3.2.1. Analytical Approach

In order to build a simple mathematical model, capable of delivering some consistent information about the investigated pressing process of a mixture of soft and hard composite powders, the following simplifications were proposed: (1) the powder mixture is introduced in an infinitely long cylinder, in order to avoid the boundary effects produced at the top and bottom plane surfaces of the cylinder, together with the circular edges, on their adjacent volumes; (2) one single spherical soft inclusion is taken into consideration (this approximation can describe the situation of small PMMA concentrations, so that the boundaries separating the hard/soft materials will not interact to each other); (3) the stiffness of the polymeric inclusion is negligible comparing to the one of hard ceramic powder; (4) the overall hard phase outside the soft sphere inclusion is a continuous homogeneous and isotropic material.

The effective mechanical characteristics of the hard matrix were firstly estimated in order to determine the role of the pressing step of the powder mixture formed by soft and hard particles on the resulted anisotropy of a unique soft inclusion. One should consider that the matrix outside the soft inclusion is not a full densified material, but it should be described by effective mechanical properties characterizing a porous structure. For this aim, mixing approaches based on Voronoi structures were employed and analytic formulae for the effective Young’s modulus and Poisson’s ratios were derived [

25,

26] as described in

Supplementary Materials, Section A (Figure S1).

While the inner radius is a constant, the external radius

is vectorially determined as shown in

Figure 3c. The stress Equations were further derived by separating an elementary volume in which normal (longitudinal)

, radial

and tangential

stresses are indicated (

Figure 3a). The normal stress is calculated by applying Hooke’s law in each slice of the cylinder containing a soft inclusion, when pressure is applied to its basis (

Figure 3b):

where

is the pressure applied on the plane surfaces,

is the radius of the soft inclusion and

is the external radius of cylinder, while the radial and tangential stresses (

Figure 3d) satisfy the equilibrium condition on vertical direction:

After some mathematical manipulations, the final form of the stress Equation becomes:

In order to compute the radial

displacement on the pore’s boundary, when the system is subjected to isostatic pressure, the following Equation is used:

A suite of C/C++ programs has been written to compute the stress-strain fields in various positions around the soft inclusion, whose axis will be considered as a reference for the Equations, and to determine the way that the boundary of the inclusion deforms. As a first step, the program computes the effective values of the external cylinder radius and, then, it applies the Equations (2) and (4)–(6), in order to determine the equivalent stress and the deformed shape of the elemental boundary. The von Mises stress derived from the modern theory of the maximum elastic potential energy [

27] represents a mathematical tool that replaces all the main and secondary stresses accumulated in the material, by a singular quantity that would introduce the same energy into the body, thus, creating similar breaking effects. The formula used for the estimation of the equivalent von Mises stress is given by the relationship:

A representative image (obtained by exporting the graphic files to MeshLab) of the deformed soft inclusions placed in various positions with respect to the cylinder axis is presented in

Figure 4, where the parameters:

= 5 mm,

= 0.5 mm,

= 150 MPa,

= 0 MPa,

2000 MPa,

= 0.25 were used. A detailed representation is shown in

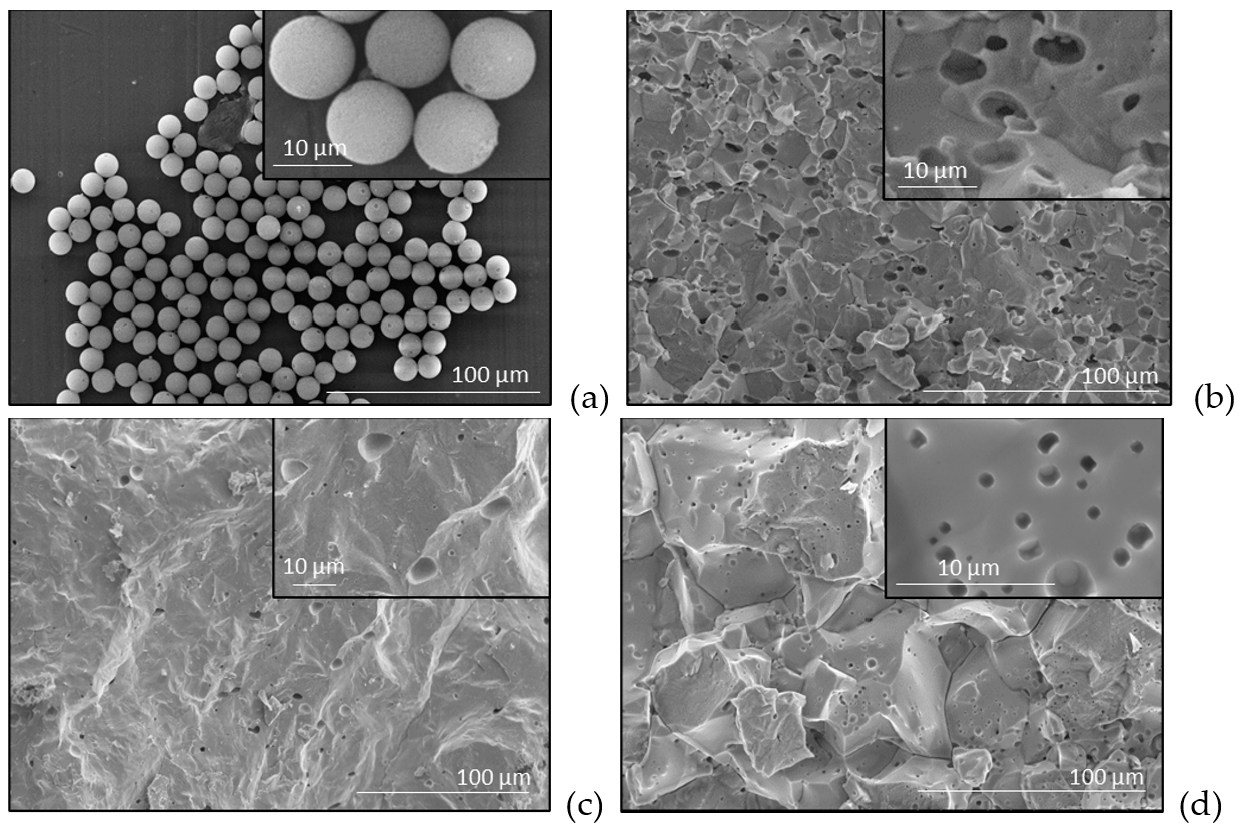

Figure S2 (Supplementary Materials, Section B). The distribution of the von Mises stress accumulated in the material just around the surface of the soft inclusion is indicated in a colour scale (the green sides represent the lowly-stressed areas, while the red ones represent highly-stressed regions). The general tendency of the deformed inclusions (initially spherical) is to take an ellipsoid-like shape, no matter their radial position, which seems to be realistic, as it was observed in the ceramic microstructures (

Figure 1b). The von Mises stress behaviour however, tends to vary considerably from a highly symmetric distribution when the inclusion is placed on the cylinder axis, up to a state where all the significant stresses tend to accumulate on a narrower strip pointing out to the exterior boundary of the system, up to such a concentration that it squeezes the material inside the hollow sphere (

Figure 4). This approach allowed to make an interesting observation: the inclusion located just in the vicinity of the cylinder boundary (

Figure 4d) displays, besides the elongation, a tendency of longitudinal squeezing. This suggests that the interactions between geometrical boundaries play an important role on the local strain-stress fields.

The present simplified approach provides qualitative results if the ratio > 500, when the stress calculation becomes inaccurate, due to a program limitation related to the machine power of approximation. This limits the possibility of mimicking a real setup because, for a 10 mm holder, the smallest usable inclusion radius is of around 0.03 mm, while a real inclusion has the radius in the order of 10−8 mm. Other important limitations are determined from the mathematical apparatus itself considering for calculations a single soft inclusion and from the effects of the top and bottom flat surfaces on the nearby material, which cannot be determined by using only the Hooke’s law. Another drawback is determined by the impossibility of studying the interaction between more soft inclusions and their geometrical boundaries. Overall, those results are promising because the deformed shape of the outermost inclusion matches the observed shape of a squeezed hollow sphere near the boundary of a solid cylinder, but these overall observations suggest that a numerical model would be more appropriate.

3.2.2. Numerical Approach by Finite Element Modelling

In order to simplify the study, instead of a 3D approach, 2D analyses were further performed in both longitudinal and transversal section of the cylinder, thus, from this point on, the inclusion shall be referred as circular. Such a numerical model would describe correctly the behaviour in the transversal section, which represents a reduction of phenomena taking place in parallel plans, which do not mechanically interfere much since the differences in the behaviour of two adjacent parallel plans may cause only the apparition of secondary stresses. Some limitations of the proposed approach are expected in the longitudinal section, in which radially disposed planes intersect much often, by means of both main and secondary stresses. Nevertheless, such analysis was chosen here for its simplicity.

As a first test, the results of the numerical approach were qualitatively compared for the case of a single soft inclusion with similar size to the ones resulted from the analytical calculations.

Figures S3 and S4 (Supplementary Materials, Section C) comparatively present the deformation and von Mises stresses in longitudinal and transversal sectioning plans determined by the analytical and numerical method. Even if the von Mises stress distributions do not fully match due to the effects of the secondary stresses that were not considered in the analytical approach, the deformed shape of the inclusion resulted from the two approaches matches fairly well and the numerical approach will be further used for a larger number of soft inclusions.

- A.

Isostatic pressing

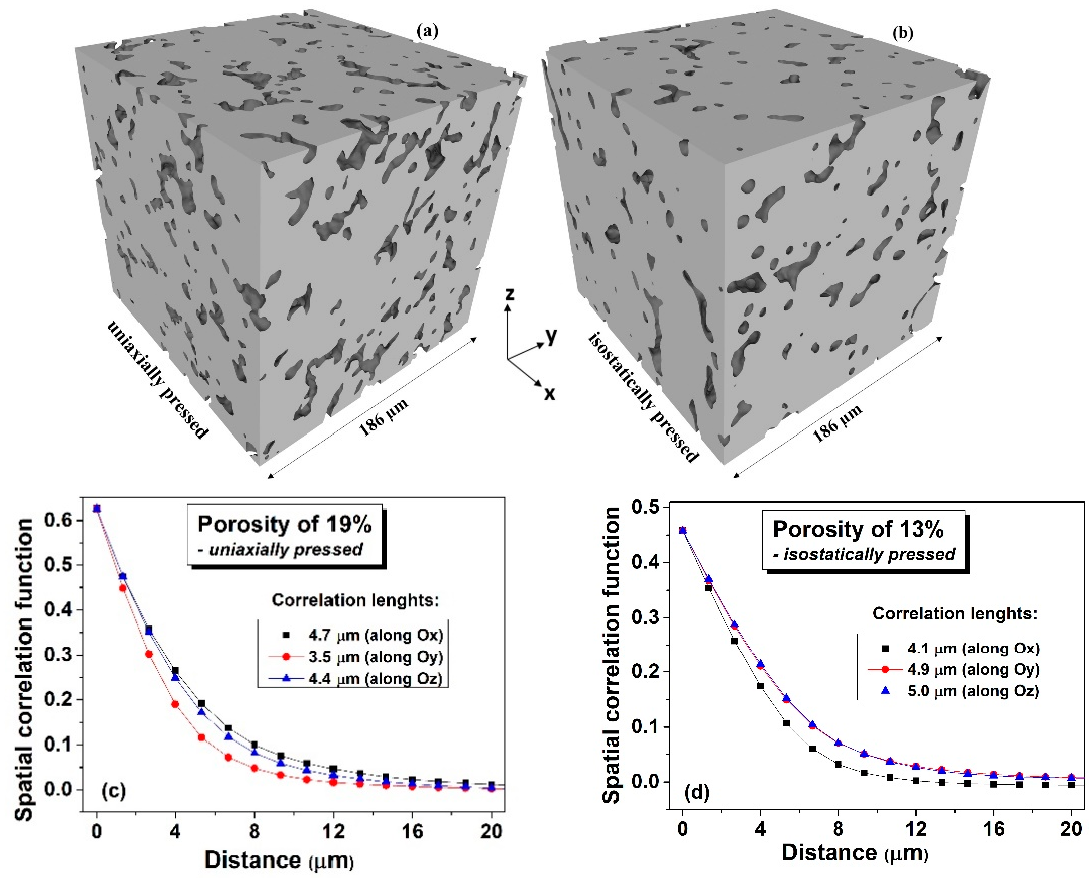

The deformation of the soft circular inclusions inside a more rigid matrix during the isostatic pressing step was simulated by using COMSOL Multiphysics platform. In a first place, a rectangle with the aspect ratio of 3:1 is filled with randomly placed hollow circles that mimic the soft inclusions, so that the hollow area of the whole system remains around ~30%. To increase the accuracy and insure the best statistical relevance, larger systems, with randomly-generated initial structures, are gradually built (

Figure 5a), with increased number of such inclusions, up to 950 (COMSOL Multiphysics does not support more than 1000 geometrical entities in a single model), while keeping as constant the aspect ratio of 3:1, the radii of the inclusions of 0.5 mm and the lack of percolation. After the system is created, another very small inclusion is placed in the center of the rectangle, acting as a fixed anchor point. In the following calculations, several randomly generated (using the same governing parameters) structures have been studied. Since the structures are very similar, the number of elements sits around 15,000 and the number of nodes around 10,000. A meshing example, together with the boundary conditions are presented in

Figures S5 and S6 (Supplementary Materials, Section D) respectively.

As an input, the material constants: Young’s modulus of 100 GPa and Poisson’s ratio of 0.25 were used, together with boundary conditions: (i) fixed anchor at the centre of the rectangle and (ii) external pressure

= 500 MPa on its edges. The mesh parameters were left to the decision of the software and several analyses have been performed.

Figure 5b displays the deformed shapes of the structures presented in

Figure 5a together with the von Mises equivalent stress by means of a colour scale (blue represents the minimum value, while red corresponds to the maximum stress). By these calculations, it clearly results that the edges of the inclusions influence very much the local displacements, which confirms one of the hypotheses of the study. Moreover, one can observe that clustering chains tend to form inside the material, which might dictate the behaviour to a greater extent than the exterior limits themselves.

In order to determine if some degree of anisotropy is generated after applying an isostatic pressure to the system, the angles between the longest diameter of each deformed inclusion and the horizontal axis were determined, as described in

Supplementary Materials, Section E and their distribution was plotted.

Figure 6 displays a broad bimodal angular distribution of the soft inclusions’ long axes for a number of 950 elements which suggests the presence of two possible main anisotropy directions approximatively placed at ±50°, not far away from being perpendicular. A higher degree of symmetry should be obtained when using a larger number of soft elements in simulations, for a better statistic. This result confirms the observation from

Figure 2b,d in which one could identify the presence of two main perpendicular anisotropy axes. Further, the model building algorithm was modified to describe rounded structures in order to simulate the transversal section. Measuring the angle between the main diameter of an inclusion and the horizontal axis was not convenient in this case, because such a statistic would be hard to visualize and to get useful information out of it. Therefore, the analysis program has been adapted to calculate the angle between the main diameter of each inclusion and the line connecting its centre of mass with the section’s centre. The obtained angular distribution of the inclusions against a radial direction is exposed in

Figure 7, which also displays the initial and deformed structure containing 850 soft inclusions in a cylinder with 24 mm diameter. It is observed that this distribution (

Figure 7d) is close to a normal one and is centred around zero degree, thus indicating a clear preference for a purely radial orientation of the inclusions, in a transversal plane, which is a sign of a very good isotropy in the plane perpendicular to the cylinder axes. This demonstrates that even the starting soft fillers were equiaxed (as shown in

Figure 1a), they deform as result of the uniaxial pressing and generate, after sintering, anisotropic porosity with elongated pores having the short axes along the pressing direction and their long axes in a plan transversal to it. As it was expectable, there is no identifiable anisotropy is the transversal section. In the longitudinal section however, slight anisotropic tendencies are observed. As already discussed, this general anisotropy is not an evident one and can be traced back to several more or less disputable sources. Even if, at this very moment, one cannot give a clear picture about the general anisotropy in the 3D structure, around particular regions, local anisotropy is clearly present and is strongly dependent on the clustering degree of the soft equiaxed inclusions used as sacrificial templates (PMMA circles) and this anisotropy would affect the functional properties (dielectric, ferro/piezo/pyroelectric, storage properties, etc.) of such a porous ceramic structure.

- B.

Uniaxial pressing

For the case of uniaxial pressing, zero pressure was considered on the sides of the rectangle (

Figure 8a). Intuitively, it feels natural that the rectangle had the tendency to shorten and the inclusions had the tendency to flatten with their main axis standing at an angle close to 90° degrees about the main axis of the cylinder (

Figure 8b). Indeed, the computed structure presents anisotropy and deformed inclusions with the long axes perpendicular to the pressing (vertical) direction, as shown in

Figure 8c and the corresponding angular distribution is bi-modal, with sharp maxima around the angle of ±90°, almost symmetrical, similar as observed in the SEM micrographs in

Figure 1b.

In order to further evaluate the specific features related to the local deformations of the soft inclusions when using the two pressing methods, the sizes of the long (

R) and respectively, of the short (

r) axes have been computed for all the soft inclusions and their weights have been plotted as a function of their specific aspect ratio

R/r. The obtained distributions presented in

Figure 9 indicates a clear difference between the boundaries’ behavior of the soft inclusions after being subjected to the two types of pressing procedures. It is observed in the case of isostatic pressing the narrow distribution with a rather Gaussian aspect, with a sharp maximum around

1.3, thus indicating a high degree of shape homogeneity, even if the angular distribution of the main axes is broader and bimodal. Meanwhile the broader, log-normal type distribution corresponding to the uniaxial case, with a shallow maximum around

2, showes a lesser gometrical homogeneity of the system, but a higher degree of anisotropy, due to the narrower, angular distribution, as shown in

Figure 8d. These results qualitatively agree with the observations from

Figure 2a,c in which more flattened pores were detected in the case of ceramics processed from uniaxially pressed powders, as resulted from a higher degree of deformation of the soft polymeric circles during the uniaxially pressing step.

The limitations of the present numerical approach are related to the simplifications and assumptions employed, like: the lack of percolation, the perfectly homogeneous and isotropic character of the material matrix, the perfectly shaped circular soft inclusions and possible mesh-related errors. One might argue that the linear-elastic material model is unsuitable to describe the behaviour of the powder matrix during the compaction process. In order to address this issue, a sequence of simulations with variable matrix material properties has been performed (

Supplementary Materials, Section F). Inspired by the Drucker-Prager model, the elastic modulus was modified at each step, according to the resulting von Mises stresses computed at the previous step. After a few computational steps, one can distinguish that the shape of the deformed inclusion is very similar to the one resulting from the constant material properties case. So, it can be concluded that the present approach is suitable for describing the behaviour of the body during the pressing process. It is worth to mention that the simplifications related to the use of a 2D approach provide valuable results describing systems with elongated soft inclusions (e.g., cylinders or very long ellipsoids) in a transversal section, rather than spherical soft inclusions. Other possible errors might be determined by the limited precision in the calculation of inclusions’ individual mass centres and in the base change of the whole structure.