Fe-Based Amorphous Magnetic Powder Cores with Low Core Loss Fabricated by Novel Gas–Water Combined Atomization Powders

Abstract

:1. Introduction

2. Materials and Methods

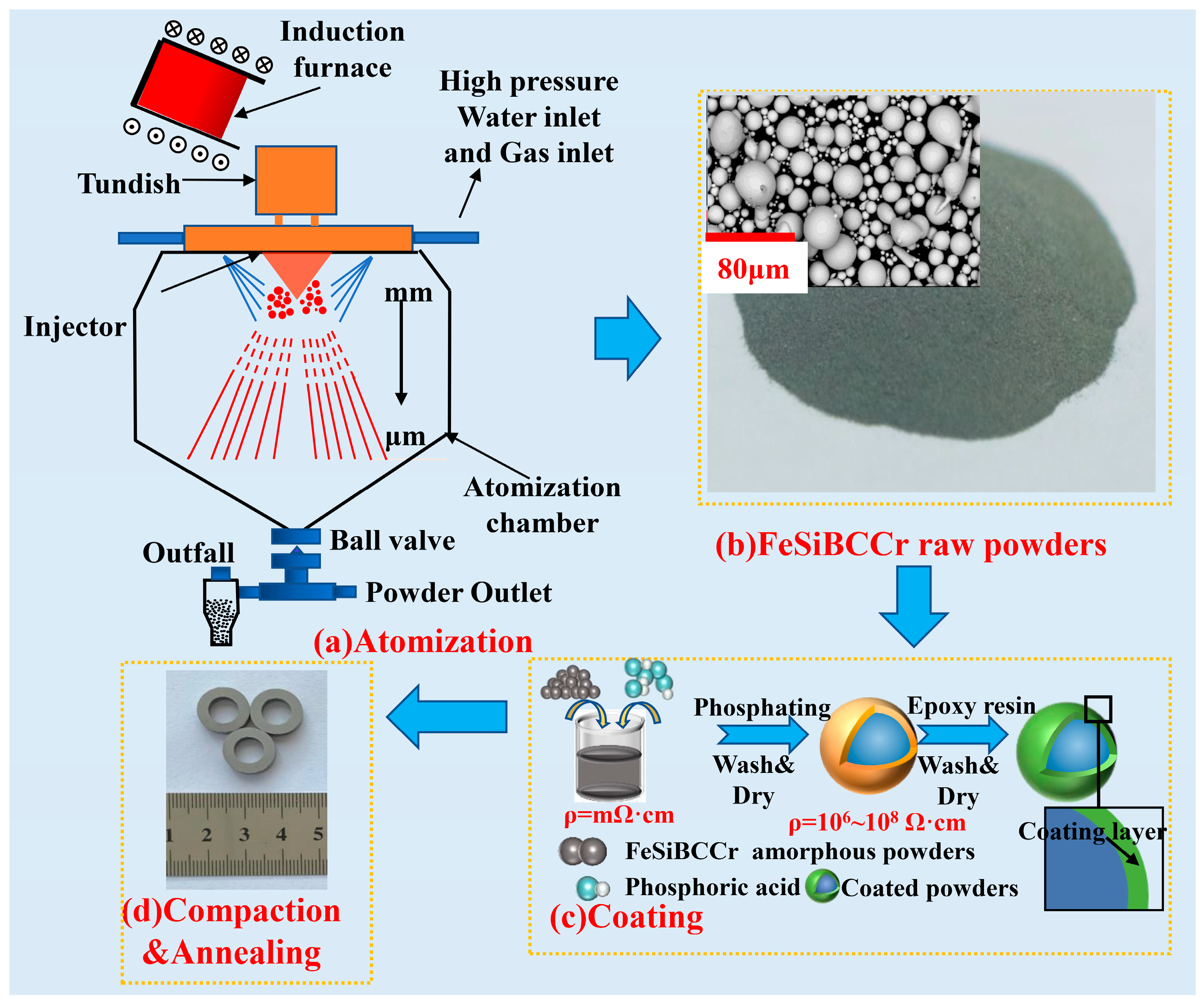

2.1. Preparation of FeSiBCCr Amorphous Powders

2.2. Preparation of MPCs

2.3. Material Characterization

3. Results

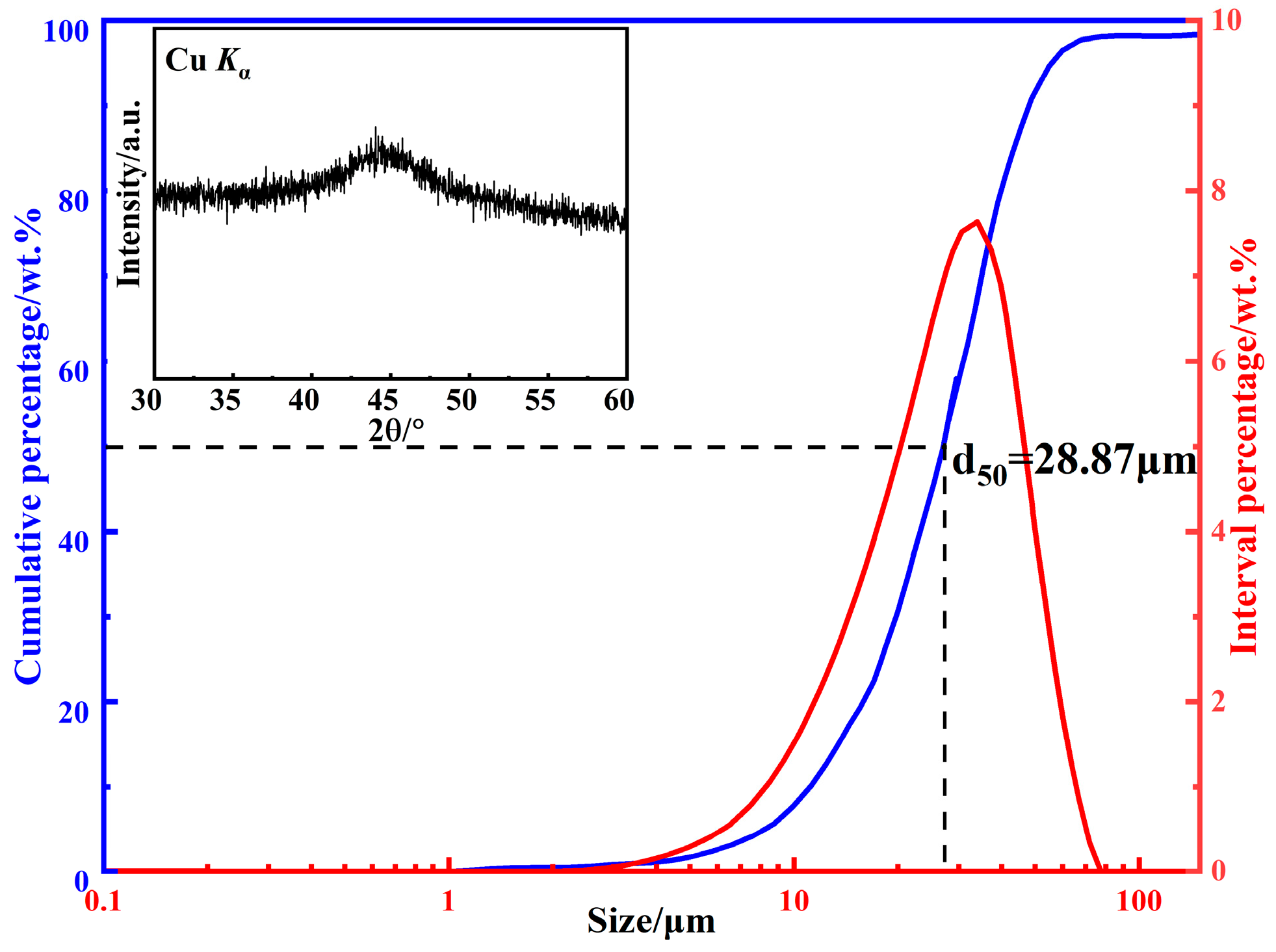

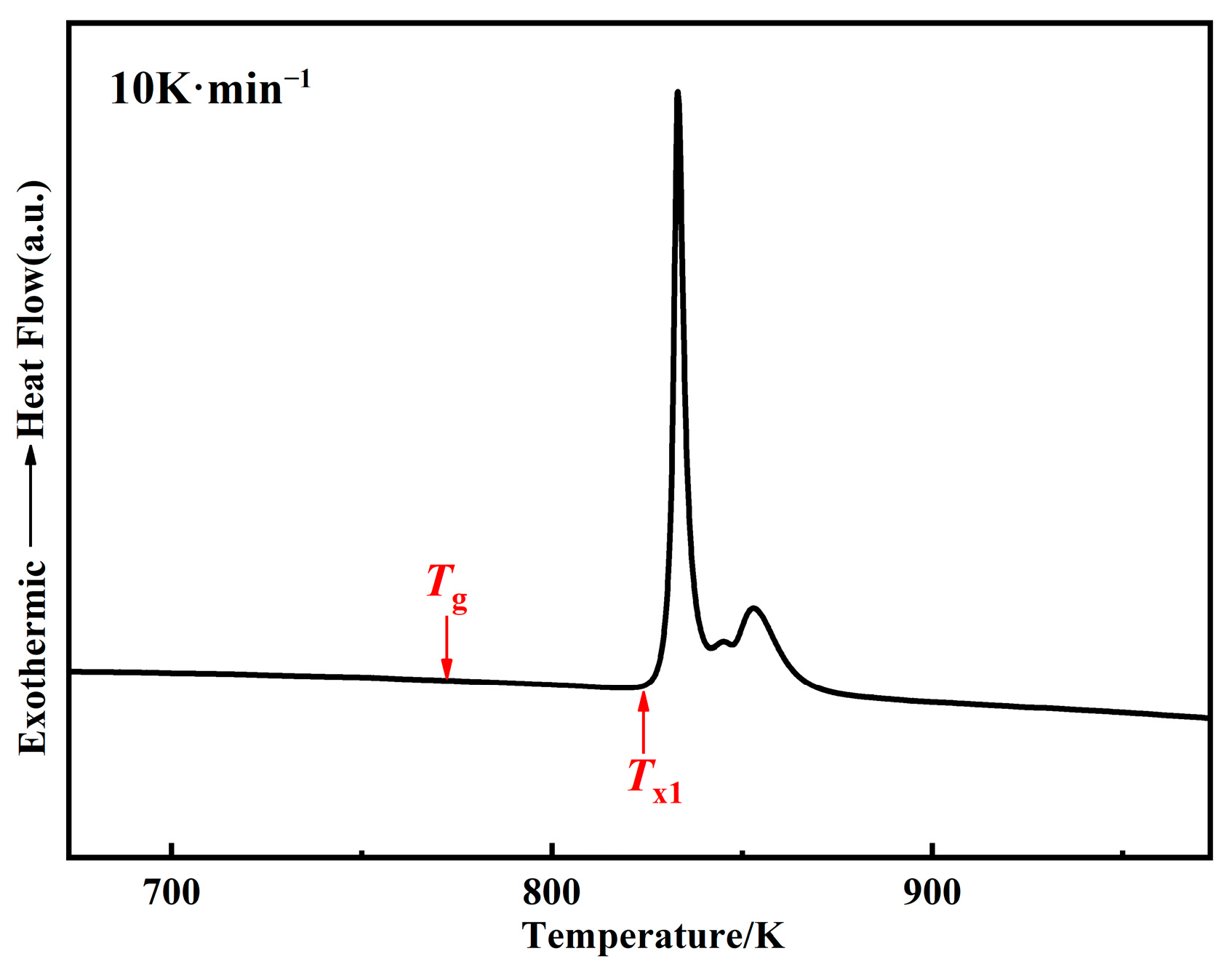

3.1. Characterization of Atomization Powder

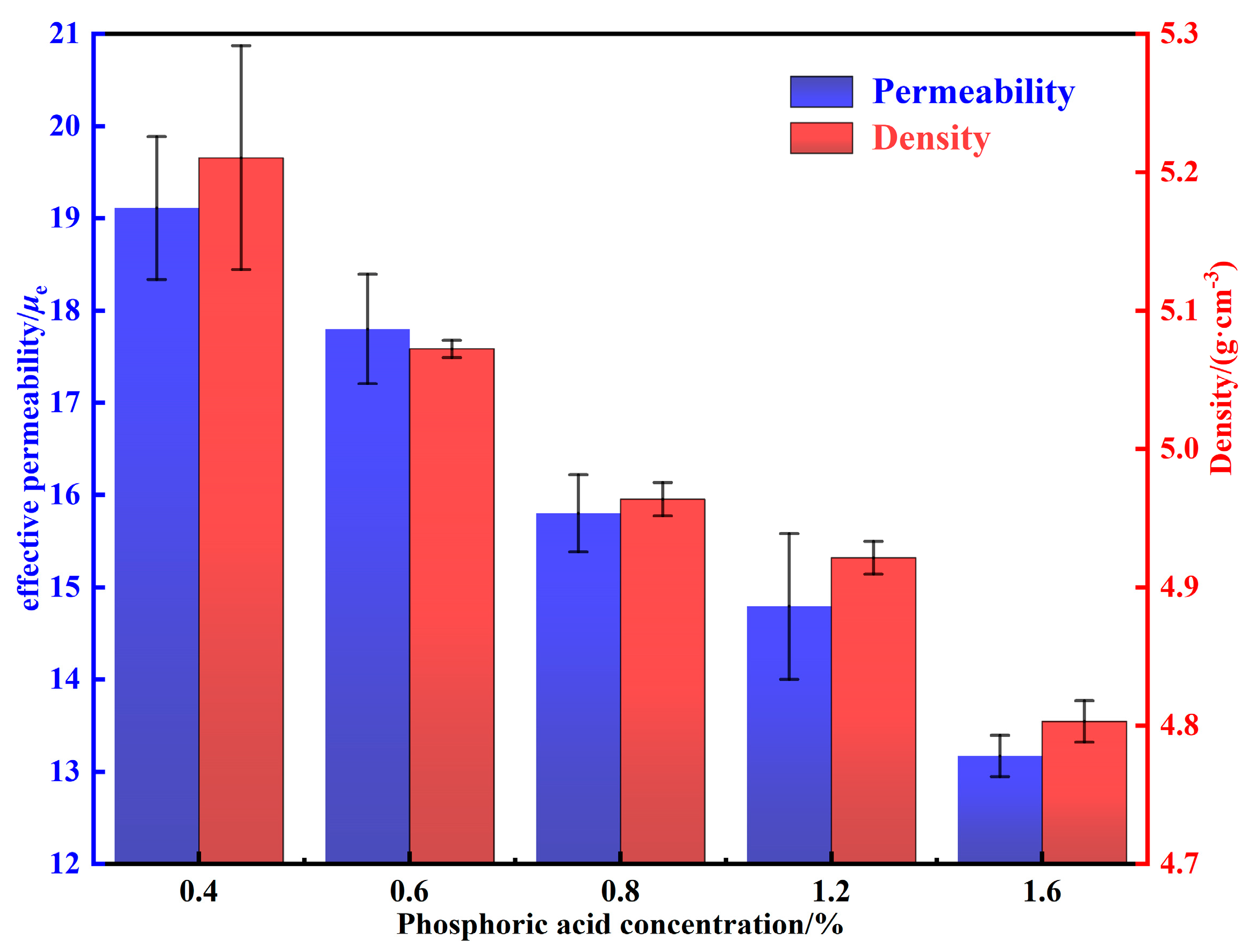

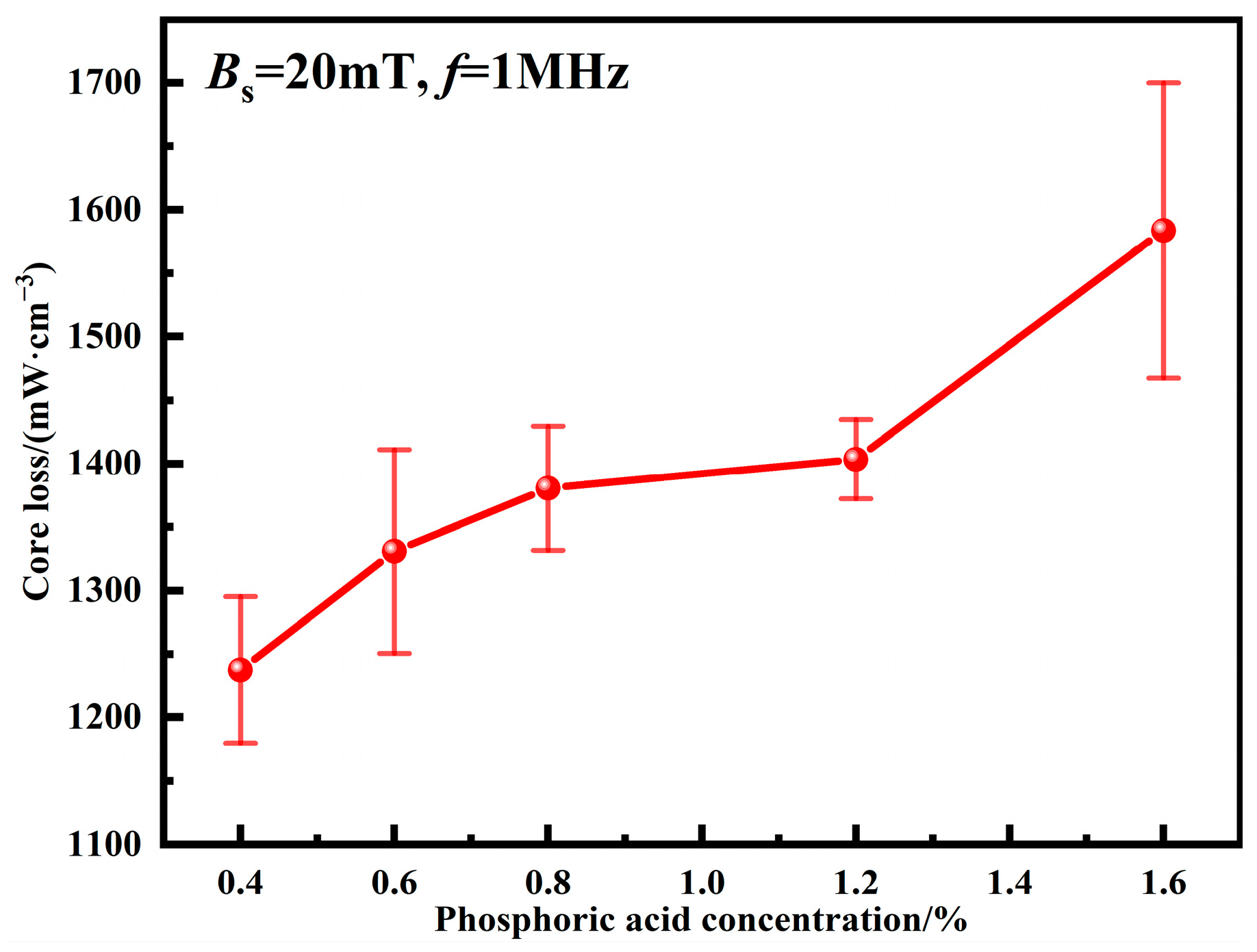

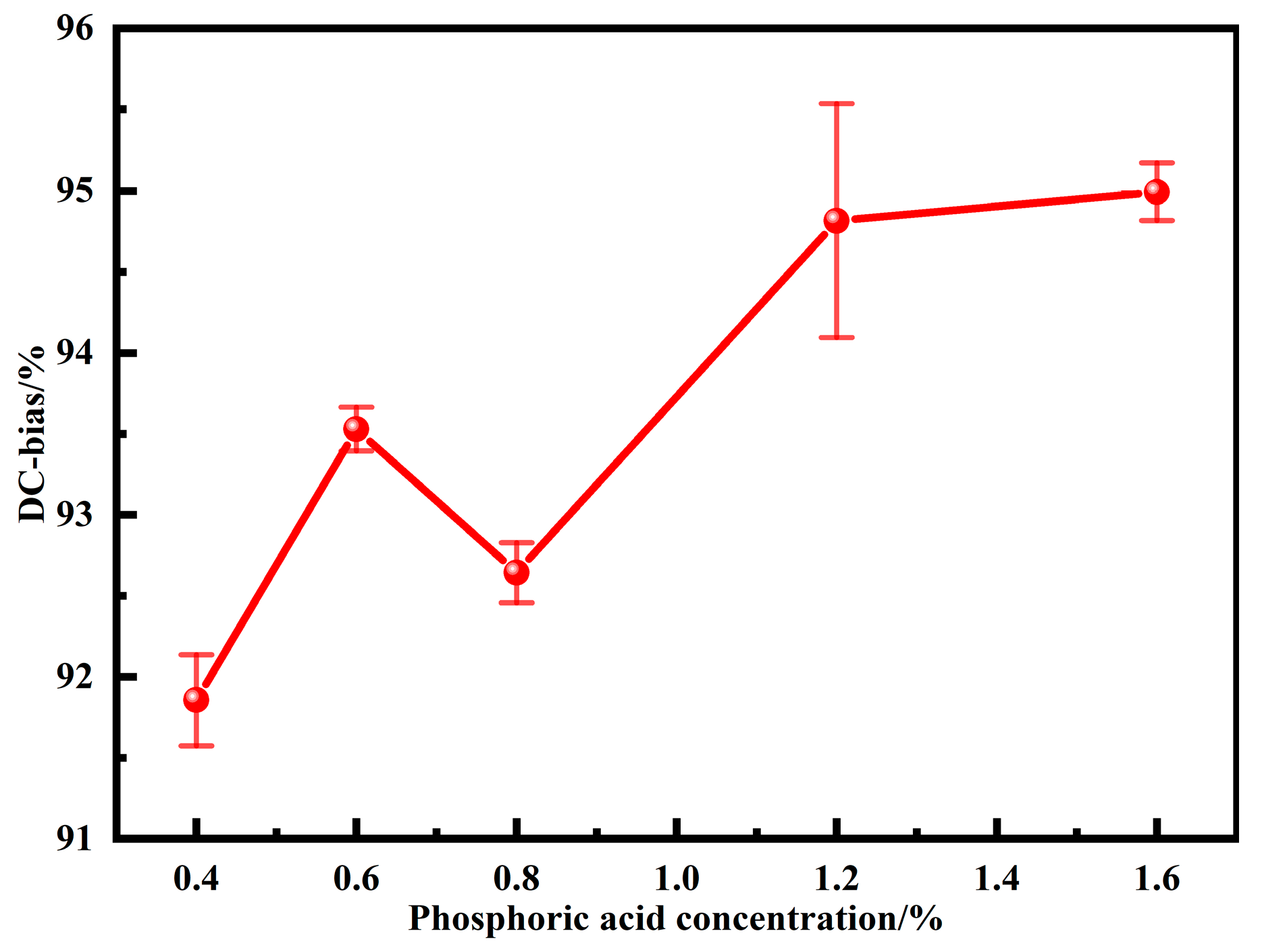

3.2. Effects of Phosphoric Acid Concentration on MPC Properties

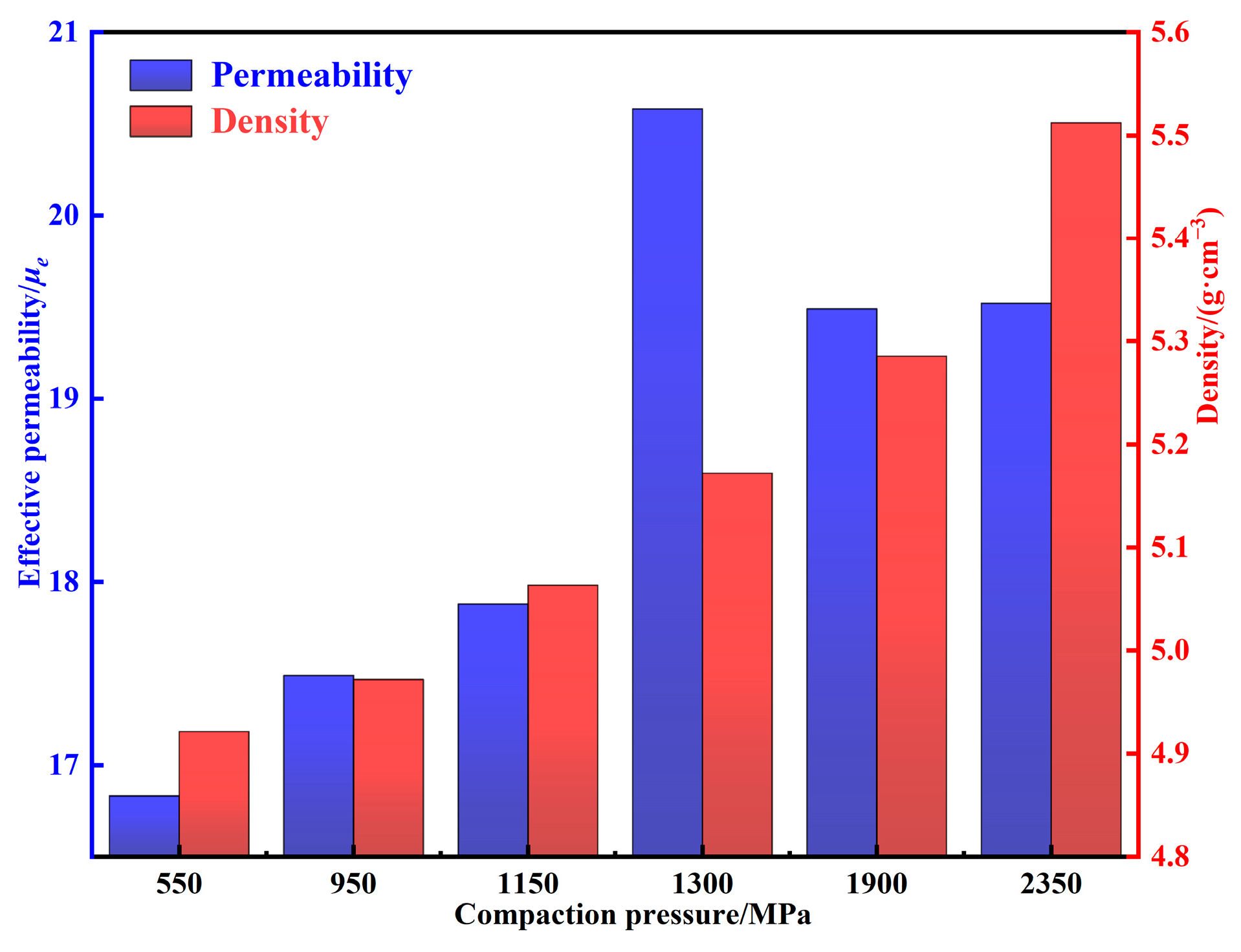

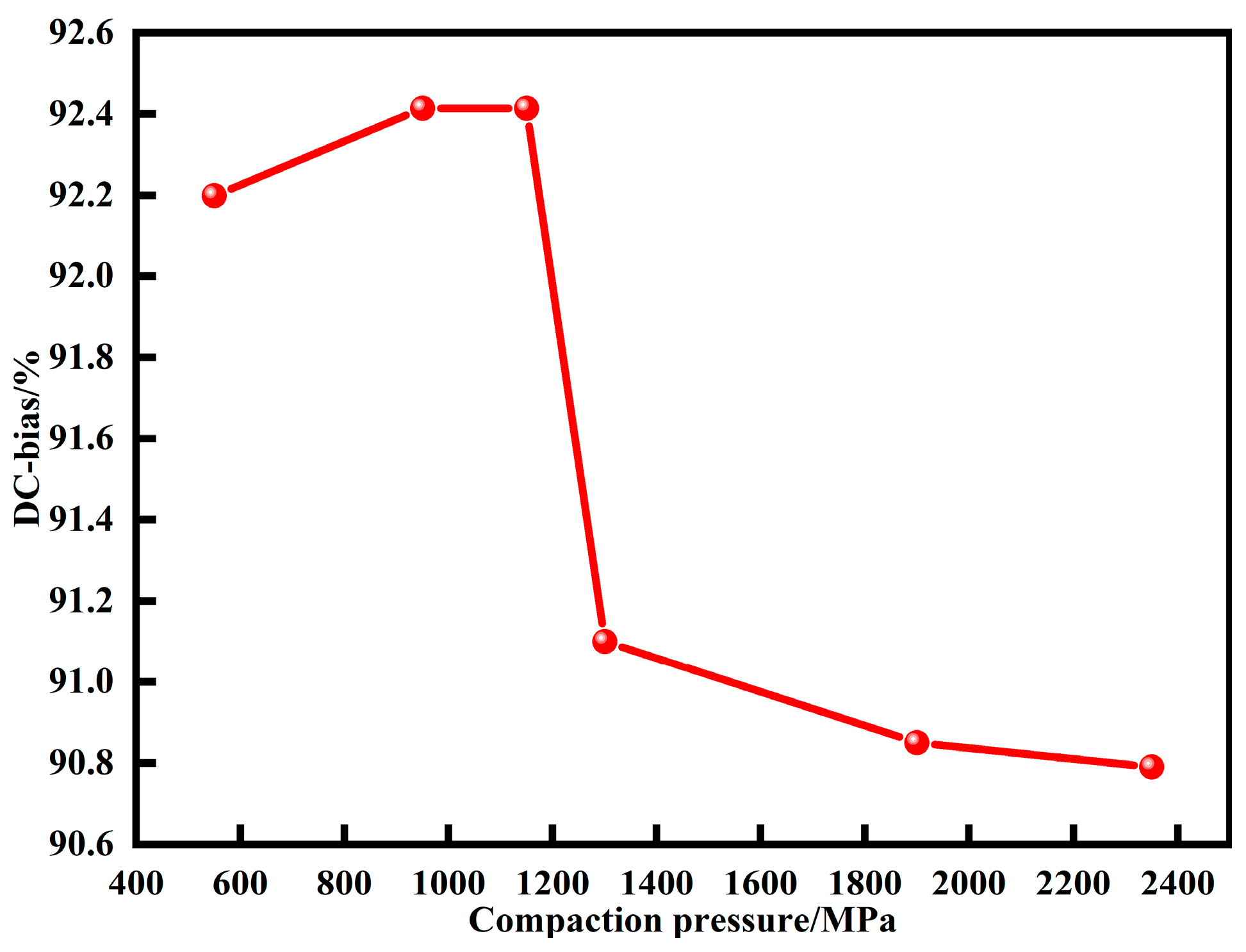

3.3. Effects of Compaction Pressures on MPC Properties

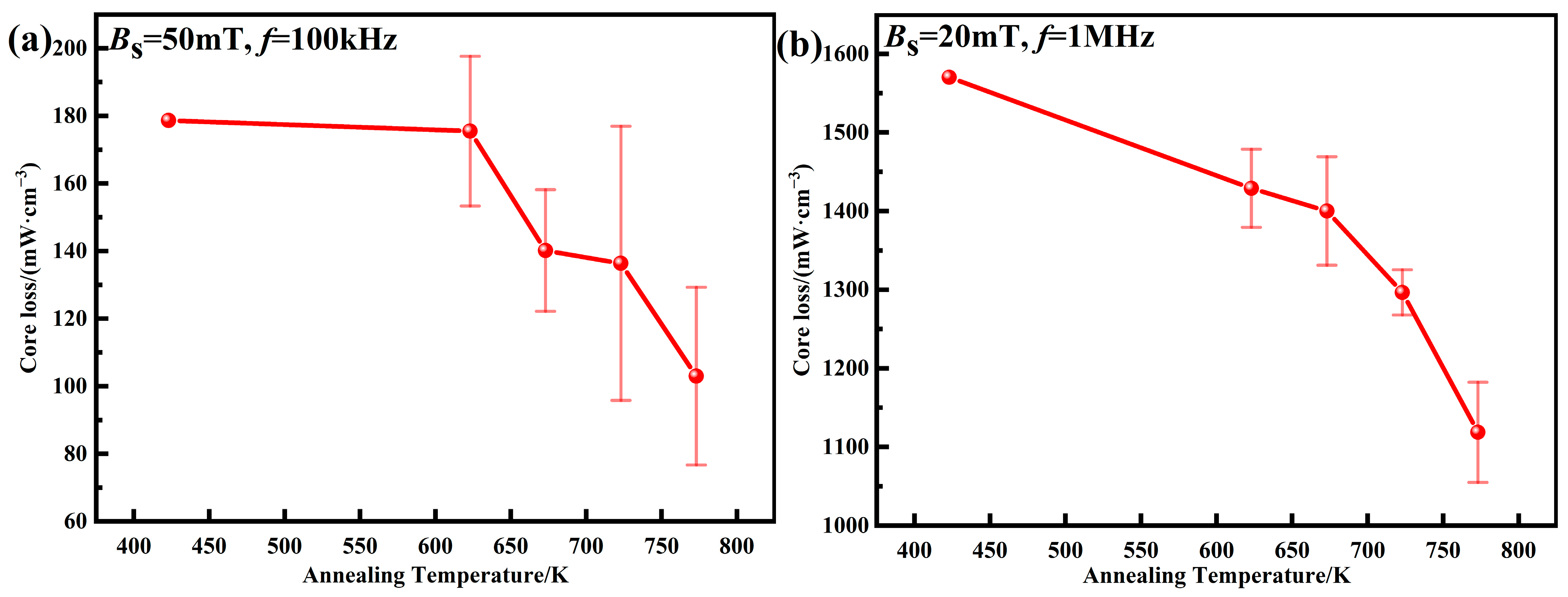

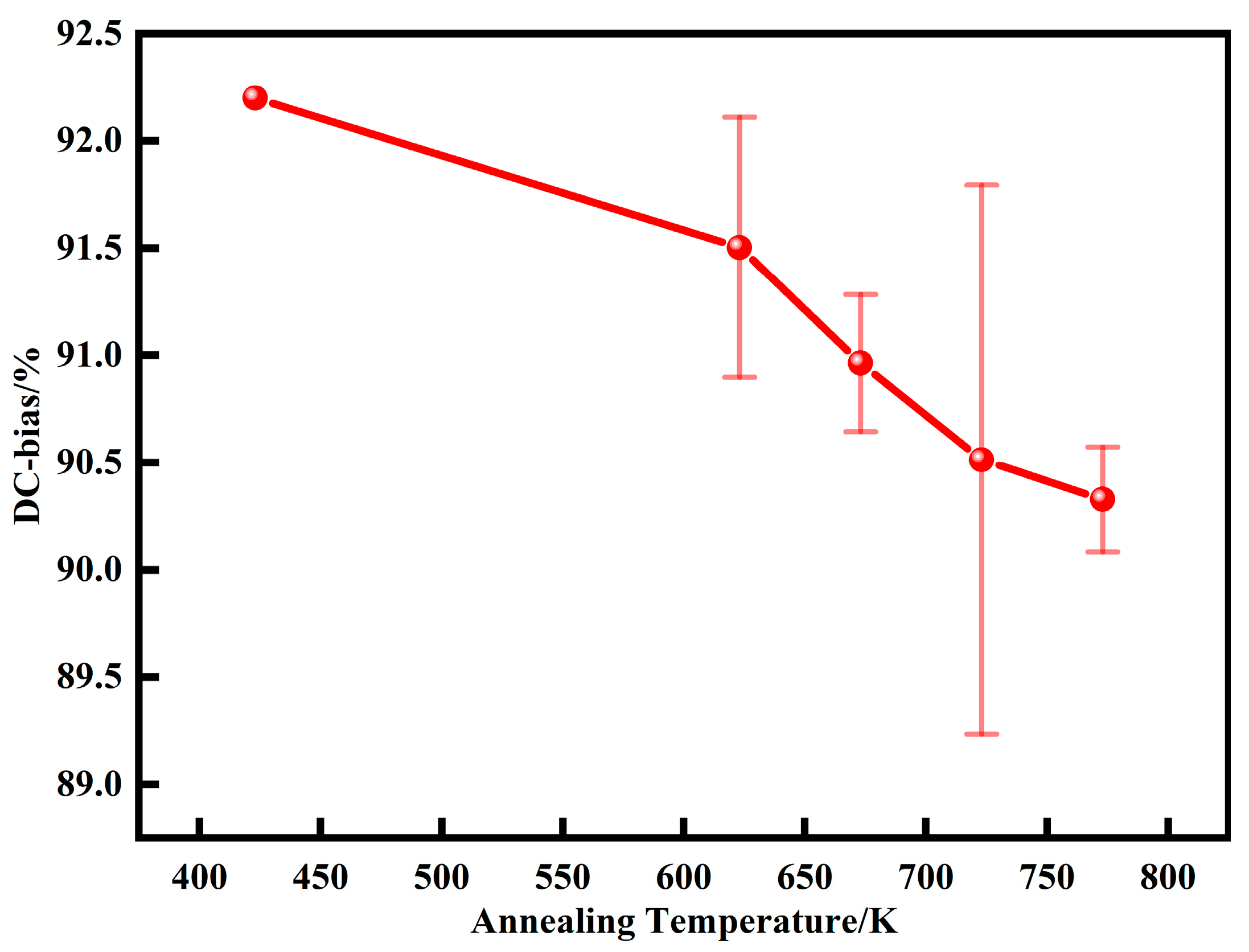

3.4. Effects of Annealing Temperatures on MPC Properties

4. Conclusions

- The raw powders have a fine size of d50 = 28.87 μm and high circularity of 0.913, which is conducive to the forming of high-density MPCs and the enhancement of high-frequency properties; the powders exhibit excellent soft magnetic properties, which can provide an excellent raw material reserve for high-performance MPCs.

- With the increase of phosphating concentrations, the inhomogeneity of phosphate layers intensifies, and the content of non-ferromagnetic phases increases, and thus the permeability, density, and core losses deteriorate despite the enhancement of DC bias performance. With the increase of pressure, although the density increases, the excessive accumulation of internal stress makes the permeability increase and then decrease and the core losses increase continuously. When annealed below the crystallization temperature, the density of internal defects decreases as the annealing temperature increases, the permeability increases gradually, the core losses decrease, and the DC-bias% decreases due to the reduction in the content of air gaps.

- The AMPCs prepared by the optimized process of 0.4 wt.% phosphoric acid treatment, cold pressing at 550 MPa, and annealing at 773 K/2 h have excellent overall performance with the permeability of 21.54 ± 1.21, DC-bias% of 90.3 ± 0.2, and core losses of 103.0 ± 26.3 mW cm−3 and 1118.7 ± 63.7 mW cm−3 at 100 kHz/50 mT and 1 MHz/20 mT. The AMPCs fabricated in this work have outstanding DC bias and low core loss under high frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, J.J.; Dong, Y.Q.; Man, Q.K.; Li, Q.; Chang, C.T.; Wang, X.M.; Li, R.W. Fabrication of FeSiBPNb amorphous powder cores with high DC-bias and excellent soft magnetic properties. J. Magn. Magn. Mater. 2016, 401, 432–435. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, eaao0195. Available online: https://www.science.org/doi/abs/10.1126/science.aao0195 (accessed on 26 October 2018). [CrossRef] [PubMed]

- Guo, Z.L.; Wang, J.H.; Chen, W.H.; Chen, D.C.; Sun, H.B.; Xue, Z.L.; Wang, C. Crystal-like microstructural Finemet/FeSi compound powder core with excellent soft magnetic properties and its loss separation analysis. Mater. Des. 2020, 192, 108769. [Google Scholar] [CrossRef]

- Fan, X.A.; Wu, Z.Y.; Li, G.Q.; Wang, J.; Xiang, Z.D.; Gan, Z.H. High resistivity and low core loss of intergranular insulated Fe–6.5 wt.% Si/SiO2 composite compacts. Mater. Des. 2016, 89, 1251–1258. [Google Scholar] [CrossRef]

- Dong, Y.N.; Liu, J.Q.; Wang, P.; Zhao, H.; Pang, J.; Li, X.Y.; Zhang, J.Q. Study of Bulk Amorphous and Nanocrystalline Alloys Fabricated by High-Sphericity Fe84Si7B5C2Cr2 Amorphous Powders at Different Spark-Plasma-Sintering Temperatures. Materials 2022, 15, 1106. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Yan, B.; Jian, Y. Fabrication of Fe-Si-B Based Amorphous Powder Cores by Spark Plasma Sintered and Their Magnetic Properties. Materials 2022, 15, 1603. [Google Scholar] [CrossRef]

- Guo, L.Y.; Geng, S.N.; Yan, Z.C.; Chen, Q.; Lan, S.; Wang, W.M. Nanocrystallization and magnetic property improvement of Fe78Si9B13 amorphous alloys induced by magnetic field assisted nanosecond pulsed laser. Vacuum 2022, 199, 110983. [Google Scholar] [CrossRef]

- Chen, D.N.; Li, K.L.; Yu, H.Y.; Zuo, J.L.; Chen, X.; Guo, B.C.; Han, G.Z.; Liu, Z.W. Effects of secondary particle size distribution on the magnetic properties of carbonyl iron powder cores. J. Magn. Magn. Mater. 2020, 497, 166062. [Google Scholar] [CrossRef]

- Zhao, T.C.; Chen, C.G.; Wu, X.J.; Zhang, C.Z.; Volinsky, A.A.; Hao, J.J. FeSiBCrC amorphous magnetic powder fabricated by gas-water combined atomization. J. Alloys Compd. 2021, 857, 157991. [Google Scholar] [CrossRef]

- Chang, L.; Xie, L.; Liu, M.; Li, Q.; Dong, Y.Q.; Chang, C.T.; Wang, X.M.; Inoue, A. Novel Fe-based nanocrystalline powder cores with excellent magnetic properties produced using gas-atomized powder. J. Magn. Magn. Mater. 2018, 452, 442–446. [Google Scholar] [CrossRef]

- Kus, A.; Pilarczyk, W.; Malachowska, A.; Ambroziak, A.; Gebara, P. Investigation of Mechanical and Magnetic Properties of Co-Based Amorphous Powders Obtained by Atomization. Materials 2021, 14, 7357. [Google Scholar] [CrossRef] [PubMed]

- Lavernia, E.J.; Srivatsan, T.S. The rapid solidification processing of materials: Science, principles, technology, advances, and applications. J. Mater. Sci. 2010, 45, 287–325. [Google Scholar] [CrossRef]

- Liu, Y.; Niu, S.; Li, F.; Zhu, Y.T.; He, Y.H. Preparation of amorphous Fe-based magnetic powder by water atomization. Powder Technol. 2011, 213, 36–40. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.; Yi, Y.; Deng, H.; Zhu, Y.Y.; Hu, G. The magnetic properties and microstructure of phosphated amorphous FeSiCr/silane soft magnetic composite. J. Magn. Magn. Mater. 2019, 474, 424–433. [Google Scholar] [CrossRef]

- Chi, Q.; Chang, L.; Dong, Y.Q.; Zhang, Y.Q.; Zhou, B.; Zhang, C.Z.; Pan, Y.; Li, Q.; Li, Q.; Li, J.W.; et al. Enhanced high frequency properties of FeSiBPC amorphous soft magnetic powder cores with novel insulating layer. Adv. Powder Technol. 2021, 32, 1602–1610. [Google Scholar] [CrossRef]

- Yu, H.; Zhou, S.X.; Zhang, G.Q.; Dong, B.S.; Meng, L.B.; Li, Z.Z.; Dong, Y.Q.; Cao, X. The phosphating effect on the properties of FeSiCr alloy powder. J. Magn. Magn. Mater. 2022, 552, 168741. [Google Scholar] [CrossRef]

- Long, H.M.; Wu, X.J.; Lu, Y.K.; Zhang, H.F.; Hao, J.J. Effect of Polyimide-Phosphating Double Coating and Annealing on the Magnetic Properties of Fe-Si-Cr SMCs. Materials 2022, 15, 3350. [Google Scholar] [CrossRef]

- Chang, C.T.; Dong, Y.Q.; Liu, M.; Guo, H.Q.; Xiao, Q.; Zhang, Y.F. Low core loss combined with high permeability for Fe-based amorphous powder cores produced by gas atomization powders. J. Alloys Compd. 2018, 766, 959–963. [Google Scholar] [CrossRef]

- Liu, M.; Huang, K.Y.; Liu, L.; Li, T.; Cai, P.P.; Dong, Y.Q.; Wang, X.M. Fabrication and magnetic properties of novel Fe-based amorphous powder and corresponding powder cores. J. Mater. Sci. 2018, 29, 6092–6097. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.D.; Yi, X.W.; Yao, Z.X.; Zhu, Y.Y.; Hu, G. Improved magnetic properties of FeSiCr amorphous soft magnetic composites by adding carbonyl iron powder. J. Non-Cryst. Solids 2021, 559, 120673. [Google Scholar] [CrossRef]

- Zhang, Y.; Sharma, P.; Makino, A. Production and properties of soft magnetic cores made from Fe-Rich FeSiBPCu powders. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sharma, P.; Makino, A. Fe-rich Fe–Si–B–P–Cu powder cores for high-frequency power electronic applications. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Wang, P.; Li, J.; Wang, X.; Liu, H.S.; Fan, B.; Gan, P.; Guo, R.F.; Ge, X.Y.; Wang, M.H. Close-coupled nozzle atomization integral simulation and powder preparation using vacuum induction gas atomization technology. Chin. Phys. B 2021, 30, 027502. [Google Scholar] [CrossRef]

- Chiba, M.; Urata, A.; Matsumoto, H.; Yoshida, S.; Makino, A. Characteristics of Fe-Si-BP-Cu nanocrystalline soft magnetic alloy powders with high Bs. IEEE Trans. Magn. 2011, 47, 2845–2847. [Google Scholar] [CrossRef]

- Otsuka, I.; Kadomura, T.; Ishiyama, K.; Yagi, M. Magnetic properties of Fe-based amorphous powder cores with high magnetic flux density. IEEE Trans. Magn. 2009, 45, 4294–4297. [Google Scholar] [CrossRef]

- Kim, H.R.; Jang, M.S.; Nam, Y.G.; Kim, Y.S.; Yang, S.S.; Kim, Y.J.; Jeong, J.W. Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids. Metals 2021, 11, 1220. [Google Scholar] [CrossRef]

- Dong, Y.Q.; Man, Q.K.; Zhang, J.J.; Chang, C.T.; Li, R.W.; Wang, X.M. Fabrication of FePBNbCr glassy cores with good soft magnetic properties by hot pressing. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Suzuki, T.; Sharma, P.; Jiang, L.X.; Zhang, Y.; Makino, A. Fabrication and Properties of Under 10μm Sized Amorphous Powders of High Bs Soft Magnetic Alloy for High-Frequency Applications. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Yoshida, K.; Bito, M.; Kageyama, J.; Shimizu, Y.; Abe, M.; Makino, A. Unusual high B s for Fe-based amorphous powders produced by a gas-atomization technique. Aip. Adv. 2016, 6, 055933. [Google Scholar] [CrossRef]

- Li, T.; Dong, Y.Q.; Liu, L.; Liu, M.; Shi, X.Z.; Dong, X.; Rong, Q.Y. Novel Fe-based nanocrystalline powder cores with high performance prepared by using industrial materials. Intermetallics 2018, 102, 101–105. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, P.; Han, S.J.; Tang, F.L.; Su, H.L.; Tong, X.C.; Zou, Z.Q.; Wu, W.M.; Wu, Y.C.; Du, W.Y. Effects of Annealing Temperature and Compaction Pressure on Magnetic Properties of Fe–Si Powder Cores Fabricated by an Improved Bluing Method. J. Supercond. Nov. Magn. 2018, 31, 1507–1513. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Xu, W.; Guo, T.; Jiang, Y.Z.; Yan, M. Effect of processing parameters on the magnetic properties and microstructures of molybdenum permalloy compacts made by powder metallurgy. J. Alloys Compd. 2014, 594, 153–157. [Google Scholar] [CrossRef]

- Xu, W.; Wu, C.; Yan, M. Preparation of Fe–Si–Ni soft magnetic composites with excellent high-frequency properties. J. Magn. Magn. Mater. 2015, 381, 116–119. [Google Scholar] [CrossRef]

- Chen, S.F.; Chen, C.Y.; Cheng, C.S. Passivation layer for the magnetic property enhancement of Fe72.8Si11.2B10.8Cr2.3C2.9 amorphous powder. J. Alloys Compd. 2015, 644, 17–24. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, J.W.; Zheng, H.D.; Qiao, L.; Ying, Y.; Cai, W.; Li, W.C.; Yu, J.; Lin, M.; Che, S.L. Effects of heat treatment and lubricant on magnetic properties of iron-based soft magnetic composites with Al2O3 insulating layer by one-pot synthesis method. J. Magn. Magn. Mater. 2019, 472, 7–13. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.Q.; Liu, L.; Chang, L.; Bi, F.Q.; Wang, X.M. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 2019, 474, 1–8. [Google Scholar] [CrossRef]

| Group | Phosphoric acid Concentration % | Pc MPa | Ta K |

|---|---|---|---|

| A | 0.4 | 550 | 423 |

| 0.6 | 550 | 423 | |

| 0.8 | 550 | 423 | |

| 1.2 | 550 | 423 | |

| 1.6 | 550 | 423 | |

| B | 0.4 | 550 | 423 |

| 0.4 | 950 | 423 | |

| 0.4 | 1150 | 423 | |

| 0.4 | 1300 | 423 | |

| 0.4 | 1900 | 423 | |

| 0.4 | 2350 | 423 | |

| C | 0.4 | 550 | 423 |

| 0.4 | 550 | 623 | |

| 0.4 | 550 | 673 | |

| 0.4 | 550 | 723 | |

| 0.4 | 550 | 773 |

| Sample | μe | Core Loss, Pcv (mW cm−3) | DC-Bias% | References | |

|---|---|---|---|---|---|

| 100 kHz | 100 kHz/0.05 T | 1 MHz/0.02 T | 71.25 Oe | ||

| FeSiBCCr@phosphate@EP | 21.5 ± 1.2 | 103.0 ± 26.3 | 1118.7 ± 63.7 | 90.3 ± 0.2 | / |

| FeSiB + FeNi | 30.1 | 314 | / | / | [3] |

| FeSiCr@phosphate@polyimide | 47.5 | 547 | / | 68.1 | [10] |

| FeSiBPC@EP@Fe3O4 | 49.5 | 187 | / | / | [15] |

| FeSiBPC@EP | 44 | 301 | / | / | [15] |

| FeSiCr@phosphate@EP | 21.5 | 1016.8 | / | 89.4 | [16] |

| FeSiBPNbCu@EP | 63 | 475 | / | 81.2 | [17] |

| FeSiCr@silicone resin | 17.2 | / | 1442 | / | [20] |

| FeSiCr + CIP@ silicone resin | 19.7 | / | 1257 | / | [20] |

| FeSiNi@phosphate@EP | / | 643.2 | / | 74.4 | [33] |

| FeSiPS + Al2O3@aluminum nitrate | 36.49 | 398.5 | / | / | [35] |

| FeSiBCCr@TiO2 | 67 | 265 | / | 75.4 | [36] |

| FeSiBCCr@TiO2 | 74 | 301 | / | 80.0 | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Dong, Y.; Zhu, Z.; Zhao, H.; Pang, J.; Wang, P.; Zhang, J. Fe-Based Amorphous Magnetic Powder Cores with Low Core Loss Fabricated by Novel Gas–Water Combined Atomization Powders. Materials 2022, 15, 6296. https://doi.org/10.3390/ma15186296

Liu J, Dong Y, Zhu Z, Zhao H, Pang J, Wang P, Zhang J. Fe-Based Amorphous Magnetic Powder Cores with Low Core Loss Fabricated by Novel Gas–Water Combined Atomization Powders. Materials. 2022; 15(18):6296. https://doi.org/10.3390/ma15186296

Chicago/Turabian StyleLiu, Jiaqi, Yannan Dong, Zhengqu Zhu, Huan Zhao, Jing Pang, Pu Wang, and Jiaquan Zhang. 2022. "Fe-Based Amorphous Magnetic Powder Cores with Low Core Loss Fabricated by Novel Gas–Water Combined Atomization Powders" Materials 15, no. 18: 6296. https://doi.org/10.3390/ma15186296

APA StyleLiu, J., Dong, Y., Zhu, Z., Zhao, H., Pang, J., Wang, P., & Zhang, J. (2022). Fe-Based Amorphous Magnetic Powder Cores with Low Core Loss Fabricated by Novel Gas–Water Combined Atomization Powders. Materials, 15(18), 6296. https://doi.org/10.3390/ma15186296