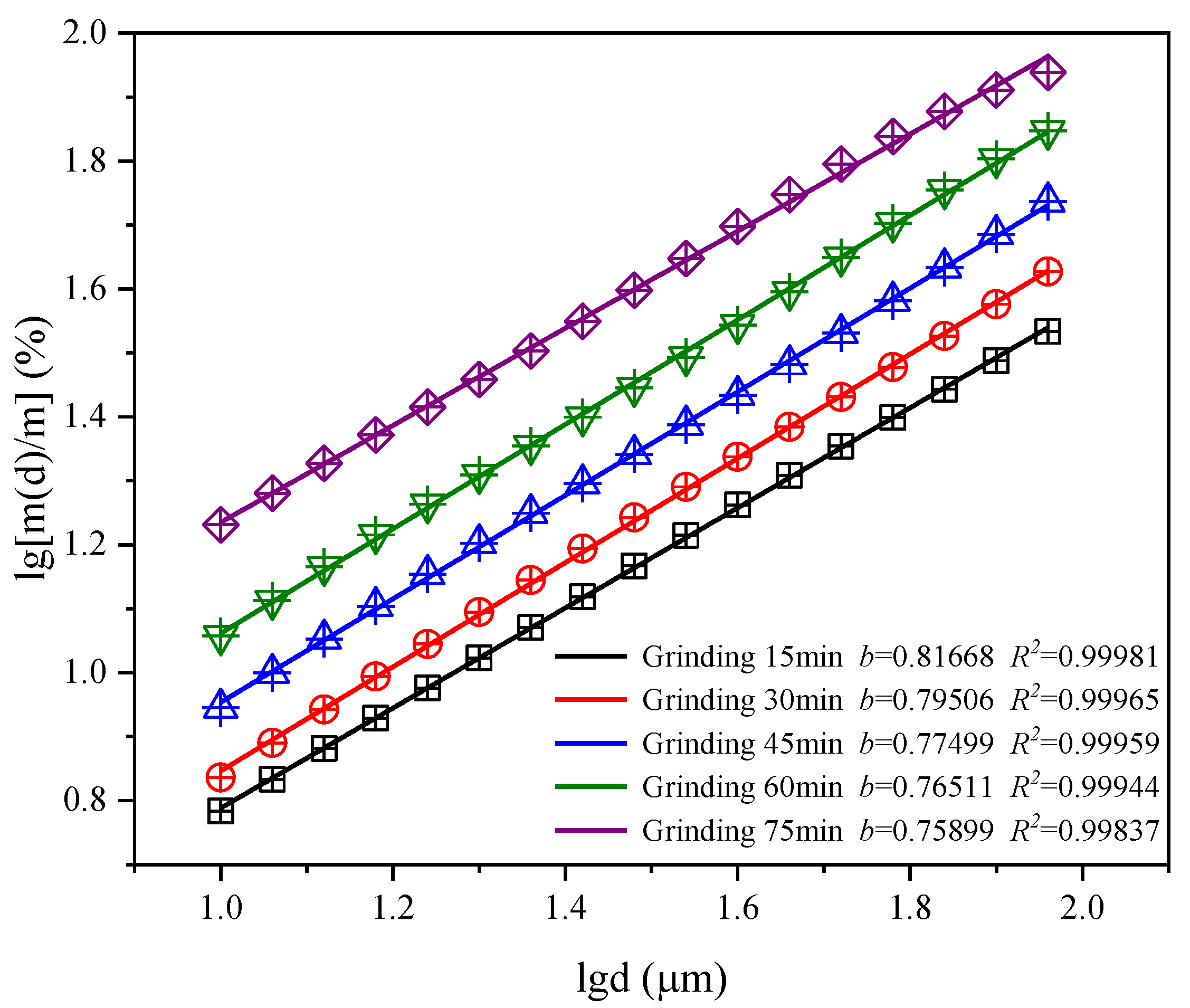

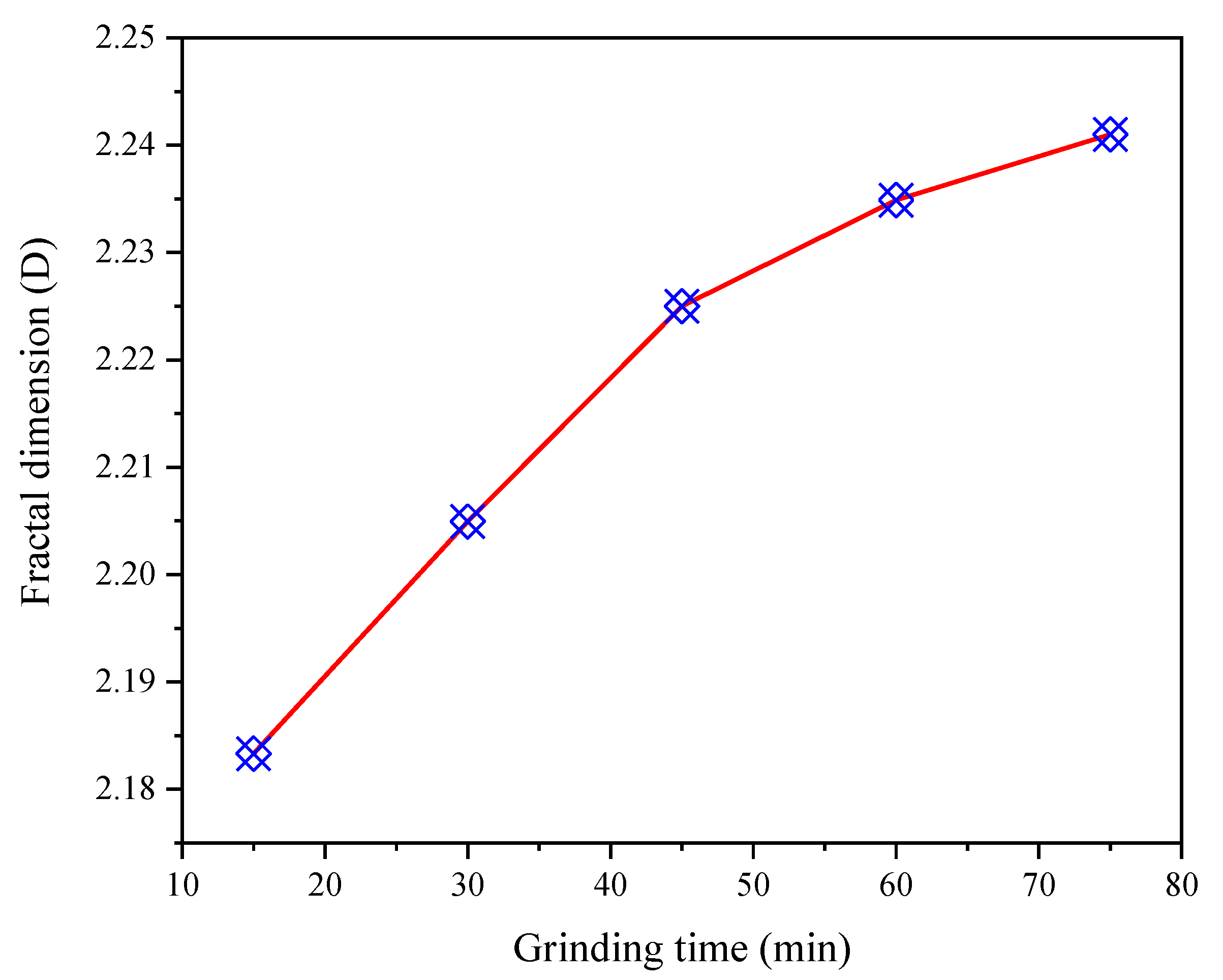

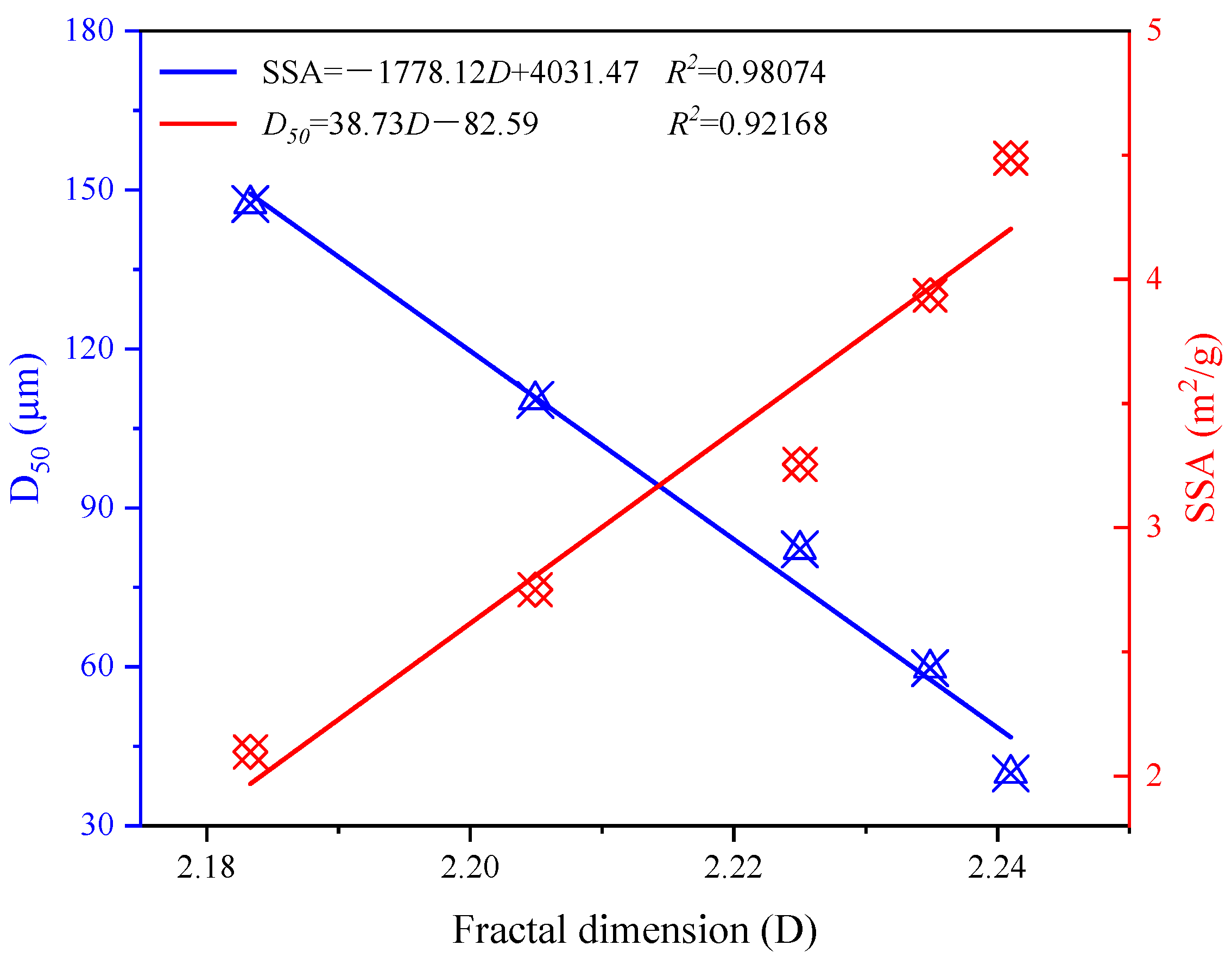

3.4. Particle Size Fractal Dimension of CGS with Different Grinding Time

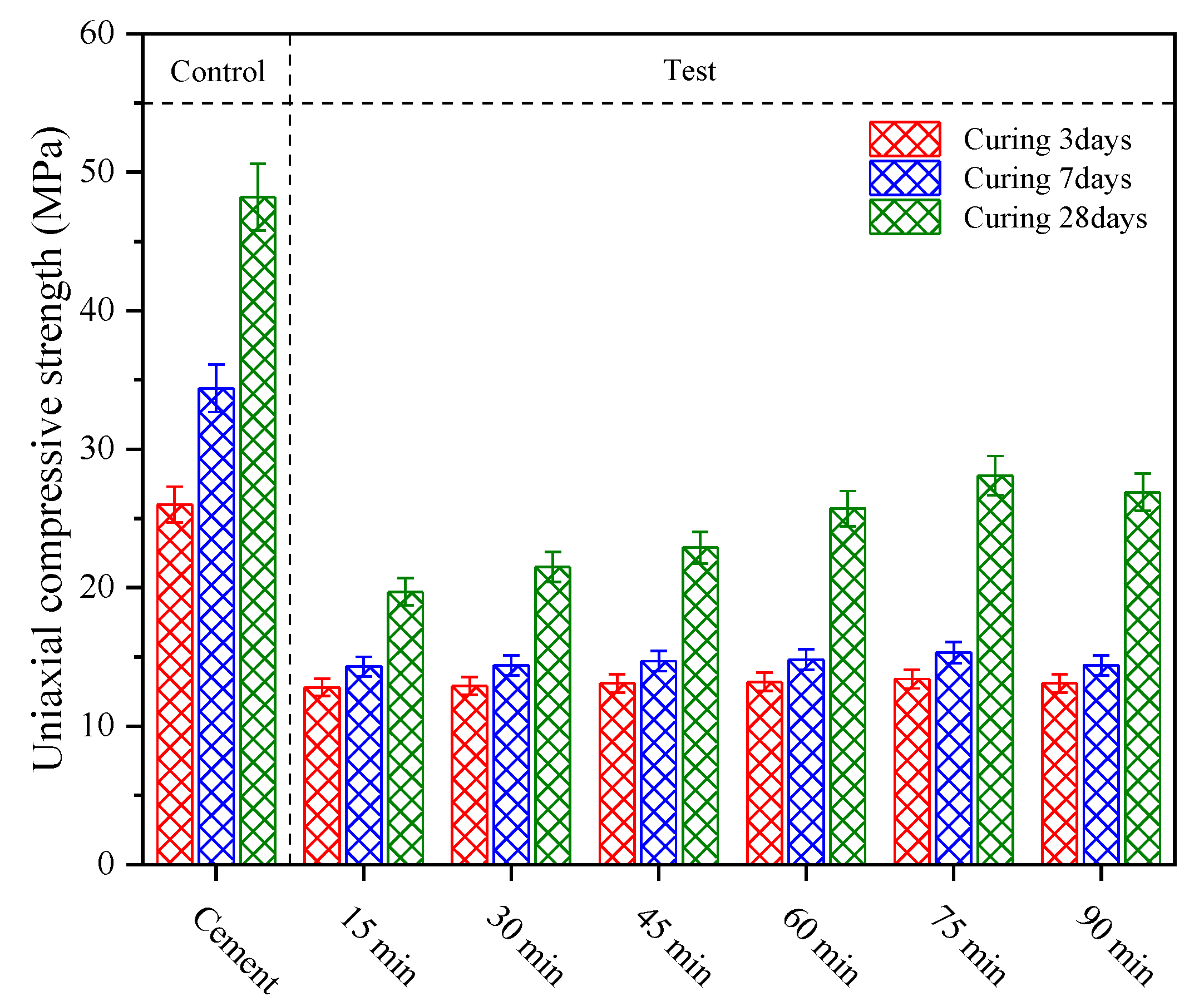

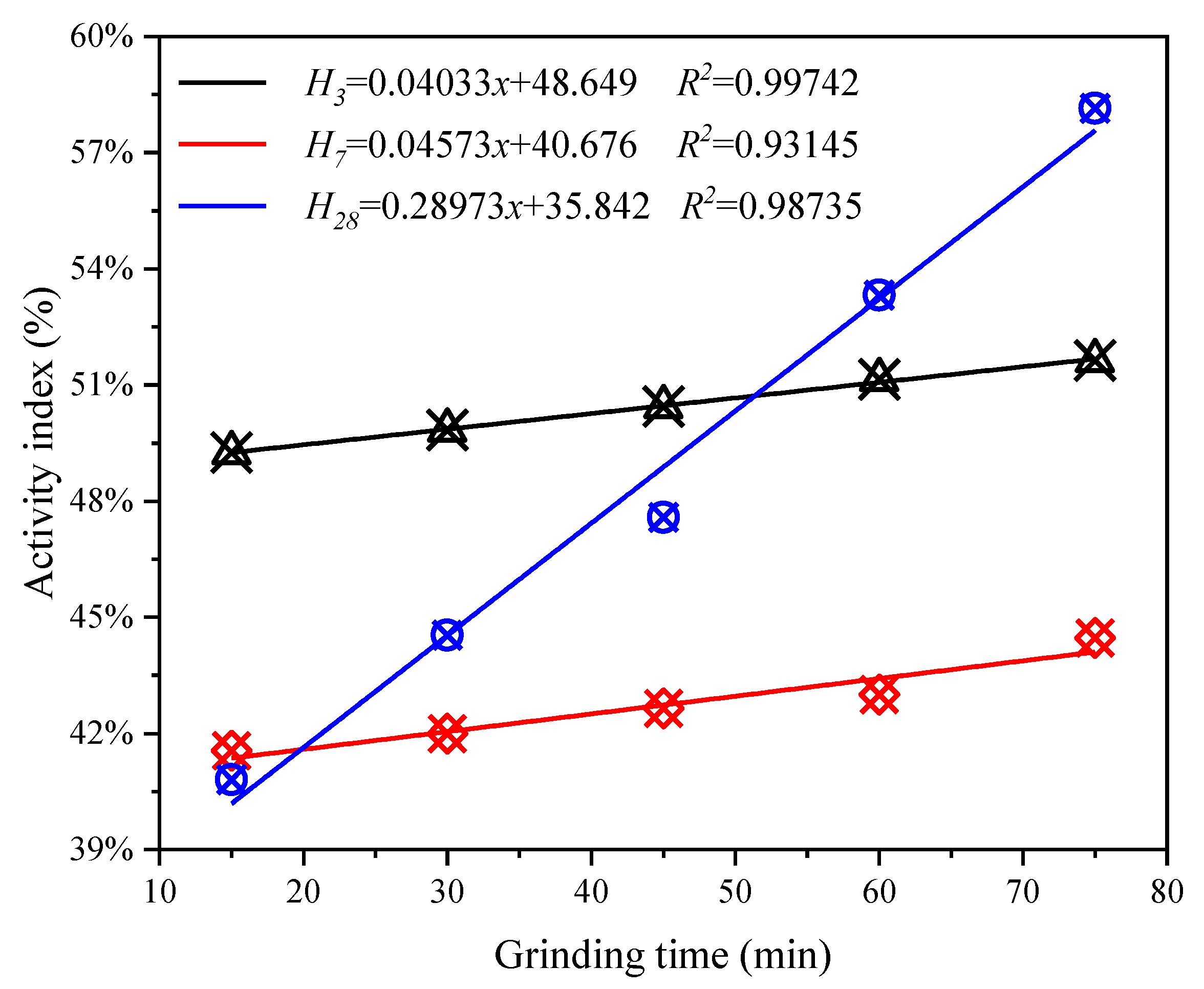

3.5. Strength Activity Index of CGS with Different Grinding Time

4. Conclusions

- (1)

- The results of PSD and microstructure of CGS by mechanical grinding show that with the increase in grinding time, the PSD of CGS is gradually concentrated, and the internal Si–O bond and water molecular structure are gradually destroyed. When the grinding time is more than 75 min, the hydroxyl layer will be formed on the surface of CGS particles. Van der Waals force and the hydrogen bond between hydroxyl groups will lead to “agglomeration phenomenon” of particles.

- (2)

- The mechanical grinding process of CGS can be quantitatively described by Divas–Aliavden grinding kinetics. The grinding efficiency of coarse particles is relatively high, and with the increase in grinding time, the grinding efficiency of coarse and fine particles gradually decreases and tends to zero. The PSD of CGS has a strong correlation with RRB model. With the increase in grinding time, the parameter particle size d* decreases and the distribution index n increases, indicating that the PSD of CGS tends to be concentrated.

- (3)

- With the increase in grinding time, the characteristic particle size of CGS gradually decreases, and the SSA gradually increases. Moreover, the characteristic particle size and SSA of CGS have a good linear relationship with the double logarithm and logarithm of the grinding time, respectively.

- (4)

- The PSD of CGS has obvious fractal characteristics. With the increase in grinding time, the fractal dimension of CGS particles increases gradually, which increases the difficulty of grinding. The fractal dimension has a good linear positive correlation with D50 and a good linear negative correlation with SSA.

- (5)

- The grinding time has a linear positive correlation with the strength activity index at different curing ages, which mainly affects the later strength activity index. The number of CGS particles at 20–30 μm and 10–20 μm has the greatest impact on the early and late strength activity indexes, respectively. Therefore, considering the economic and technical aspects, it is recommended that the optimal mechanical grinding time of CGS is 75 min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Miao, X.; Qian, M. Research on Green Mining of Coal Resources in China: Current Status and Future Prospects. J. Min. Saf. Eng. 2009, 26, 1–14. [Google Scholar]

- Huang, J.; Fang, Y.; Wang, Y. Development and progress of modern coal gasification technology. J. Fuel Chem. Technol. 2002, 30, 385–391. [Google Scholar]

- Wang, F.; Yu, G.; Gong, X.; Liu, H.; Wang, Y.; Liang, Q. Research and development of large-scale coal gasification technology. Chem. Ind. Eng. Prog. 2009, 2, 173–180. [Google Scholar]

- Qu, H.S.; Suo, Y.L.; Liu, L.; Zhou, W.W.; Yang, P.; Zhang, C.X. Research on preparation and properties of modified coal gasification slag-based filling materials for mines. J. China Coal Soc. 2022, 47, 1958–1973. [Google Scholar]

- Zhang, X. The Coal Clean Exploitation Efficiently-Coal Gasification Technology. Coal Chem. Ind. 2007, 30, 23–25. [Google Scholar]

- Xin, J.; Liu, L.; Xu, L.; Wang, J.; Yang, P.; Qu, H. A preliminary study of aeolian sand-cement-modified gasification slag-paste backfill: Fluidity, microstructure, and leaching risks. Sci. Total Environ. 2022, 830, 154766. [Google Scholar] [CrossRef] [PubMed]

- Shang, X.F.; Ma, J.L.; Zhang, J.; Xu, D.Y.; Zhang, L.Y.; Zhou, J.Q.; Duan, X.Y.; Zhang, X.M. Research status and prospects of utilization technologies of slag from coal gasification. J. Environ. Eng. Technol. 2017, 7, 712–717. [Google Scholar]

- Zhao, Y.; Wu, H.; Cai, X.; Zhuo, J.; Lai, S.; Liu, H.; Jing, Y.; Yuan, W. Basic characteristics of coal gasification residual. Clean Coal Technol. 2015, 21, 110–113. [Google Scholar]

- Fu, F.; Ma, M.; Shen, W.; Cheng, Z.; Jiang, Y. Influence of Coal Gasification Slag on Strength and Microstructure of Portland Cement. Bull. Chin. Ceram. Soc. 2020, 39, 2523–2527. [Google Scholar]

- Yin, H.; Tang, Y.; Ren, Y.; Zhang, J. Synthesis of Ca-α-Sialon-SiC Multiphase Ceramics Using Gasification Slag. J. Chin. Ceram. Soc. 2011, 39, 233–238. [Google Scholar]

- Sheng, Y.; Hu, P.; Ji, X.; Lu, Z.; Xin, D.; Long, Y. Study on the effect of pulverizing time on the properties of coal gasification slag composite cementitious material. Appl. Chem. Ind. 2020, 42, 137–141. [Google Scholar]

- Guo, Z.; Yang, W.; Zhu, X.; Cheng, B.; Li, S. Activity and Mechanical Properties of Coal Gasification Slag Admixture with Different Specific Surface Area. Bull. Chin. Ceram. Soc. 2020, 39, 8. [Google Scholar]

- Wu, F.; Li, H.; Yang, K. Effects of Mechanical Activation on Physical and Chemical Characteristics of Coal-Gasification Slag. Coatings 2021, 11, 902. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Liao, S.; Huang, Y. Grinding kinetics of waste glass powder and its composite effect as pozzolanic admixture in cement concrete. Constr. Build. Mater. 2020, 239, 117876. [Google Scholar] [CrossRef]

- Cui, X.; Di, Y. Fractal Research on the Particle Size Distribution of Molybdenum Tailings. Min. Res. Dev. 2016, 36, 32–35. [Google Scholar]

- Cui, X.; Leng, X.; Nan, N.; Liu, X.; Zhang, M. Mechanical Activation Effect on the Performance of Steel Slag Particle Size Distribution and Cementitious Properties. Bull. Chin. Ceram. Soc. 2018, 37, 3821–3826. [Google Scholar]

- Yang, S.; Cheng, Y.; Tong, B.; Zhang, J.; Sun, X. Effects of Mechanical Force on Particle Size and Activity of Low-silicon Gold Tailings. J. Kunming Univ. Sci. Technol. (Nat. Sci.) 2019, 4, 5. [Google Scholar]

- Wang, Y.; Ke, G.; Song, B.; Li, Z. Influence of Steam turbine and Governor on Low Frequency Oscillation of Resonance Mechanism and Improvement Measures. Water Resour. Power 2014, 10, 102–104. [Google Scholar]

- Stefania, G.; Grzegorz, L. Effect of content and particle size distribution of high-calcium fly ash on the rheological properties of cement pastes. Cem. Concr. Res. 1997, 27, 907–916. [Google Scholar]

- Basim, G.B.; Khalili, M. Particle size analysis on wide size distribution powders; effect of sampling and characterization technique. Adv. Powder Technol. 2015, 26, 200–207. [Google Scholar] [CrossRef]

- He, T.S.; Zhao, X.G.; Zhao, S.Y. Fractal Characteristics of Converter Steel-slag Particle Size Distribution. Bull. Chin. Ceram. Soc. 2013, 32, 2346–2351. [Google Scholar]

- Liu, S.; Li, Q.; Xie, G.; Li, L.; Xiao, H. Effect of grinding time on the particle characteristics of glass powder. Powder Technol. 2016, 295, 133–141. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Dou, J. Grey Connection Analysis between Particle Size Distribution of Slag Powder and Its Activity Coefficient. J. Build. Mater. 2001, 4, 44–48. [Google Scholar]

- Zhou, L.; Wang, Q. Grey System Study Between Particle Size Distribution of Fly Ash and Its Activity. China Powder Sci. Technol. 2009, 15, 68–71. [Google Scholar]

- Li, Z.; Zhang, Y.; Zhao, H.; Chen, H.; He, R. Structure characteristics and composition of hydration products of coal gasification slag mixed cement and lime. Constr. Build. Mater. 2019, 213, 265–274. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Song, J. Study on the grinding kinetics of copper tailing powder. Powder Technol. 2018, 330, 105–113. [Google Scholar] [CrossRef]

- Liu, S.; Shen, L.; Wang, Q.; Niu, F. Investigation on Crushing Kinetic Equation of Ball Milling of Quartz Powder. Adv. Mater. Res. 2010, 156–157, 812–816. [Google Scholar] [CrossRef]

- Zeng, F. Grinding kinetic equation of coal characterized by particle size. J. China Coal Soc. 2000, 25, 20188787. [Google Scholar]

- Kjamarani, K.M.; Ian, M.C. Characterization of particle size based on fine and coarse fractions. Powder Technol. 1997, 93, 101–108. [Google Scholar] [CrossRef]

- González-Tello, P.; Camacho, F.; Vicaria, J.M.; González, P.A. A modified Nukiyama–Tanasawa distribution function and a Rosin–Rammler model for the particle-size-distribution analysis. Powder Technol. Lausanne 2008, 186, 278–281. [Google Scholar] [CrossRef]

- Yu, L. Survey and Analysis of the Cooper Tailing Resources in China. Met. Mine 2009, 39, 179. [Google Scholar]

- Menéndez-Aguado, J.M.; PenA-Carpio, E.; Sierra, C. Particle size distribution fitting of surface detrital sediment using the Swrebec function. J. Soils Sediments 2015, 15, 2004–2011. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, J.; Wu, Z. Study on the Factors Affecting Grinding Result in Preparation of Magnetic Fe3O4 Nanoparticles by Mechanical Milling. Mater. Rep. 2015, 29, 16–18. [Google Scholar]

- Wang, X.; Chen, Y.; Zhou, H.; Yang, N. Changes of Silicate Tetrahedron of Fly Ash in Mechanical Grinding. J. Chin. Ceram. Soc. 2001, 4, 93–95. [Google Scholar]

- Li, M. Research on the Hydration Mechanism and Development of Early Strength Filling Materials Base on the Low Active Slag. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Yu, K.; Zheng, Z. Fractal Characteristics on Granularity Distribution of Powder. Chin. J. Mater. Res. 1995, 9, 539–542. [Google Scholar]

- Ozao, R.; Ochiai, M. Thermal analysis and self-similarity law in particle size distribution of powder samples. Thermochim. Acta 1992, 198, 279–287. [Google Scholar] [CrossRef]

- Ibaseta, N.; Biscans, B. Fractal dimension of fumed silica: Comparison of light scattering and electron microscope methods. Powder Technol. 2010, 203, 206–210. [Google Scholar] [CrossRef]

- Cannon, J.W.; Mandelbrot, B.B. The Fractal Geometry of Nature. Am. Math. Mon. 1984, 91, 594. [Google Scholar] [CrossRef]

- Negahban, E.; Bagheri, A.; Sanjayan, J. Pore gradation effect on Portland cement and geopolymer concretes. Cem. Concr. Compos. 2021, 122, 104141. [Google Scholar] [CrossRef]

- Rumman, R.; Bari, M.S.; Manzur, T.; Kamal, M.R.; Noor, M.A. A Durable Concrete Mix Design Approach using Combined Aggregate Gradation Bands and Rice Husk Ash Based Blended Cement. J. Build. Eng. 2020, 30, 101303. [Google Scholar] [CrossRef]

- Jiao, W.; Sha, A.; Liu, Z.; Li, S. Influence of Fineness Levels and Dosages of Light-Burned Dolomite on Portland Cement Performance. Materials 2022, 15, 5798. [Google Scholar] [CrossRef] [PubMed]

| Testing Material | Chemical Composition (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | Na2O | CaO | SrO | SO3 | K2O | MgO | TiO2 | Other | |

| ISO standard sand | +96 | - | - | - | - | - | - | - | - | - | −4 |

| CGS | 30.94 | 11.01 | 23.22 | 5.58 | 17.19 | 3.28 | 2.02 | 0.78 | 0.83 | 0.61 | 4.54 |

| Cement | 19.19 | 4.50 | 3.33 | 0.18 | 64.13 | 0.03 | 2.40 | 0.40 | 1.82 | 0.20 | 3.82 |

| Representative Particle Size | 15 min | 30 min | 45 min | 60 min | 75 min |

|---|---|---|---|---|---|

| 181.97 μm | 40.93 | 16.1 | 9.27 | 4.55 | 0.33 |

| 104.71 μm | 61.97 | 36.02 | 32.29 | 22.06 | 14.74 |

| 60.26 μm | 74.94 | 69.94 | 56.83 | 49.58 | 45.03 |

| 22.91 μm | 89.48 | 83.45 | 79.18 | 76.01 | 73.16 |

| 13.18 μm | 92.39 | 89.53 | 87.71 | 85.37 | 83.59 |

| 4.37 μm | 98.22 | 96.49 | 95.44 | 94.76 | 94.23 |

| Representative Particle Size/μm | Kinetic Equation | R2 |

|---|---|---|

| 181.97 | 0.98463 | |

| 104.71 | 0.96857 | |

| 60.26 | 0.89987 | |

| 22.91 | 0.98981 | |

| 13.18 | 0.96745 | |

| 4.37 | 0.99988 |

| Grinding Time/min | n | d*/μm | ||

|---|---|---|---|---|

| Fitting Values | Measured Values | Error/% | ||

| 15 | 1.08 | 191.31 | 199.49 | 4.1 |

| 30 | 1.11 | 143.77 | 147.51 | 2.5 |

| 45 | 1.12 | 107.26 | 109.66 | 2.2 |

| 60 | 1.15 | 77.04 | 78.88 | 2.3 |

| 75 | 1.17 | 51.73 | 53.12 | 2.6 |

| Characteristic Particle Size | 15 min | 30 min | 45 min | 60 min | 75 min |

|---|---|---|---|---|---|

| D10/μm | 18.72 | 15.31 | 11.52 | 8.76 | 5.78 |

| D25/μm | 59.99 | 47.44 | 35.77 | 26.08 | 16.45 |

| D50/μm | 147.37 | 110.38 | 82.12 | 59.72 | 39.87 |

| D75/μm | 257.99 | 188.92 | 140.86 | 100.85 | 68.39 |

| D90/μm | 373.61 | 279.84 | 207.71 | 147.37 | 100.62 |

| SSA/m2·g−1 | 2.0973 | 2.7501 | 3.2548 | 3.9356 | 4.4874 |

| Curing Age/Day | Particle Size Range/μm | |||||

|---|---|---|---|---|---|---|

| 0–3 | 3–10 | 10–20 | 20–30 | 30–60 | +60 | |

| 3 | 0.597 | 0.578 | 0.603 | 0.622 | 0.546 | 0.576 |

| 7 | 0.606 | 0.587 | 0.614 | 0.632 | 0.555 | 0.587 |

| 28 | 0.632 | 0.660 | 0.706 | 0.680 | 0.630 | 0.503 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.; Xie, G.; Liu, L.; Yang, P.; Qu, H.; Zhang, C. Influence of Mechanical Grinding on Particle Characteristics of Coal Gasification Slag. Materials 2022, 15, 6033. https://doi.org/10.3390/ma15176033

Zhu M, Xie G, Liu L, Yang P, Qu H, Zhang C. Influence of Mechanical Grinding on Particle Characteristics of Coal Gasification Slag. Materials. 2022; 15(17):6033. https://doi.org/10.3390/ma15176033

Chicago/Turabian StyleZhu, Mengbo, Geng Xie, Lang Liu, Pan Yang, Huisheng Qu, and Caixin Zhang. 2022. "Influence of Mechanical Grinding on Particle Characteristics of Coal Gasification Slag" Materials 15, no. 17: 6033. https://doi.org/10.3390/ma15176033

APA StyleZhu, M., Xie, G., Liu, L., Yang, P., Qu, H., & Zhang, C. (2022). Influence of Mechanical Grinding on Particle Characteristics of Coal Gasification Slag. Materials, 15(17), 6033. https://doi.org/10.3390/ma15176033