The Effect of Selected Factors on the Strength of Stitches of Upholstery Faux Leather

Abstract

1. Introduction

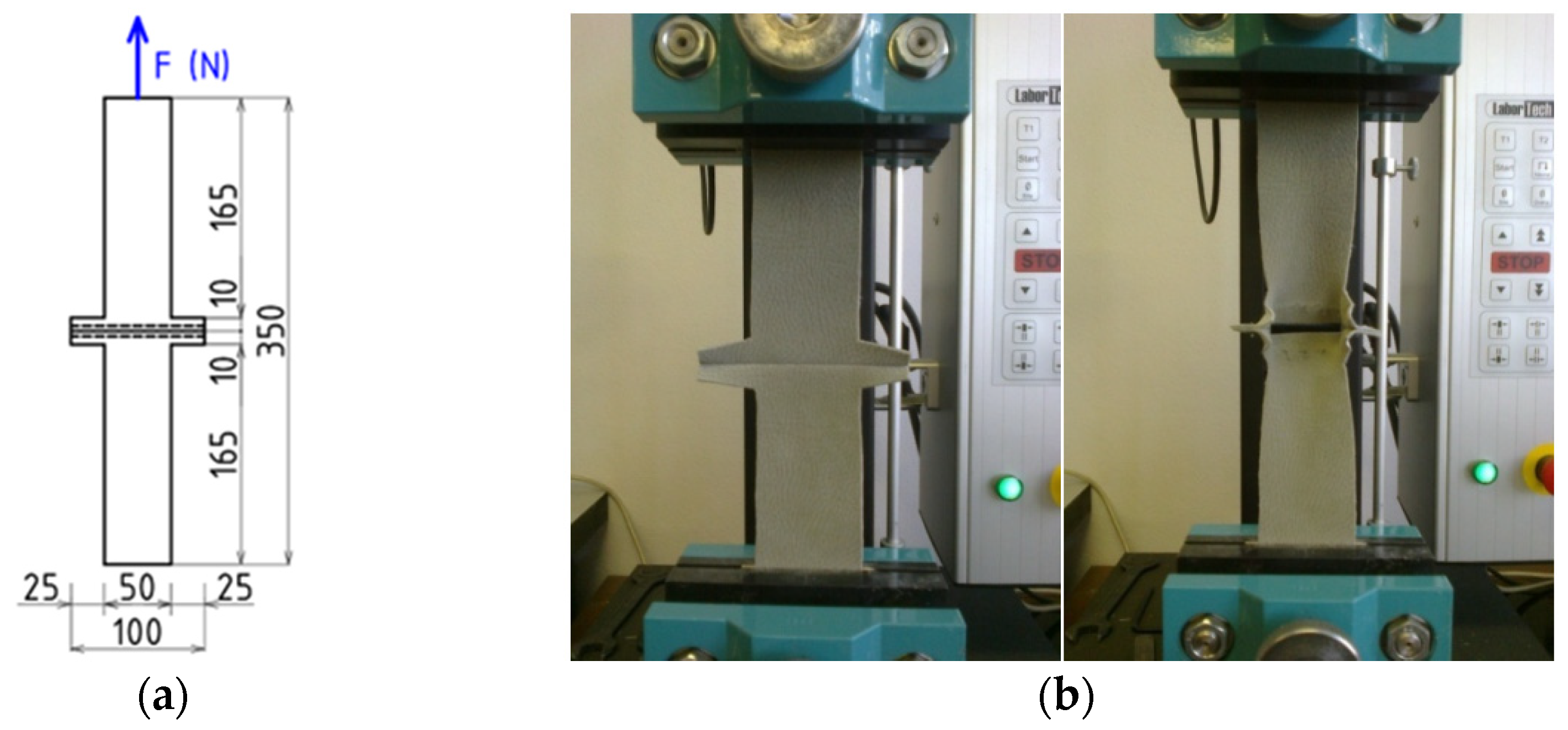

2. Materials and Methods

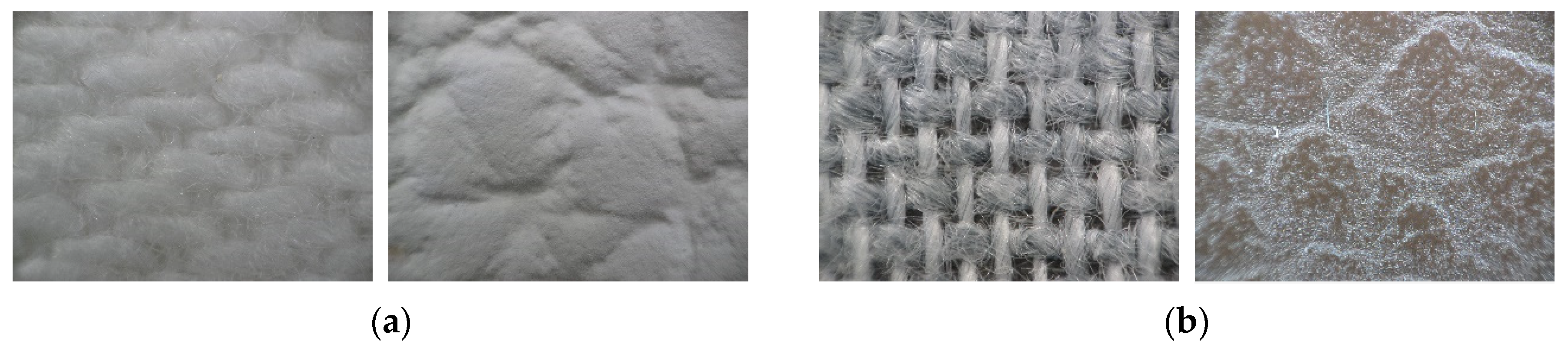

2.1. Material of Upholstery Covers

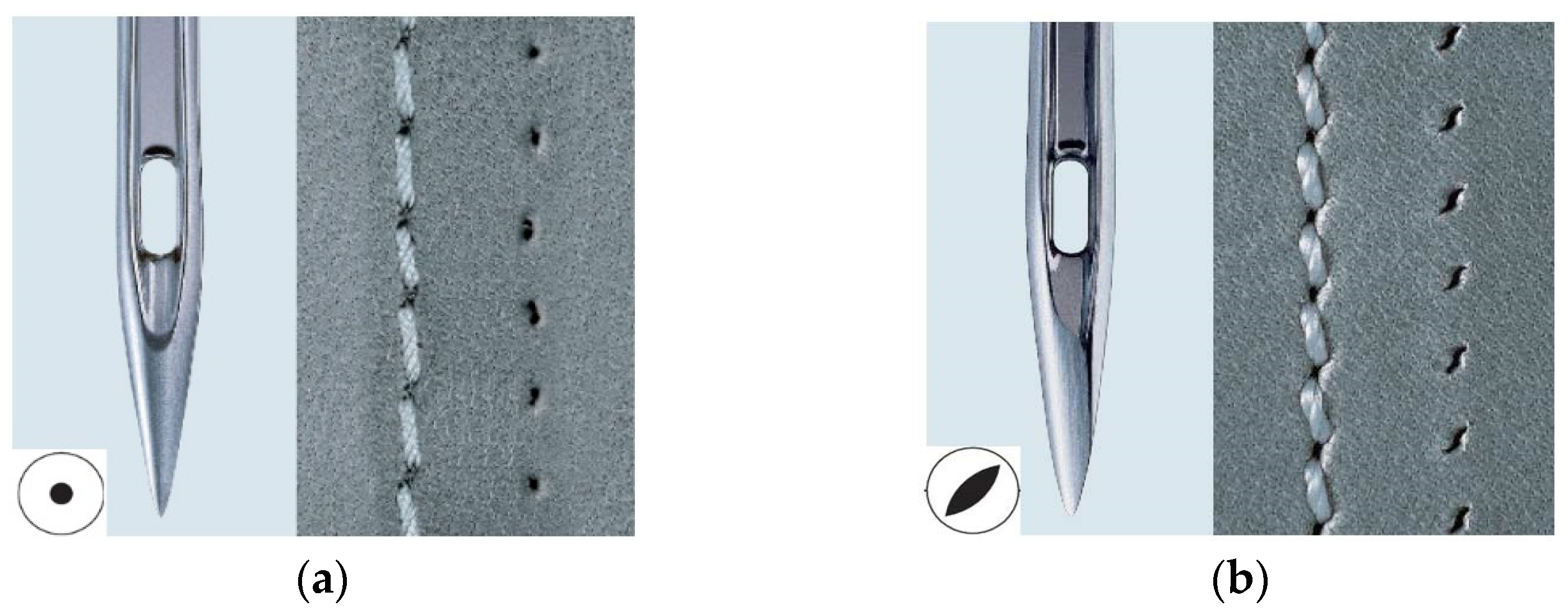

2.2. Type of Sewing Needles

3. Results

4. Discussion

4.1. Evaluation of Strength

4.2. Evaluation of Deformations and Damage

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Germanova-Krasteva, D.; Petrov, H. Investigation on the seam’s quality by sewing of light fabrics. Int. J. Cloth. Sci. Technol. 2008, 20, 57–64. [Google Scholar] [CrossRef]

- Bharani, M.; Shiyamaladevi, P.S.S.; Mahendra Gowda, R.V. Characterization of Seam Strength and Seam Slippage on Cotton Fabric with Woven Structures and Finish. Res. J. Eng. Sci. 2012, 1, 41–50. [Google Scholar]

- Stylios, G.; Sotomi, J.O. Investigation of Seam Pucker in Lightweight Synthetic Fabrics as an Aesthetic Property Part I: A Cognitive Model for the Measurement of Seam Pucker. J. Text. Inst. 1993, 84, 593–600. [Google Scholar] [CrossRef]

- Jin, T.; Yeol, J. Objective Evaluation of Fabric Wrinkles and Seam Puckers Using Fractal Geometry. Text. Res. J. 2000, 70, 469–475. [Google Scholar] [CrossRef]

- Rajput, B.; Kakde, M.; Gulhane, S.; Mohite, S.; Raichurkar, P.P. Effect of Sewing Parameters on Seam Strength and Seam Efficiency. Trends Text. Eng. Fash. Technol. 2018, 4, 4–5. [Google Scholar] [CrossRef]

- Owczarek, M. Impact of fabric parameters and properties on a 2D cutting and stitching line. Commun. Dev. Assem. Text. Prod. 2020, 1, 80–87. [Google Scholar] [CrossRef]

- Borse, S.; Sonawane, K.; Kakde, M.V.; Shinde, T.A. Review on analysis of seam quality. In Chemistry and Technology of Natural and Synthetic Dyes and Pigments; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Chen, D.; Cheng, P.; Li, Y. Investigation of interactions between fabric performance, sewing process parameters and seam pucker of shirt fabric. J. Eng. Fibers Fabr. 2021, 16, 155892502110203. [Google Scholar] [CrossRef]

- Ali, N.; Rehan, A.M.; Ahmed, Z.; Memon, H.; Hussain, A. Effect of Different Types of Seam, Stitch Class and Stitch Density on Seam Performance. J. Appl. Emerg. Sci. 2016, 5, 32–43. [Google Scholar]

- Choudhary, A.K.; Goel, A. Effect of Some Fabric and Sewing Conditions on Apparel Seam Characteristics. J. Text. 2013, 2013, 157034. [Google Scholar] [CrossRef]

- Rogina-Car, B.; Schwarz, I.; Kovačević, S. Analysis of Woven Fabric at the Place of the Sewn Seam. Autex Res. J. 2018, 18, 216–220. [Google Scholar] [CrossRef]

- Lange, J.; Ciura, A.; Majewski, A.; Wojnowska, M. Study on the Influence of Selected Fabrics and Stitching on the Strength of Upholstery Covers. Materials 2022, 15, 3854. [Google Scholar] [CrossRef]

- Daukantienė, V.; Lapinskienė, M. Influence of the deformation mode on seam slippage in woven fabrics. Fibers Polym. 2012, 13, 1086–1093. [Google Scholar] [CrossRef]

- Geršak, J.; Knez, B. Reduction In Thread Strength As A Cause Of Loading In The Sewing Process. Int. J. Cloth. Sci. Technol. 1991, 3, 6–12. [Google Scholar] [CrossRef]

- Iftikhar, F.; Hussain, T.; Malik, M.; Ali, Z.; Nazir, A.; Riaz, S.; Malik, S. Fabric Structural Parameters Effect on Seam Efficiency-Effect of Woven Fabric Structural Parameters on Seam Efficiency. J. Text. Sci. Eng. 2018, 8, 1–7. [Google Scholar] [CrossRef]

- Skorupińska, E.; Wiaderek, K.; Sydor, M. Influence of technological parameters on the upholstery seams in furniture. Ann. WULS -SGGW. For. Wood Technol. 2021, 114, 110–115. [Google Scholar] [CrossRef]

- Zelova, K.; Glombikova, V.; Havelka, A. Problems with perfect-looking two-needle decorative seams in the manufacture of leather car seat covers. Text. Res. J. 2020, 90, 49–62. [Google Scholar] [CrossRef]

- Ahmadi, M.S.; Rahimi, S. Effect of needle type and backing fabric structure on sewing needle penetration force in artificial leather. In Proceedings of the 18th AUTEX World Textile Conference, Istanbul, Turkey, 20–22 June 2018; pp. 611–614. [Google Scholar]

- Yukseloglu, S.M.; Çitoğlu, F.; Çetinkaya, B. A study on the needle heating in polyester blend upholstery fabrics. Ind. Text. 2013, 64, 246–253. [Google Scholar]

- Liasi, E.; Du, R.; Simon, D.; Bujas-Dimitrejevic, J.; Liburdi, F. An experimental study of needle heating in sewing heavy materials using infrared radiometry. Int. J. Cloth. Sci. Technol. 1999, 11, 300–314. [Google Scholar] [CrossRef]

- Mazari, A. Effect of Needle Heating on the Sewing of Medical Textiles. Polymers 2021, 13, 4405. [Google Scholar] [CrossRef]

- Kyosev, Y.; Kühn, T. Joining High Thickness Materials by Sewing–first Modelling Steps of the Stitched Place. Appl. Compos. Mater. 2022, 29, 83–93. [Google Scholar] [CrossRef]

- Brisa, V.J.D.; Helbig, F.; Kroll, L. Numerical characterisation of the mechanical behaviour of a vertical spacer yarn in thick warp knitted spacer fabrics. J. Ind. Text. 2014, 45, 101–117. [Google Scholar] [CrossRef]

- Šulgan, R.; Slabejová, G.; Navrátil, V.; Bahýl, V. Tepelné namáhanie čalúnnických materiálov sálavým teplom. Acta Fac. Xylologiae 1999, 41, 47–57. [Google Scholar]

- Dziegielewski, S.; Smardzewski, J. Badania Formatek Sprezynowych Mebli Tapicerowanych. In Čalúnnicke Dni; Technical University in Zvolen: Zvolen, Slovak, 1995; pp. 18–19. [Google Scholar]

- Lusiak, A.; Smardzewski, J. Creative thinking in designing furniture for pre-school children. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2010, 70, 270–278. [Google Scholar]

- Silber, G.; Alizadeh, M.; Salimi, M. Large Deformation Analysis for Soft Foams Based on Hyperelasticity. J. Mech. 2010, 26, 327–334. [Google Scholar] [CrossRef]

- Makovická Osvaldová, L.; Marková, I.; Vandlíčková, M.; Gašpercová, S.; Titko, M. Fire Characteristics of Upholstery Materials in Seats. Int. J. Environ. Res. Public Health 2020, 17, 3341. [Google Scholar] [CrossRef]

- Lounis, M.; Leconte, S.; Rousselle, C.; Belzunces, L.P.; Desauziers, V.; Lopez-Cuesta, J.-M.; Julien, J.M.; Guenot, D.; Bourgeois, D. Fireproofing of domestic upholstered furniture: Migration of flame retardants and potential risks. J. Hazard. Mater. 2019, 366, 556–562. [Google Scholar] [CrossRef]

- Yang, J.; Rein, G.; Chen, H.; Zammarano, M. Smoldering propensity in upholstered furniture: Effects of mock-up configuration and foam thickness. Appl. Therm. Eng. 2020, 181, 115873. [Google Scholar] [CrossRef]

- Chivas, C.; Guillaume, E.; Sainrat, A.; Barbosa, V. Assessment of risks and benefits in the use of flame retardants in upholstered furniture in continental Europe. Fire Saf. J. 2009, 44, 801–807. [Google Scholar] [CrossRef]

- Kovačević, S.; Domjanić, J.; Brnada, S.; Schwarz, I. Textile Composites for Seat Upholstery. In Textiles for Advanced Applications; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef][Green Version]

- Fatahi, I.A.; Apau, E.; Asare, T.O.; Gyamfi, E.E. The Use of Composite Textile Techniques as Upholstery Fabric for Interior Furnishing. Int. J. Innov. Res. Dev. 2022, 11. [Google Scholar] [CrossRef]

- ISO 13935-1: 2014; Textiles—Seam Tensile Properties of Fabrics and Made-Up Textile Articles—Part 1: Determination of Maximum Force to Seam Rupture Using the Strip Method. Comite Europeen de Normalisation: Brussels, Belgium, 2014.

| Material A: PU Faux Leather Fabric | Material B: PVC Faux Leather Fabric | ||

|---|---|---|---|

| Load in the warp FFLmax (N) | Load in the weft FFLmax (N) | Load in the warp FFLmax (N) | Load in the weft FFLmax (N) |

| 1008.14 | 699.32 | 630.08 | 452.24 |

| Point Needle/Needle Size | Material A: PU Faux Leather Fabric | Material B: PVC Faux Leather Fabric | ||||||

|---|---|---|---|---|---|---|---|---|

| Load in the Warp Direction | Load in the Weft Direction | Load in the Warp Direction | Load in the Weft Direction | |||||

| Steam Length (mm) | Steam Length (mm) | Steam Length (mm) | Steam Length (mm) | |||||

| 4 mm | 5 mm | 4 mm | 5 mm | 4 mm | 5 mm | 4 mm | 5 mm | |

| R/90 | 463.82 (SD = 9.05) * | 343.21 (24.02) | 386.46 (20.76) | 400.44 (10.38) | 362.46 (16.55) | 407.75 (11.01) | 408.11 (11.68) | 347.00 (18.01) |

| R/100 | 492.97 (24.56) | 456.12 (20.73) | 380.60 (13.46) | 391.32 (16.32) | 357.01 (16.54) | 400.00 (5.72) | 400.05 (15.80) | 339.12 (5.52) |

| LR/90 | 521.92 (14.25) | 413.26 (14.76) | 426.32 (22.46) | 407.99 (14.83) | 431.07 (8.17) | 407.67 (18.64) | 431.06 (18.13) | 420.93 (17.66) |

| LR/100 | 517.12 (18.21) | 409.19 (19.04) | 424.52 (23.05) | 407.43 (21.32) | 412.11 (8.91) | 410.67 (5.83) | 411.4 25.96) | 382.59 (7.70) |

| Source of Variation | Sum of Squares | DoF | MS | F | P |

|---|---|---|---|---|---|

| Intercept | 20,494,153 | 1 | 20,494,153 | 44,469.82 | 0.000000 |

| Load Direction | 69,059 | 1 | 69,059 | 149.85 | 0.000000 |

| Needle size | 33,852 | 3 | 11,284 | 24.49 | 0.000000 |

| Stitch length | 66,029 | 1 | 66,029 | 143.27 | 0.000000 |

| Load Direction × Needle size | 21,630 | 3 | 7210 | 15.64 | 0.000000 |

| Load Direction × Stitch length | 58,473 | 1 | 58,473 | 126.88 | 0.000000 |

| Needle size × Stitch length | 11,788 | 3 | 3929 | 8.53 | 0.000045 |

| Load Direction × Needle size × Stitch length | 6352 | 3 | 2117 | 4.59 | 0.004755 |

| Source of Variation | Sum of Squares | DoF | MS | F | P |

|---|---|---|---|---|---|

| Intercept | 17,651,343 | 1 | 17,651,343 | 56,459.80 | 0.000000 |

| Load Direction | 2044 | 1 | 2044 | 6.54 | 0.012129 |

| Needle size | 49,506 | 3 | 16502 | 52.78 | 0.000000 |

| Stitch length | 6196 | 1 | 6196 | 19.82 | 0.000023 |

| Load Direction × Needle size | 363 | 3 | 121 | 0.39 | 0.762619 |

| Load Direction × Stitch length | 17,933 | 1 | 17,933 | 57.36 | 0.000000 |

| Needle size × Stitch length | 1783 | 3 | 594 | 1.90 | 0.134563 |

| Load Direction × Needle size × Stitch length | 24,283 | 3 | 8094 | 25.89 | 0.000000 |

| Point Needle/Needle Size | Material A: PU Faux Leather Fabric | Material B: PVC Faux Leather Fabric | ||||||

|---|---|---|---|---|---|---|---|---|

| Load in the Warp Direction | Load in the Weft Direction | Load in the Warp Direction | Load in the Weft Direction | |||||

| Steam Length (mm) | Steam Length (mm) | Steam Length (mm) | Steam Length (mm) | |||||

| 4 mm | 5 mm | 4 mm | 5 mm | 4 mm | 5 mm | 4 mm | 5 mm | |

| R/90 | 46.01% | 34.04% | 55.26% | 55.26% | 57.53% | 64.71% | 90.24% | 76.73% |

| R/100 | 48.90% | 45.24% | 54.42% | 55.96% | 56.66% | 63.48% | 88.46% | 74.99% |

| LR/90 | 51.77% | 40.99% | 60.96% | 58.34% | 68.42% | 68.41% | 95.32% | 93.08% |

| LR/100 | 51.29% | 40.59% | 60.70% | 58.26% | 65.41% | 65.18% | 90.97% | 84.60% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilhanová, A.; Langová, N.; Kłos, R.; Máchová, E. The Effect of Selected Factors on the Strength of Stitches of Upholstery Faux Leather. Materials 2022, 15, 6585. https://doi.org/10.3390/ma15196585

Vilhanová A, Langová N, Kłos R, Máchová E. The Effect of Selected Factors on the Strength of Stitches of Upholstery Faux Leather. Materials. 2022; 15(19):6585. https://doi.org/10.3390/ma15196585

Chicago/Turabian StyleVilhanová, Anna, Nadežda Langová, Robert Kłos, and Eliška Máchová. 2022. "The Effect of Selected Factors on the Strength of Stitches of Upholstery Faux Leather" Materials 15, no. 19: 6585. https://doi.org/10.3390/ma15196585

APA StyleVilhanová, A., Langová, N., Kłos, R., & Máchová, E. (2022). The Effect of Selected Factors on the Strength of Stitches of Upholstery Faux Leather. Materials, 15(19), 6585. https://doi.org/10.3390/ma15196585