Comparative Experiment of Abrasion-Corrosion-Sliding Wear Performance of Two Kinds of Low Alloy Wear-Resistant Steel

Abstract

:1. Introduction

2. Test Scheme

2.1. Test Materials

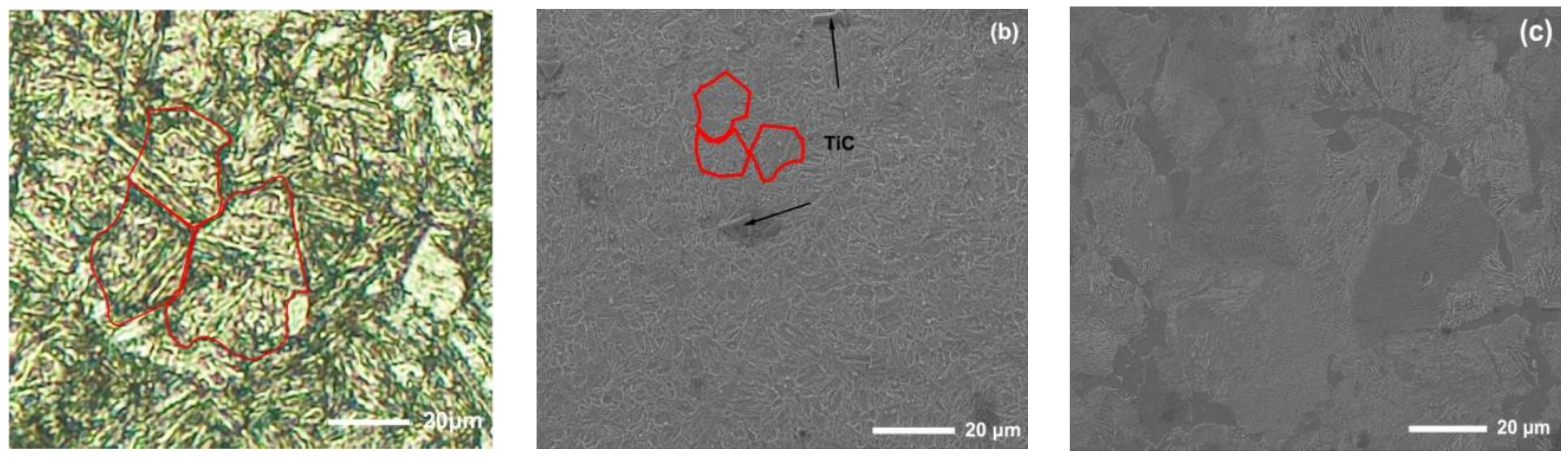

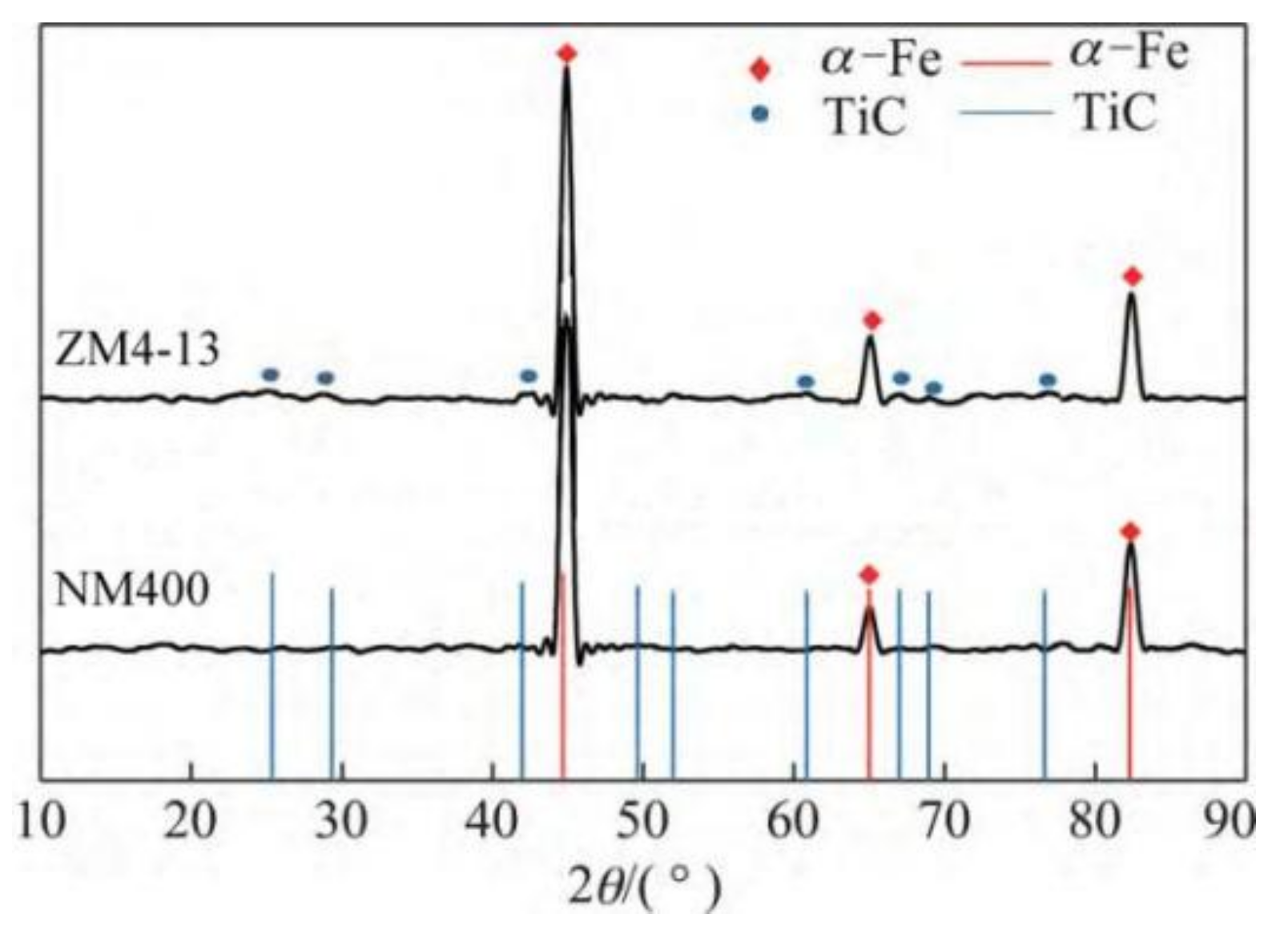

2.1.1. Materials of Samples and Characterization Methods

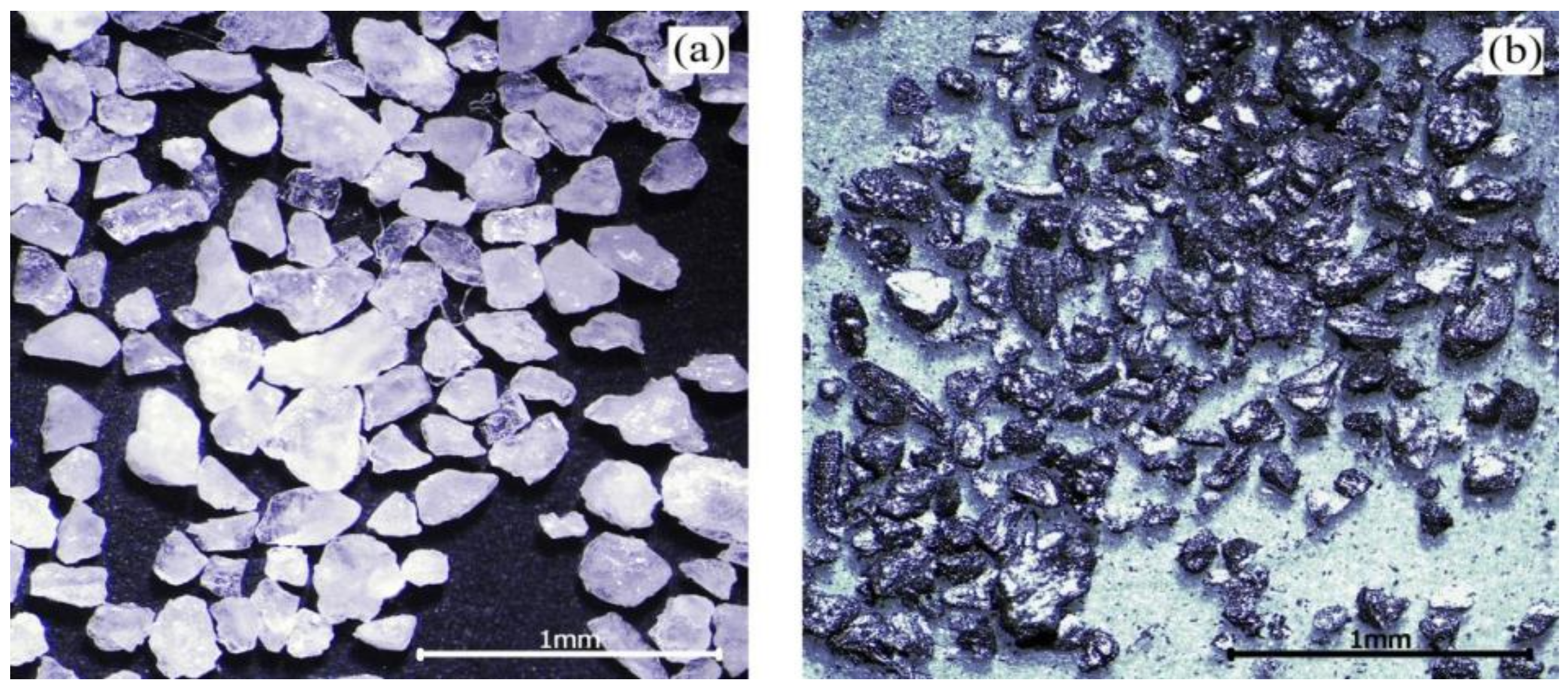

2.1.2. Preparation of Abrasive

2.1.3. Preparation of Corrosion Solution

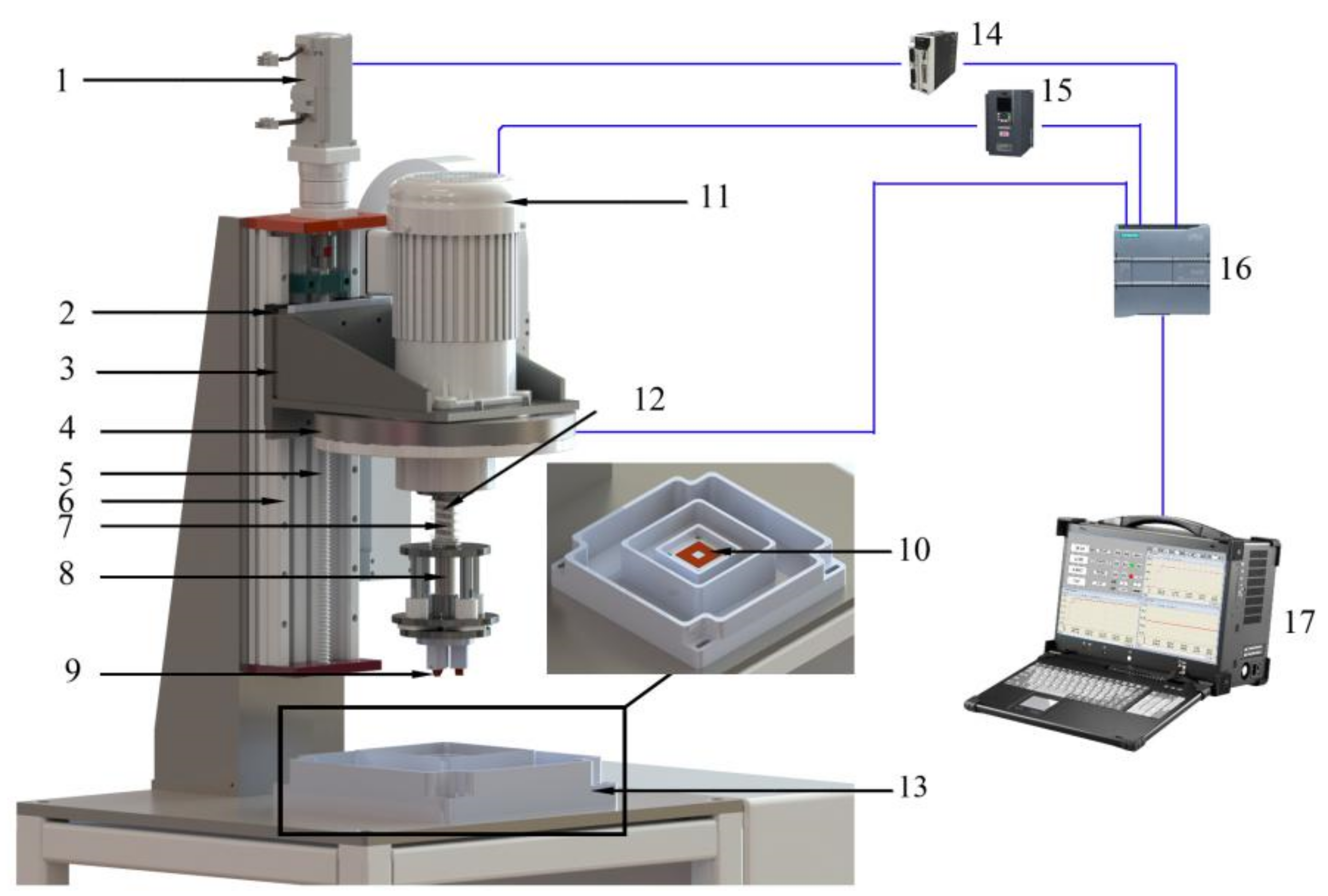

2.2. Wear Tester

2.2.1. Overall Structure and Working Principle

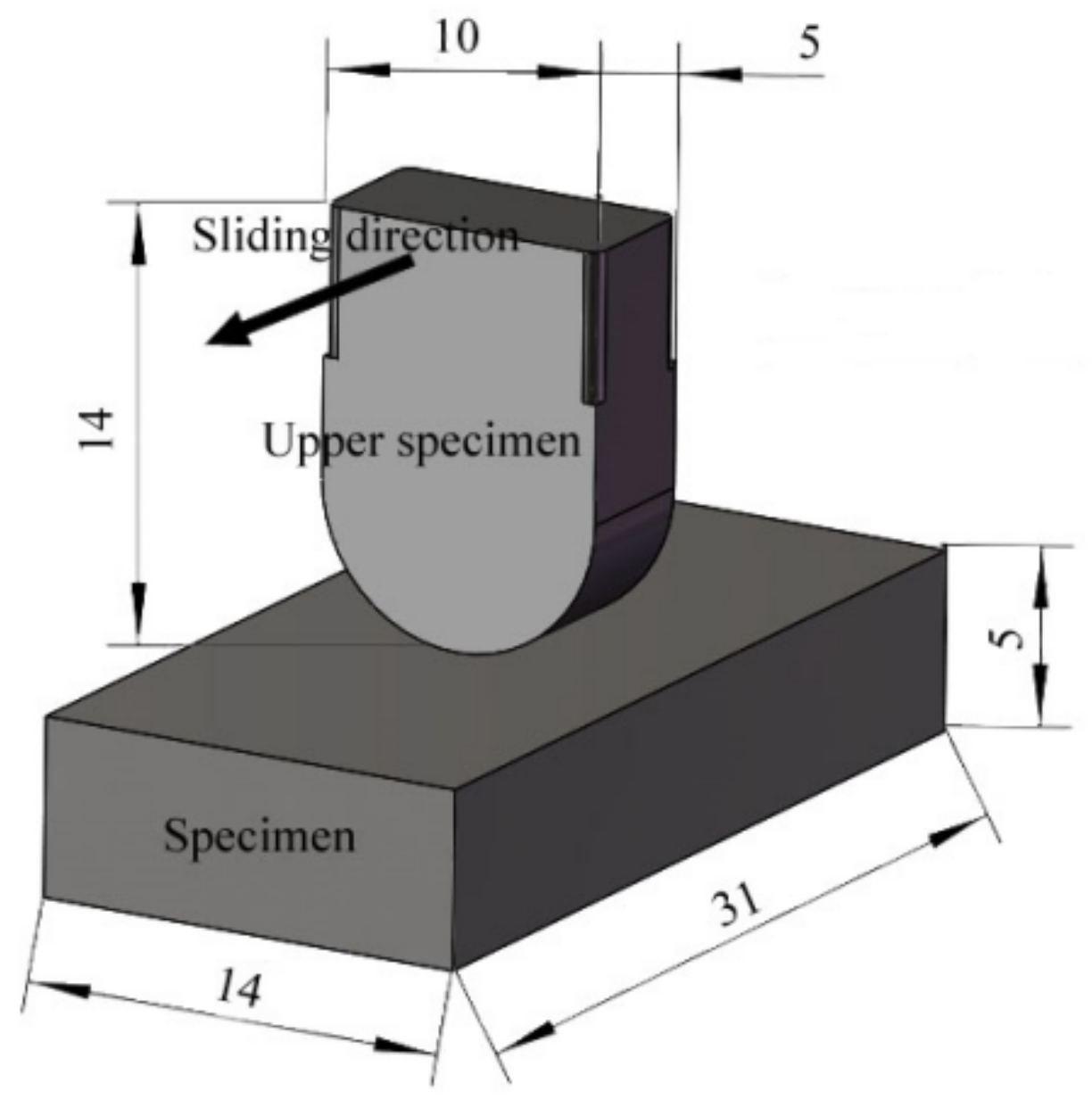

2.2.2. Sample Structure

2.3. Test Conditions and Process

3. Test Results and Analysis

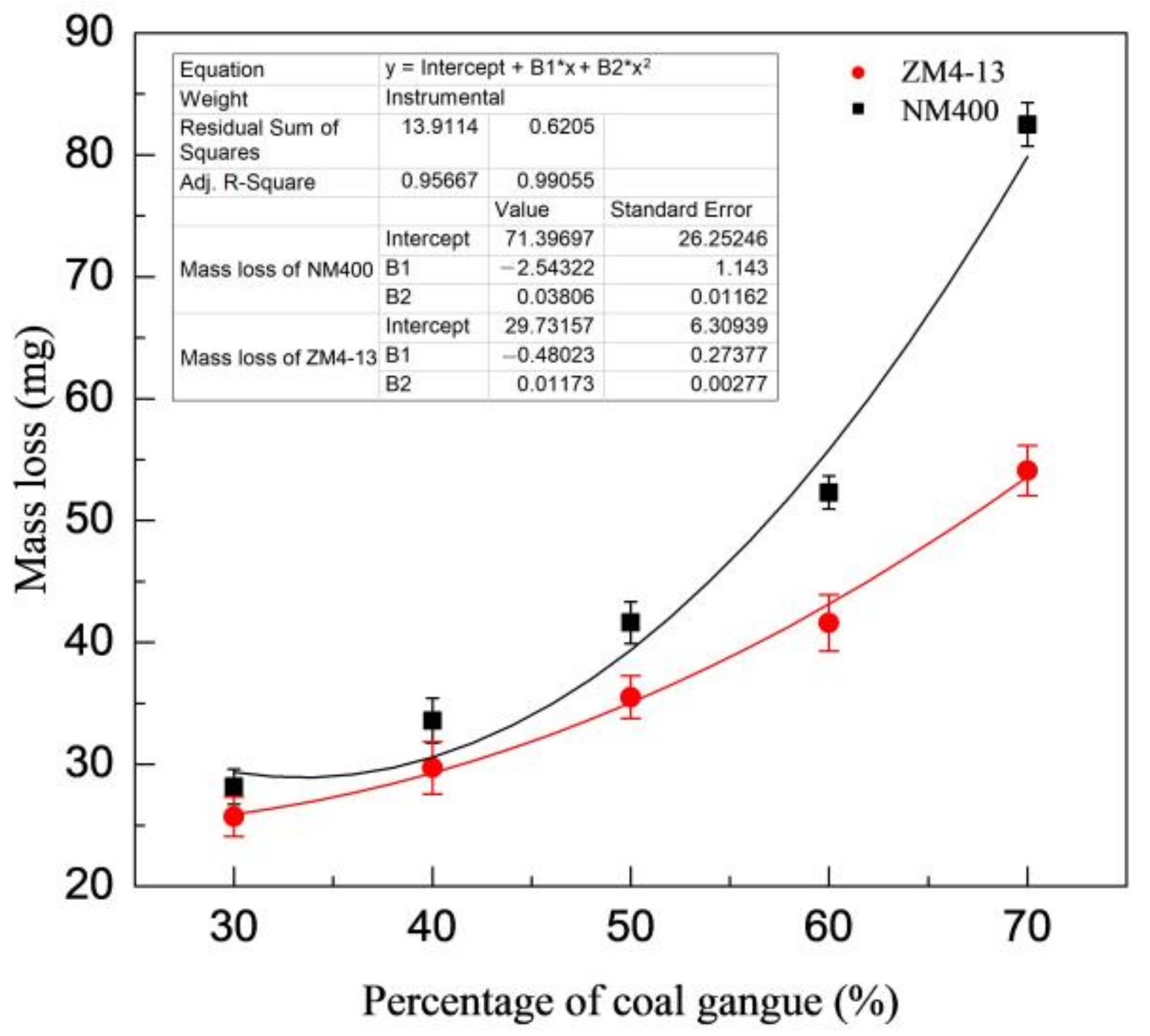

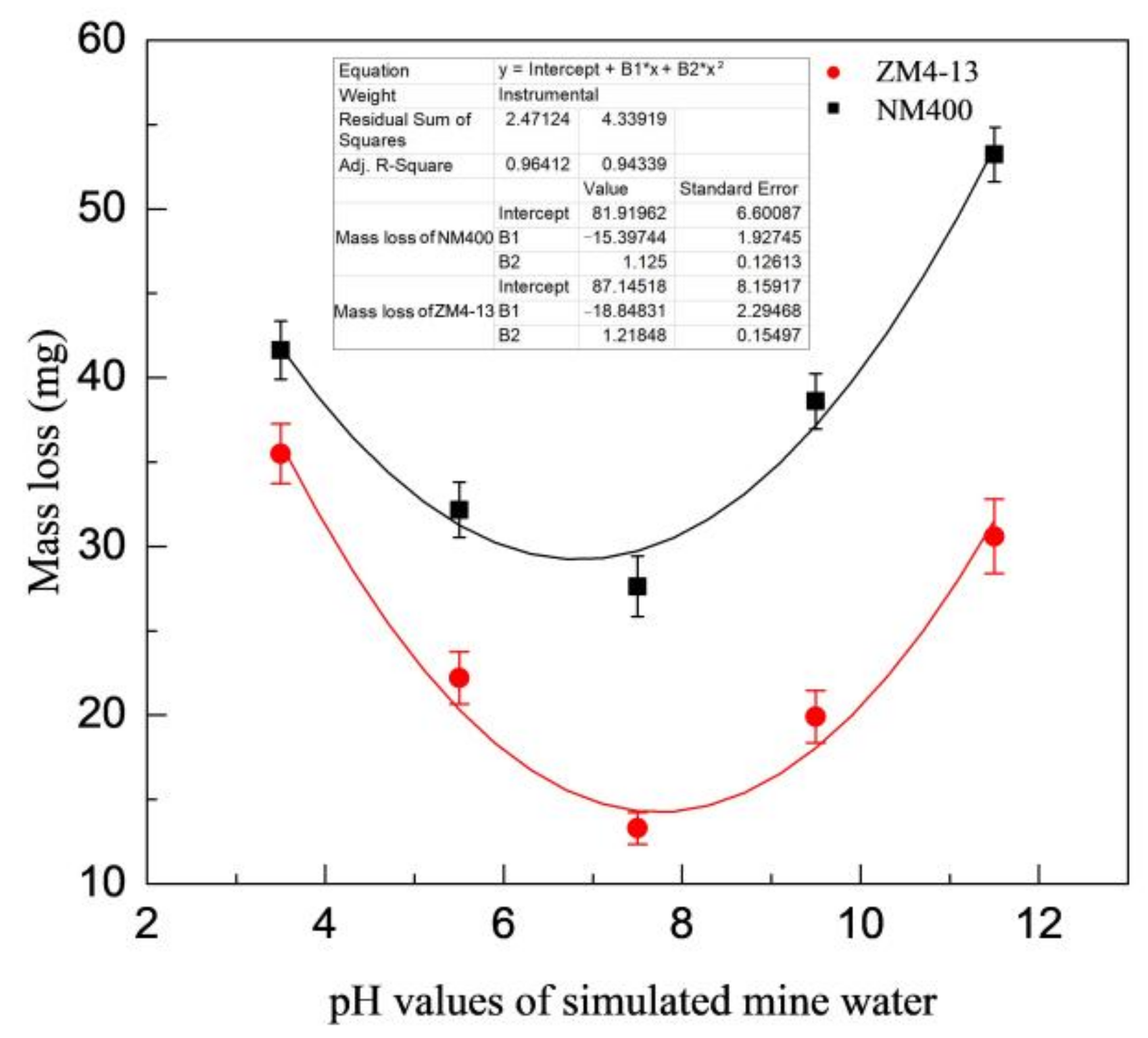

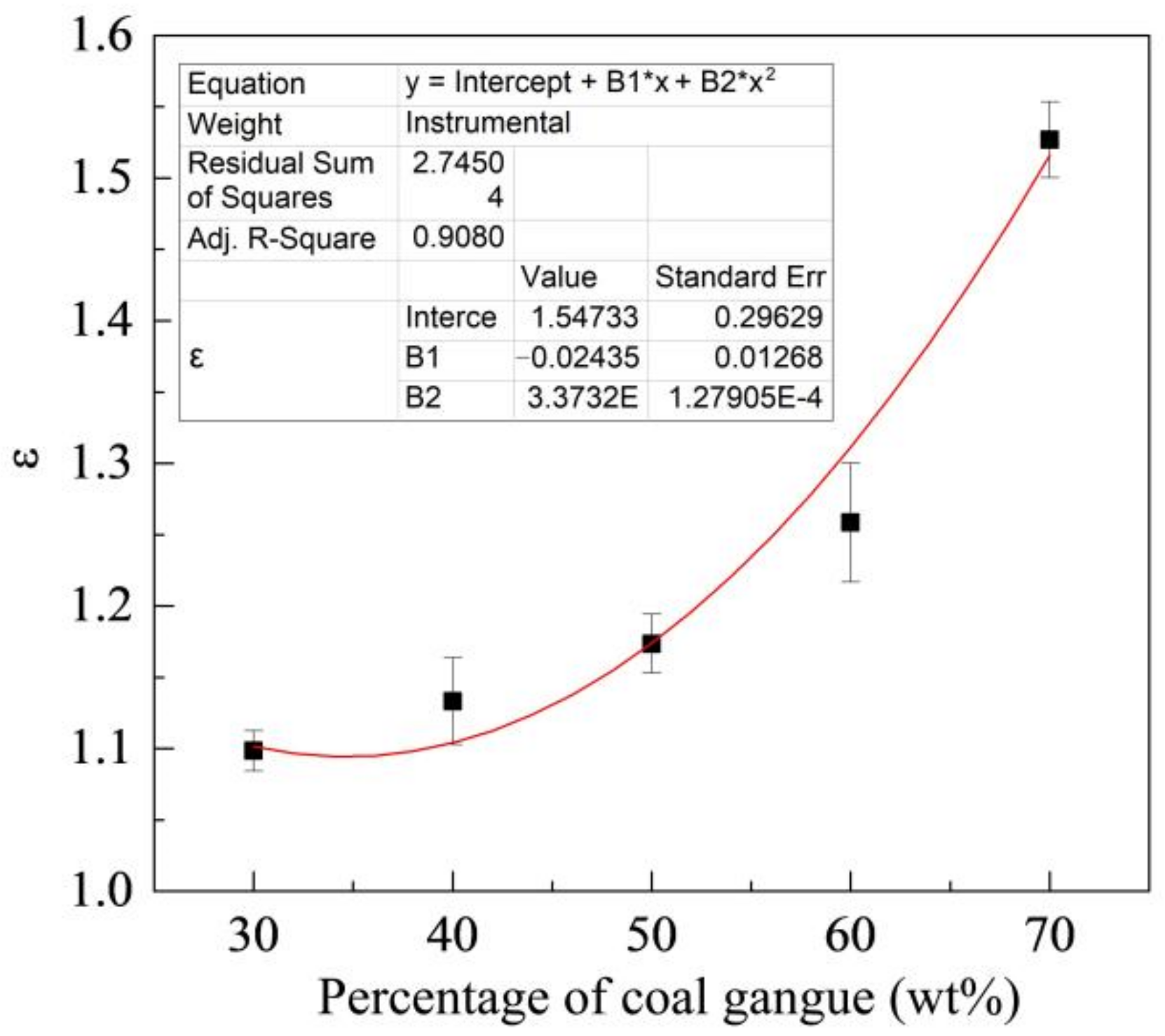

3.1. The Effect of Test Conditions

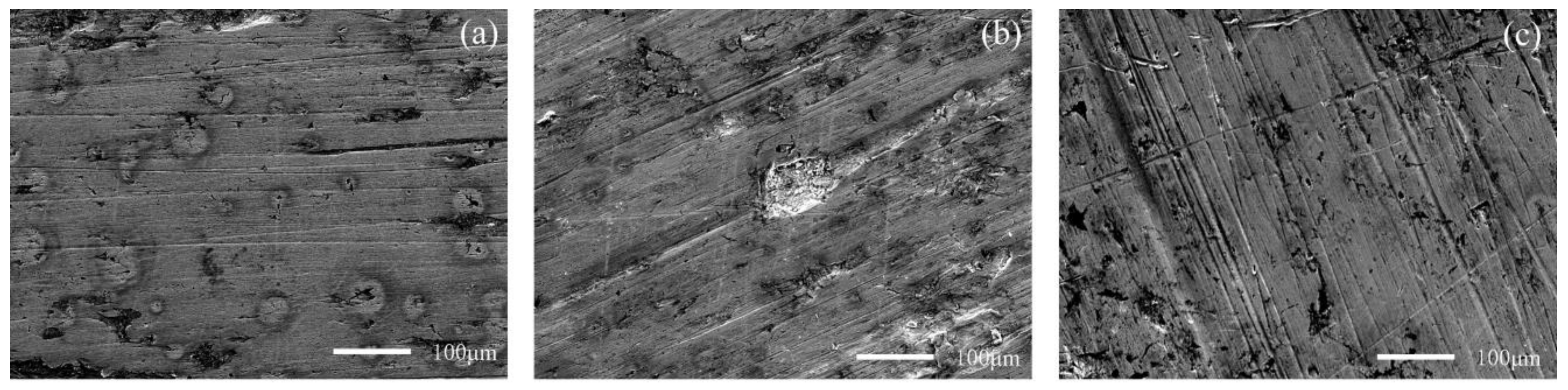

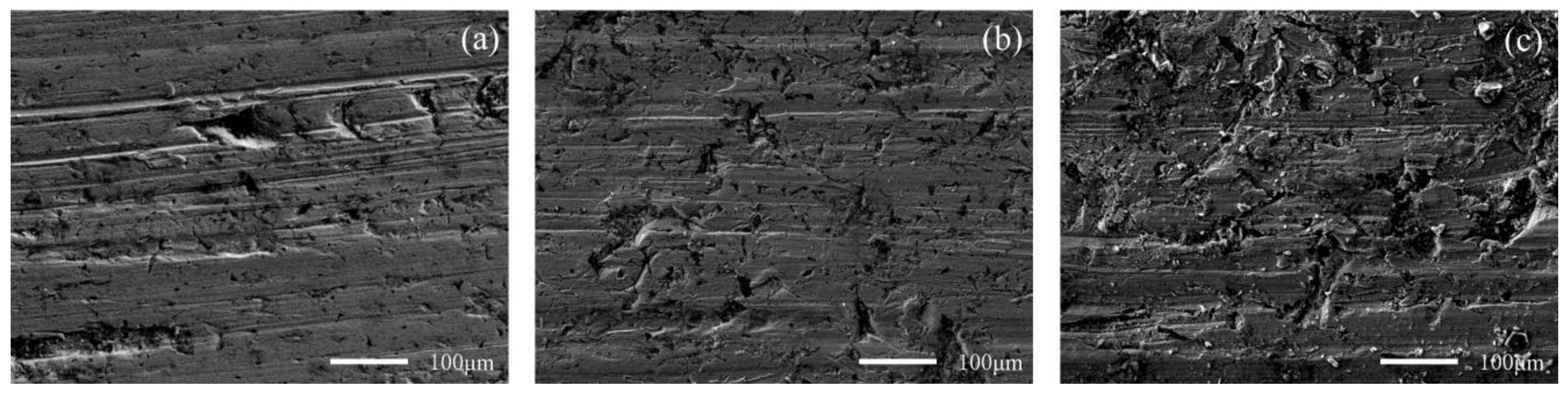

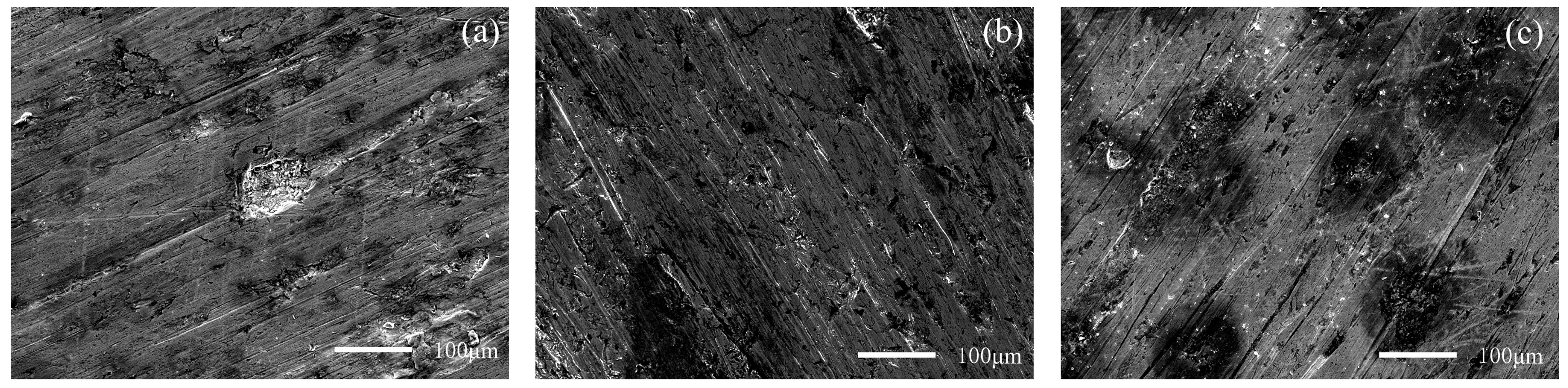

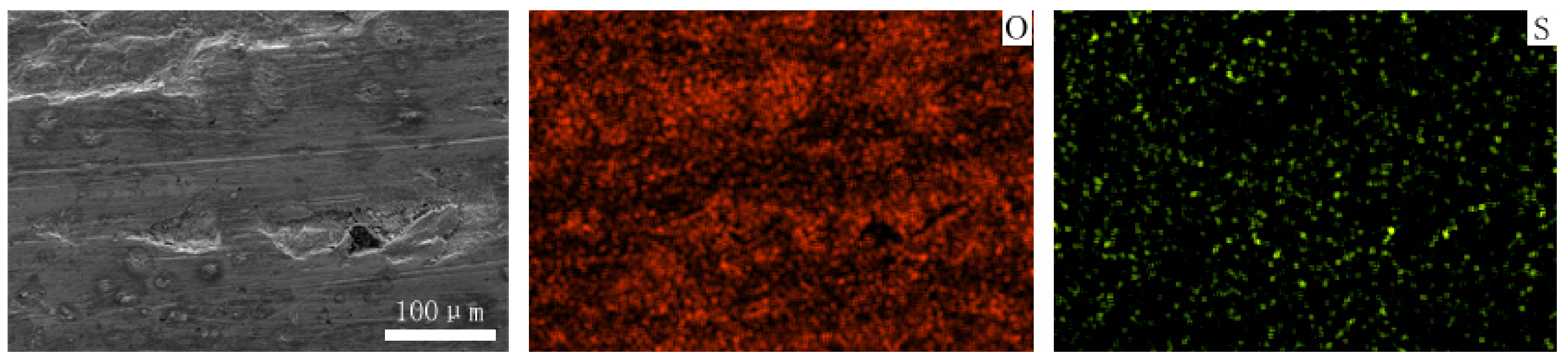

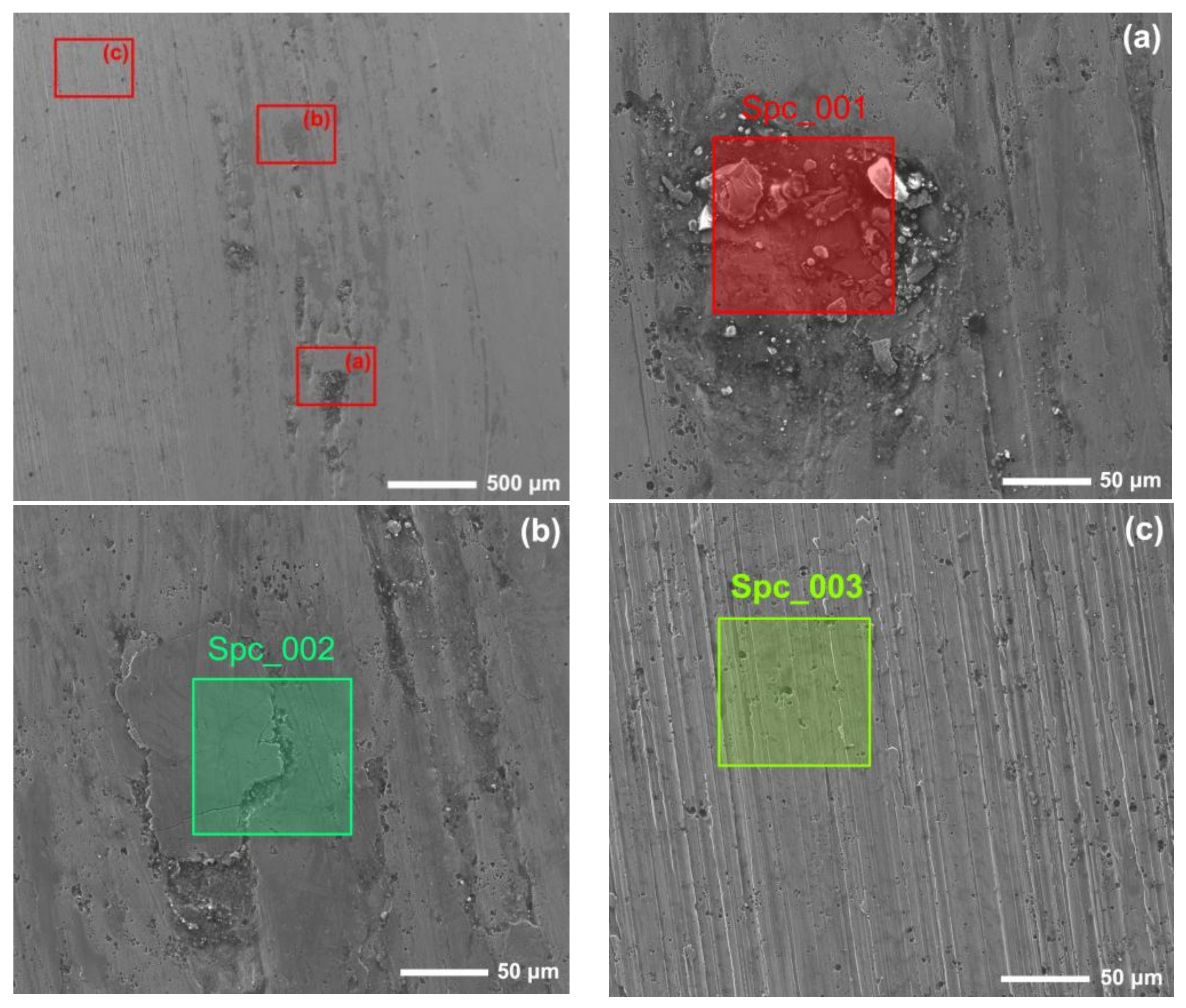

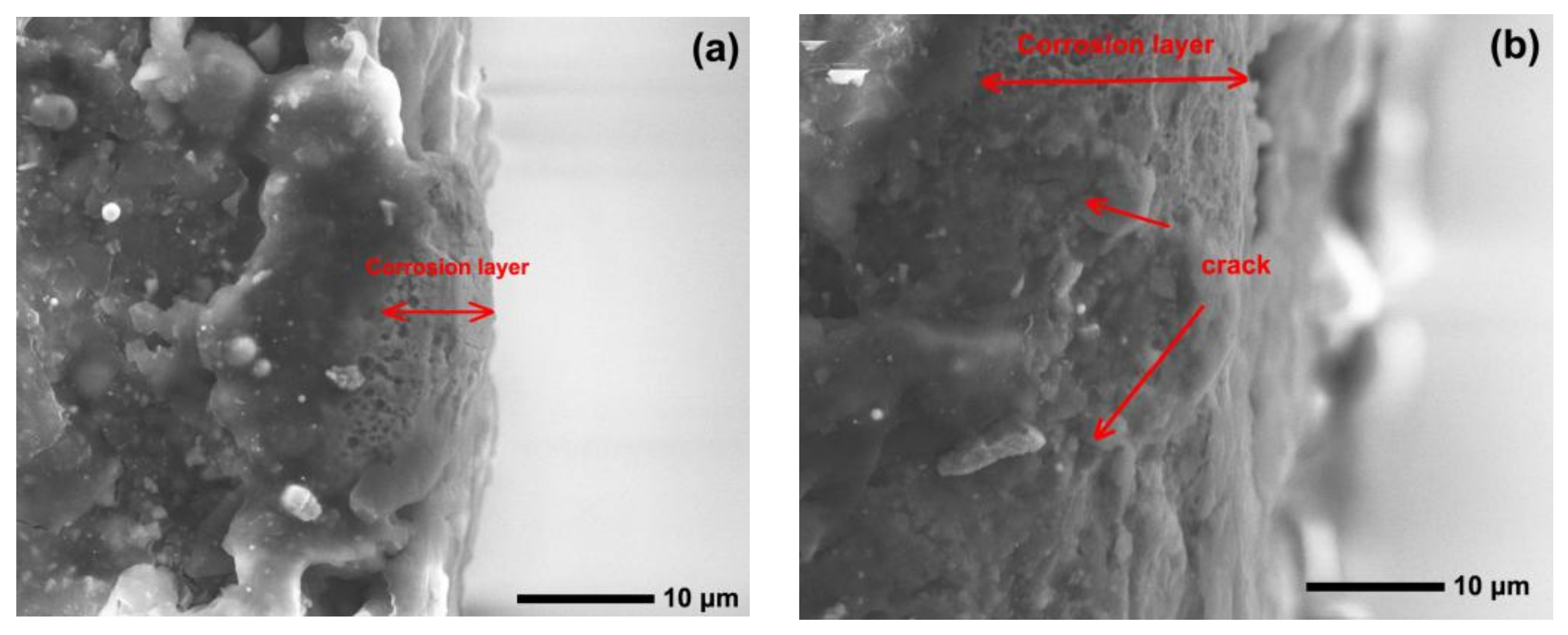

3.2. Wear Mechanism

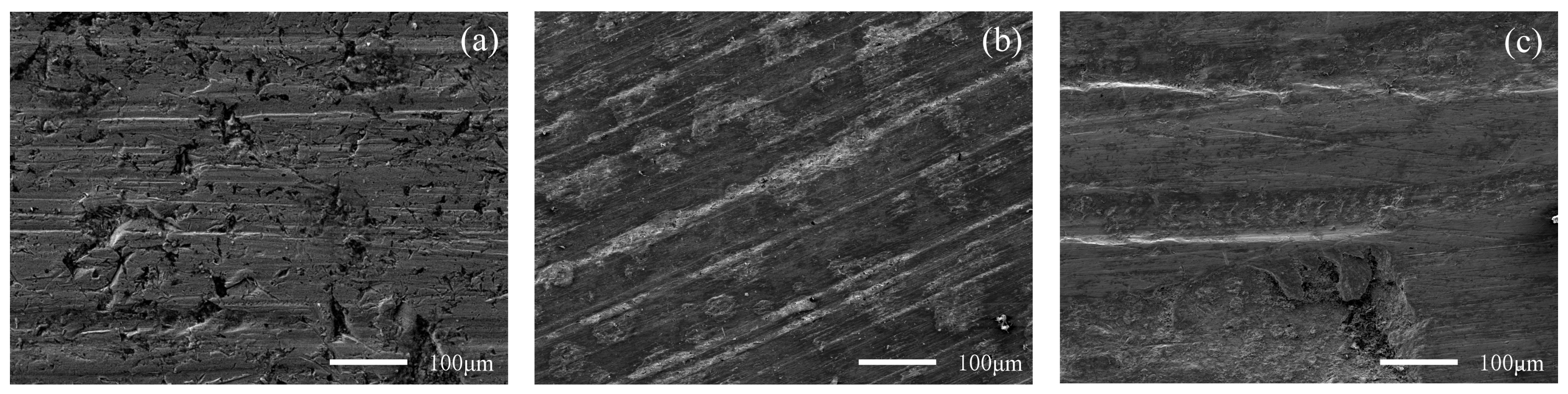

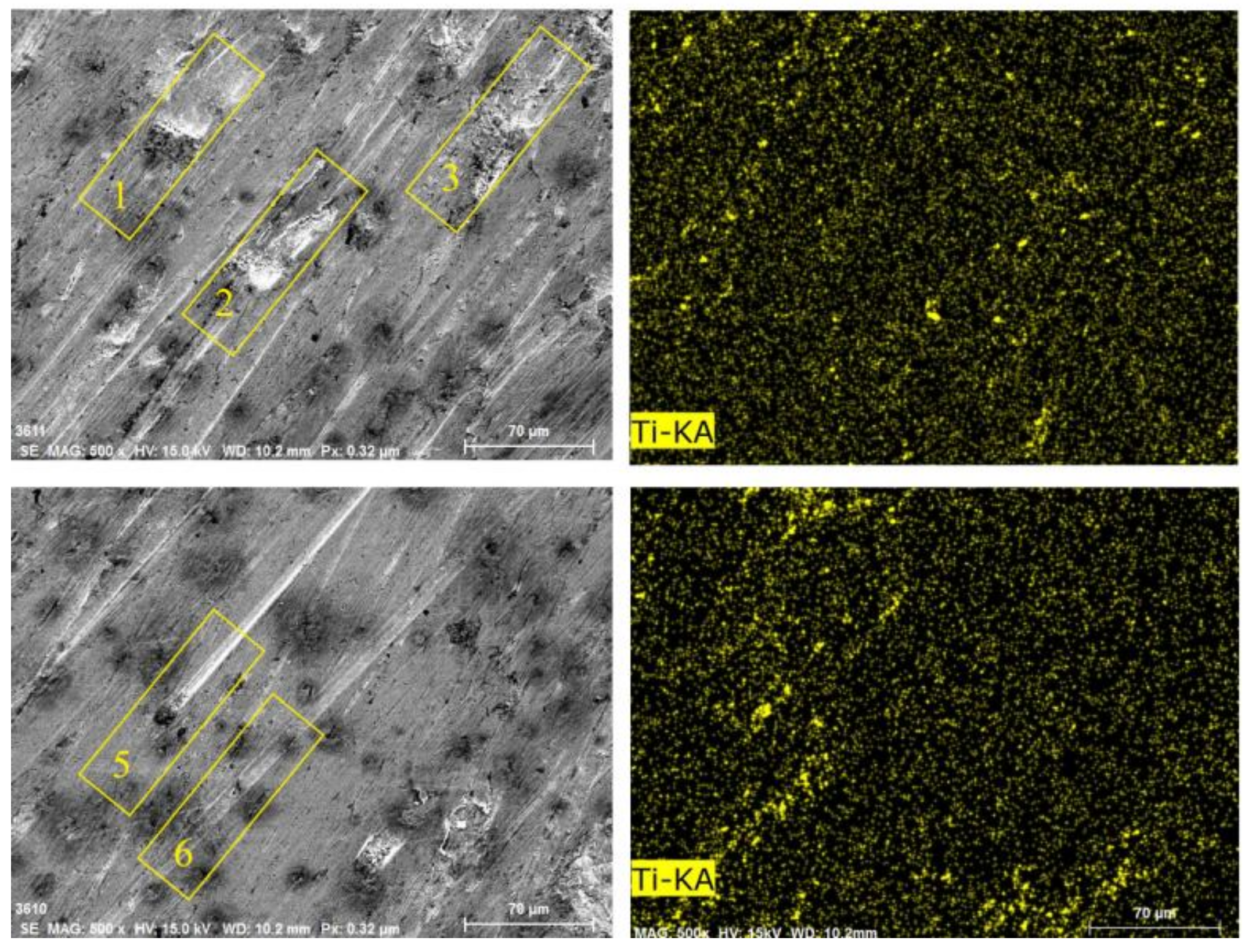

3.3. Anti-Wear Mechanism of ZM4-13

4. Conclusions

- (1)

- The mass loss of ZM4-13 and NM400 increases with the increase of the percentage of coal gangue. They don’t increase monotonically with the change of pH value, and there is a critical value: the critical value of NM400 is between 6–8, and the critical value of ZM4-13 is between 7–9. When the pH value is less than the critical value, the mass loss decreases with the increase of pH value; when the pH value is greater than the critical value, the mass loss increases with the increase of pH value. The main wear of ZM4-13 and NM400 is abrasive wear and corrosion wear in acidic and alkaline mine water, and abrasive wear in neutral mine water.

- (2)

- ZM4-13 steel is more wear-resistant than NM400 under different gangue percentages and pH values of mine water, and has better wear resistance under high gangue conditions and neutral mine water. The wear resistance of ZM4-13 is 1.09–2.10 times, compared with NM400.

- (3)

- The high hardness of TiC precipitation area in ZM4-13 hinders the plowing of hard particles and the plastic deformation, so ZM4-13 is more wear-resistant than NM400, and is especially suitable for the harsh working conditions of coal mine production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Xie, J.; Zhao, W.; Bai, S.; Zhong, S.; Chu, Z. Effect of coal slurry on the corrosion of coal-mine equipment. Int. J. Min. Sci. Technol. 2011, 21, 413–417. [Google Scholar] [CrossRef]

- Chen, H. Study on Wear of Scraper Conveyor Chute: International Conference on Intelligent Systems Research and Mechatronics Engineering; Machinery Industry Press: Beijing, China, 2015. [Google Scholar]

- Dolipski, M.; Cheluszka, P.; Remiorz, E.; Sobota, P. Follow-up chain tension in an armoured face conveyor. Arch. Min. Sci. 2015, 60, 25–38. [Google Scholar]

- Yaral, O.; Yaşar, E.; Bacak, G.; Ranjith, P.G. A study of rock abrasivity and tool wear in Coal Measures Rocks. Int. J. Coal Geol. 2008, 74, 53–66. [Google Scholar] [CrossRef]

- Li, J.; Liang, S. Friction and wear of the middle trough in scraper conveyors. Ind. Lubr. Tribol. 2018, 70, 1072–1077. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, Z.; Li, G.; Ge, S. Study on wear failures of mining machinery. J. China Coal Soc. 2006, 31, 380–385. [Google Scholar]

- Waterhouse, C.; Tuff, J.; Usher, B. Managed aquifer recharge and mine water management. Aus-IMM Bull. 2017, 10, 76–79. [Google Scholar]

- Dong, S.; Zhang, W.; Zhou, W.; Chai, R.; Wang, H.; Zhao, C.; Dong, X.; Wang, Q. Discussion on some topical issues of water prevention and control in coal mines. Mine Water Environ. 2021, 40, 547–552. [Google Scholar] [CrossRef]

- Bi, Y.; Wu, J.; Zhai, X.; Wang, G.; Shen, S.; Qing, X. Discriminant analysis of mine water inrush sources with multi-aquifer based on multivariate statistical analysis. Environ. Earth Sci. 2021, 80, 1–17. [Google Scholar] [CrossRef]

- Shi, Z.; Zhu, Z. Wear analysis of the middle plate of a heavy-load scraper conveyor chute under a range of operating conditions. Wear 2017, 380, 36–41. [Google Scholar] [CrossRef]

- Chai, J.; Ye, L.; Fan, X.; Sun, S.; Li, G. Research progress on the wear property of middle plate of scraper conveyor middle trough. China Coal 2018, 44, 75–77, 83. [Google Scholar]

- Shi, Z.; Zhu, Z. Wear behaviors of middle pan of armoured face conveyor under composite operating conditions. Tribology 2017, 37, 472–478. [Google Scholar]

- Hacısalihoğlu, İ.; Yıldız, F.; Çelik, A. Tribocorrosion behavior of plasma nitrided Hardox steels in NaCl solution. Tribol. Int. 2018, 120, 434–445. [Google Scholar] [CrossRef]

- Li, C.; Deng, X.; Huang, L.; Jia, Y.; Wang, Z. Effect of temperature on microstructure, properties and sliding wear behavior of low alloy wear-resistant martensitic steel. Wear 2020, 442, 203125. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, H.; Teng, Z. Abrasive wear behavior of new wear resistant steels applied for the middle plate of scraper conveyor. J. China Coal Soc. 2020, 45, 3607–3614. [Google Scholar]

- Deng, X.; Huang, L.; Wang, Q.; Fu, T.; Wang, Z. Three-body abrasion wear resistance of TiC-reinforced low-alloy abrasion-resistant martensitic steel under dry and wet sand conditions. Wear 2020, 452–453, 203310. [Google Scholar] [CrossRef]

- Chai, J.; Zhou, Z.; Ye, C.; Yao, C.; Li, G. Design and development of a novel sliding friction and wear tester with complex working conditions. Sci. Rep. 2021, 11, 6903. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Jiang, Y.; Zhou, R.; Lu, D.; Zhou, R. Dry three-body abrasive wear behavior of WC reinforced iron matrix surface composites produced by V-EPC infiltration casting process. Wear 2007, 262, 649–654. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | P | S | Ti | Cr | Mo | B | Ni | Cu | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ZM4-13 | 0.30–0.38 | 0.20–0.60 | 0.30–1.20 | ≤ 0.015 | ≤ 0.003 | 0.40–0.80 | 0.60–1.50 | 0.20–0.50 | 0.001–0.003 | 0.40–1.20 | 0.10–0.50 | 0.0015–0.065 |

| NM400 | 0.160 | 0.230 | 1.420 | ≤ 0.015 | ≤ 0.003 | 0.012 | 0.170 | 0.020 | 0.001 | - | - | - |

| 40Cr | 0.37–0.44 | 0.17–0.37 | 0.50–0.80 | ≤ 0.035 | ≤ 0.035 | - | 0.80–1.10 | ≤ 0.01 | - | ≤ 0.3 | ≤ 0.03 | - |

| pH Value | CaSO4 (mg/L) | MgSO4 (mg/L) | Na2SO4 (mg/L) | KCl (mg/L) | NaCl (mg/L) | CaCl (mg/L) | H2SO4 (mL/L) | NaOH (mL/L) |

|---|---|---|---|---|---|---|---|---|

| 3.5 | 70 | 50 | 40 | 12 | 141 | 10 | 40 | - |

| 5.5 | 70 | 50 | 40 | 12 | 141 | 10 | 22 | - |

| 7 | 70 | 50 | 40 | 12 | 141 | 10 | - | - |

| 9.5 | 70 | 50 | 40 | 12 | 141 | 10 | - | 32 |

| 11.5 | 70 | 50 | 40 | 12 | 141 | 10 | - | 100 |

| No. | C | O | Al | Si | S | K | Ca | Ti | Cr | Mn | Fe | Ni | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spc_001 | 48.30 | 28.79 | 0.47 | 1.01 | 0.23 | 0.57 | 0.29 | 0.12 | 0.40 | 0.20 | 19.42 | 0.21 | 100 |

| Spc_002 | 17.02 | 48.55 | - | 0.28 | 0.41 | 0.47 | - | 0.11 | 0.36 | - | 32.81 | - | 100 |

| Spc_003 | 26.90 | 3.41 | 0.32 | 0.49 | - | - | - | 0.67 | 0.82 | 0.49 | 66.91 | - | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, J.; Li, G. Comparative Experiment of Abrasion-Corrosion-Sliding Wear Performance of Two Kinds of Low Alloy Wear-Resistant Steel. Materials 2022, 15, 6463. https://doi.org/10.3390/ma15186463

Chai J, Li G. Comparative Experiment of Abrasion-Corrosion-Sliding Wear Performance of Two Kinds of Low Alloy Wear-Resistant Steel. Materials. 2022; 15(18):6463. https://doi.org/10.3390/ma15186463

Chicago/Turabian StyleChai, Jinrong, and Guohua Li. 2022. "Comparative Experiment of Abrasion-Corrosion-Sliding Wear Performance of Two Kinds of Low Alloy Wear-Resistant Steel" Materials 15, no. 18: 6463. https://doi.org/10.3390/ma15186463

APA StyleChai, J., & Li, G. (2022). Comparative Experiment of Abrasion-Corrosion-Sliding Wear Performance of Two Kinds of Low Alloy Wear-Resistant Steel. Materials, 15(18), 6463. https://doi.org/10.3390/ma15186463