Effect of Fe and C Contents on the Microstructure and High-Temperature Mechanical Properties of IN625 Alloy Processed by Laser Powder Bed Fusion

Abstract

:1. Introduction

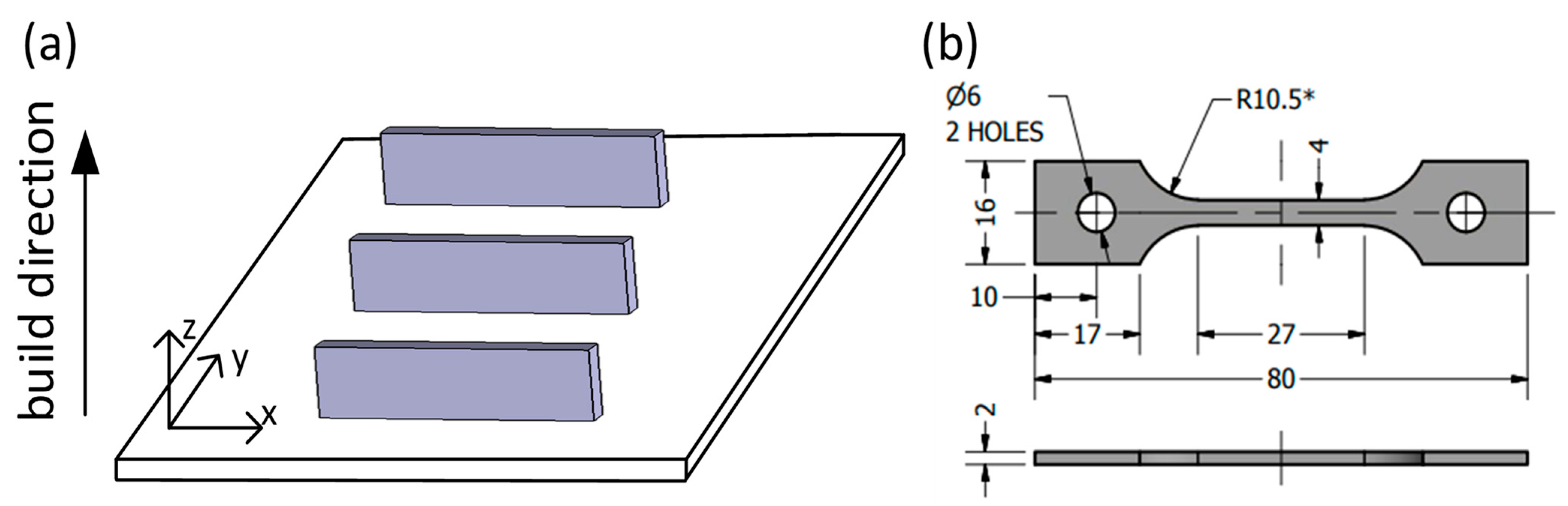

2. Materials and Methods

3. Results

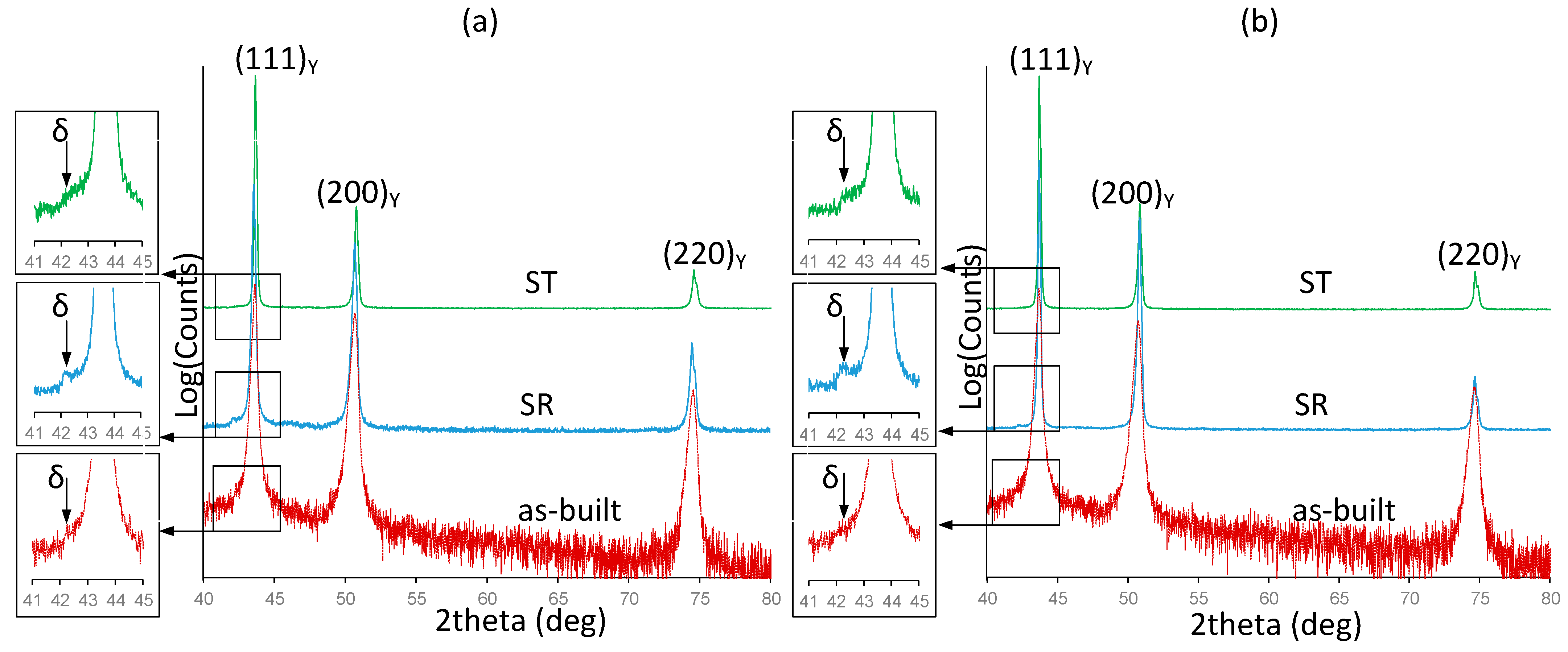

3.1. XRD Analysis

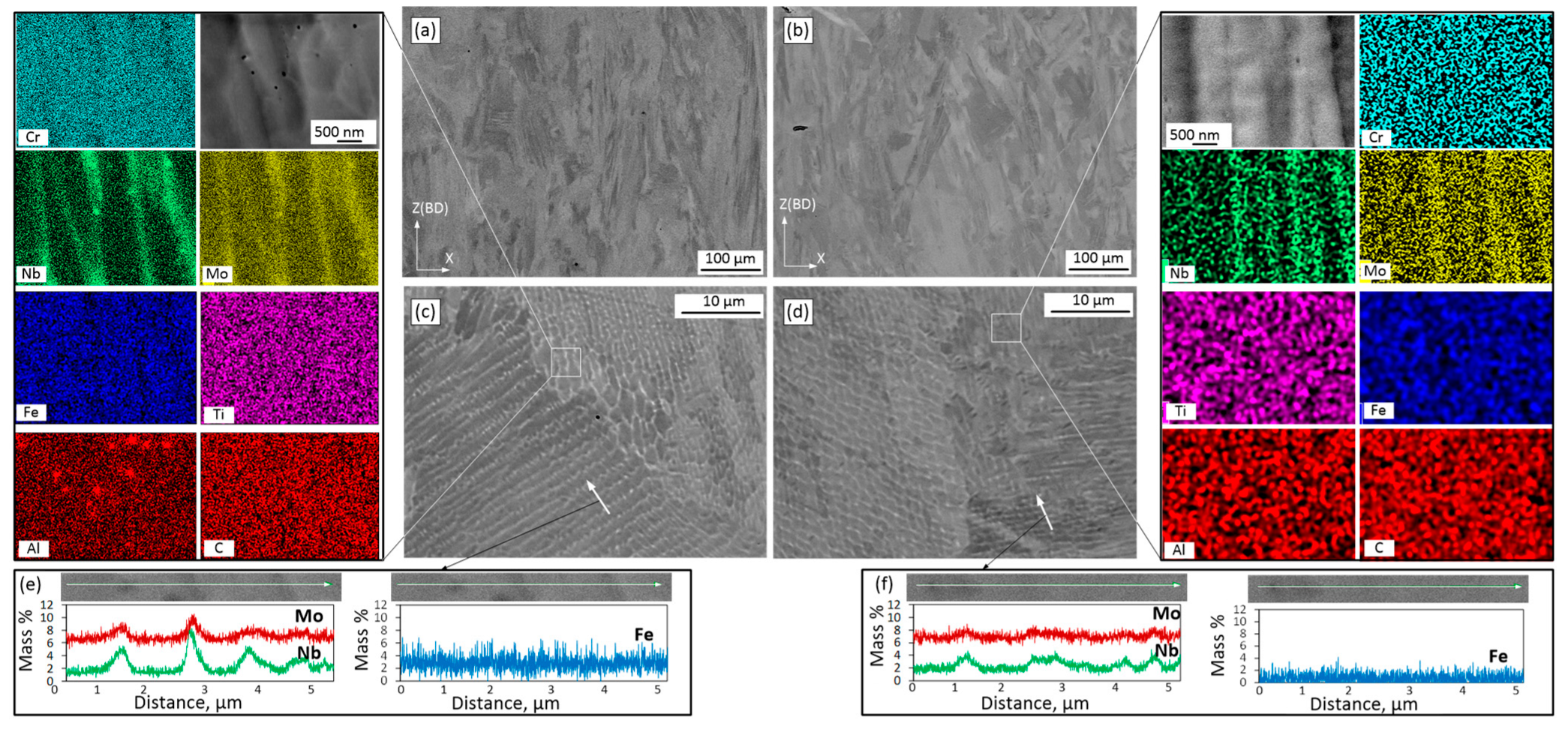

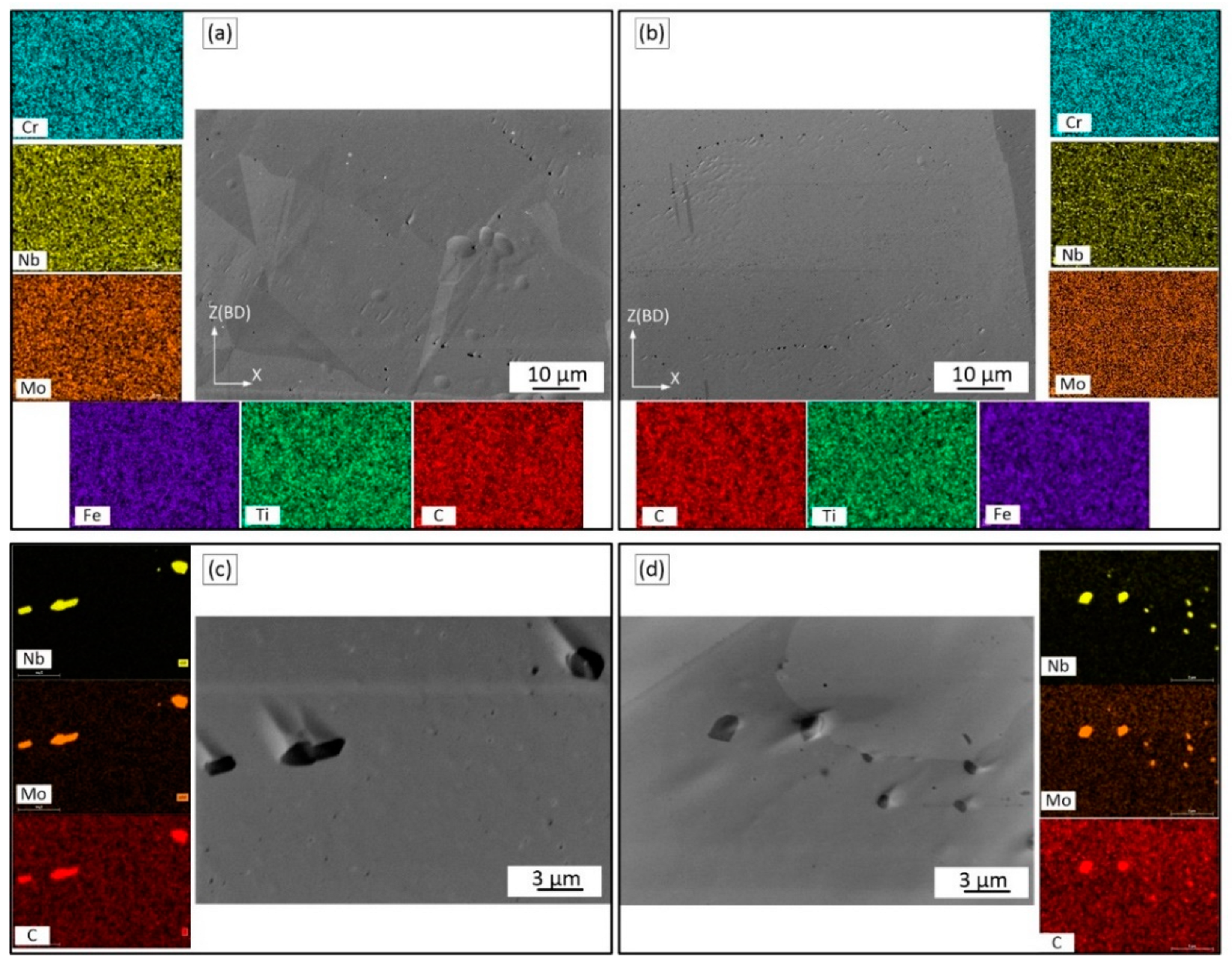

3.2. Precipitation and Segregation Features of the As-Built Alloy

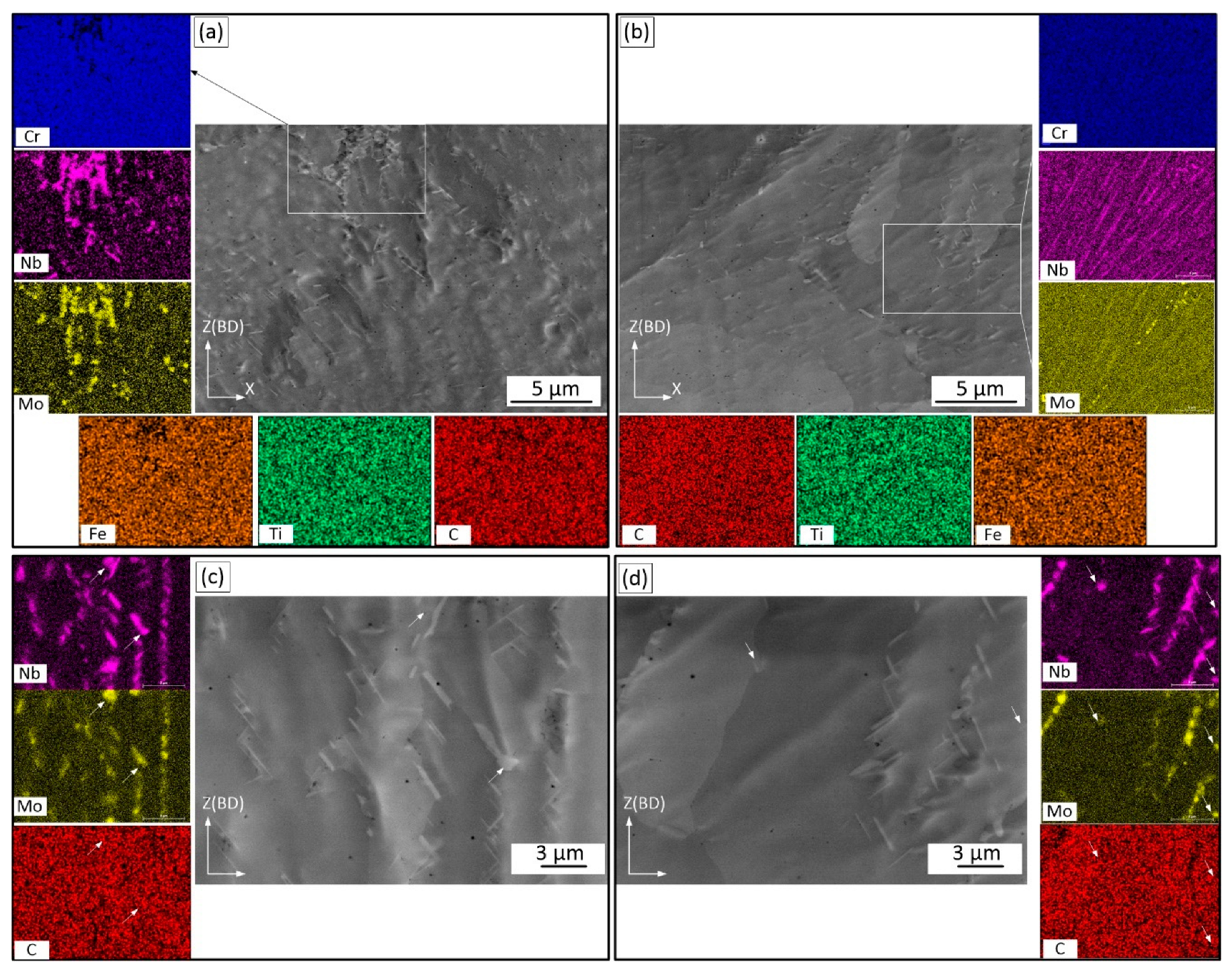

3.3. Effect of SR and ST on the Precipitation Distribution and Morphology

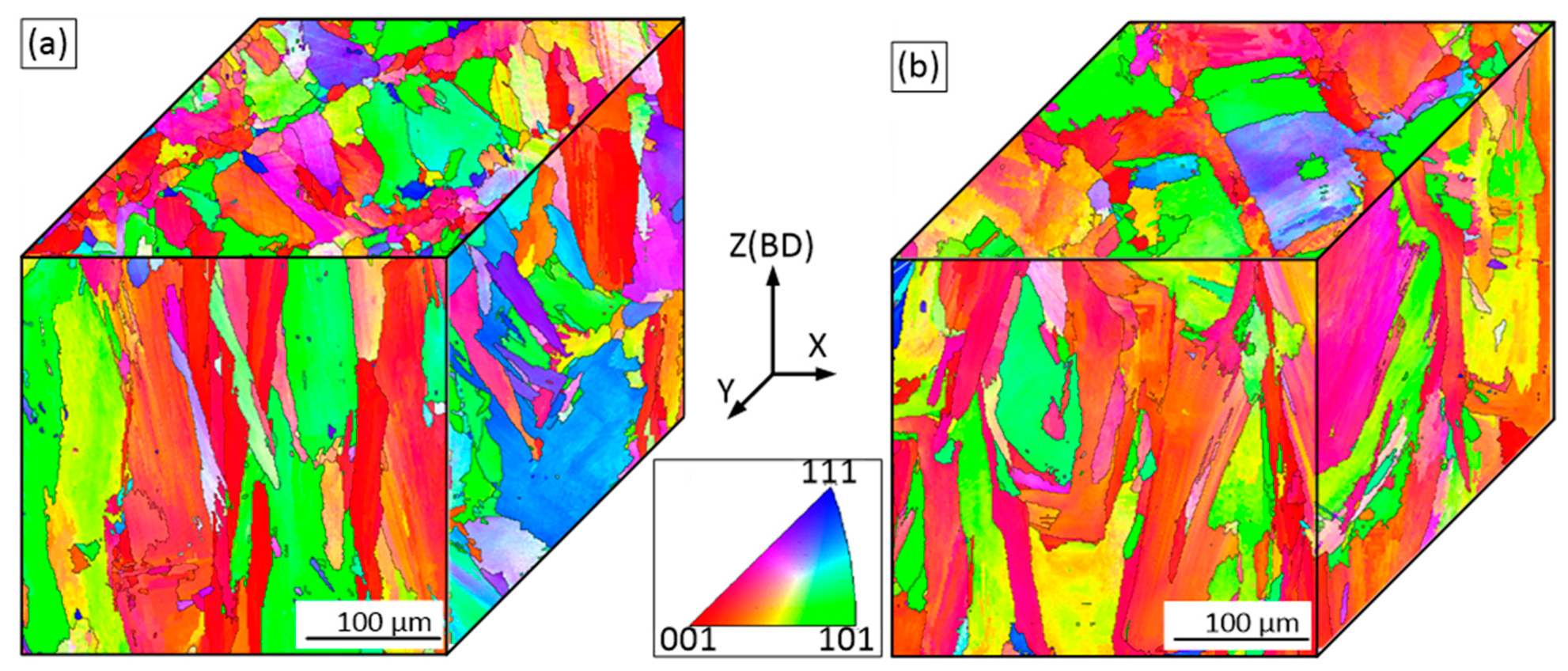

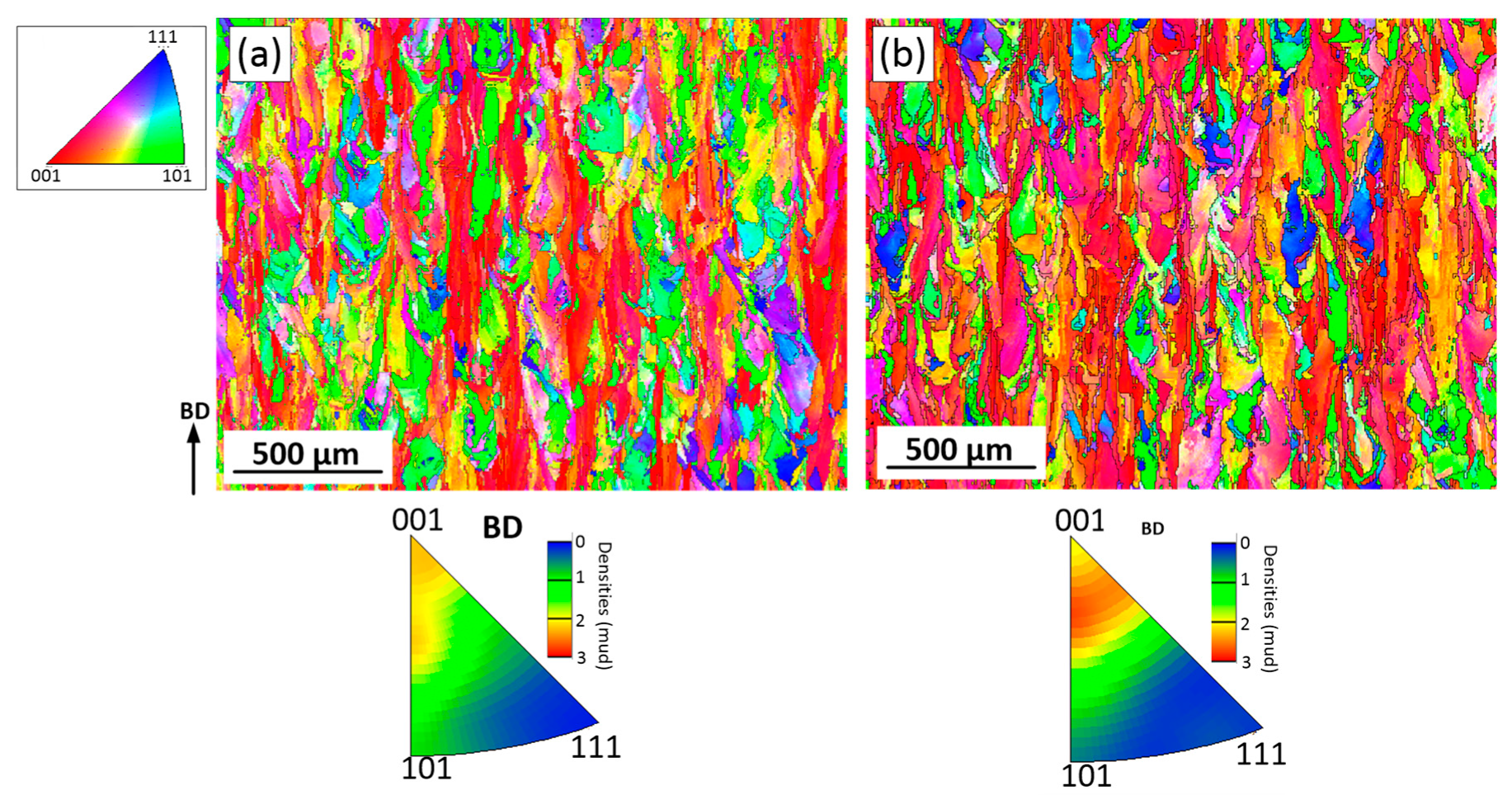

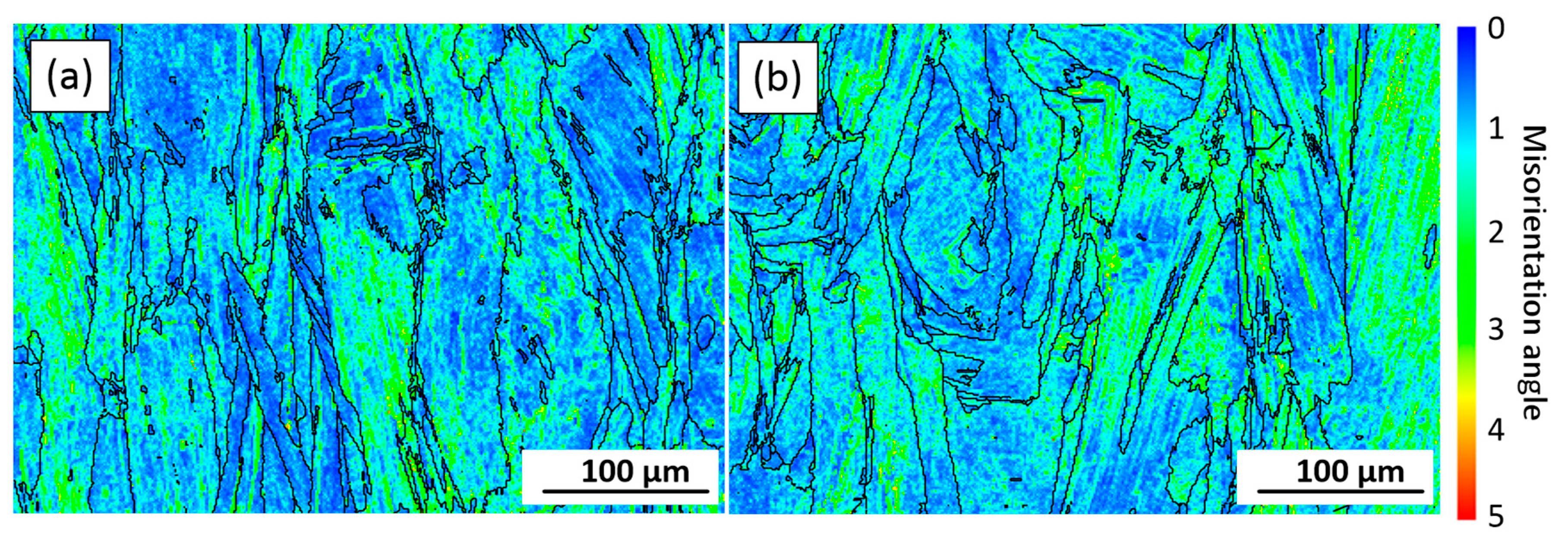

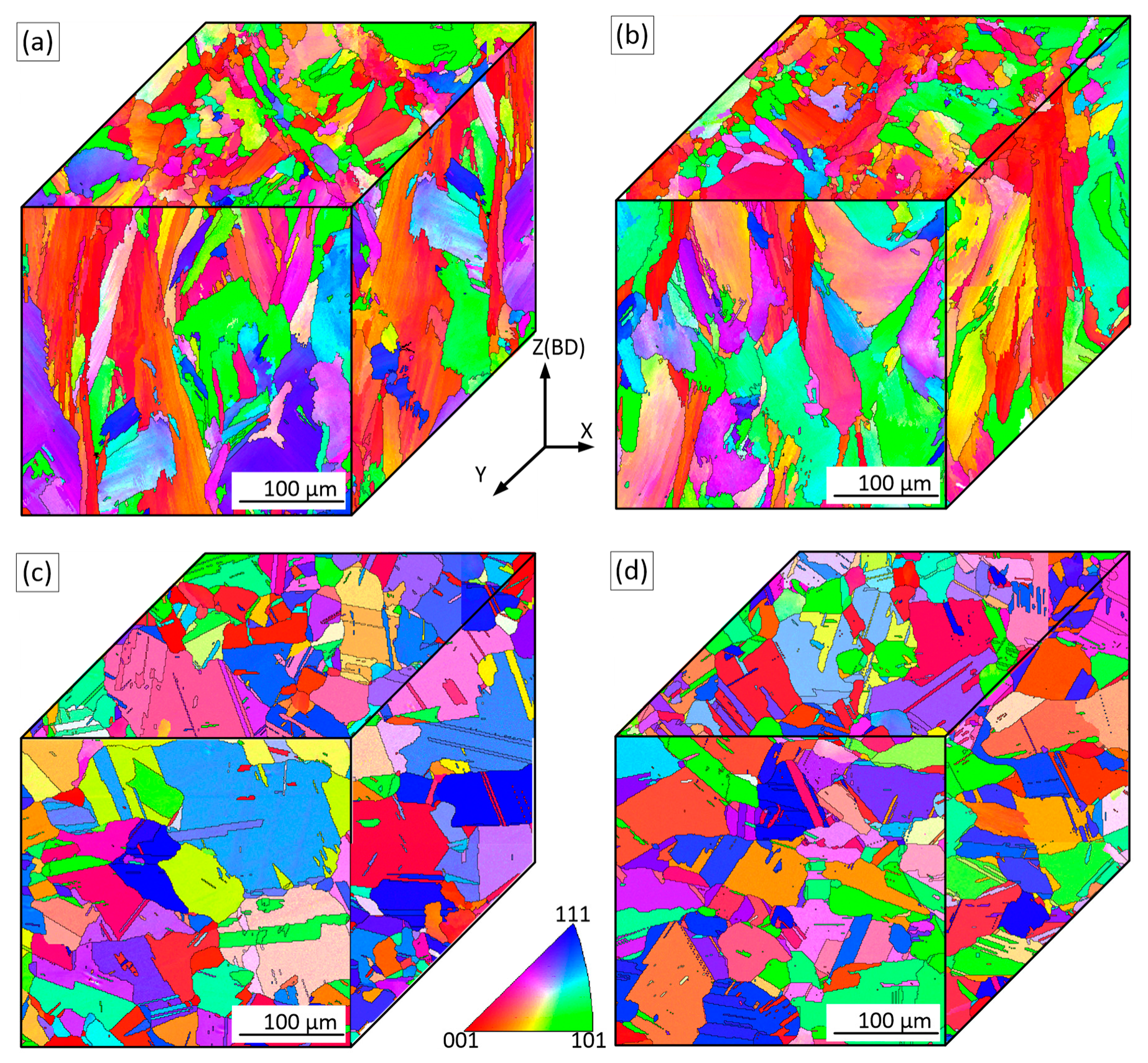

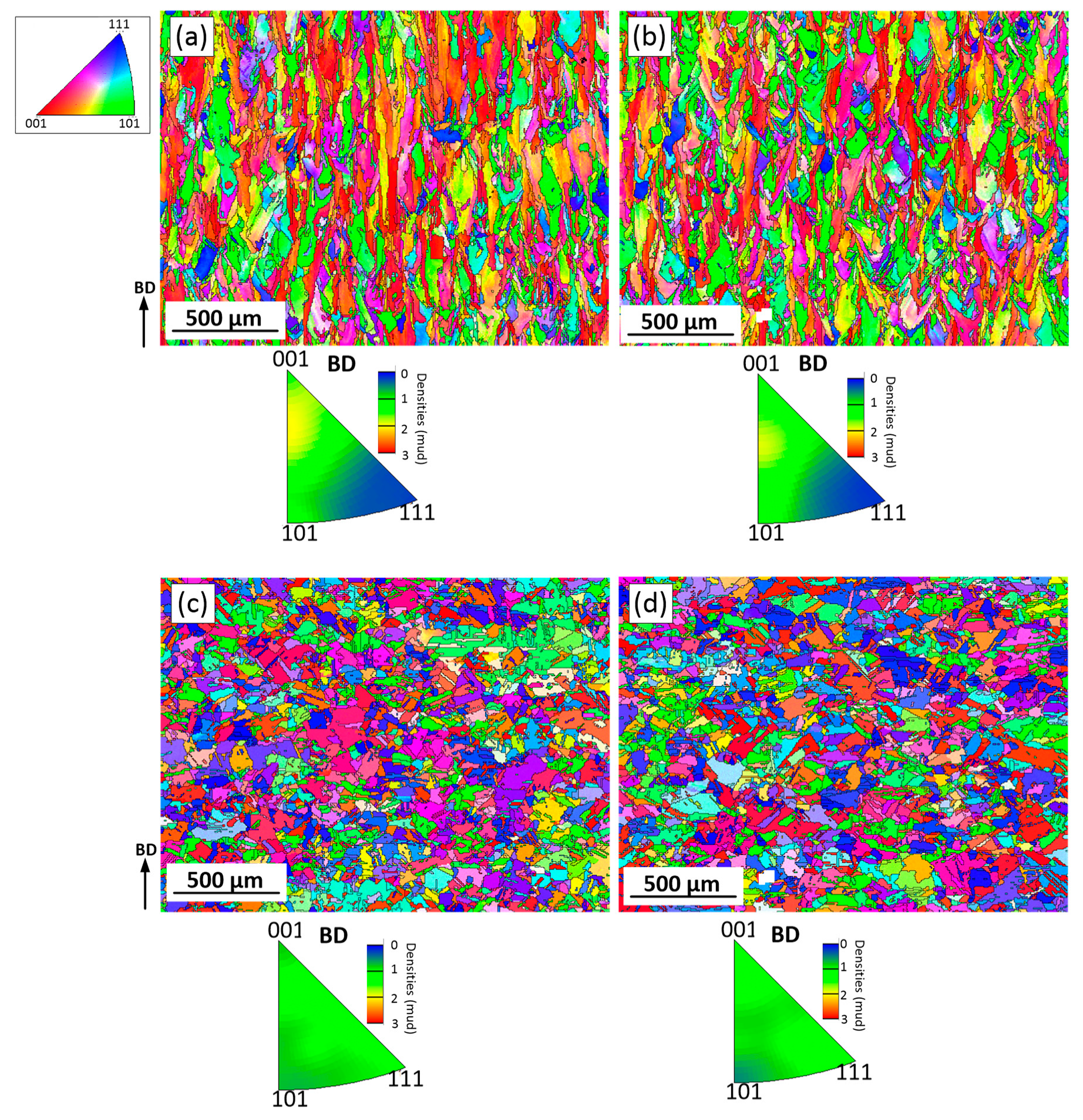

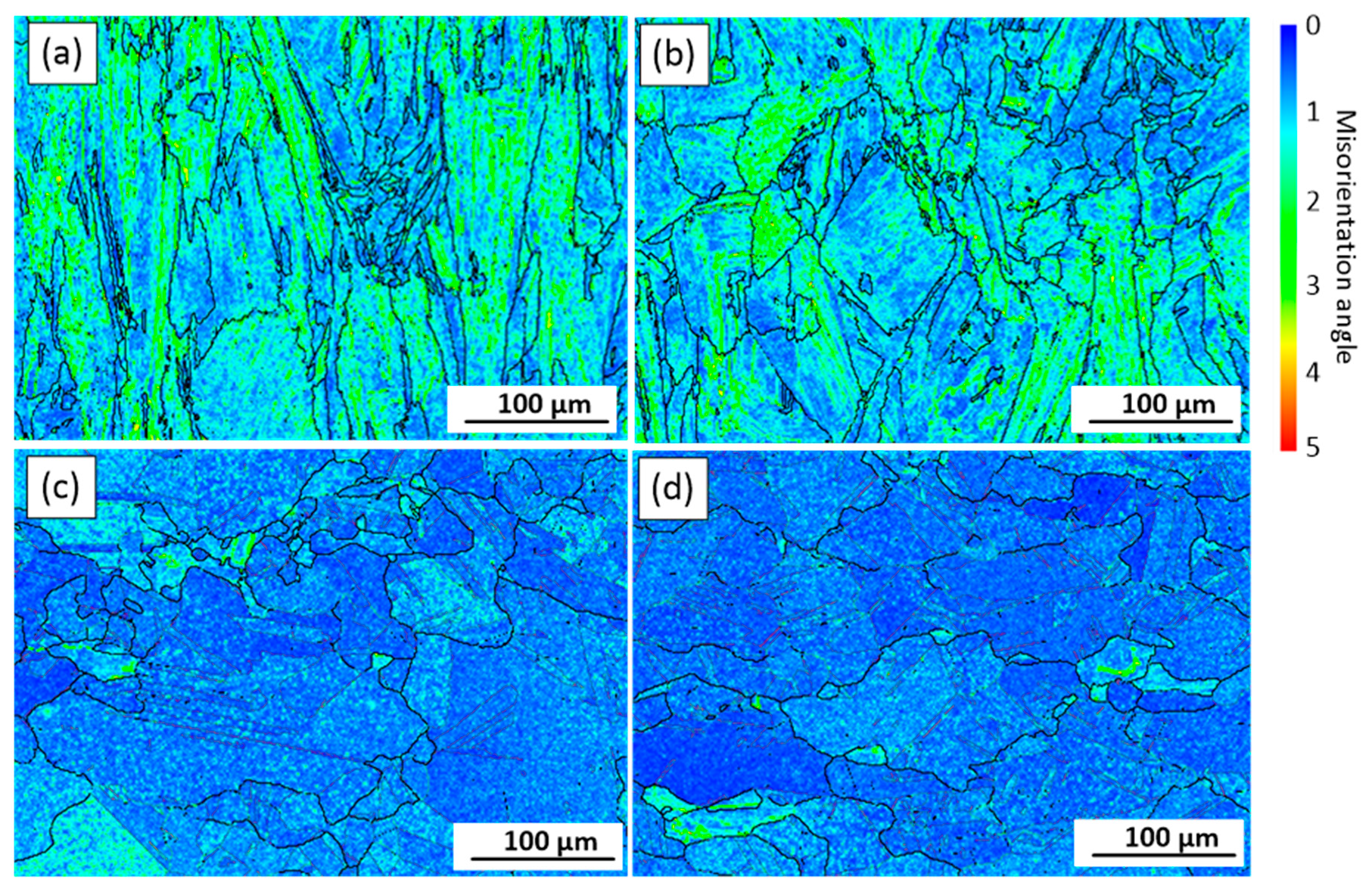

3.4. EBSD Analysis of the As-Built and Heat-Treated Alloys

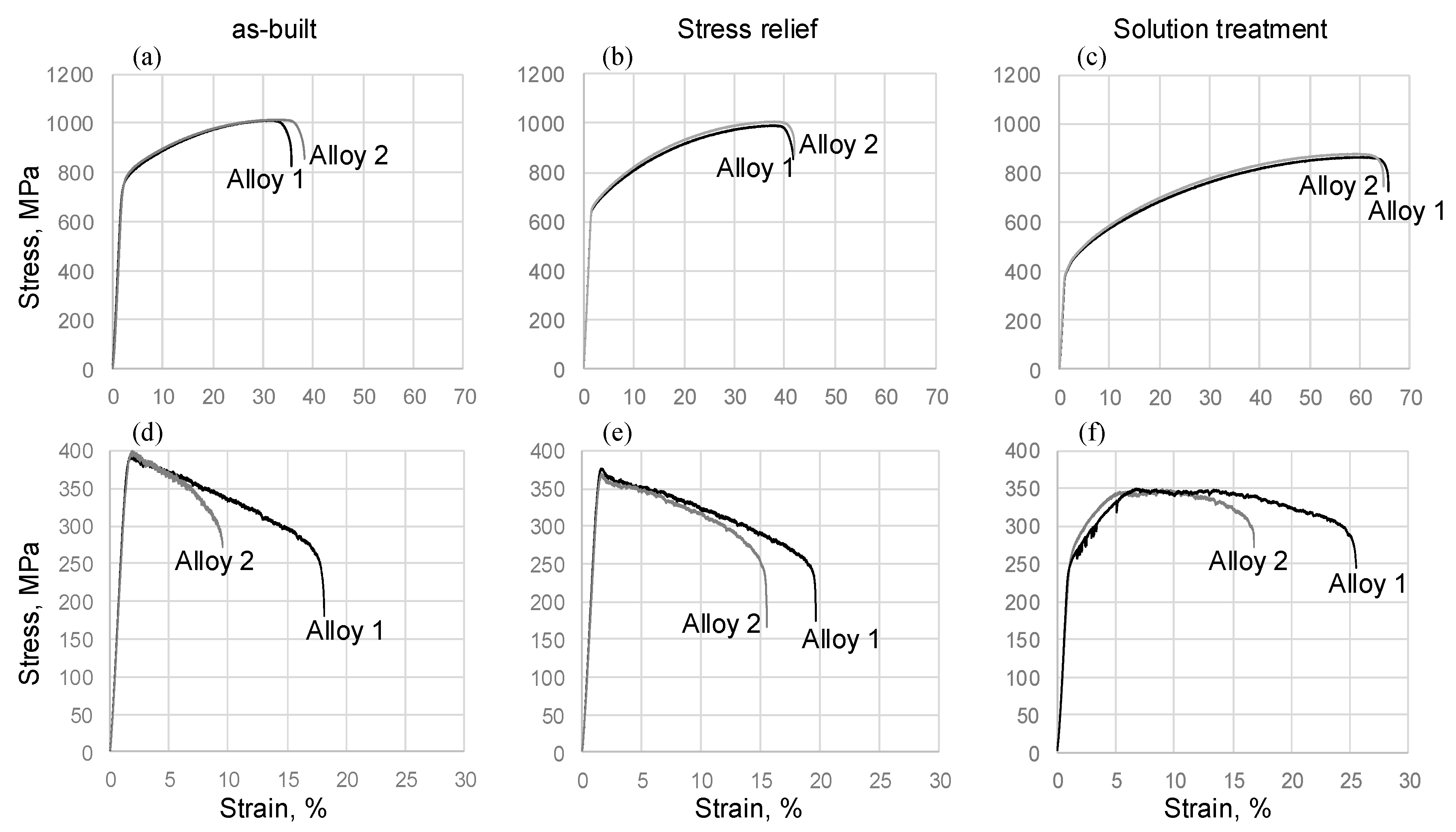

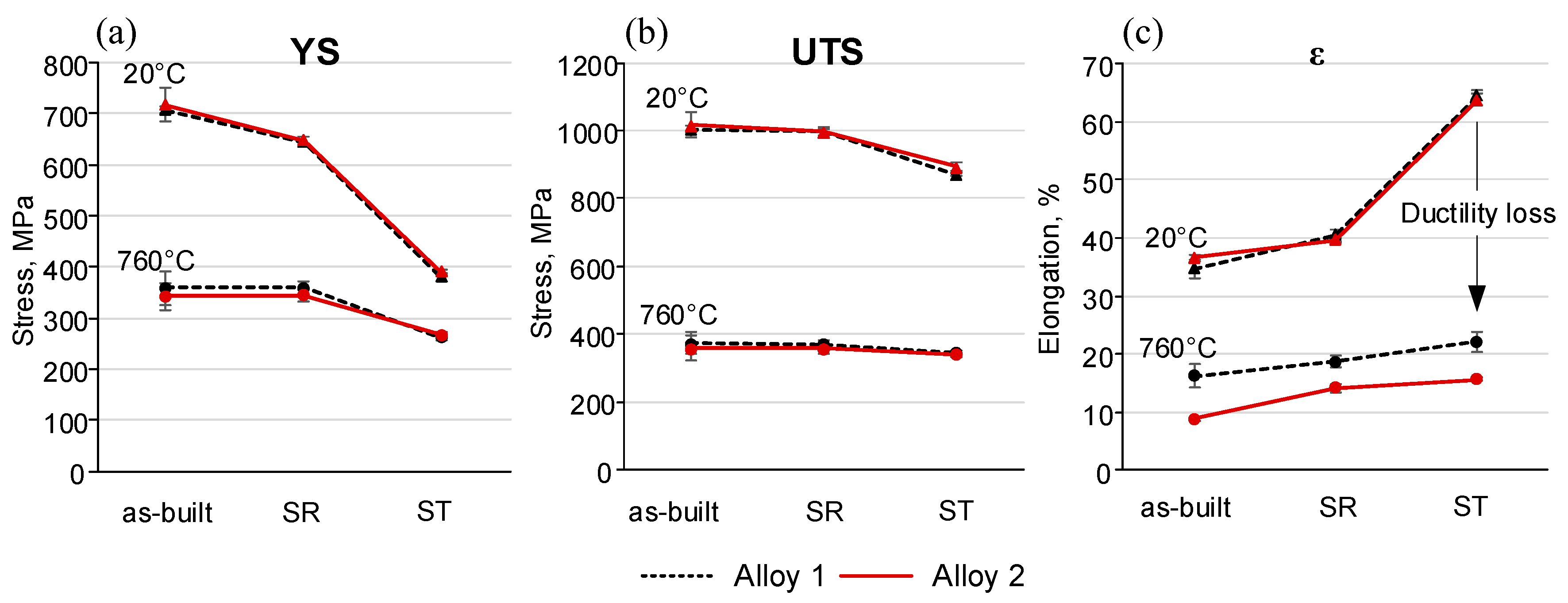

3.5. Mechanical Properties

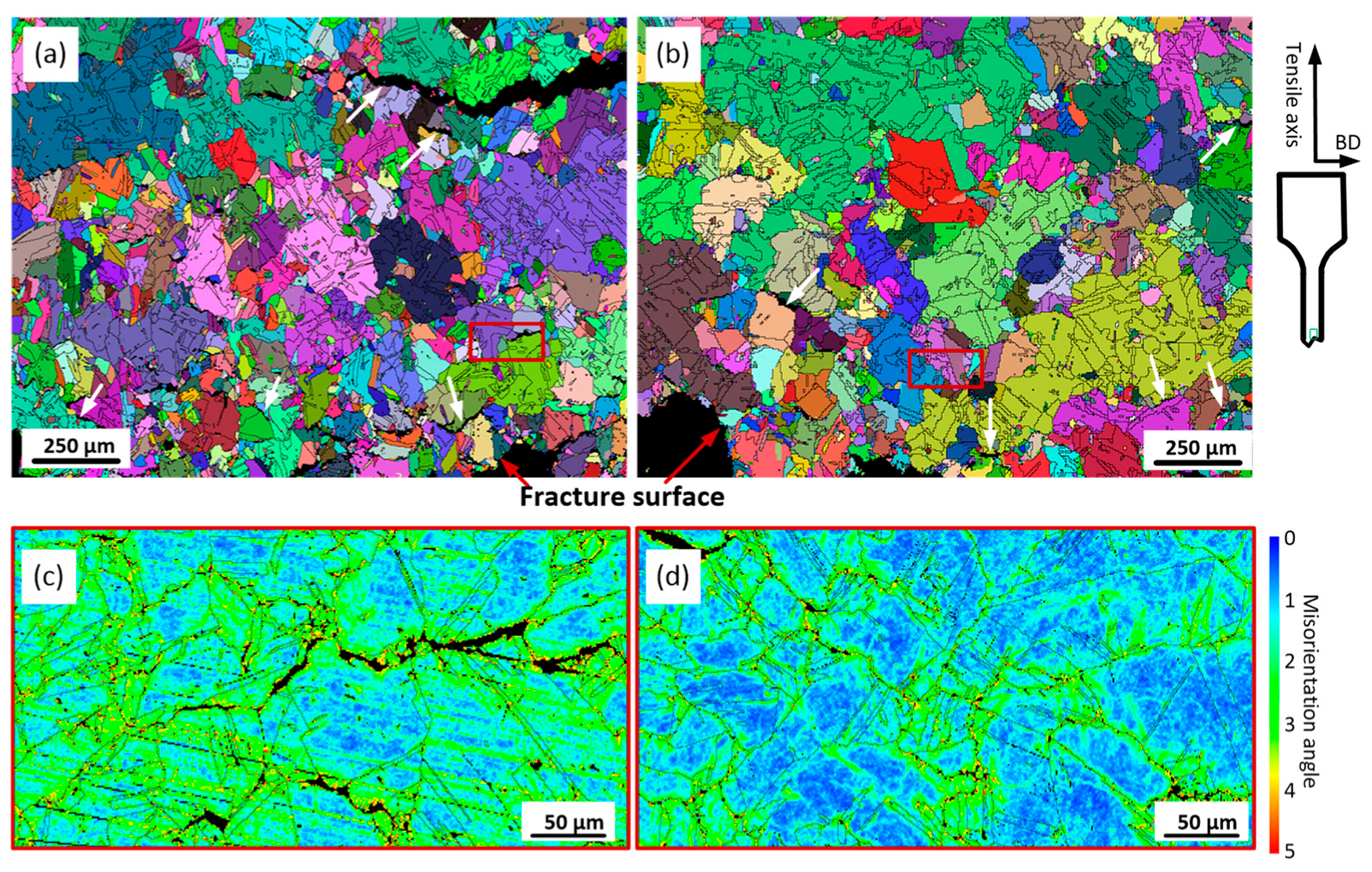

3.6. EBSD Observations after High-Temperature Tensile Testing

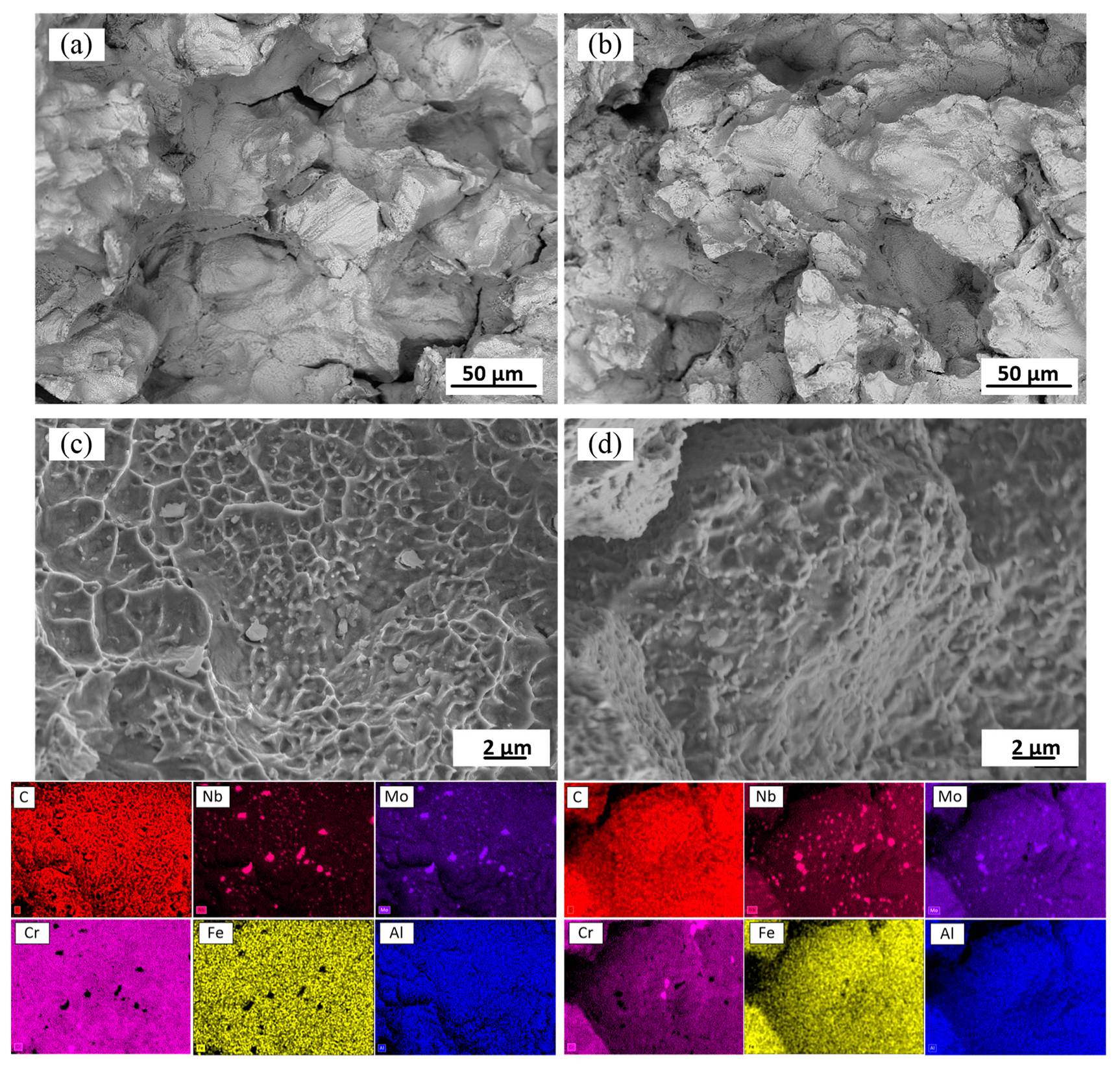

3.7. Fractography

4. Discussion

5. Conclusions

- A higher content of Fe results in a higher level of segregation in the interdendritic regions of the as-built IN625 alloy, with the grain size not being affected by this.

- More intensive segregation in the IN625 alloy with a higher Fe content leads to an enhanced formation of the δ phase and carbides during stress relief annealing at 870 °C.

- The Fe content has no effect on the carbide formation during solution treatment at 1120 °C, whereas the higher the C content, the higher the fraction of carbides formed during this treatment.

- The room temperature mechanical properties of the LPBF IN625 alloy were found insensitive to the Fe and C content variations studied in this work; the effect of processing overcame that of chemical composition. On the contrary, a higher C content in one of the IN625 powders resulted in a greater fraction of fine M6C carbide particles at the grain boundaries and a lower high-temperature ductility of the LPBF IN625 alloy. High-temperature ductility of the LPBF IN625 alloy was found insensitive to the Fe content variations studied in this work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Y.; Lin, X.; Li, Y.; Ou, Y.; Gao, X.; Zhang, Q.; Li, W.; Huang, W. Microstructural evolution and anisotropic mechanical properties of Inconel 625 superalloy fabricated by directed energy deposition. J. Alloy. Compd. 2021, 870, 159426. [Google Scholar] [CrossRef]

- Shahwaz, M.; Nath, P.; Sen, I. A Critical Review on the Microstructure and Mechanical Properties Correlation of Additively Manufactured Nickel-based Superalloys. J. Alloy. Compd. 2022, 907, 164530. [Google Scholar] [CrossRef]

- Floreen, S.; Fuchs, G.E.; Walter, J.Y. The Metallurgy of Alloy 625. In Superalloys 718, 625, 706 and Various Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1994; pp. 13–37. [Google Scholar]

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural Evolutions during Thermal Aging of Alloy 625: Impact of Temperature and Forming Process. Metall. Mater. Trans. A 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Karthik, D.; Stango, S.A.X.; Vijayalakshmi, U.; Swaroop, S. Electrochemical behavior of laser shock peened Inconel 625 superalloy. Surf. Coatings Technol. 2017, 311, 46–54. [Google Scholar] [CrossRef]

- Abioye, T.E.; McCartney, D.G.; Clare, A.T. Laser cladding of Inconel 625 wire for corrosion protection. J. Mater. Process. Technol. 2015, 217, 232–240. [Google Scholar] [CrossRef]

- Zareie Rajani, H.R.; Akbari Mousavi, S.A.A.; Madani Sani, F. Comparison of corrosion behavior between fusion cladded and explosive cladded Inconel 625/plain carbon steel bimetal plates. Mater. Des. 2013, 43, 467–474. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.; Guo, Y.B. Microstructure evolution characteristics of Inconel 625 alloy from selective laser melting to heat treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Keller, T.; Lindwall, G.; Ghosh, S.; Ma, L.; Lane, B.M.; Zhang, F.; Kattner, U.R.; Lass, E.A.; Heigel, J.C.; Idell, Y.; et al. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys. Acta Mater. 2017, 139, 244–253. [Google Scholar] [CrossRef]

- Amato, K.N.; Hernandez, J.; Murr, L.E.; Martinez, E.; Gaytan, S.M.; Shindo, P.W.; Collins, S. Comparison of Microstructures and Properties for a Ni-Base Superalloy (Alloy 625) Fabricated by Electron Beam Melting. J. Mater. Sci. Res. 2012, 1, 3–41. [Google Scholar] [CrossRef]

- Banerjee, A.; He, M.-R.; Musinski, W.D.; Shade, P.A.; Cox, M.E.; Schwalbach, E.J.; Hemker, K.J. Effect of stress-relief heat treatments on the microstructure and mechanical response of additively manufactured IN625 thin-walled elements. Mater. Sci. Eng. A 2022, 846, 143288. [Google Scholar] [CrossRef]

- Martin, N.; Hor, A.; Copin, E.; Lours, P.; Ratsifandrihana, L. Impact of annealing treatment on the fatigue behavior of Inconel 625 produced by laser-based powder bed fusion. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1258–1275. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Elevated temperature mechanical behavior of IN625 alloy processed by laser powder-bed fusion. Mater. Sci. Eng. A 2017, 700, 540–553. [Google Scholar] [CrossRef]

- Inaekyan, K.; Kreitcberg, A.; Turenne, S.; Brailovski, V. Microstructure and mechanical properties of laser powder bed-fused IN625 alloy. Mater. Sci. Eng. A 2019, 768, 138481. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Inaekyan, K.; Turenne, S.; Brailovski, V. Temperature- and Time-Dependent Mechanical Behavior of Post-Treated IN625 Alloy Processed by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2019, 3, 75. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Zhang, F.; Levine, L.E.; Allen, A.J.; Campbell, C.E.; Lass, E.A.; Cheruvathur, S.; Stoudt, M.R.; Williams, M.E.; Idell, Y. Homogenization kinetics of a nickel-based superalloy produced by powder bed fusion laser sintering. Scr. Mater. 2017, 131, 98–102. [Google Scholar] [CrossRef]

- F3056-14; Standard Specification for Additive Manufacturing Nickel Alloy (UNS N06625) with Powder Bed Fusion. ASTM International: West Conshohocken, PA, USA, 2014.

- Cieslak, M.J.; Headley, T.J.; Romig, A.D.; Kollie, T. A melting and solidification study of alloy 625. Metall. Mater. Trans. A 1988, 19, 2319–2331. [Google Scholar] [CrossRef]

- Cieslak, M.J.; Knorovsky, G.A.; Headley, T.J.; Romig, A.D. The Solidification Metallurgy of Alloy 718 and Other Nb-Containing Superalloys. In Superalloy 718: Metallurgy and Applications; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1989. [Google Scholar]

- Knorovsky, G.A.; Cieslak, M.J.; Headley, T.J.; Romig, A.D.; Hammetter, W.F. INCONEL 718: A solidification diagram. Metall. Mater. Trans. A 1989, 20, 2149–2158. [Google Scholar] [CrossRef]

- Banovic, S.W.; Dupont, J.N.; Marder, A.R. Dilution and microsegregation in dissimilar metal welds between super austenitic stainless steel and nickel base alloys. Sci. Technol. Weld. Join. 2002, 7, 374–383. [Google Scholar] [CrossRef]

- DuPont, J.; Marder, A.R.; Robino, C.V. Solidification modeling of Nb bearing superalloys. In Superalloys 718, 625 and Various Derivatives; Loria, E.A., Ed.; The Minerals Metals and Materials Society: Pittsburgh, PA, USA, 1997; pp. 87–98. [Google Scholar]

- Silva, C.C.; de Miranda, H.C.; Motta, M.F.; Farias, J.P.; Afonso, C.R.M.; Ramirez, A.J. New insight on the solidification path of an alloy 625 weld overlay. J. Mater. Res. Technol. 2013, 2, 228–237. [Google Scholar] [CrossRef] [Green Version]

- He, M.-R.; Banerjee, A.; Marvel, C.J.; Price, S.; McCue, I.; Schwalbach, E.J.; Hemker, K.J. Strong Impact of Minor Elements on the Microstructural Evolution of an Additively Manufactured Inconel 625 Alloy. Metall. Mater. Trans. A 2022, 53, 2926–2942. [Google Scholar] [CrossRef]

- Khayat, Z.R.; Palmer, T.A. Impact of iron composition on the properties of an additively manufactured solid solution strengthened nickel base alloy. Mater. Sci. Eng. A 2018, 718, 123–134. [Google Scholar] [CrossRef]

- Zuback, J.S.; Moradifar, P.; Khayat, Z.; Alem, N.; Palmer, T.A. Impact of chemical composition on precipitate morphology in an additively manufactured nickel base superalloy. J. Alloy. Compd. 2019, 798, 446–457. [Google Scholar] [CrossRef]

- Hu, Y.L.; Lin, X.; Yu, X.B.; Xu, J.J.; Lei, M.; Huang, W.D. Effect of Ti addition on cracking and microhardness of Inconel 625 during the laser solid forming processing. J. Alloy. Compd. 2017, 711, 267–277. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E.; Katz, M.B.; Levine, L.E.; Phan, T.Q.; Gnaeupel-Herold, T.H.; Ng, D.S. Formation of the Ni3Nb δ-Phase in Stress-Relieved Inconel 625 Produced via Laser Powder-Bed Fusion Additive Manufacturing. Metall. Mater. Trans. A 2017, 48, 5547–5558. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952, Erratum in 2016, 32, e1. [Google Scholar] [CrossRef]

- Marchese, G.; Colera, X.G.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition. Adv. Eng. Mater. 2017, 19, 1600635. [Google Scholar] [CrossRef]

- Verdi, D.; Garrido, M.A.; Múnez, C.J.; Poza, P. Microscale evaluation of laser cladded Inconel 625 exposed at high temperature in air. Mater. Des. 2017, 114, 326–338. [Google Scholar] [CrossRef]

- Zhang, F.; Levine, L.E.; Allen, A.J.; Stoudt, M.R.; Lindwall, G.; Lass, E.A.; Williams, M.E.; Idell, Y.; Campbell, C.E. Effect of heat treatment on the microstructural evolution of a nickel-based superalloy additive-manufactured by laser powder bed fusion. Acta Mater. 2018, 152, 200–214. [Google Scholar] [CrossRef]

- Lindwall, G.; Campbell, C.E.; Lass, E.A.; Zhang, F.; Stoudt, M.R.; Allen, A.J.; Levine, L.E. Simulation of TTT Curves for Additively Manufactured Inconel 625. Metall. Mater. Trans. A 2019, 50, 457–467. [Google Scholar] [CrossRef] [Green Version]

- Merson, S.; Evans, P. A high accuracy reference method for the determination of minor elements in steel by ICP-OES. J. Anal. At. Spectrom. 2003, 18, 372–375. [Google Scholar] [CrossRef]

- Kohler, M.; Heubner, U. The Effect of Final Heat Treatment and Chemical Composition on Sensitization, Strength and Thermal Stability of Alloy 625. Miner. Met. Mater. Soc. 1997, 795–803. [Google Scholar] [CrossRef]

- Poulin, J.-R.; Kreitcberg, A.; Terriault, P.; Brailovski, V. Fatigue strength prediction of laser powder bed fusion processed Inconel 625 specimens with intentionally-seeded porosity: Feasibility study. Int. J. Fatigue 2020, 132, 105394. [Google Scholar] [CrossRef]

- Kamaya, M.; Kubushiro, K.; Sakakibara, Y.; Suzuki, S.; Morita, H.; Yoda, R.; Kobayashi, D.; Yamagiwa, K.; Nishioka, T.; Yamazaki, Y.; et al. Round robin crystal orientation measurement using EBSD for damage assessment. Mech. Eng. J. 2016, 3, 16-00077. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Wu, B.B.; Wang, Z.Q.; Wang, X.L.; Xu, W.S.; Shang, C.J.; Misra, R.D.K. Toughening of martensite matrix in high strength low alloy steel: Regulation of variant pairs. Mater. Sci. Eng. A 2019, 759, 430–436. [Google Scholar] [CrossRef]

- Gao, Y.; Ding, Y.; Chen, J.; Xu, J.; Ma, Y.; Wang, X. Effect of twin boundaries on the microstructure and mechanical properties of Inconel 625 alloy. Mater. Sci. Eng. A 2019, 767, 138361. [Google Scholar] [CrossRef]

- Stinville, J.C.; Vanderesse, N.; Bridier, F.; Bocher, P.; Pollock, T.M. High resolution mapping of strain localization near twin boundaries in a nickel-based superalloy. Acta Mater. 2015, 98, 29–42. [Google Scholar] [CrossRef]

- Cui, C.Y.; Gu, Y.F.; Yuan, Y.; Osada, T.; Harada, H. Enhanced mechanical properties in a new Ni–Co base superalloy by controlling microstructures. Mater. Sci. Eng. A 2011, 528, 5465–5469. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.-W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.-U.; Ugues, D.; et al. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–75. [Google Scholar] [CrossRef]

- Qin, S.; Novak, T.C.; Vailhe, M.K.; Liu, Z.-K.; Beese, A.M. Plasticity and fracture behavior of Inconel 625 manufactured by laser powder bed fusion: Comparison between as-built and stress relieved conditions. Mater. Sci. Eng. A 2021, 806, 140808. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Rozmus-Górnikowska, M.; Blicharski, M. Microsegregation and Precipitates in Inconel 625 Arc Weld Overlay Coatings on Boiler Pipes. Arch. Metall. Mater. 2015, 60, 2599–2606. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Lee, J.; Terner, M.; Jun, S.; Hong, H.-U.; Copin, E.; Lours, P. Heat treatments design for superior high-temperature tensile properties of Alloy 625 produced by selective laser melting. Mater. Sci. Eng. A 2020, 790, 139720. [Google Scholar] [CrossRef]

- Beese, A.M.; Wang, Z.; Stoica, A.D.; Ma, D. Absence of dynamic strain aging in an additively manufactured nickel-base superalloy. Nat. Commun. 2018, 9, 2083. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, X.; Qin, X.; Ding, Y. High-temperature mechanical properties of Inconel-625: Role of carbides and delta phase. Mater. Sci. Technol. 2017, 33, 1610–1617. [Google Scholar] [CrossRef]

- Kohler, M. Effect of the Elevated-Temperature-Precipitation in Alloy 625 on Properties and Microstructure. In Superalloys 718, 625 and Various Derivatives; The Minerals Metals & Materials Society: Pittsburgh, PA, USA, 1991; pp. 363–374. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S.R. Carbide Precipitation in Nickel Base Superalloys 718 and 625 and Their Effect on Mechanical Properties. In Superalloys 718, 625, 706 and Various Derivatives; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1997; pp. 367–378. [Google Scholar] [CrossRef]

- Cortial, F.; Corrieu, J.M.; Vernot-Loier, C. Heat Treatments of Weld Alloy 625: Influence on the Microstructure, Mechanical Properties and Corrosion Resistance. Metall. Mater. Trans. A 1995, 26, 1273–1286. [Google Scholar] [CrossRef]

- Vernot-Loier, C.; Cortial, F. Influence of Heat Treatments on Microstructure, Mechanical Properties and Corrosion Behaviour of Alloy 625 Forged Rod. In Superalloys 718, 625 and Various Derivatives; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1991; pp. 409–422. [Google Scholar] [CrossRef]

- Ghoussoub, J.N.; Tang, Y.T.; Dick-Cleland, W.J.B.; Németh, A.A.N.; Gong, Y.; McCartney, D.G.; Cocks, A.C.F.; Reed, R.C. On the Influence of Alloy Composition on the Additive Manufacturability of Ni-Based Superalloys. Metall. Mater. Trans. A 2022, 53, 962–983. [Google Scholar] [CrossRef]

- Shaikh, A.S.; Schulz, F.; Minet-Lallemand, K.; Hryha, E. Microstructure and mechanical properties of Haynes 282 superalloy produced by laser powder bed fusion. Mater. Today Commun. 2021, 26, 102038. [Google Scholar] [CrossRef]

- Lancaster, R.; Davies, S.; Jeffs, S.; Lewis, D.; Coleman, M. The effects of thermal exposure on the high temperature behaviour of a Laser Powder Bed Fused nickel based superalloy C263. Mater. Sci. Eng. A 2021, 801, 140409. [Google Scholar] [CrossRef]

- Bai, G.; Li, J.; Hu, R.; Tang, Z.; Xue, X.; Fu, H. Effect of temperature on tensile behavior of Ni-Cr-W based superalloy. Mater. Sci. Eng. A 2011, 528, 1974–1978. [Google Scholar] [CrossRef]

- Lian, Z.W.; Yu, J.J.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Temperature dependence of tensile behavior of Ni-based superalloy M951. Mater. Sci. Eng. A 2008, 489, 227–233. [Google Scholar] [CrossRef]

- Roy, A.K.; Pal, J.; Mukhopadhyay, C. Dynamic strain ageing of an austenitic superalloy—Temperature and strain rate effects. Mater. Sci. Eng. A 2008, 474, 363–370. [Google Scholar] [CrossRef]

- Perez-Prado, M.T.; Kassner, M.E. Chapter 6-Superplasticity. In Fundamentals of Creep in Metals and Alloys, 3rd ed.; Kassner, M.E., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2015; pp. 139–157. [Google Scholar]

- Heubner, U.; Kohler, M. Effect of Carbon Content and Other Variables on Yield Strength, Ductility and Creep Properties of Alloy 625. In Superalloys 718, 625, 706 and Various Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1994; pp. 479–488. [Google Scholar] [CrossRef]

| IN625 | Ni | Cr | Mo | Nb | Fe | Ti | Al | C | O | Si | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Bal | 20–22 | 8–10 | 3.15–4.15 | <5 | <0.4 | < 0.4 | <0.1 | n/a | <0.5 | <0.015 |

| Powder 1 (15–45 µm) | Bal | 20.8 | 9.1 | 3.64 | 4.2 | 0.21 | 0.21 | 0.02 | 0.014 | 0.08 | <0.015 |

| Alloy 1 (from Powder 1) | Bal | 21.15 | 9.8 | 3.68 | 4.28 | 0.19 | 0.21 | 0.024 | - | 0.07 | <0.001 |

| Powder 2 (15–53 µm) | Bal | 21.66 | 8.86 | 3.66 | 0.95 | 0.26 | 0.15 | 0.040 | 0.011 | 0.07 | <0.001 |

| Alloy 2 (from Powder 2) | Bal | 21.89 | 9.93 | 3.79 | 0.97 | 0.12 | 0.13 | 0.035 | - | 0.03 | <0.001 |

| State | Properties | Alloy 1 | Alloy 2 | ||

|---|---|---|---|---|---|

| 20 °C | 760 °C | 20 °C | 760 °C | ||

| as-built | YS, MPa | 710 ± 5 | 360 ± 30 | 720 ± 20 | 340 ± 30 |

| UTS, MPa | 1005 ± 10 | 370 ± 30 | 1020 ± 30 | 360 ± 40 | |

| Elongation, % | 35 ± 2 | 16 ± 2 | 37 ± 1 | 9 ± 1 | |

| SR | YS, MPa | 645 ± 10 | 360 ± 15 | 650 ± 10 | 340 ± 10 |

| UTS, MPa | 1000 ± 15 | 370 ± 10 | 1000 ± 10 | 360 ± 15 | |

| Elongation, % | 40 ± 1 | 19 ± 1 | 40 ± 1 | 14 ± 1 | |

| ST | YS, MPa | 380 ± 10 | 260 ± 5 | 390 ± 5 | 270 ± 10 |

| UTS, MPa | 870 ± 5 | 345 ± 10 | 890 ± 15 | 340 ± 10 | |

| Elongation, % | 65 ± 1 | 22 ± 2 | 64 ± 1 | 16 ± 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kreitcberg, A.; Brailovski, V. Effect of Fe and C Contents on the Microstructure and High-Temperature Mechanical Properties of IN625 Alloy Processed by Laser Powder Bed Fusion. Materials 2022, 15, 6606. https://doi.org/10.3390/ma15196606

Kreitcberg A, Brailovski V. Effect of Fe and C Contents on the Microstructure and High-Temperature Mechanical Properties of IN625 Alloy Processed by Laser Powder Bed Fusion. Materials. 2022; 15(19):6606. https://doi.org/10.3390/ma15196606

Chicago/Turabian StyleKreitcberg, Alena, and Vladimir Brailovski. 2022. "Effect of Fe and C Contents on the Microstructure and High-Temperature Mechanical Properties of IN625 Alloy Processed by Laser Powder Bed Fusion" Materials 15, no. 19: 6606. https://doi.org/10.3390/ma15196606

APA StyleKreitcberg, A., & Brailovski, V. (2022). Effect of Fe and C Contents on the Microstructure and High-Temperature Mechanical Properties of IN625 Alloy Processed by Laser Powder Bed Fusion. Materials, 15(19), 6606. https://doi.org/10.3390/ma15196606