Introduction of Graphene/h-BN Metamaterial as Neutron Radiation Shielding by Implementing Monte Carlo Simulation

Abstract

:1. Introduction

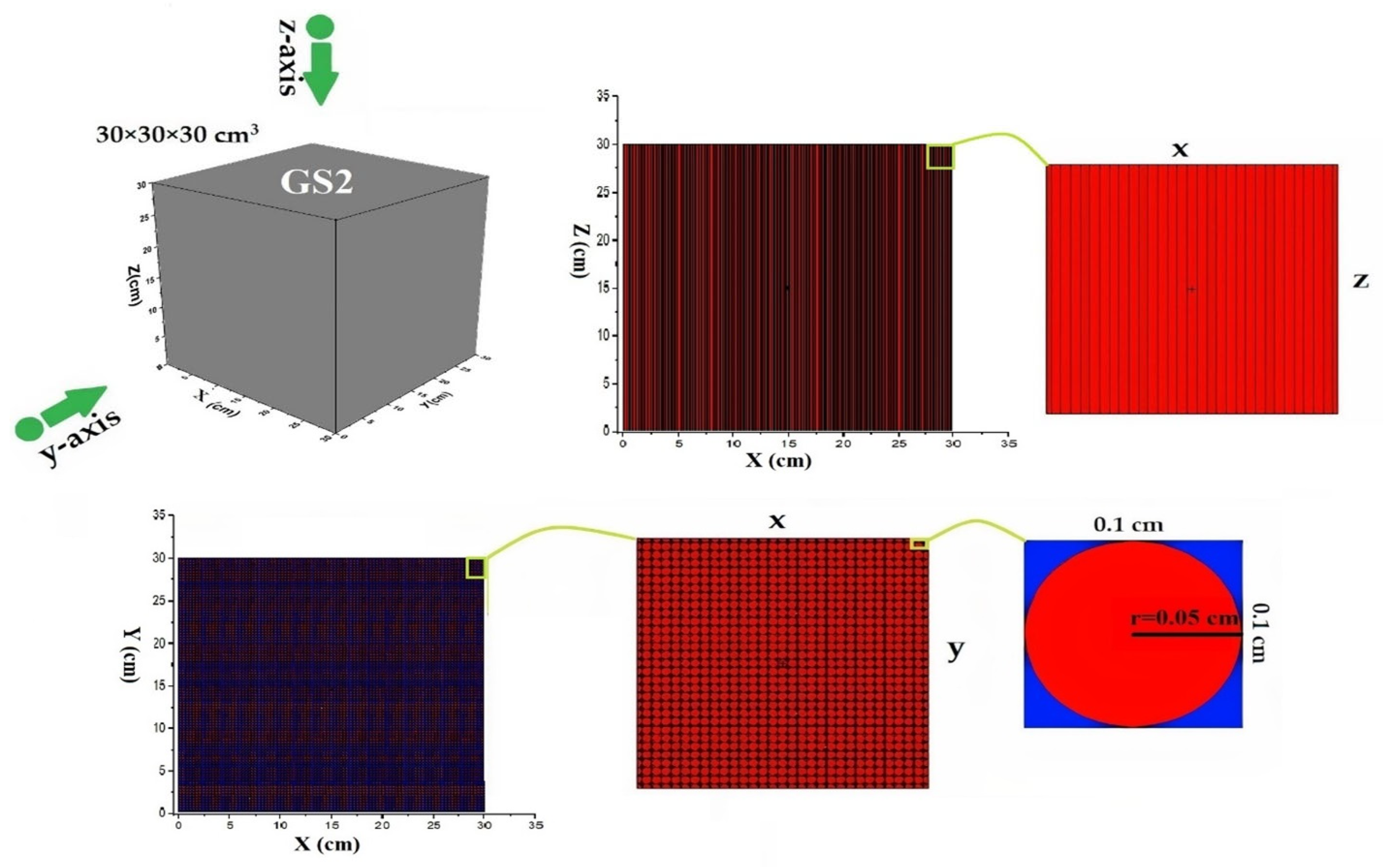

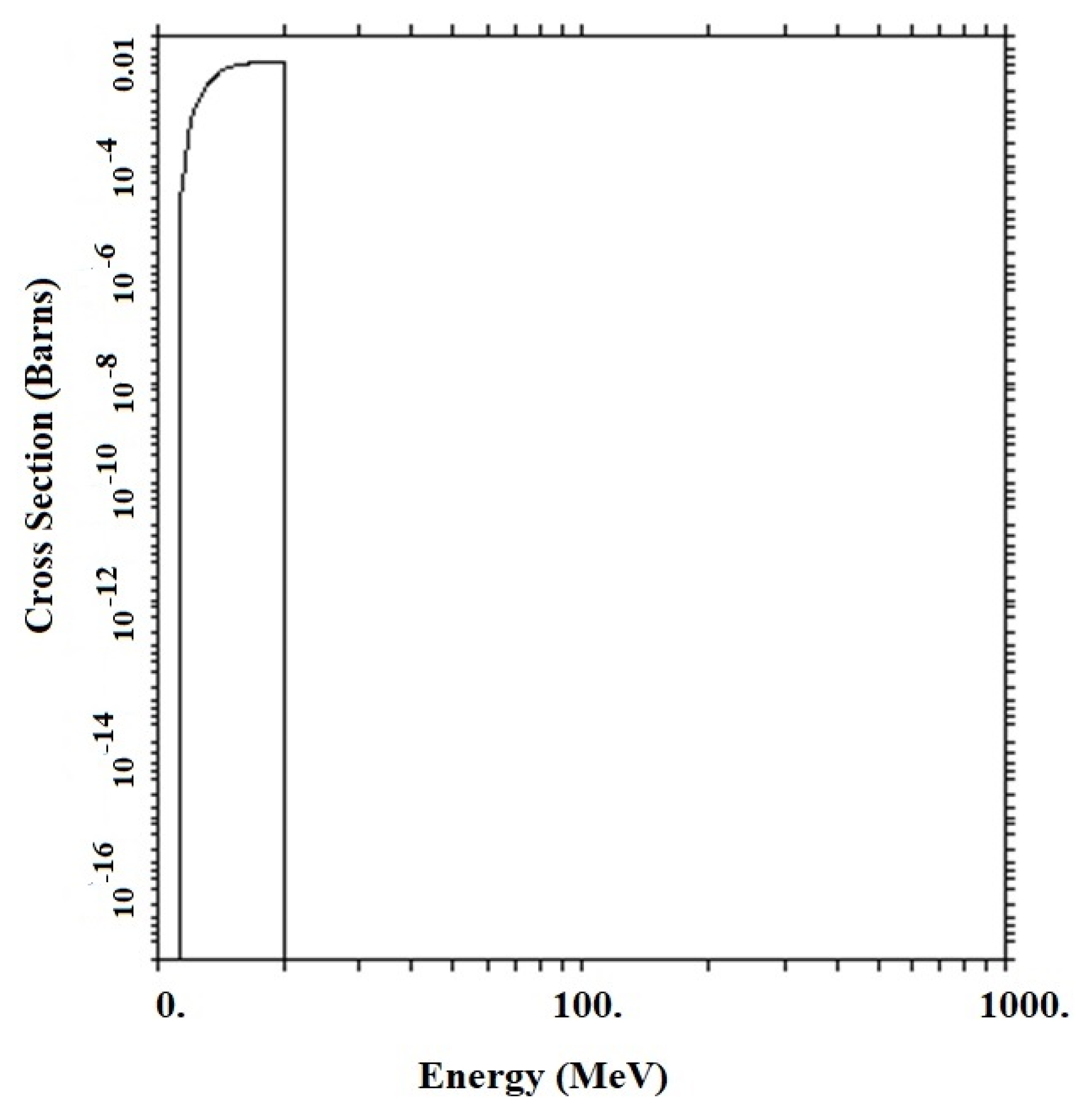

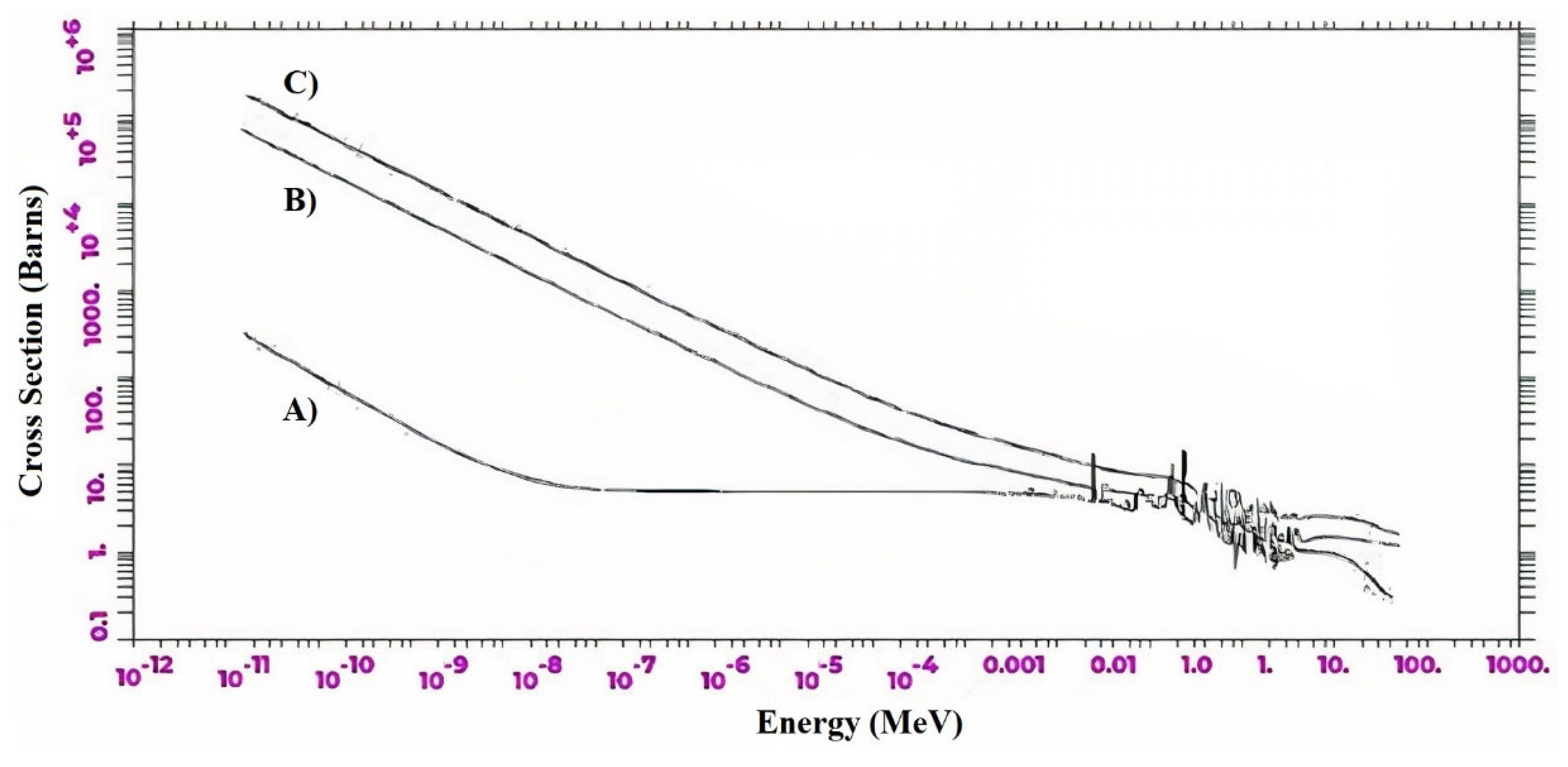

2. Materials and Methods

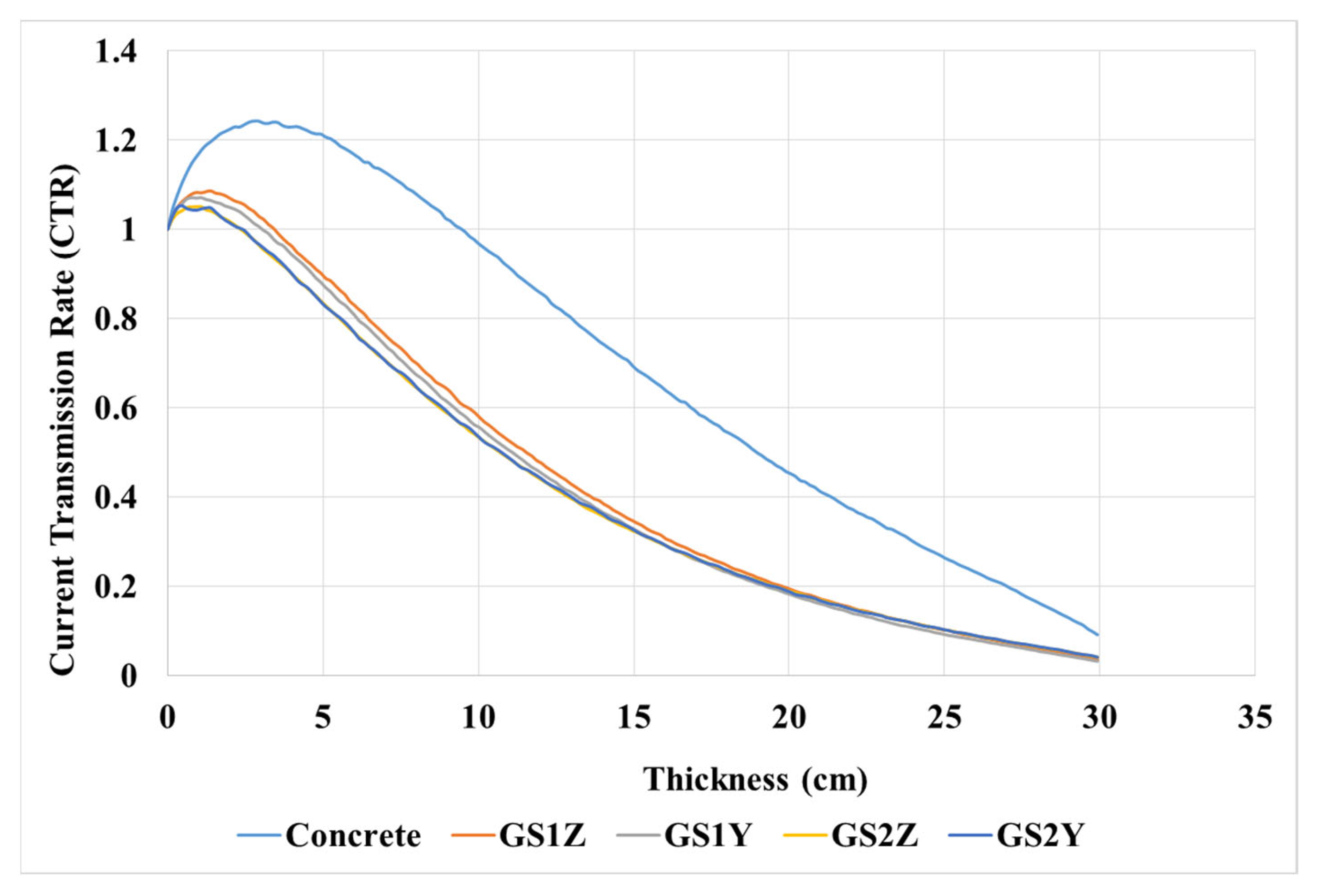

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azadegan, N.; Hassanpour, M.; Khandaker, M.U.; Faruque, M.R.I.; Al-mugren, K.S.; Bradley, D.A. Calculation of secondary radiation absorbed doses due to the proton therapy on breast cancer using MCNPX code. Radiat. Phys. Chem. 2021, 183, 109427. [Google Scholar] [CrossRef]

- Kurudirek, M. Radiation shielding and effective atomic number studies in different types of shielding concrete, lead base, and non-lead base glass systems for total electron interaction: A comparative study. Nucl. Eng. Des. 2014, 280, 440–448. [Google Scholar] [CrossRef]

- Malkapur, S.M.; Divakar, L.; Narasimhan, M.C.; Karkera, N.B.; Goverdhan, P.; Sathian, V.; Prasad, N.K. Fresh and hardened properties of polymer incorporated self-compacting concrete mixes for neutron radiation shielding. Constr. Build. Mater. 2017, 157, 917–929. [Google Scholar] [CrossRef]

- Hassanpour, M.; Hassanpour, M.; Rezaie, M.; Salajegheh, E.; Faruque, M.R.I.; Khandaker, M.U.; Bradley, D.A. Studies of the mechanical and neutron shielding features of concrete by incorporation of green additive materials: Experimental and numerical study. Radiat. Phys. Chem. 2022, 191, 109846. [Google Scholar] [CrossRef]

- Zorla, E.; Ipbüker, C.; Biland, A.; Kiisk, M.; Kovaljov, S.; Tkaczyk, A.H.; Gulik, V. Radiation shielding properties of high-performance concrete reinforced with basalt fibers infused with natural and enriched boron. Nucl. Eng. Des. 2017, 313, 306–318. [Google Scholar] [CrossRef]

- Kharita, M.H.; Yousef, S.; AlNassar, M. The effect of carbon powder addition on the properties of hematite radiation shielding concrete. Prog. Nucl. Energy 2009, 51, 388–392. [Google Scholar] [CrossRef]

- Min, J.; Lee, B.; Lee, J.S. Development of synthetic resin-based mortar for low-activation and neutron shields. Constr. Build. Mater. 2016, 124, 992–998. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Sevinc, A.H.; Cinpolat, E. Mechanical and radioactivity shielding performances of mortars made with cement, sand, and eggshells. Construct. Build. Mater. 2015, 93, 1145–1150. [Google Scholar] [CrossRef]

- DiJulio, D.D.; Cooper-Jensen, C.P.; Perrey, H.; Fissum, K.; Rofors, E.; Scherzinger, J.; Bentley, P.M. A polyethylene-B4C based concrete for enhanced neutron shielding at neutron research facilities. Nucl. Instrum. Methods Phys. Res. 2017, 859, 41–46. [Google Scholar] [CrossRef]

- Bauer, J.; Hengsbach, S.; Tesari, I.; Schwaiger, R.; Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. Proc. Natl. Acad. Sci. USA 2014, 111, 2453–2458. [Google Scholar] [CrossRef] [Green Version]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Liu, Z.; Qiu, C.; Shi, J. Metamaterial with simultaneously negative bulk modulus and mass density. Phys. Rev. Lett. 2007, 99, 093904. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chan, C.T. Double-negative acoustic metamaterial. Phys. Rev. E 2004, 70, 055602. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Wang, L.; Boyce, M.C.; Thomas, E.L. Periodic bicontinuous composites for high specific energy absorption. Nano Lett. 2012, 12, 4392–4396. [Google Scholar] [CrossRef]

- Wang, L.; Lau, J.; Thomas, E.L.; Boyce, M.C. Co-continuous composite materials for stiffness, strength, and energy dissipation. Adv. Mater. 2011, 23, 1524–1529. [Google Scholar] [CrossRef]

- Clarke, D.R. Interpenetrating phase composites. J. Am. Ceram. Soc. 1992, 75, 739–758. [Google Scholar] [CrossRef]

- Maldovan, M.; Ullal, C.K.; Jang, J.H.; Thomas, E.L. Sub-micrometer scale periodic porous cellular structures: Microframes prepared by holographic interference lithography. Adv. Mater. 2007, 19, 3809–3813. [Google Scholar] [CrossRef]

- Duty, C.; Jean, D.; Lackey, W.J. Laser chemical vapour deposition: Materials, modelling, and process control. Int. Mater. Rev. 2001, 46, 271–287. [Google Scholar] [CrossRef]

- Geim, A.K. Random walk to graphene (Nobel Lecture). Angew. Chem. Int. Ed. 2011, 50, 6966–6985. [Google Scholar] [CrossRef]

- Tang, Y.B.; Lee, C.S.; Chen, Z.H.; Yuan, G.D.; Kang, Z.H.; Luo, L.B.; Song, H.S.; Liu, Y.; He, Z.B.; Zhang, W.J.; et al. High-quality graphenes via a facile quenching method for field-effect transistors. Nano Lett. 2009, 9, 1374–1377. [Google Scholar] [CrossRef]

- Hassanpour, M.; Rezaie, M.R.; Baghizadeh, A. Practical analysis of aflatoxin M1 reduction in pasteurized Milk using low dose gamma irradiation. J. Environ. Health Sci. Eng. 2019, 17, 863–872. [Google Scholar] [CrossRef] [PubMed]

- Khezripour, S.; Negarestani, A.; Rezaie, M.R. Investigating the response of Micromegas detector to low-energy neutrons using Monte Carlo simulation. J. Instrum. 2017, 12, P08007. [Google Scholar] [CrossRef]

- Hassanpour, M.; Khezripour, S.; Rezaie, M.; Hassanpour, M.; Faruque, M.R.I.; Khandaker, M.U. The efficacy of thick gas electron multiplier detector in measuring 14C for dating purpose. Radiat. Phys. Chem. 2022, 198, 110288. [Google Scholar] [CrossRef]

- Hassanpour, M.; Rezaie, M.; Faruque, M.R.I.; Khandaker, M.U. A novel approach for the reduction of aflatoxin in pistachio nuts using experimental and MCNP simulation. Radiat. Phys. Chem. 2021, 189, 109752. [Google Scholar] [CrossRef]

- Wang, J.; Ma, F.; Liang, W.; Wang, R.; Sun, M. Optical, photonic and optoelectronic properties of graphene, h-BN and their hybrid materials. Nanophotonics 2017, 6, 943–976. [Google Scholar] [CrossRef]

- Dai, S.; Ma, Q.; Liu, M.K.; Andersen, T.; Fei, Z.; Goldflam, M.D.; Wagner, M.; Watanabe, K.; Taniguchi, T.; Thiemens, M.; et al. Graphene on hexagonal boron nitride as a tunable hyperbolic metamaterial. Nat. Nanotechnol. 2015, 10, 682–686. [Google Scholar] [CrossRef]

- Yan, D.; Wang, Y.; Qiu, Y.; Feng, Q.; Li, X.; Li, J.; Qiu, G.; Li, J. May. A Review: The Functional Materials-Assisted Terahertz Metamaterial Absorbers and Polarization Converters. Photonics 2022, 9, 335. [Google Scholar] [CrossRef]

- Khezripour, S.; Negarestani, A.; Rezaie, M.R. A new approach for alpha radiography by triple THGEM using Monte Carlo simulation and measurement. J. Instrum. 2018, 13, P05024. [Google Scholar] [CrossRef]

- Hassanpour, M.; Dehghanipour, P.; Rezaie, M.; Hassanpour, M.; Faruque, M.R.I.; Khandaker, M.U. Study of alpha spectrometry for detection of radon and progeny using gas micro-strip detector. Appl. Radiat. Isot. 2022, 187, 110344. [Google Scholar] [CrossRef]

- Kavanoz, H.B.; Akçalı, Ö.; Toker, O.; Bilmez, B.; Çağlar, M.; İçelli, O. A novel comprehensive utilization of vanadium slag/epoxy resin/antimony trioxide ternary composite as gamma ray shielding material by MCNP 6.2 and BXCOM. Radiat. Phys. Chem. 2019, 165, 108446. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Mahmoud, K.A.; Islam, S.; Tashlykov, O.L.; Lacomme, E.; Kaky, K.M. Application of the MCNP 5 code to simulate the shielding features of concrete samples with different aggregates. Radiat. Phys. Chem. 2020, 174, 108925. [Google Scholar] [CrossRef]

- Mahmoud, K.A.; Sayyed, M.I.; Tashlykov, O.L. Comparative studies between the shielding parameters of concretes with different additive aggregates using MCNP-5 simulation code. Radiat. Phys. Chem. 2019, 165, 108426. [Google Scholar] [CrossRef]

- Bagheri, R.; Moghaddam, A.K.; Yousefnia, H. Gamma ray shielding study of barium–bismuth–borosilicate glasses as transparent shielding materials using MCNP-4C code, XCOM program, and available experimental data. Nucl. Eng. Technol. 2017, 49, 216–223. [Google Scholar] [CrossRef]

- Talamo, A.; Gohar, Y.; Aliberti, G.; Cao, Y.; Smith, D.; Zhong, Z.; Kiyavitskaya, H.; Bournos, V.; Fokov, Y.; Routkovskaya, C.; et al. MCNPX, MONK, and ERANOS analyses of the YALINA Booster subcritical assembly. Nucl. Eng. Des. 2011, 241, 1606–1615. [Google Scholar] [CrossRef]

- Salgado, C.M.; Brandão, L.E.B.; Schirru, R.; Pereira, C.M.D.N.A.; Conti, C.D.C. Validation of a NaI (Tl) detector’s model developed with MCNP-X code. Prog. Nucl. Energy 2012, 59, 19–25. [Google Scholar] [CrossRef]

- Di Tigliole, A.B.; Cammi, A.; Clemenza, M.; Memoli, V.; Pattavina, L.; Previtali, E. Benchmark evaluation of reactor critical parameters and neutron fluxes distributions at zero power for the TRIGA Mark II reactor of the University of Pavia using the Monte Carlo code MCNP. Prog. Nucl. Energy 2010, 52, 494–502. [Google Scholar] [CrossRef]

- Ródenas, J.; Martinavarro, A.; Rius, V. Validation of the MCNP code for the simulation of Ge-detector calibration. Nucl. Instrum. Methods Phys. Res. 2000, 450, 88–97. [Google Scholar] [CrossRef]

- Arthur, J.; Bahran, R.; Hutchinson, J.; Sood, A.; Thompson, N.; Pozzi, S.A. Development of a research reactor protocol for neutron multiplication measurements. Prog. Nucl. Energy 2018, 106, 120–139. [Google Scholar] [CrossRef]

- Shultis, J.K.; Faw, R.E. An MCNP Primer; Department of Mechanical and Nuclear Engineering, Kansas State University: Manhattan, KS, USA, 2011; pp. 1–42. [Google Scholar]

- Shang, Y.; Yang, G.; Su, F.; Feng, Y.; Ji, Y.; Liu, D.; Yin, R.; Liu, C.; Shen, C. Multilayer polyethylene/hexagonal boron nitride composites showing high neutron shielding efficiency and thermal conductivity. Compos. Commun. 2020, 19, 147–153. [Google Scholar] [CrossRef]

- Iwata, T.; Shintani, K. Reduction of the thermal conductivity of a graphene/h-BN heterobilayer via interlayer sp 3 bonds. Phys. Chem. Chem. Phys. 2018, 20, 5217–5226. [Google Scholar] [CrossRef]

| Elements | ZAID | Wt% 1 | Elements | ZAID | Wt% 1 |

|---|---|---|---|---|---|

| H | 1001 | 1.065 | Fe | 26,056 | 0.283 |

| O | 8016 | 53.489 | Mg | 12,024 | 0.244 |

| Si | 14,028 | 30.116 | S | 16,032 | 0.178 |

| Ca | 20,040 | 12.266 | Na | 11,023 | 0.07 |

| Al | 13,027 | 0.364 | K | 19,039 | 0.078 |

| C | 6012 | 1.847 |

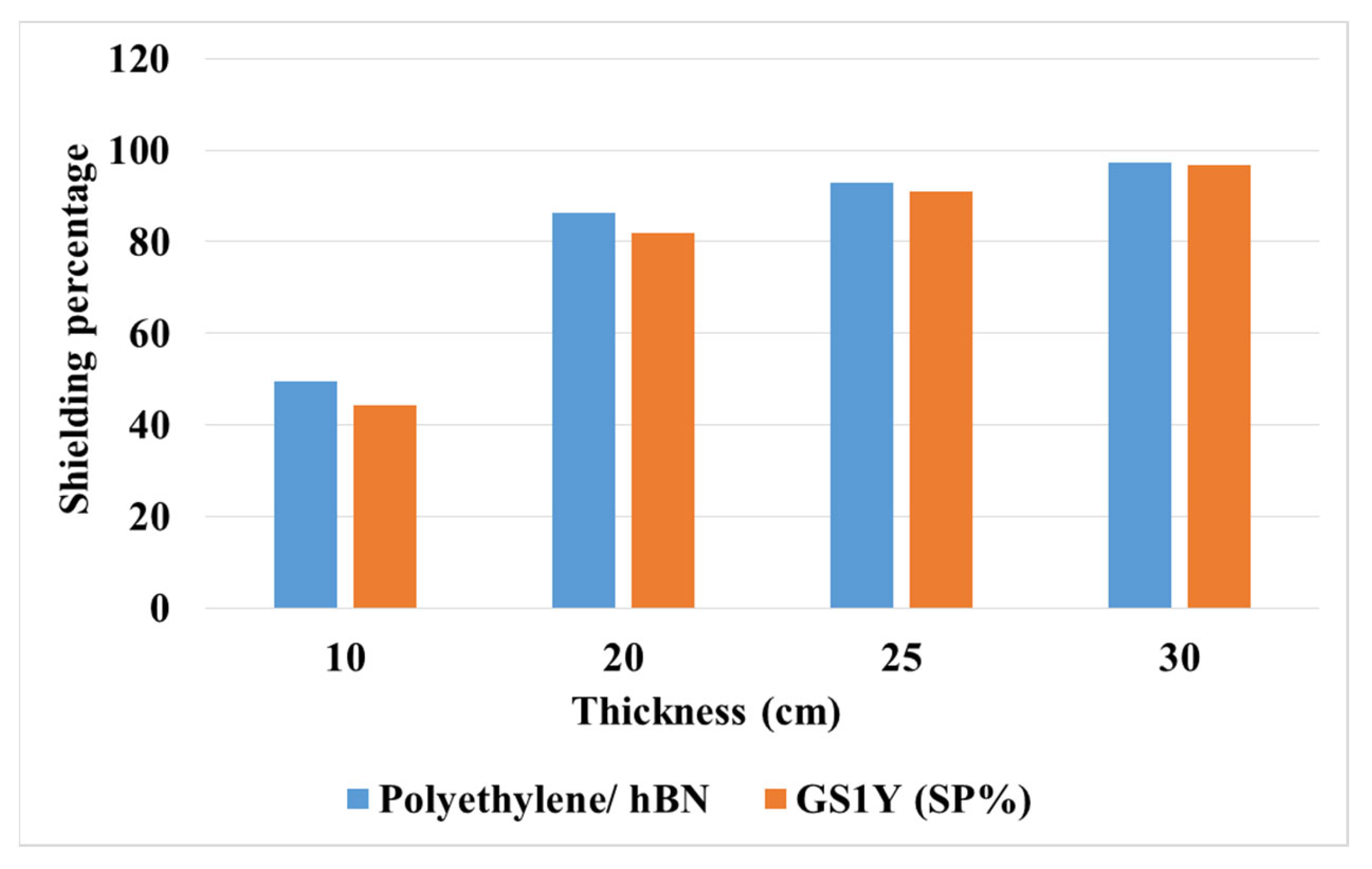

| Z | Concrete (SP%) | GS1Z (SP%) | GS1Y (SP%) | GS2Z (SP%) | GS2Y (SP%) |

|---|---|---|---|---|---|

| 10 cm | 3.31 | 42.02 | 44.34 | 46.7 | 46.57 |

| 20 cm | 54.76 | 80.69 | 81.82 | 81.12 | 81.31 |

| 25 cm | 74.08 | 89.91 | 91.01 | 89.92 | 89.9 |

| 30 cm | 90.85 | 96.43 | 96.77 | 95.86 | 95.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassanpour, M.; Hassanpour, M.; Faghihi, S.; Khezripour, S.; Rezaie, M.; Dehghanipour, P.; Faruque, M.R.I.; Khandaker, M.U. Introduction of Graphene/h-BN Metamaterial as Neutron Radiation Shielding by Implementing Monte Carlo Simulation. Materials 2022, 15, 6667. https://doi.org/10.3390/ma15196667

Hassanpour M, Hassanpour M, Faghihi S, Khezripour S, Rezaie M, Dehghanipour P, Faruque MRI, Khandaker MU. Introduction of Graphene/h-BN Metamaterial as Neutron Radiation Shielding by Implementing Monte Carlo Simulation. Materials. 2022; 15(19):6667. https://doi.org/10.3390/ma15196667

Chicago/Turabian StyleHassanpour, Marzieh, Mehdi Hassanpour, Simin Faghihi, Saeedeh Khezripour, Mohammadreza Rezaie, Parvin Dehghanipour, Mohammad Rashed Iqbal Faruque, and Mayeen Uddin Khandaker. 2022. "Introduction of Graphene/h-BN Metamaterial as Neutron Radiation Shielding by Implementing Monte Carlo Simulation" Materials 15, no. 19: 6667. https://doi.org/10.3390/ma15196667