Sintering Analysis of Porous Ti/xTa Alloys Fabricated from Elemental Powders

Abstract

:1. Introduction

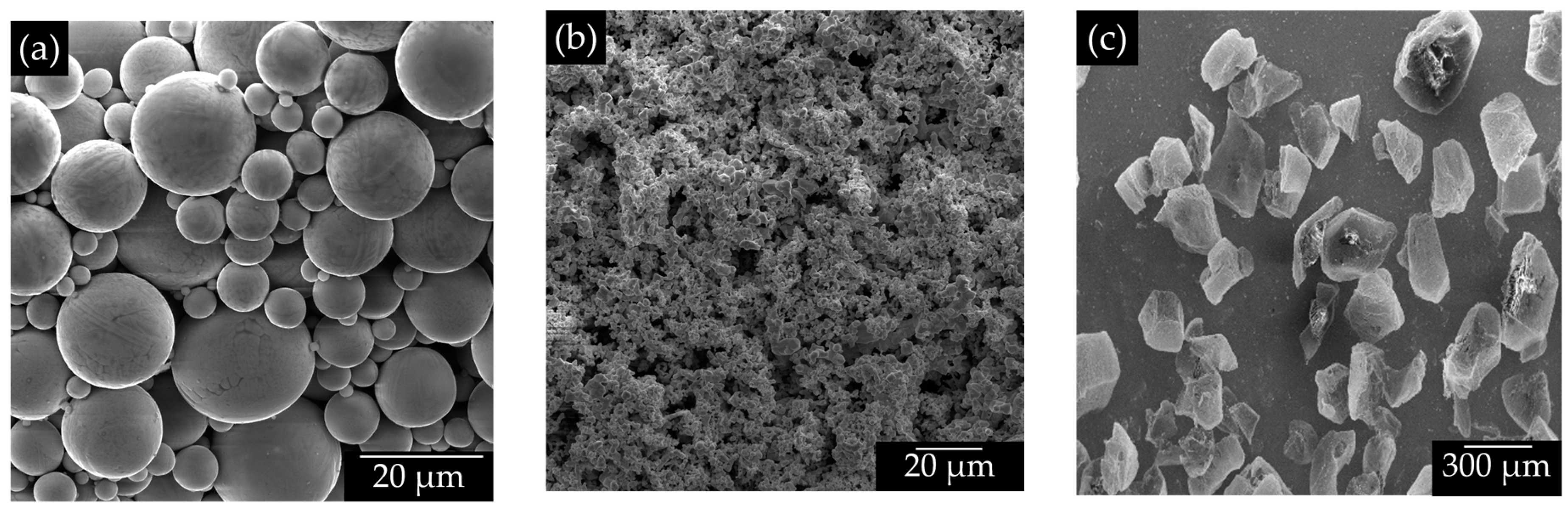

2. Materials and Methods

2.1. Sample Preparation

2.2. Microstructural Characterization

2.3. Permeability Evaluation

2.4. Mechanical Properties Evaluation

3. Results and Discussion

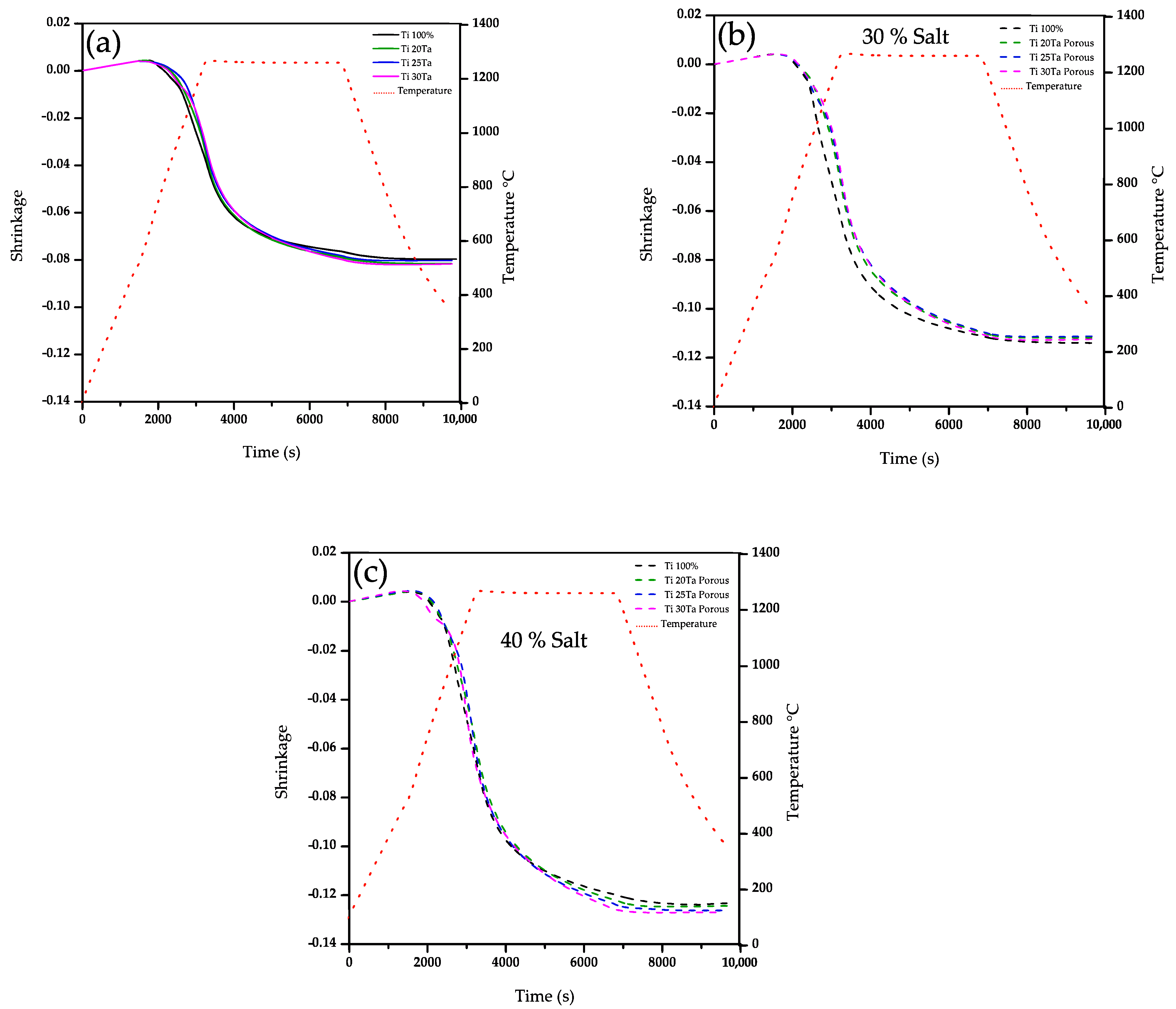

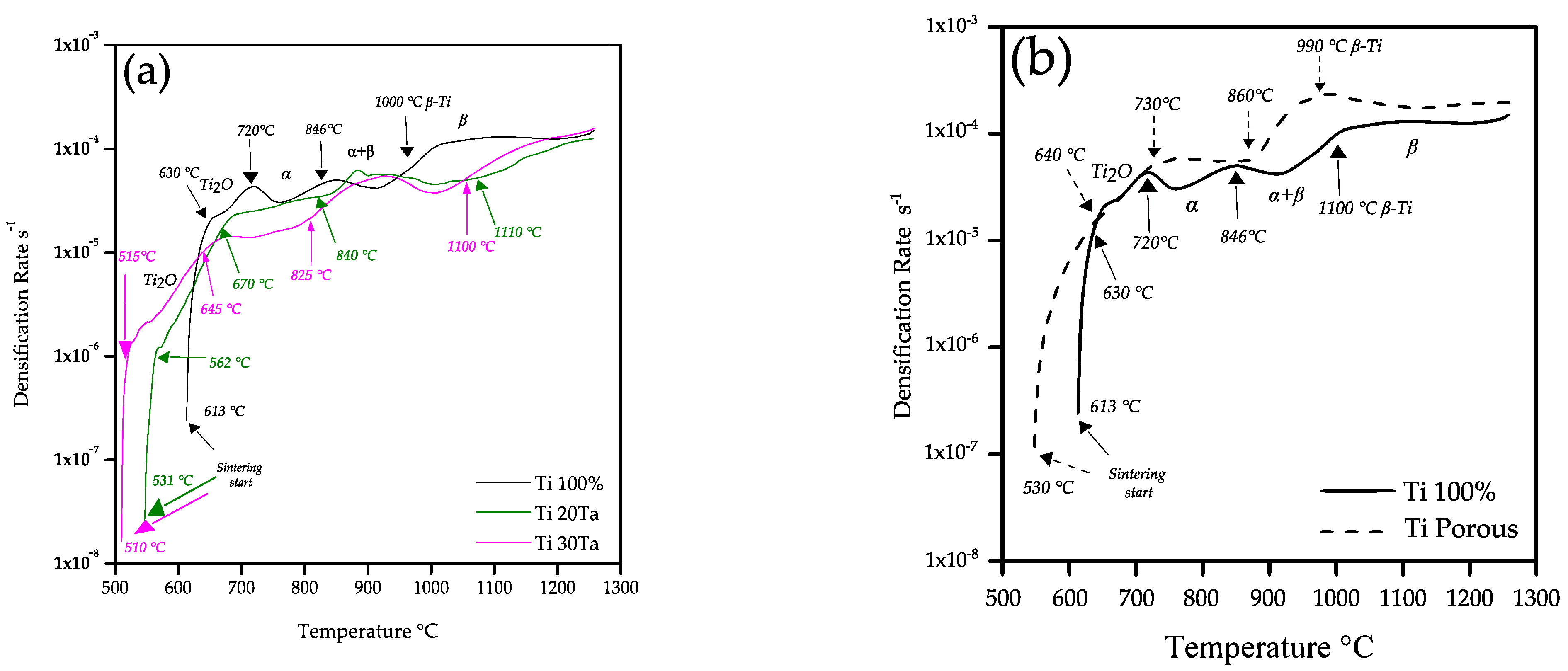

3.1. Sintering Kinetics Analysis

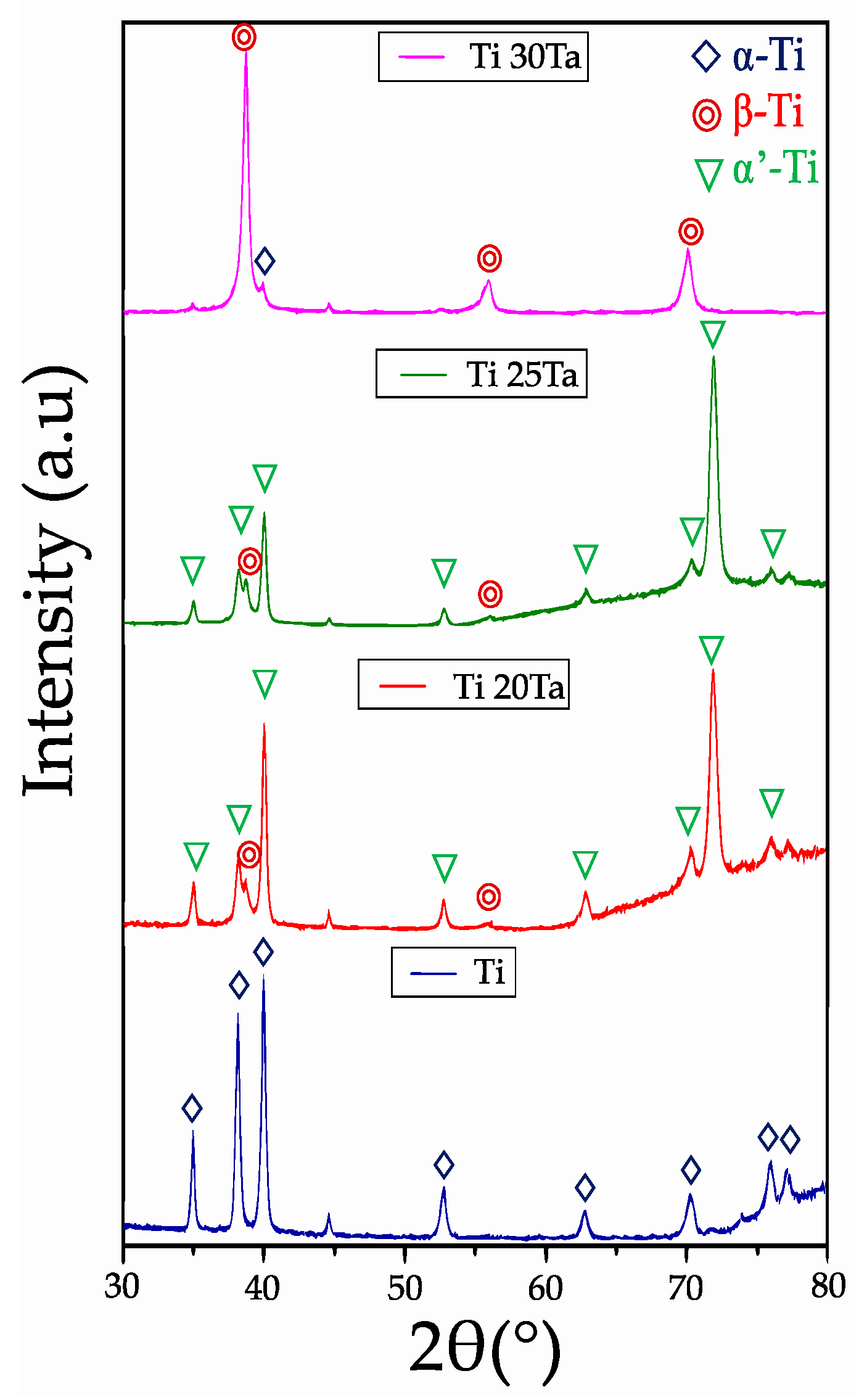

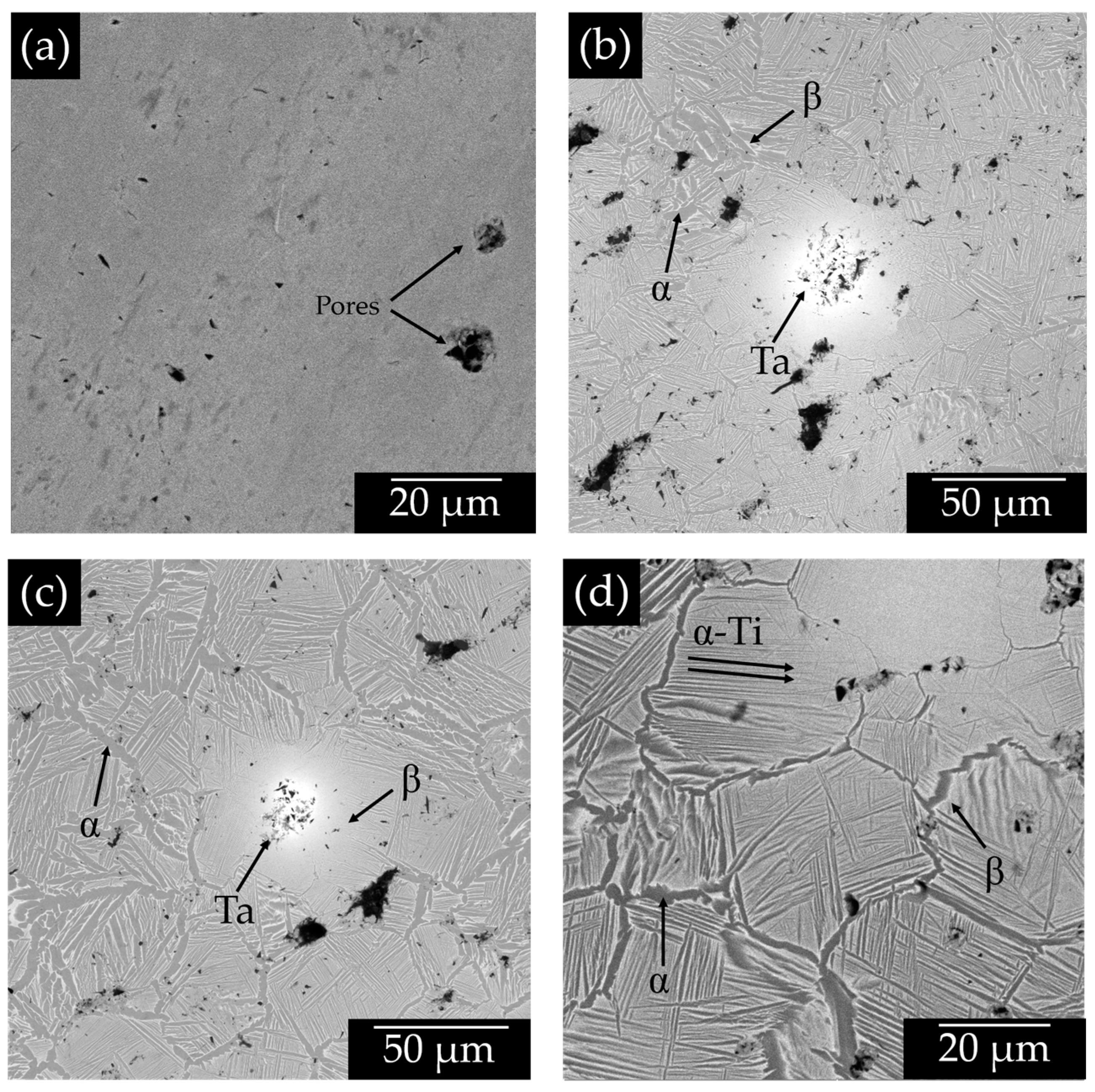

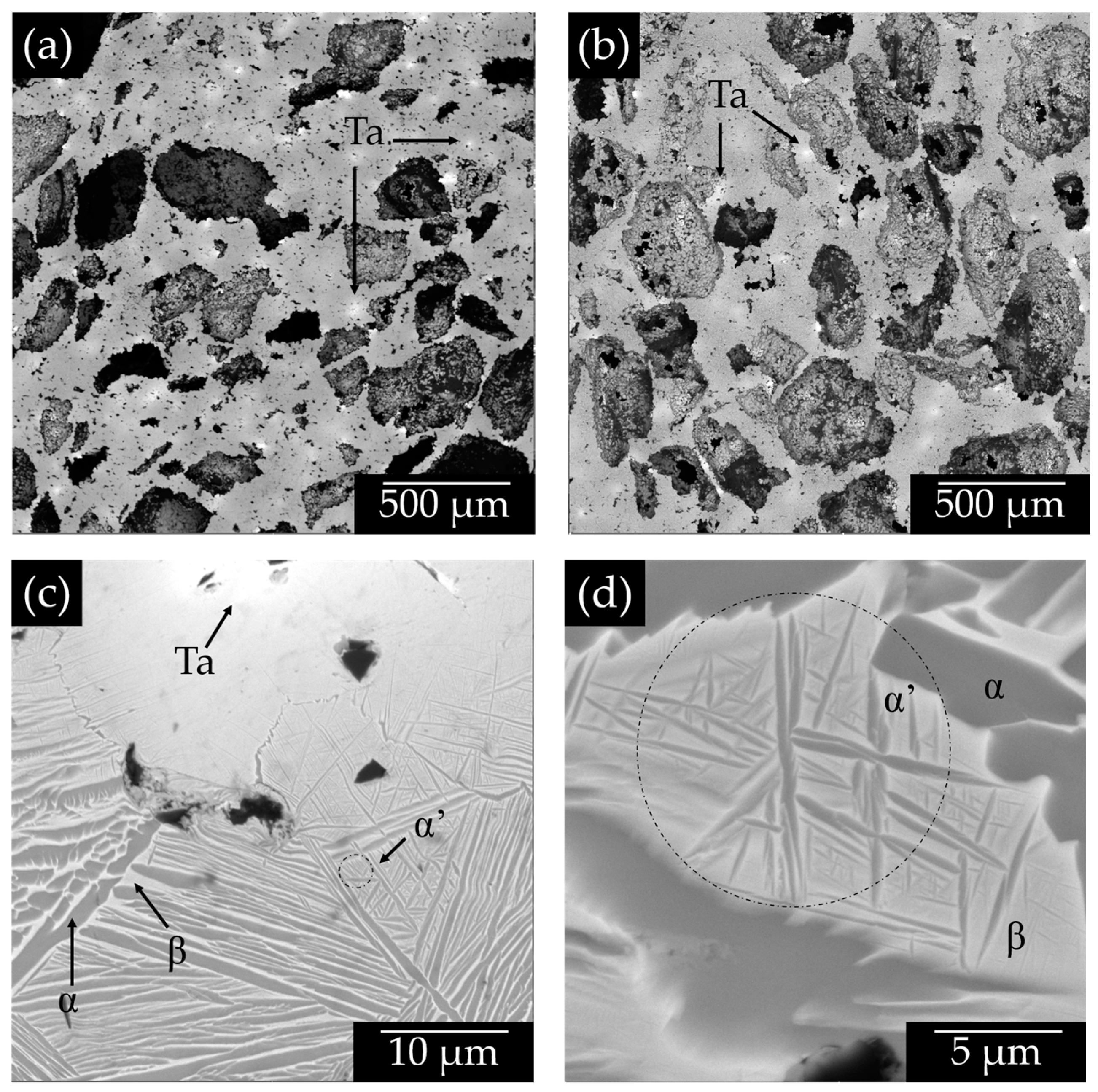

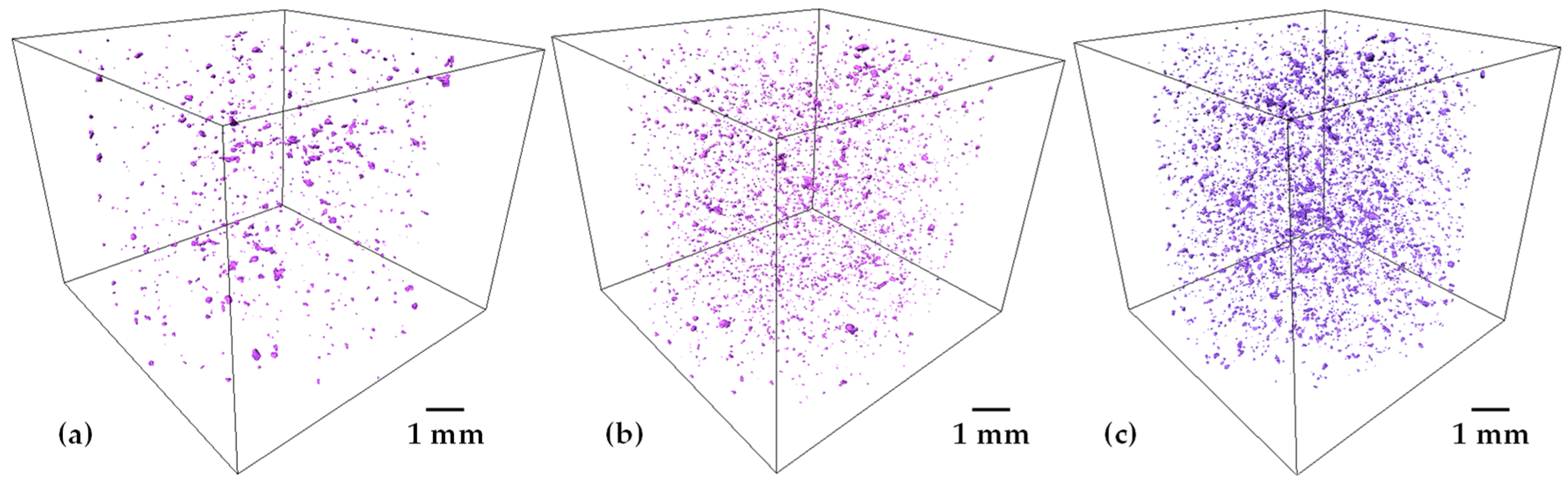

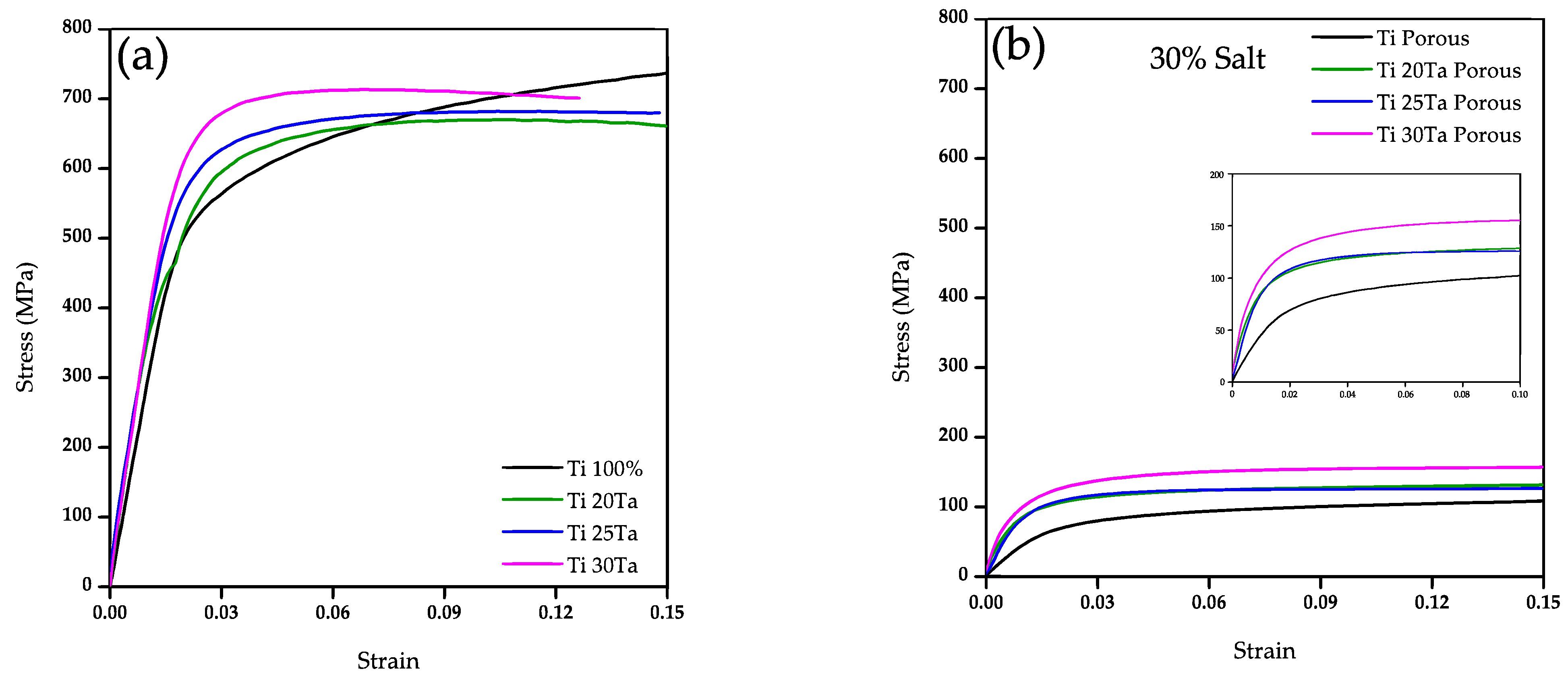

3.2. Microstructural Analysis

3.3. Permeability Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bozic, D.; Cvijovic, I.; Vilotijevic, M.; Jovanovic, M. The influence of microstructural characteristics on the mechanical properties of Ti6Al4V alloy produced by the powder metallurgy technique. J. Serbian Chem. Soc. 2006, 71, 985–992. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Powder Metallurgy Technology; Cambridge International Science Publishing: Cambridge, UK, 2002. [Google Scholar]

- Zhang, W.; Liu, Y.; Li, H.; Li, Z.; Wang, H.; Liu, B. Constitutive modeling and processing map for elevated temperature flow behaviors of a powder metallurgy titanium aluminide alloy. J. Mater. Process. Technol. 2009, 209, 5363–5370. [Google Scholar] [CrossRef]

- Long, Y.; Wang, T.; Zhang, H.; Huang, X. Enhanced ductility in a bimodal ultrafine-grained Ti–6Al–4V alloy fabricated by high energy ball milling and spark plasma sintering. Mater. Sci. Eng. A 2014, 608, 82–89. [Google Scholar] [CrossRef]

- Sim, K.; Wang, G.; Ju, J.; Yang, J.; Li, X. Microstructure and mechanical properties of a Ti−22Al−25Nb alloy fabricated from elemental powders by mechanical alloying and spark plasma sintering. J. Alloys Compd. 2017, 704, 425–433. [Google Scholar] [CrossRef]

- Fousová, M.; Vojtěch, D.; Kubásek, J.; Jablonská, E.; Fojt, J. Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. J. Mech. Behav. Biomed. Mater. 2017, 69, 368–376. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef]

- Aydoğmuş, T.; Bor, E.T.; Bor, Ş. Phase Transformation Behavior of Porous TiNi Alloys Produced by Powder Metallurgy Using Magnesium as a Space Holder. Met. Mater. Trans. A 2011, 42, 2547–2555. [Google Scholar] [CrossRef]

- Li, P.; Ma, X.; Wang, D.; Zhang, H. Microstructural and Mechanical Properties of β-Type Ti–Nb–Sn Biomedical Alloys with Low Elastic Modulus. Metals 2019, 9, 712. [Google Scholar] [CrossRef]

- Cabezas-Villa, J.L.; Lemus-Ruiz, J.; Bouvard, D.; Jiménez, O.; Vergara-Hernández, H.J.; Olmos, L. Sintering study of Ti6Al4V powders with different particle sizes and their mechanical properties. Int. J. Miner. Met. Mater. 2018, 25, 1389–1401. [Google Scholar] [CrossRef]

- Cabezas-Villa, J.L.; Olmos, L.; Bouvard, D.; Lemus-Ruiz, J.; Jiménez, O. Processing and properties of highly porous Ti6Al4V mimicking human bones. J. Mater. Res. 2018, 33, 650–661. [Google Scholar] [CrossRef]

- Jeje, S.O.; Shongwe, M.B.; Rominiyi, A.L.; Olubambi, P.A. Spark plasma sintering of titanium matrix composite—a review. Int. J. Adv. Manuf. Technol. 2021, 117, 2529–2544. [Google Scholar] [CrossRef]

- Mahmud, N.; Sulong, A.; Sharma, B.; Ameyama, K. Presintered Titanium-Hydroxyapatite Composite Fabricated via PIM Route. Metals 2021, 11, 318. [Google Scholar] [CrossRef]

- Xu, W.; Kim, K.; Das, J.; Calin, M.; Eckert, J. Phase stability and its effect on the deformation behavior of Ti–Nb–Ta–In/Cr β alloys. Scr. Mater. 2006, 54, 1943–1948. [Google Scholar] [CrossRef]

- Shen, J.; Chen, B.; Ye, X.; Imai, H.; Umeda, J.; Kondoh, K. The formation of bimodal multilayered grain structure and its effect on the mechanical properties of powder metallurgy pure titanium. Mater. Des. 2016, 116, 99–108. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Ota, M.; Watanabe, T.; Maeda, R.; Sekiguchi, T.; Kusaka, T.; Ameyama, K. The Development of High Performance Ti-6Al-4V Alloy via a Unique Microstructural Design with Bimodal Grain Size Distribution. Met. Mater. Trans. A 2014, 46, 903–914. [Google Scholar] [CrossRef]

- Taddei, E.; Henriques, V.; Silva, C.; Cairo, C. Production of new titanium alloy for orthopedic implants. Mater. Sci. Eng. C 2004, 24, 683–687. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, K.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Correa, D.; Kuroda, P.; Lourenço, M.; Fernandes, C.; Buzalaf, M.; Zambuzzi, W.; Grandini, C. Development of Ti-15Zr-Mo alloys for applying as implantable biomedical devices. J. Alloys Compd. 2018, 749, 163–171. [Google Scholar] [CrossRef]

- Kuroda, P.A.B.; Quadros, F.D.F.; de Araújo, R.O.; Afonso, C.R.M.; Grandini, C.R. Effect of Thermomechanical Treatments on the Phases, Microstructure, Microhardness and Young’s Modulus of Ti-25Ta-Zr Alloys. Materials 2019, 12, 3210. [Google Scholar] [CrossRef]

- Wang, W.; Poh, C.K. Advances in Properties Control, Titanium Alloys-Advances in Properties Control; Intech Open: Licko-Senjska, Croatia, 2013; pp. 21–44. [Google Scholar]

- Wu, C.; Xin, Y.; Wang, X.; Lin, J. Effects of Ta content on the phase stability and elastic properties of β Ti–Ta alloys from first-principles calculations. Solid State Sci. 2010, 12, 2120–2124. [Google Scholar] [CrossRef]

- Zhou, Y.-L.; Niinomi, M. Ti–25Ta alloy with the best mechanical compatibility in Ti–Ta alloys for biomedical applications. Mater. Sci. Eng. C 2009, 29, 1061–1065. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K.; Wu, H.; Song, M.; Wang, W.; Li, N.; Tang, H. Synthesis of Ti–Ta alloys with dual structure by incomplete diffusion between elemental powders. J. Mech. Behav. Biomed. Mater. 2015, 51, 302–312. [Google Scholar] [CrossRef] [PubMed]

- Balla, V.K.; Banerjee, S.; Bose, S.; Bandyopadhyay, A. Direct laser processing of a tantalum coating on titanium for bone replacement structures. Acta Biomater. 2010, 6, 2329–2334. [Google Scholar] [CrossRef] [PubMed]

- Wauthle, R.; van der Stok, J.; Yavari, S.A.; Van Humbeeck, J.; Kruth, J.-P.; Zadpoor, A.A.; Weinans, H.; Mulier, M.; Schrooten, J. Additively manufactured porous tantalum implants. Acta Biomater. 2015, 14, 217–225. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, H.; Li, Q.; Ye, L.; Gan, H.; Liu, Y.; Wang, H.; Wang, Z. Biocompatibility and osteogenic properties of porous tantalum. Exp. Ther. Med. 2015, 9, 780–786. [Google Scholar] [CrossRef]

- He, Y.H.; Jiang, Y.; Xu, N.P.; Zou, J.; Huang, B.Y.; Liu, C.T.; Liaw, P.K. Fabrication of Ti–Al Micro/ Nanometer-Sized Porous Alloys through the Kirkendall Effect. Adv. Mater. 2007, 19, 2102–2106. [Google Scholar] [CrossRef]

- Zhao, D.; Chang, K.; Ebel, T.; Nie, H.; Willumeit, R.; Pyczak, F. Sintering behavior and mechanical properties of a metal injection molded Ti–Nb binary alloy as biomaterial. J. Alloys Compd. 2015, 640, 393–400. [Google Scholar] [CrossRef]

- Wang, Z.; Jiao, X.; Feng, P.; Wang, X.; Liu, Z.; Akhtar, F. Highly porous open cellular TiAl-based intermetallics fabricated by thermal explosion with space holder process. Intermetallics 2016, 68, 95–100. [Google Scholar] [CrossRef]

- Garnica, P.; Macías, R.; Chávez, J.; Bouvard, D.; Jiménez, O.; Olmos, L.; Arteaga, D. Fabrication and characterization of highly porous Ti6Al4V/xTa composites for orthopedic applications. J. Mater. Sci. 2020, 55, 16419–16431. [Google Scholar] [CrossRef]

- Olmos, L.; Bouvard, D.; Cabezas-Villa, J.L.; Lemus-Ruiz, J.; Jiménez, O.; Arteaga, D. Analysis of Compression and Permeability Behavior of Porous Ti6Al4V by Computed Microtomography. Met. Mater. Int. 2018, 25, 669–682. [Google Scholar] [CrossRef]

- Okuma, G.; Kadowaki, D.; Shinoda, Y.; Akatsu, T.; Guillon, O.; Wakai, F. Determination of the size of representative volume element for viscous sintering. J. Ceram. Soc. Jpn. 2016, 124, 421–425. [Google Scholar] [CrossRef]

- Panigrahi, B.; Godkhindi, M.; Das, K.; Mukunda, P.; Ramakrishnan, P. Sintering kinetics of micrometric titanium powder. Mater. Sci. Eng. A 2005, 396, 255–262. [Google Scholar] [CrossRef]

- Olmos, L.; Takahashi, T.; Bouvard, D.; Martin, C.L.; Salvo, L.; Bellet, D.; Di Michiel, M. Analysing the sintering of heterogeneous powder structures byin situmicrotomography. Philos. Mag. 2009, 89, 2949–2965. [Google Scholar] [CrossRef]

- Das, K.; Das, S. A review of the Ti-Al-Ta (Titanium-Aluminum-Tantalum) system. J. Phase Equilibria Diffus. 2005, 26, 322–329. [Google Scholar] [CrossRef]

- Park, Y.; Butt, D.P. Composition Dependence of the Kinetics and Mechanisms of Thermal Oxidation of Titanium-Tantalum Alloys. Oxid. Met. 1999, 51, 383–402. [Google Scholar] [CrossRef]

- Langenkämper, D.; Paulsen, A.; Somsen, C.; Frenzel, J.; Eggeler, G. On the Oxidation Behavior and Its Influence on the Martensitic Transformation of Ti–Ta High-Temperature Shape Memory Alloys. Shape Mem. Superelast. 2019, 5, 63–72. [Google Scholar] [CrossRef]

- Murray, J.L. The Ta−Ti (Tantalum-Titanium) system. Bull. Alloy Phase Diagr. 1981, 2, 62–66. [Google Scholar] [CrossRef]

- Xu, X.; Nash, P. Sintering mechanisms of Armstrong prealloyed Ti–6Al–4V powders. Mater. Sci. Eng. A 2014, 607, 409–416. [Google Scholar] [CrossRef]

- Cameron, J.R.; Skofronick, J.G.; Grant, R. Physics of the Body; Medical Physics: Madison, WI, USA, 1999. [Google Scholar]

- Weatherall, D.J.; Ledingham, J.G.G.; Warrell, D.A. The Skeletal System Oxford Textbook of Medicine; Oxford University Press: Oxford, UK, 1996. [Google Scholar]

- Adamovic, D.; Ristic, B.; Zivic, F. Review of Existing Biomaterials—Method of Material Selection for Specific Applications in Orthopedics. In Biomaterials in Clinical Practice; Zivic, F., Affatato, S., Trajanovic, M., Schnabelrauch, M., Grujovic, N., Choy, K., Eds.; Springer: Cham, Switzerland, 2018; pp. 47–99. [Google Scholar] [CrossRef]

- Buenconsejo, P.J.S.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Shape memory behavior of Ti–Ta and its potential as a high-temperature shape memory alloy. Acta Mater. 2009, 57, 1068–1077. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T. Decomposition of martensite α″ during aging treatments and resulting mechanical properties of Ti−Ta alloys. Mater. Sci. Eng. A 2004, 384, 92–101. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T. Effects of Ta content on Young’s modulus and tensile properties of binary Ti–Ta alloys for biomedical applications. Mater. Sci. Eng. A 2004, 371, 283–290. [Google Scholar] [CrossRef]

- Dercz, G.; Matuła, I.; Zubko, M.; Kazek-Kęsik, A.; Maszybrocka, J.; Simka, W.; Dercz, J.; Świec, P.; Jendrzejewska, I. Synthesis of porous Ti–50Ta alloy by powder metallurgy. Mater. Charact. 2018, 142, 124–136. [Google Scholar] [CrossRef]

- Buenconsejo, P.J.S.; Kim, H.Y.; Miyazaki, S. Novel β-TiTaAl alloys with excellent cold workability and a stable high-temperature shape memory effect. Scr. Mater. 2011, 64, 1114–1117. [Google Scholar] [CrossRef]

- Braem, A.; Chaudhari, A.; Cardoso, M.V.; Schrooten, J.; Duyck, J.; Vleugels, J. Peri- and intra-implant bone response to microporous Ti coatings with surface modification. Acta Biomater. 2014, 10, 986–995. [Google Scholar] [CrossRef]

- Taniguchi, N.; Fujibayashi, S.; Takemoto, M.; Sasaki, K.; Otsuki, B.; Nakamura, T.; Matsushita, T.; Kokubo, T.; Matsuda, S. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater. Sci. Eng. C 2015, 59, 690–701. [Google Scholar] [CrossRef] [PubMed]

- Itälä, A.I.; Ylänen, H.O.; Ekholm, C.; Karlsson, K.H.; Aro, H.T. Pore diameter of more than 100 μm is not requisite for bone ingrowth in rabbits. J. Biomed. Mater. Res. 2001, 58, 679–683. [Google Scholar] [CrossRef]

- Nauman, E.A.; Fong, K.E.; Keaveny, T.M. Dependence of Intertrabecular Permeability on Flow Direction and Anatomic Site. Ann. Biomed. Eng. 1999, 27, 517–524. [Google Scholar] [CrossRef]

- Gordin, D.-M.; Delvat, E.; Chelariu, R.; Ungureanu, G.; Besse, M.; Laillé, D.; Gloriant, T. Characterization of Ti-Ta Alloys Synthesized by Cold Crucible Levitation Melting. Adv. Eng. Mater. 2008, 10, 714–719. [Google Scholar] [CrossRef]

- Zhou, Y.-L.; Niinomi, M. Microstructures and mechanical properties of Ti–50mass% Ta alloy for biomedical applications. J. Alloys Compd. 2008, 466, 535–542. [Google Scholar] [CrossRef]

- Fan, Z. On the young’s moduli of Ti6Al4V alloys. Scr. Mater. 1993, 29, 1427–1432. [Google Scholar] [CrossRef]

- Hao, Y.L.; Yang, R.; Niinomi, M.; Kuroda, D.; Zhou, Y.L.; Fukunaga, K.; Suzuki, A. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite. Met. Mater. Trans. A 2002, 33, 3137–3144. [Google Scholar] [CrossRef]

- Lee, C.M.; Ju, C.P.; Lin, J.H.C. Structure-property relationship of cast Ti-Nb alloys. J. Oral Rehabil. 2002, 29, 314–322. [Google Scholar] [CrossRef] [PubMed]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Kesteven, J.; Kannan, M.B.; Walter, R.; Khakbaz, H.; Choe, H.-C. Low elastic modulus Ti–Ta alloys for load-bearing permanent implants: Enhancing the biodegradation resistance by electrochemical surface engineering. Mater. Sci. Eng. C 2015, 46, 226–231. [Google Scholar] [CrossRef] [PubMed]

| Vol.% Pore Formers | ||||||

|---|---|---|---|---|---|---|

| 0% | 30% | 40% | ||||

| %Ta | Green (g/cm3) | Sintered (g/cm3) | Green (g/cm3) | Sintered (g/cm3) | Green (g/cm3) | Sintered (g/cm3) |

| 0 | 3.43 | 4.27 | 1.56 | 2.06 | 1.39 | 1.54 |

| 20 | 3.53 | 4.30 | 1.75 | 2.23 | 1.49 | 1.93 |

| 25 | 3.94 | 4.64 | 1.94 | 2.50 | 1.50 | 1.99 |

| 30 | 4.30 | 5.24 | 2.03 | 2.63 | 1.51 | 2.00 |

| Sample | Pore Volume Fraction (%) | Median Pore Size (µm) | Median Wall Size (µm) | Permeability Axial (10−10 m2) | Permeability Radial (10−10 m2) | Tortuosity |

|---|---|---|---|---|---|---|

| Ti/xTa30Salt | 42.1 | 195 | 175 | 0.18 | 0.17 | 1.56 |

| Ti/xTa40Salt | 58.3 | 224 | 150 | 1.15 | 1.12 | 1.34 |

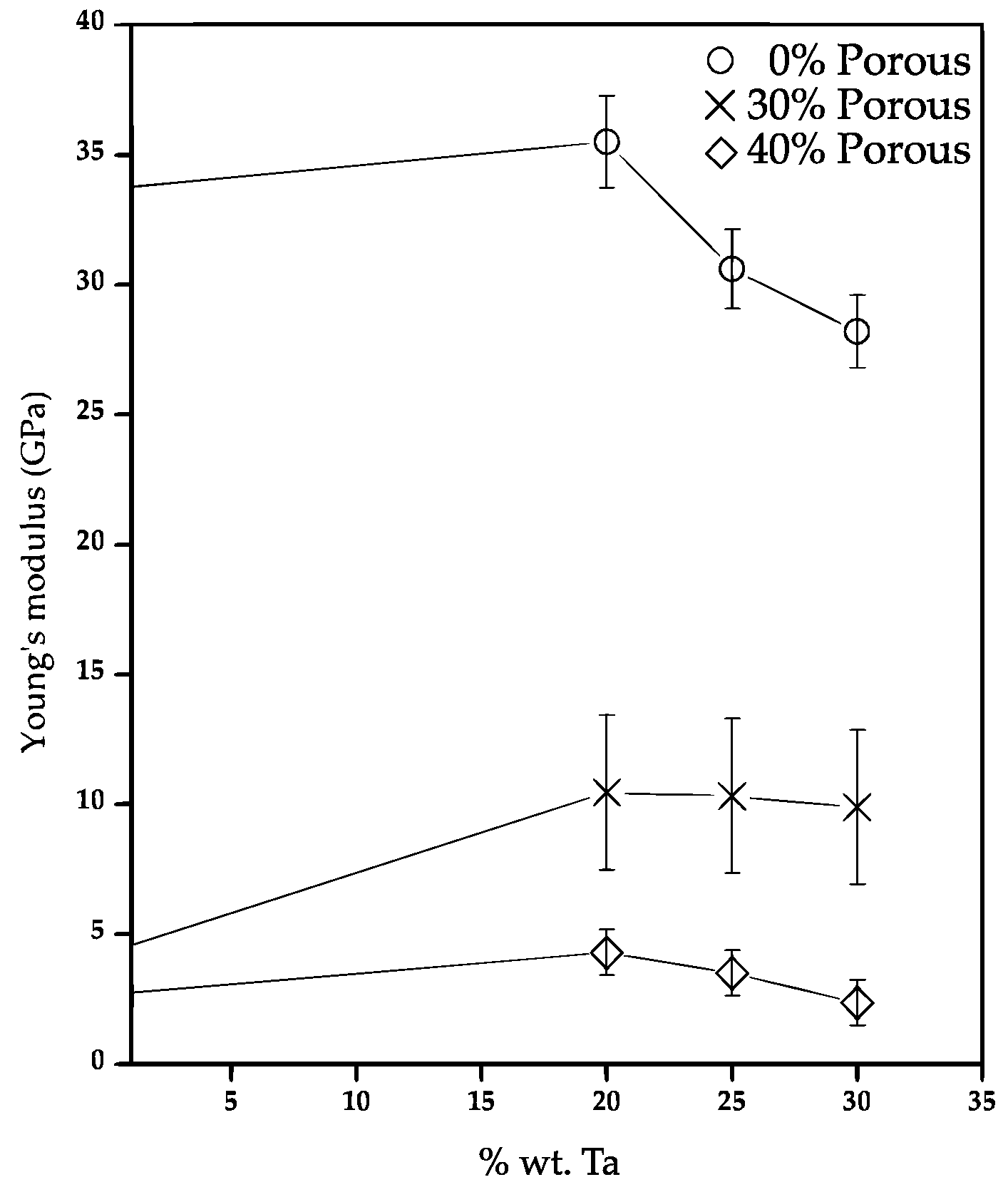

| Alloys | Young’s Modulus (GPa) | |

|---|---|---|

| Cp-Ti [53,60] | 103–105 | |

| Ti-20Ta [46,53,60] | 83–84 | |

| Ti-30Ta [46,53,60] | 69 | |

| Ti-50Ta [46,53,54] | 77–93 | |

| Bone [7] | ||

| Compact | Transverse | 17.9 ± 3.9 |

| Longitudinal | 10.1 ± 2.4 | |

| Trabecular | Vertebra | 0.067 ± 0.045 |

| Tibia | 0.445 ± 0.257 | |

| Femur | 0.441 ± 0.271 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macias, R.; Garnica-Gonzalez, P.; Olmos, L.; Jimenez, O.; Chavez, J.; Vazquez, O.; Alvarado-Hernandez, F.; Arteaga, D. Sintering Analysis of Porous Ti/xTa Alloys Fabricated from Elemental Powders. Materials 2022, 15, 6548. https://doi.org/10.3390/ma15196548

Macias R, Garnica-Gonzalez P, Olmos L, Jimenez O, Chavez J, Vazquez O, Alvarado-Hernandez F, Arteaga D. Sintering Analysis of Porous Ti/xTa Alloys Fabricated from Elemental Powders. Materials. 2022; 15(19):6548. https://doi.org/10.3390/ma15196548

Chicago/Turabian StyleMacias, Rogelio, Pedro Garnica-Gonzalez, Luis Olmos, Omar Jimenez, Jorge Chavez, Octavio Vazquez, Francisco Alvarado-Hernandez, and Dante Arteaga. 2022. "Sintering Analysis of Porous Ti/xTa Alloys Fabricated from Elemental Powders" Materials 15, no. 19: 6548. https://doi.org/10.3390/ma15196548

APA StyleMacias, R., Garnica-Gonzalez, P., Olmos, L., Jimenez, O., Chavez, J., Vazquez, O., Alvarado-Hernandez, F., & Arteaga, D. (2022). Sintering Analysis of Porous Ti/xTa Alloys Fabricated from Elemental Powders. Materials, 15(19), 6548. https://doi.org/10.3390/ma15196548