Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in High Carbon Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. XRD

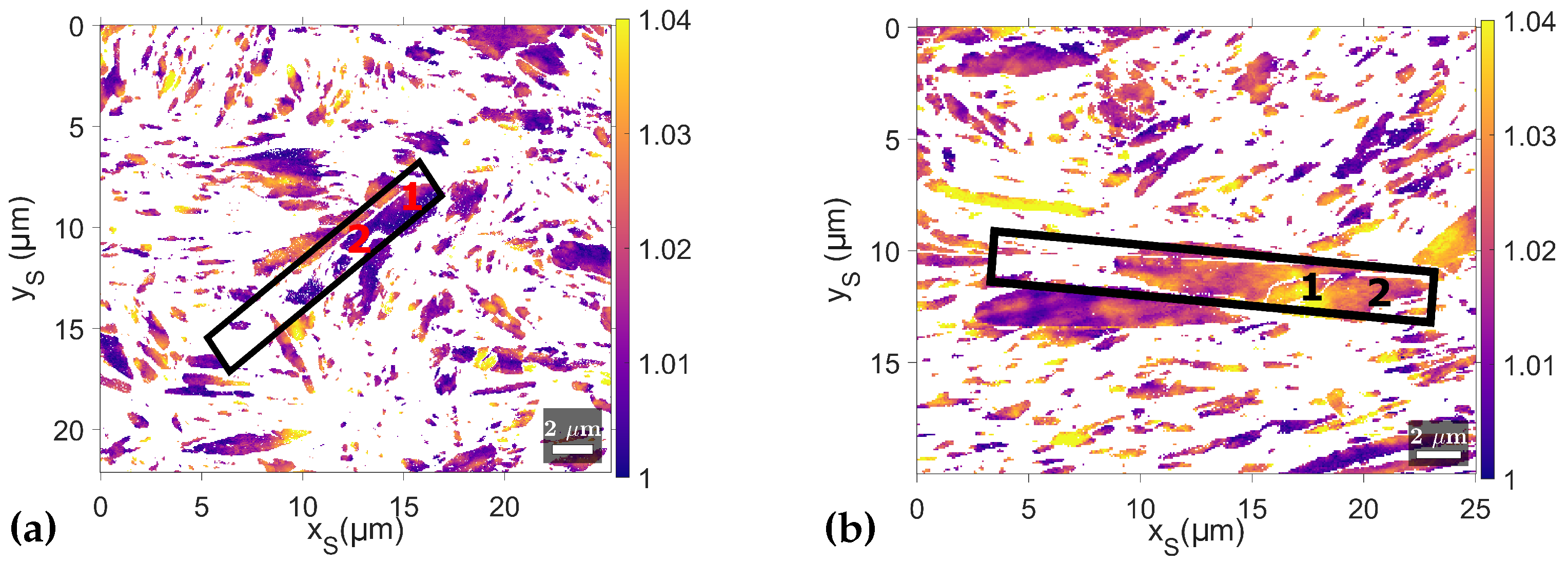

3.2. APT Preparation

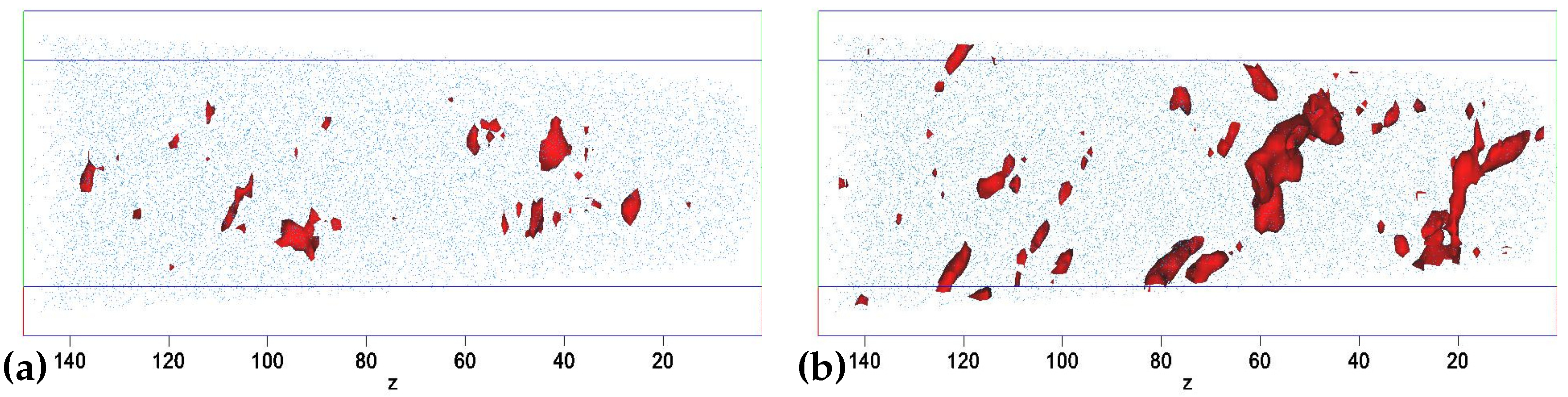

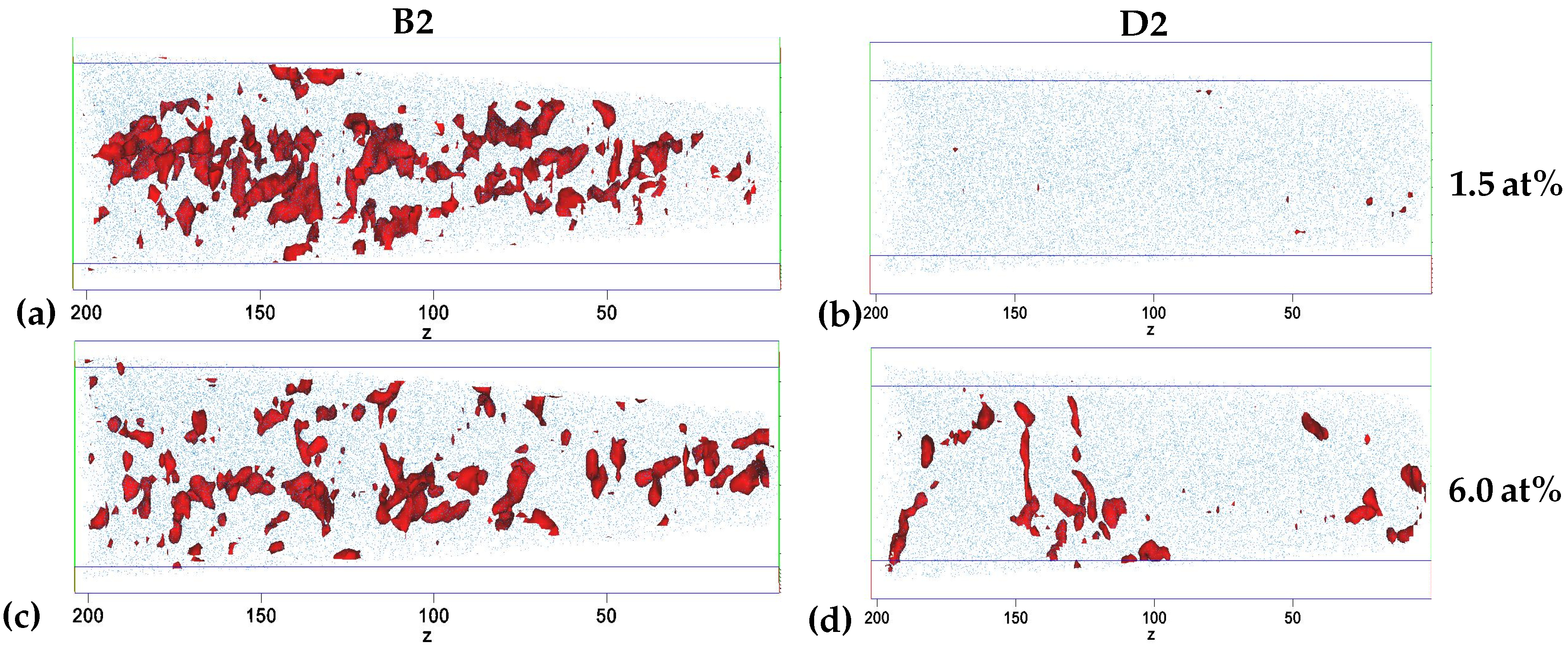

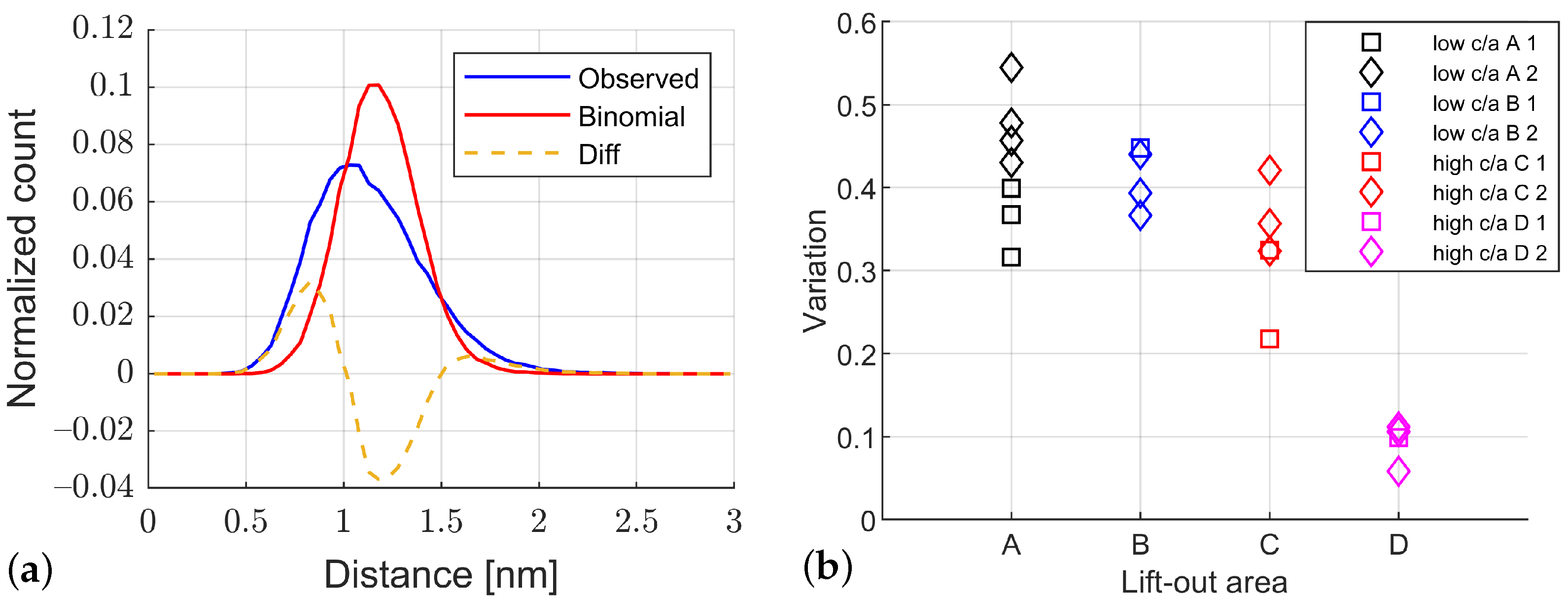

3.3. APT

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Local Tetragonality

Appendix B. Isosurface

References

- Honda, K.; Nishiyama, Z. On the nature of the tetragonal and cubic martensites. Sci. Rep. Tohoku Imp. Univ. 1932, 21, 299–331. [Google Scholar]

- Öhman, E. Crystal structure of martensite. Nature 1931, 127, 270–272. [Google Scholar] [CrossRef]

- Kurdjumov, G.; Khachaturyan, A. Phenomena of carbon atom redistribution in martensite. Metall. Trans. 1972, 3, 1069–1076. [Google Scholar] [CrossRef]

- Chen, P.; Winchell, P. Martensite lattice changes during tempering. Metall. Trans. A 1980, 11, 1333–1339. [Google Scholar] [CrossRef]

- Cheng, L.; Bottger, A.; de Keijser, T.; Mittemeijer, E. Lattice parameters of iron-carbon and iron-nitrogen martensites and austenites. Scr. Metall. Mater. 1990, 24, 509–514. [Google Scholar] [CrossRef]

- Cheng, L.; Van der Pers, N.; Böttger, A.; De Keijser, T.; Mittemeijer, E. Lattice changes of iron-carbon martensite on aging at room temperature. Metall. Trans. A 1991, 22, 1957–1967. [Google Scholar] [CrossRef]

- Lu, Y.; Yu, H.; Sisson, R., Jr. The effect of carbon content on the c/a ratio of as-quenched martensite in Fe-C alloys. Mater. Sci. Eng. A 2017, 700, 592–597. [Google Scholar] [CrossRef]

- Tanaka, T.; Maruyama, N.; Nakamura, N.; Wilkinson, A. Tetragonality of Fe-C martensite–a pattern matching electron backscatter diffraction analysis compared to X-ray diffraction. Acta Mater. 2020, 195, 728–738. [Google Scholar] [CrossRef]

- Maruyama, N.; Tabata, S.; Kawata, H. Excess solute carbon and tetragonality in as-quenched Fe-1Mn-C (C:0.07 to 0.8 mass pct) martensite. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 1085–1097. [Google Scholar] [CrossRef]

- Becquart, C.; Raulot, J.M.; Bencteux, G.; Domain, C.; Perez, M.; Garruchet, S.; Nguyen, H. Atomistic modeling of an Fe system with a small concentration of C. Comput. Mater. Sci. 2007, 40, 119–129. [Google Scholar] [CrossRef]

- Chentouf, S.; Cazottes, S.; Danoix, F.; Gouné, M.; Zapolsky, H.; Maugis, P. Effect of interstitial carbon distribution and nickel substitution on the tetragonality of martensite: A first-principles study. Intermetallics 2017, 89, 92–99. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1-0.5%C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Nolze, G.; Winkelmann, A.; Cios, G.; Tokarski, T. Tetragonality mapping of martensite in a high carbon steel by EBSD. Mater. Charact. 2021, 175. [Google Scholar] [CrossRef]

- Kohne, T.; Fahlkrans, J.; Stormvinter, A.; Maawad, E.; Winkelmann, A.; Hedström, P.; Borgenstam, A. Evolution of martensite tetragonality in high carbon steels revealed by in-situ high energy x-ray diffraction. 2022; unpublished work. [Google Scholar]

- Gaudez, S.; Teixeira, J.; Denis, S.; Geandier, G.; Allain, S. Martensite and nanobainite transformations in a low alloyed steel studied by in situ high energy synchrotron diffraction. Mater. Charact. 2022, 185, 111740. [Google Scholar] [CrossRef]

- Winkelmann, A.; Nolze, G.; Cios, G.; Tokarski, T. Mapping of local lattice parameter ratios by projective Kikuchi pattern matching. Phys. Rev. Mater. 2018, 2, 123803. [Google Scholar] [CrossRef]

- Kelly, T.; Larson, D. Atom probe tomography 2012. Annu. Rev. Mater. Res. 2012, 42, 1–31. [Google Scholar] [CrossRef]

- Allain, S.; Danoix, F.; Goune, M.; Hoummada, K.; Mangelinck, D. Static and dynamical ageing processes at room temperature in a Fe25Ni0.4C virgin martensite: Effect of C redistribution at the nanoscale. Philos. Mag. Lett. 2013, 93, 68–76. [Google Scholar] [CrossRef]

- Maugis, P.; Danoix, F.; Dumont, M.; Curelea, S.; Cazottes, S.; Zapolsky, H.; Gouné, M. Carbon diffusivity and kinetics of spinodal decomposition of martensite in a model Fe-Ni-C alloy. Mater. Lett. 2018, 214, 213–216. [Google Scholar] [CrossRef]

- Da Silva, J.; McLellan, R. Diffusion of carbon and nitrogen in BCC iron. Mater. Sci. Eng. 1976, 26, 83–87. [Google Scholar] [CrossRef]

- Taylor, K.; Cohen, M. Aging of ferrous martensites. Prog. Mater. Sci. 1992, 36, 151–272. [Google Scholar] [CrossRef]

- DeCristofaro, N.; Kaplow, R.; Owen, W. The kinetics of carbon clustering in martensite. Metall. Trans. A 1978, 9, 821–825. [Google Scholar] [CrossRef]

- Hillert, M. The kinetics of the first stage of tempering. Acta Metall. 1959, 7, 653–658. [Google Scholar] [CrossRef]

- Miller, M.; Russell, K.; Thompson, G. Strategies for fabricating atom probe specimens with a dual beam FIB. Ultramicroscopy 2005, 102, 287–298. [Google Scholar] [CrossRef]

- Miller, M.; Forbes, R. The art of specimen preparation. In Atom-Probe Tomography; Springer: Boston, MA, USA, 2014; pp. 189–228. [Google Scholar]

- Hielscher, R.; Schaeben, H. A novel pole figure inversion method: Specification of the MTEX algorithm. J. Appl. Crystallogr. 2008, 41, 1024–1037. [Google Scholar] [CrossRef]

- Gault, B.; Danoix, F.; Hoummada, K.; Mangelinck, D.; Leitner, H. Impact of directional walk on atom probe microanalysis. Ultramicroscopy 2012, 113, 182–191. [Google Scholar] [CrossRef]

- Dumas, P.; Duguay, S.; Borrel, J.; Hilario, F.; Blavette, D. Atom probe tomography quantification of carbon in silicon. Ultramicroscopy 2021, 220, 113153. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Choi, P.; Borchers, C.; Westerkamp, S.; Goto, S.; Raabe, D.; Kirchheim, R. Atomic-scale mechanisms of deformation-induced cementite decomposition in pearlite. Acta Mater. 2011, 59, 3965–3977. [Google Scholar] [CrossRef]

- Li, Y.; Choi, P.; Goto, S.; Borchers, C.; Raabe, D.; Kirchheim, R. Evolution of strength and microstructure during annealing of heavily cold-drawn 6.3 GPa hypereutectoid pearlitic steel wire. Acta Mater. 2012, 60, 4005–4016. [Google Scholar] [CrossRef]

- Toji, Y.; Matsuda, H.; Herbig, M.; Choi, P.P.; Raabe, D. Atomic-scale analysis of carbon partitioning between martensite and austenite by atom probe tomography and correlative transmission electron microscopy. Acta Mater. 2014, 65, 215–228. [Google Scholar] [CrossRef]

- Rementeria, R.; Poplawsky, J.; Aranda, M.; Guo, W.; Jimenez, J.; Garcia-Mateo, C.; Caballero, F. Carbon concentration measurements by atom probe tomography in the ferritic phase of high-silicon steels. Acta Mater. 2017, 125, 359–368. [Google Scholar] [CrossRef]

- Thuvander, M.; Weidow, J.; Angseryd, J.; Falk, L.; Liu, F.; Sonestedt, M.; Stiller, K.; Andrén, H.O. Quantitative atom probe analysis of carbides. Ultramicroscopy 2011, 111, 604–608. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Vurpillot, F.; Choi, P.P.; Li, Y.; Raabe, D.; Gault, B. On the detection of multiple events in atom probe tomography. Ultramicroscopy 2018, 189, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Philippe, T.; De Geuser, F.; Duguay, S.; Lefebvre, W.; Cojocaru-Mirédin, O.; Da Costa, G.; Blavette, D. Clustering and nearest neighbour distances in atom-probe tomography. Ultramicroscopy 2009, 109, 1304–1309. [Google Scholar] [CrossRef] [PubMed]

- Shariq, A.; Al-Kassab, T.; Kirchheim, R.; Schwarz, R. Exploring the next neighbourhood relationship in amorphous alloys utilizing atom probe tomography. Ultramicroscopy 2007, 107, 773–780. [Google Scholar] [CrossRef]

- Blavette, D.; Grancher, G.; Bostel, A. Statistical analysis of atom-probe data (I): Derivation of some fine-scale features from frequency distributions for finely dispersed systems. Le J. De Phys. Colloq. 1988, 49, C6–C433. [Google Scholar] [CrossRef]

- Kapur, J.; Casasent, D. Geometric correction of SEM images. In Proceedings of the Hybrid Image and Signal Processing VII; International Society for Optics and Photonics: Bellingham, WA, USA, 2000; Volume 4044, pp. 165–176. [Google Scholar]

- Nolze, G. Geometrically caused image distortion effects and their influence on interpretation of EBSD measurements. Mater. Sci. Technol. 2006, 22, 1343–1351. [Google Scholar] [CrossRef]

- Nolze, G. Image distortions in SEM and their influences on EBSD measurements. Ultramicroscopy 2007, 107, 172–183. [Google Scholar] [CrossRef]

- Tong, V.; Britton, T. TrueEBSD: Correcting spatial distortions in electron backscatter diffraction maps. Ultramicroscopy 2021, 221, 113130. [Google Scholar] [CrossRef]

- Danoix, F.; Grancher, G.; Bostel, A.; Blavette, D. Standard deviations of composition measurements in atom probe analyses—Part II: 3D atom probe. Ultramicroscopy 2007, 107, 739–743. [Google Scholar] [CrossRef]

- Clarke, A.; Klemm-Toole, J.; Clarke, K.; Coughlin, D.; Pierce, D.; Euser, V.; Poplawsky, J.; Clausen, B.; Brown, D.; Almer, J.; et al. Perspectives on quenching and tempering 4340 steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 4984–5005. [Google Scholar] [CrossRef]

- Sherman, D.; Cross, S.; Kim, S.; Grandjean, F.; Long, G.; Miller, M. Characterization of the carbon and retained austenite distributions in martensitic medium carbon, high silicon steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2007, 38, 1698–1711. [Google Scholar] [CrossRef]

- Hirotsu, Y.; Nagakura, S. Crystal structure and morphology of the carbide precipitated from martensitic high carbon steel during the first stage of tempering. Acta Metall. 1972, 20, 645–655. [Google Scholar] [CrossRef]

- Williamson, D.; Nakazawa, K.; Krauss, G. A study of the early stages of tempering in an Fe-1.2 Pct alloy. Metall. Trans. A 1979, 10, 1351–1363. [Google Scholar] [CrossRef]

- Thompson, S. A two-tilt analysis of electron diffraction patterns from transition-iron-carbide precipitates formed during tempering of 4340 steel. Metallogr. Microstruct. Anal. 2016, 5, 367–383. [Google Scholar] [CrossRef]

- Vaumousse, D.; Cerezo, A.; Warren, P. A procedure for quantification of precipitate microstructures from three-dimensional atom probe data. Ultramicroscopy 2003, 95, 215–221. [Google Scholar] [CrossRef]

- Jägle, E.; Choi, P.P.; Raabe, D. The maximum separation cluster analysis algorithm for atom-probe tomography: Parameter determination and accuracy. Microsc. Microanal. 2014, 20, 1662–1671. [Google Scholar] [CrossRef] [PubMed]

- Stephenson, L.; Moody, M.; Liddicoat, P.; Ringer, S. New techniques for the analysis of fine-scaled clustering phenomena within atom probe tomography (APT) data. Microsc. Microanal. 2007, 13, 448–463. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. Early stages of aging and tempering of ferrous martensites. Metall. Trans. A 1983, 14, 1057–1065. [Google Scholar] [CrossRef]

- Miller, M.; Beaven, P.; Smith, G. A study of the early stages of tempering of iron-carbon martensites by atom probe field ion microscopy. Metall. Trans. A 1981, 12, 1197–1204. [Google Scholar] [CrossRef]

- Waterschoot, T.; Verbeken, K.; De Cooman, B. Tempering kinetics of the martensitic phase in DP steel. ISIJ Int. 2006, 46, 138–146. [Google Scholar] [CrossRef]

- Chen, D.; Kuo, J.C.; Wu, W.T. Effect of microscopic parameters on EBSD spatial resolution. Ultramicroscopy 2011, 111, 1488–1494. [Google Scholar] [CrossRef] [PubMed]

- Kelly, T.; Miller, M. Atom probe tomography. Rev. Sci. Instrum. 2007, 78, 031101. [Google Scholar] [CrossRef] [PubMed]

- Fukui, D.; Nakada, N.; Onaka, S. Internal residual stress originated from Bain strain and its effect on hardness in Fe–Ni martensite. Acta Mater. 2020, 196, 660–668. [Google Scholar] [CrossRef]

| Lift-out region | A | B | C | D | ||||

| Final cooling rate | 0.5 K/s | 15 K/s | ||||||

| RT ageing time (days) | 570 | 727 | 823 | 823 | ||||

| (nm) for | 50 | 57 | 60 | 60 | ||||

| (nm) for | 446 | 503 | 535 | 535 | ||||

| EBSD | low | low | high | high | ||||

| APT tip name | A1 | A2 | B1 | B2 | C1 | C2 | D1 | D2 |

| Avg. bulk comp. C (at %) | 2.9 | 2.5 | 3.5 | 3.2 | 3.3 | 3.2 | 3.3 | 3.3 |

| Number of ROI | 3 | 4 | 1 | 3 | 2 | 3 | 1 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kohne, T.; Dahlström, A.; Winkelmann, A.; Hedström, P.; Borgenstam, A. Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in High Carbon Steel. Materials 2022, 15, 6653. https://doi.org/10.3390/ma15196653

Kohne T, Dahlström A, Winkelmann A, Hedström P, Borgenstam A. Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in High Carbon Steel. Materials. 2022; 15(19):6653. https://doi.org/10.3390/ma15196653

Chicago/Turabian StyleKohne, Thomas, Alexander Dahlström, Aimo Winkelmann, Peter Hedström, and Annika Borgenstam. 2022. "Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in High Carbon Steel" Materials 15, no. 19: 6653. https://doi.org/10.3390/ma15196653

APA StyleKohne, T., Dahlström, A., Winkelmann, A., Hedström, P., & Borgenstam, A. (2022). Correlation of Heterogeneous Local Martensite Tetragonality and Carbon Distribution in High Carbon Steel. Materials, 15(19), 6653. https://doi.org/10.3390/ma15196653