Shielding Properties of Epoxy Matrix Composites Reinforced with MgO Micro- and Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

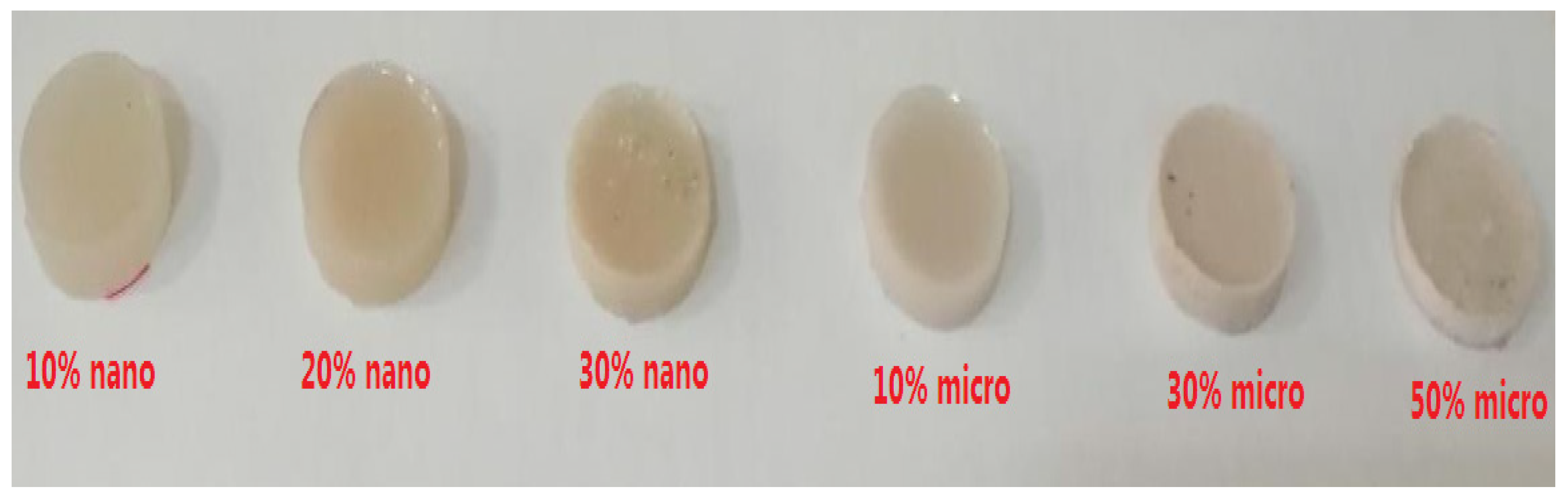

2.1. Preparation

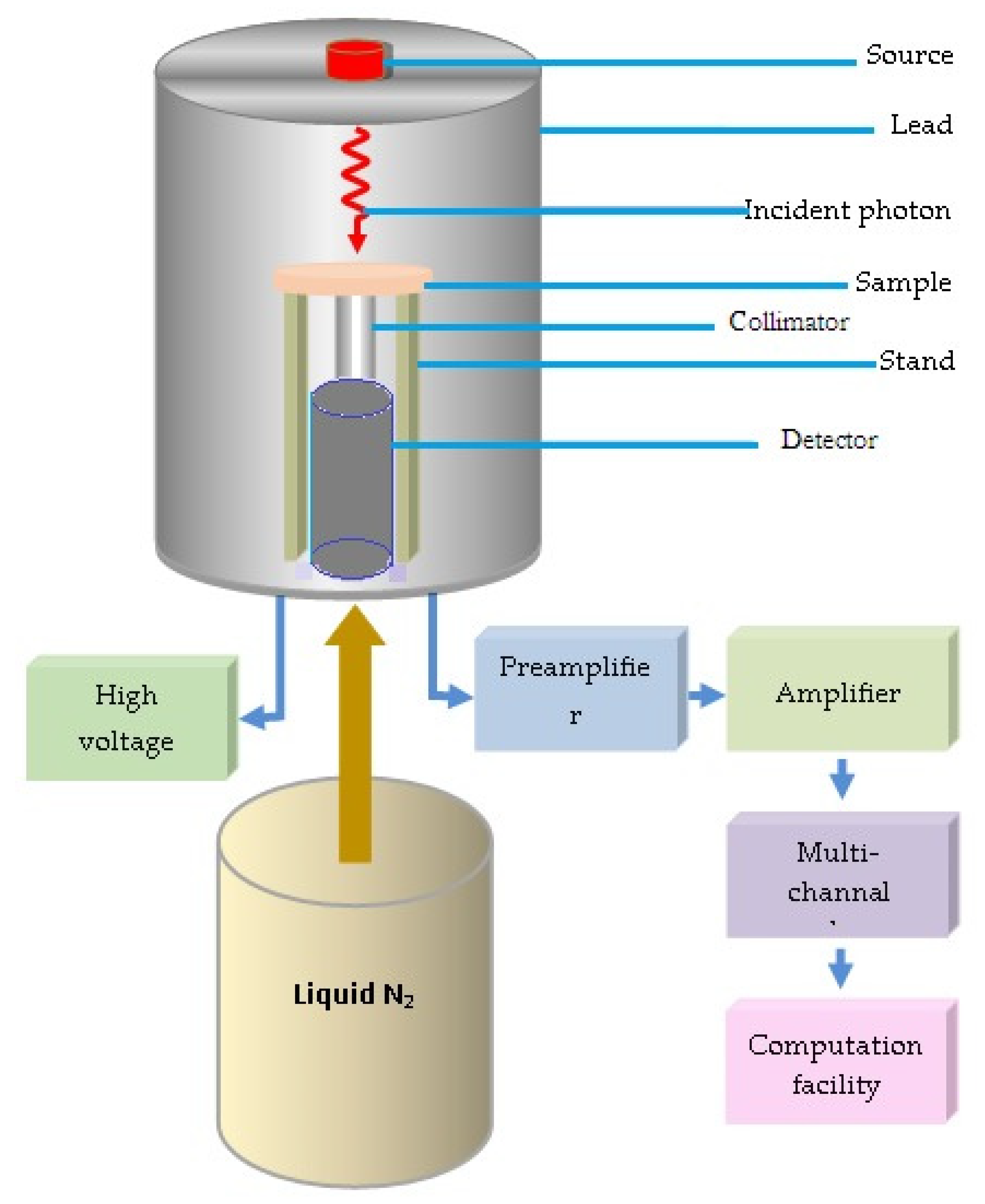

2.2. Measurements

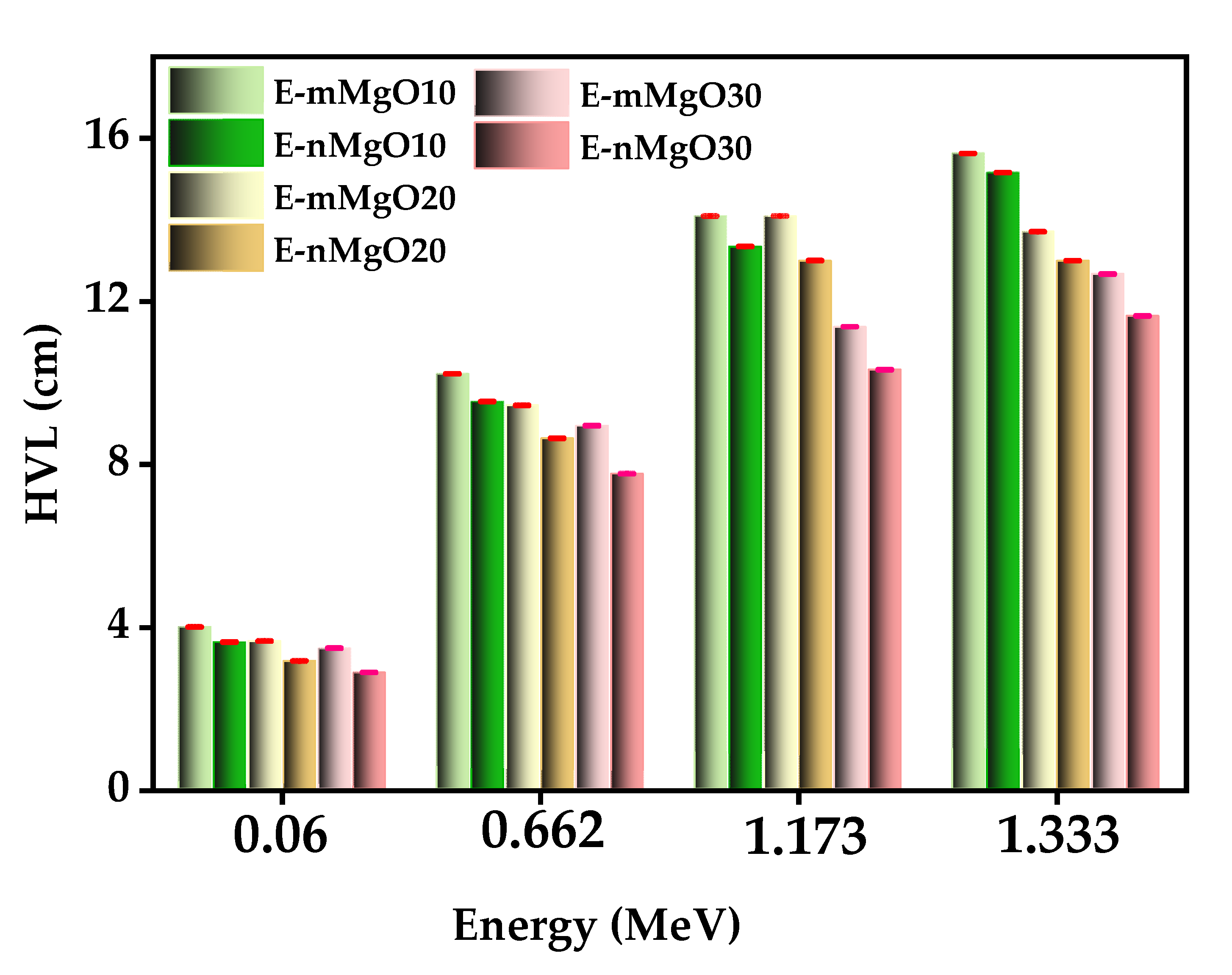

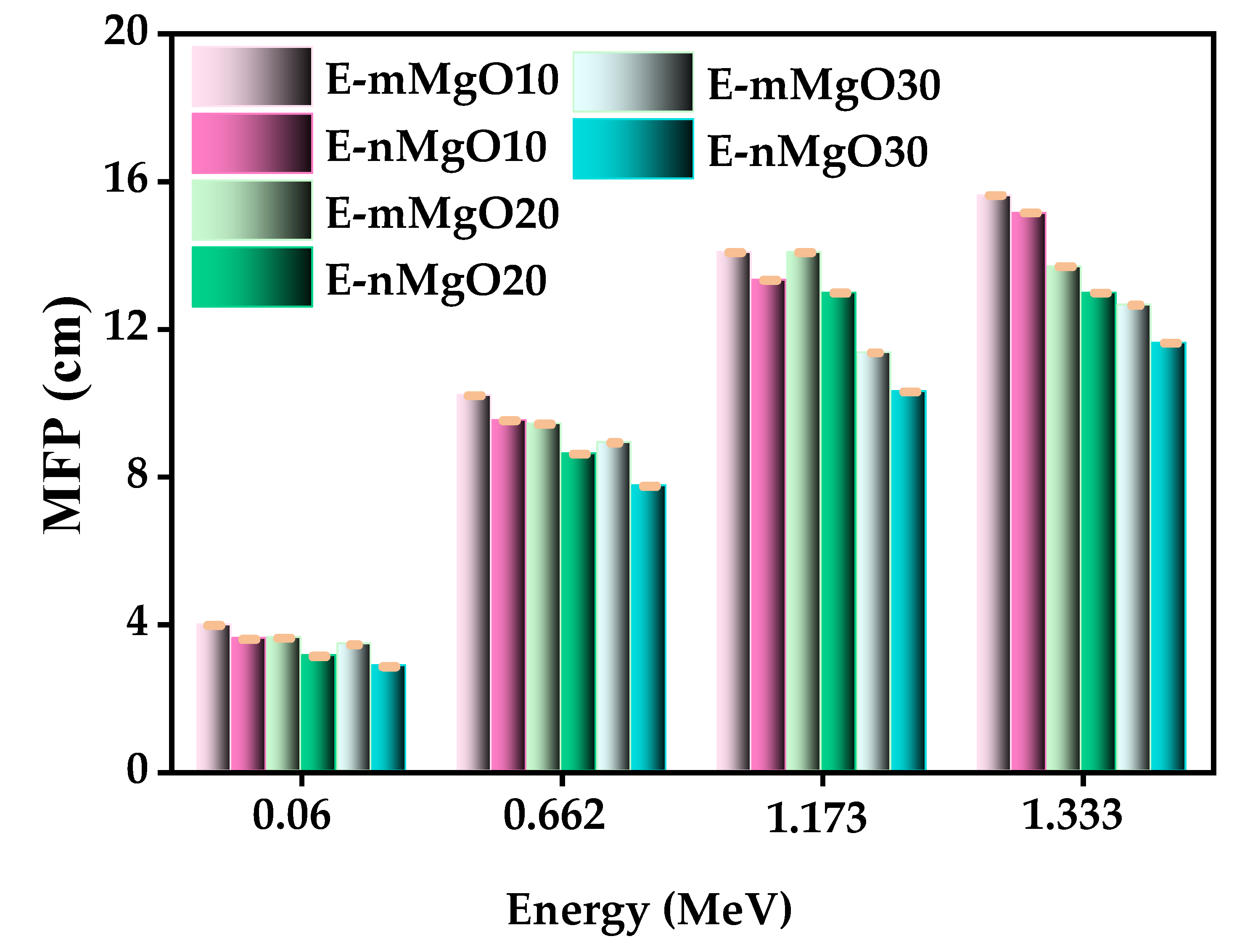

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, M.; Xue, X.; Yang, H.; Li, Z. Highly Cost-effective shielding composite made from vanadium slag and boron-rich slag and its properties. Radiat. Phys. Chem. 2017, 141, 239–244. [Google Scholar] [CrossRef]

- Kamislioglu, M. An investigation into gamma radiation shielding parameters of the (Al:Si) and (Al+Na):Si-doped international simple glasses (ISG) used in nuclear waste management, deploying Phy-X/PSD and SRIM software. J. Mater. Sci. Mater. 2021, 32, 12690–12704. [Google Scholar] [CrossRef]

- Naseer, K.A.; Sathiyapriya, G.; Marimuthu, K.; Piotrowski, T.; Alqahtani, M.S. Yousef, Optical, elastic, and neutron shielding studies of Nb2O5 varied Dy3+ doped barium-borate glasses. Optik 2022, 251, 168436. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Liu, D. A novel comprehensive utilization of vanadium slag: As gamma ray shielding material. J. Hazard. Mater. 2016, 318, 751–757. [Google Scholar] [CrossRef]

- Al-Yousef, H.A.; Alotiby, M.; Hanfi, M.Y.; Alotaibi, B.M.; Mahmoud, K.A.; Sayyed, M.I.; Al-Hadeethi, Y. Effect of the Fe2O3 addition on the elastic and gamma-ray shielding features of bismuth sodium-borate glass system. J. Mater. Sci. Mater. Electron. 2021, 32, 6942–6954. [Google Scholar] [CrossRef]

- Araz, A.; Kavaz, E.; Durak, R. Neutron and photon shielding competences of aluminum open-cell foams filled with different epoxy mixtures: An experimental study. Radiat. Phys. Chem. 2021, 182, 109382. [Google Scholar] [CrossRef]

- Albarzan, B.; Hanfi, M.Y.; Almuqrin, A.H.; Sayyed, M.I.; Alsafi, H.M.; Mahmoud, K.A. The Influence of Titanium Dioxide on Silicate-Based Glasses: An Evaluation of the Mechanical and Radiation Shielding Properties. Materials 2021, 14, 3414. [Google Scholar] [CrossRef]

- Kamislioglu, M. Research on the effects of bismuth borate glass system on nuclear radiation shielding parameters. Results Phys. 2021, 22, 103844. [Google Scholar] [CrossRef]

- Aldhuhaibat, M.J.R.; Amana, M.S.; Jubier, N.J.; Salim, A.A. Improved gamma radiation shielding traits of epoxy composites: Evaluation of mass attenuation coefficient, effective atomic and electron number. Radiat. Phys. Chem. 2021, 179, 109183. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Mousavi, S.M.; Faghihi, R.; Arjmand, M.; Sina, S.; Aman, A.M. Lead oxide-decorated graphene oxide/epoxy composite towards X-Ray radiation shielding. Radiat. Phys. Chem. 2018, 146, 77–85. [Google Scholar] [CrossRef]

- Canel, A.; Korkut, H.; Korkut, T. Improving neutron and gamma flexible shielding by adding medium-heavy metal powder to epoxy based composite materials. Radiat. Phys. Chem. 2019, 158, 13–16. [Google Scholar] [CrossRef]

- Zali, V.S.; Jahanbakhsh, O.; Ahadzadeh, I. Preparation and evaluation of gamma shielding properties of silicon-based composites doped with WO3 micro- and nanoparticles. Radiat. Phys. Chem. 2022, 197, 110150. [Google Scholar] [CrossRef]

- Alavian, H.; Samie, A.; Tavakoli-Anbaran, H. Experimental and Monte Carlo investigations of gamma ray transmission and buildup factors for inorganic nanoparticle/epoxy composites. Radiat. Phys. Chem. 2020, 174, 108960. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Y.; Liu, Y.; Fang, J.; Luan, W.; Yang, X.; Zhang, W. Preparation and characterization of tungsten/epoxy composites for c-rays radiation shielding. Nucl. Instrum. Methods Phys. Res. B 2015, 356–357, 88–93. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Zhang, G.; Yang, Z.; Li, M.; Zhang, Z. Radiation shielding property of structural polymer composite: Continuous basalt fiber reinforced epoxy matrix composite containing erbium oxide. Compos Sci. Technol. 2017, 143, 67–74. [Google Scholar] [CrossRef]

- Sahin, N.; Bozkurt, M.; Karabul, Y.; Kılıç, M.; Ozdemir, Z.G. Low cost radiation shielding material for low energy radiation applications: Epoxy/Yahyali Stone composites. Prog. Nucl. Energy 2021, 135, 103703. [Google Scholar] [CrossRef]

- El-Nahal, M.A.; Elsafi, M.; Sayyed, M.I.; Khandaker, M.U.; Osman, H.; Elesawy, B.H.; Saleh, I.H.; Abbas, M.I. Understanding the Effect of Introducing Micro- and Nanoparticle Bismuth Oxide (Bi2O3) on the Gamma Ray Shielding Performance of Novel Concrete. Materials 2021, 14, 6487. [Google Scholar] [CrossRef]

- Azman, N.Z.N.; Siddiqui, S.A.; Low, I.M. Characterisation of micro-sized and nano-sized tungsten oxide-epoxy composites for radiation shielding of diagnostic X-rays. Mater. Sci. Eng. C 2013, 33, 4952–4957. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Elsafi, M.; Almutiri, M.N.; Mahmoud, R.M.M.; Alzahrani, J.S.; Sayyed, M.I.; Abbas, M.I. Enhancement of Bentonite Materials with Cement for Gamma-Ray Shielding Capability. Materials 2021, 14, 4697. [Google Scholar] [CrossRef]

- Karabul, Y.; Içelli, O. The assessment of usage of epoxy based micro and nano-structured composites enriched with Bi2O3 and WO3 particles for radiation shielding. Results Phys. 2021, 26, 104423. [Google Scholar] [CrossRef]

- Elsafi, M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Khandaker, M.U.; Alsubaie, A.; Almalki, A.S.A.; Abbas, M.I.; El-Khatib, A.M. Enhancement of Ceramics Based Red-Clay by Bulk and Nano Metal Oxides for Photon Shielding Features. Materials 2021, 14, 7878. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.A.; Wang, Z.; Liu, W.; Wang, J.; Zhigang, Y.; Khan, M.; Ali, M.M.M.; Geldiyev, R.; Diaby, M.; Derradji, M. Thermal stability and gamma ray shielding properties of tungsten borides/epoxy micro-composites. Radiat. Phys. Chem. 2021, 189, 109769. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Alrashedi, M.F.; Almuqrin, A.H.; Elsafi, M. Recycling and optimizing waste lab glass with Bi2O3 nanoparticles to use as a transparent shield for photons. J. Mater. Res. Technol. 2022, 17, 2073–2083. [Google Scholar] [CrossRef]

- Abbas, M.I.; El-Khatib, A.M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Elsafi, M. The Influence of Bi2O3 Nanoparticle Content on the γ-ray Interaction Parameters of Silicon Rubber. Polymers 2022, 14, 1048. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Al-Ghamdi, H.; Almuqrin, A.H.; Yasmin, S.; Elsafi, M. A Study on the Gamma Radiation Protection Effectiveness of Nano/Micro-MgO Reinforced Novel Silicon Rubber for Medical Applications. Polymers 2022, 14, 2867. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Hamad, M.K.; Mhareb, M.H.A.; Kurtulus, R.; Dwaikat, N.; Saleh, M.; Elsafi, M.; Taki, M.M.; Kavas, T.; Ziq, K.A.; et al. Assessment of radiation attenuation properties for novel alloys: An experimental approach. Radiat. Phys. Chem. 2022, 110152. [Google Scholar] [CrossRef]

- Almuqrin, A.H.; Sayyed, M.I.; Elsafi, M.; Khandaker, M.U. Comparison of radiation shielding ability of Bi2O3 micro and nanoparticles for radiation shields. Radiat. Phys. Chem. 2022, 110170. [Google Scholar] [CrossRef]

- Aloraini, D.A.; Sayyed, M.I.; Mahmoud, K.A.; Almuqrin, A.A.H.; Kumar, A.; Khandaker, M.U.; Elsafi, M. Evaluation of radiation shielding characteristics of B2O3–K2O–Li2O-HMO (HMO = TeO2/SrO/PbO/Bi2O3) glass system: A simulation study using MCNP5 code. Radiat. Phys. Chem. 2022, 110172. [Google Scholar] [CrossRef]

- Al-Harbi, N.; Sayyed, M.I.; Al-Hadeethi, Y.; Kumar, A.; Elsafi, M.; Mahmoud, K.A.; Khandaker, M.U.; Bradley, D.A. A novel CaO–K2O–Na2O–P2O5 glass systems for radiation shielding applications. Radiat. Phys. Chem. 2021, 188, 109645. [Google Scholar] [CrossRef]

- D’Souza, A.N.; Sayyed, M.I.; Karunakara, N.; Al-Ghamdi, H.; Almuqrin, A.H.; Elsafi, M.; Khandaker, M.U.; Kamath, S.D. TeO2 SiO2–B2O3 glasses doped with CeO2 for gamma radiation shielding and dosimetry application. Radiat. Phys. Chem. 2022, 110233. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I.; Barasheed, A.Z.; Ahmed, M.; Elsafi, M. Preparation and radiation attenuation properties of ceramic ball clay enhanced with micro and nano ZnO particles. J. Mater. Res. Technol. 2022, 17, 223–233. [Google Scholar] [CrossRef]

- Hannachi, E.; Sayyed, M.I.; Slimani, Y.; Elsafi, M. Experimental investigation on the physical properties and radiation shielding efficiency of YBa2Cu3Oy/M@M3O4 (M = Co, Mn) ceramic composites. J. Alloys Compd. 2022, 904, 164056. [Google Scholar] [CrossRef]

- Al-Hadeethi, Y.; Sayyed, M.I.; Barasheed, A.Z.; Ahmed, M.; Elsafi, M. Fabrication of Lead Free Borate Glasses Modified by Bismuth Oxide for Gamma Ray Protection Applications. Materials 2022, 15, 789. [Google Scholar] [CrossRef]

- Hannachi, E.; Sayyed, M.I.; Slimani, Y.; Almessiere, M.A.; Baykal, A.; Elsafi., M. Synthesis, characterization, and performance assessment of new composite ceramics towards radiation shielding applications. J. Alloys Compd. 2022, 899, 163173. [Google Scholar] [CrossRef]

- Elsafi, M.; Koraim, Y.; Almurayshid, M.; Almasoud, F.I.; Sayyed, M.I.; Saleh, I.H. Investigation of Photon Radiation Attenuation Capability of Different Clay Materials. Materials 2021, 14, 6702. [Google Scholar] [CrossRef]

- Aloraini, D.A.; Almuqrin, A.H.; Sayyed, M.I.; Al-Ghamdi, H.; Kumar, A.; Elsafi, M. Experimental Investigation of Radiation Shielding Competence of Bi2O3-CaO-K2O-Na2O-P2O5 Glass Systems. Materials 2021, 14, 5061. [Google Scholar] [CrossRef]

- Hassan, H.E.; Badran, H.M.; Aydarous, A.; Sharshar, T. Studying the effect of nano lead compounds additives on the concrete shielding properties for γ-rays. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 360, 81–89. [Google Scholar] [CrossRef]

| Percentages (wt%) | Density (g/cm3) | Micro Sample Codes | Nano Sample Codes | |||

|---|---|---|---|---|---|---|

| Epoxy | Micro-MgO Particles | Nano-MgO Particles | Micro | Nano | ||

| 90 | 10 | 10 | 1.182 | 1.188 | E-mMgO10 | E-nMgO10 |

| 80 | 20 | 20 | 1.277 | 1.279 | E-mMgO20 | E-nMgO20 |

| 70 | 30 | 30 | 1.389 | 1.395 | E-mMgO30 | E-nMgO30 |

| 60 | 40 | — | 1.522 | — | E-mMgO40 | — |

| 50 | 50 | — | 1.683 | — | E-mMgO50 | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayyed, M.I.; Yasmin, S.; Almousa, N.; Elsafi, M. Shielding Properties of Epoxy Matrix Composites Reinforced with MgO Micro- and Nanoparticles. Materials 2022, 15, 6201. https://doi.org/10.3390/ma15186201

Sayyed MI, Yasmin S, Almousa N, Elsafi M. Shielding Properties of Epoxy Matrix Composites Reinforced with MgO Micro- and Nanoparticles. Materials. 2022; 15(18):6201. https://doi.org/10.3390/ma15186201

Chicago/Turabian StyleSayyed, M. I., Sabina Yasmin, Nouf Almousa, and Mohamed Elsafi. 2022. "Shielding Properties of Epoxy Matrix Composites Reinforced with MgO Micro- and Nanoparticles" Materials 15, no. 18: 6201. https://doi.org/10.3390/ma15186201