Nonlinear Creep Amplification Factor Considering Damage Evolution of Concrete under Compression

Abstract

1. Introduction

2. Medium Stress Level

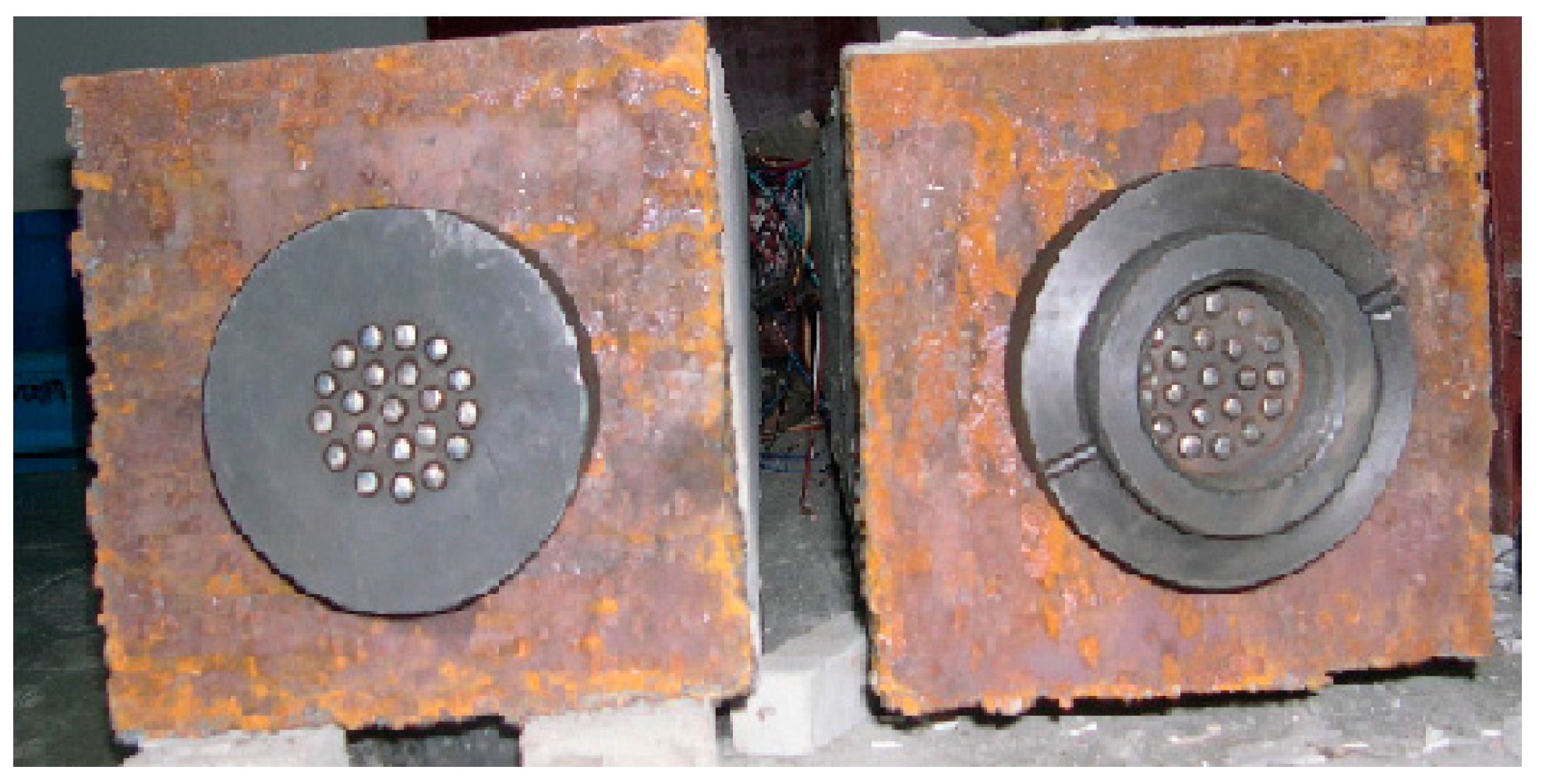

2.1. Experimental Preparation

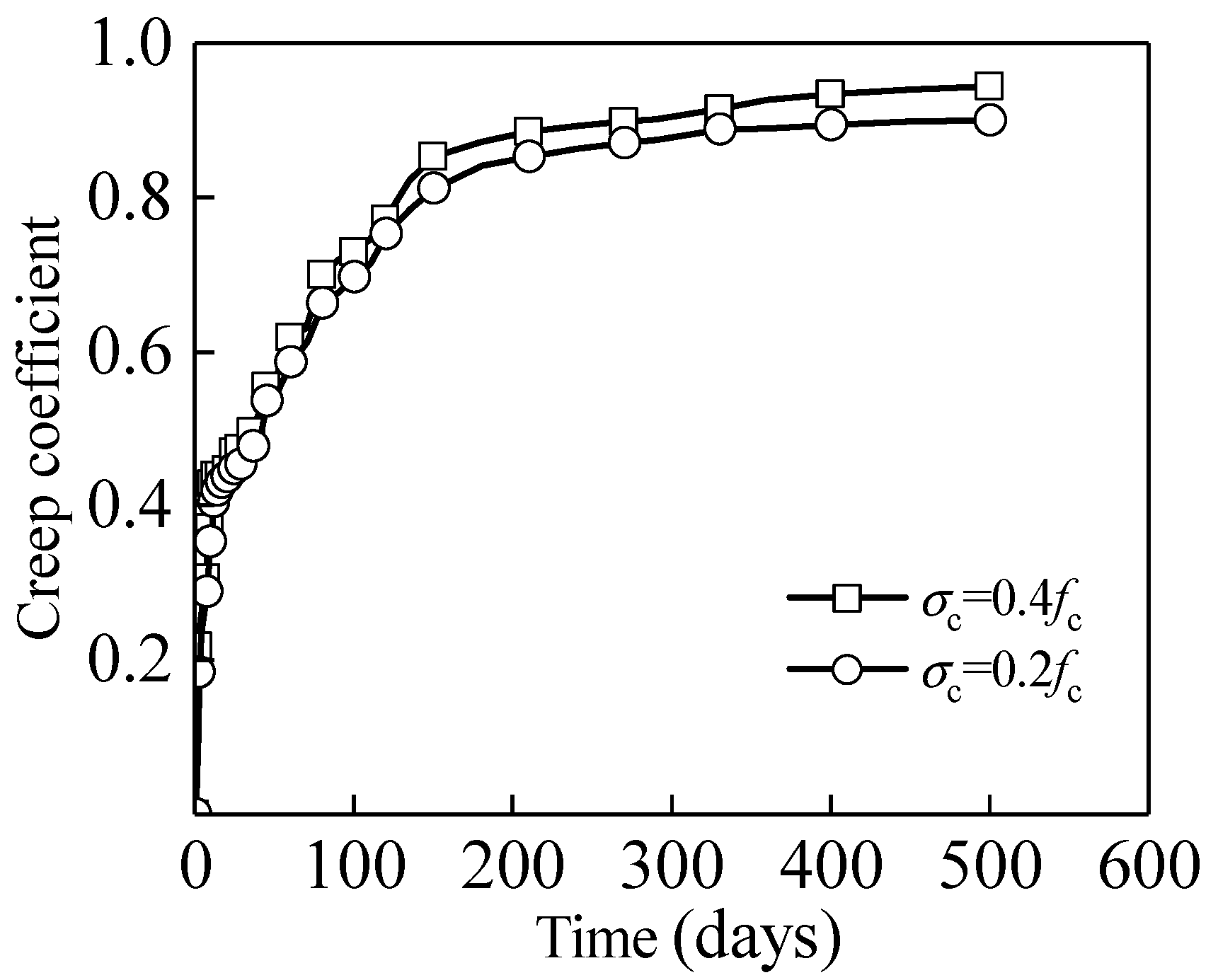

2.2. Test Results

3. Nonlinear Creep Amplification Factor Considering Damage Evolution

3.1. Calculation Method of Linear Creep

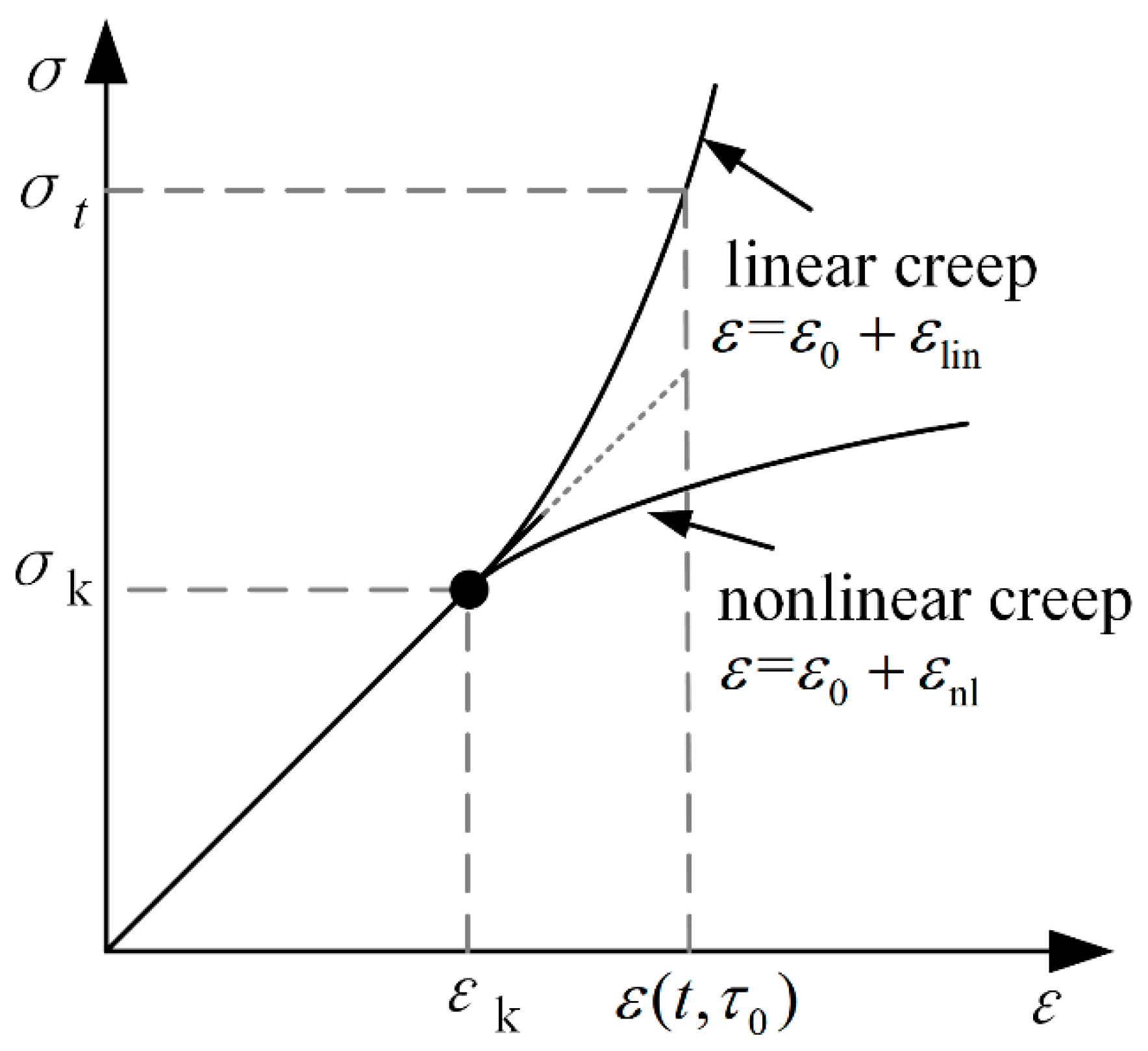

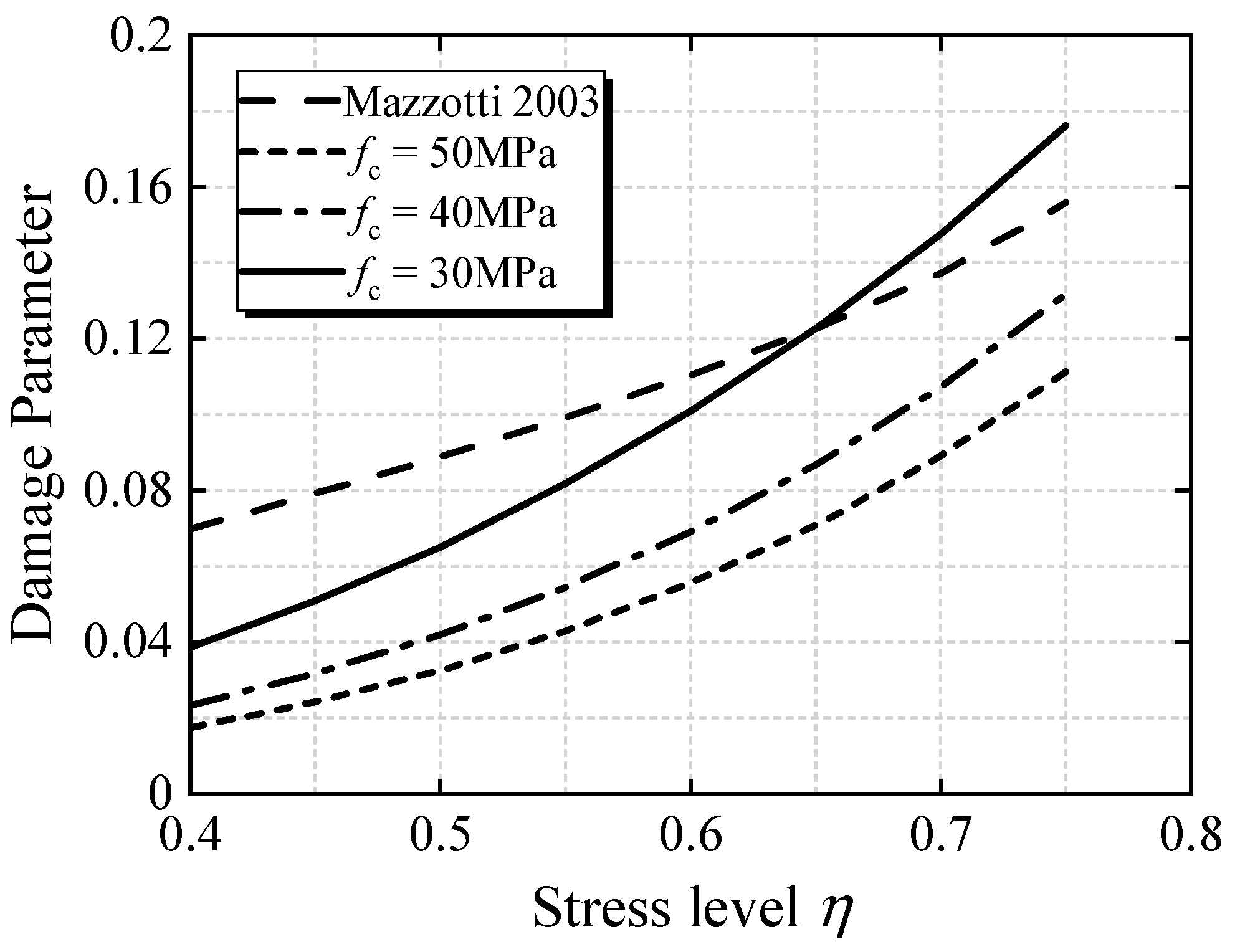

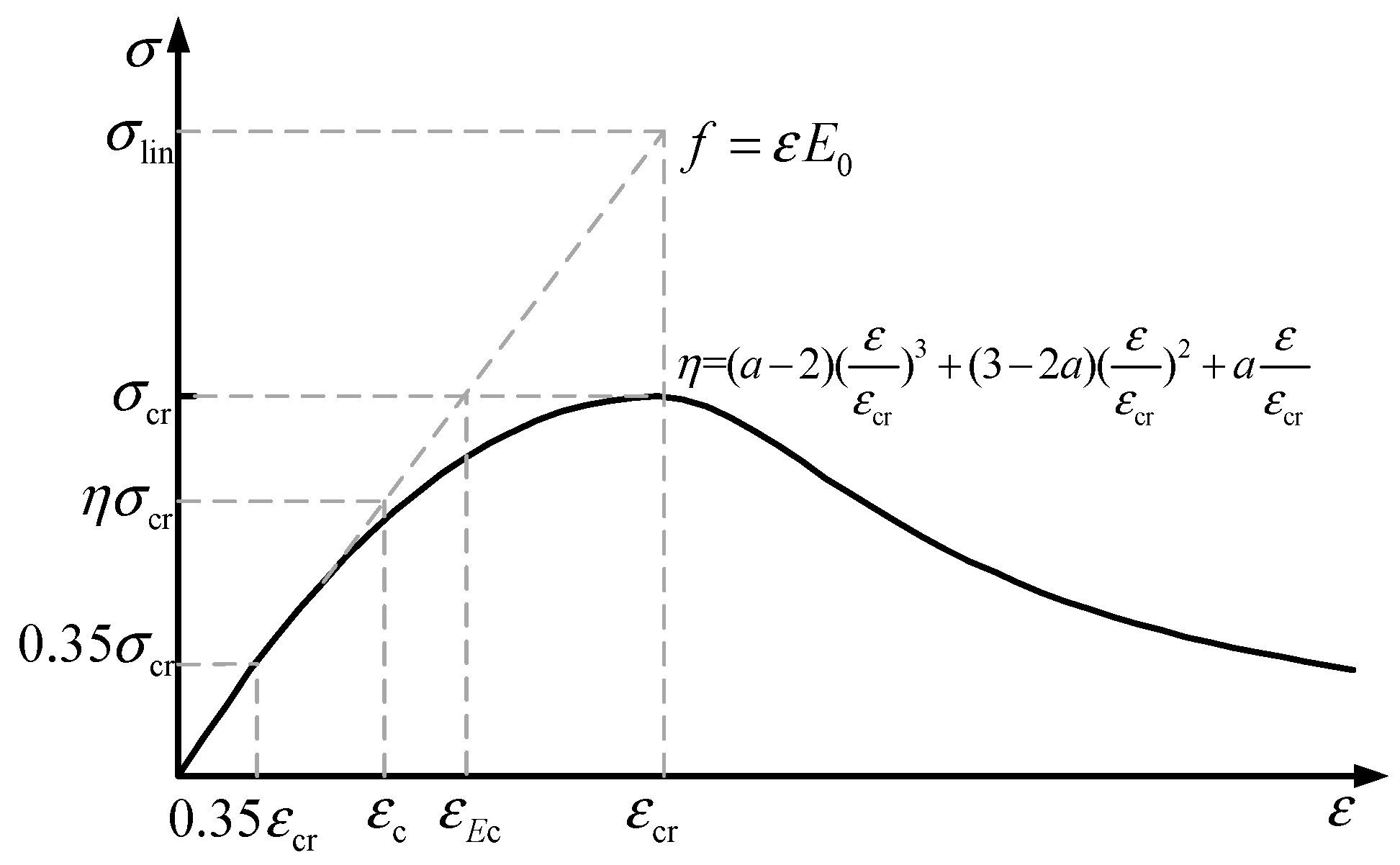

3.2. Calculation Method of Nonlinear Creep Considering Damage

4. Amplification Factor

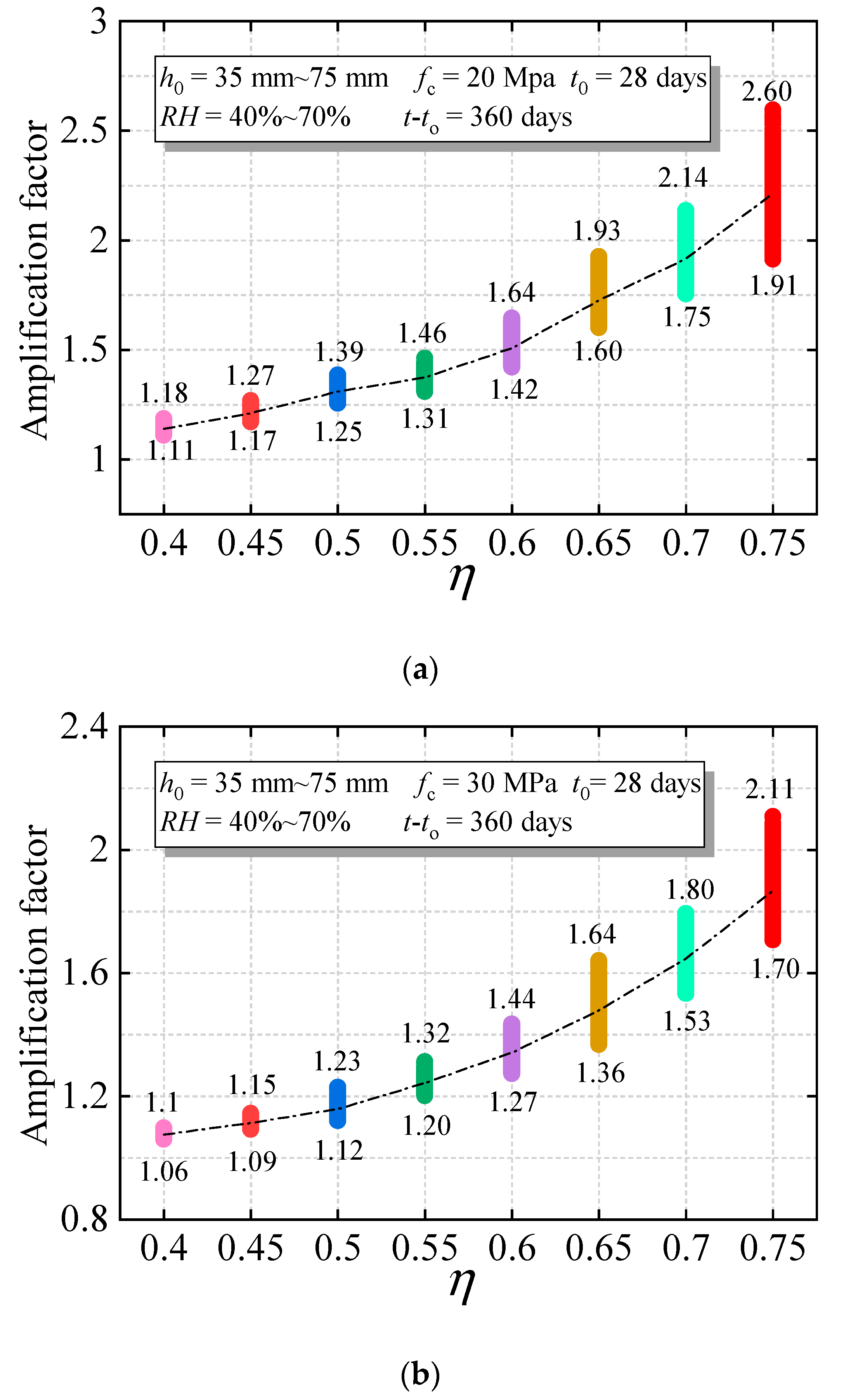

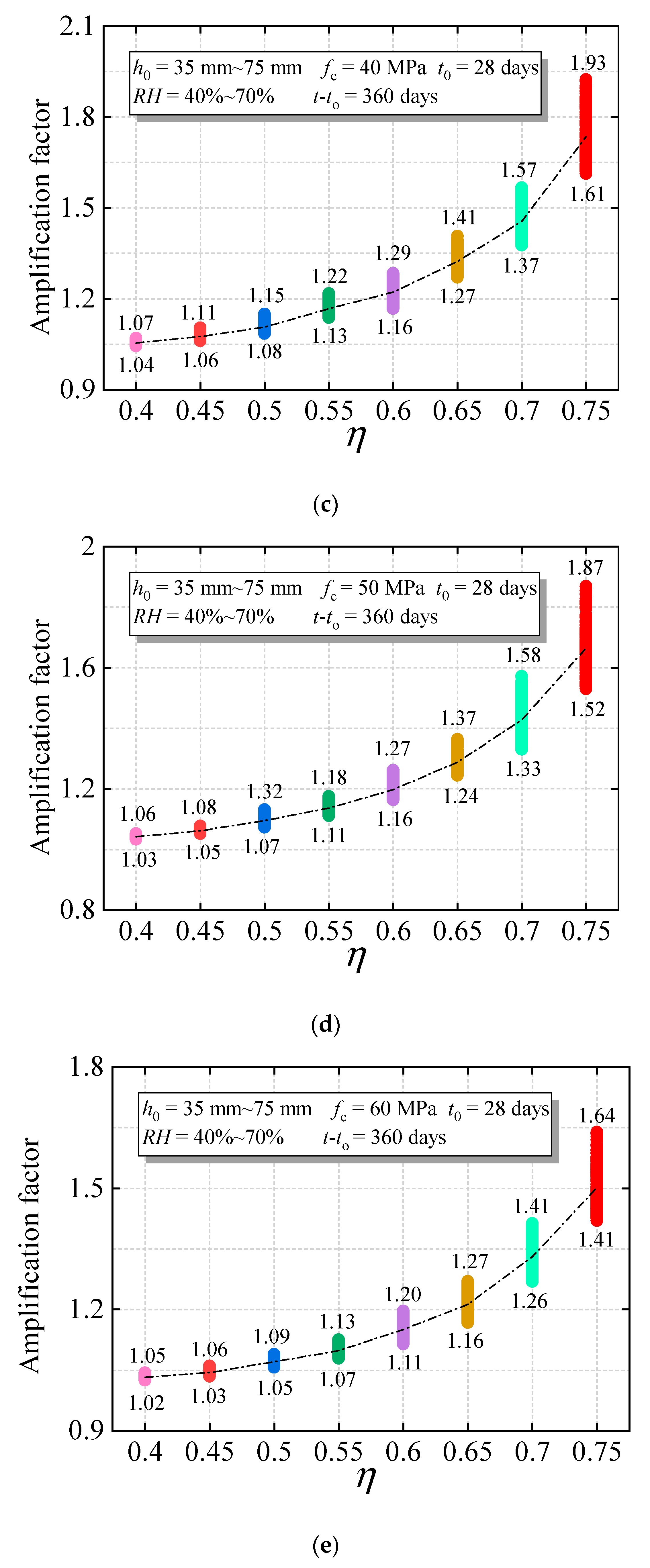

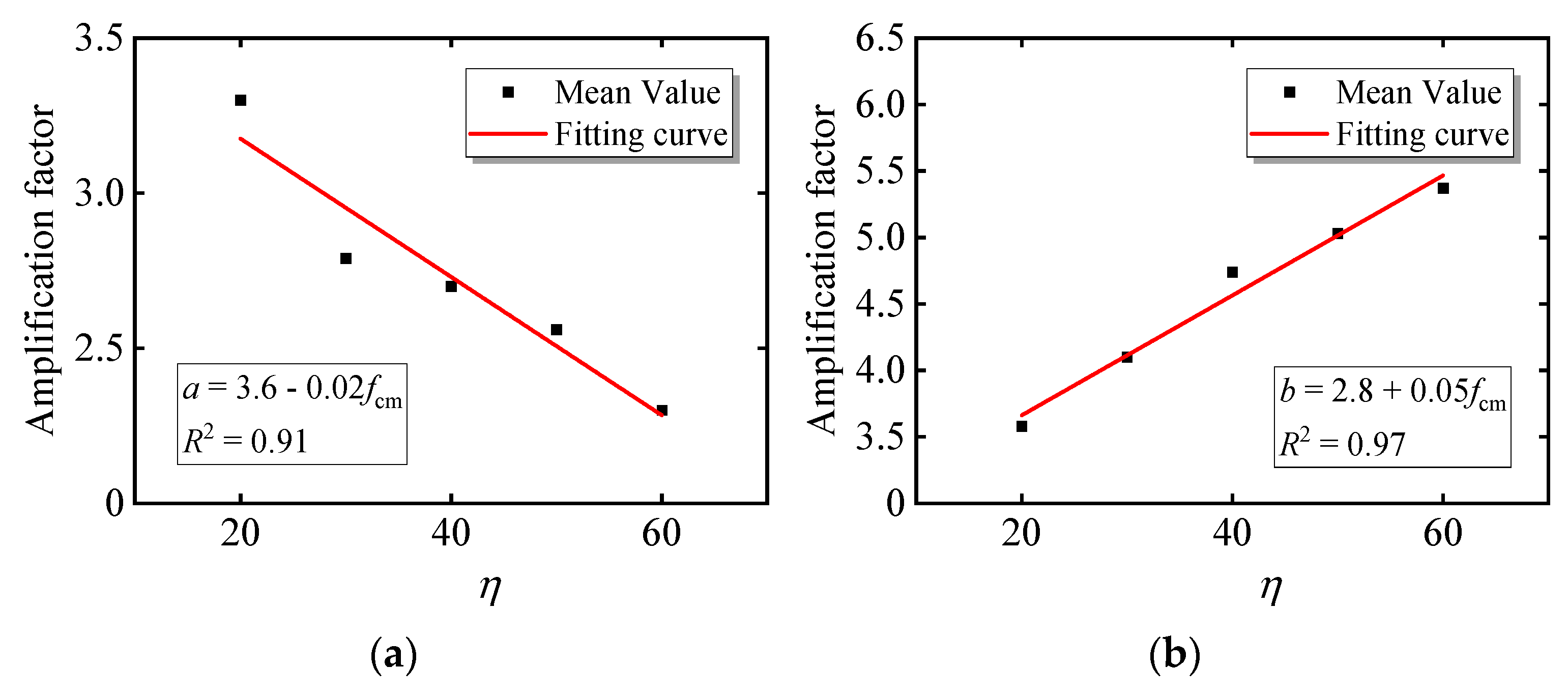

4.1. Formula Fitting

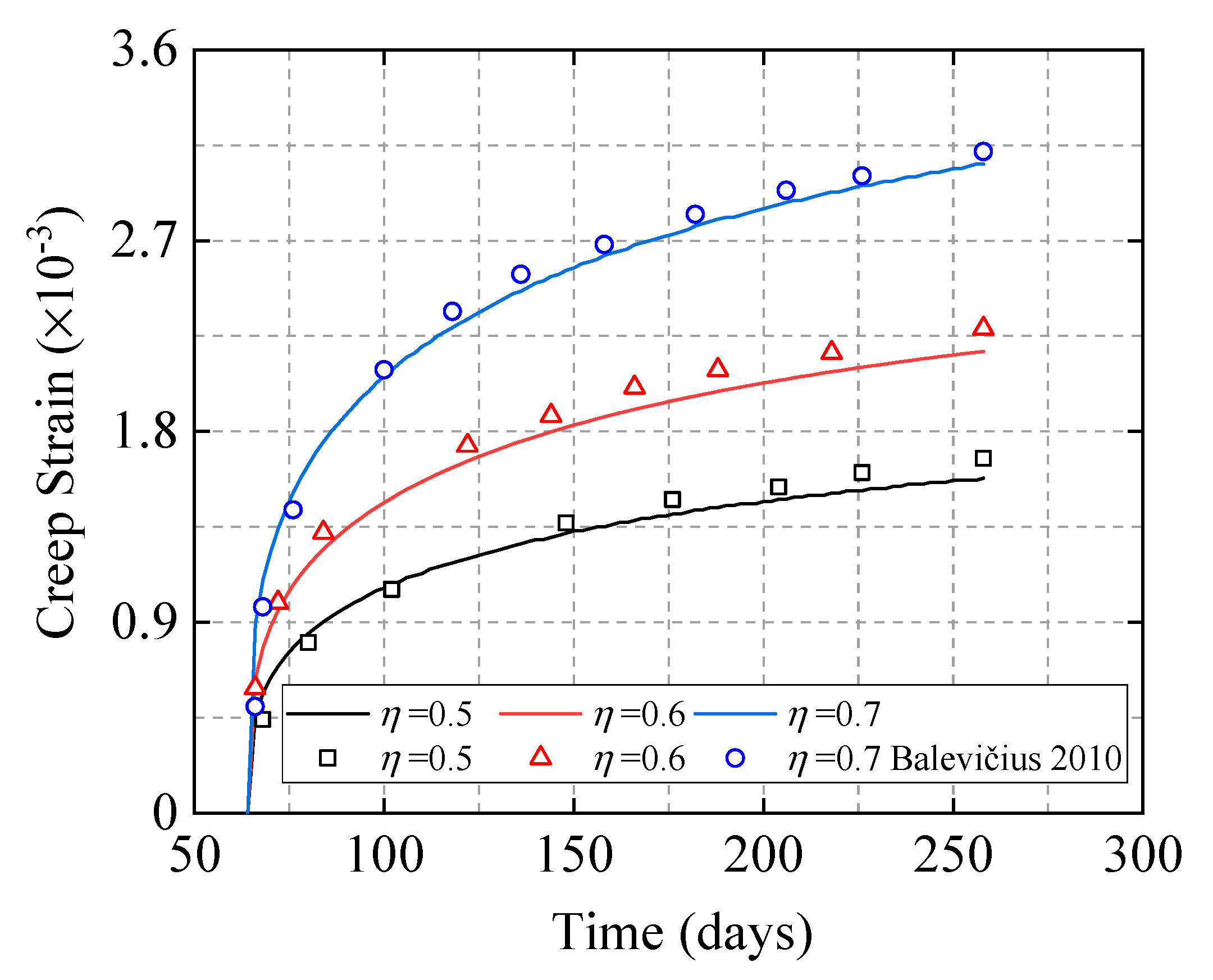

4.2. Comparative Analysis

5. Conclusions

- (1)

- Considering the multi-level effects of concrete creep, it is recommended that the study of the nonlinear creep magnification factor in the medium stress state should take a stress level range from 0.35fc to 0.75fc.

- (2)

- The nonlinear creep model of concrete under different strengths is constructed by coupling the concrete damage evolution with elastic creep, which can better reflect the nonlinear creep of the concrete under a medium stress state and simplify the calculation process.

- (3)

- Concrete nonlinear creep is related to stress level and concrete strength. The nonlinear creep amplification coefficient of concrete with the same strengths increases nonlinearly with an increase in the compressive stress level; when the concrete compressive stress level is determined, the nonlinear creep magnification factor gradually decreases significantly with an increase in the concrete strength. The nonlinear creep amplification coefficient is positively related to the stress level and negatively related to the concrete compressive strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- American Concrete Institute (ACI) Committee 209R. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; American Concrete Institute (ACI): Farmington Hills, MI, USA, 1992. [Google Scholar]

- BS EN 1992; Eurocode 2: Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Liu, W.Z.; Niu, S.W. Energy evolution properties and strength failure criterion of coal-fired slag concrete based on energy dissipation. Case Stud. Constr. Mater. 2022, 17, e01369. [Google Scholar] [CrossRef]

- Lou, B.L.; Ma, F.H. Evolution on fracture properties of concrete during steam curing. Case Stud. Constr. Mater. 2022, 16, e01105. [Google Scholar] [CrossRef]

- Denarié, E.; Cécot, C.; Huet, C. Characterization of creep and crack growth interactions in the fracture behavior of concrete. Cem. Concr. Res. 2006, 36, 571–575. [Google Scholar] [CrossRef]

- Challamel, N.; Lanos, C.; Casandjian, C. Creep damage modelling for quasi-brittle materials. Eur. J. Mech. 2005, 24, 593–613. [Google Scholar] [CrossRef]

- Benboudjema, F.; Meftah, F.; Torrenti, J.M. Interaction between drying, shrinkage, creep and cracking phenomena in concrete. Eng. Struct. 2005, 27, 239–250. [Google Scholar] [CrossRef]

- Rossi, P.; Boulay, C.; Tailhan, J.-L.; Martin, E.; Desnoyers, D. Macrocrack propagation in concrete specimens under sustained loading: Study of the physical mechanisms. Cem. Concr. Res. 2014, 63, 98–104. [Google Scholar] [CrossRef]

- Li, Y.; Qiang, S.; Xu, W.; Hua, X.; Xu, C.; Lai, J.; Yuan, M.; Chen, B. Verification of concrete nonlinear creep mechanism based on meso-damage mechanics. Constr. Build. Mater. 2021, 276, 122205. [Google Scholar] [CrossRef]

- International Federation for Structural Concrete (fib). CEB-FIP Model Code 2010 (MC2010); Ernst & Sohn: Berlin, Germany, 2013. [Google Scholar]

- Borrero, E.L.S.; Farhangi, V.; Jadidi, K.; Karakouzian, M. An Experimental Study on Concrete’s Durability and Mechanical Characteristics Subjected to Different Curing Regimes. Civ. Eng. J. 2021, 7, 676–689. [Google Scholar] [CrossRef]

- Martins, R.O.G.; Rita de Cássia, S.; Pedroti, L.G.; de Oliveira, A.F.; Mendes, B.C.; de Azevedo, A.R.G. Assessment of the durability of grout submitted to accelerated carbonation test. Constr. Build. Mater. 2018, 159, 261–268. [Google Scholar] [CrossRef]

- Li, Z.X.; Qian, J.C. Creep damage analysis and its application to nonlinear creep of reinforced concrete beam. Eng. Fract. Mech. 1989, 34, 851–860. [Google Scholar] [CrossRef]

- Bažant, Z.P. Prediction of concrete creep and shrinkage: Past, present and future. Nucl. Eng. Des. 2001, 203, 27–38. [Google Scholar] [CrossRef]

- GB 50010 2010; Code for Design of Concrete Structures. Ministry of Construction of the People’s Republic of China; China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- Mazzotti, C.; Savoia, M. Nonlinear creep damage model for concrete under uniaxial compression. J. Eng. Mech. 2003, 129, 1065–1075. [Google Scholar] [CrossRef]

- Li, Z.X. Effective creep Poisson’s ratio for damaged concrete. Int. J. Fract. 1994, 66, 189–196. [Google Scholar]

- Mazzotti, C.; Savoia, M. Nonlinear creep, Poisson’s ratio, and creep-damage interaction of concrete in compression. ACI Mater. J. 2002, 99, 450–457. [Google Scholar]

- Sellier, A.; Multon, S.; Lacarrière, L.; Vidal, T.; Bourbon, X.; Camps, G. Concrete creep modelling for structural applications: Non-linearity, multi-axiality, hydration, temperature and drying effects. Cem. Concr. Res. 2016, 79, 301–315. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Q.; Ballarini, R.; Gao, X. Coupled Creep-Damage-Plasticity Model for Concrete under Long-Term Loading. J. Eng. Mech. 2020, 146, 04020027. [Google Scholar] [CrossRef]

- Tang, C. Research on Compressive Creep Model and Stress-Strain Relationship of Concrete; Harbin Institute of Technology: Harbin, China, 2016. (In Chinese) [Google Scholar]

- Bažant, Z.P.; Prasannan, S. Solidification theory for concrete creep. I: Formulation. J. Eng. Mech. 1989, 115, 1691–1703. [Google Scholar] [CrossRef]

- Ruiz, M.F.; Muttoni, A.; Gambarova, P.G. Relationship between nonlinear creep and cracking of concrete under uniaxial compression. J. Adv. Concr. Technol. 2007, 5, 383–393. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Li, Y.N. Cohesive Crack with Rate-Dependent Opening and Viscoelasticity: I. Mathematical Model and Scaling. Int. J. Fract. 1997, 86, 247–265. [Google Scholar] [CrossRef]

- Dummer, A.; Neuner, M.; Hofstetter, G. An extended gradient-enhanced damage-plasticity model for concrete considering nonlinear creep and failure due to creep. Int. J. Solids Struct. 2022, 243, 111541. [Google Scholar] [CrossRef]

- Yu, P.; Li, R.; Bie, D.; Yao, X.; Liu, X.; Duan, Y. A coupled creep and damage model of concrete considering rate effect. J. Build. Eng. 2022, 45, 103621. [Google Scholar] [CrossRef]

- Han, B.; Xie, H.-B.; Zhu, L.; Jiang, P. Nonlinear model for early age creep of concrete under compression strains. Constr. Build. Mater. 2017, 147, 203–211. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Caner, F.C.; Adley, M.D.; Akers, S.A. Fracturing Rate Effect and Creep in Microplane Model for Dynamics. J. Eng. Mech. 2000, 126, 962–970. [Google Scholar] [CrossRef]

- Huang, H.D.; Xiang, Z.F. Nonlinear creep analysis method for concrete structures. Eng. Mech. 2014, 31, 96–102. (In Chinese) [Google Scholar] [CrossRef]

- Balevičius, R.; Marčiukaitis, G. Non-linear time-dependent analysis of layered composite structure. In Proceedings of the 10th International Conference on Modern Building Material, Structures and Techniques, Vilnius, Lithuania, 19–21 May 2010; Vilniaus Gedimino Technikos Universitetas Press: Vilnius, Lithuania, 2010; pp. 569–575. [Google Scholar]

- Carol, I.; Bažant, Z.P. Viscoelasticity with Aging Caused by Solidification of Nonaging Constituent. J. Eng. Mech. 1993, 119, 2252–2269. [Google Scholar] [CrossRef]

- Luzio, G.D. Numerical Model for Time-Dependent Fracturing of Concrete. J. Eng. Mech. 2009, 135, 632–640. [Google Scholar] [CrossRef]

- Hamed, E. Non-linear creep effects in concrete under uniaxial compression. Mag. Concr. Res. 2015, 67, 876–884. [Google Scholar] [CrossRef]

- Smadi, M.M.; Floyd, O.S.; Arthur, H.N. Shrinkage and creep of high-, medium-, and low-strength concretes, including overloads. ACI Mater. J. 1987, 84, 224–234. [Google Scholar]

- Moradi, N.; Tavana, M.H.; Habibi, M.R.; Amiri, M.; Moradi, M.J.; Farhangi, V. Predicting the Compressive Strength of Concrete Containing Binary Supplementary Cementitious Material Using Machine Learning Approach. Materials 2022, 15, 5336. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.X.; Gu, C.L. Study on nonlinear creep behavior of ordinary concrete under compression. J. Taiyuan Univ. Technol. 1987, 38–45. (In Chinese) [Google Scholar] [CrossRef]

- Balevičius, R. An average stress strain approach to creep analysis of RC uncracked elements. Mech. Time-Depend. Mater. 2010, 14, 69–89. [Google Scholar] [CrossRef]

- Sun, B.J. Effective modulus method of concrete creep theory. China Civ. Eng. J. 1993, 26, 66–68. (In Chinese) [Google Scholar]

- Nowacki, W. Theorie du Fluage; Editions Eyrolles: Paris, France, 1965. (In French) [Google Scholar]

- Hamed, E. Nonlinear creep response of reinforced concrete beams. J. Mech. Mater. Struct. 2012, 7, 435–460. [Google Scholar] [CrossRef]

- Guo, Z.H. Strength and Constitutive Relation of Concrete; Building Industry Press: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Balevičius, R.; Eugedijus, D. On the prediction of non-linear creep strains. J. Civ. Eng. Manag. 2010, 16, 382–386. [Google Scholar] [CrossRef][Green Version]

- Fu, X.B. Long-Term Behavior of Axially Loaded Concrete Filled Steel Tubular Stub Columns under High Stress; Harbin Institute of Technology: Harbin, China, 2013. (In Chinese) [Google Scholar]

| Concrete Age (Days) | Compressive Strength (MPa) | Modulus of Elasticity (GPa) | |

|---|---|---|---|

| Cubic | Prism | ||

| 7 | 59.0 | 49.0 | 42.1 |

| 14 | 67.0 | 52.8 | 44.1 |

| 28 | 79.6 | 67.0 | 46.6 |

| 45 | 84.5 | 71.2 | 47.7 |

| 90 | 88.6 | 74.0 | 47.8 |

| Concrete Compressive Strength fc (MPa) | |||||

|---|---|---|---|---|---|

| 20 | 30 | 40 | 50 | 60 | |

| 0.40 | 1.14 | 1.07 | 1.05 | 1.04 | 1.03 |

| 0.45 | 1.21 | 1.11 | 1.07 | 1.06 | 1.04 |

| 0.50 | 1.31 | 1.16 | 1.09 | 1.09 | 1.07 |

| 0.55 | 1.36 | 1.24 | 1.16 | 1.13 | 1.10 |

| 0.60 | 1.51 | 1.35 | 1.22 | 1.18 | 1.15 |

| 0.65 | 1.73 | 1.47 | 1.32 | 1.28 | 1.21 |

| 0.70 | 1.92 | 1.65 | 1.45 | 1.41 | 1.33 |

| 0.75 | 2.18 | 1.86 | 1.73 | 1.66 | 1.5 |

| Power function Coefficient | Concrete Compressive Strength fc (MPa) | ||||

|---|---|---|---|---|---|

| 20 | 30 | 40 | 50 | 60 | |

| a | 3.3 | 2.79 | 2.7 | 2.56 | 2.3 |

| b | 3.58 | 4.10 | 4.74 | 5.03 | 5.37 |

| Specimen | D | h0 | RH | σ(t0) | Ec(t0) | |

|---|---|---|---|---|---|---|

| Number | (mm) | (mm) | (%) | (MPa) | (MPa) | |

| 1 | 100 | 50 | 65 | 46.9 | 3.5 × 104 | 0.61 |

| 2 | 100 | 50 | 65 | 46.9 | 3.5 × 104 | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Cao, D.; Zeng, B.; Wang, Y. Nonlinear Creep Amplification Factor Considering Damage Evolution of Concrete under Compression. Materials 2022, 15, 6742. https://doi.org/10.3390/ma15196742

Pan Z, Cao D, Zeng B, Wang Y. Nonlinear Creep Amplification Factor Considering Damage Evolution of Concrete under Compression. Materials. 2022; 15(19):6742. https://doi.org/10.3390/ma15196742

Chicago/Turabian StylePan, Zuanfeng, Dong Cao, Bin Zeng, and Yuwei Wang. 2022. "Nonlinear Creep Amplification Factor Considering Damage Evolution of Concrete under Compression" Materials 15, no. 19: 6742. https://doi.org/10.3390/ma15196742

APA StylePan, Z., Cao, D., Zeng, B., & Wang, Y. (2022). Nonlinear Creep Amplification Factor Considering Damage Evolution of Concrete under Compression. Materials, 15(19), 6742. https://doi.org/10.3390/ma15196742