Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiCp Composite after KoBo Extrusion

Abstract

1. Introduction

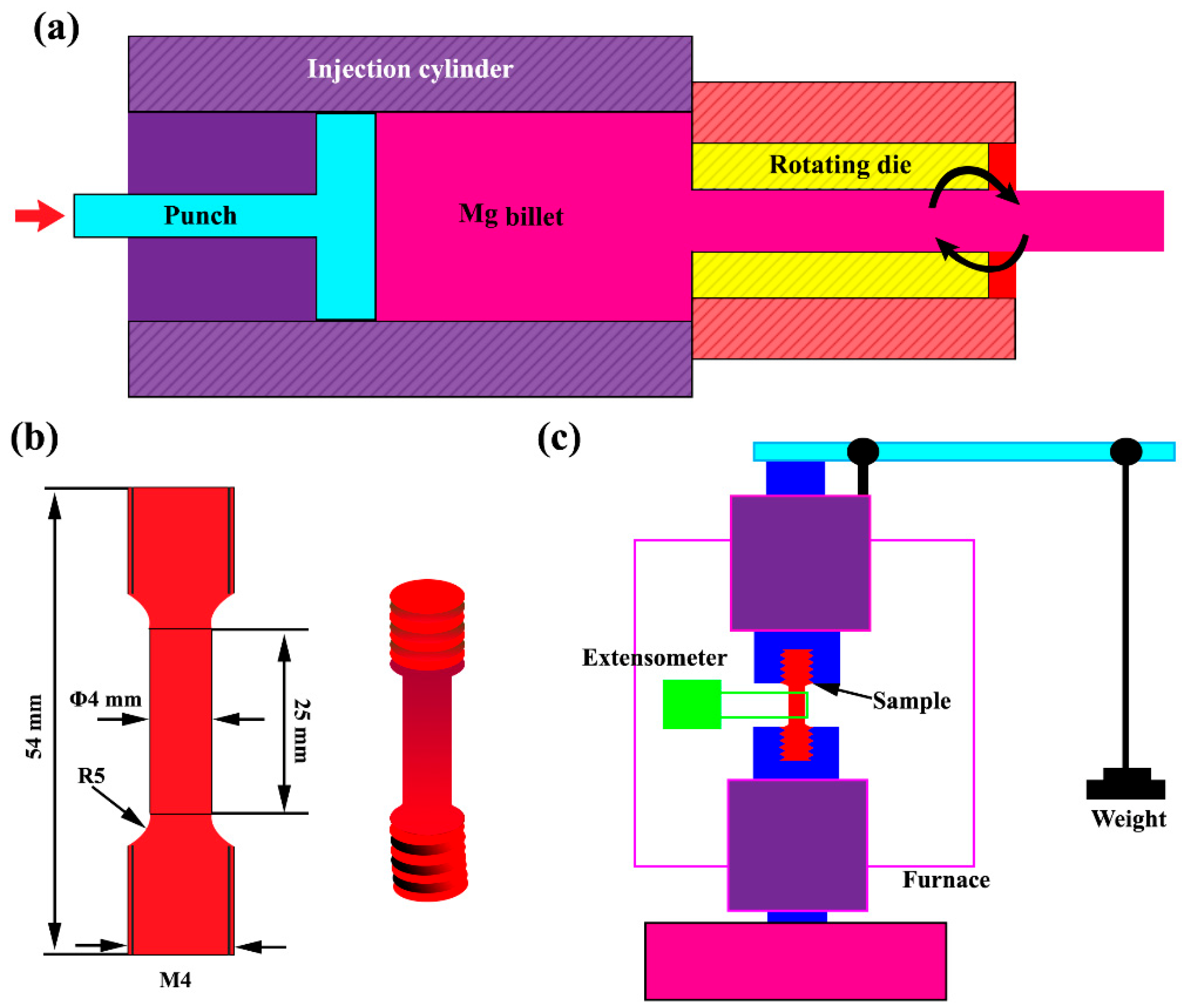

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Heat Treatment and KoBo Extrusion

2.4. Creep Test

2.5. Characterizations

3. Results and Discussion

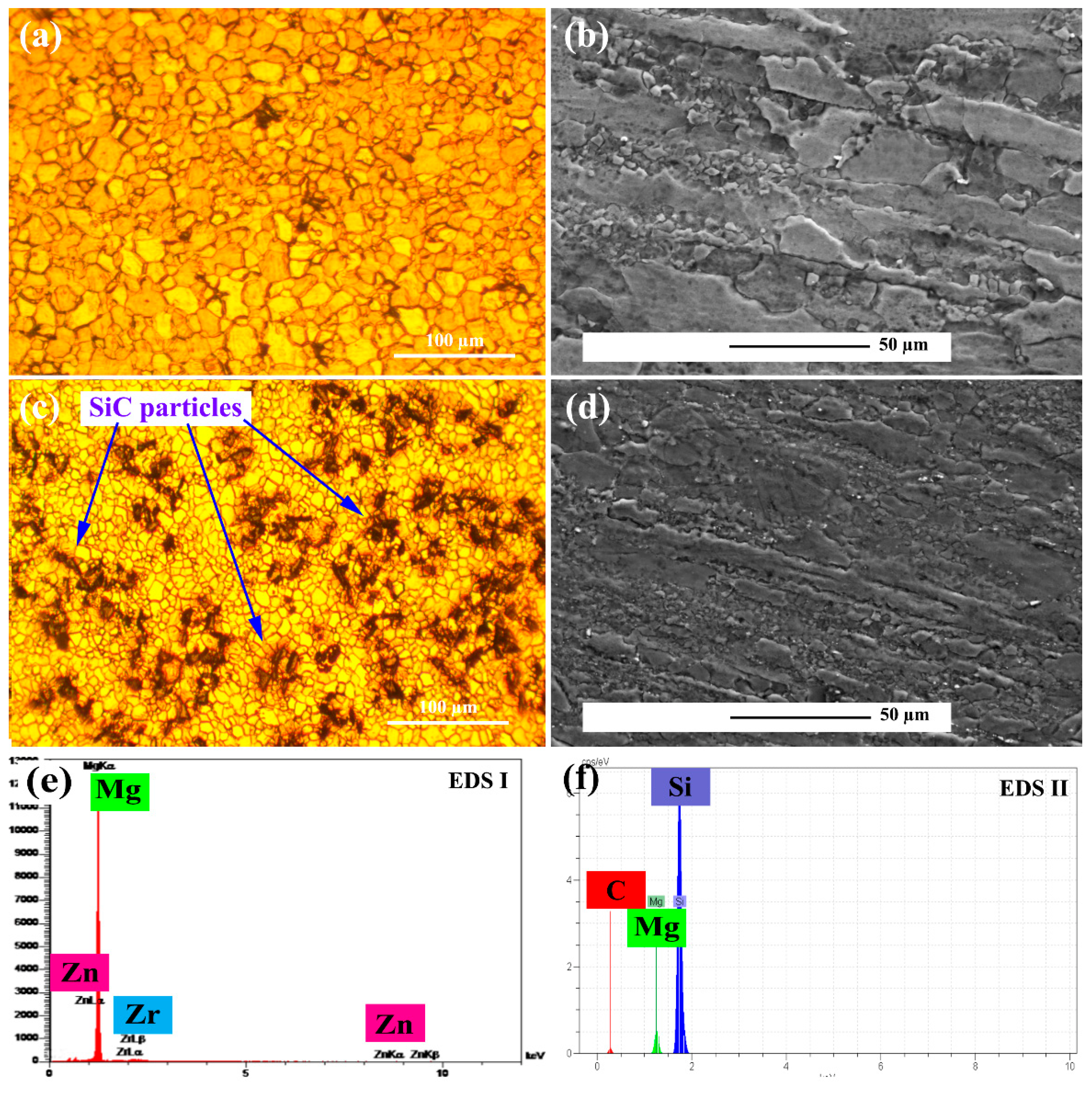

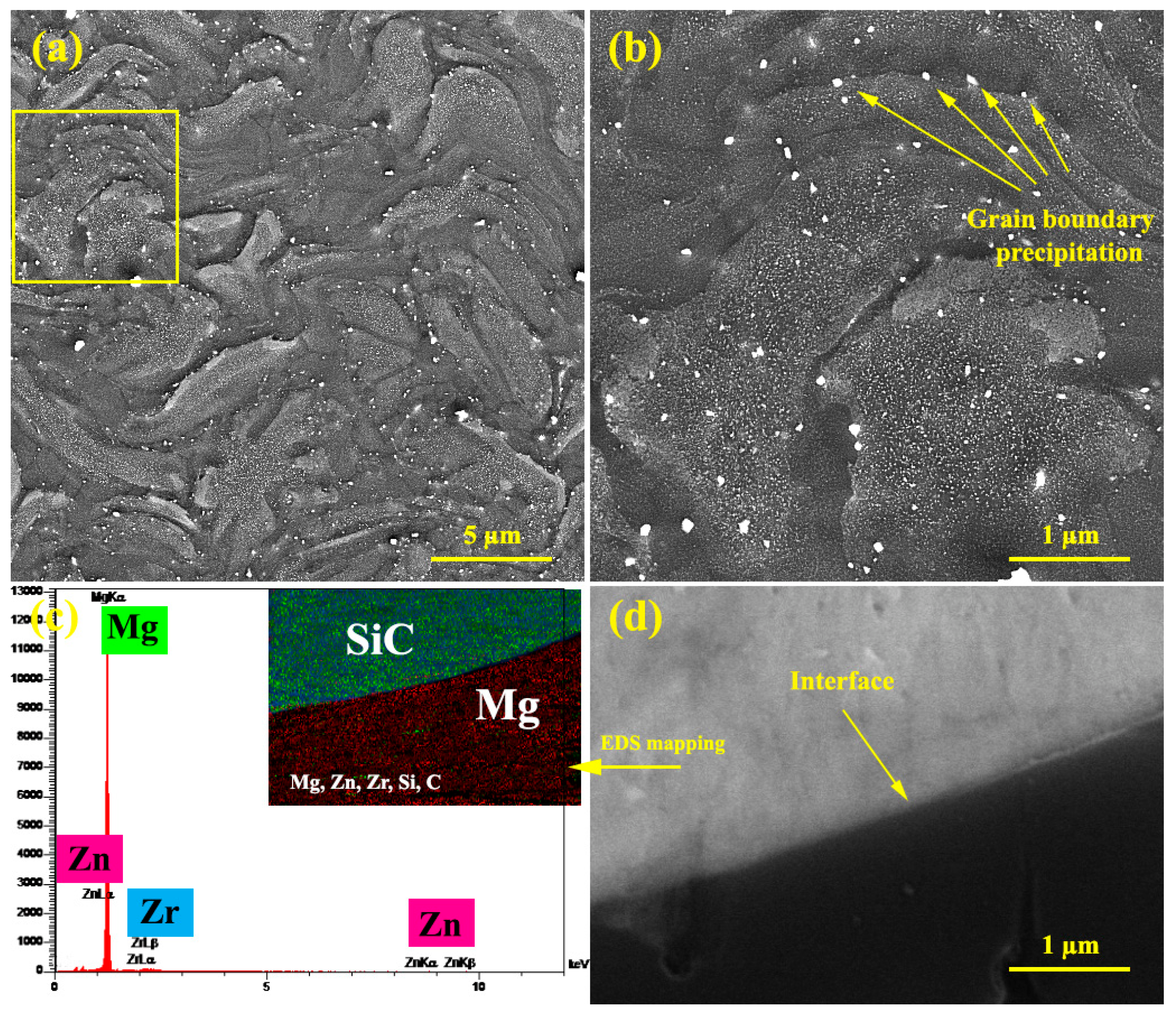

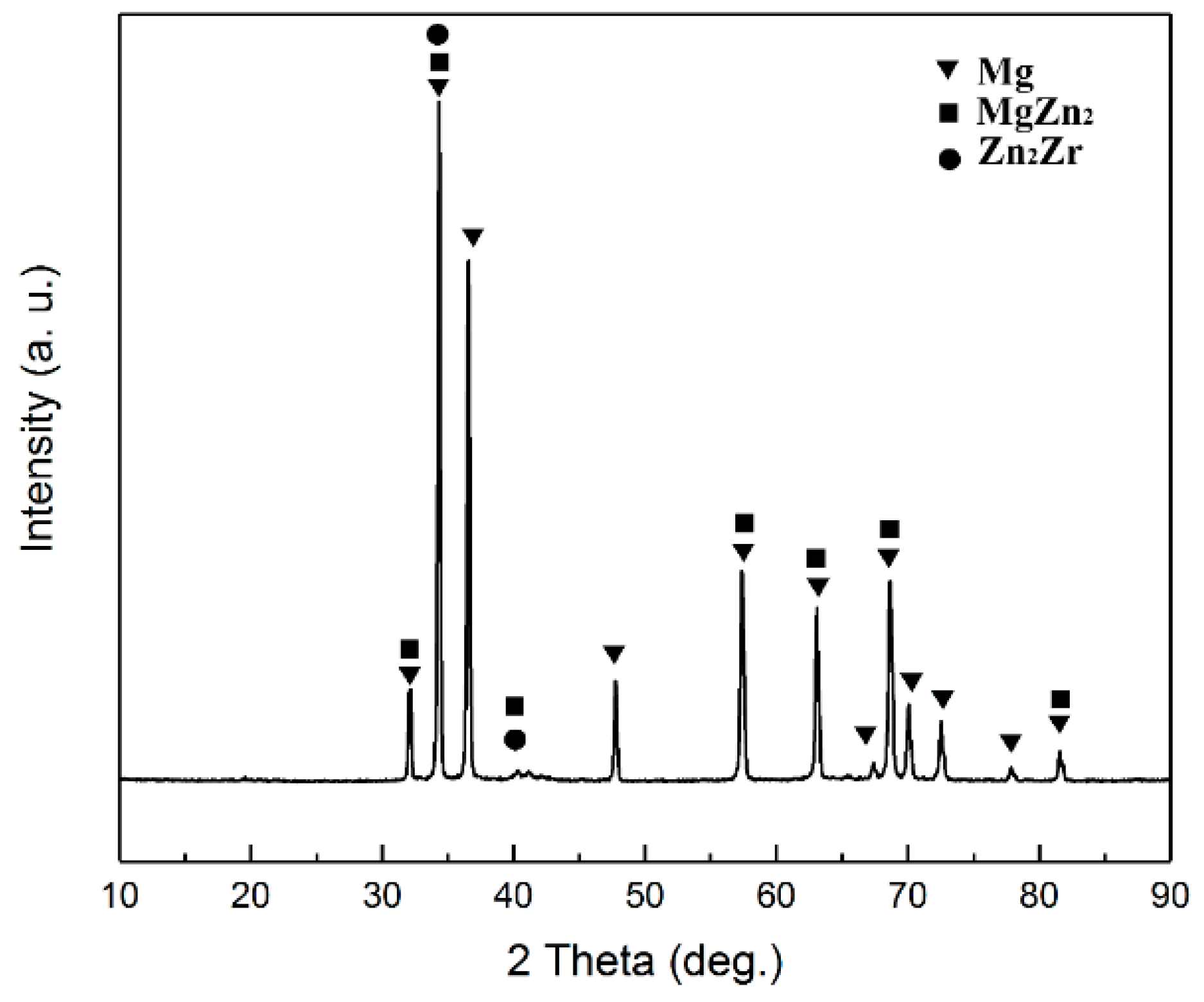

3.1. Microstructure before Creep Test

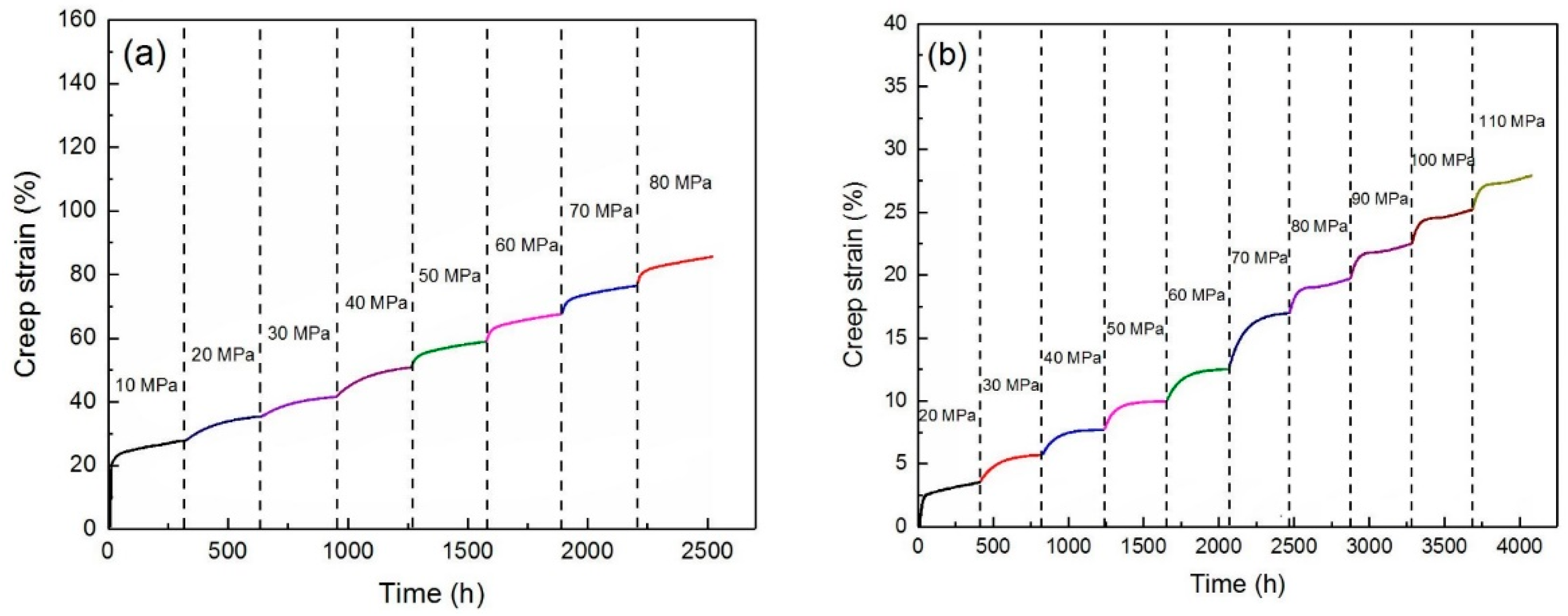

3.2. Creep Data

3.2.1. Creep Curve

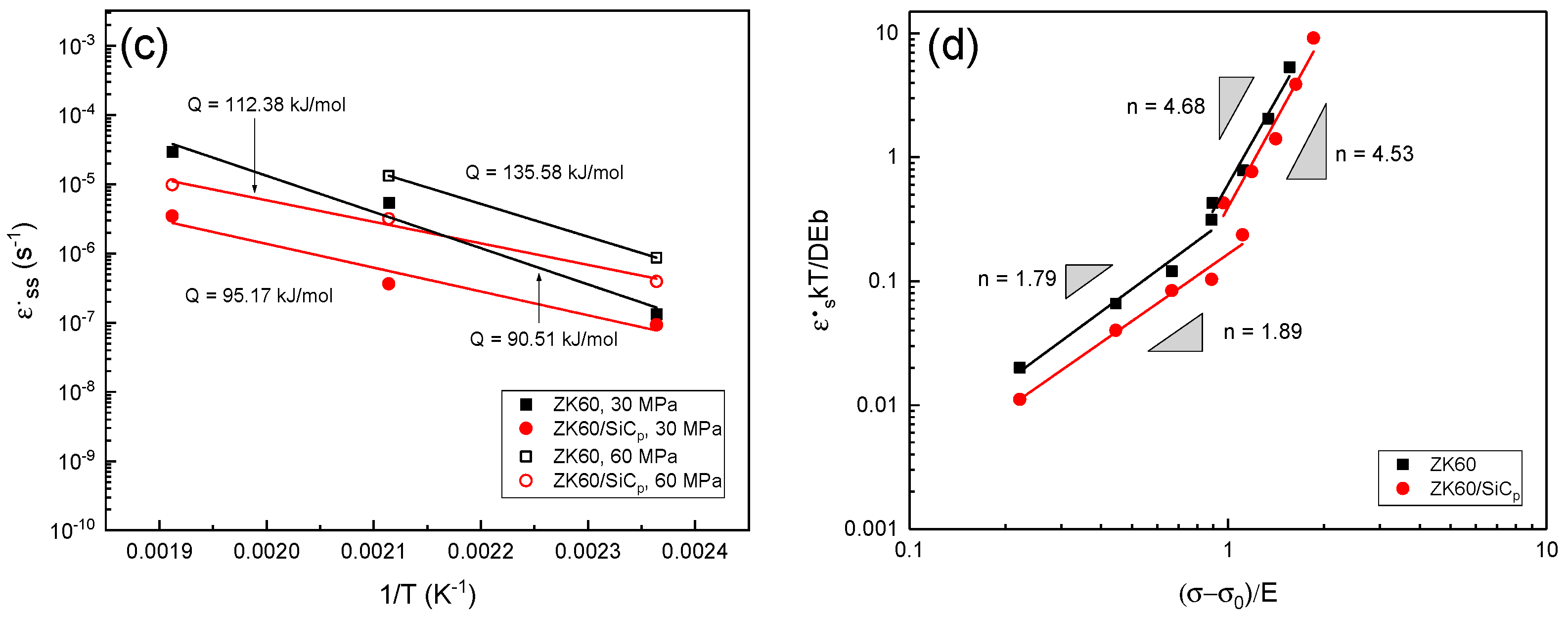

3.2.2. Minimum Creep Rate

3.2.3. Threshold Stress

3.2.4. Activation Energy

3.2.5. Mechanism

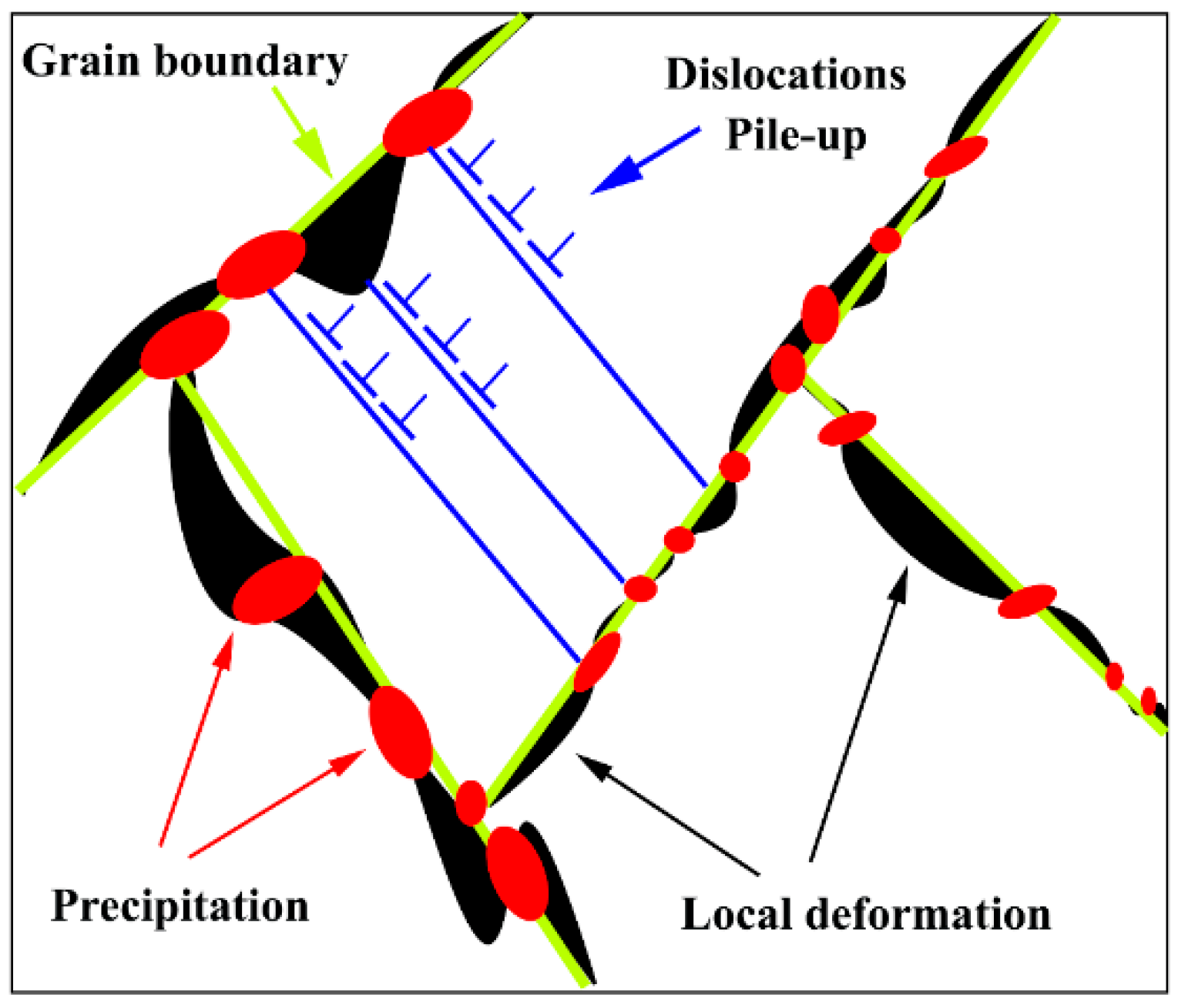

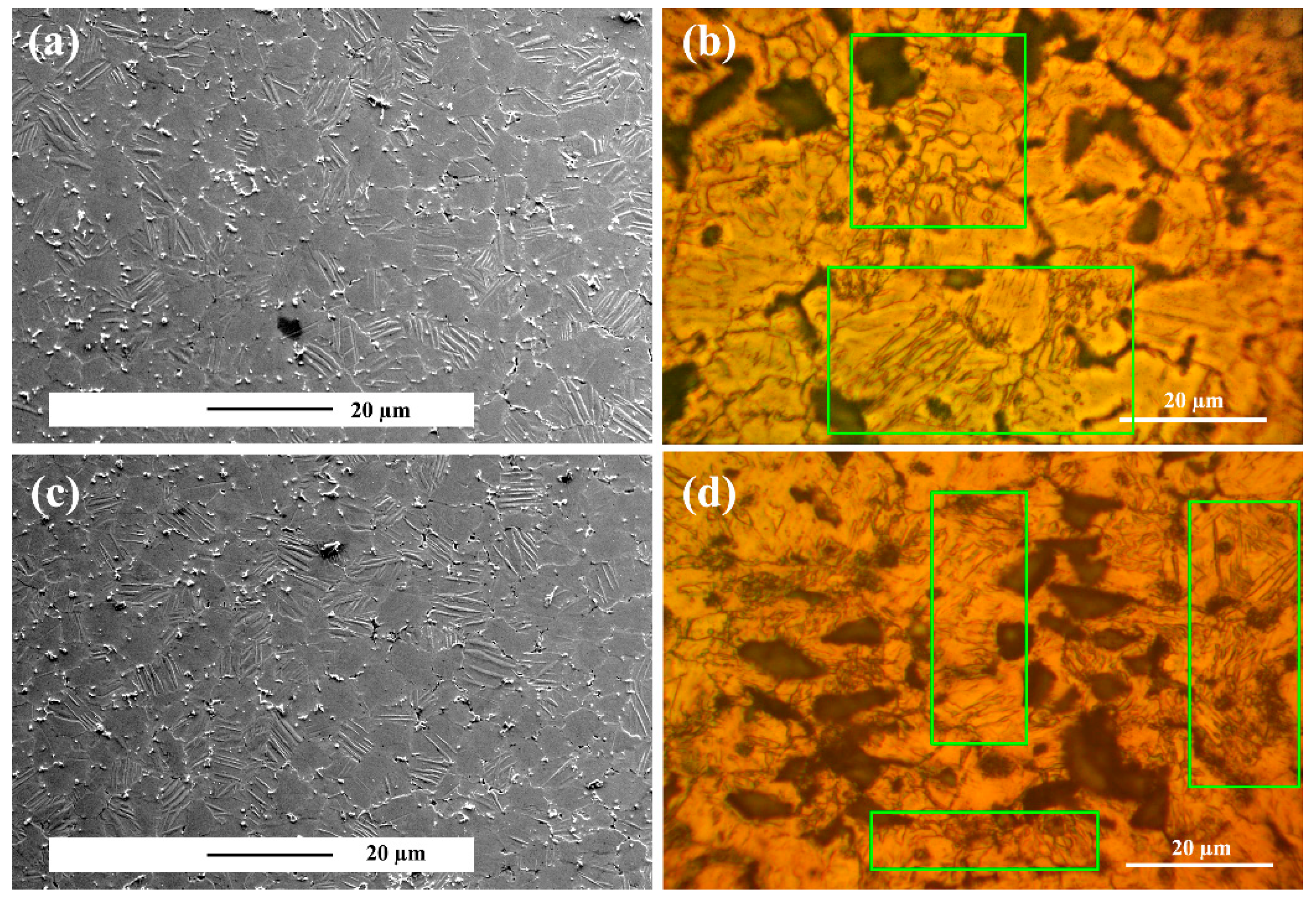

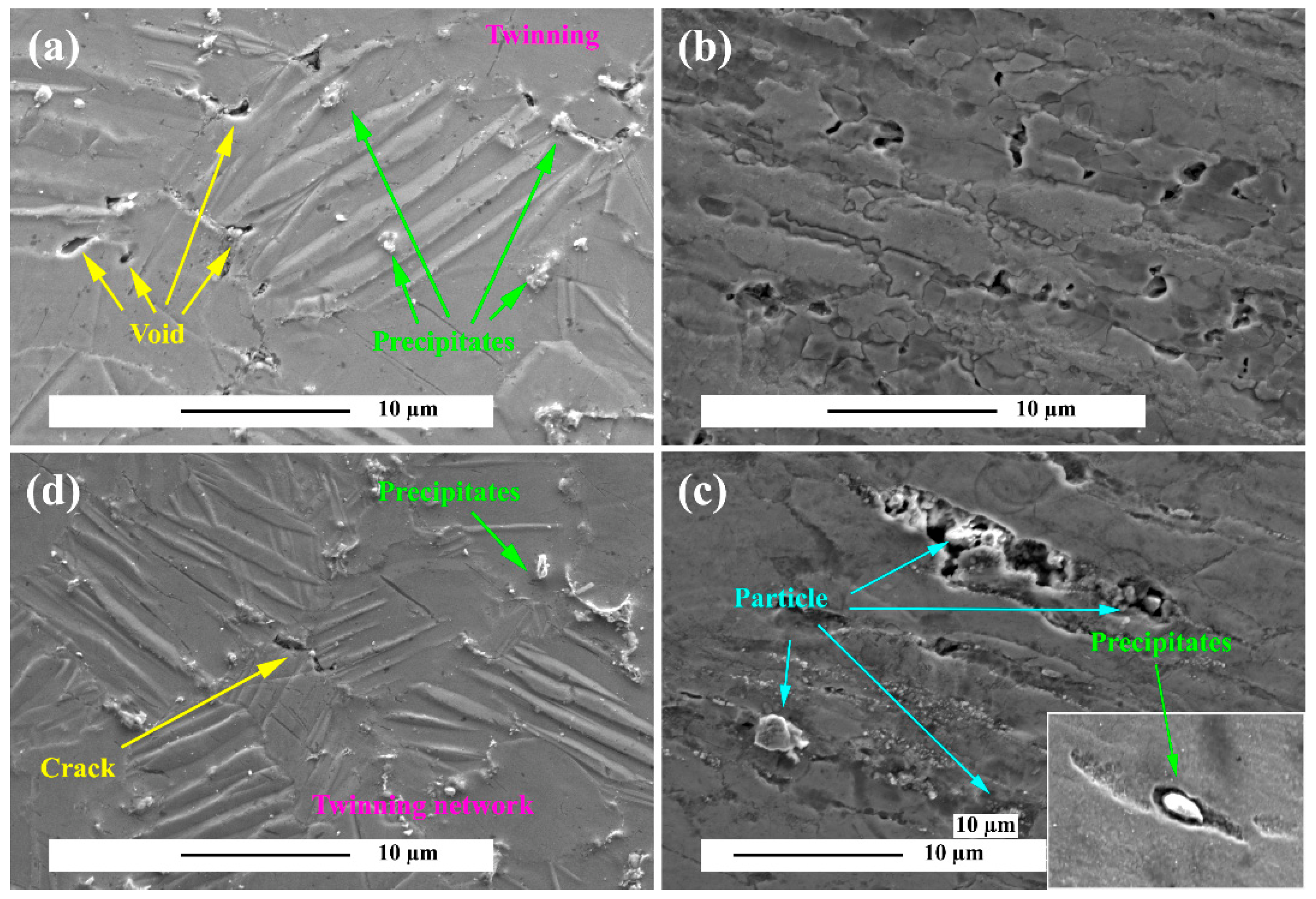

3.3. Microstructure after Creep Test

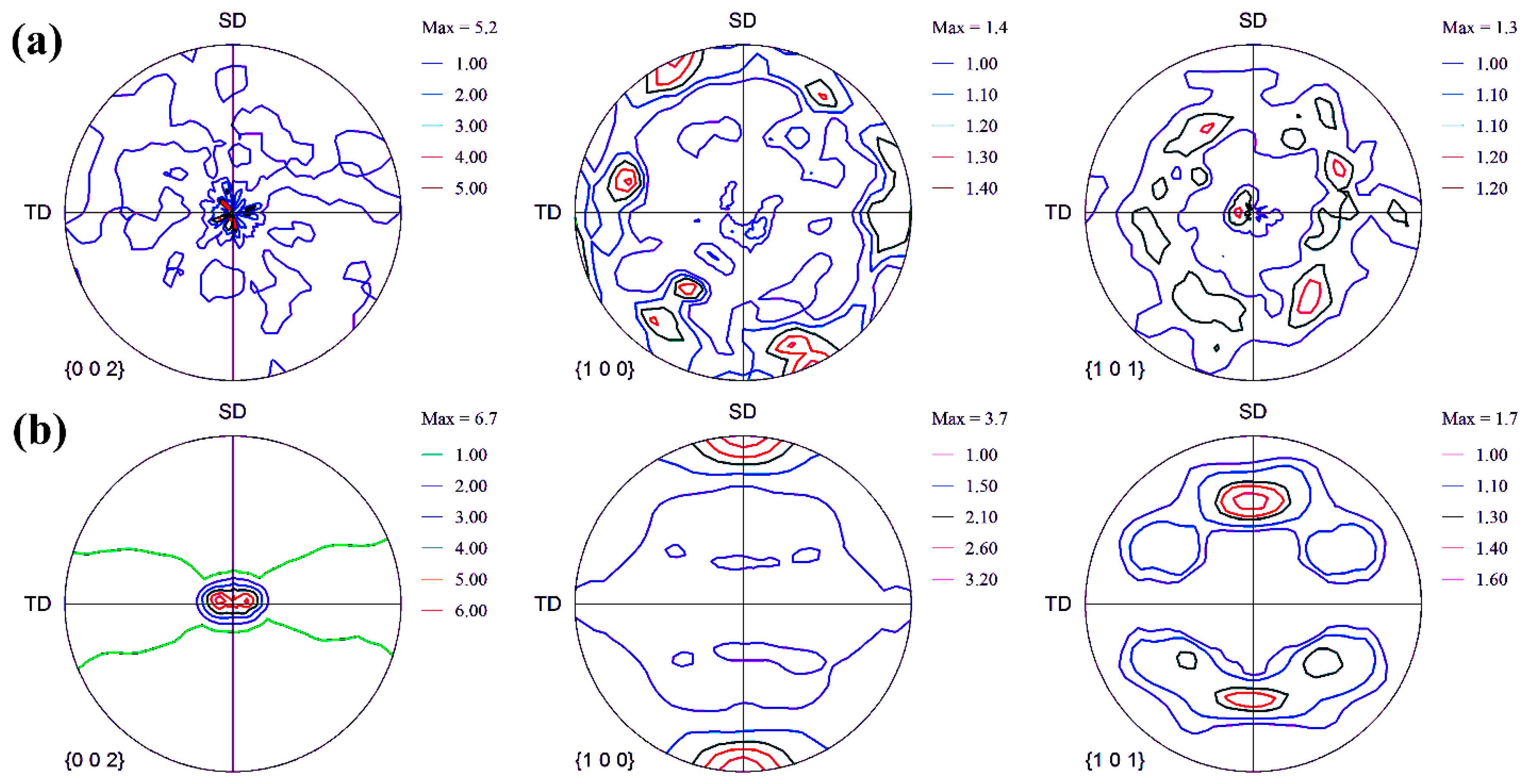

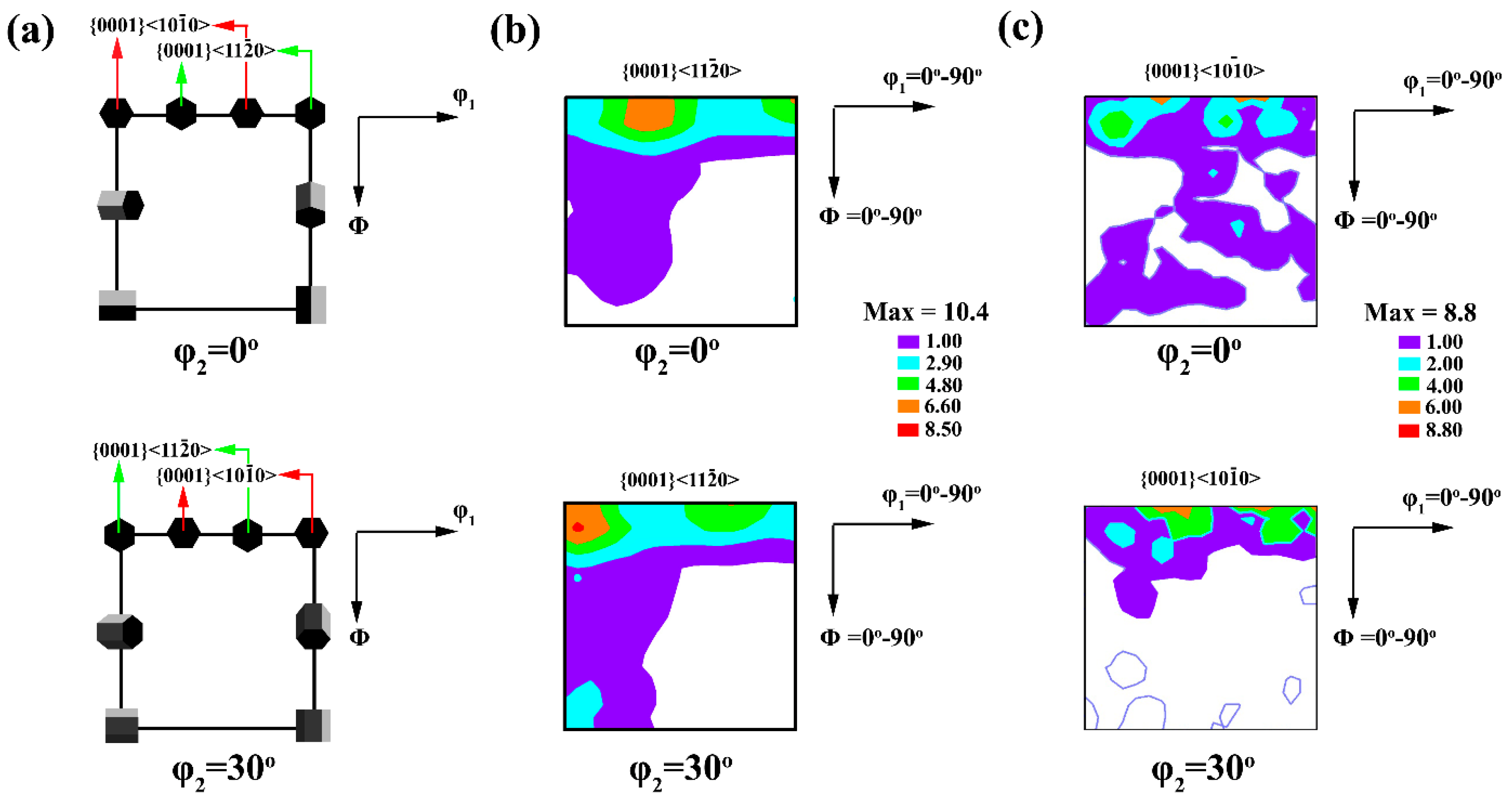

3.4. Texture

3.5. Damage Mechanism

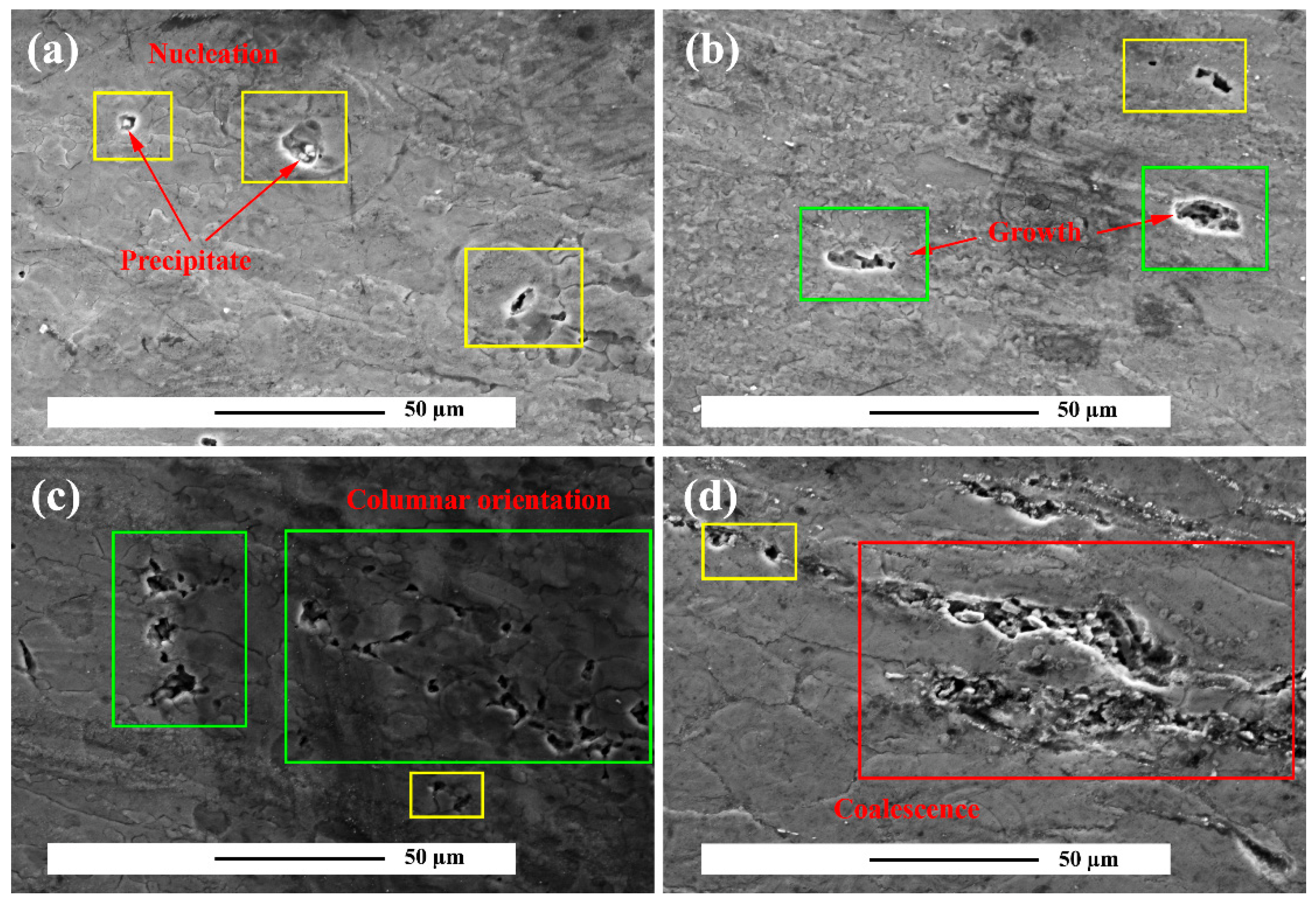

3.5.1. Perpendicular to the Fracture Surface

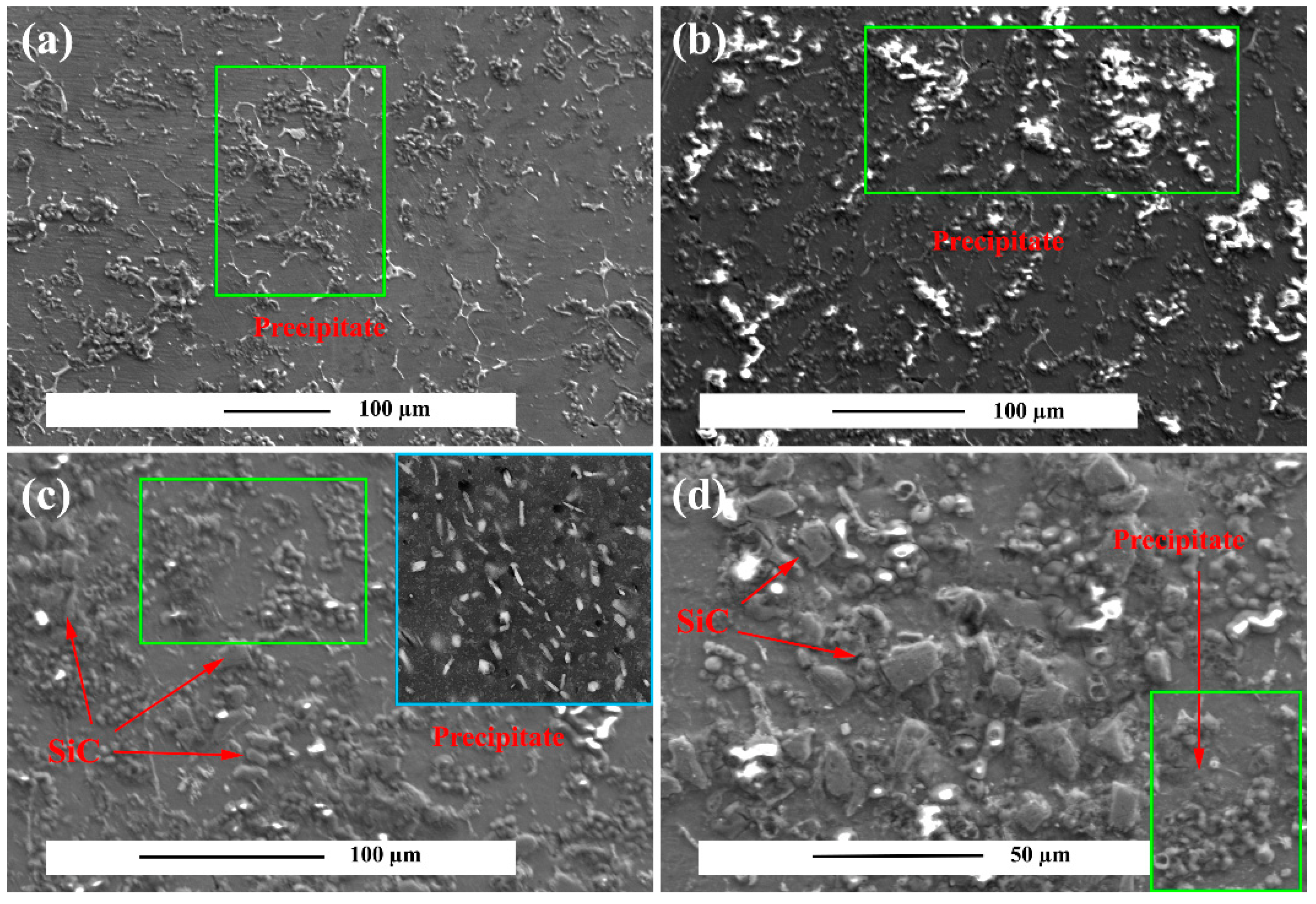

3.5.2. Fracture Surface

4. Conclusions

- Bimodal grain distribution is achieved in the alloy and composite microstructures during KoBo extrusion, in which the grain sizes were less than 5 µm.

- The results of the creep tests showed that parameters n and Qc of the samples were altered at high-stress conditions, showing the change of GBS mechanism to dislocation climb.

- It was found that pre-aging at 175 °C can achieve double aging at 150 °C under high stresses which caused precipitates growth.

- The strengthening mechanism has been the twinning, double twinning, and dynamic precipitation at low, moderate, and high stresses, respectively.

- The failure mechanism was cavitation at the tertiary grain boundaries and at the intersection of the twinning with the grain boundary and the precipitates.

- Evaluation of the elongation of the samples showed that due to the low temperature and microstructural heterogeneity, premature necking occurred and caused the elongation percentage not to exceed 23%.

- The unreinforced alloy showed a moderately strong fiber texture along the angle of ϕ1 = 0–90°, which was tilted about Φ = 10°. A new strong texture component was observed at (90°, 5°, 0°) for the composite sample, which crept due to minor splitting of the basal pole by ~5° toward RD.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moheimani, S.K.; Keshtgar, A.; Khademzadeh, S.; Tayebi, M.; Rajaee, A.; Saboori, A. Tribological behaviour of AZ31 magnesium alloy reinforced by bimodal size B4C after precipitation hardening. J. Magnes. Alloy. 2021, in press. [CrossRef]

- Wang, Z.-X.; Zhang, J.-W.; Lv, W.-G.; Chen, L.-Y.; Qi, F.; Chen, W.-W.; Lu, S. Growth Mechanism of Ceramic Coating on ZK60 Magnesium Alloy Based on Two-Step Current-Decreasing Mode of Micro-Arc Oxidation. Adv. Eng. Mater. 2021, 24, 2101232. [Google Scholar] [CrossRef]

- Alsubaie, S.A.; Bazarnik, P.; Huang, Y.; Lewandowska, M.; Langdon, T.G. Achieving Superplastic Elongations in an AZ80 Magnesium Alloy Processed by High-Pressure Torsion. Adv. Eng. Mater. 2022, 2200620. [Google Scholar] [CrossRef]

- Geng, J.; Yan, Z.; Zhang, H.; Liu, Y.; Dong, P.; Yuan, S.; Wang, W. Microstructure and Mechanical Properties of AZ31B Magnesium Alloy via Ultrasonic Surface Rolling Process. Adv. Eng. Mater. 2021, 23, 2100076. [Google Scholar] [CrossRef]

- Lv, B.-J.; Wang, S.; Xu, T.-W.; Guo, F. Effects of minor Nd and Er additions on the precipitation evolution and dynamic recrystallization behavior of Mg–6.0Zn–0.5Mn alloy. J. Magnes. Alloy. 2020, 9, 840–852. [Google Scholar] [CrossRef]

- Sklenicka, V.; Pahutova, M.; Kucharova, K.; Svoboda, M. Creep Behavior and Strength of Magnesium-Based Composites. In Metallic Materials with High Structural Efficiency; Springer: Dordrecht, The Netherlands, 2006; pp. 203–214. [Google Scholar] [CrossRef]

- Somekawa, H.; Hirai, K.; Watanabe, H.; Takigawa, Y.; Higashi, K. Dislocation creep behavior in Mg–Al–Zn alloys. Mater. Sci. Eng. A 2005, 407, 53–61. [Google Scholar] [CrossRef]

- Kandemir, S.; Gavras, S.; Dieringa, H. High temperature tensile, compression and creep behavior of recycled short carbon fibre reinforced AZ91 magnesium alloy fabricated by a high shearing dispersion technique. J. Magnes. Alloy. 2021, 9, 1753–1767. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, S.; Li, M.; Wang, H.; Cheng, W.; Wang, L.; Li, H.; Liang, W.; Liu, Y. The creep behavior of Mg–9Al–1Si–1SiC composite at elevated temperature. J. Magnes. Alloy. 2020, 8, 944–951. [Google Scholar] [CrossRef]

- Dobeš, F.; Dymáček, P. Creep behavior of AJ62 Magnesium–Aluminum–Strontium alloy. J. Magnes. Alloy. 2020, 8, 414–420. [Google Scholar] [CrossRef]

- Aghion, E.; Bronfin, B.; Eliezer, D.; Von Buch, F.; Schumann, S.; Friedrich, H.E. The Art of Developing New Magnesium Alloys for High Temperature Applications. Mater. Sci. Forum 2003, 419–422, 407–418. [Google Scholar] [CrossRef]

- Jingyuan, Y.; Jianzhong, W.; Qiang, L.; Jian, S.; Jianming, C.; Xudong, S. Effect of Zn on Microstructures and Properties of Mg-Zn Alloys Prepared by Powder Metallurgy Method. Rare Met. Mater. Eng. 2016, 45, 2757–2762. [Google Scholar] [CrossRef]

- Silva, E.; Buzolin, R.; Marques, F.; Soldera, F.; Alfaro, U.; Pinto, H. Effect of Ce-base mischmetal addition on the microstructure and mechanical properties of hot-rolled ZK60 alloy. J. Magnes. Alloy. 2020, 9, 995–1006. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, X.; Yu, S.; Zhang, J.; Lu, X.; Shu, X.; Su, Z. Effects of heat treatment on mechanical properties of an extruded Mg-4.3Gd-3.2Y-1.2Zn-0.5Zr alloy and establishment of its Hall–Petch relation. J. Magnes. Alloy. 2020, 10, 501–512. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, W.; Chen, W.; He, J.; Chen, X.; Hou, J. Microstructure, texture evolution and yield strength symmetry improvement of as-extruded ZK60 Mg alloy via multi-directional impact forging. J. Magnes. Alloy. 2021, 7, 193–202. [Google Scholar] [CrossRef]

- Ma, H.; Wang, J.; Wang, H.; Dong, N.; Zhang, J.; Jin, P.; Peng, Y. Influence of nano-diamond content on the microstructure, mechanical and thermal properties of the ZK60 composites. J. Magnes. Alloy. 2021, 10, 440–448. [Google Scholar] [CrossRef]

- Cai, J.; Wang, H.; Qiu, C.; Cao, G.; Zhang, D. Excellent High-Strain-Rate Superplasticity of Fine-Grained ZK60 Magnesium Alloy Produced by Submerged Friction Stir Processing. Adv. Eng. Mater. 2022, 2101268. [Google Scholar] [CrossRef]

- Galiyev, A.; Kaibyshev, R.; Gottstein, G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 2001, 49, 1199–1207. [Google Scholar] [CrossRef]

- Robson, J.; Paa-Rai, C. The interaction of grain refinement and ageing in magnesium–zinc–zirconium (ZK) alloys. Acta Mater. 2015, 95, 10–19. [Google Scholar] [CrossRef]

- Sha, G.; Zhu, H.; Liu, J.; Luo, C.; Liu, Z.; Ringer, S. Hydrogen-induced decomposition of Zr-rich cores in an Mg−6Zn−0.6Zr−0.5Cu alloy. Acta Mater. 2012, 60, 5615–5625. [Google Scholar] [CrossRef]

- Vinogradov, A.; Orlov, D.; Danyuk, A.; Estrin, Y. Effect of grain size on the mechanisms of plastic deformation in wrought Mg–Zn–Zr alloy revealed by acoustic emission measurements. Acta Mater. 2013, 61, 2044–2056. [Google Scholar] [CrossRef]

- Yuan, Y.; Huang, Y.; Wei, Q. Effects of Zr Addition on Thermodynamic and Kinetic Properties of Liquid Mg-6Zn-xZr Alloys. Metals 2019, 9, 607. [Google Scholar] [CrossRef]

- Wang, X.; Yang, J.; Chi, P.; Bahonar, E.; Tayebi, M. Effects of the microstructure and precipitation hardening on the thermal expansion behavior of ZK60 magnesium alloy. J. Alloy. Compd. 2021, 901, 163422. [Google Scholar] [CrossRef]

- Tayebi, M.; Bizari, D.; Hassanzade, Z. Investigation of mechanical properties and biocorrosion behavior of in situ and ex situ Mg composite for orthopedic implants. Mater. Sci. Eng. C 2020, 113, 110974. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Zhang, J.; Zhang, Z.; Yang, Q.; Guan, K.; He, Y.; Wang, R.; Zhang, H.; Qiu, X.; Wu, R. New insights on the different corrosion mechanisms of Mg alloys with solute-enriched stacking faults or long period stacking ordered phase. Corros. Sci. 2022, 198, 110163. [Google Scholar] [CrossRef]

- Mo, N.; Tan, Q.; Bermingham, M.; Huang, Y.; Dieringa, H.; Hort, N.; Zhang, M.-X. Current development of creep-resistant magnesium cast alloys: A review. Mater. Des. 2018, 155, 422–442. [Google Scholar] [CrossRef]

- Bettles, C.; Gibson, M.; Zhu, S. Microstructure and mechanical behaviour of an elevated temperature Mg-rare earth based alloy. Mater. Sci. Eng. A 2009, 505, 6–12. [Google Scholar] [CrossRef]

- Von Buch, F.; Lietzau, J.; Mordike, B.; Pisch, A.; Schmid-Fetzer, R. Development of Mg–Sc–Mn alloys. Mater. Sci. Eng. A 1999, 263, 1–7. [Google Scholar] [CrossRef]

- Zhang, P. Creep behavior of the die-cast Mg–Al alloy AS21. Scr. Mater. 2005, 52, 277–282. [Google Scholar] [CrossRef]

- Dobkowska, A.; Cieślak, B.A.; Koralnik, M.; Chromiński, W.; Kubasek, J.; Ciftci, J.; Kuc, D.; Mizera, J. Corrosion behavior of fine-grained Mg-7.5Li-3Al-1Zn fabricated by extrusion with a forward-backward rotating die (KoBo). J. Magnes. Alloy. 2021, 10, 811–820. [Google Scholar] [CrossRef]

- Amanda, D.Z.; Mach, R.; Chessa, J.F.; Stewart, C.M. An Accelerated Creep Testing (ACT) Program for Advanced Creep Resistant Alloys for High Temperature Fossil Energy (FE) Applications; The University of Texas at El Paso: El Paso, TX, USA, 2021. [Google Scholar]

- Giannopoulos, I.P.; Burgoyne, C.J. Accelerated and real-time creep and creep-rupture results for aramid fibers. J. Appl. Polym. Sci. 2012, 125, 3856–3870. [Google Scholar] [CrossRef]

- Tayebi, M.; Nategh, S.; Najafi, H.; Khodabandeh, A. Tensile properties and microstructure of ZK60/SiCw composite after extrusion and aging. J. Alloy. Compd. 2020, 830, 154709. [Google Scholar] [CrossRef]

- Tayebi, M.; Najafi, H.; Nategh, S.; Khodabandeh, A. Creep Behavior of ZK60 Alloy and ZK60/SiCw Composite After Extrusion and Precipitation Hardening. Met. Mater. Int. 2020, 27, 3905–3917. [Google Scholar] [CrossRef]

- Kassner, M.E. (Ed.) Fundamentals of Creep in Materials, 3rd ed.; Butterworth-Heinemann: Boston, MA, USA, 2015; Chapter 1; pp. 1–6. [Google Scholar]

- Athul, K.R.; Pillai, U.T.S.; Srinivasan, A.; Pai, B.C. A Review of Different Creep Mechanisms in Mg Alloys Based on Stress Exponent and Activation Energy. Adv. Eng. Mater. 2015, 18, 770–794. [Google Scholar] [CrossRef]

- Sklenička, V.; Langdon, T.G. Creep properties of a fiber-reinforced magnesium alloy. J. Mater. Sci. 2004, 39, 1647–1652. [Google Scholar] [CrossRef]

- Ishimatsu, N.; Terada, Y.; Sato, T.; Ohori, K. Creep characteristics of a diecast AM50 magnesium alloy. Met. Mater. Trans. A 2006, 37, 243–248. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sitdikov, O. Dynamic Recrystallization of Magnesium at Ambient Temperature. Int. J. Mater. Res. 1994, 85, 738–743. [Google Scholar] [CrossRef]

- Abdu, M.; Soliman, M.; El-Danaf, E.; Almajid, A.A.; Mohamed, F.A. Creep characteristics and microstructure in nano-particle strengthened AA6082. Mater. Sci. Eng. A 2012, 531, 35–44. [Google Scholar] [CrossRef]

- Kumar, H.; Chaudhari, G. Creep behavior of AS41 alloy matrix nano-composites. Mater. Sci. Eng. A 2014, 607, 435–444. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celikin, M. Creep resistance in magnesium alloys. Int. Mater. Rev. 2010, 55, 197–217. [Google Scholar] [CrossRef]

- Kunst, M.; Fischersworring-Bunk, A.; L’Esperance, G.; Plamondon, P.; Glatzel, U. Microstructure and dislocation analysis after creep deformation of die-cast Mg–Al–Sr (AJ) alloy. Mater. Sci. Eng. A 2008, 510–511, 387–392. [Google Scholar] [CrossRef]

- Blum, W.; Li, Y.J.; Zeng, X.H.; Zhang, P.; Von Großmann, B.; Haberling, C. Creep deformation mechanisms in high-pressure die-cast magnesium-aluminum-base alloys. Met. Mater. Trans. A 2005, 36, 1721–1728. [Google Scholar] [CrossRef]

- Mukherjee, A.K. Superplasticity in Metals, Ceramics and Intermetallics; VCH Verlagsges: Weinheim, Germany, 1993; Available online: http://inis.iaea.org/search/search.aspx?orig_q=RN:24052780 (accessed on 12 August 2022).

- Soer, W.A. Interactions between Dislocations and Grain Boundaries; University of Groningen: Groningen, Germany, 2006. [Google Scholar]

- Masuda, H.; Tobe, H.; Sato, E.; Sugino, Y.; Ukai, S. Diffusional mass flux accommodating two-dimensional grain boundary sliding in ODS ferritic steel. Acta Mater. 2019, 176, 63–72. [Google Scholar] [CrossRef]

- Ashby, M. Boundary defects, and atomistic aspects of boundary sliding and diffusional creep. Surf. Sci. 1972, 31, 498–542. [Google Scholar] [CrossRef]

- Nautiyal, P.; Jain, J.; Agarwal, A. A comparative study of indentation induced creep in pure magnesium and AZ61 alloy. Mater. Sci. Eng. A 2015, 630, 131–138. [Google Scholar] [CrossRef]

- Regev, M.; Aghion, E.; Rosen, A. Creep studies of AZ91D pressure die casting. Mater. Sci. Eng. A 1997, 234–236, 123–126. [Google Scholar] [CrossRef]

- Tarigan, I.; Takata, N.; Takeyama, M. Grain Boundary Precipitation Strengthening Mechanism by Fe2Nb Laves Phase in Creep of Fe-20Cr-30Ni-2Nb Austenitic Heat Resistant Steel. In Proceedings of the 12th international conference on creep and fracture of engineering materials and structures, Kyoto, Japan, 27–31 May 2012; pp. 55–58. [Google Scholar]

- Del Valle, J.; Ruano, O. Superplasticity in a magnesium alloy prepared with bimodal grain size distributions developed by dynamic recrystallisation. Mater. Lett. 2008, 62, 3391–3394. [Google Scholar] [CrossRef]

- Gerashi, E.; Alizadeh, R.; Langdon, T.G. Effect of crystallographic texture and twinning on the corrosion behavior of Mg alloys: A review. J. Magnes. Alloy. 2021, 10, 313–325. [Google Scholar] [CrossRef]

- Zhu, Y.; Hou, D.; Li, Q. Quasi in-situ EBSD analysis of twinning-detwinning and slip behaviors in textured AZ31 magnesium alloy subjected to compressive-tensile loading. J. Magnes. Alloy. 2021, 10, 956–964. [Google Scholar] [CrossRef]

- Shi, G.-L.; Zhang, K.; Li, X.-G.; Li, Y.-J.; Ma, M.-L.; Yuan, J.-W.; Zhang, H.-J. Dislocation configuration evolution during extension twinning and its influence on precipitation behavior in AZ80 wrought magnesium alloy. J. Magnes. Alloy. 2021, in press. [CrossRef]

- Gui, Y.; Li, Q.; Xue, Y.; Ouyang, L. Twin-twin geometric structure effect on the twinning behavior of an Mg-4Y-3Nd-2Sm-0.5Zr alloy traced by quasi-in-situ EBSD. J. Magnes. Alloy. 2021, in press. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, J.; Jiang, K.; Li, P.; Li, Y.; Zhang, Y.; Suo, T. Gradient structure induced simultaneous enhancement of strength and ductility in AZ31 Mg alloy with twin-twin interactions. J. Magnes. Alloy. 2021, in press. [CrossRef]

- Stanford, N.; Taylor, A.; Cizek, P.; Šiška, F.; Ramajayam, M.; Barnett, M. Twinning in magnesium-based lamellar microstructures. Scr. Mater. 2012, 67, 704–707. [Google Scholar] [CrossRef]

- Yang, Q.; Dai, Q.; Lou, C.; Dai, J.; Zhang, J.; Jiang, B.; Pan, F. Twinning, grain orientation, and texture variations in Mg alloy processed by pre-rolling. Prog. Nat. Sci. Mater. Int. 2019, 29, 231–236. [Google Scholar] [CrossRef]

- Shi, B.; Cheng, Y.; Shang, X.; Yan, H.; Chen, R.; Ke, W. Hall-Petch relationship, twinning responses and their dependences on grain size in the rolled Mg-Zn and Mg-Y alloys. Mater. Sci. Eng. A 2019, 743, 558–566. [Google Scholar] [CrossRef]

- Guan, D.; Rainforth, W.M.; Ma, L.; Wynne, B.; Gao, J. Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy. Acta Mater. 2017, 126, 132–144. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Mokdad, F.; Amirkhiz, B.S.; Wells, M.; Williams, B.; Chen, D. Bimodal grain microstructure development during hot compression of a cast-homogenized Mg-Zn-Zr alloy. Mater. Sci. Eng. A 2018, 724, 421–430. [Google Scholar] [CrossRef]

- Jiang, L.; Jonas, J.; Mishra, R. Effect of dynamic strain aging on the appearance of the rare earth texture component in magnesium alloys. Mater. Sci. Eng. A 2011, 528, 6596–6605. [Google Scholar] [CrossRef]

- Shi, X.; Li, Y.; Zeng, X.; Liu, Y.; Chen, B.; Lu, J.; Li, D. Deformation mechanism and dynamic precipitation in a Mg-7Al-2Sn alloy processed by surface mechanical attrition treatment. J. Mater. Sci. Technol. 2019, 35, 1473–1478. [Google Scholar] [CrossRef]

- Couret, A.; Caillard, D. Prismatic slip in beryllium. Philos. Mag. A 1989, 59, 783–800. [Google Scholar] [CrossRef]

- Galiyev, A.; Sitdikov, O.; Kaibyshev, R. Deformation Behavior and Controlling Mechanisms for Plastic Flow of Magnesium and Magnesium Alloy. Mater. Trans. 2003, 44, 426–435. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, Z.; Huo, Q.; Luo, L.; Li, K.; Hashimoto, A.; Yang, X. Effects of initial texture on the three-dimensional creep anisotropic behaviors of dilute Mg–Y binary alloy sheets. Mater. Sci. Eng. A 2019, 766, 138336. [Google Scholar] [CrossRef]

- Huo, Q.; Xiao, Z.; Yang, X.; Ando, D.; Sutou, Y.; Koike, J. Enhanced fatigue properties of cast AZ80 Mg alloy processed by cyclic torsion and low-temperature annealing. Mater. Sci. Eng. A 2017, 696, 52–59. [Google Scholar] [CrossRef]

- Partridge, P.G. The crystallography and deformation modes of hexagonal close-packed metals. Met. Rev. 1967, 12, 169–194. [Google Scholar] [CrossRef]

- Knezevic, M.; Levinson, A.; Harris, R.; Mishra, R.K.; Doherty, R.D.; Kalidindi, S.R. Deformation twinning in AZ31: Influence on strain hardening and texture evolution. Acta Mater. 2010, 58, 6230–6242. [Google Scholar] [CrossRef]

- Jiang, L.; Jonas, J.J.; Luo, A.A.; Sachdev, A.K.; Godet, S. Twinning-induced softening in polycrystalline AM30 Mg alloy at moderate temperatures. Scr. Mater. 2006, 54, 771–775. [Google Scholar] [CrossRef]

- Obara, T.; Yoshinga, H.; Morozumi, S. {112}〈1123〉 Slip system in magnesium. Acta Met. 1973, 21, 845–853. [Google Scholar] [CrossRef]

- Koike, J.; Kobayashi, T.; Mukai, T.; Watanabe, H.; Suzuki, M.; Maruyama, K.; Higashi, K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys. Acta Mater. 2003, 51, 2055–2065. [Google Scholar] [CrossRef]

- Korla, R.; Chokshi, A.H. Strain-rate sensitivity and microstructural evolution in a Mg–Al–Zn alloy. Scr. Mater. 2010, 63, 913–916. [Google Scholar] [CrossRef]

- Li, Q. Mechanical properties and microscopic deformation mechanism of polycrystalline magnesium under high-strain-rate compressive loadings. Mater. Sci. Eng. A 2012, 540, 130–134. [Google Scholar] [CrossRef]

- Jain, J.; Cizek, P.; Hariharan, K. Transmission electron microscopy investigation on dislocation bands in pure Mg. Scr. Mater. 2016, 130, 133–137. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, Ö. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Long, S.-L.; Liang, Y.-L.; Lu, Y.-M.; Yang, M.; Yin, C.-H. Study on the formation of micro-voids during ductile fracture. Mater. Res. Express 2018, 5, 016515. [Google Scholar] [CrossRef]

- Wang, H.; Xie, J.; Chen, Y.; Liu, W.; Zhong, W. Effect of CoCrFeNiMn high entropy alloy interlayer on microstructure and mechanical properties of laser-welded NiTi/304 SS joint. J. Mater. Res. Technol. 2022, 18, 1028–1037. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Wang, Y.; Liu, X.; An, Q.; Li, H.N.; Zhang, Y.; Cao, H.; Liu, B.; Wang, D.; et al. Carbon fiber reinforced polymer in drilling: From damage mechanisms to suppression. Compos. Struct. 2022, 286, 115232. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Y.; Li, C.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol. Int. 2022, 169, 107461. [Google Scholar] [CrossRef]

- Kassner, M.E. (Ed.) Creep Fracture; Butterworth-Heinemann: Boston, MA, USA, 2015; pp. 233–260. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, Z.; Wu, Y.; Wang, Y.; Ma, G.; Shi, J.; Zhong, Z.; Jin, Z.; Zhao, Y. Synergic realization of electrical insulation and mechanical strength in liquid nitrogen for high-temperature superconducting tapes with ultra-thin acrylic resin coating. Supercond. Sci. Technol. 2022, 35, 75014. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Said, Z.; Debnath, S.; Sharma, S.; Ali, H.M.; Yang, M.; Gao, T.; Li, R. Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J. Manuf. Process. 2022, 80, 273–286. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Said, Z.; Liu, X. Tribology of enhanced turning using biolubricants: A comparative assessment. Tribol. Int. 2022, 174, 107766. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; Qin, J.; Zhang, D.; Lu, W. Microstructure and mechanical properties of investment casted titanium matrix composites with B4C additions. Mater. Sci. Eng. A 2015, 628, 366–373. [Google Scholar] [CrossRef]

- Bai, Y.; Nardi, D.C.; Zhou, X.; Picón, R.A.; Flórez-López, J. A new comprehensive model of damage for flexural subassemblies prone to fatigue. Comput. Struct. 2021, 256, 106639. [Google Scholar] [CrossRef]

- Zhong, Y.; Xie, J.; Chen, Y.; Yin, L.; He, P.; Lu, W. Microstructure and mechanical properties of micro laser welding NiTiNb/Ti6Al4V dissimilar alloys lap joints with nickel interlayer. Mater. Lett. 2021, 306, 130896. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Sirohi, S. Fracture behaviour of crept P91 welded sample for different post weld heat treatments condition. Eng. Fail. Anal. 2018, 95, 18–29. [Google Scholar] [CrossRef]

- Das, S.; Mukhopadhyay, G.; Bhattacharyya, S. Failure analysis of axle shaft of a fork lift. Case Stud. Eng. Fail. Anal. 2015, 3, 46–51. [Google Scholar] [CrossRef]

| UTS (MPa) | YS (MPa) | Elongation (%) | Grain Size (µm) | |

|---|---|---|---|---|

| ZK60 alloy | 265 | 230 | 15 | 10 |

| ZK60/SiCp composite | 365 | 320 | 6 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-Y.; Jia, C.; Tayebi, M.; Hamawandi, B. Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiCp Composite after KoBo Extrusion. Materials 2022, 15, 6428. https://doi.org/10.3390/ma15186428

Wang Y-Y, Jia C, Tayebi M, Hamawandi B. Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiCp Composite after KoBo Extrusion. Materials. 2022; 15(18):6428. https://doi.org/10.3390/ma15186428

Chicago/Turabian StyleWang, Yang-Yang, Chen Jia, Morteza Tayebi, and Bejan Hamawandi. 2022. "Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiCp Composite after KoBo Extrusion" Materials 15, no. 18: 6428. https://doi.org/10.3390/ma15186428

APA StyleWang, Y.-Y., Jia, C., Tayebi, M., & Hamawandi, B. (2022). Microstructural Evolution during Accelerated Tensile Creep Test of ZK60/SiCp Composite after KoBo Extrusion. Materials, 15(18), 6428. https://doi.org/10.3390/ma15186428