Investigation and Modelling of the Weight Wear of Friction Pads of a Railway Disc Brake

Abstract

:1. Introduction

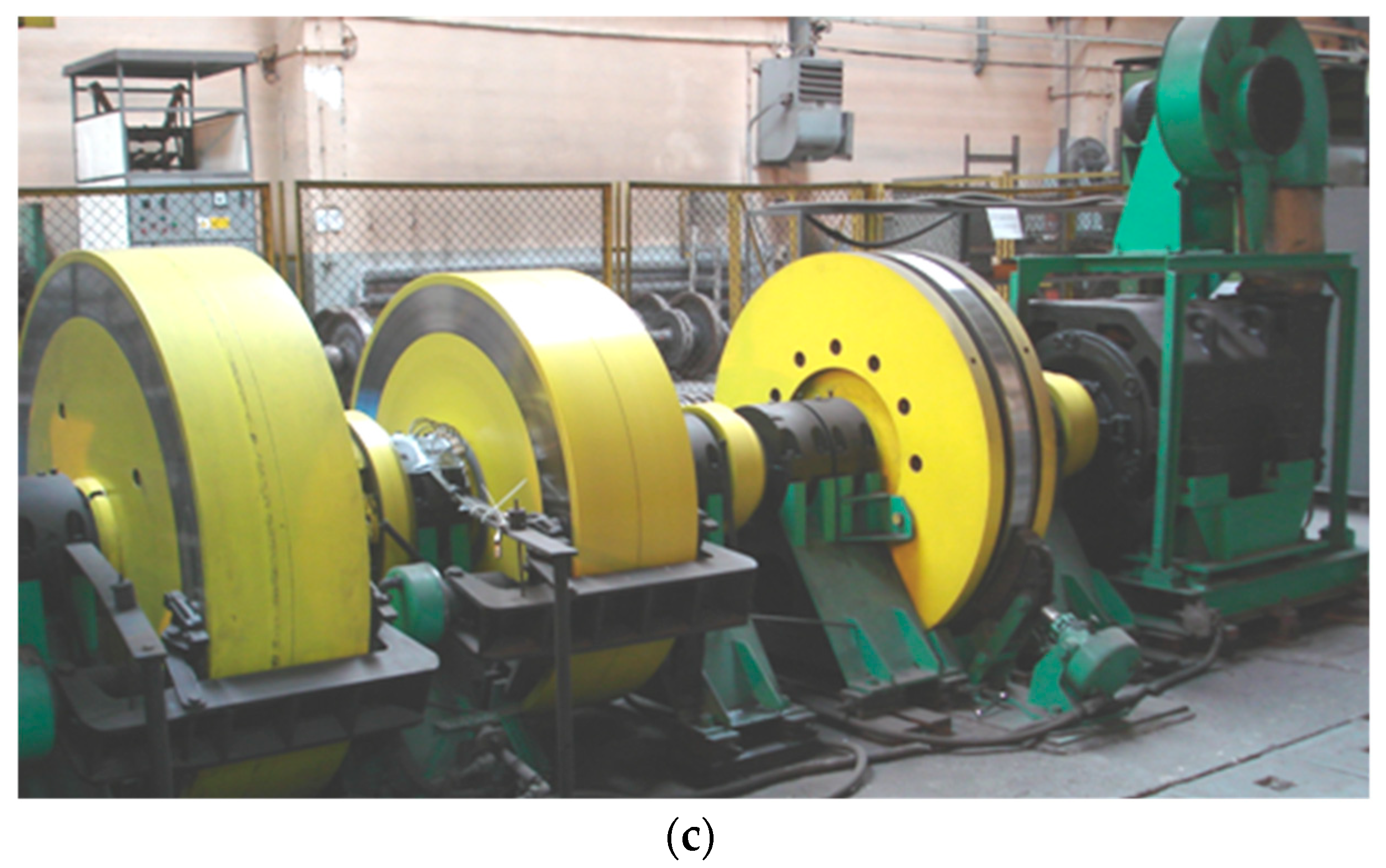

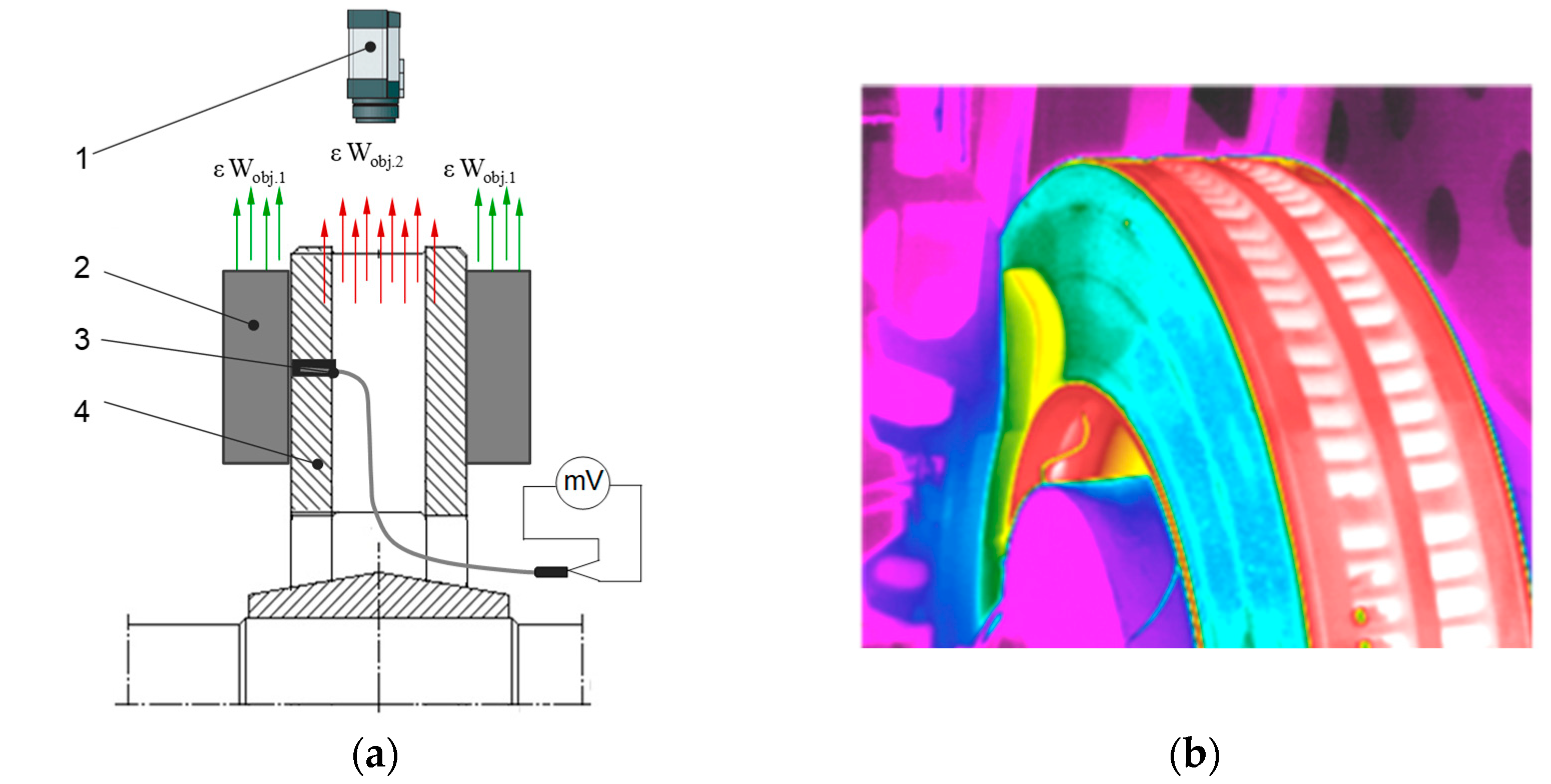

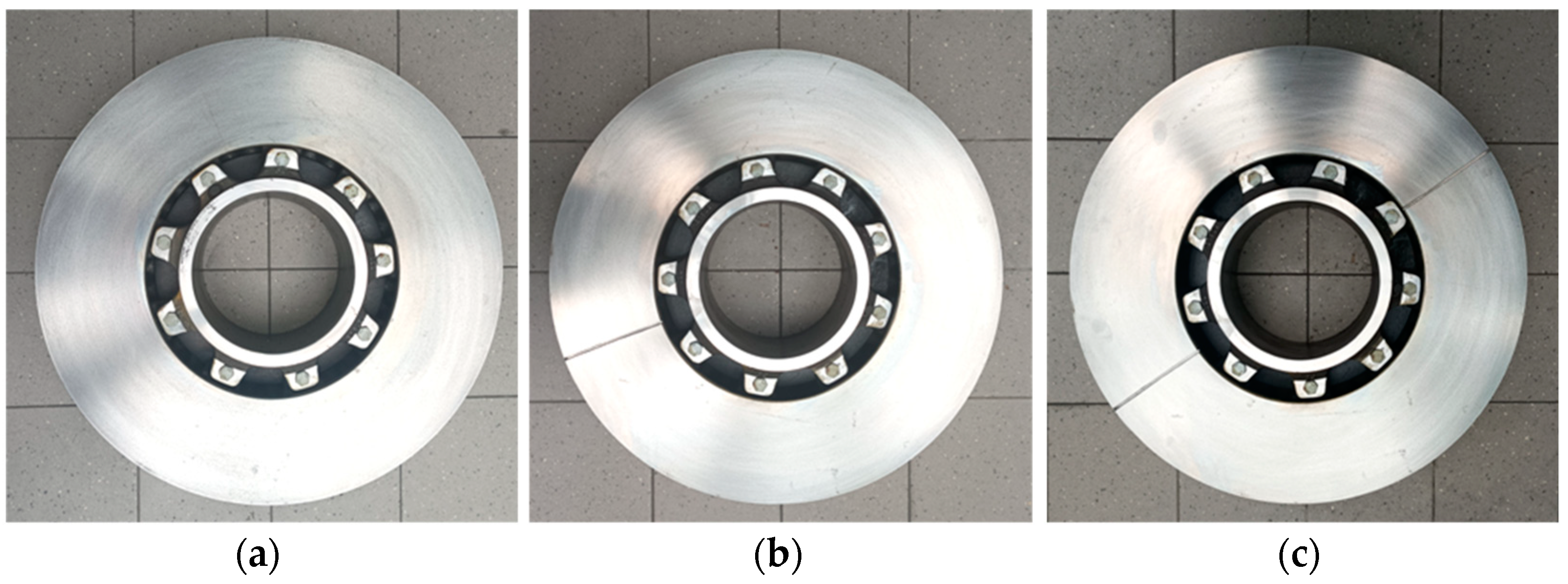

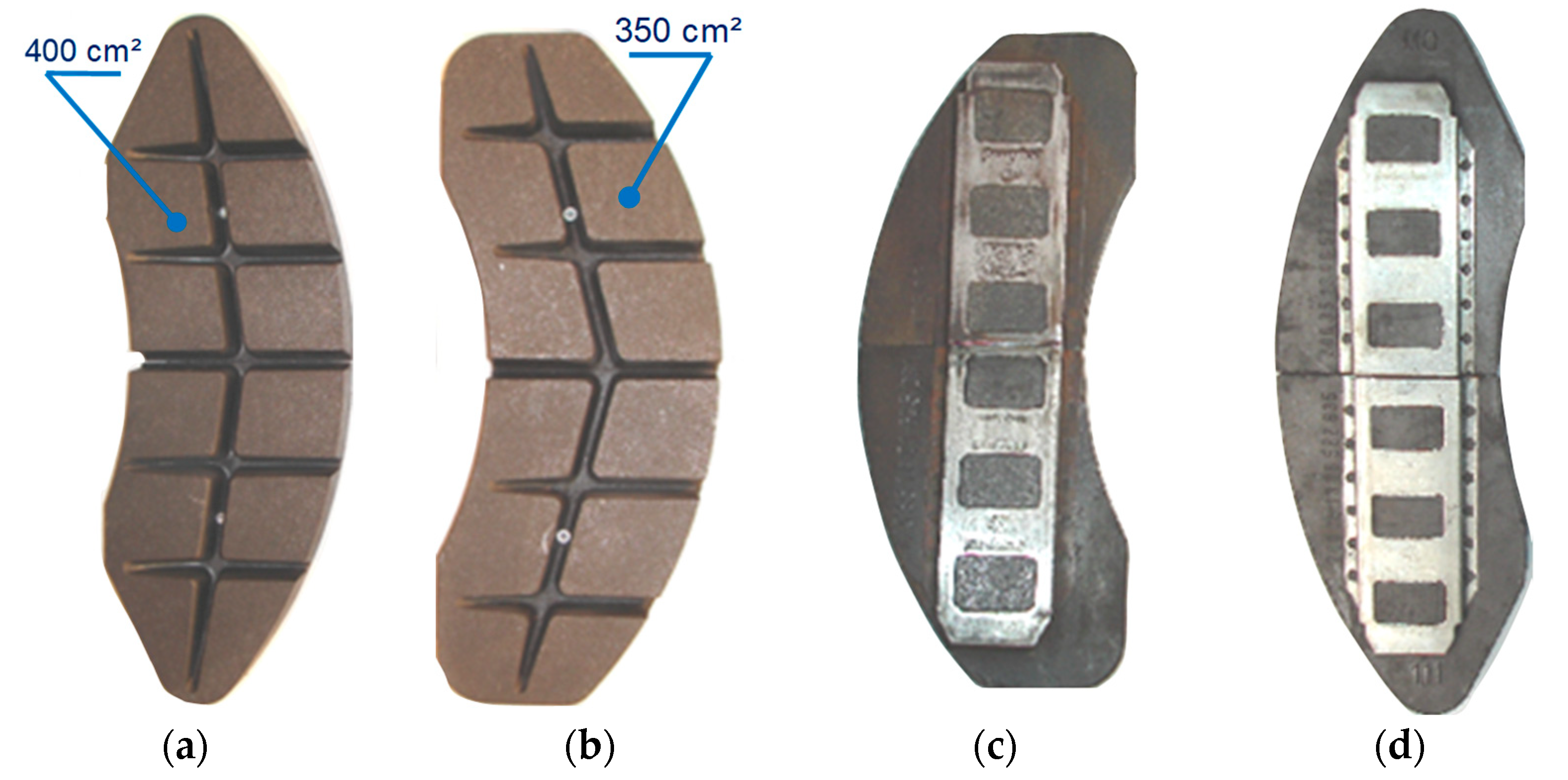

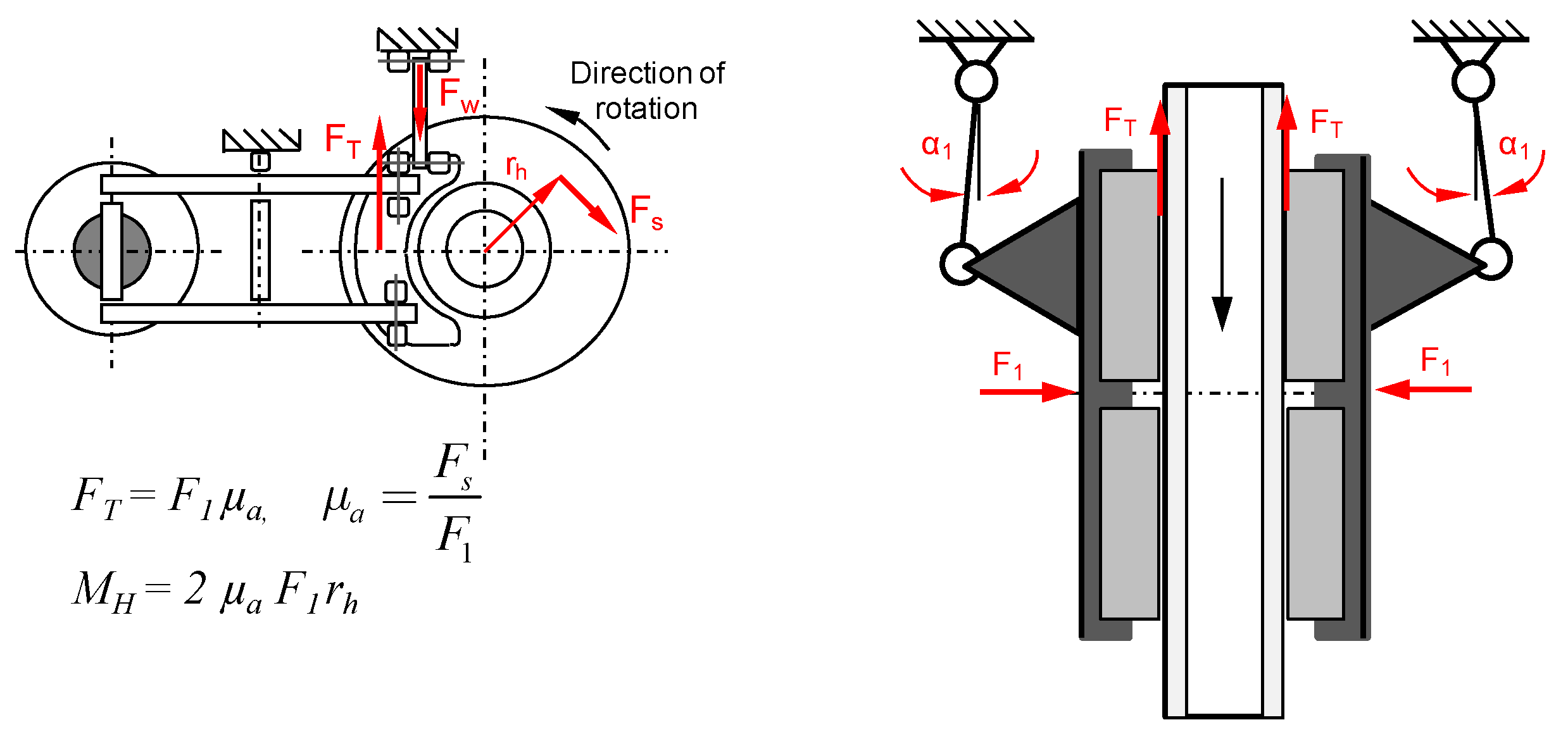

2. Methodology and Research Object

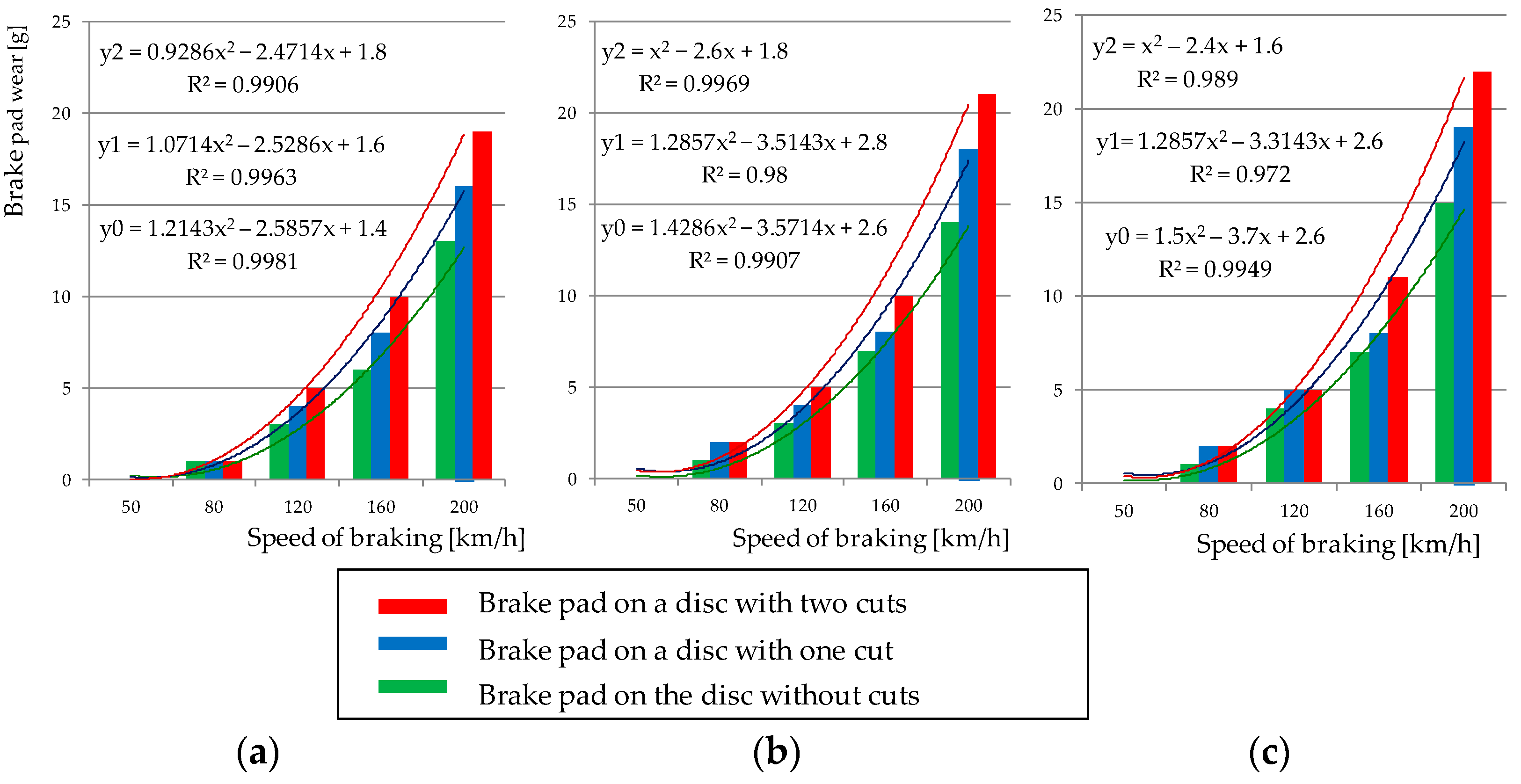

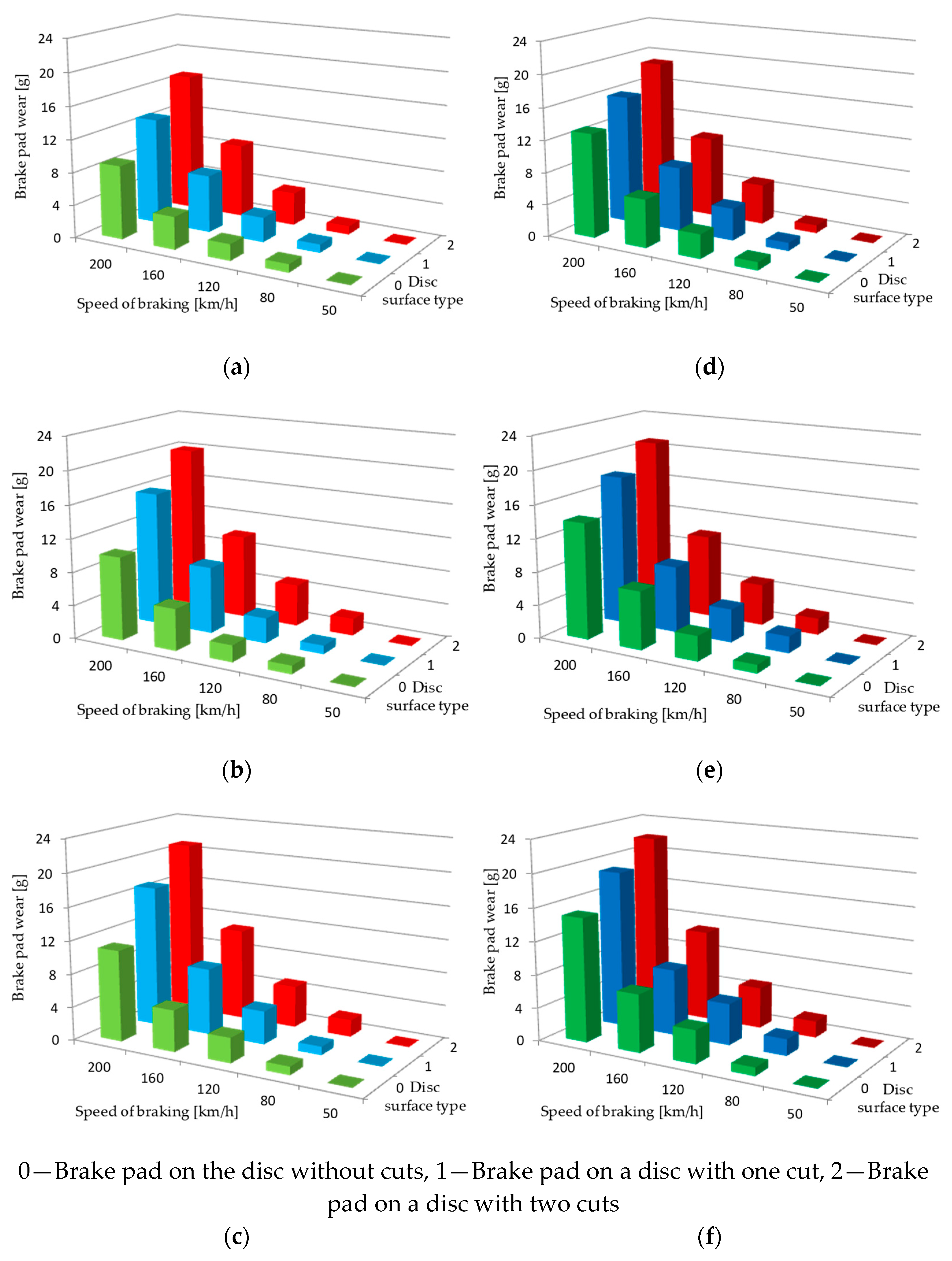

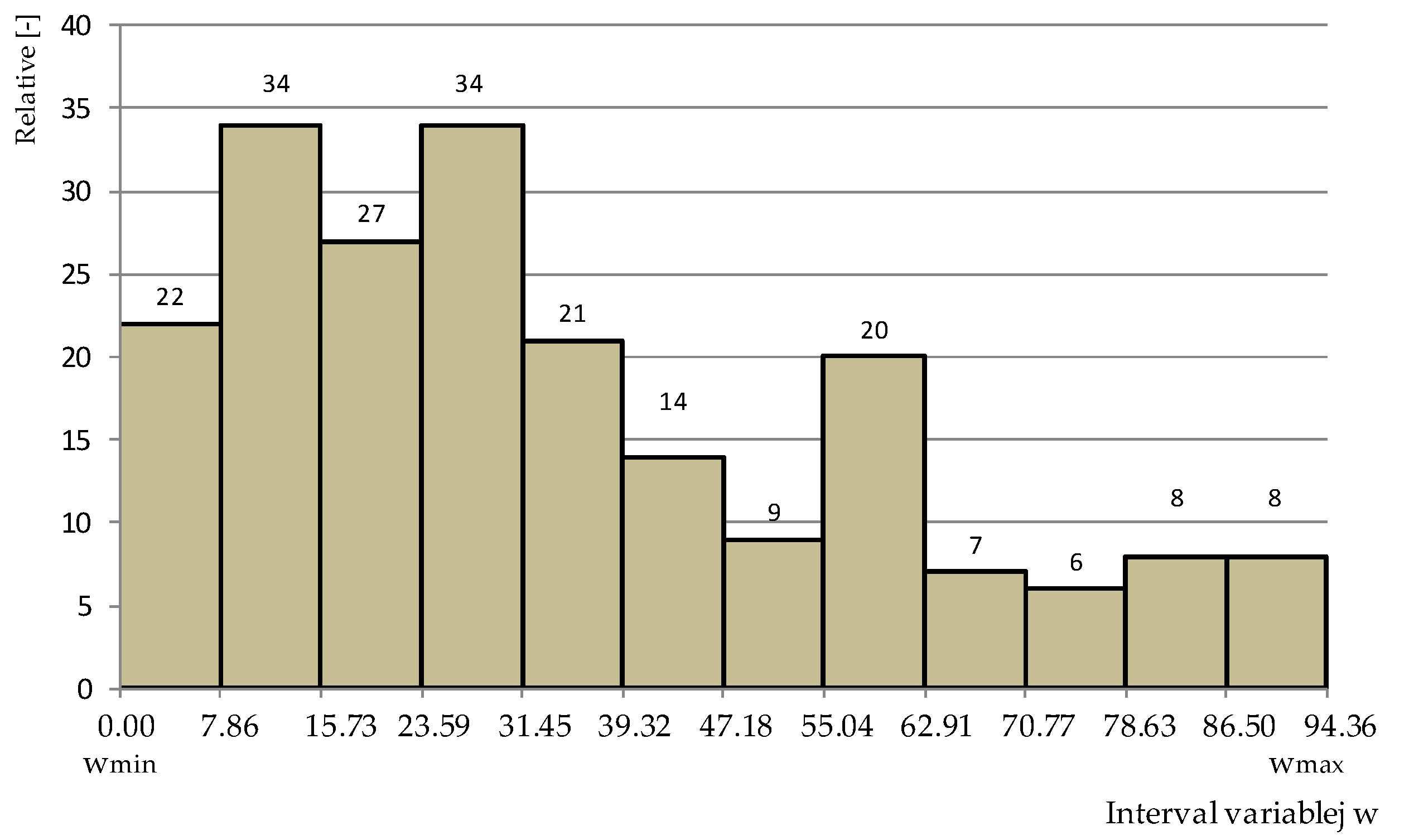

3. Analysis of Bench Test Results

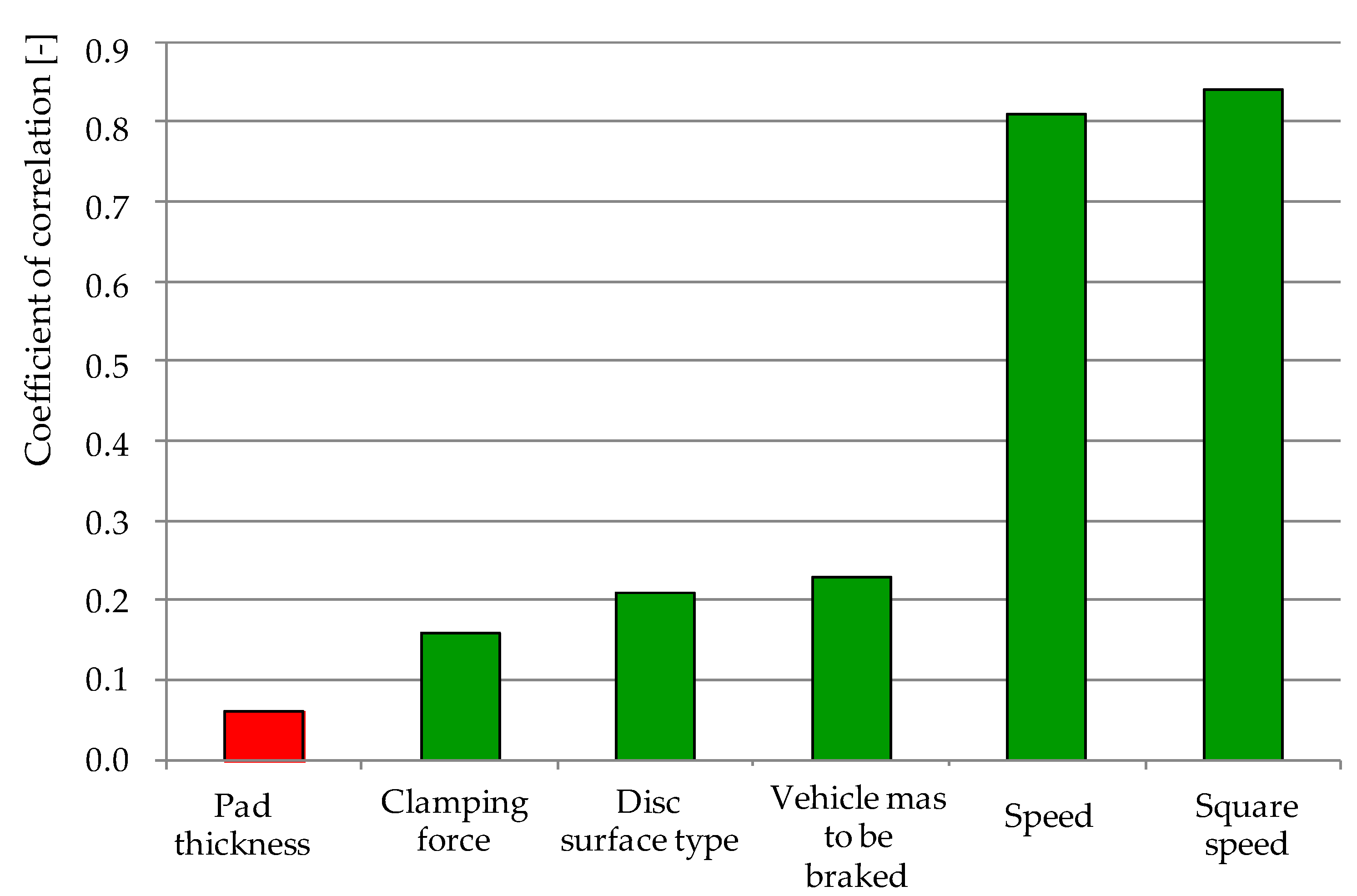

4. Modeling of Weight Wear of Friction Pads

5. Verification of the Friction Pad Weight Wear Model

6. Conclusions

- from the braking process parameters, the significant increase in the weight wear of friction pads is most strongly influenced by braking velocity and the correlation coefficient of the regression model for this parameter was 0.81. For the other input data, the following correlation coefficients were obtained: braking mass r = 0.23 and type of disc surface perforation r = 0.21.

- the pressure of the friction pad to the brake disc and the thickness of the friction pad do not show any influence on the results of the wear weight model (correlation coefficient r below 0.2).

- Thermal imaging tests proved about uneven temperature distribution on the pads on the right and left sides. This indicates uneven pressure distribution and uneven wear of the pads located on the two sides of the brake disc.

- The weight wear model proposed in the article applies to all pads, regardless of their side of contact with the brake disc.

- despite the symmetrical lever system, the pads in a disc brake do not wear uniformly, which was proven by thermographic imaging tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rymaniak, L.; Kaminska, M.; Szymlet, N.; Grzeszczyk, R. Analysis of Harmful Exhaust Gas Concentrations in Cloud behind a Vehicle with a Spark Ignition Engine. Energies 2021, 14, 1769. [Google Scholar] [CrossRef]

- Bajerlein, M.; Karpiuk, W.; Smolec, R. Use of Gas Desorption Effect in Injection Systems of Diesel Engines. Energies 2021, 14, 244. [Google Scholar] [CrossRef]

- Bajerlein, M.; Bor, M.; Karpiuk, W.; Smolec, R.; Spadlo, M. Strength analysis of critical components of high-Pressure fuel pump with hypocycloid drive. Mech. Aeronaut. Eng. Thermodyn. 2020, 68, 1341–1350. [Google Scholar] [CrossRef]

- Farroni, F.; Sakhnevych, A.; Timpone, F. Physical modelling of tire wear for the analysis of the influence of thermal and frictional effects on vehicle performance. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 151–161. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Wu, S.; Gao, J.; Li, Y.; An, Z.; Mao, B.; Tu, R.; Li, T. Impact of vehicle type, tyre feature and driving behaviour on tyre wear under real-World driving conditions. Sci. Total Environ. 2022, 842, 156950. [Google Scholar] [CrossRef] [PubMed]

- Glišović, J.; Pešić, R.; Lukić, J.; Miloradović, D. Airborne wear particles from automotive brake system: Environmental and health issues. In Proceedings of the 1st International Conference on Quality of Life, Kragujevac, Serbia, 9–10 June 2016; pp. 289–295. [Google Scholar]

- UIC Code 541-3: Brakes—Disc Brakes and Their Application—General Conditions for the Approval of Brake Pads, 7th ed.; Union Internationale des Chemins de Fer: Paris, France, 2010.

- UIC Code 541-4: Brakes—Brakes with Composite Brake Blocks—General Conditions for the Certification of Composite Brake Blocks, 6th ed.; Union Internationale des Chemins de Fer: Paris, France, 2020.

- Bernstein, D.M.; Toth, B.; Rogers, R.A.; Kunzendorf, P.; Phillips, J.I.; Schaudien, D.S. Final results from a 90-Day quantitative inhalation toxicology study evaluating the dose-Response and fate in the lung and pleura of chrysotile-Containing brake dust compared to TiO2, chrysotile, crocidolite or amosite asbestos: Histopathological examination, confocal microscopy and collagen quantification of the lung and pleural cavity. Toxicol. Appl. Pharmacol. 2021, 424, 115598. [Google Scholar] [CrossRef]

- Bernstein, D.M.; Toth, B.; Rogers, R.A.; Kling, D.E.; Kunzendorf, P.; Phillips, J.I.; Ernst, H. Evaluation of the exposure, dose-Response and fate in the lung and pleura of chrysotile-Containing brake dust compared to TiO2, chrysotile, crocidolite or amosite asbestos in a 90-Day quantitative inhalation toxicology study—Interim results Part 1: Experimental design, aerosol exposure, lung burdens and BAL. Toxicol. Appl. Pharmacol. 2020, 387, 114856. [Google Scholar] [CrossRef]

- Chandradass, J.; Baskara Sethupathi, P.; Amutha Surabi, M. Fabrication and characterization of asbestos free epoxy based brake pads using carbon fiber as reinforcement. Mater. Today Proc. 2021, 45, 7222–7227. [Google Scholar] [CrossRef]

- Pinca-Bretotean, C.; Josan, A.; Putan, V. Testing of brake pads made of non asbestos organic friction composite on specialized station. Mater. Today Proc. 2021, 45, 4183–4188. [Google Scholar] [CrossRef]

- Ahmadijokan, F.; Shojaei, A.; Dordanihaghighi, S.; Jafarpour, E.; Mohammadi, S.; Arjmand, M. Effests of hybrid carbon-Aramid fiber on performance of non-Asbestos organic brake friction composite. Wear 2020, 452–453, 203280. [Google Scholar] [CrossRef]

- Amaren, S.G.; Yawas, D.S.; Aku, S.Y. Effect of periwinkles shell particle size on the wear behavior of asbestos free brake pad. Results Phys. 2013, 3, 109–114. [Google Scholar] [CrossRef]

- Anoop, S.; Natarajan, S.; Kumaresh Babu, S.P. Analysis of factors influencing dry sliding wear behavior of Al/SiCp–Brake pad tribosystem. Mater. Des. 2009, 30, 3831–3838. [Google Scholar] [CrossRef]

- Pujari, S.; Srikiran, S. Experimental investigations on wear properties of Palm kernel reinforced composites for brake pad applications. Def. Technol. 2019, 15, 295–299. [Google Scholar] [CrossRef]

- Park, J.; Joo, B.; Seo, H.; Song, W.; Lee, J.J.; Lee, W.K.; Jang, H. Analysis of wear induced particle emissions from brake pads during the worldwide harmonized light vehicles test procedure (WLTP). Wear 2021, 466–467, 203539. [Google Scholar] [CrossRef]

- Wahlström, J.; Gventsadze, D.; Olander, L.; Kutelia, E.; Gventsadze, L.; Tsurtsumia, O.; Olofsson, U. A pin-On-Disc investigation of novel nanoporous composite-Based and conventional brake pad materials focussing on airborne wear particles. Tribol. Int. 2011, 44, 1838–1843. [Google Scholar] [CrossRef]

- Mahale, V.; Bijwe, J. Exploration of plasma treated stainless steel swarf to reduce the wear of copper-Free brake-Pads. Tribol. Int. 2020, 144, 106111. [Google Scholar] [CrossRef]

- Maiorana, S.; Teoldi, F.; Silvani, S.; Mancini, A.; Sanguineti, A.; Mariani, F.; Cella, C.; Lopez, A.; Potenza, M.A.C.; Lodi, M.; et al. Phytotoxicity of wear debris from traditional and innovative brake pads. Environ. Int. 2019, 123, 156–163. [Google Scholar] [CrossRef]

- Verma, P.C.; Menapace, L.; Bonfanti, A.; Ciudin, R.; Gialanella, S.; Straffelini, G. Braking pad-Disc system: Wear mechanisms and formation of wear fragments. Wear 2015, 322–323, 251–258. [Google Scholar] [CrossRef]

- Kalel, N.; Bhatt, B.; Darpe, A.; Bijwe, J. Argon low-Pressure plasma treatment to stainless steel particles to augment the wear resistance of Cu-Free brake-Pads. Tribol. Int. 2022, 167, 107366. [Google Scholar] [CrossRef]

- Gurunath, P.V.; Bijwe, J. Friction and wear studies on brake-Pad materials based on newly developed resin. Wear 2007, 263, 1212–1219. [Google Scholar] [CrossRef]

- Jacob Moses, A.; Suresh Babu, A.; Ananda Kumar, S. Analysis of physical properties and wear behavior of phenol formaldehyde—Basalt fiber reinforced brake pad. Mater. Today Proc. 2020, 33, 1128–1132. [Google Scholar] [CrossRef]

- Tavangar, R.; Moghadam, H.A.; Khavandi, A.; Banaeifar, S. Comparison of dry sliding behavior and wear mechanism of low metallic and copper-Free brake pads. Tribol. Int. 2020, 151, 106416. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wei, D.; Wu, P.; Cao, J.; Shijia, C.; Qu, X. A high-Performance copper-Based brake pad for high-Speed railway trains and its surface substance evolution and wear mechanism at high temperature. Wear 2020, 444–445, 203182. [Google Scholar] [CrossRef]

- Chandradass, J.; Amutha Surabi, M.; Baskara Sethupathi, P.; Jawahar, P. Development of low cost brake pad material using asbestos free sugarcane bagasse ash hybrid composites. Mater. Today Proc. 2021, 45, 7050–7057. [Google Scholar] [CrossRef]

- Świderski, A.; Borucka, A.; Jacyna-Gołda, I.; Szczepański, E. Wear of brake system components in various operating conditions of vehicle inthe transport company. Maint. Reliab. 2019, 21, 1–9. [Google Scholar] [CrossRef]

- Thendral Selvam, P.; Pugazhenthi, R.; Dhanasekaran, C.; Chandrasekaran, M.; Sivaganesan, S. Experimental investigation on the frictional wear behaviour of TiAlN coated brake pads. Mater. Today Proc. 2021, 37, 2419–2426. [Google Scholar] [CrossRef]

- Idris, U.D.; Aigbodion, V.S.; Akubakar, I.J.; Nwoye, C.I. Eco-Friendly asbestos free brake-Pad: Using banana peels. J. King Saud Univ.—Eng. Sci. 2015, 27, 185–192. [Google Scholar] [CrossRef]

- Chen, F.; Li, Z.; Luo, Y.; Li, D.; Ma, W.; Zhang, C.; Tang, H.; Li, F.; Xiao, P. Braking behaviors of Cu-Based PM brake pads mating with C/C–SiC and 30CrMnSi steel discs under high-Energy braking. Wear 2021, 486–487, 204019. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Liew, K.W. Effect of water spray on friction and wear behaviour of noncommercial and commercial brake pad materials. J. Mater. Processing Technol. 2008, 208, 135–144. [Google Scholar] [CrossRef]

- Jiang, L.; Jiang, Y.L.; Yu, L.; Yang, H.L.; Li, Z.S.; Ding, Y.D.; Fu, G.F. Fabrication, microstructure, friction and wear properties of SiC3D/Al brake disc−Graphite/SiC pad tribo-Couple for high-Speed train. Trans. Nonferrous Met. Soc. China 2019, 29, 1889–1902. [Google Scholar] [CrossRef]

- Polajnar, M.; Kalin, M.; Thorbjornsson, I.; Thorgrimsson, J.T.; Valle, N.; Botor-Probierz, A. Friction and wear performance of functionally graded ductile iron for brake pads. Wear 2017, 382–383, 85–94. [Google Scholar] [CrossRef]

- Xiao, J.K.; Xiao, S.X.; Chen, J.; Zhang, C. Wear mechanism of Cu-Based brake pad for high-Speed train braking at speed of 380 km/h. Tribol. Int. 2020, 150, 106357. [Google Scholar] [CrossRef]

- Hatam, A.; Khalkhali, A. Simulation and sensitivity analysis of wear on the automotive brake pad. Simul. Model. Pract. Theory 2018, 84, 106–123. [Google Scholar] [CrossRef]

- Ingo, G.M.; D’Uffizi, M.; Falso, G.; Bultrini, G.; Padeletti, G. Thermal and microchemical investigation of automotive brake pad wear residues. Thermochim. Acta 2004, 418, 61–68. [Google Scholar] [CrossRef]

- Elzayady, N.; Elsoeudy, R. Microstructure and wear mechanisms investigation on the brake pad. J. Mater. Res. Technol. 2021, 11, 2314–2335. [Google Scholar] [CrossRef]

- Sawczuk, W. Application of vibroacoustic diagnostics to evaluation of wear of friction pads rail brake disc. Maint. Reliab. 2016, 18, 565–571. [Google Scholar] [CrossRef]

- Sawczuk, W.; Ulbrich, D.; Kowalczyk, J.; Merkisz-Guranowska, A. Evaluation of Wear of Disc Brake Friction Linings and the Variability of the Friction Coefficient on the Basis of Vibroacoustic Signals. Sensors 2021, 21, 5927. [Google Scholar] [CrossRef]

- Abbasi, S.; Wahlströma, J.; Olander, L.; Larssonc, C.; Olofssona, U.; Sellgren, U. A study of airborne wear particles generated from organic railway brake pads and brake discs. Wear 2011, 273, 93–99. [Google Scholar] [CrossRef]

- Laguna-Camacho, J.; Juárez-Morales, G.; Calderon, C.; Velázquez-Martínez, V.; Hernández-Romero, I.; Mendez, J.V.M.; Vite-Torres, M. A study of the wear mechanisms of disk and shoe brake pads. Eng. Fail. Anal. 2015, 56, 348–359. [Google Scholar] [CrossRef]

- Söderberg, A.; Andersson, S. Simulation of wear and contact pressure distribution at the pad-To-Rotor interface in a disc brake using general purpose finite element analysis software. Wear 2009, 267, 2243–2251. [Google Scholar] [CrossRef]

- Yevtushenko, A.A.; Grzes, P. Axisymmetric FEA of temperature in a pad/disc brake system at temperature-Dependent coefficients of friction and wear. Int. Commun. Heat Mass Transf. 2012, 39, 1045–1053. [Google Scholar] [CrossRef]

- Rakov, V.; Kapustin, A.; Danilov, I. Study of braking energy recovery impact on cost-Efficiency and environmental safety of vehicle. Transp. Res. Procedia 2020, 50, 559–565. [Google Scholar] [CrossRef]

- Varazhun, I.; Shimanovsky, A.; Zavarotny, A. Determination of Longitudinal Forces in the Cars Automatic Couplers as Train Electrodynamic Braking. Procedia Eng. 2016, 134, 415–421. [Google Scholar] [CrossRef]

- Chen, J.; Hu, H.; Ge, Y.; Wang, K.; Huang, W.; He, Z. An Energy Storage System for Recycling Regenerative Braking Energy in High-Speed Railway. IEEE Trans. Power Deliv. 2020, 36, 320–330. [Google Scholar] [CrossRef]

- Rajambal, K.; Umamaheswari, B.; Chellamuthu, C. Electrical braking of large wind turbines. Renew. Energy 2005, 30, 2235–2245. [Google Scholar] [CrossRef]

- Urbaniak, M.; Kardas-Cinal, E. Optimization of using recuperative braking energy on a double-Track railway line. Transp. Res. Procedia 2019, 40, 1208–1215. [Google Scholar] [CrossRef]

- Sawczuk, W. The evaluation of a rail disc brake braking process by using a thermal camera. Meas. Autom. Monit. 2015, 61, 265–270. [Google Scholar]

- Glowacz, A.; Tadeusiewicz, R.; Legutko, S.; Caesarendra, W.; Irfan, M.; Liu, H.; Brumercik, F.; Gutten, M.; Sulowicz, M.; Daviu, J.A.A.; et al. Fault diagnosis of angle grinders and electric impact drills using acoustic signals. Appl. Acoust. 2021, 179, 108070. [Google Scholar] [CrossRef]

- Smoczynski, P.; Gill, A.; Kadziński, A. Maintenance layers for railway infrastructure in Poland. Transport 2020, 35, 605–615. [Google Scholar] [CrossRef]

- Sawczuk, W.; Jüngst, M.; Ulbrich, D.; Kowalczyk, J. Modeling the Depth of Surface Cracks in Brake Disc. Materials 2021, 14, 3890. [Google Scholar] [CrossRef]

- Domański, C.; Parys, D. Statystyczne Metody Wnioskowania Wielokryterialnego; WUL: Lódź, Poland, 2021; pp. 80–85. [Google Scholar]

- Żakowski, W.; Decewicz, G. Matematyczna, Analiza Matematyczna Cz. 1; Wydawnictwo WNT: Warszawa, Poland, 2017; pp. 128–132. [Google Scholar]

- Sawczuk, W.; Merkisz-Guranowska, A.; Rilo Cañás, A.M. Assessment of disc brake vibration in rail vehicle operation on the basis of brake stand. Maint. Reliab. 2021, 23, 221–230. [Google Scholar] [CrossRef]

| Chemical Composition | |||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | Cu | S | Ce | Sc |

| 3.5 | 1.5 | 0.7 | 0.5 | 0.15 | - | - | - |

| Mechanical properties | |||||||

| Modulus of elasticity E [N/mm2] | Thermal conductivity coefficient λ [W/mK] | Heat capacity (specific heat) Cw [J/kgK] | Thermal expansion coefficient α [(1/K)·10−5] | Elongation A5 [%] | Density ρ [(kg/m3)·103] | Tensile strength Rm [N/mm2] | Hardness HB |

| 110,000 | 50.2 | 598.7 | 1.80 | 0.5 | 7.1 | 250 | 180 |

| Velocity km/h | Disc without Notch | Disc with One Notch | Dial with Two Notches | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Brake Pad Thickness TP1 = 35 mm | Brake Pad Thickness TP2 = 25 mm | Brake Pad Thickness TP3 = 15 mm | Brake Pad Thickness TP1 = 35 mm | Brake Pad Thickness TP2 = 25 mm | Brake Pad Thickness TP3 = 15 mm | Brake Pad Thickness TP1 = 35 mm | Brake Pad Thickness TP2 = 25 mm | Brake Pad Thickness TP3 = 15 mm | |

| 50 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 80 | 1 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 2 |

| 120 | 3 | 3 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| 160 | 6 | 7 | 7 | 8 | 8 | 8 | 10 | 10 | 11 |

| 200 | 13 | 14 | 15 | 16 | 18 | 19 | 19 | 21 | 21 |

| Coefficient | Value | Value F * |

|---|---|---|

| δ1 | 1.53 | 4.41∙10−7 |

| δ2 | −2.17∙10−2 | 0.21 |

| δ3 | −4.14∙10−2 | 3.23∙10−2 |

| δ4 | 8.48∙10−2 | 5.98∙10−5 |

| δ5 | 1.18 | 1.46∙10−11 |

| δ6 | −5.92∙10−2 | 7.03∙10−4 |

| δ7 | 5.78∙10−4 | 4.01∙10−15 |

| δ0 | −3.21 | 0.37 |

| R2 | 0.84 | |

| F ** | 2.00∙10−77 |

| Coefficient | Value | Value F * |

|---|---|---|

| δ1 | 1.78 | 2.04∙10−14 |

| δ2 | −4.14∙10−2 | 3.26∙10−2 |

| δ3 | 8.36∙10−2 | 7.56∙10−5 |

| δ4 | 1.17 | 1.87∙10−11 |

| δ5 | −5.92∙10−2 | 7.14∙10−4 |

| δ6 | 5.78∙10−4 | 4.22∙10−15 |

| δ0 | −7.35 | 1.03∙10−6 |

| R2 | 0.84 | |

| F ** | 3.12∙10−78 |

| Variable | Disc Type D | Pad Thickness TP | Pressure N | Mass MB | Velocity v | Velocity v2 | Correlation Coefficient |

|---|---|---|---|---|---|---|---|

| Disc type D | 1 | −1.42·10−18 | −0.05 | −0.04 | 5.17·10−18 | 5.17·10−18 | 0.21 |

| Pad thickness TP | −1.42·10−18 | 1 | 9.41·10−18 | −4.1710−18 | 0 | 0 | −0.06 |

| Pressure N | −0.05 | 9.41·10−18 | 1 | 0.28 | 5.71·10−18 | 5.32·10−17 | 0.16 |

| Mass MB | −0.04 | −4.1710−18 | 0.28 | 1 | 1.52·10−17 | 2.56·10−18 | 0.23 |

| Velocity v | 5.17·10−18 | 0 | 5.71·10−18 | 1.52·10−17 | 1 | 0.98 | 0.81 |

| Velocity v2 | 5.17·10−18 | 0 | 5.32·10−17 | 2.56·10−18 | 0.98 | 1 | 0.84 |

| Correlation coefficient | 0.21 | −0.06 | 0.16 | 0.23 | 0.81 | 0.84 | 1.0 |

| Left Upper Pad | Right Upper Pad | ||||

|---|---|---|---|---|---|

| Measurement | Outer Radius of Pad | Inner Radius of Pad | Measurement | Outer Radius of Pad | Inner Radius of Pad |

| 1 | 137.2 °C | 146.8 °C | 1 | 134.9 °C | 120.8 °C |

| 2 | 139.0 °C | 141.4 °C | 2 | 140.3 °C | 124.5 °C |

| 3 | 139.7 °C | 138.2 °C | 3 | 135.4 °C | 123.3 °C |

| Bottom left pad | Bottom right pad | ||||

| Measurement | Outer radius of pad | Inner radius of pad | Measurement | Outer radius of pad | Inner radius of pad |

| 1 | 146.5 °C | 139.7 °C | 1 | 139.7 °C | 124.5 °C |

| 2 | 142.1 °C | 141.7 °C | 2 | 139.9 °C | 119.3 °C |

| 3 | 134.3 °C | 136.1 °C | 3 | 124.8 °C | 111.3 °C |

| Mean value | 139.8 °C | 140.7 °C | Mean value | 135.8 °C | 120.6 °C |

| Difference 1 | 0.9 °C | Difference 2 | 15.2 °C | ||

| Difference 3 | 20 °C | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawczuk, W.; Merkisz-Guranowska, A.; Ulbrich, D.; Kowalczyk, J.; Cañás, A.-M.R. Investigation and Modelling of the Weight Wear of Friction Pads of a Railway Disc Brake. Materials 2022, 15, 6312. https://doi.org/10.3390/ma15186312

Sawczuk W, Merkisz-Guranowska A, Ulbrich D, Kowalczyk J, Cañás A-MR. Investigation and Modelling of the Weight Wear of Friction Pads of a Railway Disc Brake. Materials. 2022; 15(18):6312. https://doi.org/10.3390/ma15186312

Chicago/Turabian StyleSawczuk, Wojciech, Agnieszka Merkisz-Guranowska, Dariusz Ulbrich, Jakub Kowalczyk, and Armando-Miguel Rilo Cañás. 2022. "Investigation and Modelling of the Weight Wear of Friction Pads of a Railway Disc Brake" Materials 15, no. 18: 6312. https://doi.org/10.3390/ma15186312

APA StyleSawczuk, W., Merkisz-Guranowska, A., Ulbrich, D., Kowalczyk, J., & Cañás, A.-M. R. (2022). Investigation and Modelling of the Weight Wear of Friction Pads of a Railway Disc Brake. Materials, 15(18), 6312. https://doi.org/10.3390/ma15186312