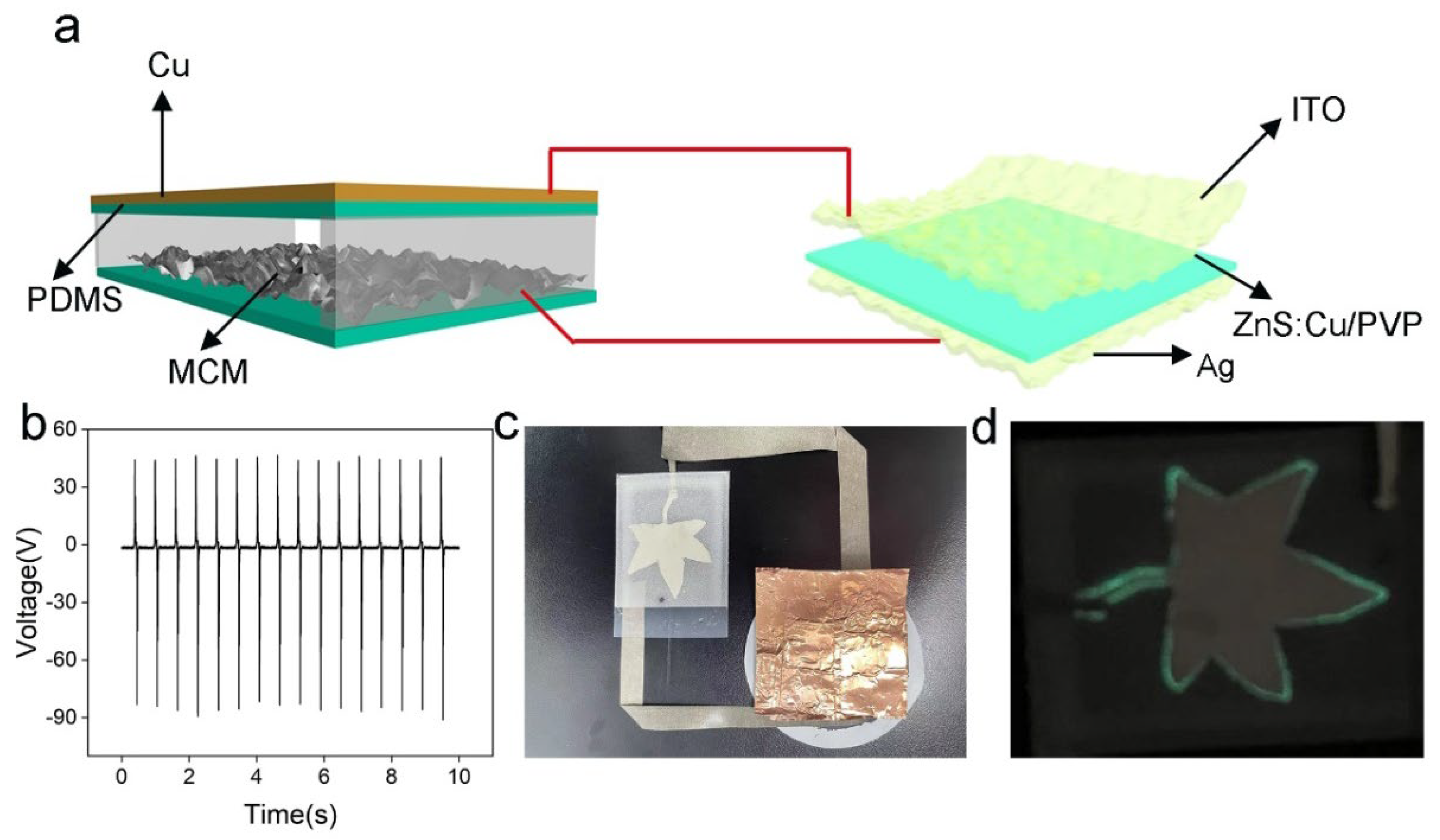

A Flexible Triboelectric Nanogenerator Based on Multilayer MXene/Cellulose Nanofibril Composite Film for Patterned Electroluminescence Display

Abstract

1. Introduction

2. Materials and Methods

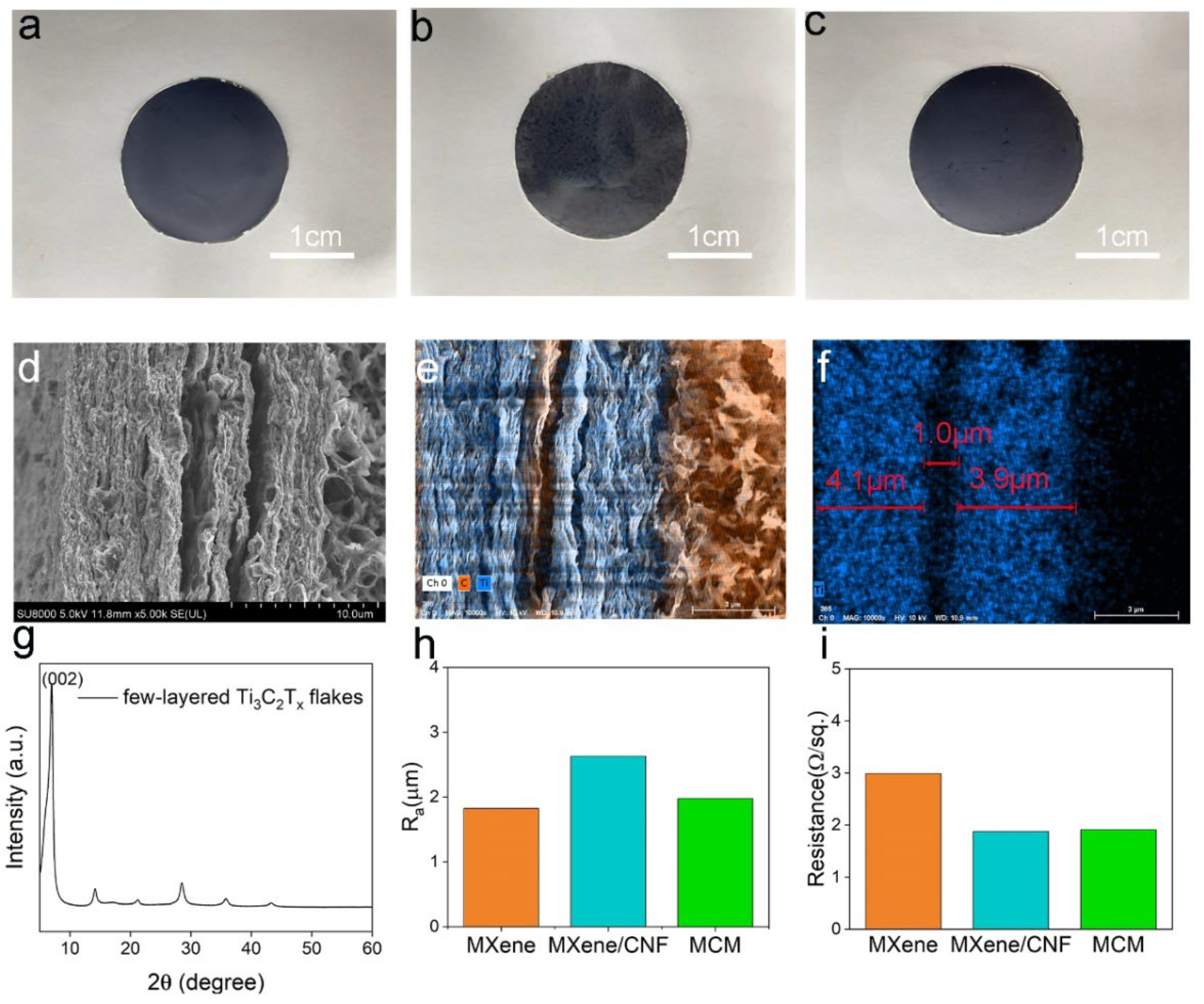

2.1. Preparation of Composite Electrode

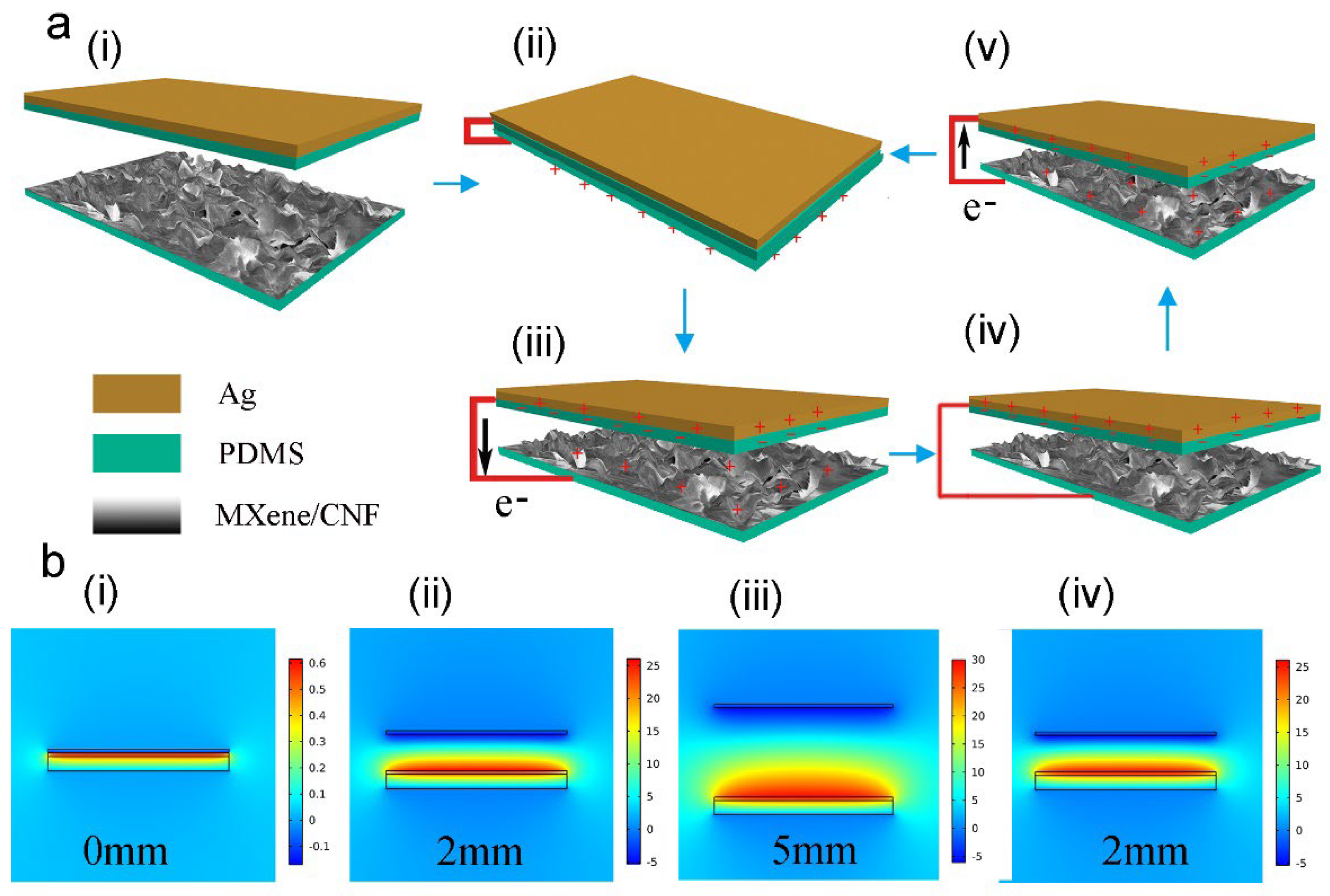

2.2. Construction of Flexible MXene/CNF-Based TENG

2.3. Characterization

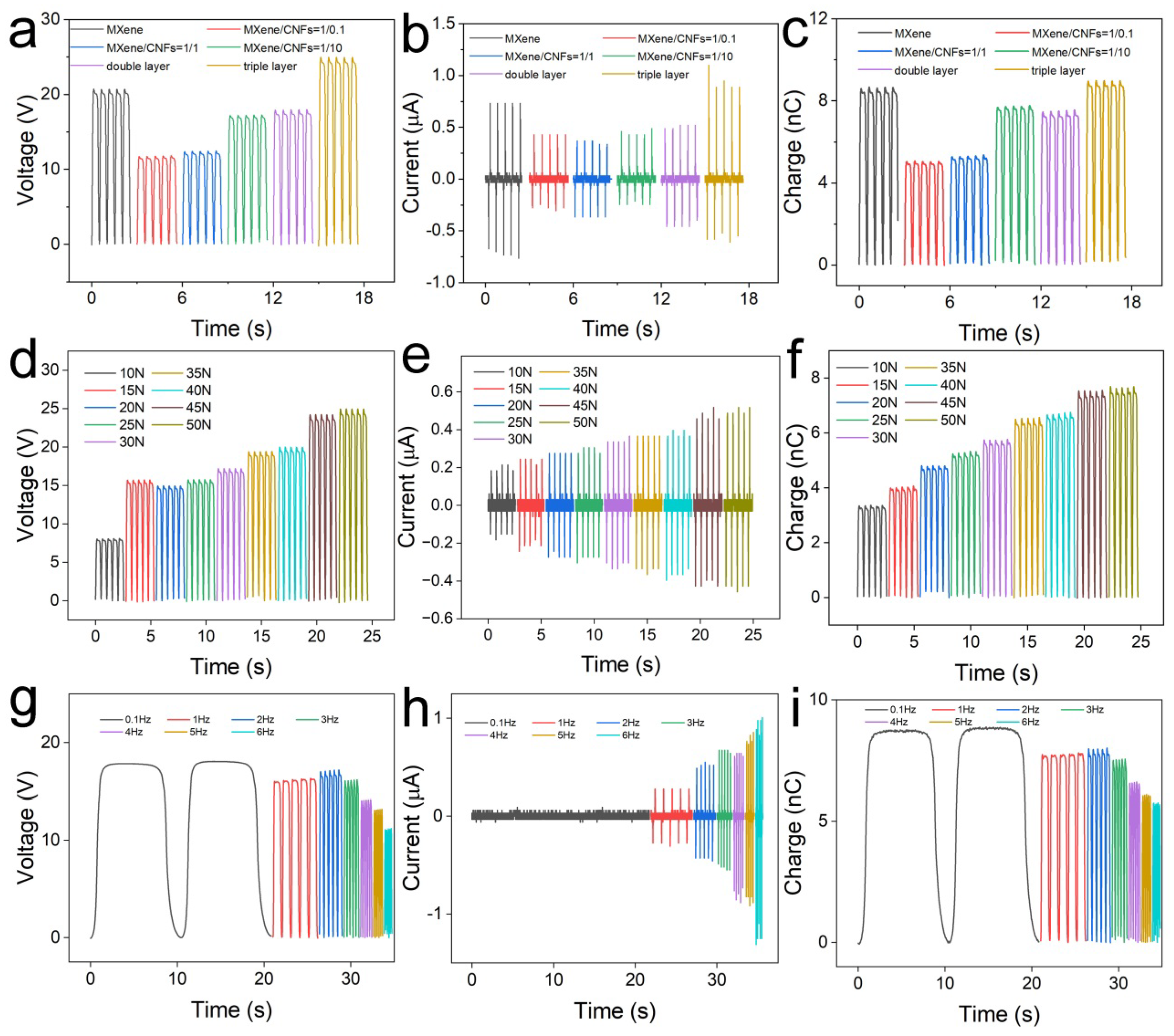

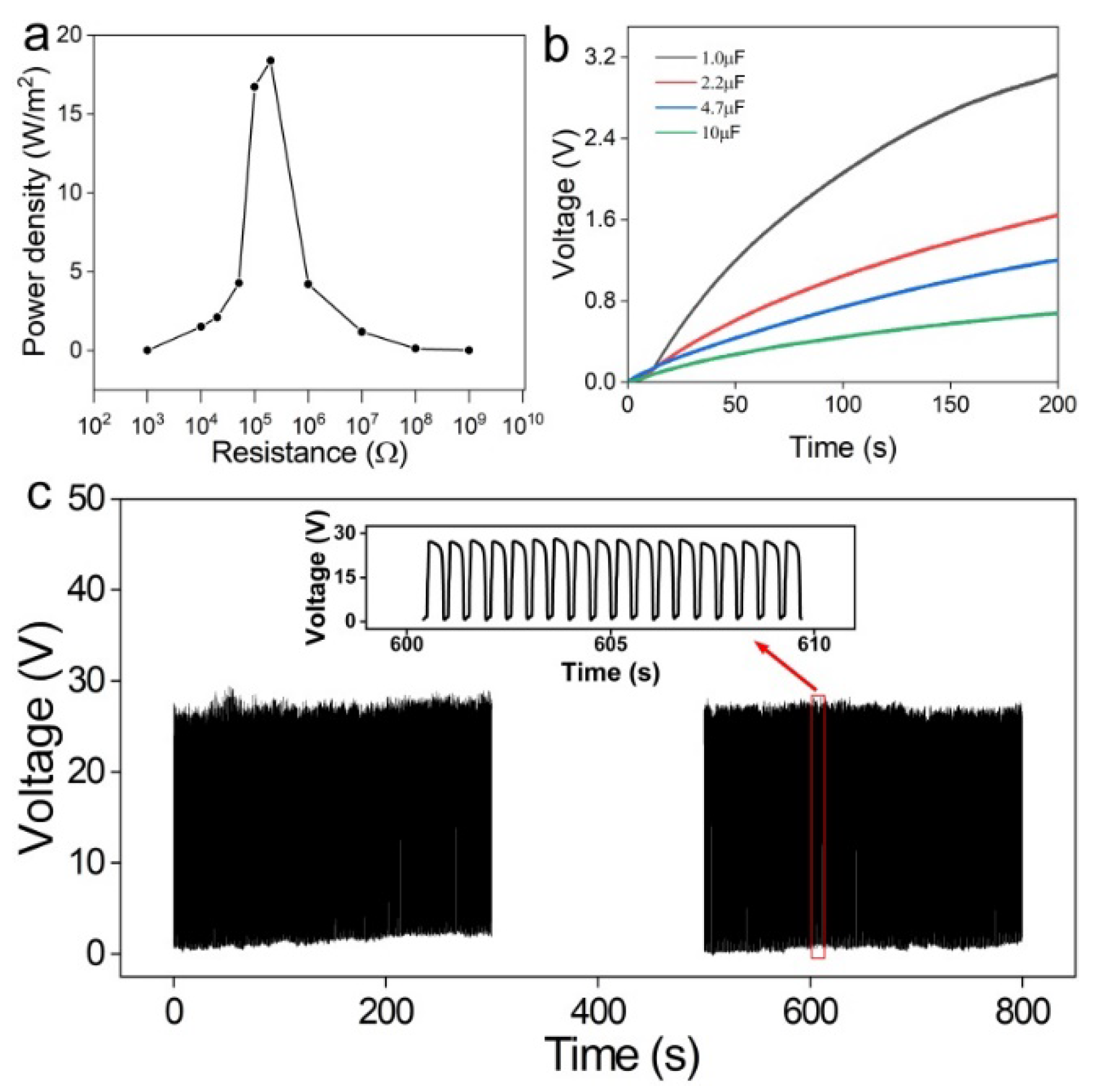

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.J.; Wang, Y.; Wang, H.; Lee, S.; Yokota, T.; Someya, T. Skin Electronics: Next-Generation Device Platform for Virtual and Augmented Reality. Adv. Funct. Mater. 2021, 31, 2170286. [Google Scholar] [CrossRef]

- Yu, X.; Xie, Z.; Yu, Y.; Lee, J.; Vazquez-Guardado, A.; Luan, H.; Ruban, J.; Ning, X.; Akhtar, A.; Li, D.; et al. Skin-integrated wireless haptic interfaces for virtual and augmented reality. Nature 2019, 575, 473–479. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Ma, K.; Yang, B.; Li, H.; Tao, X. Textile Electronics for VR/AR Applications. Adv. Funct. Mater. 2021, 31, 2007254. [Google Scholar] [CrossRef]

- Shi, Q.; Zhang, Z.; Chen, T.; Lee, C. Minimalist and multi-functional human machine interface (HMI) using a flexible wearable triboelectric patch. Nano Energy 2019, 62, 355–366. [Google Scholar] [CrossRef]

- Heng, W.; Solomon, S.; Gao, W. Flexible Electronics and Devices as Human–Machine Interfaces for Medical Robotics. Adv. Mater. 2022, 34, 2107902. [Google Scholar] [CrossRef]

- Xue, J.; Zou, Y.; Deng, Y.; Li, Z. Bioinspired sensor system for health care and human-machine interaction. EcoMat 2022, 4, e12209. [Google Scholar] [CrossRef]

- Aditya, T.; Allain, J.P.; Jaramillo, C.; Restrepo, A.M. Surface modification of bacterial cellulose for biomedical applications. Int. J. Mol. Sci. 2022, 23, 610. [Google Scholar] [CrossRef]

- Gai, Y.; Wang, E.; Liu, M.; Xie, L.; Bai, Y.; Yang, Y.; Xue, J.; Qu, X.; Xi, Y.; Li, L.; et al. A self-powered wearable sensor for continuous wireless sweat monitoring. Small Method 2022, 2200653. [Google Scholar] [CrossRef]

- Zhang, S.; Qu, C.; Xiao, Y.; Liu, H.; Song, G.; Xu, Y. Flexible alternating current electroluminescent devices integrated with high voltage triboelectric nanogenerators. Nanoscale 2022, 14, 4244–4253. [Google Scholar] [CrossRef]

- Liu, K.; Ouyang, B.; Guo, X.; Guo, Y.; Liu, Y. Advances in flexible organic field-effect transistors and their applications for flexible electronics. NPJ Flex. Electron. 2022, 6, 1. [Google Scholar] [CrossRef]

- Qu, C.; Xu, Y.; Xiao, Y.; Zhang, S.; Liu, H.; Song, G. Multifunctional Displays and Sensing Platforms for the Future: A Review on Flexible Alternating Current Electroluminescence Devices. ACS Appl. Electron. Mater. 2021, 3, 5188–5210. [Google Scholar] [CrossRef]

- Jayathilaka, W.A.D.M.; Chinnappan, A.; Tey, J.N.; Wei, J.; Ramakrishna, S. Alternative current electroluminescence and flexible light emitting devices. J. Mater. Chem. C 2019, 7, 5553–5572. [Google Scholar] [CrossRef]

- Zhu, H.; Shin, E.-S.; Liu, A.; Ji, D.; Xu, Y.; Noh, Y.-Y. Printable Semiconductors for Backplane TFTs of Flexible OLED Displays. Adv. Funct. Mater. 2020, 30, 1904588. [Google Scholar] [CrossRef]

- Choi, M.K.; Yang, J.; Hyeon, T.; Kim, D.-H. Flexible quantum dot light-emitting diodes for next-generation displays. NPJ Flex. Electron. 2018, 2, 10. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, J.; Dong, X.; Yu, W.; Liu, G. Flexible Janus Nanoribbons Array: A New Strategy to Achieve Excellent Electrically Conductive Anisotropy, Magnetism, and Photoluminescence. Adv. Funct. Mater. 2015, 25, 2436–2443. [Google Scholar] [CrossRef]

- Qu, L.; Tang, L.; Bei, R.; Zhao, J.; Chi, Z.; Liu, S.; Chen, X.; Aldred, M.P.; Zhang, Y.; Xu, J. Flexible Multifunctional Aromatic Polyimide Film: Highly Efficient Photoluminescence, Resistive Switching Characteristic, and Electroluminescence. ACS Appl. Mater. Inter. 2018, 10, 11430–11435. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Kang, C.B.; Prodanov, M.F.; Vashchenko, V.V.; Srivastava, A.K. Inkjet-Printed, Flexible Full-Color Photoluminescence-Type Color Filters for Displays. Adv. Eng. Mater. 2022, 24, 2101553. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Yu, R.; Dong, L.; Peng, D.; Zhang, A.; Zhang, Y.; Liu, H.; Pan, C.; Wang, Z.L. Dynamic Pressure Mapping of Personalized Handwriting by a Flexible Sensor Matrix Based on the Mechanoluminescence Process. Adv. Mater. 2015, 27, 2324–2331. [Google Scholar] [CrossRef]

- Wang, W.X.; Wang, Z.N.; Zhang, J.C.; Zhou, J.Y.; Dong, W.B.; Wang, Y.H. Contact electrification induced mechanoluminescence. Nano Energy 2022, 94, 106920. [Google Scholar] [CrossRef]

- Wang, C.; Peng, D.; Pan, C. Mechanoluminescence materials for advanced artificial skin. Sci. Bull. 2020, 65, 1147–1149. [Google Scholar] [CrossRef]

- Perumal, A.; Lüssem, B.; Leo, K. High brightness alternating current electroluminescence with organic light emitting material. Appl. Phys. Lett. 2012, 100, 103307. [Google Scholar] [CrossRef]

- Wood, V.; Halpert, J.E.; Panzer, M.J.; Bawendi, M.G.; Bulovic, V. Alternating Current Driven Electroluminescence from ZnSe/ZnS:Mn/ZnS Nanocrystals. Nano Lett. 2009, 9, 2367–2371. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.S.; Zhu, L.P.; Yang, J.; Zhang, J.J.; Chen, B.D.; Wang, Z.L. Flexible Alternating-Current Electroluminescence Plunging to Below 1 Hz Frequency by Triboelectrification. Adv. Opt. Mater. 2022, 10, 2101918. [Google Scholar] [CrossRef]

- Schrage, C.; Kaskel, S. Flexible and Transparent SWCNT Electrodes for Alternating Current Electroluminescence Devices. ACS Appl. Mater. Interf. 2009, 1, 1640–1644. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, S.H.; Kim, R.H.; Jeong, B.; Hwang, S.K.; Hwang, I.; Kim, K.L.; Kim, E.H.; Lee, T.-W.; Park, C. A field-induced hole generation layer for high performance alternating current polymer electroluminescence and its application to extremely flexible devices. J. Mater. Chem. C 2016, 4, 4434–4441. [Google Scholar] [CrossRef]

- Wang, Z.L. On Maxwell’s displacement current for energy and sensors: The origin of nanogenerators. Mater. Today 2017, 20, 74–82. [Google Scholar] [CrossRef]

- Wang, Z.L. On the first principle theory of nanogenerators from Maxwell’s equations. Nano Energy 2020, 68, 104272. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, L.; Zheng, Q.; Kang, Y.; Shi, B.; Jiang, D.; Li, H.; Qu, X.; Fan, Y.; Wang, Z.L.; et al. Human Motion Driven Self-Powered Photodynamic System for Long-Term Autonomous Cancer Therapy. ACS Nano 2020, 14, 8074–8083. [Google Scholar] [CrossRef]

- Zou, Y.; Bo, L.; Li, Z. Recent progress in human body energy harvesting for smart bioelectronic system. Fundam. Res. 2021, 1, 364–382. [Google Scholar] [CrossRef]

- Lee, D.-M.; Rubab, N.; Hyun, I.; Kang, W.; Kim, Y.-J.; Kang, M.; Choi, B.O.; Kim, S.-W. Ultrasound-mediated triboelectric nanogenerator for powering on-demand transient electronics. Sci. Adv. 2022, 8, eabl8423. [Google Scholar] [CrossRef]

- Chen, H.; Xing, C.; Li, Y.; Wang, J.; Xu, Y. Triboelectric nanogenerators for a macro-scale blue energy harvesting and self-powered marine environmental monitoring system. Sustain. Energ. Fuels 2020, 4, 1063–1077. [Google Scholar] [CrossRef]

- Zhu, G.; Chen, J.; Liu, Y.; Bai, P.; Zhou, Y.S.; Jing, Q.; Pan, C.; Wang, Z.L. Linear-grating triboelectric generator based on sliding electrification. Nano Lett. 2013, 13, 2282–2289. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Wang, Z.L. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes. Adv. Mater. 2014, 26, 2818–2824. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, H.; Chen, J.; Jing, Q.; Zhou, Y.S.; Wen, X.; Wang, Z.L. Single-Electrode-Based Sliding TENG. ACS Nano 2013, 7, 7342–7351. [Google Scholar] [CrossRef]

- Wu, H.; Wang, S.; Wang, Z.; Zi, Y. Achieving ultrahigh instantaneous power density of 10 MW/m2 by leveraging the opposite-charge-enhanced transistor-like triboelectric nanogenerator (OCT-TENG). Nat. Commun. 2021, 12, 5470. [Google Scholar] [CrossRef] [PubMed]

- Lei, R.; Shi, Y.; Ding, Y.; Nie, J.; Li, S.; Wang, F.; Zhai, H.; Chen, X.; Wang, Z.L. Sustainable high-voltage source based on triboelectric nanogenerator with a charge accumulation strategy. Energ. Environ. Sci. 2020, 13, 2178–2190. [Google Scholar] [CrossRef]

- Tang, W.; Jiang, T.; Fan, F.R.; Yu, A.F.; Zhang, C.; Cao, X.; Wang, Z.L. Liquid-Metal Electrode for High-Performance Triboelectric Nanogenerator at an Instantaneous Energy Conversion Efficiency of 70.6%. Adv. Funct. Mater. 2015, 25, 3718–3725. [Google Scholar] [CrossRef]

- Xie, Y.N.; Wang, S.H.; Niu, S.M.; Lin, L.; Jing, Q.S.; Yang, J.; Wu, Z.Y.; Wang, Z.L. Grating-Structured Freestanding Triboelectric-Layer Nanogenerator for Harvesting Mechanical Energy at 85% Total Conversion Efficiency. Adv. Mater. 2014, 26, 6599–6607. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, B.; Liu, J.; Wang, X.; Wang, L.; Chen, X.; Yang, C. A flexible and biocompatible triboelectric nanogenerator with tunable internal resistance for powering wearable devices. Sci. Rep. 2016, 6, 22233. [Google Scholar] [CrossRef]

- Chen, H.; Bai, L.; Li, T.; Zhao, C.; Zhang, J.; Zhang, N.; Song, G.; Gan, Q.; Xu, Y. Wearable and robust triboelectric nanogenerator based on crumpled gold films. Nano Energy 2018, 46, 73–80. [Google Scholar] [CrossRef]

- Chen, H.; Yang, W.; Zhang, C.; Wu, M.; Li, W.; Zou, Y.; Lv, L.; Yu, H.; Ke, H.; Liu, R.; et al. Performance-enhanced and cost-effective triboelectric nanogenerator based on stretchable electrode for wearable SpO2 monitoring. Nano Res. 2022, 15, 2465–2471. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Qu, X.; Shi, B.; Zheng, Q.; Lin, X.; Chao, S.; Wang, C.; Zhou, J.; Sun, Y.; et al. Ultra-Stretchable and Fast Self-Healing Ionic Hydrogel in Cryogenic Environments for Artificial Nerve Fiber. Adv. Mater. 2022, 34, 2105416. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, C.; Gao, Y.; Zhao, Z.; Hu, Y.; Yang, O.; Liu, L.; Zhou, L.; Wang, J.; Wang, Z.L. A highly efficient constant-voltage triboelectric nanogenerator. Energ. Environ. Sci. 2022, 15, 1334–1345. [Google Scholar] [CrossRef]

- Gao, Q.; Xu, Y.; Yu, X.; Jing, Z.; Cheng, T.; Wang, Z.L. Gyroscope-Structured Triboelectric Nanogenerator for Harvesting Multidirectional Ocean Wave Energy. ACS Nano 2022, 16, 6781–6788. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, L.; Zheng, Y.; Qin, Y.; Wang, Z.L. Enhancing the performance of triboelectric nanogenerator through prior-charge injection and its application on self-powered anticorrosion. Nano Energy 2014, 10, 37–43. [Google Scholar] [CrossRef]

- Cao, W.T.; Ouyang, H.; Xin, W.; Chao, S.; Ma, C.; Li, Z.; Chen, F.; Ma, M.G. Astretchable highoutput triboelectric nanogenerator improved by MXene liquid electrode with high electronegativity. Adv. Funct. Mater. 2020, 30, 2004181. [Google Scholar] [CrossRef]

- Ahmed, A.; Sharma, S.; Adak, B.; Hossain, M.M.; LaChance, A.M.; Mukhopadhyay, S.; Sun, L. Two-dimensional MXenes: New frontier of wearable and flexible electronics. InfoMat 2022, 4, e12295. [Google Scholar] [CrossRef]

- Sun, J.; Chang, Y.; Dong, L.; Zhang, K.; Hua, Q.; Zang, J.; Chen, Q.; Shang, Y.; Pan, C.; Shan, C. MXene enhanced self-powered alternating current electroluminescence devices for patterned flexible displays. Nano Energy 2021, 86, 106077. [Google Scholar] [CrossRef]

- Wei, X.Y.; Wang, H.L.; Wang, Y.; Kuang, S.Y.; Zhu, X.X.; Zou, J.; Wang, L.; Zeng, X.; Rao, F.; Zhu, G. Fully-integrated motion-driven electroluminescence enabled by triboelectrification for customized flexible display. Nano Energy 2019, 61, 158–164. [Google Scholar] [CrossRef]

- Jia, C.; Xia, Y.; Zhu, Y.; Wu, M.; Zhu, S.; Wang, X. High-Brightness, High-Resolution, and Flexible Triboelectrification-Induced Electroluminescence Skin for Real-Time Imaging and Human–Machine Information Interaction. Adv. Funct. Mater. 2022, 32, 2201292. [Google Scholar] [CrossRef]

- Su, L.; Jiang, Z.; Tian, Z.; Wang, H.; Wang, H.; Zi, Y. Self-powered, ultrasensitive, and high-resolution visualized flexible pressure sensor based on color-tunable triboelectrification-induced electroluminescence. Nano Energy 2021, 79, 105431. [Google Scholar] [CrossRef]

- Wang, X.C.; Sun, J.L.; Dong, L.; Lv, C.F.; Zhang, K.K.; Shang, Y.Y.; Yang, T.; Wang, J.Z.; Shan, C.X. Stretchable and transparent electroluminescent device driven by triboelectric nanogenerator. Nano Energy 2019, 58, 410–418. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Chen, H.; Wu, M.; Yang, W.; Zhao, J.; Wang, Z.; Guo, S.; Wang, H.; Wang, W.; Wang, J. A Flexible Triboelectric Nanogenerator Based on Multilayer MXene/Cellulose Nanofibril Composite Film for Patterned Electroluminescence Display. Materials 2022, 15, 6770. https://doi.org/10.3390/ma15196770

Sun Z, Chen H, Wu M, Yang W, Zhao J, Wang Z, Guo S, Wang H, Wang W, Wang J. A Flexible Triboelectric Nanogenerator Based on Multilayer MXene/Cellulose Nanofibril Composite Film for Patterned Electroluminescence Display. Materials. 2022; 15(19):6770. https://doi.org/10.3390/ma15196770

Chicago/Turabian StyleSun, Zhaoyang, Huamin Chen, Mingqiang Wu, Wei Yang, Jiang Zhao, Zefeng Wang, Shujun Guo, Huining Wang, Weiguo Wang, and Jun Wang. 2022. "A Flexible Triboelectric Nanogenerator Based on Multilayer MXene/Cellulose Nanofibril Composite Film for Patterned Electroluminescence Display" Materials 15, no. 19: 6770. https://doi.org/10.3390/ma15196770

APA StyleSun, Z., Chen, H., Wu, M., Yang, W., Zhao, J., Wang, Z., Guo, S., Wang, H., Wang, W., & Wang, J. (2022). A Flexible Triboelectric Nanogenerator Based on Multilayer MXene/Cellulose Nanofibril Composite Film for Patterned Electroluminescence Display. Materials, 15(19), 6770. https://doi.org/10.3390/ma15196770